The impact of external factors on various foundation designs

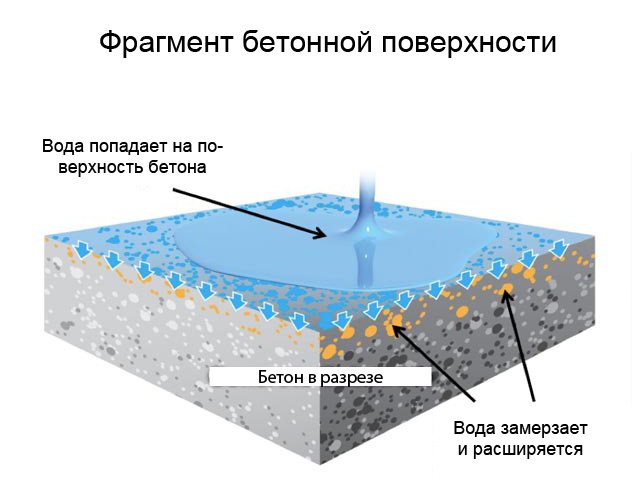

In whatever area the structure is erected, the foundation is subject to wear and tear from the effects of surface and underground moisture. Water is especially dangerous in the cold season. Getting on the surface of the foundation, it penetrates deep into the pores and cracks of the material. And passing into a solid state of aggregation and expanding, harmless water is capable of breaking even reinforced concrete.

Destruction of concrete by water.

Regular precipitation is typical for any region, but in this case, the blind area acts as a reliable protection for the foundation. It is an indispensable element of any building, regardless of the location of the site.

The situation with groundwater is much more complicated. They are present almost everywhere, only the depth of their occurrence is different.

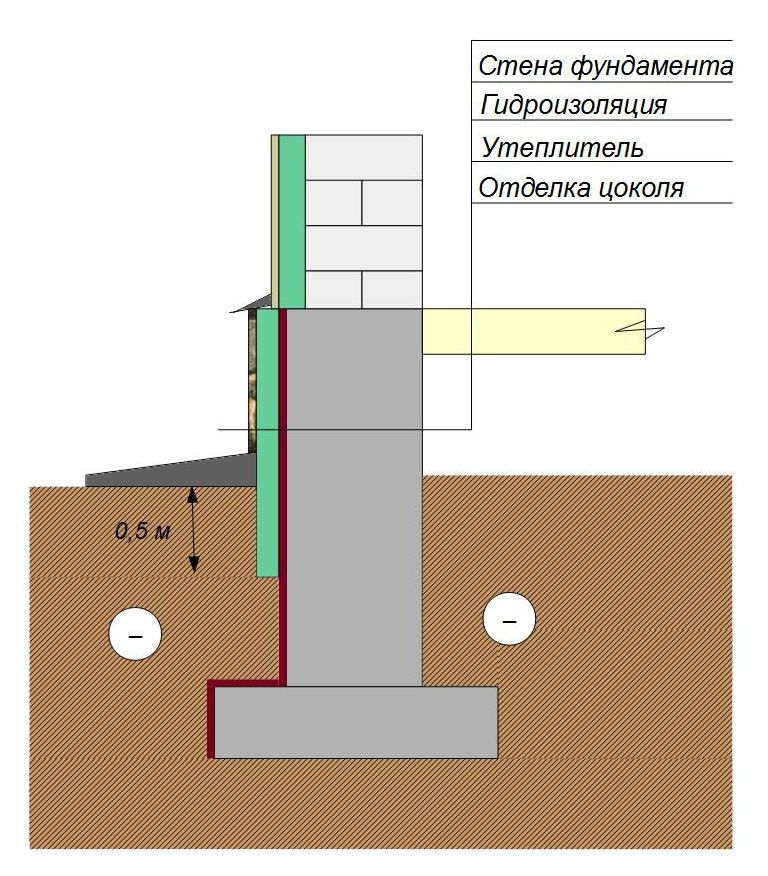

- If groundwater is located significantly below the base of the foundation, more than 1 meter, this does not mean at all that waterproofing can be neglected. With intensive development of nearby territories, drainage works and the construction of asphalt roads are inevitable. These activities can cause groundwater fluctuations over the years. The simplest coating waterproofing will guarantee the durability of the foundation.

- If the groundwater level is in the immediate vicinity of the supporting structure, at a depth of less than 1 meter from the level of the base of the foundation, waterproofing protection is required. During spring floods, the groundwater table (GWL) can rise by several meters. And moisture will rush through the soil capillaries to the walls of the foundation. Vertical (coating or roll) and horizontal waterproofing will become a reliable barrier.

- The most difficult option is when groundwater literally washed the walls of the foundation. In this case, it is necessary to provide not only maximum waterproofing, but also to equip the space around the building with a drainage system. Even the best quality waterproofing materials will not be able to withstand the hydrostatic pressure on the foundation. And this is fraught with shifts and deformations of the supporting structure, which is subjected to colossal loads from the entire structure as a whole. Waterproofing, coupled with a drainage system, will be the optimal barrier to excess moisture.

- In some cases, it is necessary to reliably protect the foundation regardless of the groundwater level. The reason for this is the composition of the soil itself. The high content of clay or loam in the soil prevents the absorption of atmospheric moisture into the deeper layers of the soil. And she rushes to the walls of the foundation.

Regardless of rainfall, groundwater levels and seasonal factors, the chemical composition of the water must be considered. Agricultural fertilizers, the use of powerful reagents in the winter, industrial and sewage effluents saturate underground and surface waters with aggressive impurities, which gradually corrode even such durable materials as concrete. And when it reacts with oxygen chemicals, the process of corrosion of the reinforcement mesh is irreversible. Thus, the integrity of the entire structure is violated. You can learn more about the technologies for installing drainage systems in a special article: groundwater drainage systems, design and installation. Here we will talk in more detail about waterproofing the foundation.

Construction of the blind area

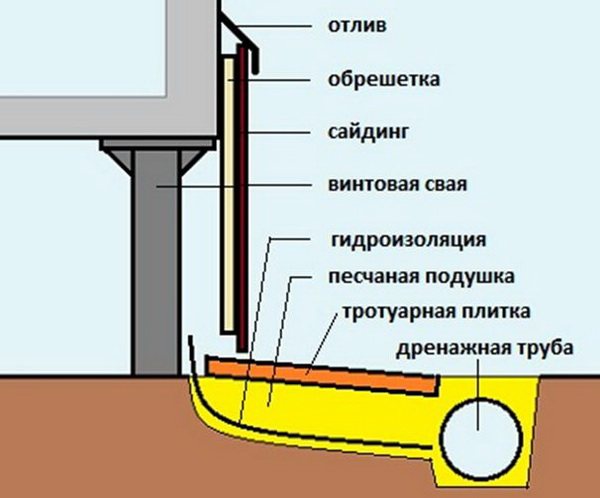

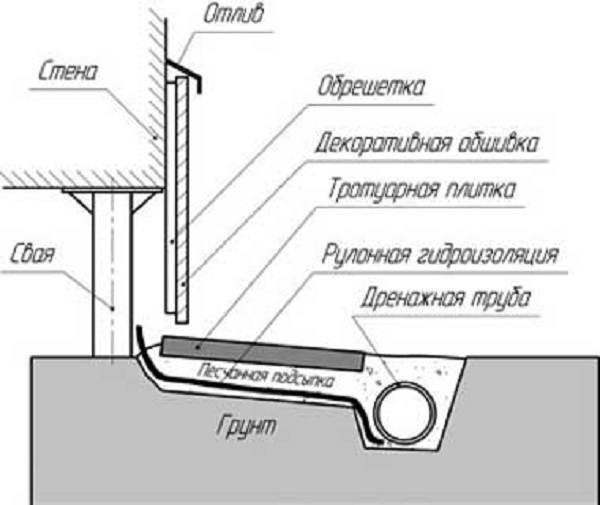

A well-made blind area of the screw foundation is half of an excellent result, and therefore, during the installation of the blind area, it is necessary to delve into all the nuances of the process as carefully as possible. Work begins on the creation of such a structure as a blind area of the base, with a marking of the site.This will make it easier to maintain the desired width around the perimeter of the entire belt. After that, it is the turn of the earthworks. At this stage, a trench of suitable width and depth is dug.

The next step in the process of arranging the base area is to form a pillow - first from clay, and then from sand. Then a small layer of crushed stone of the middle fraction is poured, on top of which a reinforcing mesh is placed. When all of the above work is completed, you can pour the structure with concrete and level it. This is approximately how the installation of the most elementary blind area, made of concrete mortar, looks like.

To obtain the maximum result, it is not enough just to build a blind area of the pile foundation. It still needs to be insulated. For this, a horizontal insulation technique is used. The first step is to install a waterproofing layer. The thermal insulation panels used must be of high strength. Otherwise, they can then be damaged due to the severity of the concrete screed.

You can start facing the pile foundation blind area only after the concrete has completely hardened. The facing of the blind area has nothing to do with its technical characteristics, it performs an exclusively aesthetic function and is performed at will.

And now - practice

In my case, let me remind you, a concrete coating was chosen, and crushed stone and a coarse-grained fraction of sand as a pillow. Thanks to this choice, the seasonal deformation of the soil is slightly compensated.

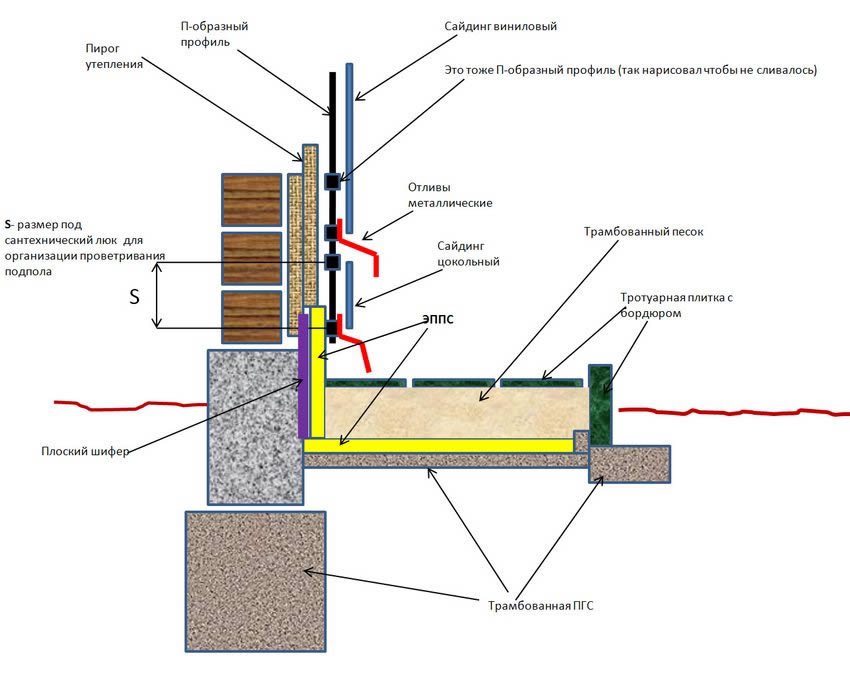

It is worth noting that the blind area and the basement in houses with a screw foundation are one whole, and this is best ensured by concreting. True, there are many errors associated with this.

Firstly, in a pile house, the basement must be ventilated. I made holes around the perimeter of the base at a height of 50 centimeters from the blind area, and then covered them with a net to prevent animals from entering the underground. You should know that for the winter, the holes are closed with plugs, since otherwise they will provoke cold in the house.

Arrangement of the blind area of the house with concrete also provokes its seasonal deformation under the influence of seasonal soil movement. To prevent the formation of cracks in the concrete blind area after the first wintering, I laid several expansion joints. For this I used regular wooden planks.

It’s very simple. First, I prepared the wood, for which I used bitumen, which I thoroughly impregnated the boards with.

After that, I laid them in a ditch, observing the angle I chose to ensure the outflow of water from the house. I chose a slope of five degrees. You can, of course, more, but my blind area plays the role of a path, so the standard 7 degrees would be inconvenient for the movement of my family members.

I poured concrete into the sections formed between the boards, and then carefully leveled them with a trowel. After the concrete was completely dry, I made a tile cladding.

