Instructions for self-erection of the foundation

To perform the strip part of the foundation, it is necessary to mount the formwork

To perform the strip part of the foundation, it is necessary to mount the formwork

To make a pile-strip foundation with your own hands, you will need step-by-step instructions. All work is performed in the order indicated in it sequentially one after another.

The technology used to create a foundation from bored piles consists of the following stages:

- performing preliminary calculations;

- preparation of the building site: garbage collection, removal of the grass layer and leveling (if possible)

- marking for walls and partitions;

- digging a trench under the foundation tape along the mark lines, no more than 0.5 m deep and creating a sandy or gravel layer at its bottom;

- drilling wells for piles is done to a depth greater than the freezing mark (by 0.5 m) with a step of 1-2 m, and a diameter of 15 cm larger than the pile;

- a sand pillow (15-20 cm) is poured into them, after which it is compacted;

- pipes are installed (metal or asbestos-cement), concrete is poured;

- until he grabs - the supports are leveled;

- after solidification, a reinforcement frame is installed, reaching in height to the top of the concrete foundation;

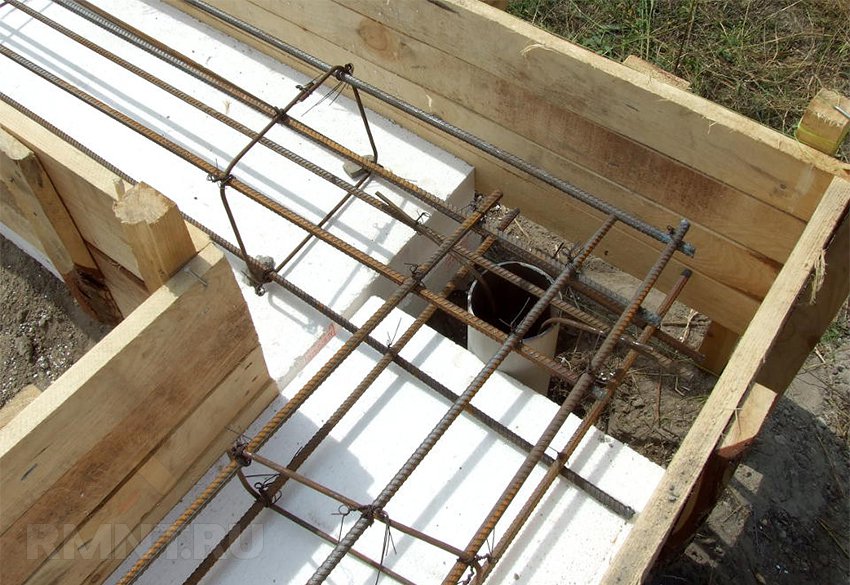

- using self-tapping screws and nails, they assemble a sealed wooden formwork;

- the entire structure is poured with concrete, compacted, the top of the foundation is leveled;

- a certain time is expected for the concrete solution to harden;

- after which the surface is primed, waterproofing, insulation of the base is done. For more information on calculations, see this video:

Pile reinforcement is knitted separately

Pile reinforcement is knitted separately

Reinforcement is carried out with metal rods 8-16 mm in diameter, laid with a mesh in 3 directions. The intersection points are tied with a knitting wire.

The protruding formwork elements must face outward.

Its corners are held together with bars. The whole structure is reinforced with struts and braces.

The solution is mixed in the proportion: 1 part of cement (500 brands) to 5 parts of sand with the addition of a plasticizer.

The solution is mixed in the proportion: 1 part of cement (500 brands) to 5 parts of sand with the addition of a plasticizer.

The structure from the effects of precipitation is covered with plastic wrap. The drying time of concrete depends on the climatic conditions of the area and varies in a wide range. If the air temperature is high, it is necessary to avoid drying out the concrete by periodically moistening it with water.

Varieties of piles

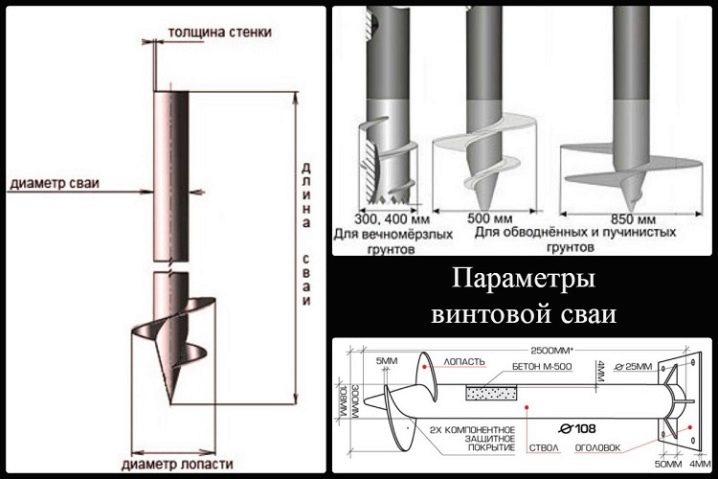

Such a foundation is arranged on screw and bored piles. The first group includes products made of metal pipes. At the end of the piles there are blades designed to be screwed into the ground. By the principle of action, these elements can be compared to screws. The blades give rigidity to the screw pile. They sink into solid soil.

Piles are made of different diameters - from 57 to 133 mm. For low-rise buildings, pipes with a length of 165 to 350 cm are chosen. Such piles are screwed into the ground using special equipment. Hand-held devices can be used. To prolong the life of the piles, they are coated with a primer and a coat of paint.

