Insulation of a columnar foundation

After the columnar foundation with the grillage has been erected, a pick-up should be made. It is a replacement for a plinth. The fence protects the space between the ground and the base of the house from snow drifts and drafts.

Wooden pick-up is an affordable and easy-to-install option for lining the basement. It is made of boards that are placed vertically or horizontally. The work process includes:

- a 40 cm deep trench is dug between the supports;

- one third of the depth is covered with fine sand and gravel;

- wooden bars with a groove 40-60 mm wide are attached to the pillars of the base;

- grooved boards are attached to each other;

- from below, the filling is poured with expanded clay.

With the vertical position of the boards, the first beam is laid on the pillow in the trench. The second is fixed at the bottom of the building. Boards are vertically inserted into the grooves made on the bars.

To make a brick or stone filling between the supports, you should also dig a trench into which the pillow will be poured. The thickness of the filling in this case will be 1.5 bricks. Stone walls should not be more than 30 cm.

With a support height of 0.7 m, the filling is made of heat-insulating plates. They create it in the following sequence:

- a structure in the form of a frame, which is made of a steel profile, is fixed on the supports;

- from the inside, heat insulation is fixed - expanded polystyrene;

- from the side of the street, corrugated board is fixed on self-tapping screws;

- the resulting gap between the elements of the corrugated board and the ground level is sealed with thermal insulation material.

With any option for creating a filling, remember about the ventilation windows through which the space under the house will be ventilated. The diameter of these holes ranges from 100 to 150 mm. In winter, the vents are covered with rags.

Types of grillage on piles

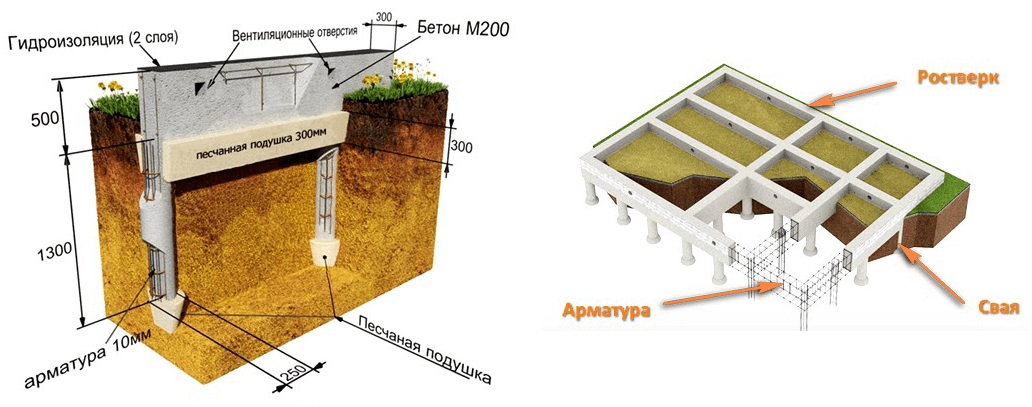

Loads from the house on unstable soil through the grillage are transferred to the deep layers. They are dense enough to withstand heavy loads. A pile foundation with a grillage is erected in regions with a soil freezing depth of up to half a meter. If the house is being built in an area with difficult terrain, this type of foundation is the only possible one.

Grillages placed on piles are divided into groups, taking into account the production technology:

