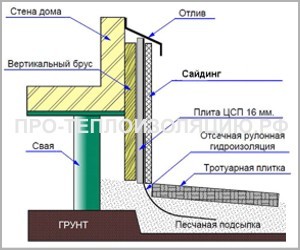

Plinth made of piece materials

For the construction of the basement, bricks, building blocks (aerated concrete, foam concrete, etc.), foam glass are suitable. In the latter case, the material itself serves as a good heat insulator.

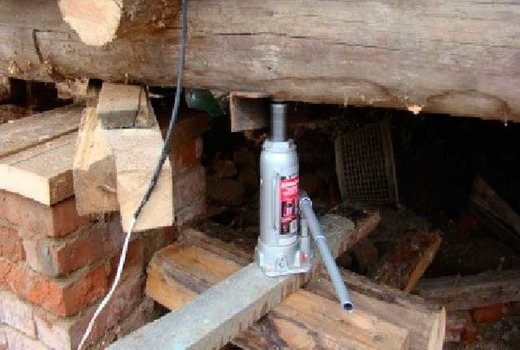

For masonry made of piece materials, it is required to create a strip foundation made of reinforced concrete. To do this, a trench is dug around the perimeter of the house with a depth of about 20 cm. If the house is on a slope, in order to reduce the material consumption of the structure, the strip foundation is made stepwise, observing the horizontality of the surfaces.

After the concrete has set, a wall of piece materials is laid out. If we are talking about brick, then for a low-height basement, a shallow foundation and a masonry thickness of half a brick are enough. For a full-fledged basement floor, it is required to prepare a more solid foundation and lay out walls one and a half bricks thick.

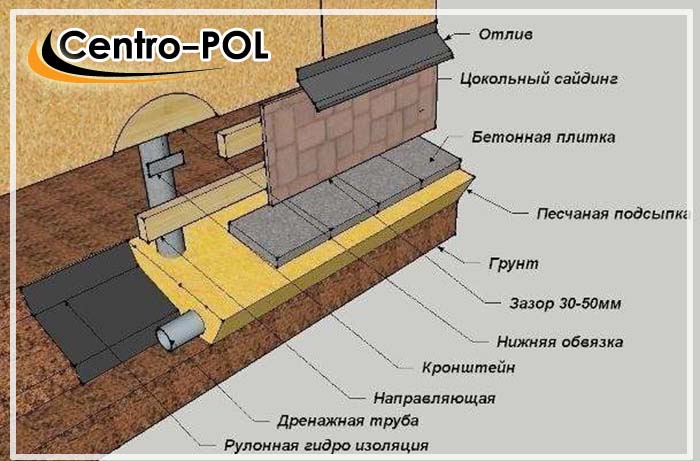

It is important to take care of high-quality waterproofing between the concrete foundation of the basement and the masonry, as well as between the masonry and the grillage - the horizontal supports between the piles on which the wall structures of the wooden house rest. For waterproofing, roll bitumen material is used - roofing material or its analogs, laying in two layers

Selection of materials for thermal insulation

Different requirements are put forward for the materials used to insulate the floor and basement of a house on screw piles:

- Thermal insulation of the floor along the logs can be done with any kind of insulation, be it expanded clay crumbs, mineral wool or polystyrene - the material laid between the logs is not exposed to loads, so its density is not critical.

- For thermal insulation of the concrete floor and grillage, it is necessary to use rigid and durable materials, since the floor insulation must withstand the weight of the front screed and the load from people, and the basement - the weight of the facing material with which the false base is sheathed.

We recommend using basalt wool for thermal insulation of a log floor in a frame house on piles. It is one of the most effective insulation materials (thermal conductivity coefficient - 0.035), which is a refractory material with high vapor permeability (does not form condensation). Use panels with a density of 30-50 kg / m2.