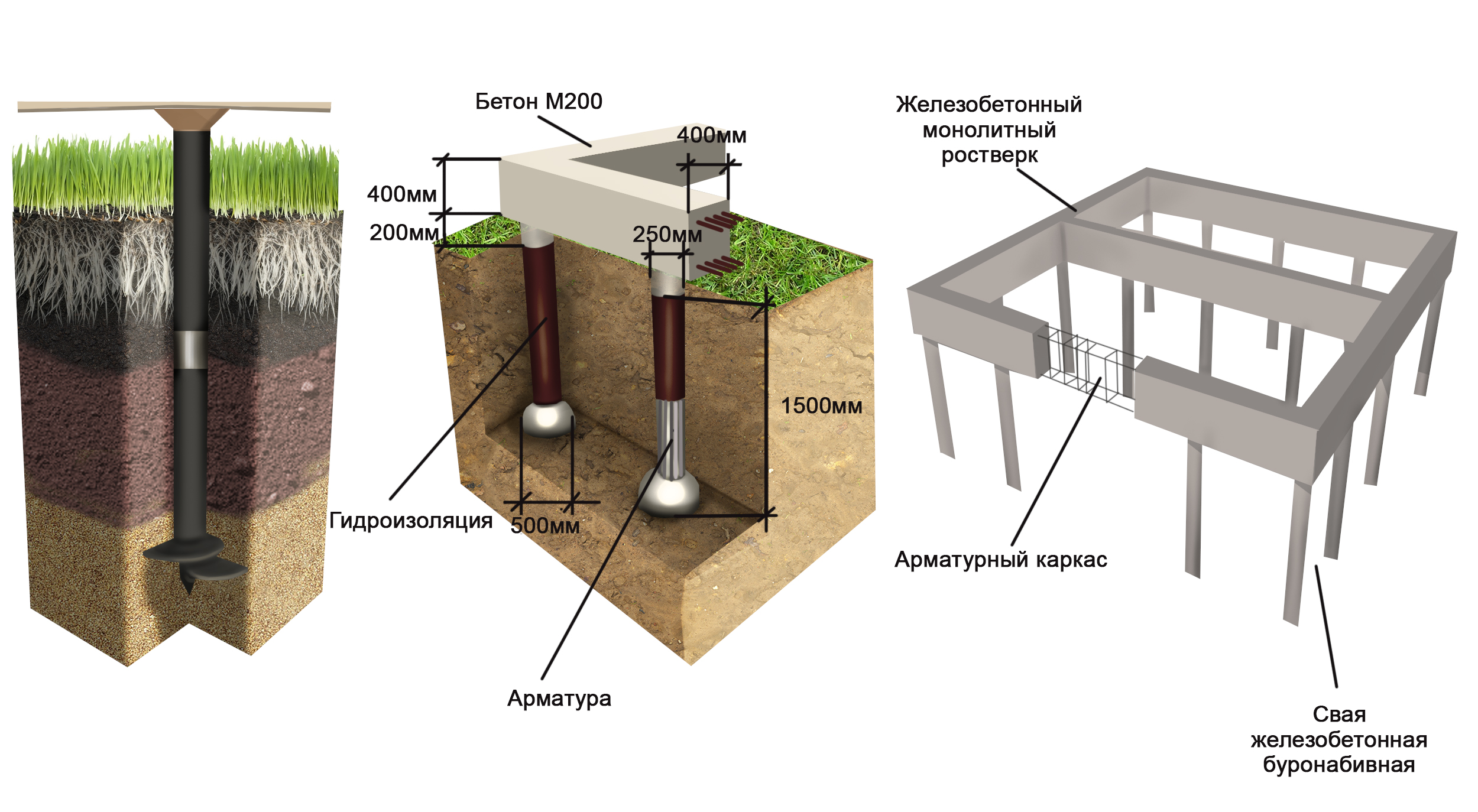

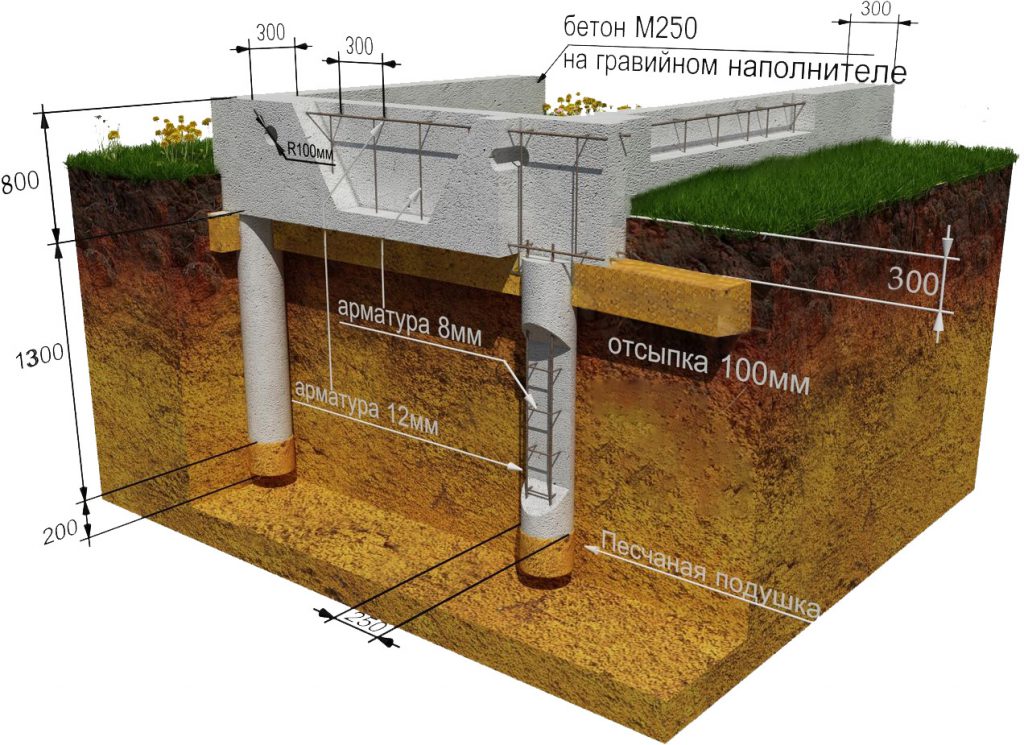

Bored piles are made by hand. First, a well is drilled until it is immersed in a solid layer of soil by 60 cm. The bottom should be covered with sand by 30 cm. Then the pillow is carefully compacted. The well is reinforced with steel rods. Then it is poured with concrete. For pile formwork, pipes are chosen from asbestos cement, cardboard or plastic. The job does not require special skills or knowledge.