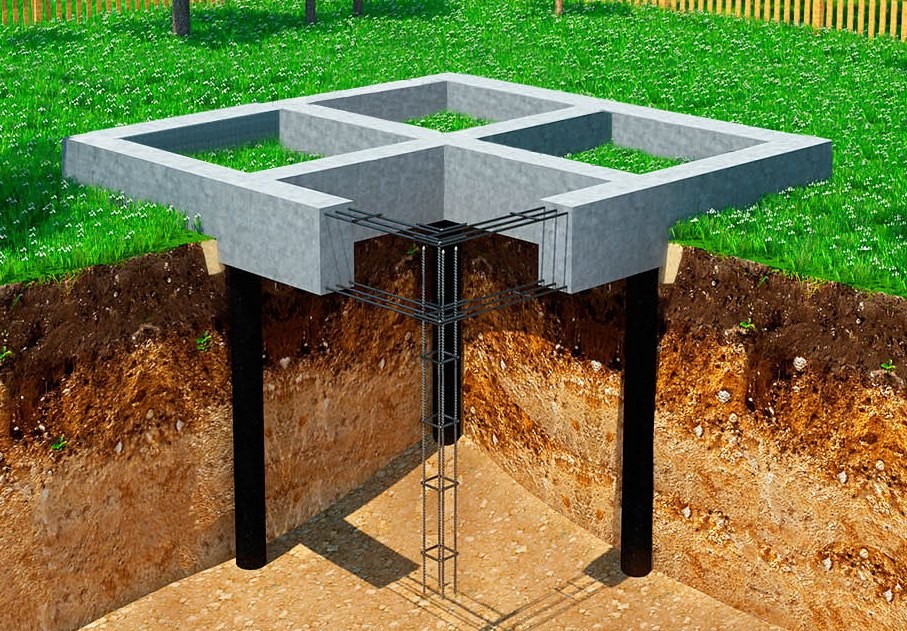

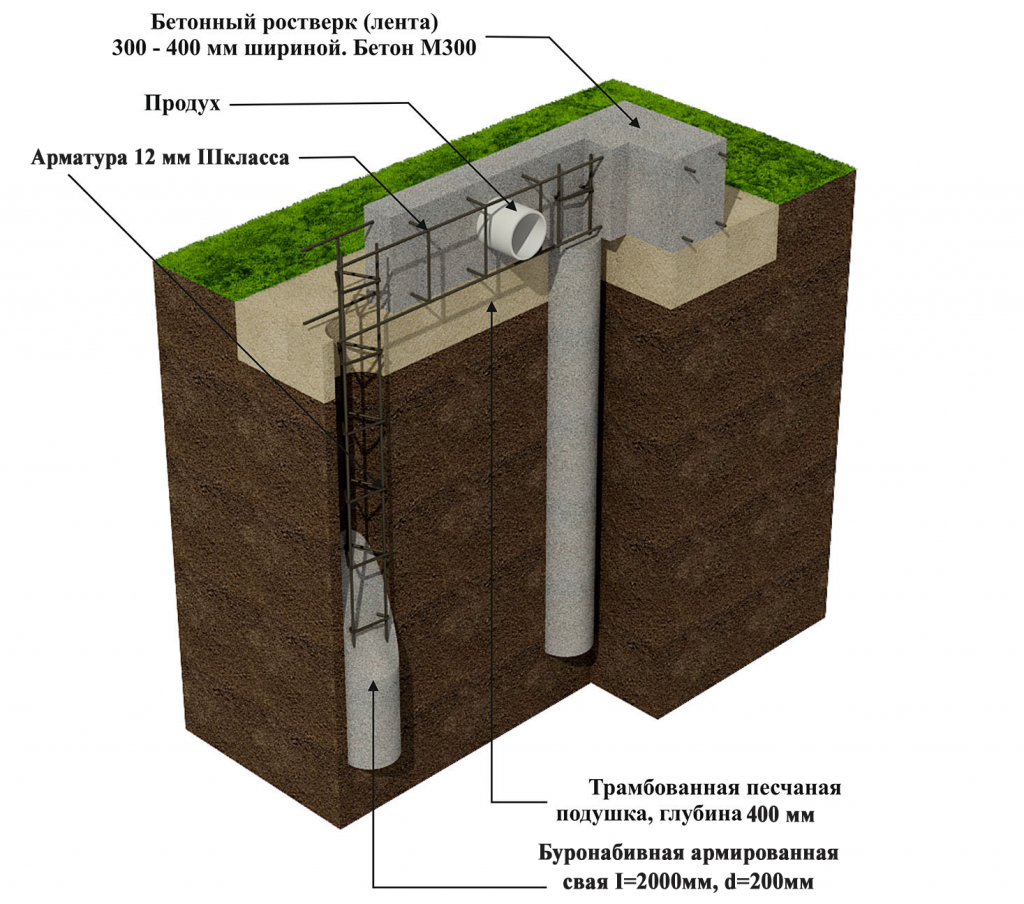

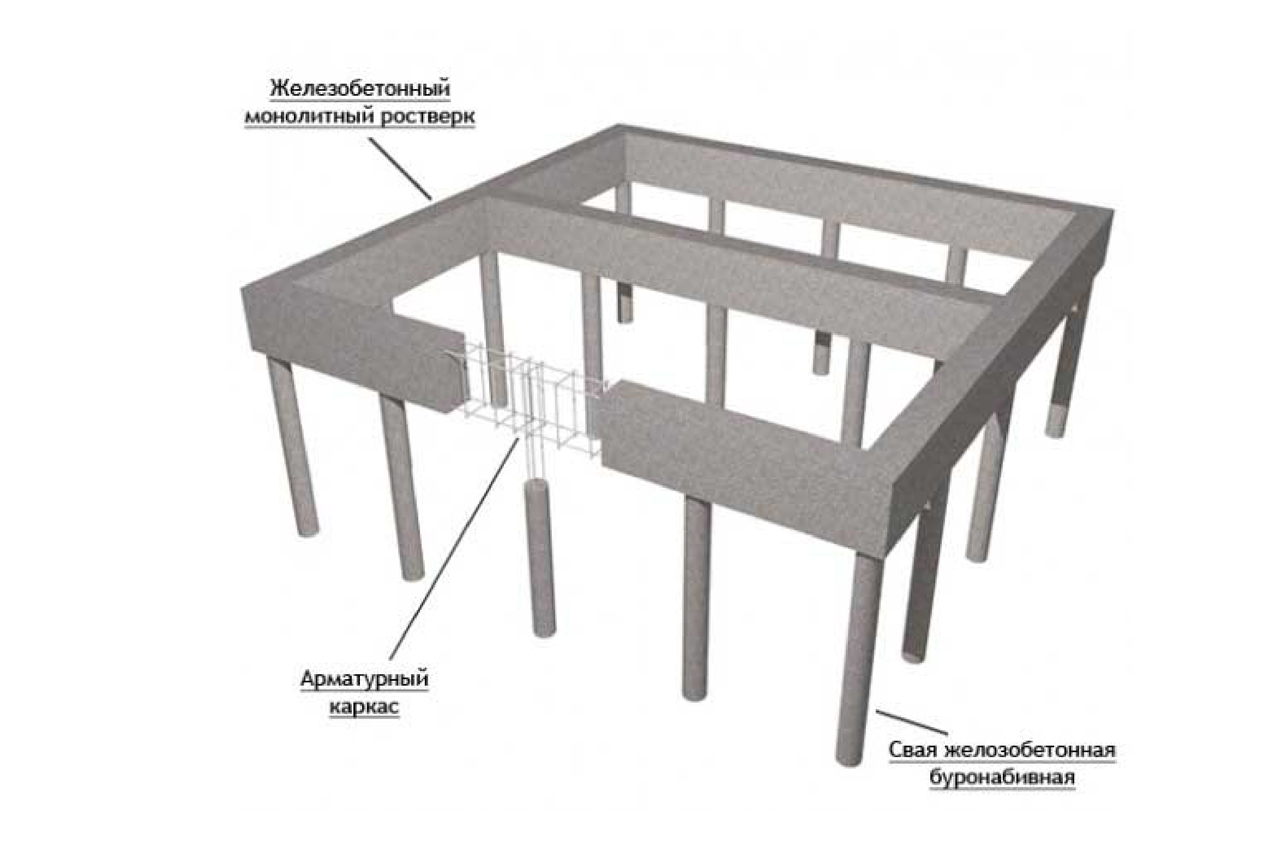

Monolithic. They are reinforced tapes. They are built on the principle of a simple tape base. However, sometimes they can be made in the form of a plate. In this case, more money and time is spent on filling. The binding of the pile heads with a tape grillage occurs along the perimeter, and in the locations of the bearing walls

It is important to understand that the pile-strip foundation is erected only in cases where it is permissible according to the calculated strength indicators.

National teams. They are built from reinforced concrete beams.

You can create a full-fledged grillage by connecting several ready-made elements. Subsequently, they are monolithic.

Prefabricated monolithic - combined structures.

The dimensions of the grillage on the pile foundation are determined in accordance with the design. The width of the tape usually exceeds 40 cm and exceeds the width of the wall by several centimeters. You can understand what a pile foundation grillage is when studying the differences between such structures:

- High is capable of transferring the load from the supporting structures of the house to the deep layers of the earth. It is erected on highly heaving soils. In this case, the action of the forces of frost heaving does not affect the state of the sole. There is a ventilated area under the houses with high grillages. In cold weather, large heat losses pass through it.To exclude drafts, the floor is insulated, and the basement is covered with shields.

- Short. When supported on the ground, it partially relieves the load from the piles. It is placed at a height of 10-15 cm above ground level. It is necessary to take measures to prevent the soil from crumbling under the belt. Otherwise, the earth will be hammered under the grillage, and will raise it during the winter heaving. The tape may come loose from the piles.

- Recessed. It is placed in a trench to a depth of 30-40 cm. In this version, it is much easier to make a monolithic grillage. The trench will partially replace the formwork. In this case, the floors of the first floor will not be very cold.

Each of these types of grillage is chosen depending on the characteristics of the site and the future house.

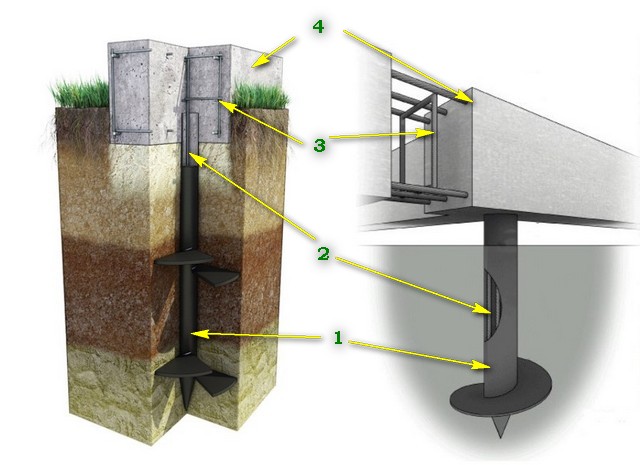

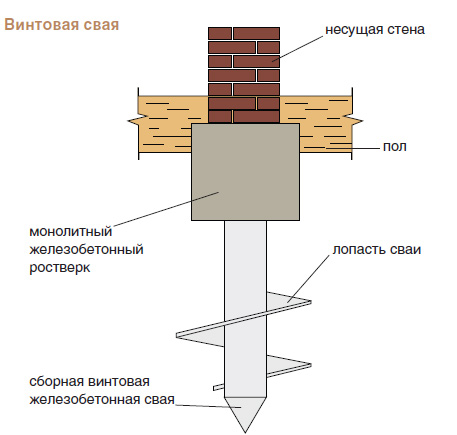

How does a screw pile work?