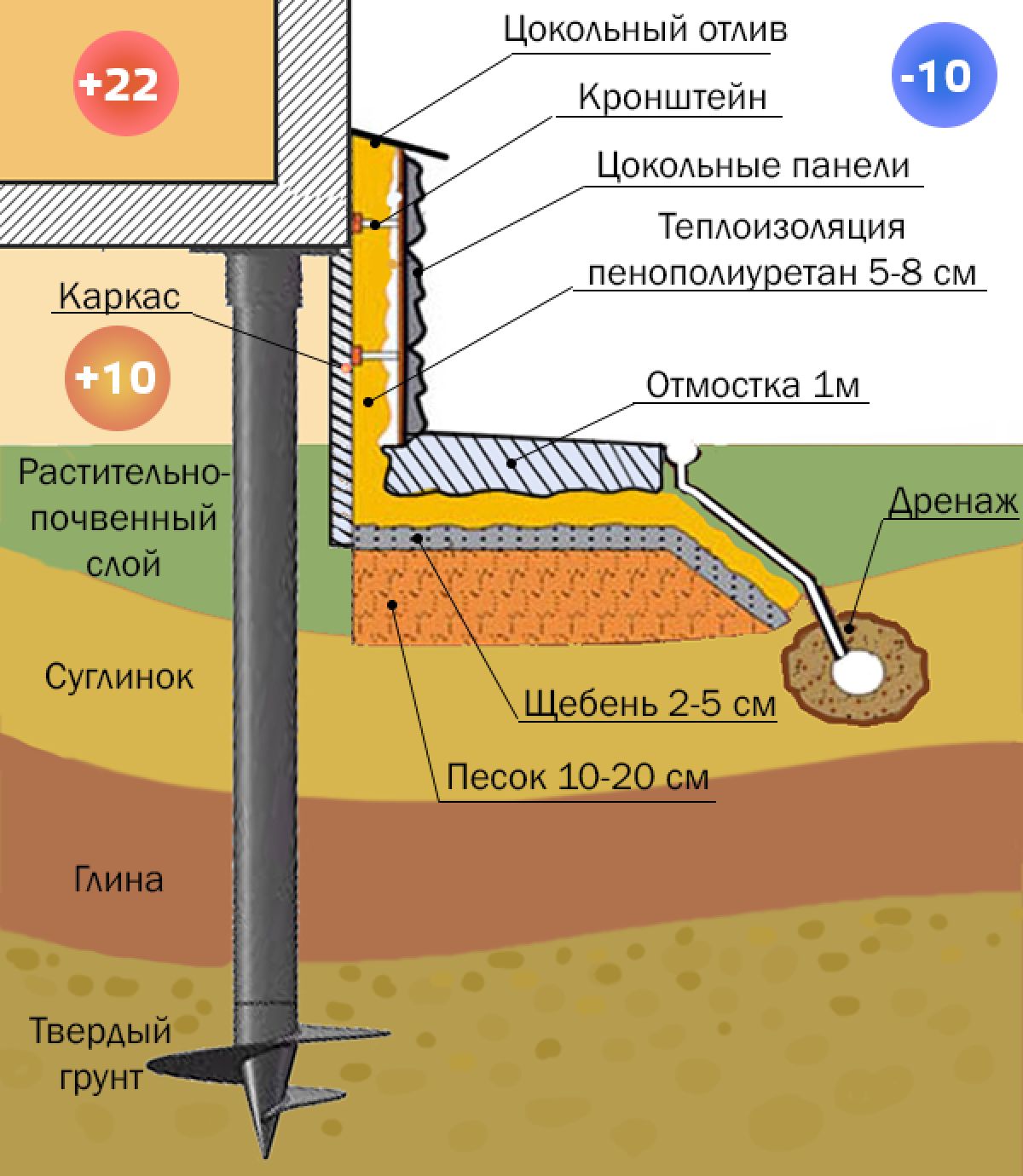

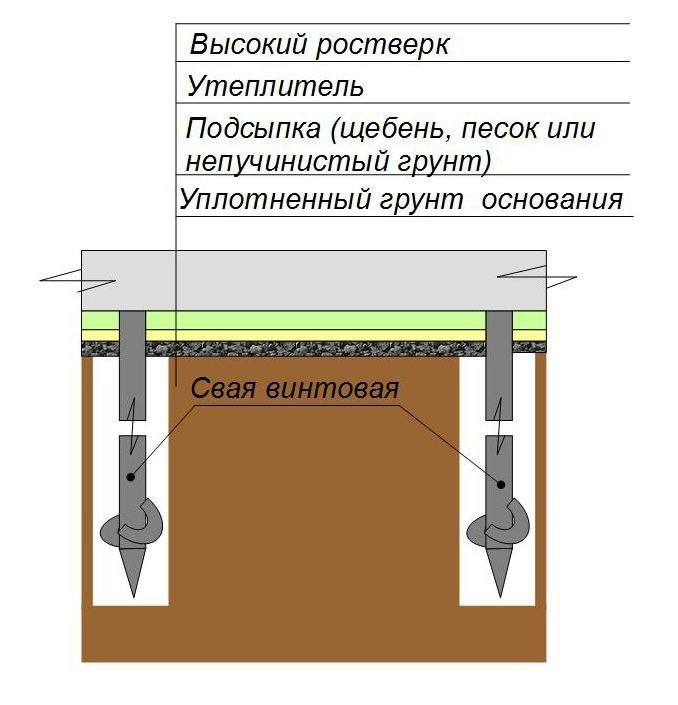

Thermal insulation of the EPPS screw foundation

The best material for floor insulation under the screed and grillage is extruded polystyrene foam. EPPS is an improved analog of foam, it has a lower coefficient. thermal conductivity - 0.033, the minimum level of water absorption and low weight. For insulation of the grillage, EPSP with a density of 30-40 kg / m2 is used.

Extruded polystyrene foam is a vapor barrier material, therefore it cannot be used inside a building - this is fraught with the "effect" of a thermos. The advantages of EPPS also include durability (up to 50 years without loss of performance) and unattractiveness for rodents, in contrast to foam.

EPPS is sold by a fairly large number of companies. When choosing how to insulate the foundation from the outside, give preference to trusted manufacturers - Penoplex, Technonikol, URSA, Isover. The actual quality of their products always matches the declared one.

