Correcting errors

Diagram of a buried columnar foundation on heaving soil.

In order for the base of the house to be even, you must first set the level correctly. This operation implies the designation of the extreme points of the foundation, beyond which one cannot go. If you need to level the flaws in the already finished foundation, then you will need to re-level the level and do additional leveling of the surface. Experienced builders, faced with such a situation, state the fact that in this situation it is necessary to correctly bring the base to zero. This means making sure that all its extreme points are located in the same plane.

You cannot fix the bottom of the foundation in any way. Therefore, do not skimp on the material for the sand cushion. And be sure to study the characteristics of the soil on which you plan to build the structure. Since the most popular type of foundation that is found in the construction of residential buildings is the tape option for laying the foundation, it would be logical to follow the recommendations of SNiP II-B.1-62, which indicate the standards for. So, for example, if the estimated freezing depth of a conventionally non-porous soil is more than 3 meters, then the depth of the foundation will be at least 1 m.And if the calculated freezing depth of a weakly porous soil of solid and semi-solid consistency approaches a mark of up to 1 meter, then the depth of the foundation will be equal to 0 , 5 m.

Foundation sides

Diagram of the recessed strip foundation.

They are aligned based on how strong the bias is. If the difference is small enough, then you can nail a special Rabitz mesh with dowels or staples, and apply a layer of plaster on it.

If the difference is noticeable to the naked eye, your actions should be as follows:

- We are rebuilding the formwork.

- If the distortions are small enough, the cement slurry is simply re-poured into the voids between the formwork and the foundation.

- And if the difference is more than 5 cm, then you will need to apply a reinforcing mesh in those places where concrete will be poured. This technique will help to achieve maximum adhesion between the liquid concrete and the already dried formwork.

Top surface

The most critical part of the foundation leveling work is precisely in this part of the foundation of the house. It is on it that the waterproofing will be laid, and it is she who will be in contact with the walls. Proceeding from this, the presence of even the smallest distortions on its surface is strictly not allowed. So, what you will need to do if the top surface of the base of the house is uneven:

- We are rebuilding the formwork.

- Now you need to set the level correctly again. Since we need an even top, we need to shoot it with a leveling height. The term "shoot height" means a process when the highest and lowest point (in this case, the foundation) is measured and the value of one of them is taken as the starting point (in this case, the highest). Be sure to make marks on the formwork that will allow you to make sure that this time the mortar lies flat. Do not use a pencil or a marker for these purposes; the best fit are some kind of "beacons" made of self-tapping screws.

- When preparing the grout for re-grouting, remember that it must be much more liquid than the grout used to fill the main foundation.

In construction, there are several terms for denoting the leveling of the foundation: leveling along the horizon, bringing the basement to zero, setting the level, etc., but they have the same essence. This is the most flat foundation surface.

Pile foundation

If placing a bathhouse and other utility rooms under the same roof as the house is not essential, you should pay attention to the pile foundation. This variety is the most successful option for areas with a slope.

- Time-consuming and costly earthworks are minimized.

Excavation work in preparation for pouring the foundation on a slope

- The threat of destruction of the building is prevented when the upper layers of the soil are crumbling - the piles reach the deep layers of the soil.

- The construction will also not be threatened by storm water and groundwater - a problem for all areas on the slopes.

- In areas with heavy types of soils, large soil freezing, the pile foundation remains the only correct solution for the construction of reliable and durable structures.

- The pile foundation can be used for any type of building - from light wooden country houses to heavy and tall structures.

Pile structures differ in various parameters: by the method of immersion, by bearing loads, by the shape of the section, by the type of foundation.

Depending on the need for strengthening, the pile foundation is of several types:

- The pile foundation along the perimeter of the house, combined with the strip foundation, is an extended structure along the entire length of the perimeter.

Diagram of the device of the pile foundation on a site with a slope

- Single piles are used to support individual elements such as columns.

- Pile Bush - Piles are concentrated to reinforce one of the most difficult areas. For example, a house fits into the slope with three corners, and the fourth must be supported by a support.

- On a site with a slope, the most common use of a pile field is when structures are located under the entire area of the future building.

A necessary element for the construction of a foundation using piles is a grillage. These are structures that connect the piles. They are monolithic or prefabricated.