The pile-screw foundation, in contrast to the pile foundation, has a reinforced concrete grillage. Tape bases are buried, shallow and not buried. In some cases, concrete grillages are created that are above the zero mark.

When self-erecting, a strip foundation with piles is usually made shallow. A monolithic reinforced concrete tape is buried in the ground by 20-40 cm. It is placed on a cushion of gravel and sand 30 cm deep and piles. These foundations are poured on slightly heaving and non-heaving soil. If the soil is heaving, make a hinged-type tape.

Any construction on your own requires a thoughtful approach, so the best helper will be a self-made step-by-step instruction for working with a strip-pile foundation. Well-thought-out steps will help you avoid gross mistakes. For example, before planning a construction with a strip pile foundation with your own hands, as in the video, you must first perform drainage on the site. Otherwise, rain and high water will nullify all efforts to make wells and cast the pile-strip foundation:

Payment

At the stage of calculating materials, it is necessary to determine the type and number of piles, their suitable length and diameter. This stage of work must be approached as responsibly as possible, since the strength and durability of the object depends on the accuracy of the calculation.

The determining factors in calculating the required amount of materials are the following items:

- foundation load, including wind load;

- the size of the object, the number of floors in it;

- features and technical characteristics of materials used for construction;

- soil features.

When calculating the number of piles, it is taken into account that they should be located at all corners of the object, as well as at the junction of the supporting wall structures. Supports are installed along the perimeter of the building in steps of 1-2 m.The exact distance depends on the chosen wall material: for surfaces made of cinder block and porous concrete bases, it is 1 m, for wooden or frame houses - 2 m.

The diameter of the supports depends on the number of storeys of the building and the materials used. For an object on one floor, screw supports with a diameter of at least 108 mm are required; for bored piles or asbestos pipes, this figure is 150 mm.

When using screw piles, you should choose models with a diameter of 300-400 mm for permafrost soils, 500-800 mm - for medium and heavily loamy, moisture-saturated soils.

The annexes - terraces and verandas - and heavy structures inside the building - stoves and fireplaces - require their own foundation, reinforced around the perimeter with supports. It is also necessary to install at least one pile on each side of the perimeter of the second (additional) foundation.

Purpose and main types of pile foundations

To build a house, you can use various types of foundations, including piles

To build a house, you can use various types of foundations, including piles

To build a house, you can use various types of foundations, including pile foundations. Through this foundation, not only residential, but also industrial facilities, auxiliary buildings and multi-storey buildings on soft soils are being erected. The technology allows you to speed up the process of arranging basements, basements, or to exclude such construction work from the estimate. The main reasons for erecting a foundation on piles are the following indicators:

- Weakness of the top soil layer. Such mixtures can consist of peat, humus mixtures, sand and clay. At the same time, saturation with water makes the soil floating, unstable, which means that you have to build a pile foundation with your own hands in order to transfer the load of the structure to deeper soil layers.

- Excessive soil density also interferes with the arrangement of another type of base. But pile structures allow you to minimize the amount of land work, as well as reduce preparatory work: digging pits, transporting soil, buying concrete mix, and so on.

Pile foundations are of several types: pile-grillage, screw and tape. There are pros and cons for each type, it is worth considering them in more detail.

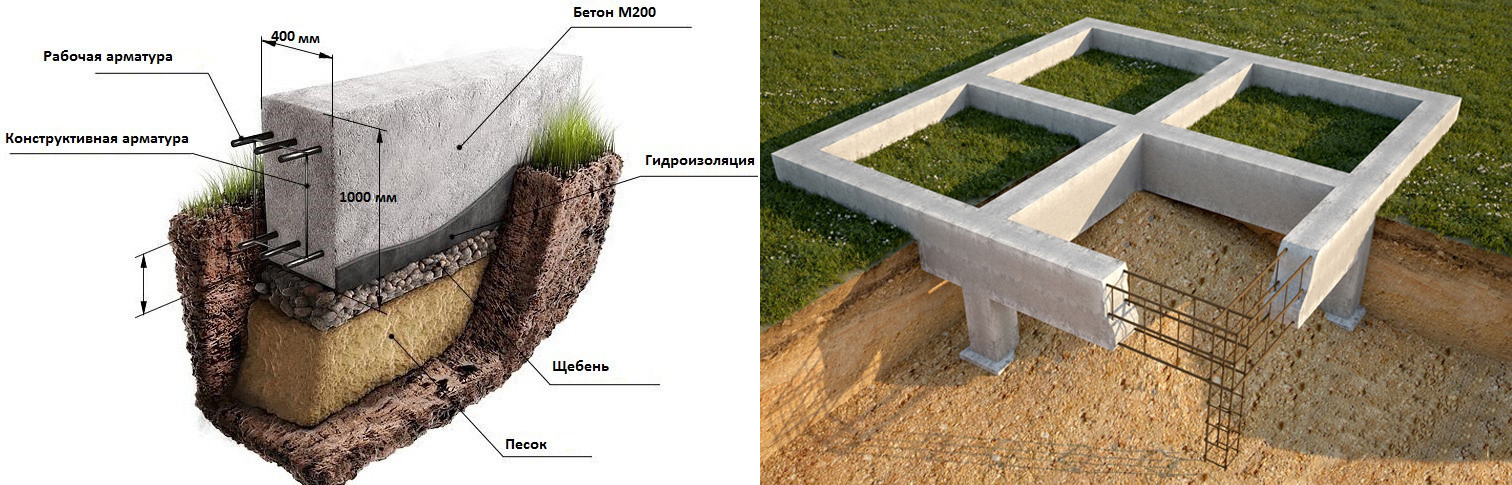

Pile-grillage base

In the case of choosing this particular type of foundation, it is necessary to increase the accuracy of calculations and adherence to the technological features of construction