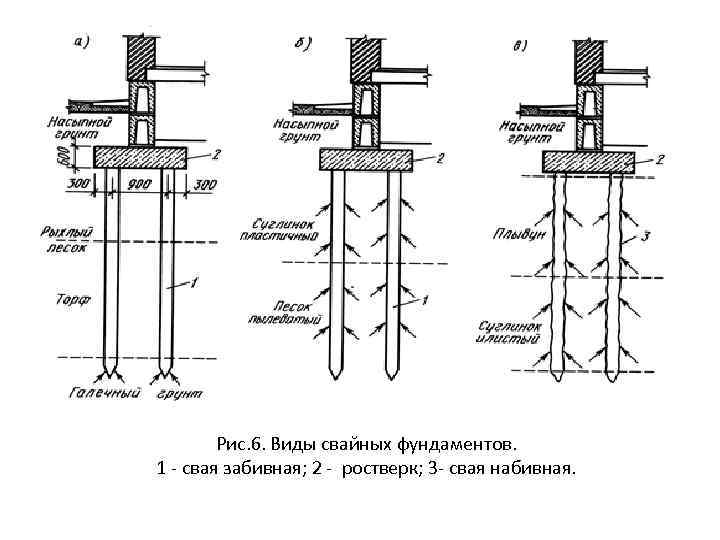

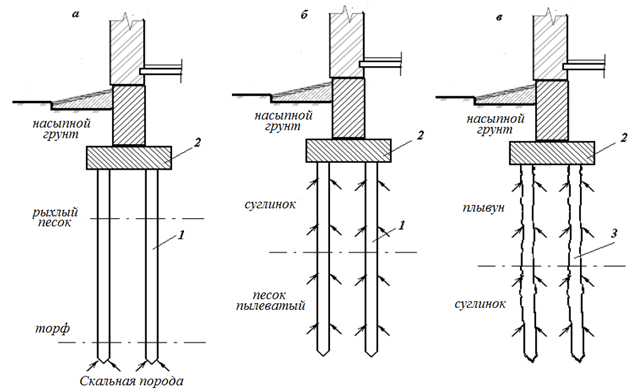

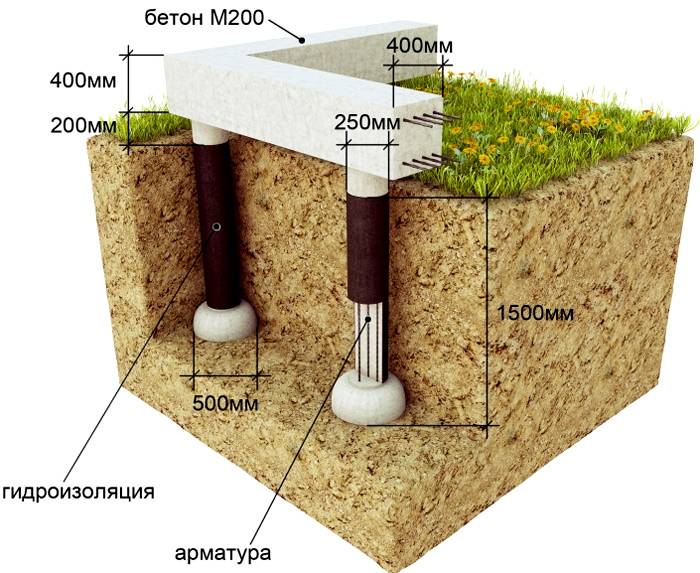

Let us analyze the case of the arrangement of soil layers, typical for the middle zone of the Russian Federation, see Fig. on right:

Work of a screw pile in the ground

Above - humus, gradually turning into sandy loam, with a total thickness of 0.15-3 m

In this case, it is not their fertility that is important, but the fact that the soils are very weak, the bearing capacity is less than 2 kg / sq. cm, loose and deep in depth, and before winter and abundantly, moist.

Loam layer with a bearing capacity of 3-4 kg / sq.

cm. Its capacity for the possibility of using conventional screw piles must be at least 0.7-1.2 m, and it itself must be solid within the construction site.

Loose, strong, up to quicksand, water-laden alluvium of high thickness; bearing capacity no more than 2-3 kg / sq. m.

In the chernozem belt, humus on sandy loam can reach a thickness of more than 5 m on one side. On the other hand, there in some places the so-called. ergeni - sandy-clayey sediments of the Ergen River during the last glaciation, along which the waters of the melting ice sheet of Fennoscandia flowed into the ancient Sarmatian Sea, which united the Black, Azov, Caspian and Aral. It got its name in geology from the Ergen moraine ridge, in which these characteristic deposits were first discovered. By the way, according to geological data, this "river" reached 200 km of channel width, and its floodplain - 600 km.

The bearing capacity of ergene already at a depth of 0.5 m reaches 5-6 kg / sq. m, and when the pile is screwed in, the compaction cone grows extremely quickly. If the pile went into the yergen before jamming deeper than 2.5 m, great, the foundation will be very strong. If it is less than 2 m, it is impossible to build on piles here. But back to the usual soils.

The upper layer of humus with sandy loam, subject to freezing, is heaving. When freezing, water expands evenly in all directions, so in winter the heaving soil will firmly grip the pile from all sides and pull it up with tremendous force. And in the spring, having thawed, it will move to the sides and give it the opportunity to sag and bend freely. In our area, alas, almost all the load on the screw pile is transferred by its fifth lower, and almost nothing holds its weight from the sides. Squeezing out water and pressing the soil around the pile into a conglomerate, as when driving a hammer, does not occur when screwing in a screw.

Sandy loam below the freezing depth almost does not resist pile pulling. If the loam layer, which only takes the load, is less than its minimum thickness of 0.7-1.2 m, then only 2 outputs remain:

- Drive the pile into loam only for 1 turn of the screw, and the end of the pile should not pierce the supporting layer by more than half, otherwise it will be washed away around the pile with soil water. Another condition is that there must be at least 2.5 m from the lowest point of the construction site to the bearing layer, otherwise the foundation will not have adequate lateral stability.

- Take a very long, not shorter than 5 m, pile of a special design for heaving and floating soils, see below. The same piles are suitable for the upper layer over 3 m thick, for example. on black soil. But they can be wrapped only with heavy special equipment. Not only is the pile long, but also the earth is viscous and sticky.

Types and purpose of grillages

Grillage structures differ in type and purpose. Many factors are taken into account when choosing the required design.