Depending on the type of soil and the required degree of reinforcement, piles can be laid in one of several ways:

- Driving reinforced concrete, metal or wooden structures into the ground. Earthwork is excluded here altogether;

Slope pile foundation construction

- Pouring concrete mixes and installing reinforced concrete pillars requires minor work in the ground, which consists in preparing trenches;

- Screwing in screw piles using a special technique. Excavation of the earth layer is also not required.

The foundation for a house on stilts is reduced to the following stages:

- The first elements of the pile foundation are screwed in, hammered in or poured into the highest point of the future foundation. The depth from the entry into the ground will be the greatest, and the above-ground part is equal to the smallest height of the plinth.

- The next part is mounted that will be the highest. A rope is pulled between the low and high edges, and with the help of a level they are aligned strictly along horizontal lines.

- Subsequent piles are driven in the required places between the corner piles with alignment to the required horizontal level.

The finished project of a two-story house from a bar on a pile foundation

- The last stage is the pouring of a monolithic grillage or the installation of its prefabricated structure.

Basic methods

Scheme for calculating loads on the foundation.

Leveling the base of the house is necessary, since a waterproofing material (roofing material and other material) is laid on it, which does not adhere well to an uneven surface. The tape is erected by pouring mortar into a pre-assembled wooden formwork. For its strength and bonding, reinforcement is installed between the layers of the solution. If there is a large difference in height, a board of the required width is placed under the building frame.

In the case when this figure exceeds 5 cm, house builders using a solution. Formwork is being built again from boards, the width of which ranges from 10-15 cm.They are fixed to vertical walls, after which they are filled with mortar. The height of the foundation is also regulated by adding additional reinforcement.

In the case when the strip foundation "walks" in width, during plastering work, a reinforcing mesh is stuffed on it. The resulting surface can be leveled by using a concrete solution.

Elimination of lateral irregularities

Their alignment is performed taking into account the amount of skew. If the discrepancies are small, you can fix the mesh-netting with staples or dowels and lay out a new layer of plaster mortar on it.

In the case when the difference is large enough, resort to the following actions:

- the formwork is set according to the level;

- with slight distortions, the solution is distributed over the void areas formed between the walls of the foundation and the formwork panels;

- when the gaps exceed five centimeters, it is necessary to apply a reinforcing mesh in the places where concreting is planned.

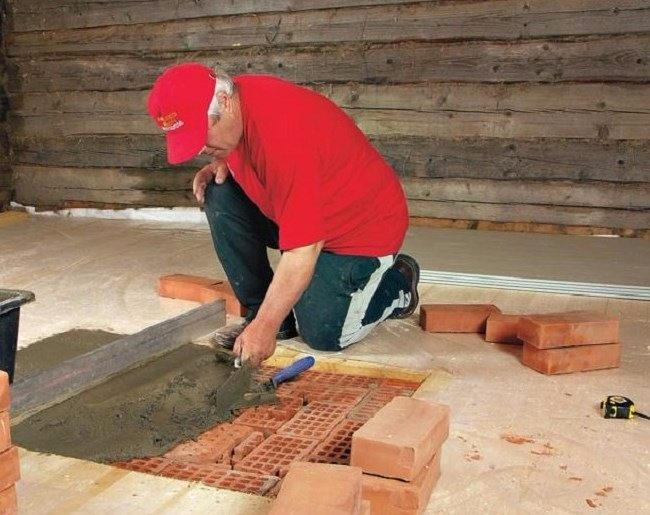

Leveling foundations with bricks

Leveling the foundation-plinth with bricks

When erecting foundations, especially without initial careful calculations, the occurrence of subsidence or slope of the structure in different directions is inevitable. This is especially noticeable in tape structures, where prefabricated elements are used.

It is strictly forbidden to build load-bearing walls on such an uneven foundation. First you need to level the surface, eliminate all irregularities and achieve the most even horizontal plane. How can the plinth of a building be leveled?

- Using concrete mortar. Small irregularities, bumps or depressions are eliminated there. Also, with its help, a plinth is prepared for the installation of finishing materials, as well as primary plaster. Too large slopes cannot be eliminated this way.

- With the help of brickwork. This eliminates distortions and too large altitude differences.