To all those who are going to build a mansion, a bathhouse or any other building on a foundation of screw piles, I advise you to use my experience, since the blind area is already several years old, but there is not a single crack on it.

More on this topic on our website:

- Concrete blind area around the house - photo and characteristics of a concrete blind area with insulation Why do you need a blind area around the house and how to make a blind area? For a person who is not associated with construction, the installation of a blind area will seem to be a very difficult process. But for a specialist ...

Insulation of the foundation and blind area - how does the insulated blind area of the house work

- There are many opinions about the insulation of the blind area, but most experts are inclined to the need for this procedure, which forms the strength and optimal protection of the foundation of home ownership. The foundation will receive ...

Hanging grillage - photo of grillage on screw piles and columnar foundation

- The type of base of the building is selected depending on local conditions. The columnar foundation with the grillage is not very widespread, in terms of its popularity it lags behind the strip foundation, but ...

Do-it-yourself private house on piles - the distance between the foundation piles, insulation, decoration

- Screw pile foundations are used in the construction of detached houses with various structural heights, regardless of the type of soil….

Waterproofing of pile and columnar foundations

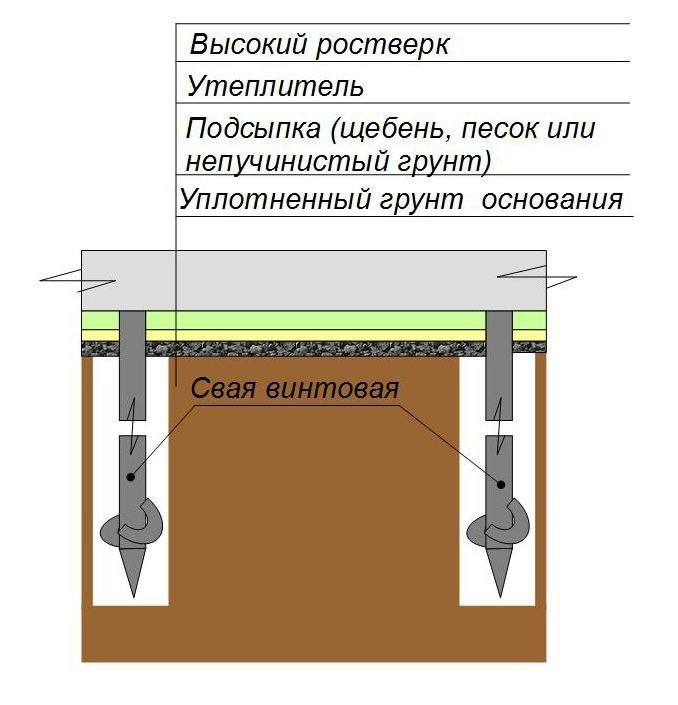

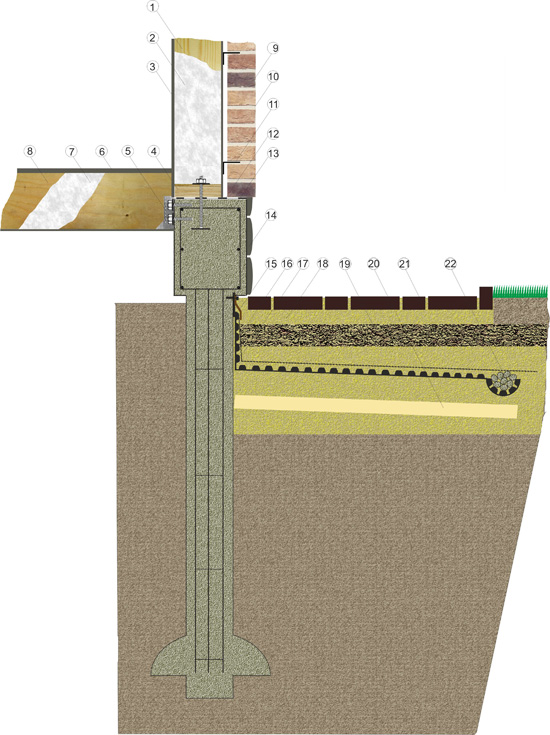

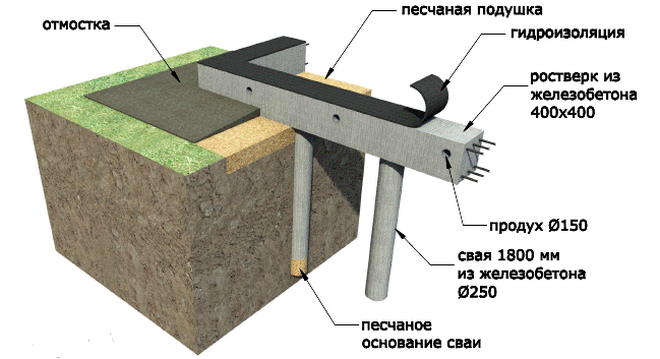

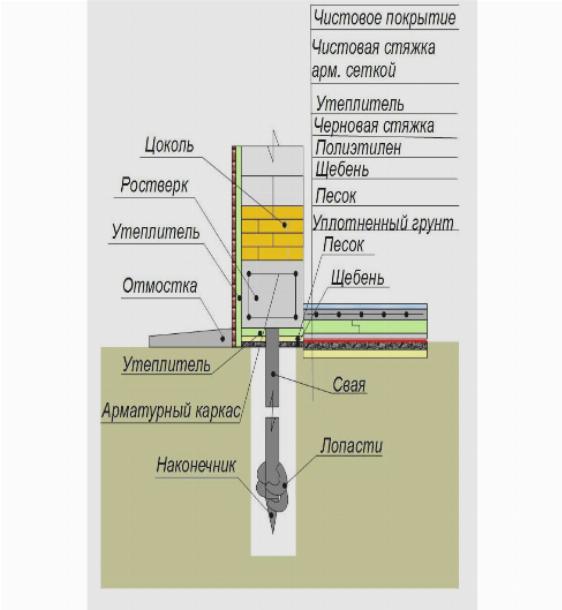

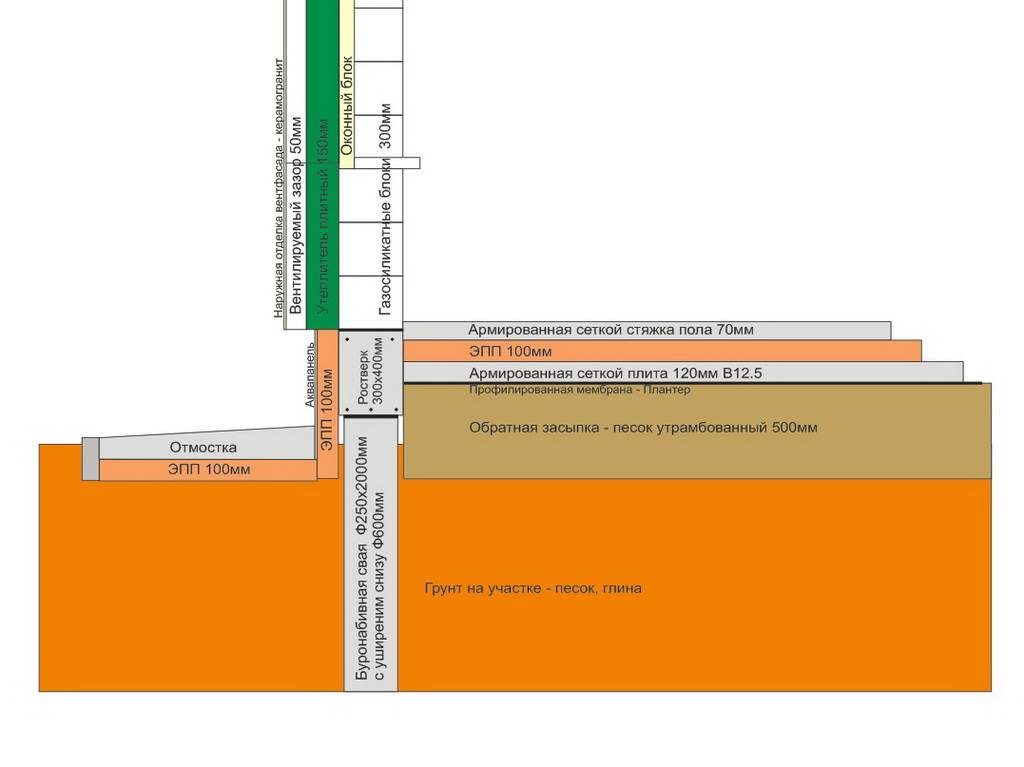

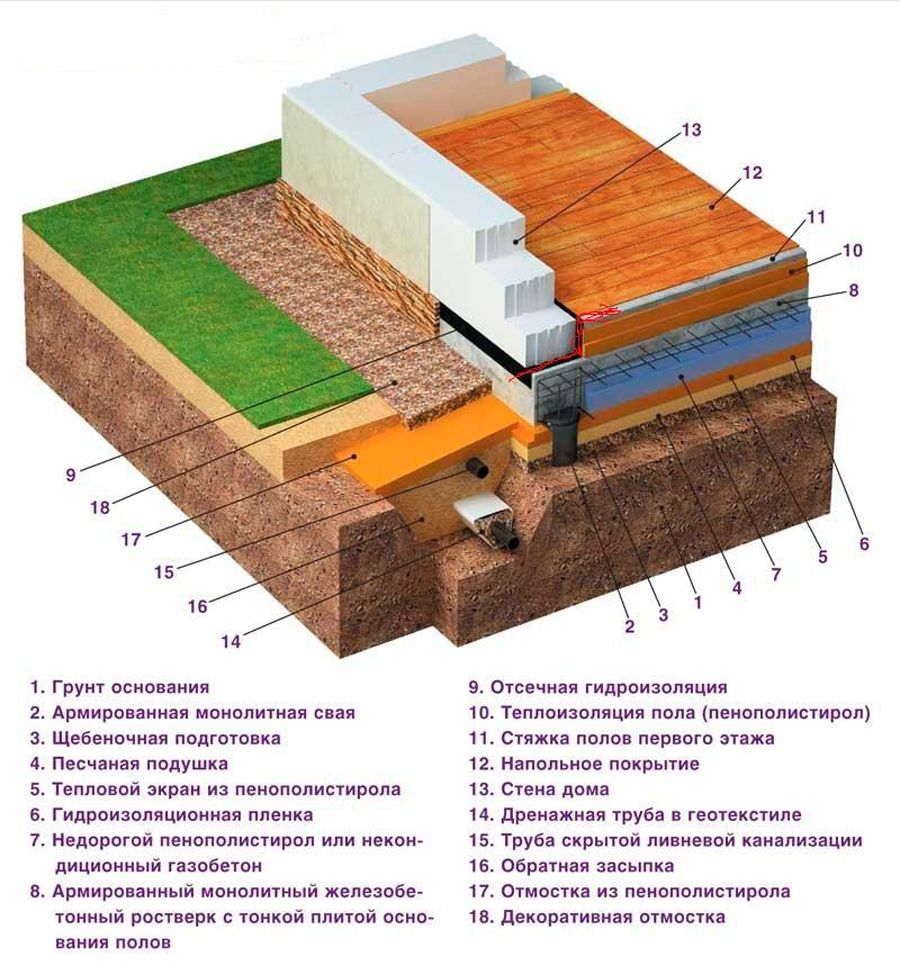

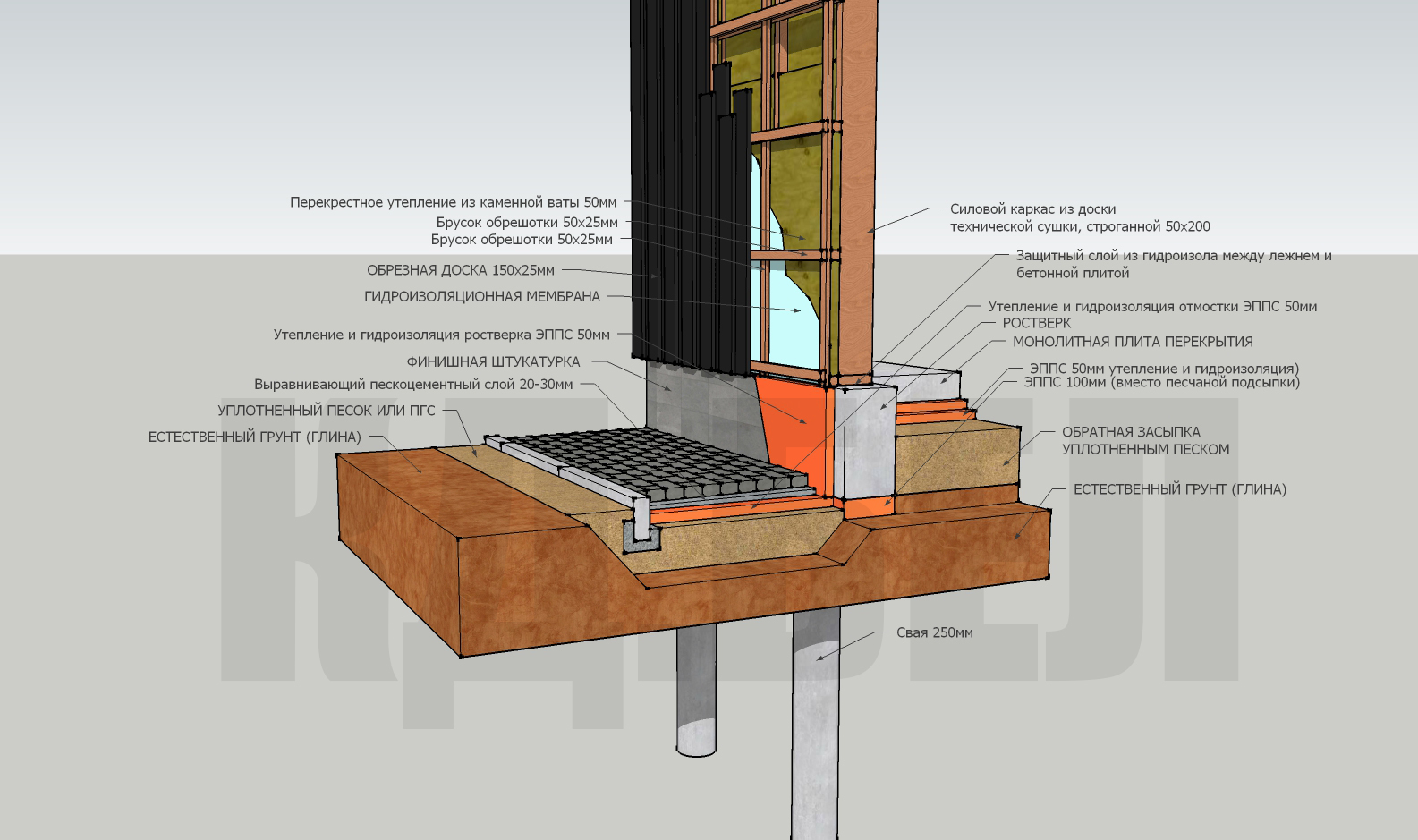

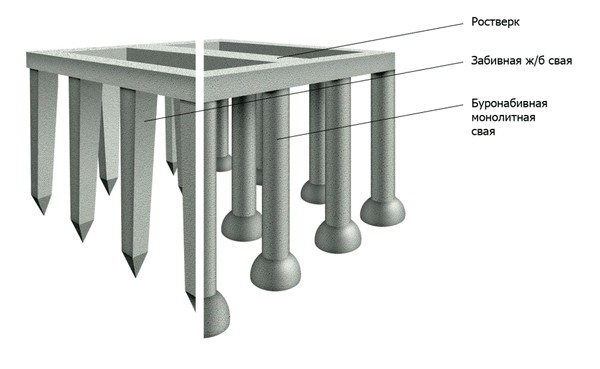

The pile foundation is used in areas with restless soil. Its structure consists of piles that are driven deep into the soil, until a dense layer is reached. And from above they are united by strapping beams or slab grillage. Waterproofing a pile foundation is very problematic. If the waterproofing compound is applied to the concrete part of the piles before driving them into the ground, then it will peel off from friction with the soil. And it is impossible to process piles driven into the soil with a moisture-proof composition. Therefore, for the impregnation of the concrete part of the piles, a hydrophobic composition is used during the production process. In the future, it can be treated with impregnations and coatings, which will increase the degree of protection against moisture.

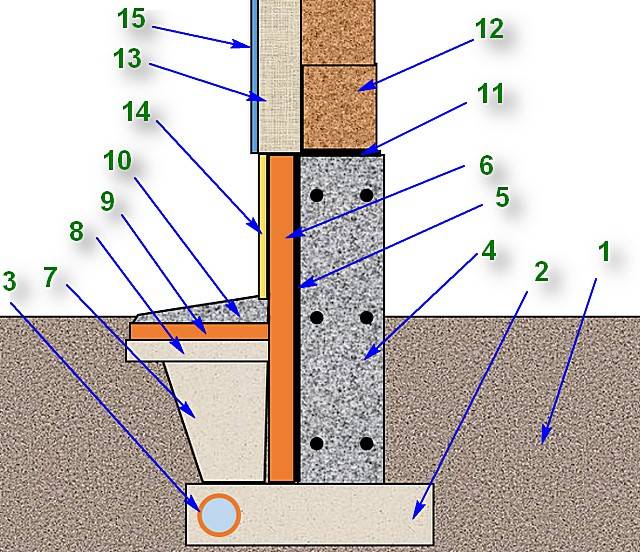

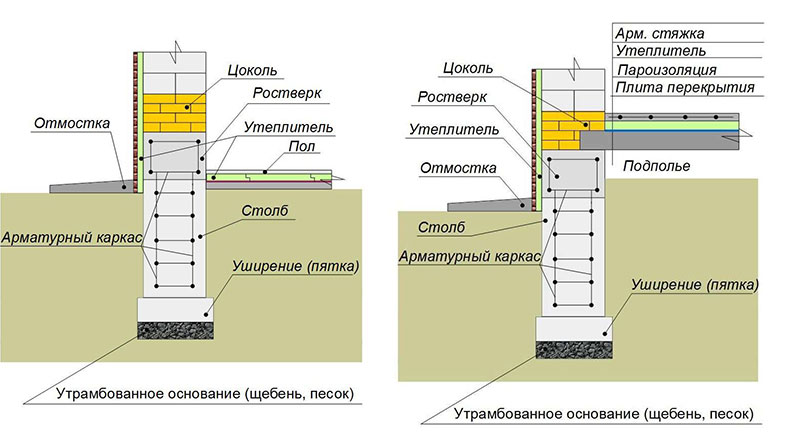

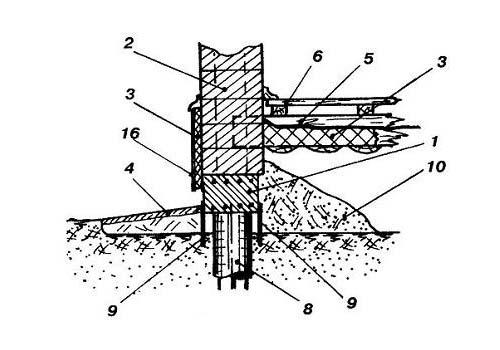

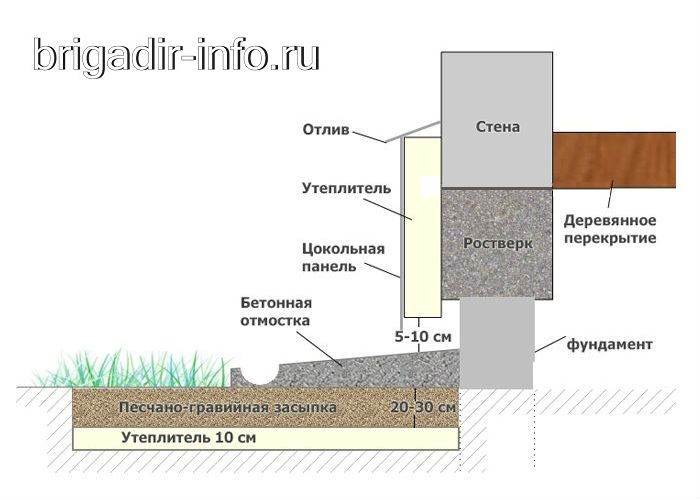

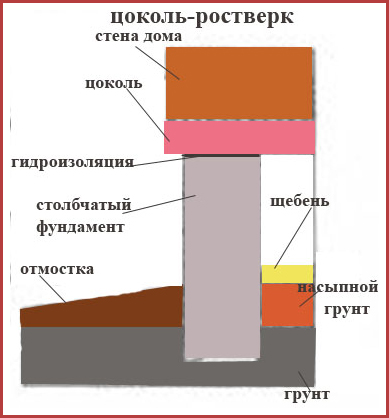

Columnar foundations are used in the construction of buildings with light walls. Pillars made of reinforced concrete, rubble concrete are placed in the prepared pits, or the technology of pouring concrete into the formwork is used. For waterproofing a columnar foundation, methods typical for a strip foundation are used.

Since the grillage that connects the piles and pillars is a full-fledged part of the foundation, it also requires reliable waterproofing. The grillage can be made either in the form of a tape or in the form of a monolithic slab uniting all pillars or piles.