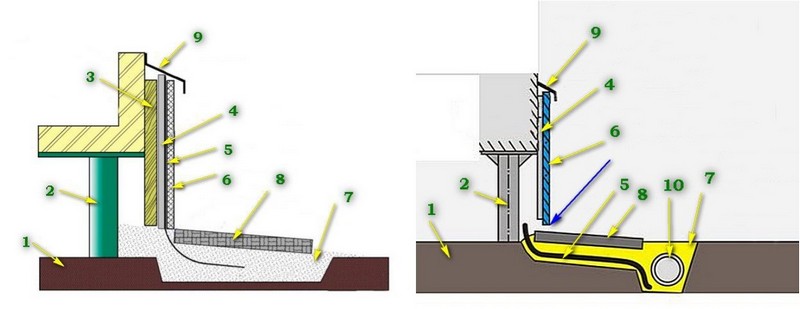

Insulation technology of the screw foundation grillage

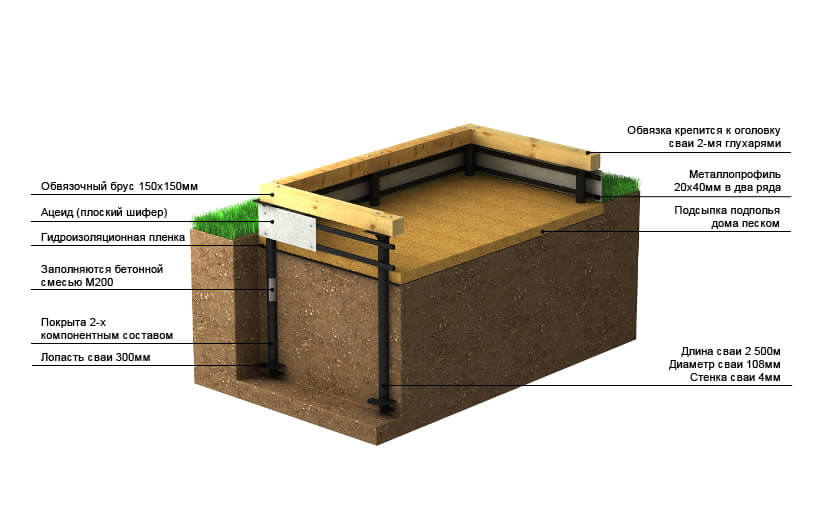

To insulate the grillage, you will need to build a supporting frame to fix the insulation around the perimeter of the building. The frame consists of two longitudinal beams fixed on piles from a square metal profile (20 * 40 mm), fixed by welding.

Longitudinal guides are installed at an equidistant distance from the center of the part of the piles rising above the ground.Upon completion of welding, the welded joint must be coated with an anti-corrosion primer in order to prevent rust during the operation of the foundation.

Transverse guides made of planed boards are attached to the longitudinal frame using self-tapping screws. The step between the jumpers should correspond to the size of the insulation panel so that the joint of adjacent panels falls on the center of the guide.

Frame for sheathing with insulation

Upon completion of the installation, the frame is sheathed with foam. Insulation panels are fixed by means of dowels with flat caps. There are two important points to consider here:

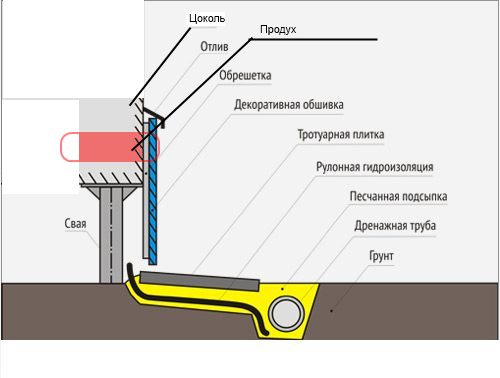

- The heat insulation of the grillage can be damaged by heaving of the soil - in the spring the soil increases in volume and breaks the plinth plating. To prevent this, you need to leave a gap between the ground line and the lower contour of the insulation of 5 cm, or dig a trench 30-40 cm deep around the perimeter of the house and replace the soil with sand. In this case, penoplex can be sheathed without a gap;

- Insulation technology requires the arrangement of ventilation of the subfloor. It is necessary to make air vents with a diameter of 10 cm around the perimeter of the basement (2 on each side of the building). The ventilation holes are left open in summer and closed in winter.

After the installation of the insulation, the joints between the insulation panels are filled with polyurethane foam. Further work consists in trimming the plinth with decorative cladding, the choice of which depends on your aesthetic preferences. You can use basement siding, corrugated board or lining. The cladding is fixed over the insulation using self-tapping screws screwed into the wooden frame guides.

Pile foundation

How to insulate the foundation of a wooden house on piles? For a pile foundation, as well as for a columnar foundation, they construct a pick-up - an imitation of a basement, closing the space between the piles. This alone will reduce heat loss to some extent. For effective thermal insulation of the pile foundation, you need:

- arrange a plinth,

- insulate it from the inside and outside,

- insulate the floor.

You can build a thin brick wall around the perimeter, or you can use slab materials that are attached to the crate. If the option with a brick wall is chosen, you need to fill in a shallow concrete tape 20 cm thick, on which the wall will be built. It is not necessary to use ceramic bricks, you can take foam blocks or foam glass.

Important! Do not make the space under the floor airtight. After the device of the pick-up, air vents must be made in it - ventilation holes measuring 10-15 cm.They are placed evenly on all sides of the house so that they fall opposite each other

They are placed evenly on all sides of the house so that they are opposite each other.

For fastening panels or slabs, a crate is made of a metal profile or wooden bars. As an external cladding, you can use, for example, DSP. There are already insulated facade panels that perform a decorative and heat-insulating function.

A shallow trench is dug under the cladding, where a layer of sand (2-3 cm) is poured, expanded clay is placed on it, and the trench is covered with earth on top, so that there is no gap between the soil and the cladding.

The video shows the device and insulation of the false base:

To insulate the pile foundation, use

- expanded polystyrene,

- Styrofoam,

- foamed glass in blocks,

- liquid penoizol (urea foam).