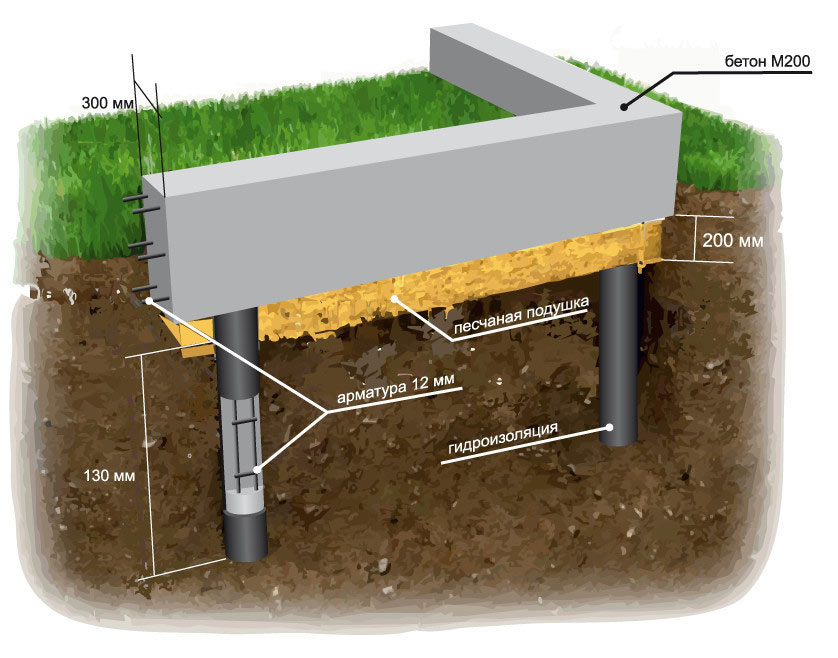

Strip foundations with grillages

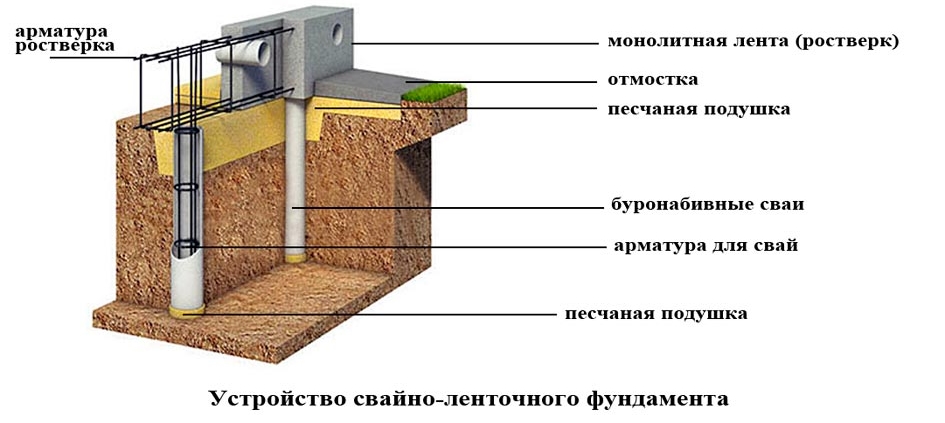

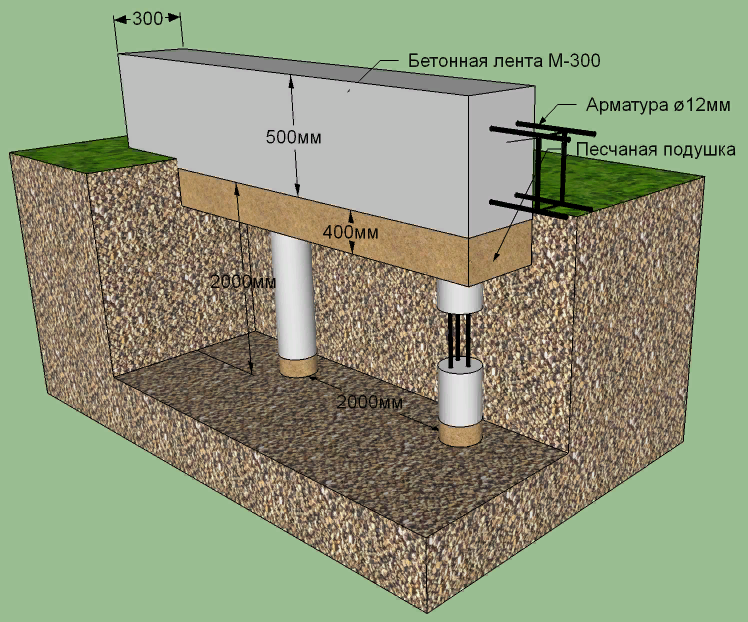

For buildings, pile foundations with a tape grillage are quite strong and reliable support, for the construction of which two technologies are used. One of them is used when arranging foundations above ground level, and the second is used at the stage of creating a lattice structure, which takes on part of the load.

Sectional strip foundation with grillage

A strip foundation is the best option for constructing a foundation on slopes and areas with difficult terrain, since it does not require complex preparatory work for planning the site with the involvement of special equipment. This design is perfect for the construction of structures made of lightweight materials.

Using a strip foundation during the construction of a house is imperative:

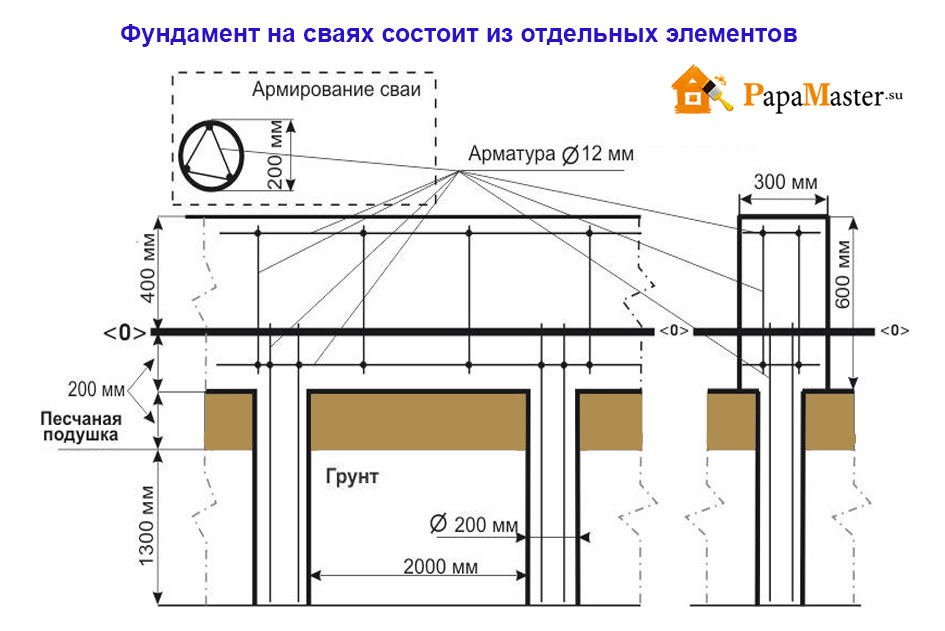

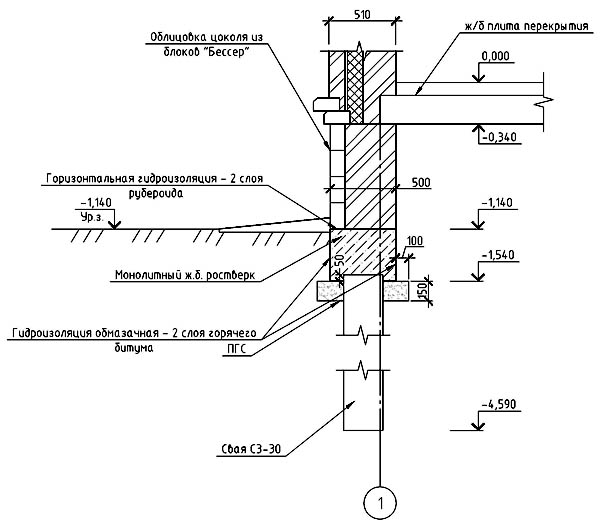

- Sand cushion, thickness of which is 200-300 mm. It is created under the concrete frame and piles to protect them from the destructive effects of soil moisture.

- Waterproofing of the grating and supports, for which they use polyethylene film, roofing material or asbestos-cement pipes.

When arranging the foundation, it is necessary to carefully calculate the number and pitch of piles in the band grillage, as well as its thickness and other parameters.

For the fence

The device of a grillage for fences is necessary for full protection of the structure, which the plane of the fence cannot provide. The creation of the belt is due not only to the provision from external factors, but also so that, for example, pets cannot get out of the site. The reasons can be any, but the performance must always be of high quality, to ensure the strength and durability of the structure.

Fence grillage

In principle, the grillage under the fence practically does not differ from the belt used in the arrangement of the foundations of houses. It uses the same construction, building materials and performs similar functions.

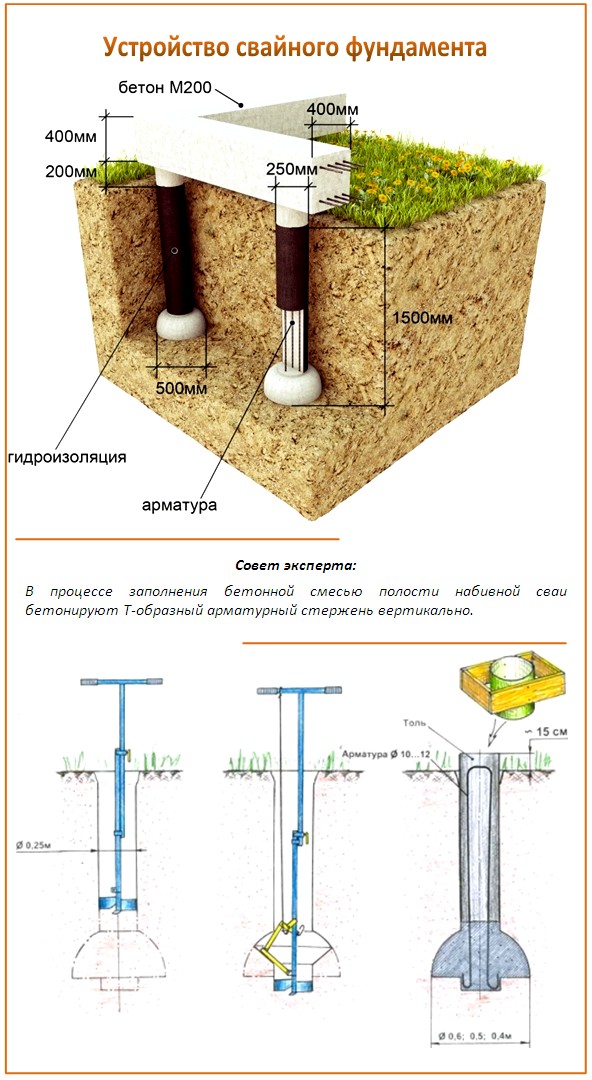

For pile foundations

The need for a columnar foundation with a grillage is directly determined by the specific structure of the building, its weight and the rigidity of the structure's frame. In order to prevent the supporting columns from collapsing, they are obliged to use a monolithic reinforced concrete, metal or even wooden belt.