Waterproofing of the pillar foundation grillage

To make a pillar foundation grillage, waterproofing is applied to the pile heads, then sand is poured up to the upper edge of the piles, roofing material is spread on the sand and wooden formwork is installed. It is sheathed from the inside with roll waterproofing, filled with reinforcement and poured with concrete. After the concrete has hardened and the formwork and sand have been removed, all parts of the grillage must be carefully treated with a waterproofing material. Before this, the surface of the grillage must be leveled and cleaned. It is possible to use coating technology or pasting on heated bitumen.

Waterproofing of the pillar foundation grillage

Waterproofing of slab foundation grillage

The grillage of a slab foundation is made similar to the grillage of a columnar foundation, only the formwork is a large box with a bottom, which is installed on the pile heads. After the concrete dries, a monolithic slab is obtained, which connects the foundation together. The entire grillage must be waterproofed with rolled roofing material and hot bitumen. Before applying waterproofing, you need to make a screed from the solution.

Protection of a columnar foundation with a fill

To prevent moisture from getting under the space between the grillage and the ground, a pick-up will be required. This is a kind of basement version, which is made of wood, timber, brick or stone. The fence will reliably protect the base of the building from rainwater and snow. It is installed as follows:

- A shallow trench is dug between the piles, about 30-40 cm.

- Sand and gravel are poured inside in a small layer.

- A timber or brick is laid on this pillow to the base of the house.

If the intake is equipped with all the necessary ventilation holes, then moisture will not accumulate under the house. Waterproofing is required on the outside of such a plinth to provide protection against surface water. For this, rubber-bitumen mastics are used.

In addition to protecting it from moisture, it helps in keeping warm in a house with columnar foundations.There is a separate detailed article on how to make a warm filling on our website: insulation of a columnar foundation.

List of works to ensure reliable waterproofing of the entire foundation

In order to prevent premature wear and tear of the load-bearing element of the building, it is necessary to carry out a set of measures aimed at protecting against the influence of moisture. Depending on the project of the building, as well as the specifics of the geological and climatic indicators, the following actions are carried out:

- Installation of a drainage system for water drainage.

- Correct organization of storm sewage and drainage.

- Construction of a foundation equipped with ventilation ducts for the natural weathering of moisture.

- Installation of waterproofing materials on the walls and base of the foundation, waterproofing the basement floor and basement, as well as protecting the joints between the levels of the structure.

- Application of special water-repellent solutions.

Types of waterproofing by the method of application

Depending on the method of applying moisture-proof material, the following technologies are distinguished:

- Okalechnaya;

- Coating;

- Sprayed;

- Plastering.

It is possible to combine different waterproofing methods for different structures of the same foundation.