The first two options are most often used. Foamed glass is too expensive for a private house, and liquid penoizol requires special equipment or the work of specialists, which is also expensive. It is easier to insulate the foundation in a wooden house with your own hands with polystyrene or expanded polystyrene outside. The main thing is that the material does not absorb water, so mineral wool will not work here.They glue the foam on glue-foam, for reliability, you can use additional wooden strips, which are attached with self-tapping screws to the crate through the foam.

Important! It is advisable to fix the expanded polystyrene or polystyrene on the guides, and not between them. In this case, there will be no gaps and cold bridges, since the thermal conductivity of wood, and even more so of metal, is greater than that of foam. It is possible to insulate the pile foundation with foam or EPSP from the outside or from the inside

If this is done outside, then the insulation is attached before finishing. If the finish is already attached to the plinth, for example, if these are facade panels or DSP slabs, then the insulation is mounted from the inside

It is possible to insulate the pile foundation with foam or EPSP from the outside or from the inside. If this is done outside, then the insulation is attached before finishing. If the finish is already attached to the plinth, for example, if these are facade panels or DSP slabs, then the insulation is mounted from the inside.

Floor insulation

To insulate the floor in a wooden house on a pile foundation, I usually use mineral wool, basalt wool, expanded polystyrene, polystyrene, liquid insulation.

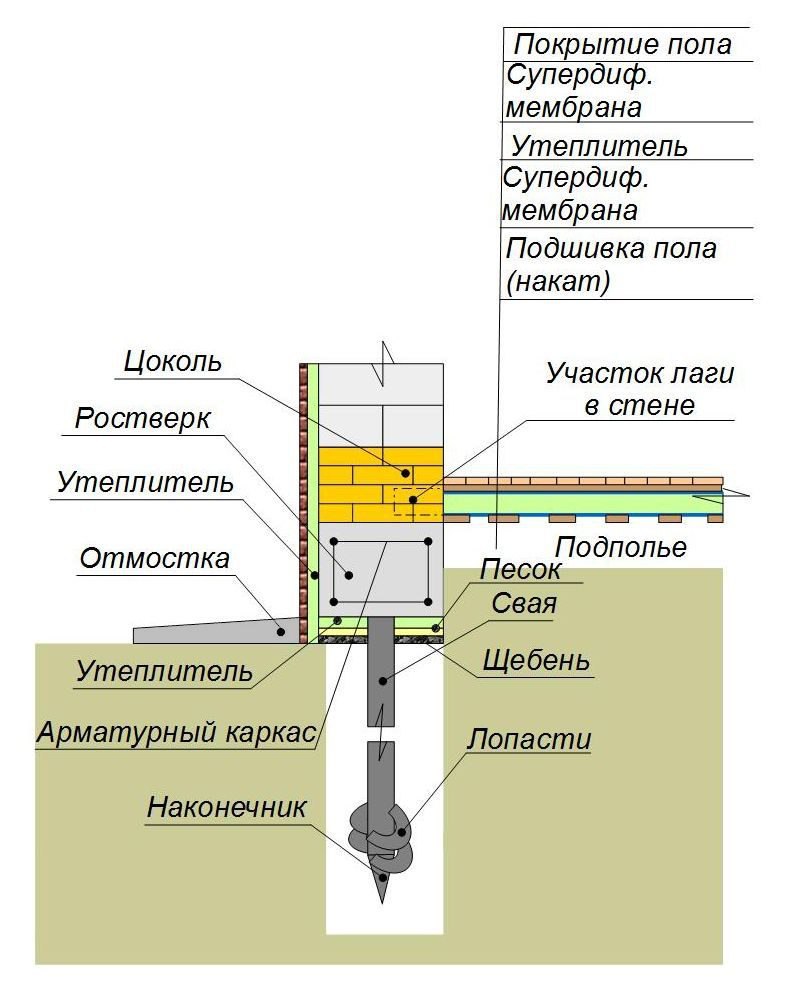

Thermal insulation is done during construction and flooring as follows:

- They make a rough floor on which the insulation will lie.

- A vapor barrier and windproof layer is first placed on the crate.

- Then they put insulation.

- Vapor barrier and waterproofing are placed on top.

- After that, a finishing floor is built.

The layer of mineral wool should be at least 10 cm. If it is necessary to put cotton wool in two or more layers, this is done in a checkerboard pattern (so that the seams do not coincide). The video shows floor insulation in a house on a pile foundation.

For waterproofing, you can use glassine, polyethylene, isospan, wind-moisture protective film. Polyethylene is the cheapest option, but not the best.

Important! In a house made of wood on a pile foundation, it is imperative to treat all wooden floor elements with an antiseptic. Insulation of a columnar foundation differs little from insulation of a pile foundation, the same materials and techniques are used. Insulation of a pillar foundation differs little from insulation of a pile foundation, the same materials and techniques are used

Insulation of a columnar foundation differs little from insulation of a pile foundation, the same materials and techniques are used.

Waterproofing

Any variant of the arrangement of the filling must be reliably protected from the negative effects of atmospheric precipitation; this requires waterproofing.

Experts advise making a waterproofing layer using sheets of roofing material and bitumen mastic. For this, the mastic is heated and the inside of the pick-up is treated while hot. Roofing material is laid on top of the mastic and the surface is re-treated with bitumen. After that, sheets of roofing material are laid again.

