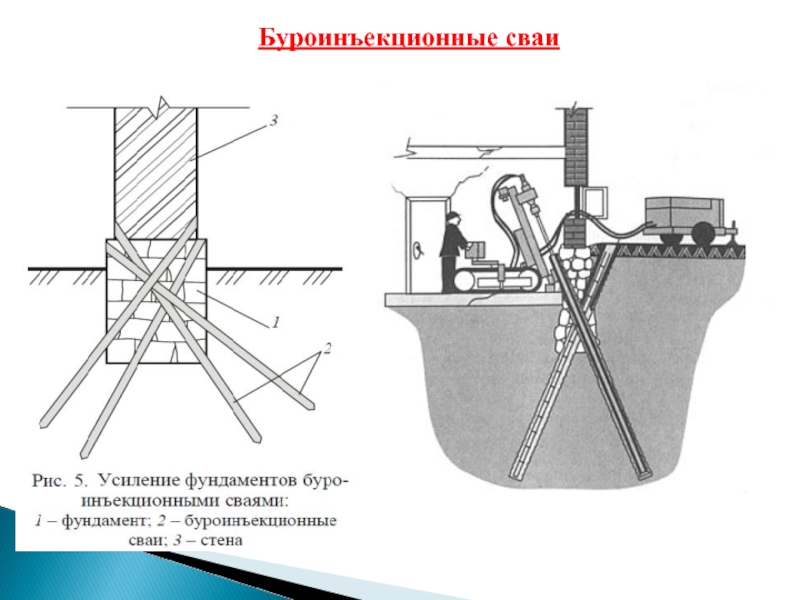

Reinforcement of foundations with bored piles

This method has found wide application in Russia and foreign countries in the restoration of historical monuments and residential buildings.

Main advantages:

- can be used on any soils without harming neighboring buildings, which allows application even with dense buildings;

- successfully strengthens not only foundation, but also other load-bearing structures (walls, ceilings, vaults);

- even distribution of loads on soil foundations;

- high-quality additional waterproofing;

- the possibility of strengthening the foundations with vertical bore-injection piles and inclined in cramped conditions of work.

Bored piles are a type of bored piles. Their diameter is 50 ... 300 mm, with a length of ≤ 40 m (for residential buildings, a large length is not required, deepening below the sole by 0.5 m is sufficient). Drilling is performed with mobile core drilling rigs through any constructs, further drilling of wells is performed by rotary drilling rigs. The use of diamond bits significantly increases the drilling speed.

Work order:

- site preparation with marking of pile locations;

- drilling a well to the depth of the structure;

- plugging with cement mortar under pressure;

- technological break for three days;

- re-drilling below the foundation base;

- reinforcement with single rods, welded reinforcement cages, steel profiles or metal pipes with fixation in the center of the well;

- injection under pressure of plastic fine-grained concrete mixture with the provision of a protective concrete layer around the reinforcement of at least 2.5 cm;

- pressurization by creating overpressure with a mortar pump.

In soft soils, casing pipes are used.

Vertical piles are mainly located next to the foundation. Then both constructs are combined into a rigid one-piece structure.

More reliable through reinforcement passing through the foundation and the ground at an angle. Such wells are located with alternating directions - one with an inclination towards the house, next from it. After complete hardening of the mixture, reliable reinforcement is provided on any soil base. The method is costly but extremely effective.

Carrying out work to strengthen the foundations is unacceptable without the involvement of specialists. The greater the risk of getting the opposite result, causing even more damage to the structure.

Strengthening the foundation with screw piles

With the development of new technologies in construction, more technologically advanced methods of strengthening emergency foundations have become available. One of them is strengthening the base with piles.

At this point in time, the technology of using screw piles to strengthen the foundation of a building has gained great popularity. They are used in areas with a heterogeneous soil structure. The uniqueness of the technology lies in the construction of the pile itself, namely, the design of the blade, thanks to which it can withstand enormous pressure - up to 25 tons.

It should be noted that this method is quite expensive, as it requires special equipment. That is why it is performed, as a rule, by professional builders.