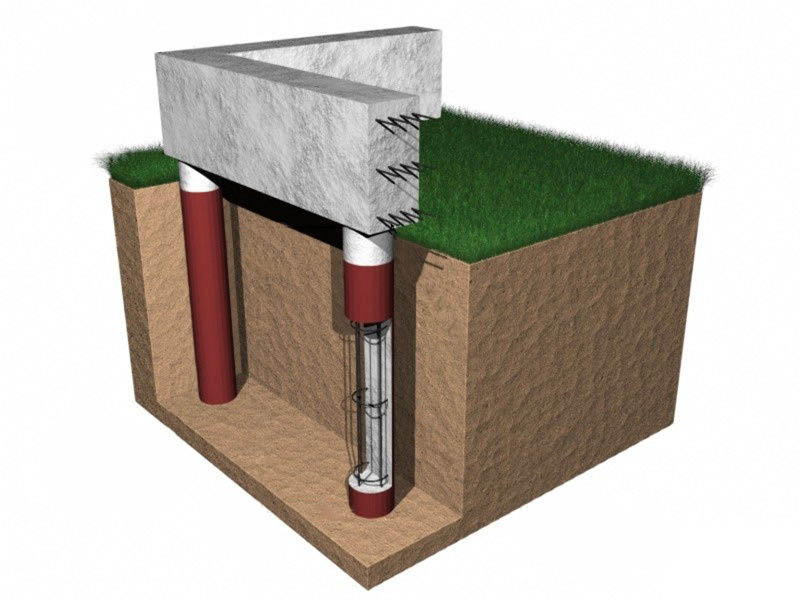

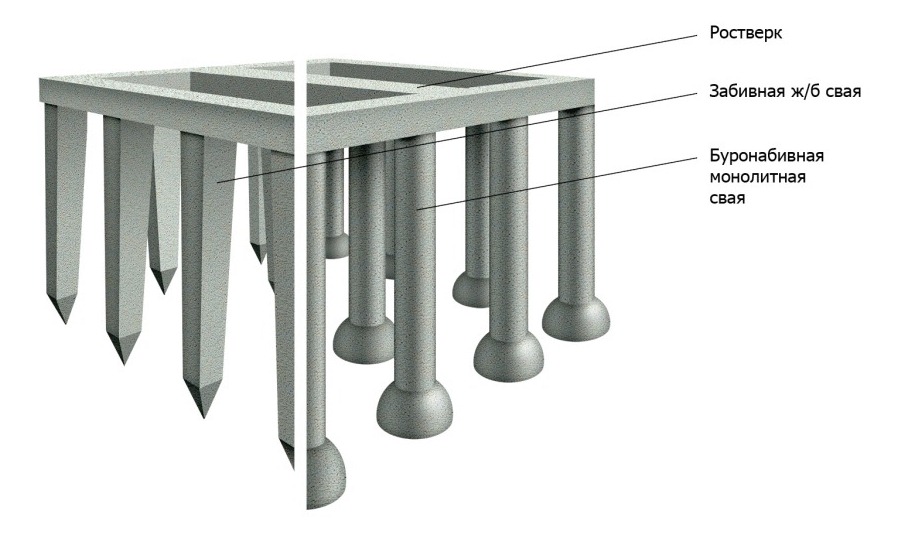

Pile foundation with grillage

In construction, several schemes of the pile foundation of buildings are used:

- Columns with a hinged belt are buried in the ground. This scheme is used in 90% of all pile foundations;

- The pillars rest on a crushed stone embankment without deepening into the ground. With such a scheme, the high rigidity of the base of the house is ensured, which makes it possible to minimize the likelihood of subsidence of the structure as much as possible;

- Without grillage. This option is used for the construction of small houses.

Piles

Piles are selected taking into account the load and type of soil. They are made from metal, reinforced concrete, rarely - from wood. By the method of installation, they are divided into:

- hammered;

- bored;

- reinforced concrete eyebrows;

- screw.

Hammer beams are buried in the ground under the influence of shock loading. For this, a special technique is often used.