In the case of choosing this particular type of foundation, it is necessary to increase the accuracy of calculations and adherence to the technological features of construction

It has its positive and negative qualities. The advantages of a foundation for a house are:

- applies to almost any type of soil;

- has increased stability;

- good load-bearing capacity (holds walls with sufficient specific gravity);

- economy of arrangement - there is no need to buy a solution, you can make everything with your own hands;

- the bond by means of the grillage of the entire structure into a monolith adds strength in the event of soil shrinkage;

- there is no need to additionally clear the construction site;

- possesses the natural ventilating ability of the building plane, which reduces humidity indicators (elimination of condensation);

- provides safety in the event of a flood or if there are increased seasonal floods in the area;

- efficiency of construction.

Cons of the foundation:

- can not be equipped on rocky and stony soils;

- when there is a threat of horizontal soil movements, installation difficulties arise;

- high cost of the foundation in comparison with other types;

- if you need a basement or basement floor, it is better to abandon the pile foundation;

- use is indicated only for light, medium-light, medium-heavy structures;

- the need for extremely accurate calculations, which requires professional research, and this is expensive.

Pile-screw foundation: advantages and disadvantages

This is one of the oldest technologies, so its pros and cons have been studied thoroughly.

This is one of the oldest technologies, so its pros and cons have been studied thoroughly.

This is one of the oldest technologies, so its pros and cons have been studied thoroughly. So, the advantages:

- the cheapness of the arrangement;

- efficiency of construction;

- there is no need to level the ground, dig trenches and generally carry out large-scale excavation work;

- the landscape and soil structure are not disturbed;

- there is no vibration during installation, which means that the house can be installed next to an architectural monument, century-old trees and other objects prohibited from destruction;

- easily erected on marshy, coastal soils;

- built regardless of weather conditions;

- the design can be used repeatedly;

- installation requires minimal physical and financial costs.

Minuses:

- support elements are corroded;

- short service life;

- lack of a basement.

Pile-strip foundation: advantages and disadvantages

The base is quite popular, but has its own specific features

The base is quite popular, but has its own specific features

The base is quite popular, but it has its own specific features. Pros:

- available for arrangement on construction sites with difficult terrain;

- the minimum involvement of technical and human resources allows us to talk about efficiency;

- such a foundation can withstand and hold weak shocks and ground movements;

- piles are made literally from scrap material;

- speed of arrangement.

Minuses:

- the obligation to conduct thorough geodetic surveys of the soil;

- the need for accurate calculation of the parameters of each pile element;

- lack of a basement / basement floor;

- compulsory insulation work on the first floor;

- application for buildings of no more than 3 floors is shown.