Work order:

- The first stage in the production of work is research and calculations. It is necessary to determine the density of the soil along the entire length of the foundation, for which point samples of the soil are taken, in which its moisture and density are determined. If conflicting results are obtained, additional samples are analyzed.

- Based on the survey of the soil and the condition of the foundation, the number of required piles is calculated, as well as their location.

- The question of taking additional measures to strengthen the foundation is being resolved, depending on the degree of its destruction.

- The additional volume of concrete is calculated in the case of pile concreting and the need for additional stops.

- The second step in strengthening the foundation with piles is to reinforce the corners of the building with bulls. Trenches are being dug in the corners of the building to completely expose the foundation. Then it is washed from dirt and allowed to dry for a day.

- After that, a reinforcing belt is erected at an angle of the building so that the reinforcement rods come out from under the foundation into the trench. On their basis, a reinforcing belt is built in the trench itself.

- Then, on two sides of the corner of the building, two or more piles are screwed into the ground to a certain depth, to which the reinforcement rods are welded. The result is a monolithic metal structure made of piles and a reinforcing belt.

- Concrete is poured into the pit. The filling is done in two stages. In the first stage, concrete is poured half the height of the original foundation and compacted with a vibrator. After the first layer has dried, you can install the formwork smaller than the size of the pit and fill in the rest. Thus, the consumption of concrete mix can be reduced.

- The next step is to strengthen individual sections of the strip foundation. A trench with a width of at least 0.5 m is dug around the entire perimeter of the base.

- A complete opening of the foundation and its strengthening is carried out gradually; it is not allowed to open the entire wall at the same time. To speed up the repair process, work can be carried out simultaneously from different sides of the building.

- The depth of the trench should be equal to the bottom level of the foundation. If the project for carrying out the work provides for an additional gravy of the base, then the trench is deepened, however, the soil under the foundation itself is left untouched.

- If, after opening the foundation, defective areas with chipped concrete are found, they must be removed. Depending on the location of the collapsed areas, the pile installation locations are changed.

- The next step is to screw steel piles into the ground at an angle to the foundation. This is done using special equipment, namely a drilling and crane mechanism, which is installed on a self-propelled unit.

- After the completion of work on the installation of piles, a reinforcing structure is installed in the pit and poured with concrete. When the concrete in one area hardens, you can start working on the next.

Thanks to this complex of measures, the strength of the foundation increases by one and a half times, which allows the completion of the house.

Benefits of using bored piles to strengthen foundations

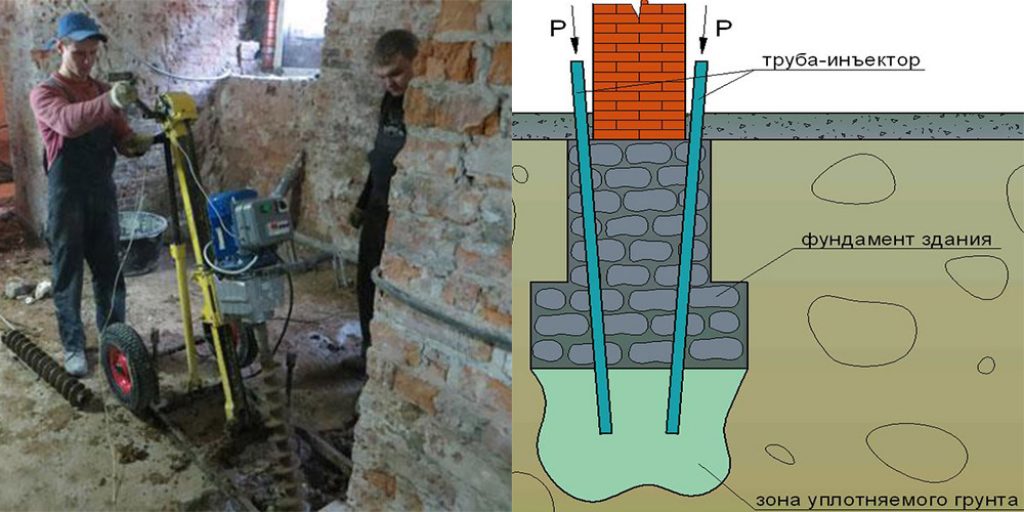

Compact drilling equipment allows you to work in cramped basement conditions

Compact drilling equipment allows you to work in cramped basement conditions

- Possibility of assembling structures in areas that are difficult to access for equipment;