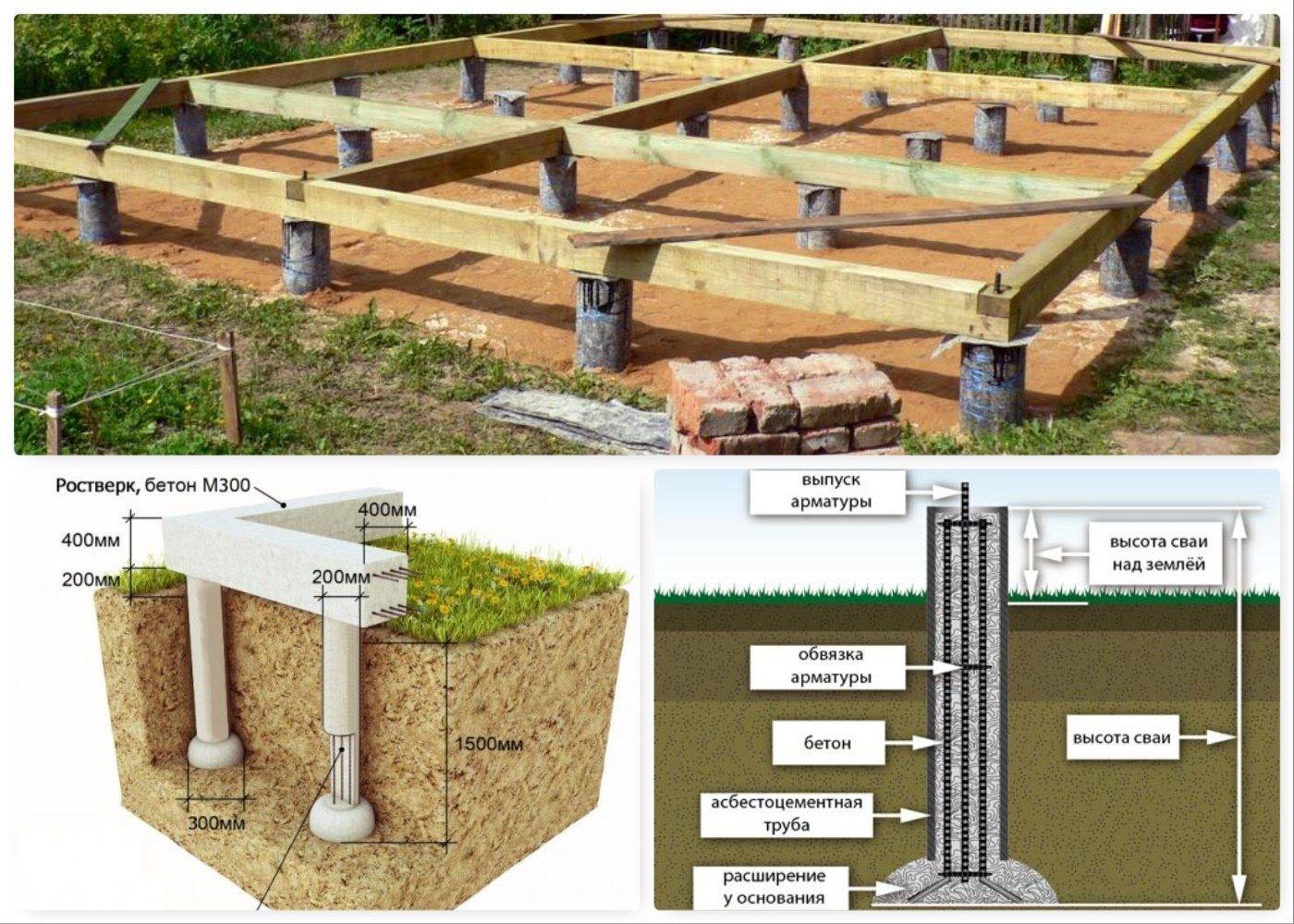

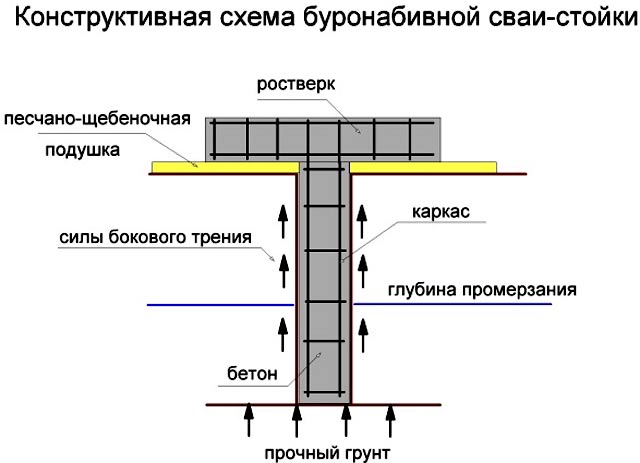

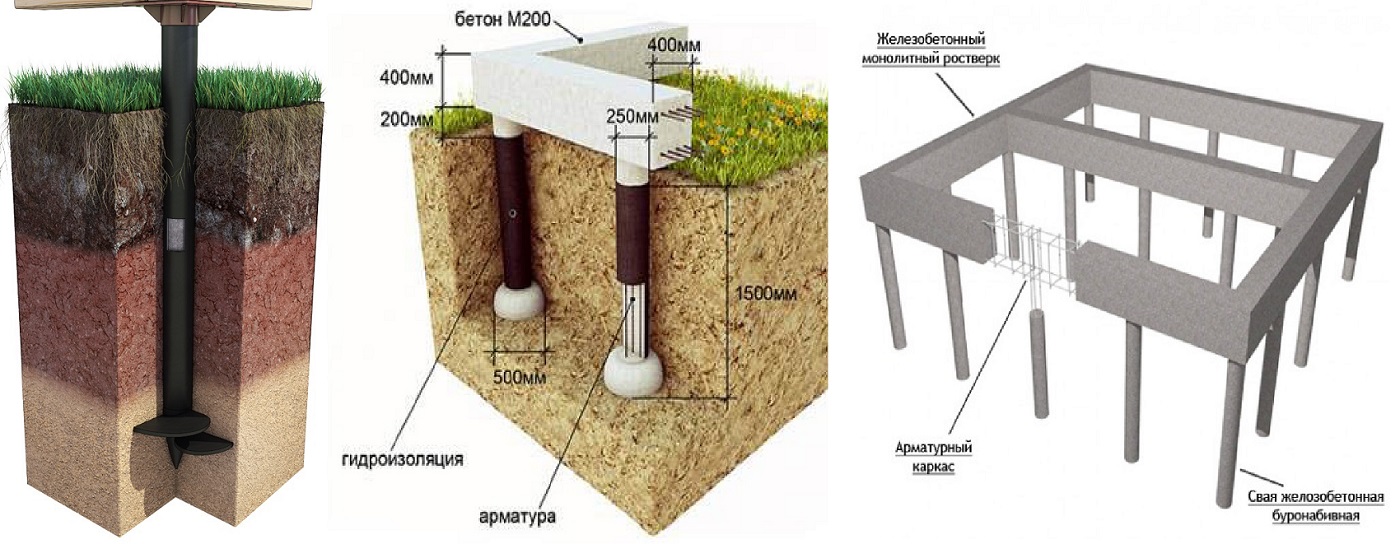

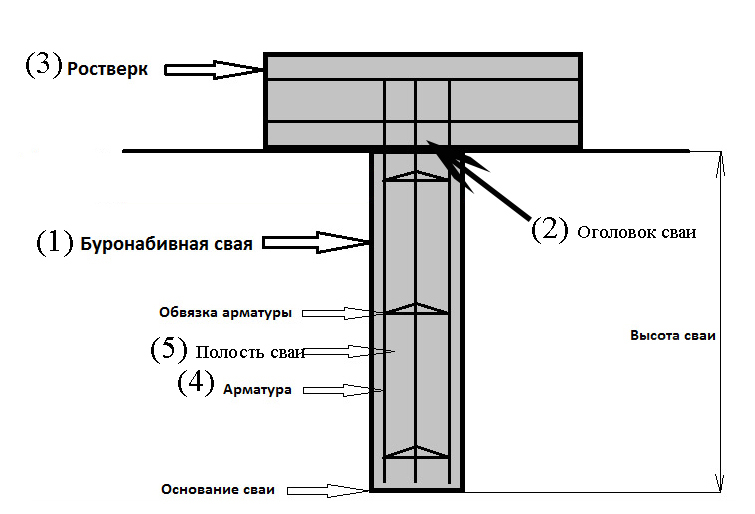

When installing bored supports in a drilled well, formwork is arranged, metal reinforcement is mounted, and it is poured with concrete. Finished reinforced concrete drill supports are driven into a pre-drilled well.

The helical beams are made of metal with a pointed end and have metal helical blades that easily cut the soil. They are screwed into the ground. To install screw supports to a depth of more than 2-3 m, special equipment is required.

By the nature of the transfer, the loads are divided into:

- racks;

- hanging.

The struts transfer the received load to stable soil layers. Their lower part is made wider, in the form of a heel. The TISE supports are made in the form of a cylinder expanded downward.

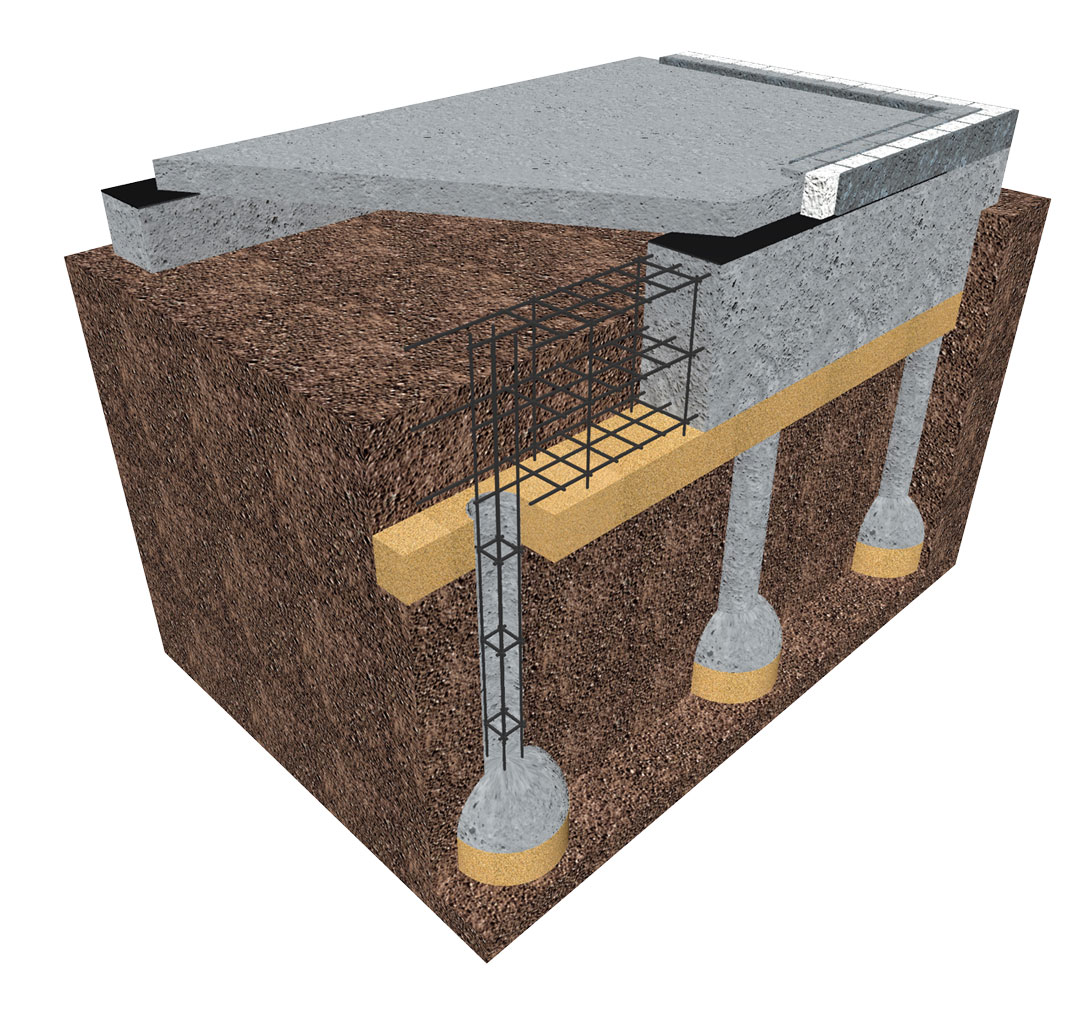

Types of pile connections with grillage

The connection of the pile to the grillage is a key element in the creation of the structure. This is what ensures the strength and the correct distribution of the impact on the soil. Simple piles with a grillage are connected in various ways. Which are determined at the design stage. In addition, the joining method is taken into account when calculating the strength of the entire structure.