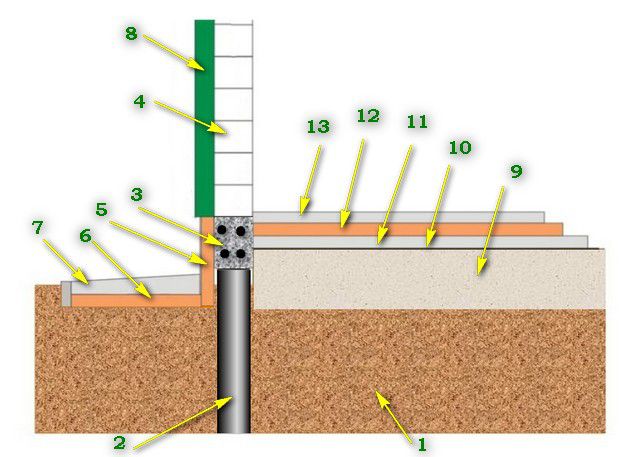

Insulation of the pile-grillage base from the outside

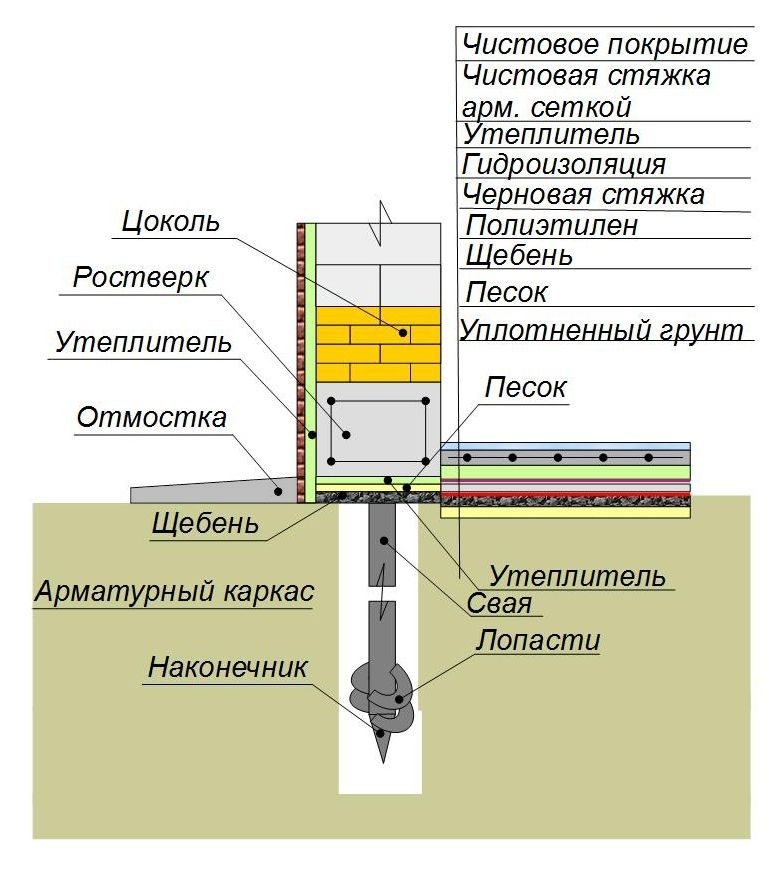

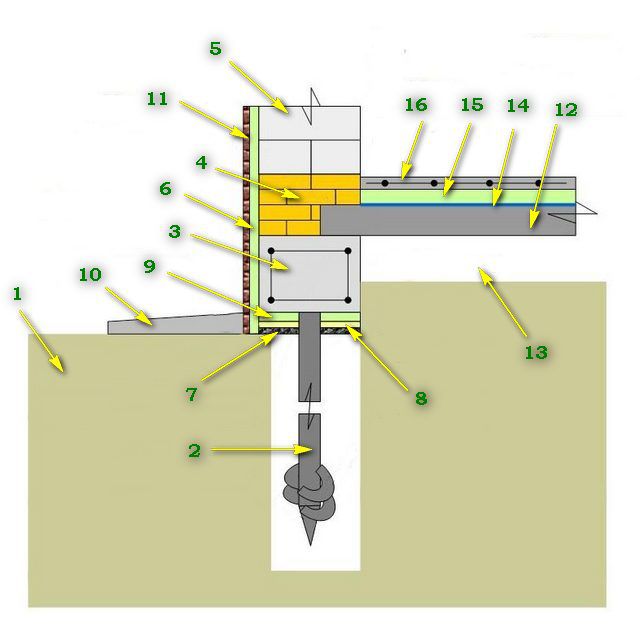

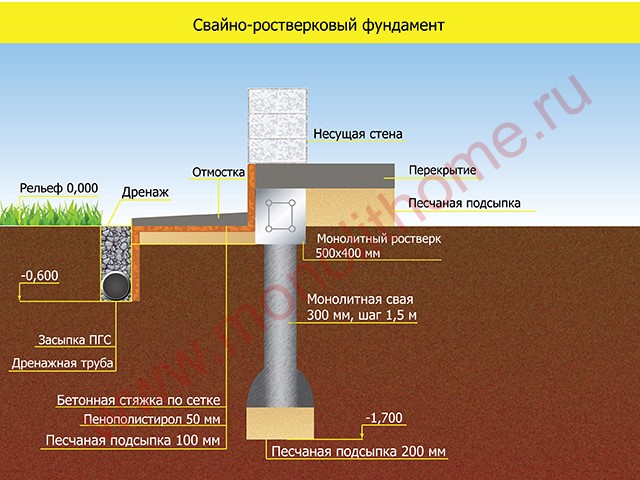

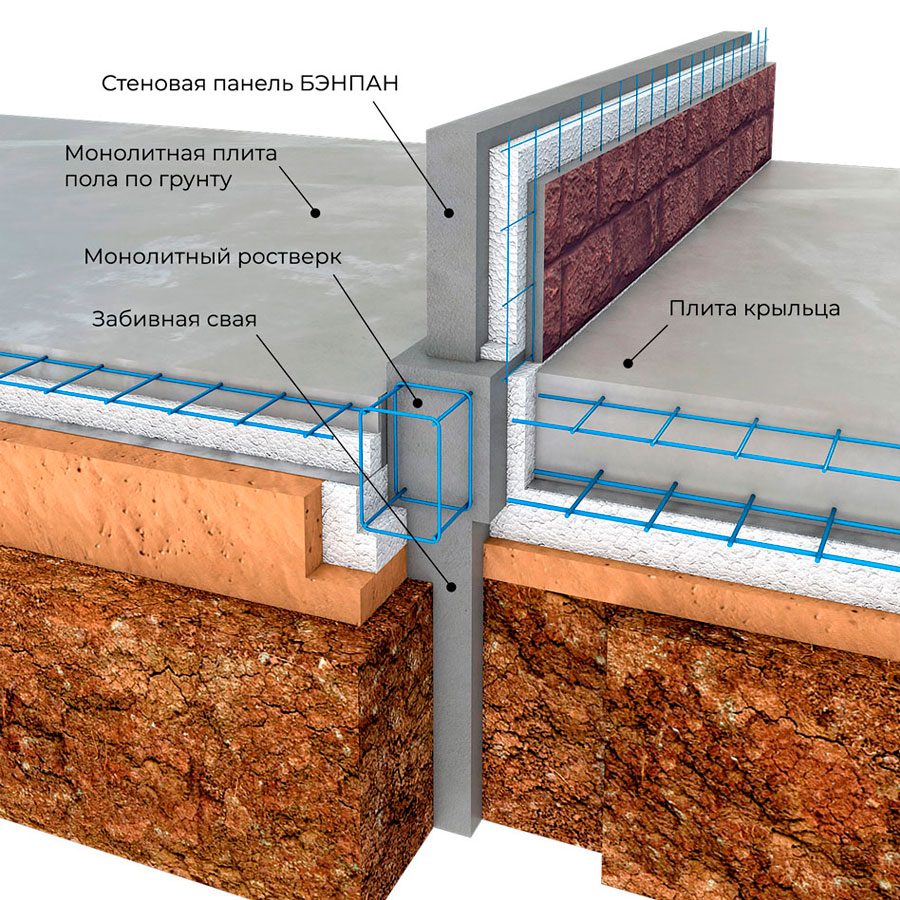

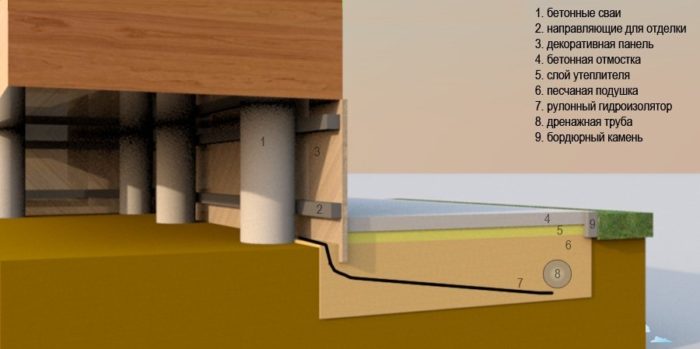

Option for the device of the pile foundation

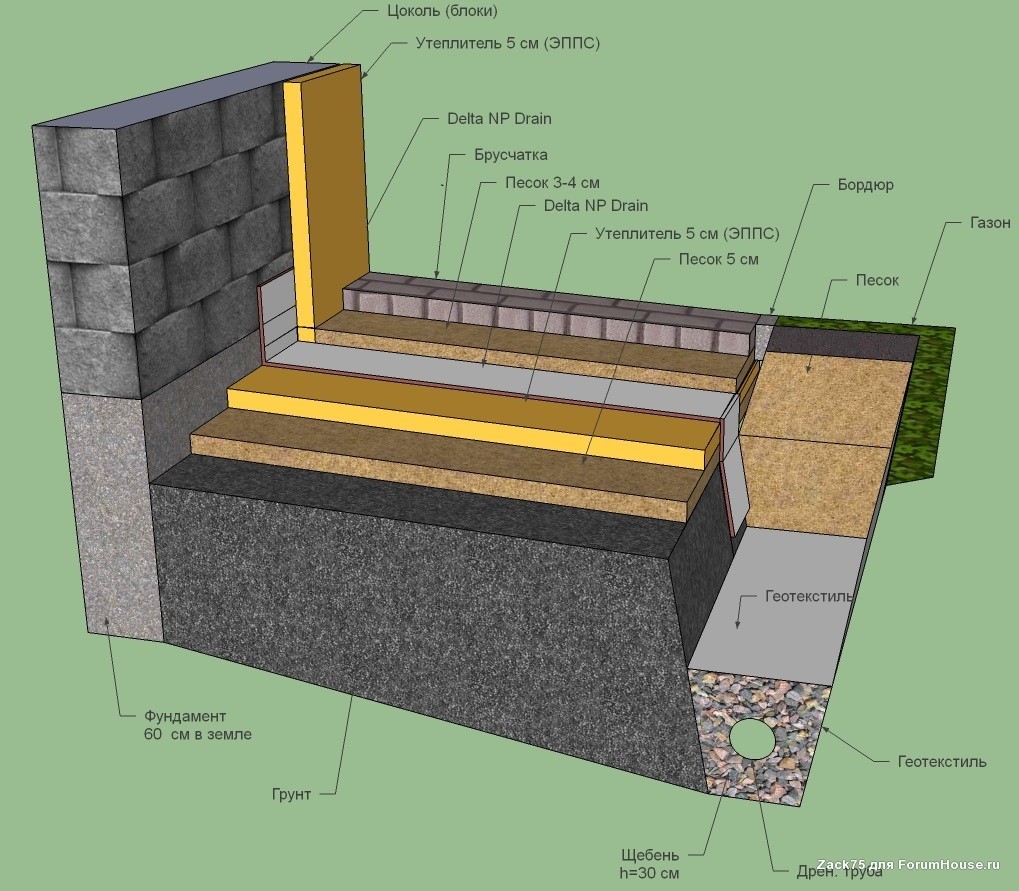

As a rule, the construction of a pile-grillage foundation provides only external insulation and waterproofing. The side edges here serve as a basement floor and they just insulate it. To do this, you can use:

- A layer of bitumen, which is used to cover the lateral edges of the grillage. This is a good waterproofing. After all, bitumen forms a strong and reliable layer of protection.

- Expanded polystyrene or polystyrene. This is a polymer thermal insulation, glued to bitumen or directly to the leveled surface of the grillage.

- Then all seams must be sealed with polyurethane foam to prevent the formation of cold bridges. But when using penoplex in several layers, it is not advisable to do this, because the sheets of penoplex have a contour shape and are attached to each other.