- Reinforcement of foundations in areas subject to strong vibrations is being carried out;

- It is possible to carry out restoration of old bases made of natural stone;

- When designing piles, classical methods of calculating the number and type of structures are used;

- They perfectly withstand the load from a building built on loose soils, because the sole rests on solid layers of soil.

Strengthening the foundation by this method is carried out when:

An example of cracks in the foundation

An example of cracks in the foundation

- Cracks found in the base of the building;

- There is a local drawdown in the corner of a house or a whole section;

- If the house is in disrepair, but it needs to be saved before the start of restoration work;

- When you need to protect a damaged base or reinforce a foundation from powerful vibrations from railway tracks or highways;

- When it becomes necessary to replace a damaged or destroyed screw or base pillar with piles;

- When piles are used to reinforce buildings in dense urban areas.

Repair conditions

Installing a screw foundation as an alternative to the existing foundation of an operated house is possible only for frame houses or log cabins.

Brickwork does not maintain its integrity under bending variable loads arising during the production of work. In this situation, you can repair the problem area by strengthening the reinforced concrete foundations by installing steel screw elements under them, as shown in this photo:

Strengthening from subsidence MZLF

Strengthening from subsidence MZLF

The versatility of this method is also explained by the fact that SP 24.13330 - 2011 allows not to take into account the effect of the heaving forces of the surrounding soil due to the small area of the contact surface of the rack.

Common reasons for the partial destruction of the support of buildings are the following positions:

- Geological. Buildings on soils with high mobility (swampy, wet soils, peat bogs, strongly swollen, freezing) contributes to the rapid destruction of monolithic, brick / block strip or post foundations.

- Climatic. Large fluctuations in seasonal temperatures, weathering, wetting have a negative impact on unprotected materials at the surface of the earth.

- Temporary. The deterioration of the characteristics of building materials as a result of aging, wear and tear occurred earlier than the walls and roofs came to the same state.

- Estimated. A significant change in the parameters that were used in calculating the loads on the base during the initial construction: weighting reconstruction, an additional extension on a common foundation (without sharing the influence).

- Human factor. Violations and mistakes made in the design, counterfeit and low quality of materials used in construction, deviations from the established production technology.

Why screw

The main parameters of such a pile

The main parameters of such a pile

Unlike bored, reinforced concrete or wooden piles, finished screw products increase the bearing capacity without time delay for shrinkage, significant radial soil compaction, soil vibrations during installation

This is important when carrying out work close to emergency structures, in densely built-up areas

Comparing the results of calculations of various types of piles for the same section according to SNiPu 2.02.03-85, they come to the conclusion that the use of screw structures turns out to be much easier than other options in terms of defining conditions.

A tangible gain will be obtained in the estimated cost and man-hours for carrying out the transfer of the house to new supports.

To make a pile foundation with your own hands, you will need the following tools and materials:

- jacks, a set of dies;

- crowbar, shovel, hammer, trowel;

- welding machine;

- tape measure / ruler, building level, chalk;

- screw piles, I-beam, channel.

If the financial side is not decisive, then a special installation for screwing in products, shown in the photo, will help speed up the process:

Effective approach

Effective approach

It is possible to strengthen the foundation with piles for such types of foundations of buildings and structures:

- tape;

- pile;

- columnar;

- slab.

What should be considered when using bored piles?

The method has gone through numerous studies. The experience of reconstruction of foundations using bore-injection piles is substantial. Proceeding from it, experts recommend to pay attention to some features before and during work. This information will simplify your work and avoid serious mistakes.