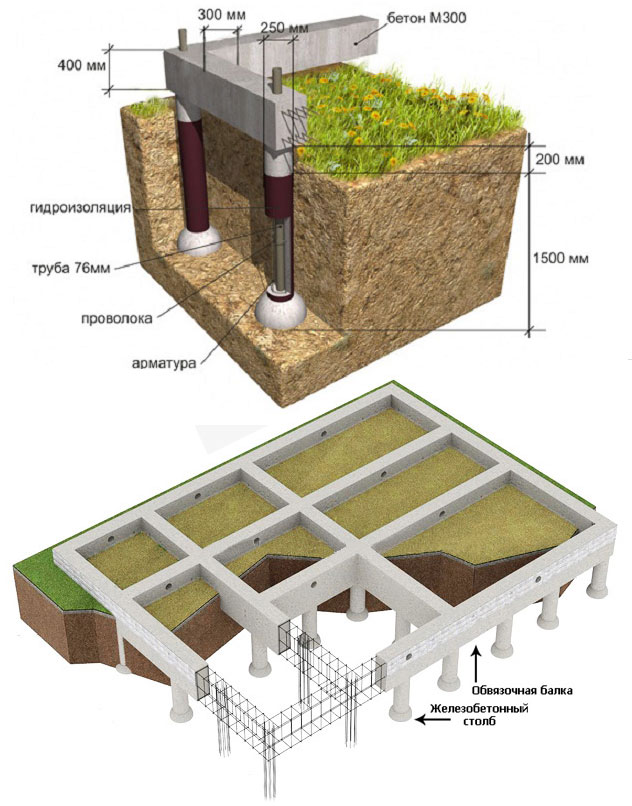

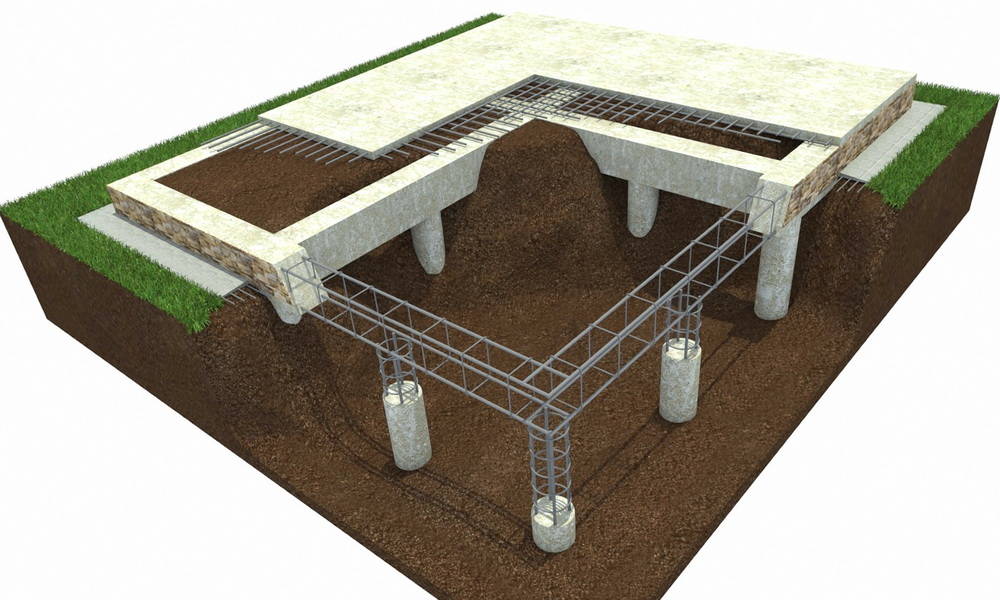

Pile-strip foundation: design, scope

The tape on the piles is laid shallow

The tape on the piles is laid shallow

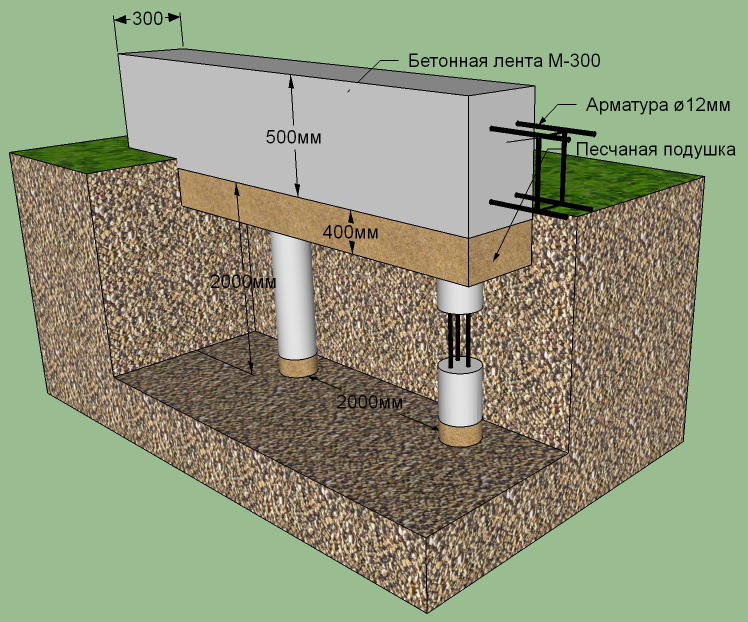

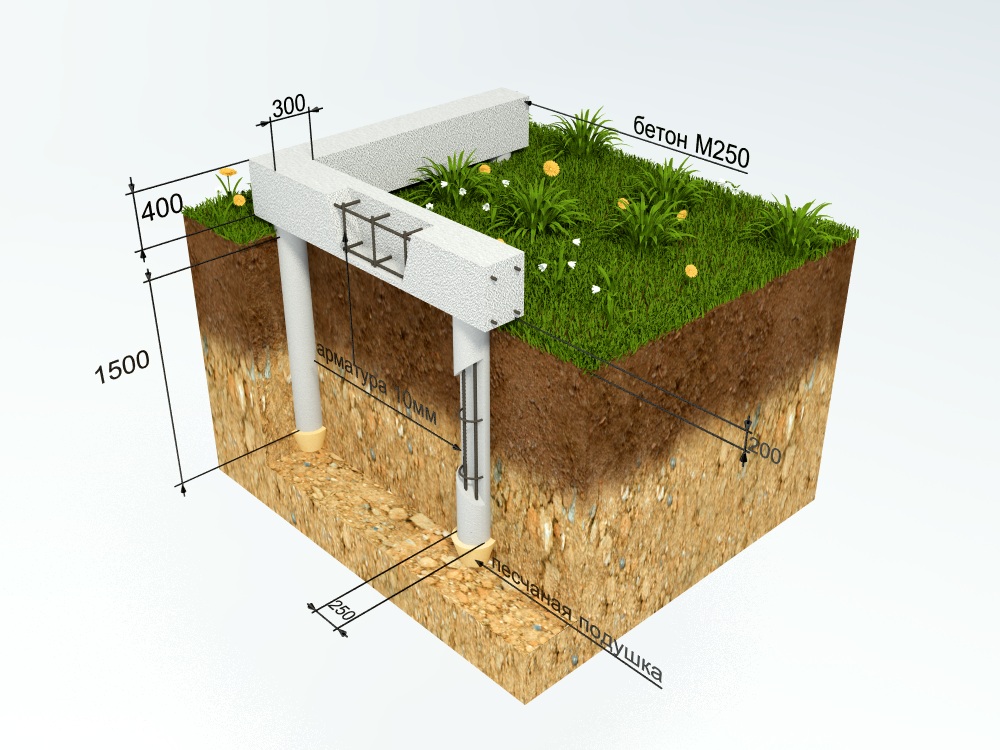

A strip foundation on piles is a structure consisting of a shallow monolithic foundation resting on piles driven into the ground. They are buried lower than the depth of soil freezing in a given area. They are often supported by hard rocks. Differences in relief heights, loose soils are not an obstacle to construction.

The top of such a foundation is a grillage foundation, which transfers most of the load created by the structure to the piles, and a smaller part of it to the ground.External walls and partitions rest on it. It differs from the usual tape in height and depth. The foundation tape is created by pouring concrete.

Bored piles are poured with mortar

Bored piles are poured with mortar

By the type of interaction with the ground installed supports are subdivided into rack piles and hanging ones. The first ones run into the underlying hard rocks. The latter are held by the friction force arising between their body and the soil.