From the outside, a cement-sand mixture can be used as waterproofing. The composition is made in the ratio of cement and sand 1: 3. Cement is applied to the surface of the filling, leveled, sprinkled with a small amount of dry concrete and wait until the insulation hardens.

Then a layer of roofing material or other similar material is laid on top. After it is finished with decor: special slabs that imitate masonry, profiled sheet, natural or artificial stone.

How to insulate a pile screw foundation with your own hands

The process can be divided into 5 main stages: waterproofing a metal structure, making a frame for fastening thermal insulation, installing insulation with a waterproofing film, if necessary, attaching decorative panels to the basement of the house, arranging an insulated blind area around the perimeter of the house, filling with soil or expanded clay inside the foundation of the house. Let us consider these stages in more detail below.

1. Waterproofing of the pile foundation

Regardless of the material of the grillage - wood or metal, careful waterproofing is necessary so that moisture from the soil does not penetrate into the structure, leading to metal corrosion and wood decay. It is necessary to protect with roll or liquid waterproofing all parts of the structures where thermal insulation will be made. The tree should be treated with antiseptics, and the metal frame should be treated with bitumen mastic.

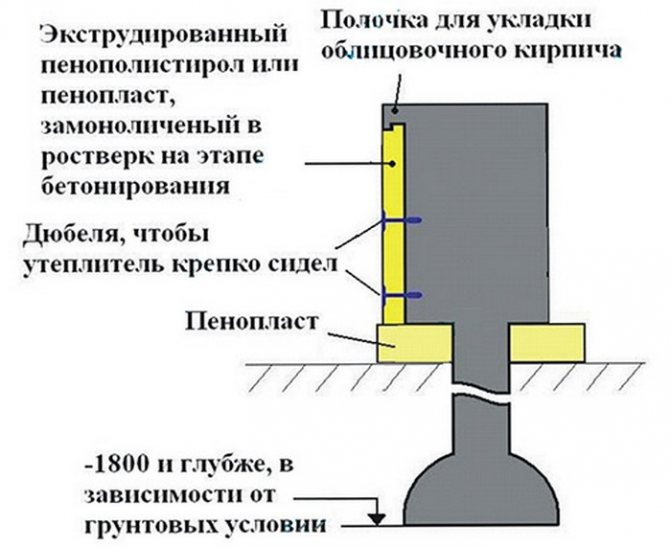

To create a heat-saving cladding between the ground and the facade of the house, it is necessary to create a structure that imitates the basement of the house. This structure can be made of light brickwork on a finely corroded foundation. The brick plinth is insulated from the outside with foam or polystyrene plates and sheathed with siding or panels. You can create a frame from timber or metal guides.

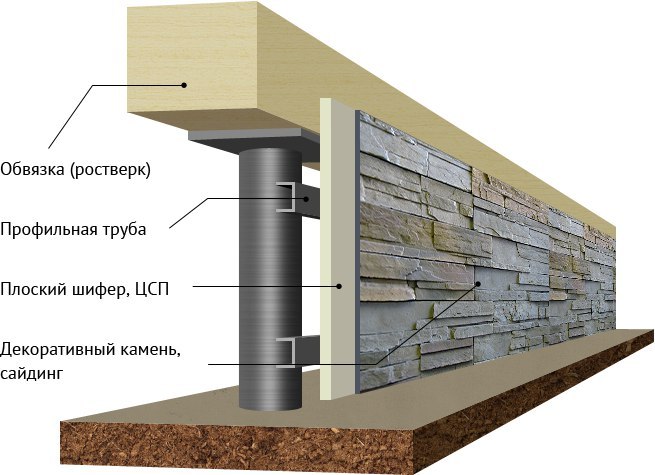

2. Making the basement of the house

Photo. Pile foundation insulation scheme

To make a brick base, it is necessary to fill in a shallow reinforced foundation up to 20 cm. After the concrete hardens, a red brick base is laid out. Fastening of thermal insulation boards from the outside is carried out on the brickwork with polystyrene foam and glue for expanded polystyrene. The insulated brickwork of the pile foundation is sheathed with decorative panels that imitate natural stone or brickwork.

The second method, a frame made of timber or metal, is a simpler and more inexpensive method. It consists in attaching horizontal guides to piles using bolts or welding. Thermal insulation plates are fixed between the guides, the joints should be treated with polyurethane foam. Further, decorative panels or siding are mounted on the guides outside. On our website, you can calculate the thickness of the insulation for the base on a heat engineering calculator.

3. Thermal insulation of the basement of the house

Sheathing the basement of the house with pvc panels

When self-insulating the facade with mineral wool or the basement of a house on a pile screw foundation, a distance of 10-15 mm should be left between the guides less than the width of the insulation. In this case, the mineral wool will sit tightly between the guides, leaving no cold bridges. Mineral wool should be covered with waterproofing, we remind you that you should put the vapor barrier on the insulation on the right side.

When insulating the foundation on screw piles with penoplex or expanded polystyrene, the seams between the plates should be foamed with polyurethane foam. If the characteristics of the foam ensure that the material will not absorb moisture and will not suffer from rodents, then the foam plates should be protected from rodents and possible mechanical damage. You can cover the insulation on the basement of the house with vinyl or metal siding.

4. Fastening decorative panels

To clad the basement from below, it is necessary to fix the starting profile for siding at the level along the entire perimeter of the house. Then siding panels or decorative PVC panels are attached from the bottom up from the starting profile. This facing material will protect the insulation on the pile foundation from precipitation, mechanical damage and the penetration of rodents. Do not forget to carry out additional waterproofing of the facade for siding.