The angle of inclination of the piles does not greatly affect the amount of settlement and reliability of the structure.

There is no particular need to increase the angle.

It is very important to securely anchor the piles in the foundation.An old foundation, consisting of rubble or individual stones, is extremely important to strengthen with cement injection

If the strength of the foundation is too low or the pile is embedded in the foundation by less than 5 diameters, additional reinforcement will have to be done.

Preliminary calculations have shown that an increase in the slope significantly increases the internal forces in the piles. Much depends on the properties of the soil on which the building is built. If the initial conditions are difficult, it is recommended to use inert materials together with the cementitious mortar. Sand showed itself excellently in this role.

Together with the use of reinforcing cages, experts recommend that equal-strength joints be included in the project and performed. The design can include metal profiles, durable pipes or special glass. The use of reinforcement in various sections and the use of special glass on very weak soils works especially well.

The length of the piles depends on the distance to the dense soil layer. The diameter is calculated depending on the conditions, the state of the foundation and the materials from which it is made.

A special moment appears in the case of the passage of the reinforcing structure through the groundwater. Passing through a layer of water, concrete cannot set normally and retain its functional characteristics. In this case, the problem can be eliminated by using bored piles. Having drilled holes in the foundation, install pipes in them, which will become a kind of formwork.

For the injection method, grout can be ordered. Although experienced craftsmen recommend stirring the solution yourself. This will help reduce labor costs. But this is not the main thing. By stirring the solution, you can make sure that the crushed stone is in it of a fine fraction and control the required density. This will help to avoid the formation of voids, which greatly reduce the reliability of the structure.

Technology principle

For drilling-injection supports, wells with a diameter of up to 40 cm are made in the ground. When the required depth is reached, they are filled with a water-cement or cement-sand composition, fed inside under high pressure using a hollow screw. By supplying the solution under pressure, it can be poured into both horizontally and vertically made wells. Then a reinforced frame base is installed in the concrete that has not yet hardened.

Reinforcement and concreting requirements

Taking into account the current SNiP, there are certain requirements for concreting and the use of reinforcement in bored injection piles. Installation technology:

- The section of the frame to be installed must always be 14 cm less than the diameter of the drilled cavity. This avoids jamming of the casing in the well.

- For reinforcement, spatial frames are used, in which the longitudinal chords are at the same distance in relation to each other. The minimum number of longitudinal rods is 6 pieces, the class of reinforcement is A3 (section is at least 18 mm).

- Reinforcing frames are subject to high rigidity requirements. The elements are fastened by welding, the reinforcement must be additionally reinforced with steel rings located from the outer part of the frame with a distance of 2 m. Rings with a width of 5-10 cm and a thickness of 8-10 mm are installed.

- The greatest length of the reinforcement is 11.7 m. If it is required to install the frame in a larger well, then the individual parts are welded to each other at the construction site.

- For the installation of bored piles, M300 concrete with a compression class of at least B22.5 is used.

It is also required to pour a protective concrete layer around the frame with a layer of at least 7 cm. The uniform arrangement of the reinforcement in the well is achieved by fixing the clamps on the metal stiffening rings.

Installation conditions

There are also requirements for the direct installation process of the LSI.Taking into account SNiP, the following conditions must be met:

- During continuous work, you can drill nearby wells with a step that does not exceed 3 diameters of an existing pile. If the distance is less than the allowable one, it is possible to develop a new support only after a day after the previous support has been poured with concrete.

- The process of pouring concrete is carried out with constant reciprocating movements of the screw.

- Mandatory preservation of a constant supply pressure of the concrete solution when filling the cavity; when it decreases, it is required to reduce the extraction time of the screw column.

- After the end of the process of pouring concrete, the MBU must drive away from the well. The soil that was worked out during the installation of the support is removed using an excavator.

- After cleaning the territory, a conductor is installed at the wellhead and the aboveground part of the support pillar is poured with concrete.

- The pile is reinforced immediately after filling the cavity with concrete and cleaning the wellhead.