As a rule, small irregularities can already be noticed at the stage of gaining strength with concrete.

But distortions always arise already during the construction of load-bearing walls, they arise through the uneven distribution of soil layers, design errors and calculation of the foundation depth, as well as errors in the calculation of the boundary of soil freezing.

Depending on the type of foundation, there can be many methods for leveling the basement, but the cheapest, practical and most popular is with the help of bricks.

How to level the top plane of the foundation with a brick

Leveling the foundation with a laser level

Considering that leveling the upper plane of the base requires a considerable investment of time and resources, this must be done competently, with knowledge of the matter. First you need to figure out why the foundation was skewed.

In most cases, these are errors in the design and calculation of the load-bearing elements of the building frame. Brick leveling technology:

- Installation of vertical guides along all bearing edges of the foundation. You can use an indicator tape, rope or other device here. Alignment must be performed using a hydro level, laser level or other devices.

- Then a layer of brick is laid on the concrete, and installation at an angle is allowed. The brick is connected with liquid concrete mortar.

- In case of slight differences in height, you can use broken brick, which is used as a filler for concrete mortar.

- After laying the bricks and checking the horizontal, the top layer is covered with concrete and left to dry for several days.

When a single brick is used to level the surface of the foundation, it must be remembered that it does not have as good load-bearing characteristics as concrete.

Therefore, in order to achieve optimal structural strength, it is necessary to use the masonry to the maximum, breaks must not be allowed, as well as voids.

How to properly level the base with concrete mortar

The process consists of several stages of varying importance, and here materials are used that are optimal for leveling vertical and horizontal surfaces. Thus, depending on the characteristics of the substrate and the type of unevenness, sometimes it is enough to just plaster and level the surface. But this is possible only if the difference is insignificant and is more characterized by irregularities.

And if the height difference is significant, then a whole technology is used:

But this is possible only if the difference is insignificant and is more characterized by unevenness. And if the height difference is significant, then a whole technology is used:

- First, the surface is cleaned from adhering dirt and stones.

- Then formwork is erected from wood or roofing material. Here it is recommended to make horizontal and vertical strapping so that the formwork itself is as even as possible. This determines the highest and lowest point of the base, where the alignment is carried out. Considering that the entire structure will be filled with concrete, it is better to mark key points on the formwork.

- On the inside of the formwork, where the concrete strip of the supporting structure passes, horizontal lines are drawn using a level and poured with concrete. If the distortions are minor, then it is better to use a more liquid solution. And, if the distortions are significant, then it is better to fill it with a thick solution.

After pouring the concrete, the base is left to dry for several days and the formwork is dismantled. In some cases, it can be left, because the outer surface is perfectly flat. A waterproofing layer can be installed on the formwork and foam plastic can be glued for thermal insulation.

Leveling the top layer of the foundation

Top layer leveling process

If the side surfaces of the foundation can be leveled quickly and relatively cheaply, then the top layer is already more difficult. After all, load-bearing walls will then be erected on it, so the surface should be perfectly flat. If the irregularities are insignificant, then with the help of the level marks are set and the formwork is mounted on them. The lower edge is connected to the foundation, the joint is closed with roofing material. Then everything is poured with concrete.

If the surface has minor errors or irregularities, then it is enough to level it with liquid concrete according to the rules. When the foundation of the house is made of wood, then it can be successfully leveled with additional planks. And the combined method in such cases is to use concrete mortar, moss, wooden beams and several balls of brickwork. It is advisable to lay such mixtures on a waterproofing layer.

Construction of profile membranes

Polymeric membranes, which have recently appeared on the construction market, are used in works of this type as a means of waterproofing. Fiber protects the building from moisture rising from the soil. The spiked profile at the same time strengthens the soil, and this is a fundamentally new property of such materials.

- reduce the likelihood of formation and the number of cracks during shrinkage;

- redistribute efforts when transferring the load to the base;

- ventilate voids between insulation and concrete;

- water is guaranteed not to leak out due to a section of a certain shape;

- are distinguished by their durability and strength;

- able to withstand too high and too low temperatures.

Fiber is laid on a layer of geotextile on an already formed sand and crushed stone. preparation before concrete is poured.

Leveling the ground

Preparation of the site for the foundation includes the stage of leveling the soil. In practice, foundations are poured without preparation.