In general, the device of the pile foundation is a combination of single supports, laid along the perimeter of the building, into a single system. With improper arrangement or lack of reinforced sections, the building may not withstand the loads.

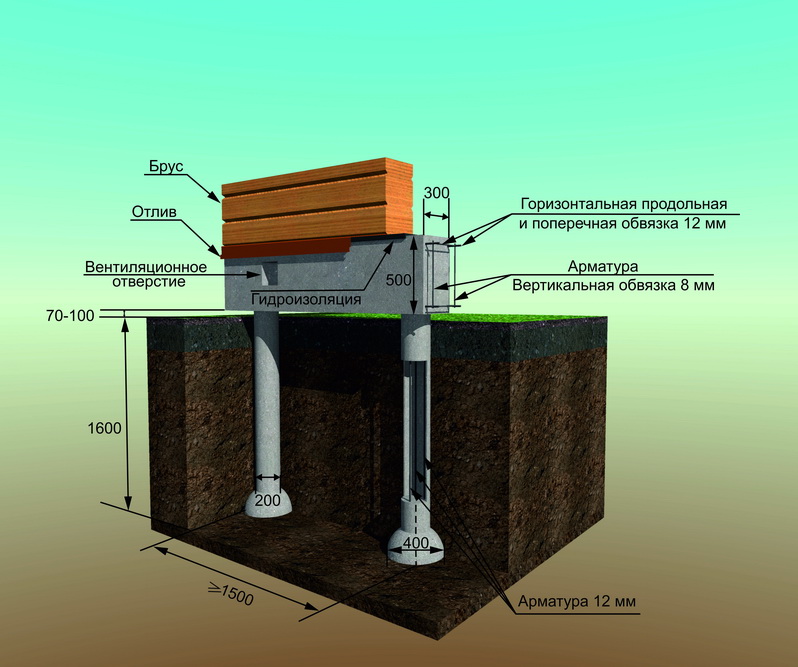

The connection of the pile reinforcement with the grillage is carried out by a specialist and must be extremely accurate. The minimum diameter of the rods used is 10 mm. The technology for placing reinforced belts is set in accordance with the project, but most often it is done in two parallel strips.

Pile connection with grillage

First of all, on the building site, markings and fastening of the foundation piles are carried out. Depending on the type of supports, they can be driven in, screwed in or inserted into the prepared grooves.

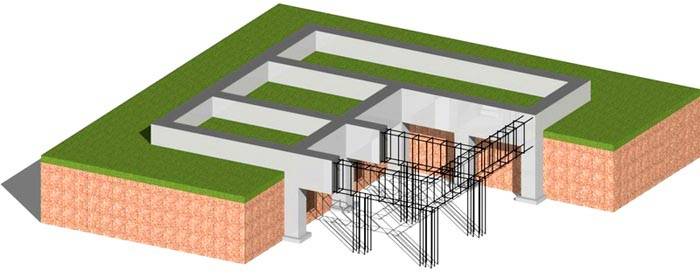

After completing the fastening of the piles, they proceed to preparatory work before pouring the concrete mixture. To do this, you need to install formwork, which will serve as a form for the future grillage.

If you plan to install a buried grillage, then you will need to prepare a trench. Concrete is poured into them, having previously installed asbestos pipes for the supports.

Inside the installed formwork, a special frame made of reinforcement is mounted and installed. This "skeleton" is carefully associated with the obligatory uniform arrangement of the rods. The reinforcement of this frame must be connected to the piles. The junction of the bored pile with the grillage plays a decisive role in the entire structure being erected.

Before dealing with the question of how to connect the grillage with piles, you should understand in detail the principles of the system being created.

The reinforcement from which the frame is assembled must be completely filled with concrete during the formation of the grillage. The concrete is laid in layers with gradual compaction. After the final hardening of the concrete mixture, the formwork can be dismantled.

In order for the grillage and the base to comply with the established construction qualities, the indents, blind area and other structural elements established by the project should be followed.

The joint between the pile and the grillage determines the feasibility of this technology. This node can be performed in two ways:

- A grillage with freely resting mates.

- A grillage with a rigid interface.

With free support, there is no rigid connection - just the pile is inserted into a 10 cm recess on the grillage. In the design documentation, this type is referred to as a hinge joint.

The rigid mating option involves the installation of a grillage in close connection with the supports. Provides maximum reliability with this hitch option.

Coupling the pile and grillage is the last important step in creating a quality foundation. The simplest and most reliable way of connection is the connection of reinforcement specially released from the grillage frame, which is connected to the existing reinforcement at the support. This creates a strong, high performance hitch. When connecting piles and grillages, builders require high accuracy of work and competent selection of performers.

Piles, fastened with a grillage, provide the owner of the house with quality and reliability at a minimum cost of time and money.

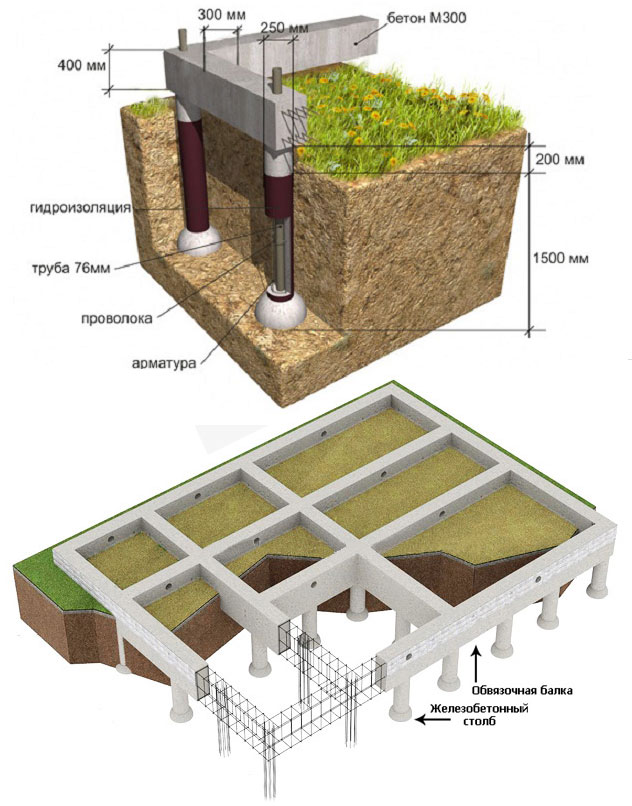

Features of the device of bored pile foundations

For all its simplicity of the device, the foundation made using bored technology also requires a serious approach to its construction. In the process of work, it is necessary to take into account some features that in the future may affect the life of the building.

- When arranging a bored foundation, it is recommended to use cement with a marking of at least M100. Moreover, for the construction of buildings made of heavy materials, such as a project of a brick building or a house made of aerated concrete, it would be optimal to use cement marked M400;

- When calculating the number and points of placement of pile supports, it is necessary to take into account that the grillage, regardless of its type, does not take part in the distribution of the load, but is only a connecting element for strengthening the common foundation;

- When constructing reinforcing cages, it is necessary to use the rule of binding the reinforcement or to weld the rods to each other, since the reliability of fastening the reinforcement directly affects the reliability of the future foundation;

- For the installation of pile supports, it is necessary to install a frame of four vertical rods of the corresponding thickness with horizontal bridges at least every 30 cm.

Given these features, the bored foundation will have a long service life.

Thus, high quality and reliable foundation on bored piles with a grillage in many cases is the optimal solution for the construction of a foundation base for the construction of various types of buildings and structures for both private and industrial use. The technology of its device is simple and economical, it allows you to do the whole range of work with your own hands without the involvement of third-party organizations and workers.

Self-production of piles

When creating piles with your own hands, earthwork is performed using an earth drill. If necessary, drill holes over 0.3 m in diameter and 5 m in depth, use a motorized apparatus.

You can make piles yourself in the following sequence:

- Construct "glasses" from roofing material, the width of which will be equal to the diameter of the wells. They are made 25 cm longer than the immersion depth of the supports. Several layers are made from above and tightened with wire. The result is a formwork. The pipe will be installed in it.