Reinforcement of the foundation with bored piles

Bored piles consist of drilled wells, into which reinforcing cages are placed and concreting is performed with careful compaction with deep vibrators. Drilling is carried out with special equipment or manually, using hand-held or motor-drills. The piles work as pile-piles, resting on a solid solid rock, or as hanging piles, working due to the frictional forces of the side surfaces with the contacting soils. Depth of immersion in all cases ≥ mark of seasonal frost penetration.

The scope of work to strengthen the columnar foundations:

- development of a trench along the perimeter of the foundation structure to a depth of ≥ 0.5 m;

- drilling in unstable soil or to great depths is carried out in casing pipes;

- production of reinforcing cages. Longitudinal bars made of periodic reinforcement А-II or А-III with diameters from 12 to 22 mm. Transverse reinforcement is performed with a smooth wire rod with a cross section of 6 ... 10 mm. The step of placement is 20 ... 30 cm. Joining of elements of thin knitting wire softened by firing using reinforcing hooks or nippers;

- installation of the frame. To provide a protective layer of ≥ 2.5 cm, plastic clamps or rectangular cement “croutons” are attached to the frame, and a 10 cm layer of lean concrete is preliminarily placed in the well. If the well is without casing, for additional insulation it is recommended to protect with 2 layers of roofing material twisted into a cylinder. Longitudinal rods should be released from the well to enter the grillage by 2/3 of its thickness;

- laying the concrete mixture, if water is present, it must be pumped out. Concrete consolidation;

- drilling holes in the existing structure, laying reinforcement pieces in them with fixation with cement mortar;

- the device of a compacted sandy 20 cm pillow;

- installation of formwork and reinforcement cage of a monolithic grillage, with joining with reinforcement outlets of piles;

- laying and vibration compaction of concrete.

Strengthening the strip foundation with piles is performed in a similar way. A trench along the perimeter of the tape is developed at the level of its sole from the outside, and, if possible, from the inside, which will significantly increase the bearing area. To prevent displacement of the tape structure, it is fixed with side stops made of wooden logs, abutting against the walls of the trench.

Beforehand, visible defects of the existing foundation must be eliminated: jointing and sealing cracks, repairing damaged areas.

In case of difficulties with pumping water, laying of plastic concrete mixture using the method of vertical lifting pipe (VLT) is used. The structure of the VHT includes concrete-cast pipe links and a receiving hopper. Mixture from the bunker comes from the bunker through the lower cavity of the pipe and displaces water. After the end of concreting, it is enough to remove the layer of fragile concrete (sludge) formed at the top.But for lifting the HVAC, crane equipment is required.

Instead of bored piles, it is possible to reinforce the foundation with screw piles, consisting of a hollow steel pipe, equipped at the end with blades for the possibility of screwing into the ground. Such products have reliable anti-corrosion protection applied in the factory.

The pitch of the pillars, their required diameter and the order of reinforcement and concreting are indicated in the project.

These progressive methods allow you to increase the bearing capacity of the foundation with a minimum amount of excavation and low labor costs.

In some cases, drilling near the existing structure is impossible due to its strong destruction or extreme dilapidation of the house. The way out is the pressed piles. When installing special technical equipment, they are pressed into the ground with powerful jacks. This is a complex and expensive method, therefore it is used when it is impossible to perform other amplification options.

Features of bored piles

Bored piles are prefabricated boreholes filled with reinforced concrete. As the concrete hardens in the soil, a reinforced concrete rod with a high bearing capacity is formed, submerged without piling rigs and other piling equipment. The main advantage of this method is the absence of vibration during immersion. No vibration loads on the ground - no risk to nearby structures and the landscape in general. This is the fundamental difference between bored piles and all others (with the exception of screw).

Screw metal piles are driven by screwing, which is also a safe method for the landscape. But their dimensions are limited, which means that the bearing capacity is also limited (most often screw piles are used for the construction of private country houses).

It is important!

Bored piles have no load restrictions. The values of the bearing capacity depend on the dimensions of the pile and the design resistance of the soil (i.e., on its composition).