- Reinforcing steel mesh is used as additional thermal insulation. It is used to protect insulation from rodents, and also as a base for further plastering of the basement.

- As soon as the glue under the plates is completely dry and the mesh is tightened. From above you need to cover the structure with plaster.

There is also an alternative to this insulation technology. This is the construction of a tape-type base. In most cases, it is installed around the girder grillage on the outside, forming a "warm masonry".

How to insulate the foundation

In the insulation of any house, it is important to follow the procedure and perform them in a complex with other stages. When only the foundation is insulated, cold air will penetrate into the room through the walls and roof, which means that the result of the work will not be noticeable

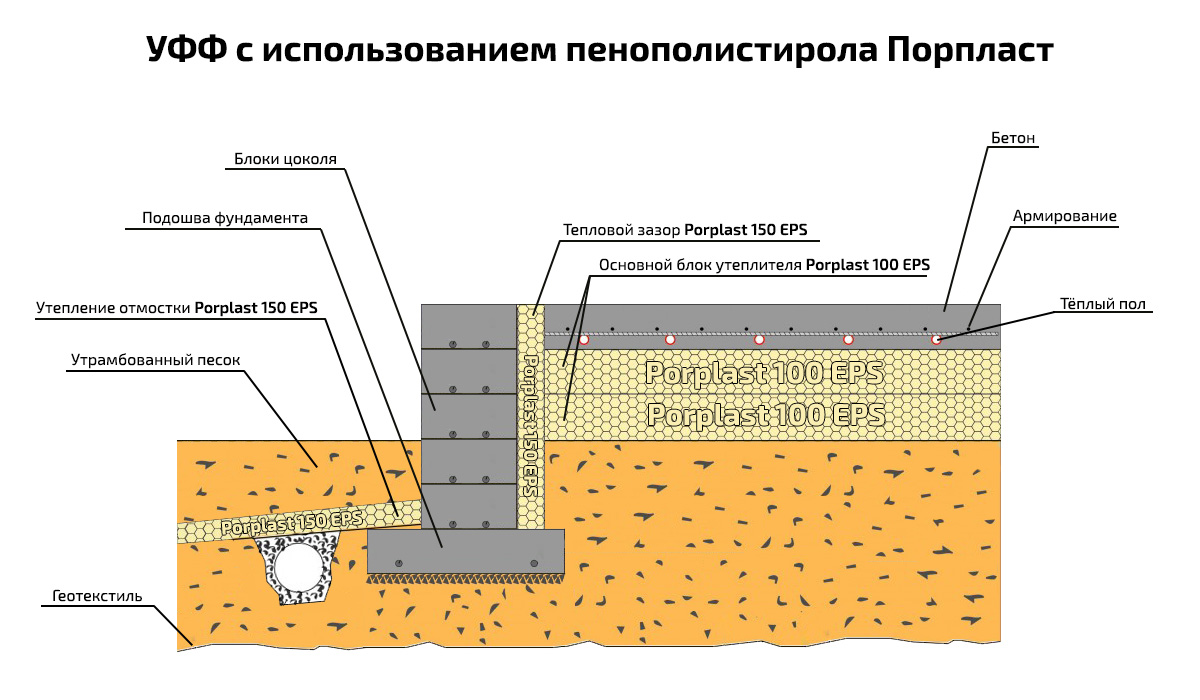

In order to correctly calculate the width of the required blind area, it is necessary to take into account the soil on which the building stands, to select the correct thermal insulation material. All heaters can be divided into:

- solid;

- soft (liquid);

- free flowing.

Recently, expanded clay, which belongs to the last category of materials, is often used for warming foundations. It is very lightweight and has low thermal conductivity. Externally, expanded clay is a brown granules that are made by firing clay. To insulate the outer part of the foundation with them, a minimum amount of material is required, which means that material costs will not be large.

If you count on small expenses, then it is better to insulate the inside of the base with foam, which is considered a solid insulation. It is inexpensive, lightweight and non-flammable. It is not difficult to work with such a material, and its thermal conductivity is quite low.Also, it does not absorb moisture, which means it is suitable for insulating rooms with high humidity, for example, baths. Also, foam is optimal for insulating basements and basements of buildings on piles. As already mentioned, even inexperienced builders can work with this material. It is produced in slabs of different sizes, thicknesses and densities, is easy to cut and is adapted for any construction work.

The most effective material at the moment is polyurethane foam, which belongs to liquid materials. It is applied to the surface to be insulated using a spray gun and is suitable for any building. This material is high-tech and has minimal thermal conductivity.

Technologies for insulating pile-grillage foundations

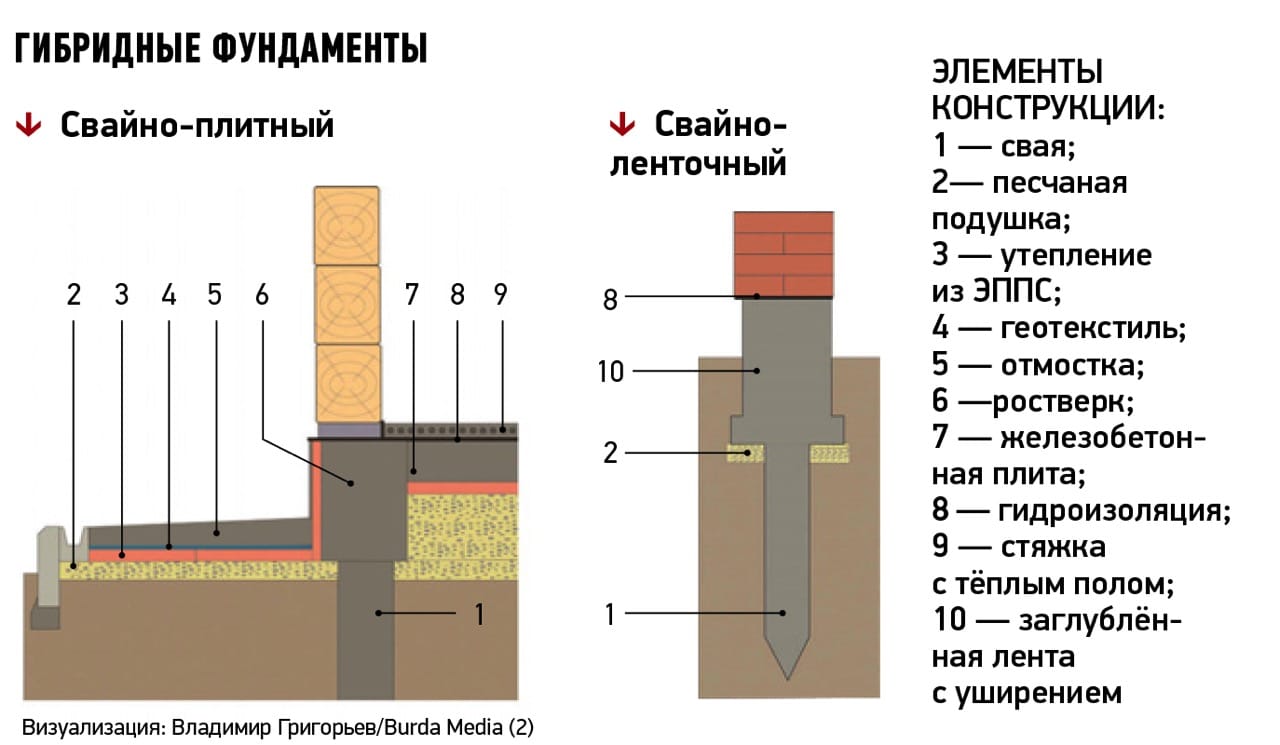

Diagram of the pile-grillage foundation

Diagram of the pile-grillage foundation

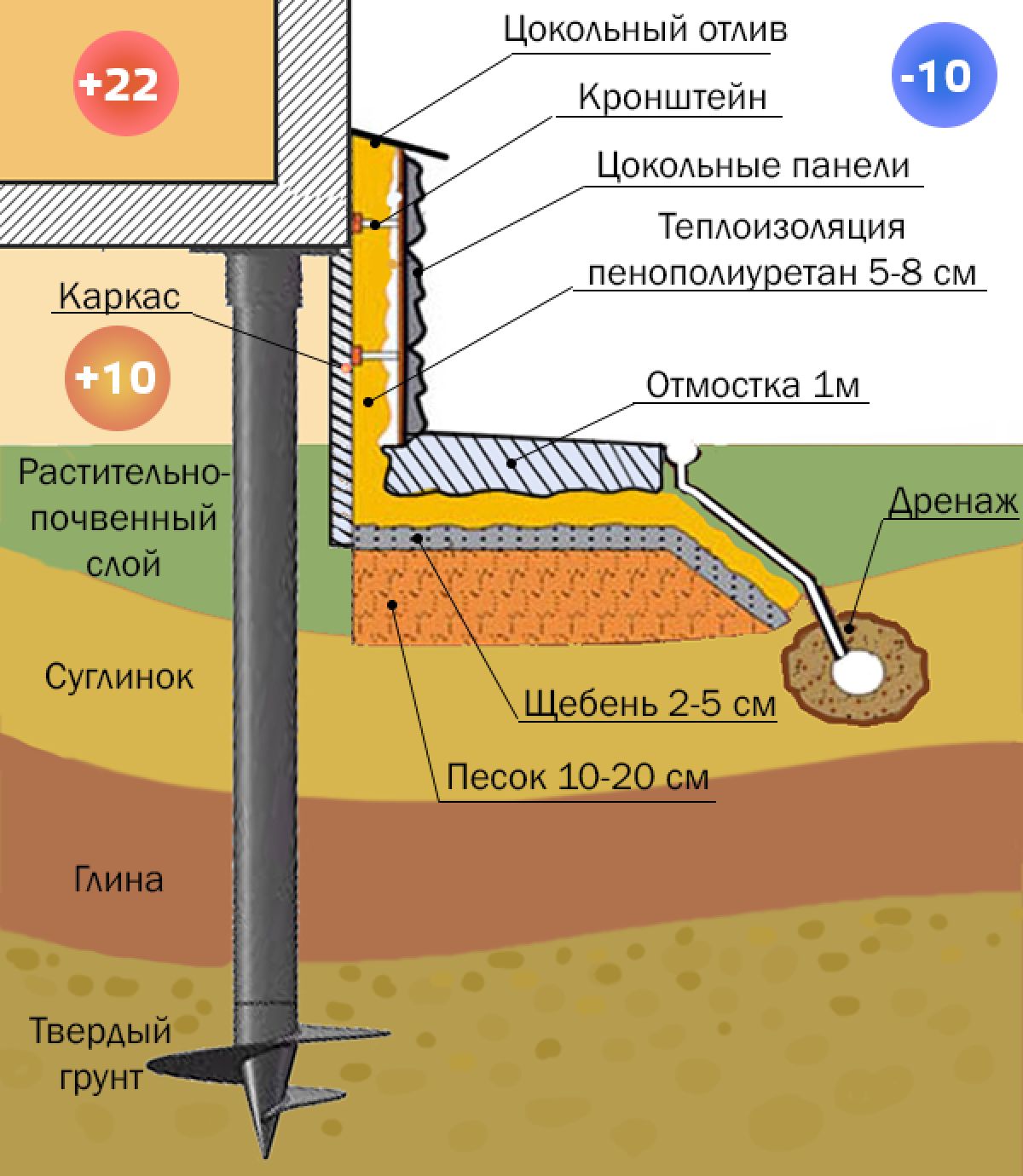

At the moment, there are a large number of different technologies for insulating grillages, ranging from the use of polymeric materials, ending with the device of the blind area. But here the key task is to choose the optimal technology that is suitable for a specific foundation and takes into account not only the climatic conditions of a given territory, but also the properties of the soil and the height of the aquatic ground horizons. Therefore, the popular technologies for insulating pile-grillage foundations are as follows:

- Adding expanded clay in the sinuses;

- Installation of modern polymer insulation;

- Blind area device;

- Combining all three techniques and using them simultaneously.