5. Backfilling with soil or expanded clay

Photo. Air vents in the basement of the house (ventilation holes)

From the inside, the pile-insulated screw foundation can be covered with soil or expanded clay - this will additionally insulate the underground space of the house. Outside the building, an insulated blind area should be arranged in order to reduce freezing of the soil under the house and reduce the heat loss of the house during the heating season. Ventilation holes (air vents) should be made on opposite sides of the basement, closed from rodents and insects with gratings.

The ventilation openings are used to remove moisture from the subfloor of the house; for the winter, the ventilation openings should be covered with rags.At the end of the material, we posted a video instruction from experienced builders on the issue in question, how to independently insulate the foundation baths on screw piles or a country house to remove all possible questions.

Materials used for the construction of the filling

When choosing building materials, one must not forget that this part of the building must be practical and beautiful. If you do not organize the filling of the pile-screw foundation, then the front part of the house will lose its attractiveness, in addition, air will begin to circulate under the floor, so any heating systems will not be able to heat the building.

When installing the pick-up, one must not forget about the passage of various communication systems through this element. For their installation, the required number of holes is left. You also need to organize a ventilation system using air windows, which are closed for the winter. The pick-up should not be firmly attached to the piles. She needs a little "freedom", this will help keep the structure from possible deformations when heaving the ground.

Pick-up dimensions:

- for brick structures, it is recommended to install a filling with a thickness of at least 130 mm;

- for rubble structures (stones of irregular shape are laid), the thickness must be 210 mm;

- for the concrete version, the thickness is chosen at least 100 mm.

You can build a pick-up for a pile foundation in various ways. It depends on the building materials at hand, or the material capabilities of the owner of the house.

Most often, the pick-up is made from boards. The design can be carried out either with mounting in a horizontal or vertical position. In this case, the underground part is made in the form of backfill, which is characterized by its heat-insulating properties; ordinary slag can be used.

This way of organizing the pickup is the most economical. But also the structure can be made from a wide variety of materials.

Stone, brick

A layer of sand is poured into a previously dug trench, a cushion of concrete mortar (7-15 cm thick) and reinforcement is made on top of it. As reinforcement, you can choose rods with a cross section of 7-9 mm. Then, when the cement mixture dries up, a brick or stone is laid.

Siding

The siding pile foundation pick-up is cheaper and easier to perform. For this option of arrangement, it is necessary to build a frame from a bar. The frame must be treated with special compounds to protect it from fire, fungus, mold and other negative factors.

First, prepare the blind area. It is required to drain water from the foundation that flows from the roof of the house. Then the frame is fixed to the support pillars and to the bottom of the building. Siding is attached on top of it.

There is a large selection of different types of siding on the market today. This material is highly resistant to the negative effects of the external environment, in particular to ultraviolet light. It can have a different palette of colors, and even imitate natural materials, for example, granite, stone, wood.

The service life of the siding is over 35 years. But it has one drawback - it does not protect well enough from severe frosts, therefore, mandatory insulation is required.

A rather economical solution in this case is a multilayer material for thermal insulation. This is, by and large, ordinary foam with a layer of decorative material glued on top. Inexpensive plastic or more expensive granite or marble plates can be used as decor.

Concrete

The pick-up in this manufacturing version is more difficult to execute. But the high aesthetic and thermal insulation properties are worth it. Why do you need to dig a small trench around the perimeter of the house, measuring 40x40 cm.

A sand cushion is poured into the bottom of the ditch. Water is poured on top of the well-tamped sand, and then filled with cement mortar with a layer of about 30 cm.It is not recommended to connect the foundation supports with the screed, as this will subsequently lead to the appearance of cracks on the plinth.

DSP

The cut-to-size cement particle boards are fixed to the base with the help of bars. The main disadvantage of this design is the poor thermal insulation characteristics of the material. Mandatory insulation is required inside.

Sheet materials

Profiled decking is most often used as sheet material. The sheets are attached to a frame base, which is made of galvanized profiles or beams.

The lathing is constructed in several stages:

- Guides are set taking into account the vertical and horizontal levels.

- The selected material for thermal insulation is laid and fixed, and the sheathing is attached on top.

- Ebb tides are installed.

- Ventilation holes are made at a height of about 25 cm from the ground level, and they are closed with special plugs.

The profiled flooring must first be cut into pieces of the required dimensions.

Recommendation: A pick-up made of asbestos sheets is a more economical way of arranging, but this design is usually used in the construction of ordinary country houses.

Variety of heaters for pile foundations

Learn about the variety of heaters for pile foundations and the peculiarities of working with them from Table 1.

| Type of material | Features of work |

| Polyurethane foam (PPU) | Easy to use. It is sprayed onto the treated surface from a balloon. Lays down in a thin layer. During installation, the lathing boards are placed as close as possible, without gaps. Processing both outside and inside is possible. |

| Extruded polystyrene foam (Penoplex) | Attached to the crate with umbrella dowels. At the final stage of work, the joints between the plates are filled with polyurethane foam. Polystyrene plates are mounted on the outside of the foundation. |

| Facade thermal panels with clinker tiles | Modern building material. Two in one: aesthetic appearance and thermal insulation properties of polyurethane foam. Thermal panels are attached to the crate with special fasteners. |

| Expanded clay | Eco-friendly lightweight bulk material. Easy to use: even a beginner can handle expanded clay backfill. It is used for floor insulation or for filling cavities in the ground. |

It is quite simple to insulate the pile foundation on your own, the main thing is to decide on the materials. On the building materials market there is an opportunity to choose mineral or polymer heaters for any wallet.