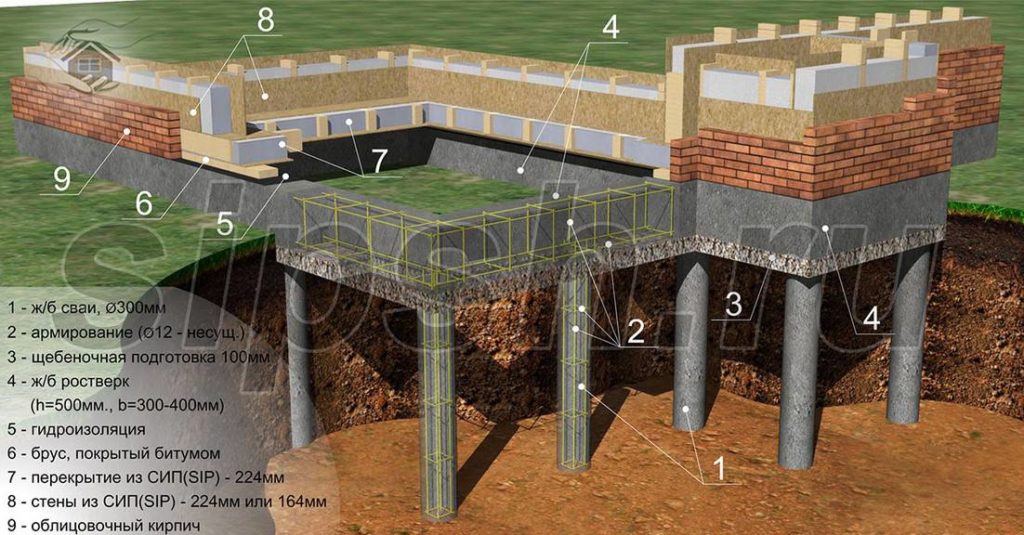

For the foundation, piles of the following types are used:

- bored ones, the formation of which occurs directly during construction work by filling drilled wells with concrete;

- driven - are ready-made pointed rods, for the use of which the use of special equipment is required;

- screw - metal pipes with a cast or welded tip.

Bored piles are suitable for country cottages

Bored piles are suitable for country cottages

Bored supports are characterized by the greatest strength, because they form a single structure with a grillage.

Such a combined base is used for the construction of the following buildings:

- cottages;

- low-rise houses;

- buildings with basement rooms.

On a pile foundation with a grillage, construction is carried out with light materials:

- tree;

- foam block;

- aerated concrete;

- ceramic blocks;

- various frame panels.

Screw piles can be screwed by hand

Screw piles can be screwed by hand

You can create a screw foundation with your own hands and from bored piles.

The process can be carried out using only hand tools.

This explains the popularity of these types of supports in individual construction.

We do the calculation of the foundation

In order to make a rational calculation, you need to decide on the characteristics of the piles, the type of reinforcement and waterproofing

It is very difficult to make the correct calculation according to the step-by-step instructions that you will take from specialized literature or an amateur video lesson. This is a difficult process and it is better to entrust it to professionals. By eliminating possible errors, you can save not only money, but also extend the life cycle of the building.

In order to make a rational calculation, you must have the following information:

- Geological results of the study, which include data on the structure of the soil, the level of groundwater and freezing of the earth and the features of the relief map;

- Estimate and project;

- Estimated data on the load on the foundation;

- Dimensions of the planned area for construction work;

- Crisis plan for possible land deformations;

- Data on the dimensions of the base from the tapes.

How to make a strip-pile foundation correctly?

Pile-strip foundation on bored piles

First of all, what is it! It is a monolithic concrete structure, which consists of concrete or reinforced concrete piles and a belt grillage that connects the piles to each other and serves as a load-bearing lintel. Accordingly, the construction of such a foundation should not begin with marking the location of the piles, but with a preliminary sketch of the future building. Why is it needed? And this is a simple calculation that includes the following parameters:

- Selection of building materials for the future building, execution of a sketch of a structure with a detailed specification of all materials for load-bearing walls and floors;

- Calculation of the maximum mass of the designed structure;

- Calculation of the maximum load on the existing soil, taking into account horizontal and vertical movements, as well as the possibility of soil displacement through seasonal movements;

- The choice of the type of grillage. As a rule, for massive buildings, a tape grillage is used, which can consist of concrete blocks or brickwork and is mounted under all load-bearing walls;

- Calculation of the type and diameter of piles. But here they often make mistakes, because there are ready-made formulas for calculating the load on piles, but they do not take into account the parameters of the state of the soil and the degree of its deformation.If they are not taken into account, then there will be a deflection in a weak point with further destruction of the structure.

Instructions for the construction of the pile-strip foundation

When conducting construction work, so to speak, by amateurs or handicraft teams, the following method of building a foundation can be recommended.

1. Cleaning, planning and marking of the territory

At this stage, the area is cleaned of debris and foreign objects, the site is leveled and the foundation trench is marked.