It is clear that all these are traditional methods of insulation, which are suitable in one climatic region, but cannot be used in another. The advantages of such methods are that they are relatively simple and easy to implement. And materials for insulation and waterproofing are available commercially. But the key drawback of these technologies is far from excellent efficiency in conditions of high groundwater content, as well as the unpresentable appearance of the base. It is clear that the blind area can eliminate such disadvantages, but this is more of a foundation waterproofing than a decorative design.

Arrangement of the basement of the house

The main purpose of the basement is to insulate the home. But, besides this, it also protects the base from moisture, so the base is made of moisture-resistant materials with low thermal conductivity, which should not attract rats and mice. To give the space of the basement its appearance, it is sewn up with decorative trim. Ceramic tiles, stone or wall paneling can be a suitable material for decorative finishes.

When choosing a material for outdoor decoration, the wishes and financial capabilities of the owner are taken into account. However, ceramic tiles are optimal. This choice is justified by the fact that it reliably protects the base and the base itself from moisture and the appearance of corrosion on metal parts. If the basement has a certain height, it is used to store household items and products that require coolness.

The plinth is an important element in the construction of a house. It protects the structure from the effects of groundwater and getting wet.

Basic rules for building a blind area at home

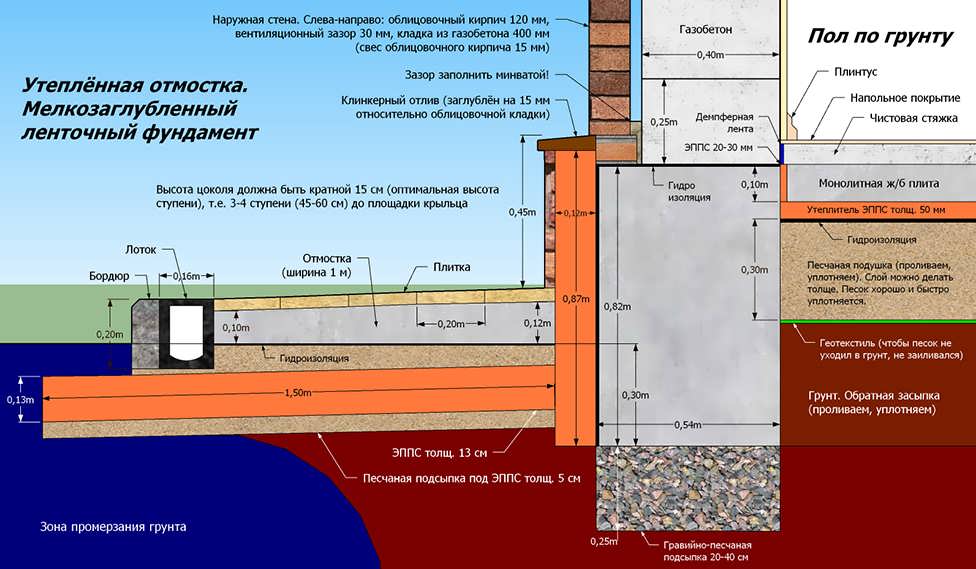

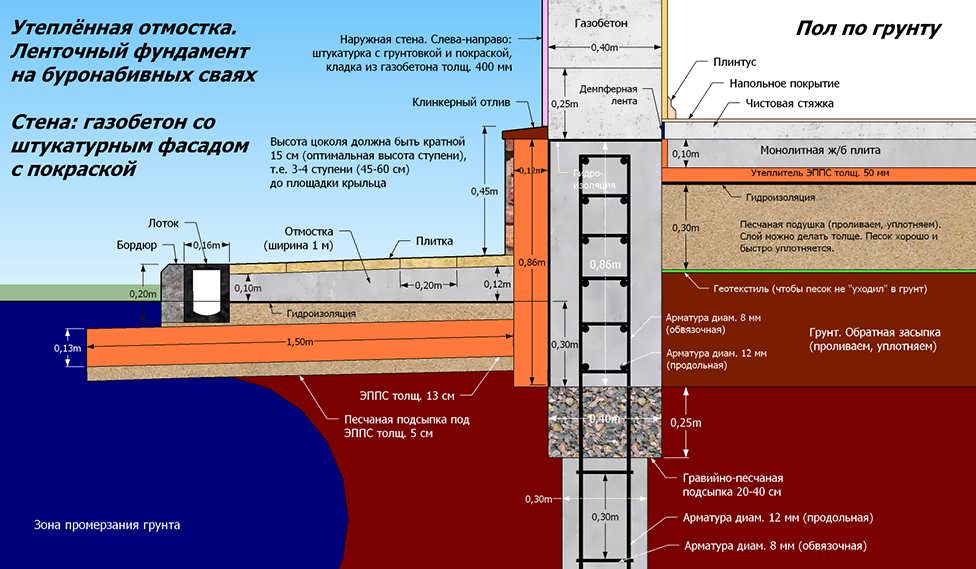

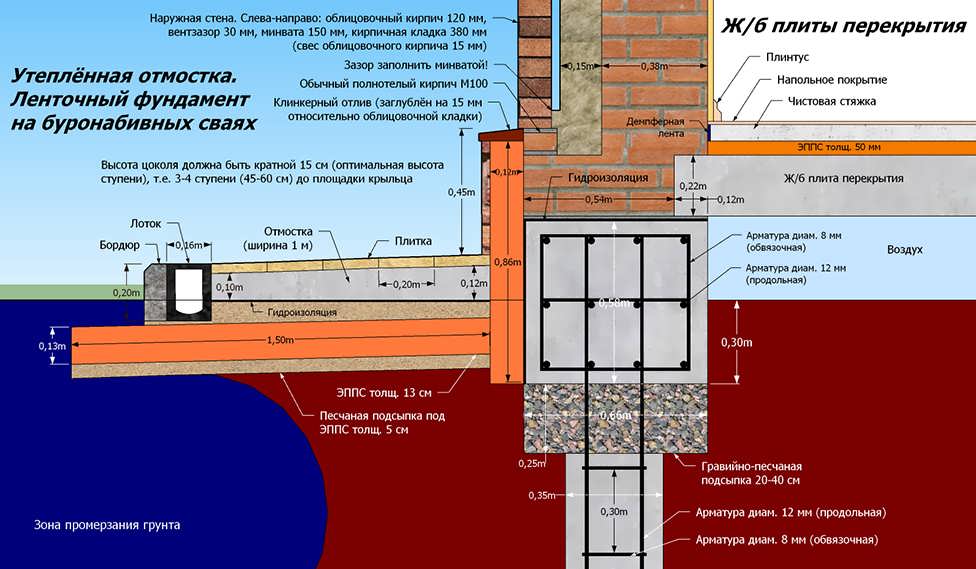

The construction of a blind area with strip and monolithic-slab foundations begins after work on the vertical external waterproofing of its walls. How these works should be carried out, read here (link) or here (link).

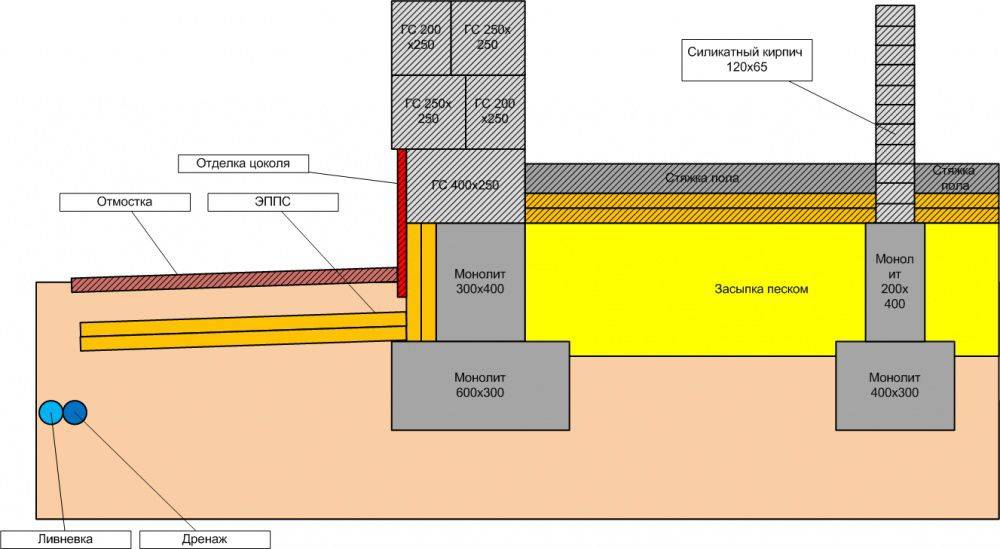

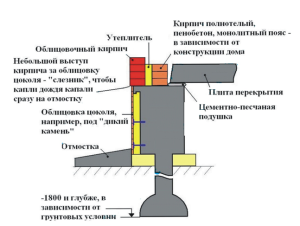

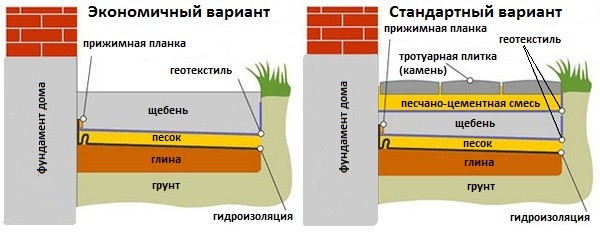

The bosom or the space between the soil, untouched when tearing off the foundation pit under the house or the trench under the tape and the foundation itself, is covered with soil. This operation is called backfilling. In this case, the layer directly next to the wall can be covered with clay and tamped. Lay the clay layer just below the ground level, for example, by 100 - 150 mm. The "thickness", or rather the width of the clay castle at the level of the base sole, should be at least 250 - 300 mm. As backfill progresses, this width can increase up to 400 - 500 mm. Further away from the walls, there may be ordinary soil.

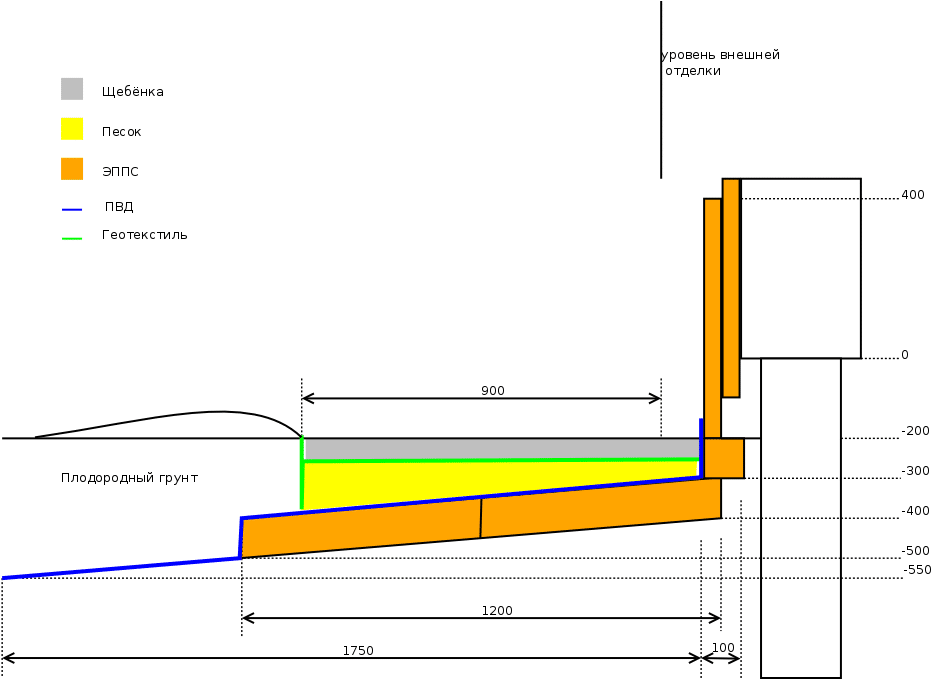

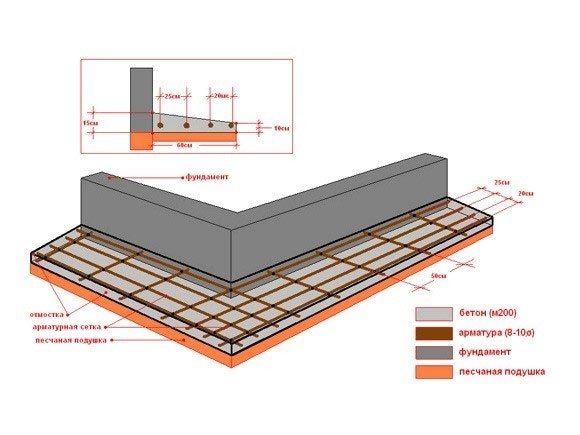

All backfill must be compacted in layers. Around the whole house it is necessary to leave an unfilled “groove” up to 150 - 250 mm deep. Coarse sand or screenings with a slope of at least 1.5 - 2%, that is, at least 20 mm / m, are poured into the groove as a sublayer, which are leveled and tamped. Sublayer thickness 50 - 80 mm.