Relatives or friends will not refuse to help in the work. It is easier for a company of two or three people to cope with the process of warming the foundation on its own than on its own.

Workshop on insulating a pile foundation wooden house outside on heaving soils, see the video:

Warming options

The plinth cladding can be of several types. The decision which one to use is made based on aesthetic considerations, financial capabilities, and the qualifications of the workers who will carry out the finishing.

Warming of the basement can be carried out in two ways:

- on a separate tape structure;

- along the crate, which is attached to the piles.

Belt design

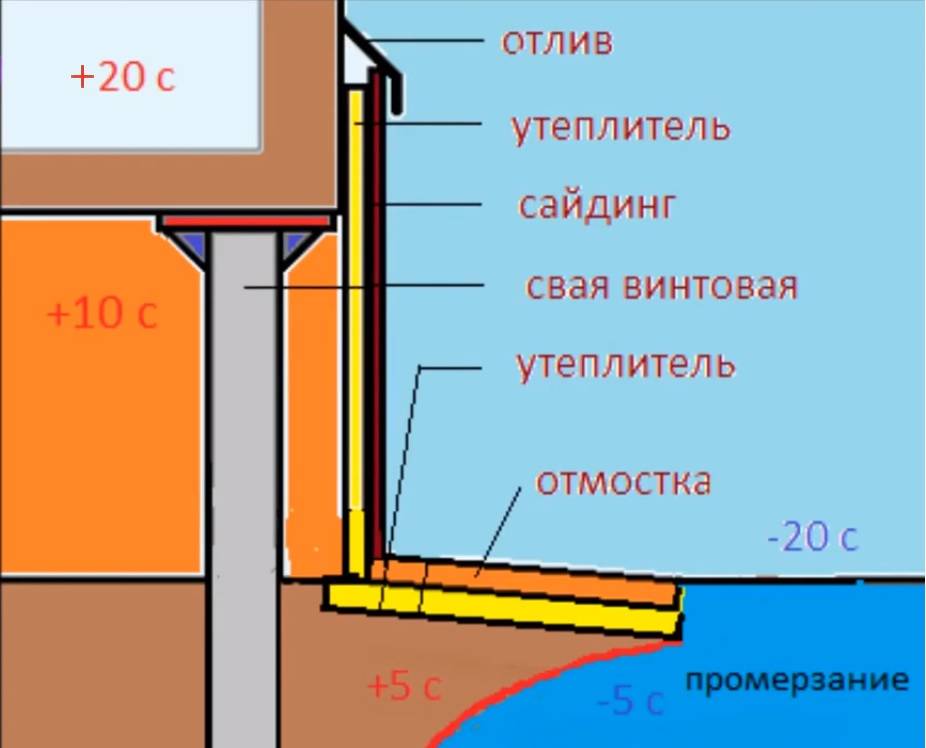

The first option is more complicated and also has a number of limitations. A shallow-type belt structure can be made of concrete or brick. Most often, it rests on the ground or its small monolithic foundation (more about the device of a shallow strip foundation). But when building on heaving soils, it is strongly discouraged to use this option. Especially when it comes to a brick plinth. In this case, the earth rises (swells) in winter. Moreover, the process is uneven.Having dug out the construction of the basement from the snow, at some point you will have to see inclined cracks, which indicate damage by frost heaving.

Tape base, on which, if necessary, you can even fix the insulation

Tape base, on which, if necessary, you can even fix the insulation

This phenomenon can be prevented by excluding one of the heaving factors:

- low temperature;

- moisture.

It is impossible to fulfill the first condition in the manufacture of a non-buried tape. The soil under the plinth of the house will still freeze and deform. Moisture wicking can also be ineffective.

It is reasonable to use tape sheathing only on those soils that are not prone to heaving. Such bases include coarse-grained soils, medium or coarse sand. Also, the option is suitable for regions with a warm climate, where freezing temperatures are rare.

The insulation is fastened to the brick according to the standard scheme. Penoplex is best suited

The insulation is fastened to the brick according to the standard scheme. Penoplex is best suited

Fastening of the insulation is carried out on a concrete or brick wall according to the type of thermal insulation of the external enclosing elements of the building. It can be performed both without an additional frame, and with its use. The method depends on the type of finish chosen.

Insulation of the basement on the frame

This option for the home will become less costly and easier. In this case, the insulation of the foundation on piles can be performed using a variety of materials. Examples include:

- basement siding;

- clinker panels;

- metal profiled sheet.

The choice among the options is based on financial possibilities and aesthetic considerations. All options are attached in about the same way. Read a detailed article on finishing the base of the pile-screw foundation. To provide a base for facing the basement of the house, it is necessary to provide a frame.

The frame can be made of wood or rolled metal. When cladding with metal materials, it is wiser to use steel as a lathing. The frame is usually made of two longitudinal straps. More longitudinal elements can be provided if necessary. It all depends on the height of the base. It is also possible to provide vertical frame elements. The need for them depends on the chosen material for facing the basement of the house.

Before insulating the foundation on screw piles, it is required to provide for fastening the frame to them. The method depends on the material:

- When attaching the cladding to wooden slats and bars, it is necessary to provide metal embedded parts in the upper part of the piles in advance. They can be made from a corner or other similar types of rolled products. Fastening to piles is carried out for welding.