A number of small mistakes add up to a big one and lead to disaster. Errors start with cracks. Doing it right is not ignoring the preparatory phase. Consult a structural engineer and designer.Experts will select the best option.

There are three types of preparation of a site for a foundation:

- Crushed stone;

- Sandy;

- Cement.

Crushed stone is used under the foundation slab. Preparation is needed when the water table is high enough. The weak bottom layer is covered with crushed stone, rammed and built a foundation.

Additionally, you will need a leveling layer of concrete, waterproofing, a protective layer over the waterproofing and a reinforcing cage. Crushed stone is used to distribute the load. The material is poured into a trench, tamped and a monolithic slab is placed on top.

Sand preparation is often used in cases where foundation blocks or prefabricated soles need to be placed under the base.

The concrete preparation is designed to level the trench and distribute the load correctly. Many people choose the cement option using B7.5 concrete. It is convenient to fix the formwork during installation. Cement preparation plays the role of an additional protective layer of concrete and a convenient location of the reinforcement in the clamps.

Foundation leveling instructions

To remove the foundation in the process of pouring "under zero", you must perform the following work:

In one of the corners of the foundation, with chalk or a marker, you need to put a zero point on the inside of the planned surface. Using a hydraulic level (if possible, you can use a level), similar zero marks are determined in the remaining corners of the foundation, and then marked.

In the absence of a hydraulic level, the zero points in the corners can be set using an ordinary hose. For this purpose, the ends of the hose are located in two corners to be checked.

Then water should be poured into it, it is important that air locks do not form. The edge of one end of the hose is then positioned exactly at the reference zero point.

The second end of the hose must be lowered or raised so that the water at the first end is at the level of the edges of the hose, namely at the level of the original zero mark

The position in which the liquid is established at the second end of the hose must be fixed. This position fully corresponds to the zero point level. It should be noted on the formwork.

In each corner of the foundation in the formwork, it is necessary to make two vertical cuts, so that they are located in the center of the enclosing structures of the foundation, while the lowest mark should be at the level of the zero points. Now, if you pull the cord through the corresponding cuts, it will accurately mark the zero level on the surface of the foundation.

Then, to the level of the stretched cords, the concrete mixture is poured into the formwork. As a result, thanks to these works, it was possible to set the foundation “to zero”.

Correction of the shortcomings of the strip foundation

To make a perfectly flat base or basement of a house, you need to set the level and find the point of maximum discrepancy. In simple words, you should redefine the value, which will be a guide when leveling the surface.

Professionals in the construction field refer to this procedure as "zeroing the base". Under this term, there is a simple interpretation - to set the maximum point and align the rest with respect to it in one horizontal plane.

Since we will no longer be able to influence the bottom of the support after pouring the foundation, it is more expedient not to save on materials for a sand and gravel substrate from the beginning.

Sides of the base

The presented foundation elements are leveled after the curvature index is established. In the event that the difference between the required and actual values is not too high, then the mistakes can be corrected by fixing a special metal mesh. Subsequently, the installed frame is plastered with a special solution.

We recommend watching a video on how to align the sides of the base.

In the case of a strong curvature of the side faces, you must perform the following actions:

- re-equip the formwork system according to the level;

- then we fill the leveling concrete solution in the gaps between the formwork and the foundation;

- to increase the rigidity of the adhesion, it will not be superfluous to install a metal mesh.

Upper end of the foundation

The alignment of the presented part of the base is a more important undertaking than the alignment of the side faces. This is primarily due to the laying of waterproofing sheets and the subsequent formation of the structure along the level of the load-bearing supports.

The alignment of the strip base with a brick is done by sawing and laying it

The duration of the further period of operation of the structure and its reliability depend on the ideally flat surface of the foundation or basement. Thus, even the presence of small discrepancies after the surface arrangement is not allowed. Support alignment can be done in several ways:

- We equip the formwork system along the perimeter of the working plane with a margin. Then, using a building level or level, we set the alignment boundary and make marks around the perimeter of the formwork. We prepare the cement mortar and fill it to the marked height. In the case of leveling in this way, it should be borne in mind that the prepared cement mixture must have a more liquid state than that which was originally used when erecting the base or basement.