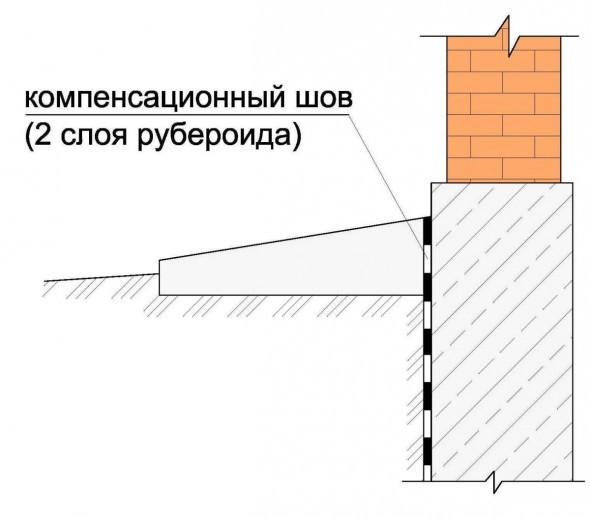

There should not be a rigid connection between the monolith of the blind area and the wall of the foundation or basement. Very often, especially in loose soils, a monolithic blind area can move relative to the basement. In this case, the destruction of the waterproofing layer of the base and basement is possible, and during rains or in spring, when the snow melts, it will freeze.

To prevent this, when concreting the formwork, it is necessary to lay two or three layers of waterproof material between the waterproofing and the end of the protective layer. You can use two strips of roofing material or thick polyethylene, laying them on tamped sand or screenings, lifting them along the wall and securing the upper edge.

If the waterproofing layer is extended under the entire formwork and brought out into the drainage groove, then you can use materials that allow water to pass through - a layer of rubble, pebbles, paving slabs, paving stones, etc.

After that, a layer of concrete is laid at least 50, and preferably 70 - 100 mm. When concreting, it is advisable to use a mesh of reinforcement with a rod diameter of 3-5 mm and cells of 100 x 100 or 150 x 150 mm.

After about 4 - 6 meters, an expansion joint is made so that the concrete does not burst in winter or bulge in the heat in summer in cold weather. In the area of the expansion joint, it is worth laying on the backfill two layers of waterproofing - roofing material or thick polyethylene with a width of 700 - 1,000 mm. Fill it with bituminous mastic, sealant or even sand.

Along the outer edge of the layer below its surface, a drainage groove is made to drain storm water. This can be a groove in the ground, in the form of a concrete strip, or from concrete blocks.

This is how the correct foundation blind area is made.

If you have the necessary tool and skills in owning it, then having bought the necessary materials, you can make a blind area of the foundation with your own hands.

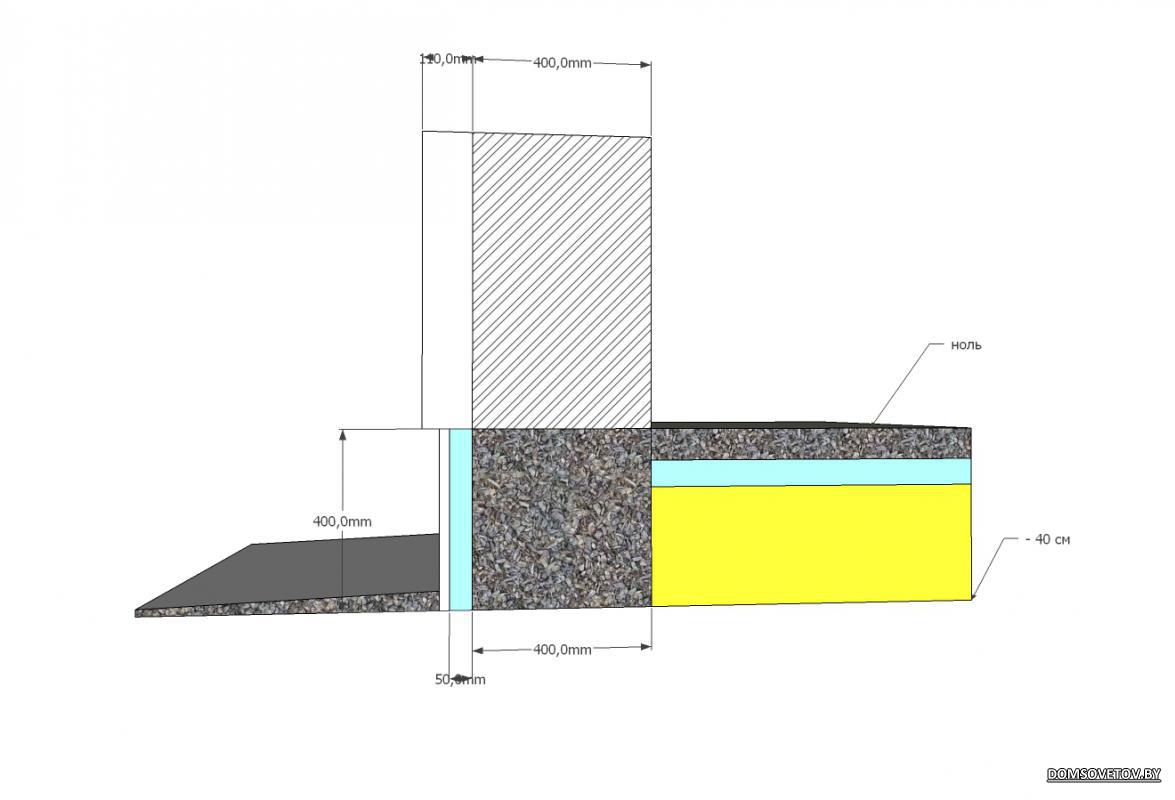

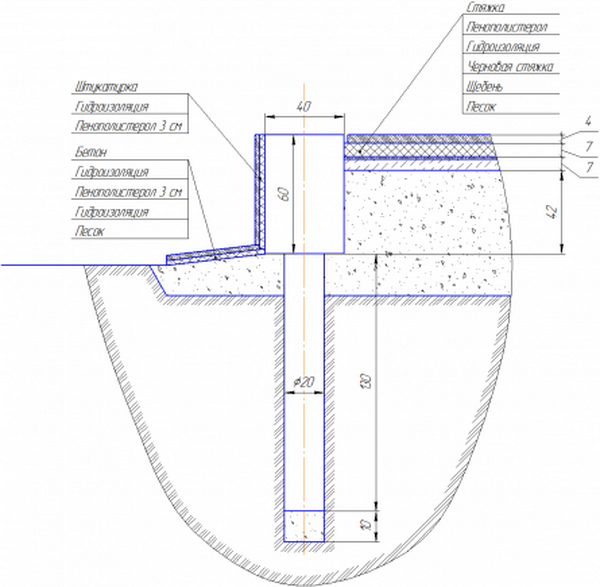

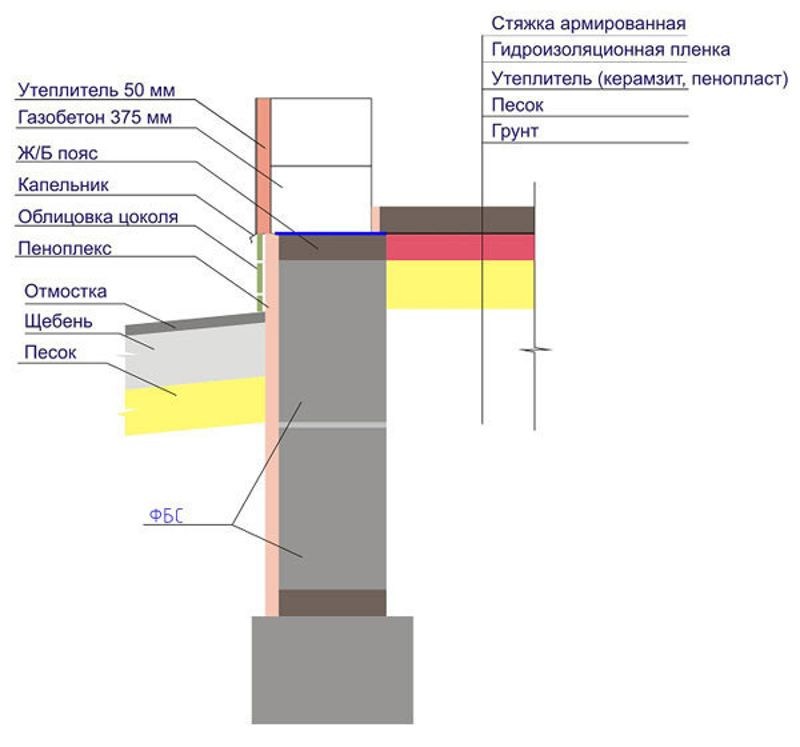

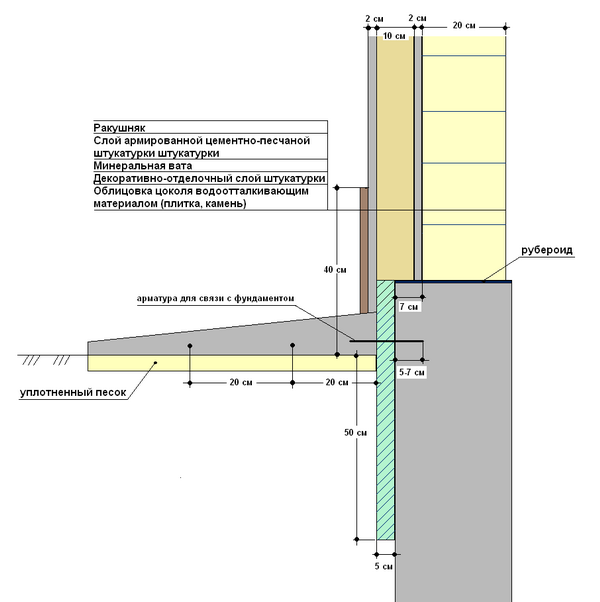

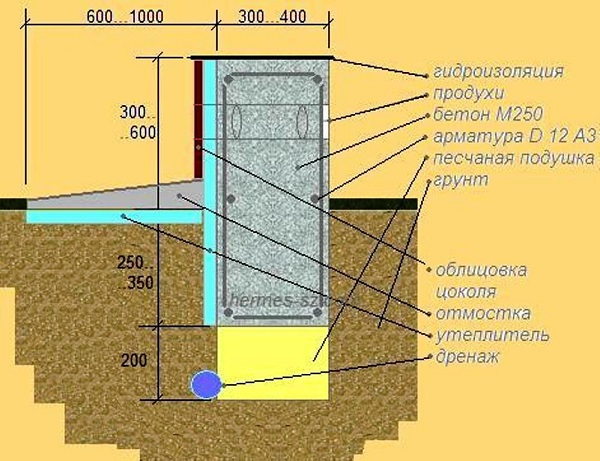

Strip foundation

First, dig a trench to the very bottom of the foundation. Its width is 80-100 cm, since the insulation of the blind area is also carried out at the same time. If the foundation is of a buried type, then the first 40 cm in depth, the trench is dug to the width of the blind area, and then, to save energy, you can make it 50 cm wide.

If the house was built some time ago, then cracks may appear on the concrete. They are covered with a mixture of cement with construction glue, if the cracks are small. Larger damage is repaired with cement mortar.

The next step is waterproofing. For this, the surface of the foundation tape is covered with bitumen mastic, on which roofing material is glued. The sheets are glued with an overlap, the seams are additionally coated with mastic. More modern roll materials are also used, such as self-adhesive roll waterproofing.