2. Preparing the trench for the grillage

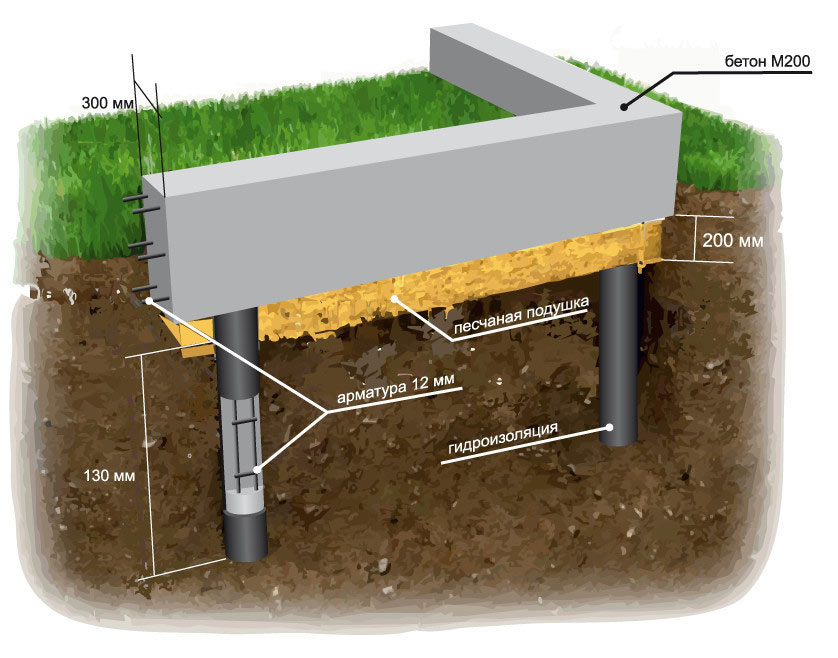

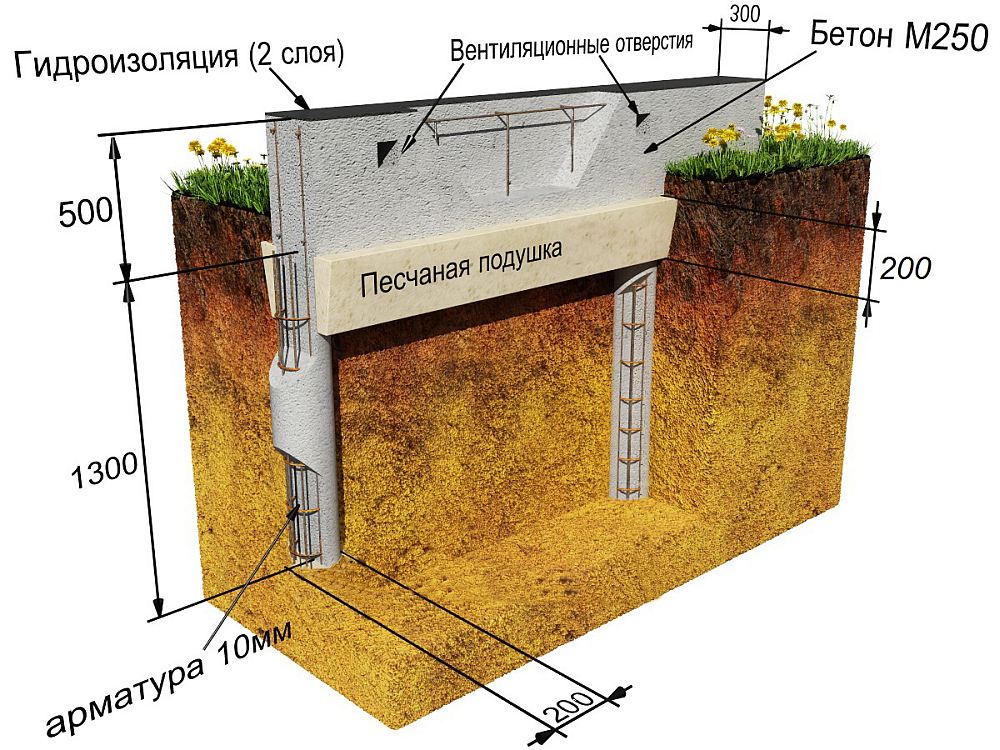

If the construction is carried out on non-heaving or slightly heaving soil, the grillage is made shallow, while its sole is located 20-40 cm below the zero mark. The trench must be made 10-15 centimeters deeper, which will be needed for the construction of sand and crushed stone cushion.

If the construction is carried out on non-heaving or slightly heaving soil, the grillage is made shallow, while its sole is located 20-40 cm below the zero mark. The trench must be made 10-15 centimeters deeper, which will be needed for the construction of sand and crushed stone cushion.

The required width of the trench is determined by summing the width of the foundation, which should be 10 cm more than the thickness of the walls with thermal insulation.

In conditions of heaving soil, the grillage is made unburied or placed above the zero mark, so that its ribbons in the spans between the piles are in a suspended state.

3. Preparation of wells for piles

For the production of wells, a drill with a diameter of 15 cm is used. They should be located in the corners of the foundation and along the grillage belts every 1.5 - 2 m. Wells should not only abut against solid ground, but sink 60 cm into it.

For the production of wells, a drill with a diameter of 15 cm is used. They should be located in the corners of the foundation and along the grillage belts every 1.5 - 2 m. Wells should not only abut against solid ground, but sink 60 cm into it.

At the bottom of each well, a cushion of cleaned sand of a coarse or medium fraction is formed, which should be poured abundantly with water and tamped.

Next, we immerse pipes sewn from roofing material using a fishing line, or asbestos-cement pipes, which will simultaneously play the role of formwork and waterproofing, into the wells.

Now it remains to install in each well a frame of three equally spaced reinforcement rods with a nominal diameter of 10 - 12 mm. The frame ribs are made of thin reinforcement with a diameter of 6 - 8 mm, to which the working reinforcement is tied with annealed wire.

4. Formwork device

Most often, in individual construction, an edged board is used for the construction of formwork. A smoother concrete surface is provided by the use of plywood, but this option will turn out to be too costly, since the slabs must have a thickness of at least 15 mm.

Most often, in individual construction, an edged board is used for the construction of formwork. A smoother concrete surface is provided by the use of plywood, but this option will turn out to be too costly, since the slabs must have a thickness of at least 15 mm.

In order for the formwork boards not to be damaged by contact with concrete and in the future could be used for other needs, it is better to wrap them with foil. The formwork must have a solid structure, for which it is strengthened with ties and struts.

5. Thermal insulation and waterproofing

Extruded polystyrene foam used as thermal insulation is waterproof, therefore waterproofing (roofing material) should be laid only along the bottom and inner walls of the trench.

Extruded polystyrene foam used as thermal insulation is waterproof, therefore waterproofing (roofing material) should be laid only along the bottom and inner walls of the trench.

The use of expanded polystyrene is due to its high ability to withstand mechanical loads from frozen soil during the cold season.

6. Reinforcement of the foundation

The strength and durability of the entire structure depends on how correctly the reinforcement is selected and the reinforcing cage is built. Once again, we note that when erecting a pile-strip foundation, it is better to entrust the calculation to a professional by contacting a construction or design company.