- When using steel frame elements, there is no need for preliminary preparation. The metal profile is welded directly to the foundation elements.

To prevent soil moisture and frost heaving from destroying the finish and thermal insulation, it is worth raising the basement above the ground. The damping gap can be from 5 to 15 cm. At the final stage, this distance can be closed with some kind of bar.

Air vents can be provided in the place indicated on the diagram or in the gap between the cladding and the blind area

Air vents can be provided in the place indicated on the diagram or in the gap between the cladding and the blind area

Insulation for the basement of the house is attached to the same frame as the finish. Depending on the type chosen, a number of additional activities will have to be carried out.

When insulating, it is important not to forget about underground ventilation. For this, special holes or vents are provided in the finishing design.

According to the standards, their total area should be equal to 1/400 of the area of the underground. Also, a gap between the ground and the casing can serve for ventilation. To do this, it is covered with a special mesh that prevents the entry of rodents and insects, but does not impede the movement of air.

Methods for closing the foundation on piles

The following two methods are most often used (the rest are described below):

- concreting the perimeter of the foundation

- pick-up

- How to calculate a pile foundation

- Insulation of the pile foundation

The first option is performed as follows:

- formwork is installed around the entire perimeter of the foundation

- the lower part of the formwork on the sides is laid out with asbestos-cement slabs or a board treated with antiseptic impregnation in order to reduce the effects of heaving forces on the basement when constructing a foundation on heaving soils

- install reinforcement in the form of 150-200 mm. steel mesh 5-6mm. wire or assemble it yourself from steel rods 8-10mm.

- fill the perimeter with concrete

For the second option, you will need the following materials:

- reinforcing mesh made of steel wire 5-6mm with a mesh of 130x130mm.

- ceramic brick

- asbestos cement slabs

- steel hooks for tying the plinth to the masonry

A pick-up is carried out (a lintel between pile posts), as a rule, in small brick houses (if there is a brick for pick-up) or is made of reinforced concrete.

The choice of finishing of the insulated base

From a technological point of view, it is permissible to use all types of facings and topcoats. It can be plaster, decorative clinker, and lining of various types. Some EPS collections come with a topcoated finish, which saves costs and speeds up work.

Insulation of the pile foundation with decorative EPS boards

If we talk about the aesthetic side, then using imitation of any materials, one should think about naturalness. For example, is it worth using clinker bricks as cladding for the plinth of a timber house?

If we turn to tradition, then in the days of mass wooden housing construction, a stone base was much more often used. Today, it is much more logical to use special EPPS slabs imitating masonry in the construction of cottages from a bar on a screw foundation.

Why carry out insulation

Indeed, the question arises: is it necessary to insulate the pile foundation? After all, he digs deep into the ground and he is not afraid of swelling. But vulnerabilities remain that require a special solution:

- If a reinforced concrete grillage is being poured, this structure itself is a conductor of cold at low temperatures. It will absorb significant amounts of heat, which will have to be replenished by increasing the cost of heating the house;

- If the house is built on a metal or wooden grillage, everything would be fine, but there is a lot of space in the underground space that is not protected from blowing winds and frosts. You can use multi-layer insulation, but it is better to completely cover the base with an insulated structure;

- If engineering communications are provided in the house, they will pass precisely through the underground space under the house. Therefore, thermal insulation of the pile foundation is required to prevent freezing of the pipeline;

- Outwardly, the house will look much more spectacular. The closed basement can be beautifully finished on the outside to create a single finished home design.

These reasons convince many owners of the need to properly insulate the pile foundation of their house. To do this, you first need to understand what material is best for this.

Features of the construction of the foundation on piles

Most often, a foundation on a pile foundation is erected for a number of the following reasons:

- When the construction process is carried out on a site with a complex type of soil - swampy, loose, rocky, weakened or prone to heaving.

- With significant differences in horizontal levels on the construction site, when the house is being built in a hilly or mountainous area.

- If there is no financial opportunity to equip an expensive foundation made of monolithic concrete.

- When the time limit for the construction of the building is limited.Most often, in such a situation, they resort to the construction of a wooden house or on a frame, and screw piles are used as the foundation.

- If the soil on the site is characterized by high humidity, and there is no way to carry out work on its drainage.

Screw piles are used as the basis for a foundation of this type. They are pipes made of metal, at the end of which a tip of a special shape is placed. The piles are immersed in the soil in a rather unusual way - not by hammering, but by screwing them manually or using mechanization. The rotating pile penetrates the soil layer with its cone-shaped tip. To make the fastening more reliable, in the course of work, the soil is compacted in parallel. The tops of the already installed piles must be leveled according to the horizontal level, and the heads must be installed. This is done so that the load from the mass of the building is distributed over the base more evenly. A special grillage is installed on the pile heads, which is a continuous strapping. It combines the disparate support elements of a building into a single structure.

Finally

If you are far from the topic of construction, the issue of insulation may seem insignificant. As the owner of a private home, you can consider this topic from the point of view of the load-bearing properties of the building. Lack of insulation can lead to a number of problems when using the house:

- the appearance of condensation drops in the underground area;

- a decrease in the thermal protection of the house and an increase in the cost of heating it;

- high humidity levels can become factors that provoke the formation of rot, mold, accelerate the exit of building structures from operation and require expensive repair work to restore it.