After that, the insulation is glued. Although penoplex is often attached to dowels, it is still better to give preference to glue or liquid nails - they do not violate the integrity of the sheets. How to insulate a strip foundation with expanded polystyrene, see the video:

The joints between the sheets are foamed with liquid foam.

After installing the insulation, geotextiles are glued to it. It will reduce the effect of soil heaving on the heat-insulating layer.

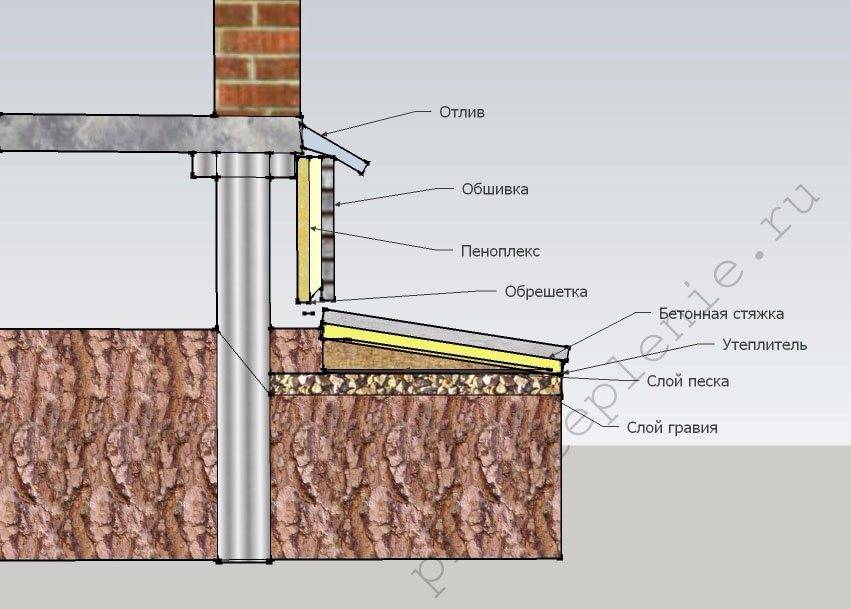

Next, the trench is filled up to the level of the blind area. Sand and fine gravel are poured under the blind area with a layer of 0.15-0.2 m, the pillow is carefully tamped. This layer will protect the blind area from the loads arising from the movement of the soil. A layer of dense insulation is placed on top. The same penoplex is suitable due to its resistance to compressive loads. Concrete is poured from above, in addition it can be reinforced with a mesh.

Attention! To reduce the effect of frost heaving, a layer of insulation is placed at the level of the basement sole. The most effective combination of foam insulation to the level of the walls in combination with insulation of the blind area at the level of the sole

Decorative finishing

Decorative finishing is made at the request of the owner of the house. This can be done by pouring asphalt, laying cobblestones, paving slabs or paving stones. When equipping the transition zone around the house, a slope of 5-7 degrees is observed. Such measures are necessary in order to remove moisture.

Use of paving stones

Most often, the blind area is decorated with paving stones or natural stone. These materials must be applied in the following order:

- First, the bottom of the dug trench is filled with sand;

- The sand is compacted;

- Concrete is poured 5 cm;

- Reinforcing mesh is laid;

- Refilling in progress.

- A dry sand-cement mixture is poured onto the frozen solution.

- Paving stones are placed on top of the mixture. Its outer edge can be decorated with a border. The blind area made using this technology is considered quite reliable.

Paving slab cladding

Paving stones and paving slabs do not differ in laying. If the house has a pile-screw foundation, then a blind area is required for it. When arranging a foundation of a different type, for example, a strip foundation, the technology will be slightly different.

Waterproofing materials

Roofing material in rolls

Roofing material in rolls

In this case, roofing material is often used. Moreover, it is used for horizontal and vertical waterproofing. Roofing material is different. It is better not to use it on a cardboard base for waterproofing, since such a material has weak hydraulic properties.

But if it has already been purchased, then laying a couple of its layers in the foundation base on bituminous mastic. Roofing material with a polyester base has higher quality characteristics. The highest quality roofing material in this matter is fiberglass-based material.

This material is well suited for pile foundations. It is more expensive than coating waterproofing, but it is distinguished by its durability and strength.

Membranes for waterproofing are available flat and profiled.

Membranes are made of polyvinyl chloride and polyethylene. They are adhesive and weldable. A tape is needed to strengthen the membranes.

Bituminous mastic

Bituminous mastic

Bituminous mastic is needed for vertical waterproofing of the foundation. In this case, an important condition is the treatment of brick bases with plaster.

But, it should be remembered that the usual plaster mixture for a pile foundation, which is prepared from sand and cement, is by no means suitable.

The mastic is applied with a brush or roller. After that, a waterproof shell is formed.

Work is also carried out using materials that have a penetrating effect, such as, for example, a mixture of high-quality cement, hydro-additives and quartz sand, which is one of the most expensive options for protection. Typically used for columnar foundations.

Insulation

If the house is placed on a pile-screw foundation (which is often done in areas with moving soils), the blind area is made less rigid. Since with small displacements of the soil, the protective strip located around the building and the decorative elements of the basement of the structure will inevitably begin to collapse. To prevent this from happening, you need to make a special compensatory, or expansion, seam about 3 cm wide. It is made of cement-bonded particleboard, foam, roofing material or boards with bitumen impregnation. Thanks to the blind area, the foundation of the house can be reliably protected.

However, when making it, it must be remembered that holes with a diameter of about 100 mm are needed for ventilation of the underground space of the basement. The holes are made at a height of 50 cm from the blind area. They are covered with decorative grilles that protect the subfloor from rodents and other insects.

To organize a good blind area, consider the type of base of the house, and ensure that a number of mandatory requirements are met. Then the structure will effectively protect the base for a long time.

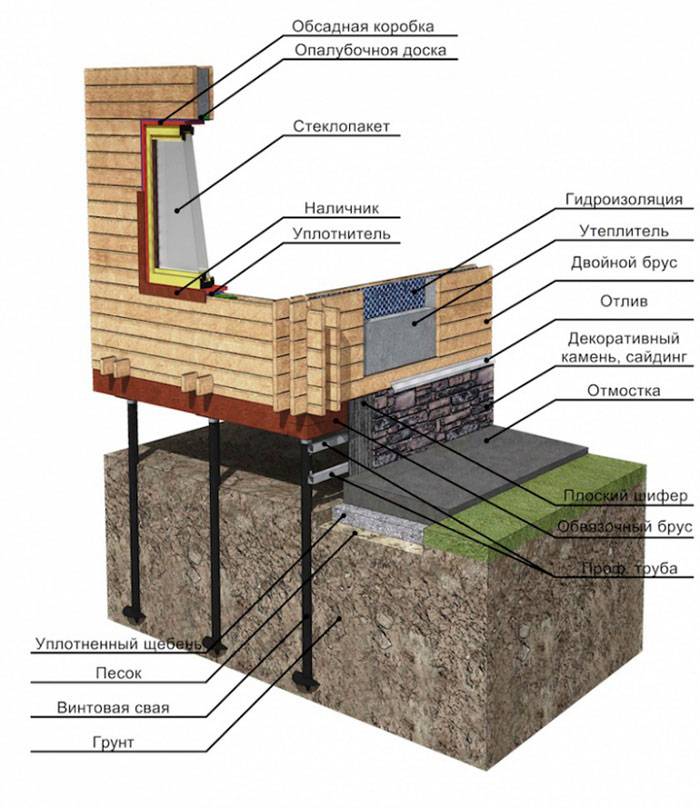

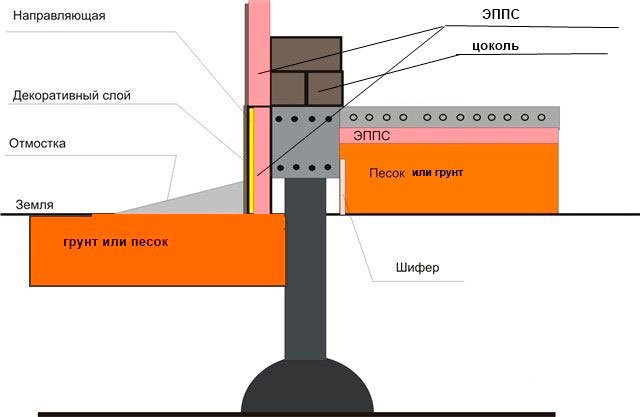

Do-it-yourself options for warming the pile foundation

Correct thermal insulation of the base / plinth cladding can be done in several ways. The final decision may depend on the tastes of homeowners, their material capabilities and the level of qualifications of employees who will carry out all the finishing work.

There are two most popular methods for insulating the basement area:

- Arrangement of a separate belt-type structure.

- Installation of the lathing and fixing the heat-insulating material on it.

Belt design

The first option is structurally more complex and has some limitations. A shallowly recessed belt-type structure can be brick-built or concrete. It will rely either on a layer of soil or on its own monolithic foundation

It is important to take into account that if the construction is carried out on a site with a heaving type of soil from the bottom of the foundation, this option for arranging insulation is not recommended. Especially if the basement is planned to be built of bricks

In this case, in winter, the soil will swell or rise, and this process will be uneven. Over time, if you remove the snow from the basement, you will see sloping cracks. Their appearance will indicate damage to the basement by frost heaving processes.

To prevent phenomena of this kind, it will be necessary to exclude one of the reasons provoking heaving:

- low temperature;

- high level of humidity.

The use of a tape type of cladding can be effective and reasonable only on soils that do not have a tendency to heave. Grounds of this kind include:

- coarse;

- sandy types of soil (medium or coarse fraction).

Warming in this way is also suitable for warm climatic regions where winters are mild and frosts are rare.

Insulation of the basement on the frame

This type of building insulation is simpler and cheaper. In this case, it will be possible to insulate the pile foundation with various materials. These include the following options:

- plinth siding;

- clinker-type panels;

- profiled metal sheet.

It is recommended to select options based on the material capabilities and personal tastes of the owners of the residential building. The fastening methods for each of the options are almost the same. In order to provide the plinth cladding with a reliable base, it is recommended to assemble a special frame.

The crate can be made from wooden beams or rolled metal. If the cladding will be made using metal, it would be reasonable to create a lathing from a similar material. Usually, the frame includes two longitudinal straps, but if necessary, the number of longitudinal elements can be increased, depending on the height of the base. It is possible to envisage the presence of vertical elements of the crate. Their need may be due to the type of material chosen for finishing the basement space of the building.

Before starting work on the insulation of the screw pile foundation, it is necessary to provide for how the frame will be attached. The technique will depend on the material chosen for insulation:

- If the cladding will be fixed to a base assembled from wooden bars and slats, it will be necessary to provide for the presence of metal embedded parts located in the upper part of the piles. They can be made from a corner or similar rolling elements. It is necessary to fasten such connections to the piles by welding.

- If you will be using metal steel elements to assemble the frame, no preliminary preparation is required. The metal profile will simply need to be welded to the very structural elements of the base of the house.

In order for the moisture penetrating from the ground and the processes of frost heaving not to destroy the finishing materials and insulation, the base should be slightly raised above the ground surface. The gap width can vary from 5 to 15 centimeters. At the final stage of work, this gap can be closed with a decorative strip.

The heat insulator for the basement area of the building is fixed to the same frame as the finishing elements. Additional activities may be required depending on the type of materials selected.

What is a blind area

Foundations operated underground or in direct contact with the ground are exposed to aggressive environments. Even with high-quality waterproofing, moisture is harmful to concrete, therefore storm, flood and waste water should be diverted from the supporting structures.

The classic blind area has a design:

- compacted soil or an underlying layer of non-metallic material adjacent to the base;

- concrete screed, a strip of waterproof material (asphalt) or paving slabs / paving stones with a transverse slope of 3 degrees outward, a little wider than the overhang of the roofing material above the facades.

In addition to the main purpose, the blind area can solve several more problems:

- increasing the perimeter of non-freezing soils adjacent to the foundation;

- use as a garden path to save the area of the site;

- collection of storm water and their transportation to an underground reservoir.

Scheme of the insulated blind area.

To make the blind area correctly, you need to have at least a general idea of the structure and technology for manufacturing the foundation and take into account the recommendations below.