- After installing the pipe, a reinforced frame is made. It is placed inside the support. Three rods with a diameter of 8 mm are enough. They are connected to each other with jumpers. The vertical rods should be extended 4 cm above the edge of the grillage.

- Concrete is poured into the pipes, compacting it with a vibrator.

- Equip the grillage.

When creating a feed, several recommendations are taken into account. For example, the grillage should not be crossed by pipelines. Piles are installed strictly vertically. The permissible deviation is 5 cm. Each seam and joint, which was formed during the creation of the grillage, is filled with concrete.

The grillage must be reinforced. For this, rods with a diameter of 1.4 cm are used. They must have a length equal to the length of the walls. In the absence of such rolled metal, rods of at least 60 cm are chosen.Their number is determined by diameter:

- 1 cm - 8 rods are required;

- 1.2 cm - 6;

- 1.4 cm - 5.

Before installing the walls, make sure that the grillage surface is horizontal. Flaws are corrected with concrete mortar.

After the completion of the construction of the foundation on piles with a grillage, the basement is finished. The upper edge of the finishing elements is attached to the lower part of the building wall. From above, the edge is closed with an ebb. From below, the finish does not reach the ground surface by a few centimeters. This avoids deformation of the base during frost heaving.

Important! Drainage should be provided to drain sediment. Equip and a blind area 70 cm wide

It is better to lay it with paving slabs.

If you follow all the recommendations and correctly calculate the grillage, you can create a reliable foundation with your own hands. It will not be affected by frost heaving or shrinkage forces.

Advantages and disadvantages

Pile foundations with a grillage are popular due to their undeniable advantages:

- Suitable for types of soil in which no other types of bases provide strength: deep freezing of the soil, weak, heaving soils.

- Provide stability and high load-bearing capacity.

- They can be laid on slopes.

- It is possible to conduct work in the winter.

- Low cost of materials and work, cheap type of foundation.

- The entire structure can be erected, concrete can be poured in a couple of days.

- Thorough preliminary site preparation is not required.

In addition to the advantages, such a foundation has disadvantages:

It is necessary to insulate the structure due to the presence of space under the floor.

Cannot be used for massive structures.

A careful calculation of the foundation is necessary, since the uncertainty of the behavior of the soil is great.

In general, this is an excellent option for low-rise buildings, where speed, cheap construction is appreciated, or there is a need to erect a building on the slopes.

Types of piles

The main types of screw piles

The main types of screw piles for foundations are shown in Fig. On the left - a pile for permafrost soils, sandstones and dense loams with a high bearing capacity. The column of soil inside it is compressed, so it also holds the pile from the inside. This pile is unsuitable for concreting, but soils suitable for it hold very well. s = (8-20 mm); L = (4-16) m in 4 m steps; d = 219 or 325 mm. Carrying load - up to 4.5 tons. The cost of one - from 4500 rubles.

Piles of the same design, due to the low rib of the screw, are used as bored piles, see at the end. For the possibility of concreting, the soil from their shafts is then taken out with special drilling tools - a spoon drill or a bailer. The technology is labor-intensive, but it makes it possible to build 3-5-storey capital buildings directly on the permafrost, swamps and peat bogs.

In the center is the pile for the normal soils described above. For fences and light non-residential buildings, such piles can be made by yourself. s = (4-16 mm); L = (2.5-15) m with a step of 2.5 m; d = 47, 75, 89, 108, 133, 159, 219, 325 mm. Carrying load - (0.7-2.5) tons. The cost of one - from 2000 rubles.

On the right is a pile with a widened heel for loose, heaving and floating soils. s = (4-16 mm); L = (3-15) m in 3 m steps; d = 159, 219, 325 mm. Carrying load - (1-3.5) tons. The cost of one - from 3500 rubles. Although its tip with a screw may not be cast or forged, but welded from sheet metal, it is difficult to make one yourself. the blade of its propeller must have at least 2 turns and, narrowing, reach almost to the tip of the tip.

In addition to these basic types, a fairly wide range of special piles is on sale: with multi-turn and multi-threaded screws, additional blades, with a built-in drainage system, made of chemically resistant materials, etc. They are expensive, they are almost never used in individual construction, and they require complex technology for installing the foundation. Therefore, we will just mention that there are, they say, such.

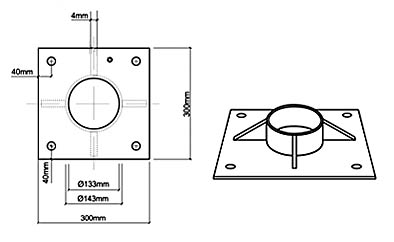

About tops

There are piles for sale with assembly and technological heads welded onto them. They are, of course, more expensive. It should be borne in mind that the mounting head is only necessary for assembling wooden houses on piles; in other cases, it is quite possible to do without it: the foundation grillage (see below) from the metal profile is welded directly to the pile shaft, it is manually screwed in using technological holes, and a light machine, using a mini-excavator, does not require a special technological head. How the pile head is arranged, just in case, is shown in the figure, for a pile of 133 mm. For piles of other diameters, the slab dimensions remain unchanged.

Assembly and technological head of the screw pile

Creating a pile-grillage foundation with your own hands

It is quite possible to do the construction of a pile-grillage foundation with your own hands. For the construction of small buildings (gazebos, country houses), a grillage on a columnar base is chosen, the pile option is suitable for buildings of permanent use. Work is best done in late spring, early summer or early autumn. First, the site is prepared, clearing it of vegetation and debris, then further stages of the work are carried out.

First, you need to prepare materials and tools, order concrete of strength class B17.5-22.55, or purchase ingredients from which it will be prepared in a concrete mixer. If necessary, it is necessary to add gravel or fine crushed stone under the future strapping.

Formwork

The formwork is mounted 10 centimeters higher than the height of the band grillage. The formwork is made of wooden boards or boards of a sufficient level of strength in order not to crack and not to disperse under the weight of concrete.

How is reinforcement done

The prefabricated monolithic grillage must be reinforced. For reinforcement, steel rods with a cross section of 12-18 millimeters are chosen, the depth depends on the project, but the mesh is laid evenly, in increments of 15-30 centimeters. The harness is mounted around the entire perimeter of the tape base.

The wire is cut in advance, the frame is installed in the mounted formwork, there they are tied to the reinforcement of the piles as rigidly as possible. Holes are drilled in the upper part of the piles protruding above the soil level, mortgages are passed through them, longitudinal whips of reinforcement are attached to them. Steel rods are driven inside the piles, the whips are tied together, with the upper whips. Inside the piles, the reinforcement is laid in a layer of 2-3 rods.

Concrete

The concrete is poured in equal horizontal layers, the thickness of which should be 10-15 centimeters. After pouring, each layer is sequentially rammed with a vibrating tool, then only the next one is poured.

For pouring the grillage, concrete grade M300 or M350 is suitable.

Rostwerk: weather and temperature-humid conditions

The grillage device is carried out in hot weather, preferably calm, no precipitation. Direct sunlight should not hit the surface either. If the air temperature is negative, the concrete must be provided with minimal heat loss at all stages - from preparation to laying. If work is carried out on heaving soils, the ground is first warmed up to a positive temperature, protected from freezing.

Dismantling the formwork

After completing the pouring of concrete, the formwork is dismantled, first removing the fasteners and spacers, only after that the boards. The formwork panels should easily move away from the frozen monolith, if such a situation is not observed, this indicates that the solution has not yet frozen and has not gained the required strength.

Drying and care

When a concrete grillage is poured, proper care of the monolith must be ensured. The design is reliably protected from sunlight, wind, precipitation. The surface is covered with plastic wrap, periodically moistened with water if the air temperature exceeds + 22C.

Waterproofing

The concrete grillage must be waterproofed, this is especially important when building pile-grillage foundations of a buried type. It is also advisable to isolate elevated grillages from moisture.

Waterproofing options:

- Penetrating - a special mortar with excellent adhesion characteristics covers the foundation.

- Coating - the strapping is covered with bituminous mastic.

- Sprayed - liquid formulations with high water-repellent properties are applied using a spray bottle.

- Roll - the tape is coated with mastic, roll material is placed on top.

The choice of method and material for waterproofing depends on the type of soil, groundwater level, type of grillage, financial capabilities and other factors.