- Leveling with masonry. The presented method is ideal for situations where the possibility of installing a plinth is allowed. However, brick laying can be performed in several rows with insignificant discrepancies of the working surface.

The procedure for laying bricks involves laying and fixing a waterproofing layer, applying mortar to both the brick and the foundation, laying brick, processing the erected brick wall with mastic.

Watch the video on how to level the top level of the base with your own hands.

Alternative alignment methods

If you look at any strip foundation, it becomes clear that it has 4 surfaces: an upper horizontal, two sides and a sole (lower horizontal). And each of these surfaces should be as flat as possible so that the base turns out to be strong and durable.

At the beginning of the article, we said that in order to level the foundation, it is necessary, first of all, to organize a flat construction site or use a concrete solution. But with minor differences, it makes sense to use an alternative and less costly method. Insignificant defects on the outer sides of the foundation can be eliminated by lining with bricks. The additional thickness of half a brick creates not only a strong and even support for the foundation, but also serves as the basis for applying decorative plaster, tiling or other materials.

Some experts prefer to use a chain-link construction mesh instead of bricks. To do this, it is tightly fixed on the surface of the walls, after which it is covered with a layer of cement-based mineral plaster. After drying, such a basement can be tiled with tiles, artificial stone or other materials for exterior decoration.

If irregularities are found on the inside of the foundation, they can be completely ignored (of course, if the differences are insignificant). In the event that you live in a region with harsh climatic conditions, it is recommended to cover irregularities with heat-insulating materials. In such a simple way, you will give the outer walls of the basement an aesthetic look and insulate the house.For such work, it is better to select waterproof insulation like expanded polystyrene (conventional and extruded), basalt wool, etc.

For houses built from timber or logs, the following alternative method is suitable - to put boards of different thicknesses. These boards must be treated with a plane and impregnated with antiseptics so that they do not cause rotting of the upper tiers. It is worth noting that such a solution is only relevant for eliminating small differences in height.

For stone houses, this method is not suitable due to excessive load. Here you can operate only with a cement-sand mortar (to increase the strength, you can add a little crushed stone to the solution). If the difference in height is more than 10 cm, it is necessary to install the formwork and pour a leveling layer of concrete.

Leveling the lightweight foundation

To level the foundations on which it is planned to build a lightweight structure, it is necessary to install the frame of the future terrace (grillage). After that, placing wooden blocks in the right places, you can bring the frame to a perfect horizontal at all points. However, since there is no support on the plane, this method of action is not entirely correct, and it can be applied only in extreme cases.

To reach the required height, a sand-cement mortar is plastered into the lining, after which bricks are laid out on the resulting layer, which will serve as the basis of the basement. Only red fired bricks are suitable for such work, since any other will not cope with the load.

It is possible to compensate for the missing height not only with the help of bricks. We remind you that here we are talking about leveling the foundation for lightweight buildings, and therefore expanded clay blocks will also work. It all depends on the difference in height, and the resulting seams must be reinforced with a reinforcing mesh and covered with cement plaster.

Leveling the foundation on a slope

Current building technologies allow you to build houses literally anywhere, even on sloped plots. If the soil is very hard and cannot be leveled, the foundation will have to be made taking into account the slope of the surface, but at the same time it must be brought out to a strict horizontal.

If the slope is not too steep, then the foundation can be built on a surface leveled by backfilling. For backfilling, gravel of different grades and crushed stone mixed with soil are used. The height of the embankment should correspond to the difference in heights of the highest and lowest points of the construction site. When composing a project for such a house, be sure to take into account the features of the relief and soil characteristics. The embankment should be made of low-heaving or non-heaving soil, since it has sufficient bearing capacity.

So, now you know how to level the foundation, compensate for height differences and organize a level construction site. But even if you are lucky enough to work on a perfectly flat surface, in the process of pouring concrete into the formwork, whether it is a strip or columnar foundation, do not be lazy to check the level indicators as often as possible.

Types of uneven foundations

Foundations serve as the basis for the construction of a building structure, and therefore increased requirements for strength, reliability and stability are imposed on them. The reliability of the entire building depends on how correctly the foundation is poured. There may be several foundations defects after pouring: vertical deflection of the structure walls and an uneven surface horizontally. Such errors can be corrected, you just need to know some subtleties.