Examples (well section - from 10 to 50 cm):

- gravelly and coarse sand - permissible load on piles from 275 to 8831 kg;

- medium-sized sand - from 196 to 6869;

- small, low-moisture - from 157 to 5888;

- shallow water-saturated - from 196 to 6869;

- hard clay - 236-11775;

- plastic clay - 79-5888;

- coarse soil, gravel, etc. - 393-11775.

These two features explain the main purpose of bored piles: foundations for residential high-rise buildings, heavy industrial buildings within the city and in areas of dense industrial development.

If you contact us, we will calculate for you the expected loads at your facility and help you choose the type of foundation that is suitable in terms of characteristics and cost.

First, about the causes of trouble

It's time to do something

Strengthening the foundation of a private house with your own hands may be required if the following facts took place:

- Calculation errors. The base of the building is not the part of the building that can be saved on. It happens that inaccuracies in determining the optimal strength characteristics are allowed simply due to incompetence. And in other situations, they are the result of attempts to minimize the cost of building a foundation. In any case, after a relatively short period of time, the homeowner will have to face an unpleasant surprise.

- Failure to comply with the construction technology. Here the information presented in the spinning paragraph will be relevant. Although it should be added that a deviation from the rules can be provoked not only by the desire to reduce financial costs, but also by an attempt to save time. Neither one nor the other can serve as an excuse.

- Changes in the landscape that occurred after the construction of the building - heaving, rise in the level of groundwater, excessive saturation of the soil with moisture, etc.

- Large-scale excavation work carried out in the immediate vicinity of the building. This can be, for example, high-rise construction, laying of trunk communications, etc.

- Redevelopment of the building with an increase in the load on the supporting structures.

- Vibration loads - internal and external.

How can piles help?

If you find the above problem, then tackle it immediately. And your best assistant in this matter will be bored, screw, rammed or bored piles to strengthen the foundations.

After all, any pile is primarily a rod that dampens unnecessary deformation of the foundation structure.

Therefore, with the help of any pile, the following foundation problems can be eliminated:

- Sagging or bulging of the foundation body - simply add piles in the center or at the edges and the destructive moment of forces will be balanced by the forces in the new supports.

- Base Roll - Reinforce one corner or one side with new supports and deformation is compensated by the counter force.

- Skewed building - reinforce the sliding part of the foundation with additional supports and your home will be saved.

In addition, with the help of piles, you can simply increase the bearing capacity of the old foundation. In addition, piles are used in the construction of temporary foundations that hold the structure during the restoration or lifting of the old foundation.

Strengthening old foundations

Strengthening the foundation with bored piles is possible for any of its types:

Strengthening the foundation with bored piles is possible for any of its types:

- holes are drilled in strips (rubble and concrete) at an angle of at least 30 degrees. The drilling depth depends on how deep the hard soils are. At each point of hardening, two wells are made - on the sides opposite from the tape. Prepared cavities are filled with mortar and fittings;

- in pile-grillage foundations, reinforcement with injection piles can be done in two ways: by completely replacing damaged piles or by installing additional supports by injection.

Strengthening the foundation of a private house with drill injection piles is fraught with certain difficulties.

Firstly, it is impossible to do without professional heavy equipment when performing this work. And secondly, it is difficult to select pile parameters without engineering calculations.

It is these conditions that are the reason for the high cost of this method of strengthening the foundation. But if you do decide to do this, it is unwise to save on the help of professionals.

Read about other methods of repairing the foundation in the following articles:

- foundation repair with screw piles;

- about repairing the foundation of a brick private house with your own hands;

-

repairing the foundation of an old wooden house

with your own hands; - about repairing the foundation of a country house with your own hands;

- how to reinforce the foundation with a reinforced concrete jacket;

- technology of replacing the foundation with screw piles.

Video about the technology of drilling injection piles.

Protection of the foundation from weathering

If the base is made of brickwork, which does not have high moisture resistance and strength, chemical or physical weathering of the materials may occur. A plaster metal mesh is used to restore the damaged surface. For it, a cement mortar is used, with which the surface is plastered.