The strength and durability of the entire structure depends on how correctly the reinforcement is selected and the reinforcing cage is built. Once again, we note that when erecting a pile-strip foundation, it is better to entrust the calculation to a professional by contacting a construction or design company.

In the general case, if we are talking, for example, about the construction of a pile-strip foundation for a house made of aerated concrete or other light material, the following rule is applied: the reinforcement should account for 0.1% of the entire cross-sectional area of the foundation.

From reinforcement with a diameter of 10 or 12 mm, two belts are made in the upper and lower parts of the foundation, which are connected by transverse and vertical rods with a diameter of 6 - 8 mm into a single frame.

Reinforcement cages in trenches and wells are combined into a single structure. For this, they are also tied with annealed wire.

7. Pouring concrete

The work on pouring piles and grillages should be planned so that all the concrete is poured in one go, only then the foundation will be truly monolithic. Use heavy concrete (M400 or higher).

The work on pouring piles and grillages should be planned so that all the concrete is poured in one go, only then the foundation will be truly monolithic. Use heavy concrete (M400 or higher).

It is important that no air bubbles remain in the concrete layer, therefore, after pouring, it is pierced in several places with a reinforcing bar and only then leveled. The finished foundation is covered with a film to protect it from rain. To prevent the concrete from drying out, especially in hot weather, it should be watered periodically with clean water.

To prevent the concrete from drying out, especially in hot weather, it should be watered periodically with clean water.

The formwork is kept from 7 to 9 days, after this period it can be dismantled.

How to make a pile-strip foundation with your own hands, see the video

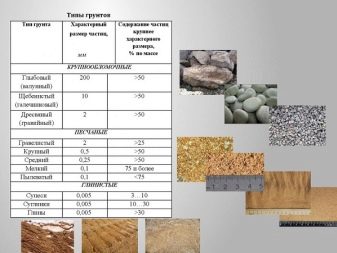

When can a pile foundation be used?

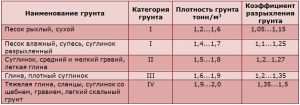

Soil density table

Soil density table

Of course, before proceeding with the story about how to correctly put a pile foundation with your own hands, you need to understand not only how this is done, but also what features of the structure and soil such a foundation is suitable for.

The first thing you need to pay attention to when choosing this type of foundation is the quality of the soil cover on the site where the construction will take place. The pile foundation can be effectively used on weak soils, which have a large freezing depth, a high level of groundwater, as well as an unstable topsoil (silt, clay, sand, loam, peat, purulent deposits)

The pile foundation can be effectively used on weak soils, which have a large freezing depth, a high level of groundwater, as well as an unstable topsoil (silt, clay, sand, loam, peat, purulent deposits).

The second thing you need to pay attention to is that the pile foundation can be used for certain houses. In individual construction, houses standing on piles should not have a lot of weight, that is, they should be built of light building materials (gas-foam concrete, wood, frame house options)

The erection of heavy structures is not recommended. Now you can move on to talking about the stages of its construction.

Preliminary calculation and required materials

It is recommended to start the construction of the pile-strip type of foundation with preliminary calculations. Why make them? And then, to avoid problems after the construction of the building.

It is recommended to start the construction of the pile-strip type of foundation with preliminary calculations. Why make them? And then, to avoid problems after the construction of the building.

In the course of their implementation, it is required to determine the required number of piles, their diameter, the depth of the foundation and the width of the monolithic strip of the base, which contributes to the uniform distribution of the load.

It is preferable to entrust the calculations to specialists with relevant work experience. The service life of the structure under construction directly depends on the correctness of the calculations.

The calculations take into account:

- wind load on the structure;

- number of storeys, dimensions of the future building;

- characteristics of materials used in construction;

- geological characteristics of the soil. For more information on the construction of this foundation, see this video:

Before making a strip foundation for a house from aerated concrete or other lightweight material, you need to stock up on the tools and materials indicated in the table.

| № | Materials (edit) | Instruments |

|---|---|---|

| 1 | sand or gravel | shovels: bayonet, shovel |

| 2 | plastic wrap or roofing felt | set of earth drills |

| 3 | antiseptic, primer, waterproofing compounds | concrete mixer or container for manual mixing of mortar |

| 4 | pipes made of metal or asbestos cement | Bulgarian |

| 5 | fittings | perforator |

Soil category, effect on concrete base

In sagging soil, piles buried below the freezing line feel confident

In sagging soil, piles buried below the freezing line feel confident

In the summer period, weak soil in some places under the foundation is washed out, subsidence occurs, and then the destruction of the base.With the arrival of cold weather, wet soil freezes and swells, pressure is created on the foundation, which also leads to its destruction.

The problem is solved with the help of piles buried below the soil freezing boundary, resting on a solid layer of earth.

A shallow strip foundation is cast on piles and does not depend on the changing state of the upper soil layer. The number and dimensions of piles, the dimensions of the tape depend on the load and the location of the building under construction.

Piles for tape are made in a bored version, forming a single monolithic structure. The choice of the base for the house depends on the category of soil. With heaving soil, it is advisable to use a pile-strip base.

| Name of soil | Soil category | Density of soil t / m3 | Loosening ratio |

|---|---|---|---|

| Loose, dry sand | 1 | 0,6– 1,6 | 1.05 - 1.15 non-porous |

| Wet sand, sandy loam, loosened loam | 1 | 1,4 – 1, 7 | 1.1 - 1.25 slightly loose |

| Loam, fine to medium gravel, light clay | 2 | 1,5 – 1,8 | 1.2 - 1.27 heaving |

| Clay, dense loam | 3 | 1,75 – 1,9 | 1.2 - 1.35 heaving |

| Heavy clay, shale, loam with crushed stone, gravel, light rocky soil | 4 | 1,9 -2 | 1.35 - 1.5 heaving |