Defects of lateral unevenness of foundations

The reason for the deviation of the linear verticals of the side edges of the foundation may be an incorrectly installed or poorly reinforced wooden or panel formwork.If the boards or formwork boards are not set at a vertical level, then when pouring concrete, the walls of the foundation will be crooked and uneven. Depending on the magnitude of the deviation from the vertical level, various methods are used to eliminate the defects that have arisen:

- If the deviations in the vertical level are insignificant, within the range of up to 20 or 30 mm, then in this case it is enough to fill a metal plaster or reinforcing mesh on the walls of the foundation and apply a plaster cement-sand mortar, carefully aligning the side edges of the foundation with the level or plaster beacons.

- Instead of leveling plaster, you can stick extruded polystyrene foam 20 or 50 mm thick on the curved side wall instead of leveling plaster. In this case, in addition to correcting linear roughness defects, additional thermal insulation of the foundation walls will be performed.

- In the case of a significant level of curvature of the foundation (more than 50 mm), it is necessary to re-install the formwork, fix a metal mesh made of reinforcing steel to the side walls and pour concrete mixture.

Leveling the side of the foundation

Defects of the horizontal surface of the foundation

The foundation for the building should have not only smooth walls, but also a strictly horizontal surface of the upper part. When building houses, horizontal cushioning waterproofing from two layers of roofing material or other waterproofing material is laid dry on the upper part of the foundation, and only after that the construction of walls begins.

The unevenness of the upper level of the foundation can occur in several cases:

- Incorrect foundation preparation. Before installing the formwork for pouring the foundation, it is imperative to make a sand preparation of at least 100 mm, this thickness will allow to level the unevenness of the ground. The sand is filled up, spilled with water and carefully compacted. At this stage, it is easy to achieve the horizontal level of the base of the foundation using the building level. The strength of spilled water and compacted sand cushion is comparable to that of a cement screed of the same thickness. The horizontal sand cushion guarantees a level foundation.

- Inconsistency with the zero level of the foundation. In construction, it is customary to consider the level of the finished floor of the first floor under the zero mark. The upper part of the foundation of the building, protruding above the ground, is called the base of the building by the builders. From all these definitions, it is clear that the zero level of the foundation is nothing more than the upper level of the basement. If the poured foundation is below the design level of the clean floor, then such a foundation must be leveled.

Correction of defects in the horizontal part of the foundation

Injection anchorage of the foundation for masonry and columns

Strengthening the base foundation with a monolithic slab.

Here, bore-injection piles are used, which differ from pneumatic supports in the design and method of supplying the solution. Strengthening the foundation is done as follows: concrete solution is pumped into such supports under pressure, which then creates a so-called monolithic cushion under the foundation of the masonry itself.

When concrete is pumped, the soil is compacted, a monolithic slab is created, drilling is carried out by various methods, the soil movement is practically not felt, therefore the method sometimes helps to save architectural monuments, where the masonry itself is a work of architectural art. But this method is worth a lot of investment, because sophisticated drilling equipment is used, detailed geodetic studies and calculations are carried out, and architects and drilling specialists are involved.

Making a monolithic slab on your own is almost impossible from a technical point of view. It is also worth using the method to strengthen single supports, because then the distribution of the mass of the structure is normalized, and the concrete masonry will withstand additional loads.

How to strengthen the foundation should be decided only by specialists, and not by the owner of the house. But the reinforcement methods will be the same, be it a strip base or a columnar base with columns.

How to build a foundation on slopes

Sketch of a stepped foundation structure on a site with difficult terrain

As a rule, the construction of such foundations is too complicated and financially costly. The slope is considered large if the height difference is a meter or more, and these are full-fledged slopes. Here you need to immediately design a stepped base structure, but it is too expensive. But the columnar bases here will be just optimal.

The construction of such foundations consists of several stages:

- Territory marking, vegetation removal and initial leveling of the ground.

- Digging grooves for future pillars. The depth is selected in such a way that the future pillars have a horizontal plane, and the grillage protrudes slightly from the ground at the highest point.

- Then the reinforcement is installed and the structure is poured with concrete.

It is clear that it is earthwork here that will account for at least half of the estimated costs for the construction of the building's foundation.