As you can see, there are many ways to restore the bearing capacity of a structure, to protect it from destruction, as well as to strengthen it in the event of an expected additional load, for example, the construction of a second floor.

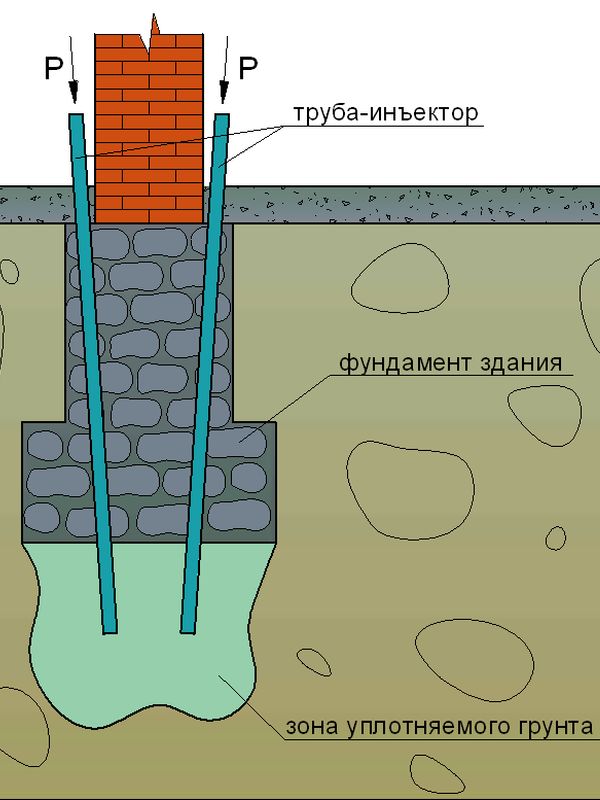

Cementation

Cementation

Reinforcement of foundations by cementation involves the introduction of special cement mortars into the base body. What exactly this composition should be depends on the materials used in the construction of the existing foundation. Most often we are talking about a classic cement mortar, sand-cement mixture or bentonite.Previously, holes are made in the base with a drill, into which the solution is fed under pressure. Using special formulas and data, the optimal number of injections for the damaged area of the foundation is calculated. Upon completion of all manipulations, the concrete base is hardened and becomes monolithic. This technology is also known as reinforcement of foundations by injection.

Preparation for strengthening the foundation

Before strengthening the foundation, carry out its external and internal inspection. During an external examination, the following parameters are determined:

- dimensions of the building;

- condition of supporting structures;

- load on the platform;

- the presence of cracks and bevels.

During underground research, indicators are determined:

- device and dimensions of the platform;

- strength properties of the material used;

- the depth of its bookmark.

Before starting work on strengthening the foundation, you need to make sure that it has finished shrinking. It usually lasts at least a month. To understand that the shrinkage is over, gypsum beacons are installed across the revealed cracks. Their condition will allow you to determine when to start strengthening the base.

At the final stage of preparation for strengthening, the platform is unloaded. It can be complete or partial. An important factor is to avoid distortions that will negatively affect during the restoration of the foundation.

For the subsequent strengthening of the foundation, the building is lifted with jacks

Partial unloading of the house platform is carried out using wooden or metal supports and struts.

- Install support cushions in the basement, 2 m away from the wall.

- Place a support bar on top.

- Secure the racks.

- Then connect them with a beam to the floor, and then to the support beam using wedges.

For capital unloading of the platform, steel beams are mounted.

- Under the row of masonry, in which the bricks are laid with short edges to the wall, punch the grooves on both sides, observing a distance of 2 m between them.

- Place the tie beams in them and secure with 25mm bolts.

- Using the overlays, weld the joints of the beams, and fill in the sand-cement mortar in the intervals from the wall to the beam.

- Punch holes in the lower part of the walls, keeping the distance between them no more than 3 m, insert the beams into the holes.

- Place the crossbeams on support cushions on both sides of the wall.