On the need for reinforcement

To what extent is it necessary to reinforce the concrete mass with steel wire? After all, concrete has a fairly high strength characteristics. Indeed, concrete has increased resistance to compressive loads, but requires reinforcement from the destructive effects of breaking forces.

The greatest likelihood of stretching is on the surface of the base, this is where the reinforcement should be placed

This feature of concrete can be compensated for by laying steel rods on two levels of the base. This solution increases the strength characteristics of the rock mass, allowing it to maintain integrity under the influence of bending loads, torques and breaking forces.

Calculations

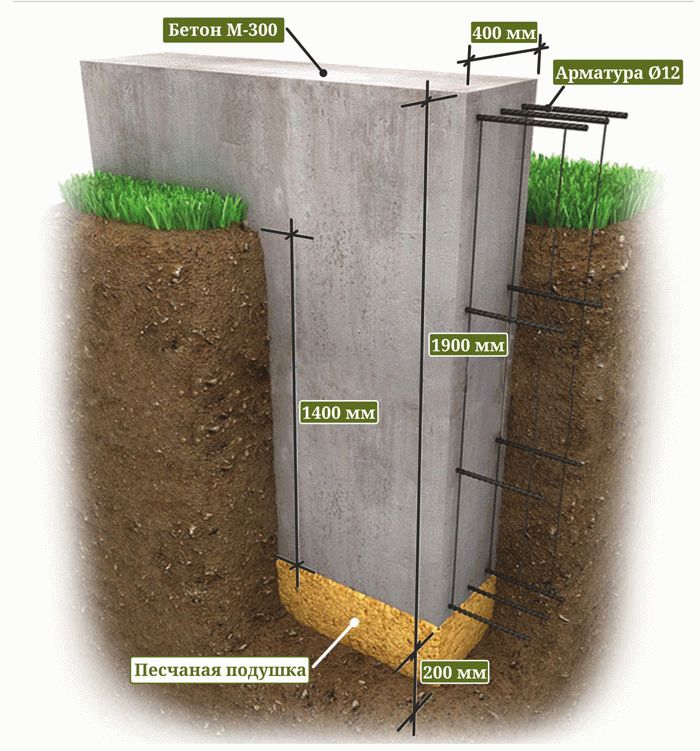

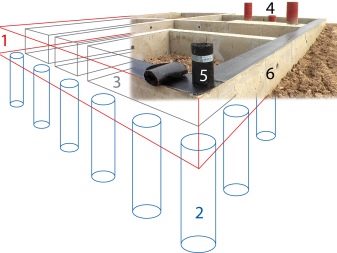

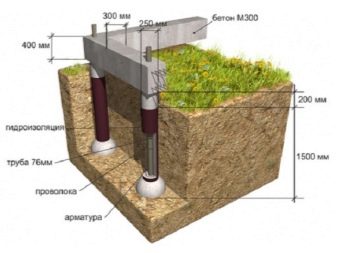

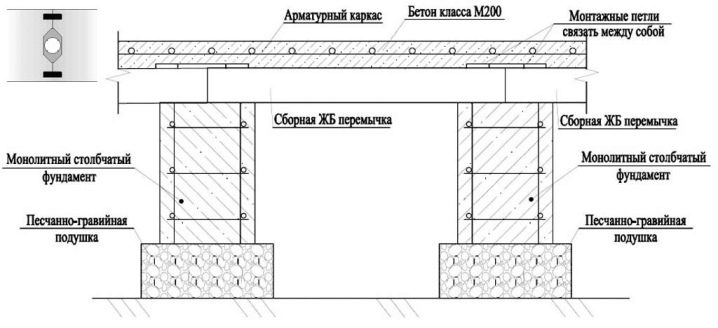

Determination of the number of piles and their length is carried out according to the calculation documentation. For areas with sufficiently stable ground, supports with a length of 2500 mm are sufficient. When erecting an object on uneven terrain, the height of the support takes into account the differences in the height of the soil. When building on highly mobile soils, the height of the support should be such that it reaches solid soil layers plus 15-20 cm.

You can calculate the number of pillars by adding up all the loads on the foundation. To do this, calculate the load (weight) of 1 m3 of wall material and multiply this indicator by the number of cubes of the entire room. This coefficient is summed up with the weight of the floor, floors, windows and doors, roofing, as well as internal equipment (furniture, finishing materials, equipment, communications).

Further, the load factor is multiplied by the safety factor (this is a constant value according to SNiP). The resulting number should be divided by the value of the bearing capacity of one support.

The distance between the posts is maintained within the range of 100-250 cm. The heavier the object is, the less distance is maintained between the supports. It is not recommended to increase the step by more than 250 cm, since in this case the strength of the finished building decreases.

For wooden buildings, it is recommended to put pillars with a step of 3 m, in structures made of foam and aerated concrete - 2 m.For brick houses, this figure is 1.5-1.7 m. In other words, the foundation under foam block house with dimensions of 9x8 m, on average, it requires at least 16 pillars, and a wooden counterpart of the same size requires 12-14 pillars.

Advantages and disadvantages of strip foundation

The strip foundation is ideal for building a bathhouse, garage, summer kitchen and other buildings with your own hands. It is also suitable for building your own country house. Such a base is distinguished by a simple design and an understandable manufacturing technique. Among its other advantages are:

-

Low cost. All materials used in construction are relatively inexpensive. In addition, the involvement of complex special equipment is not required.

-

High construction speed. All work can be done in one day. It will take several more weeks for the structure to dry.

-

The possibility of self-construction. Minimum skills and knowledge of technology are required.

-

Durability. Provided the proper organization of heat and waterproofing, the structure will last for several decades.

-

Versatility. This base is suitable for any type of soil. Even if the soil on the site is heterogeneous in structure, the strip foundation will protect the structure from uneven subsidence and the appearance of cracks.

-

Ability to withstand heavy loads. On the basis of this type, multi-storey buildings can be erected.

-

Possibility of organizing a basement.

The disadvantage of this type of bases is the need for accurate preliminary calculations. Design errors cannot be corrected in the future.

The disadvantages include the need to carry out all the work in one day. A large amount of concrete will be required. Kneading it yourself is difficult. Therefore, when building houses, you will most likely have to buy a ready-made solution. But when building a garage or a bath, it will be possible to get by with a household concrete mixer.

Stages of work on the arrangement of the reinforcing cage

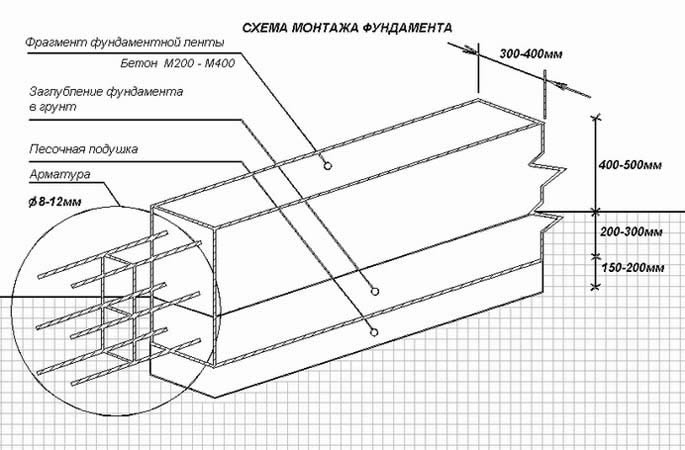

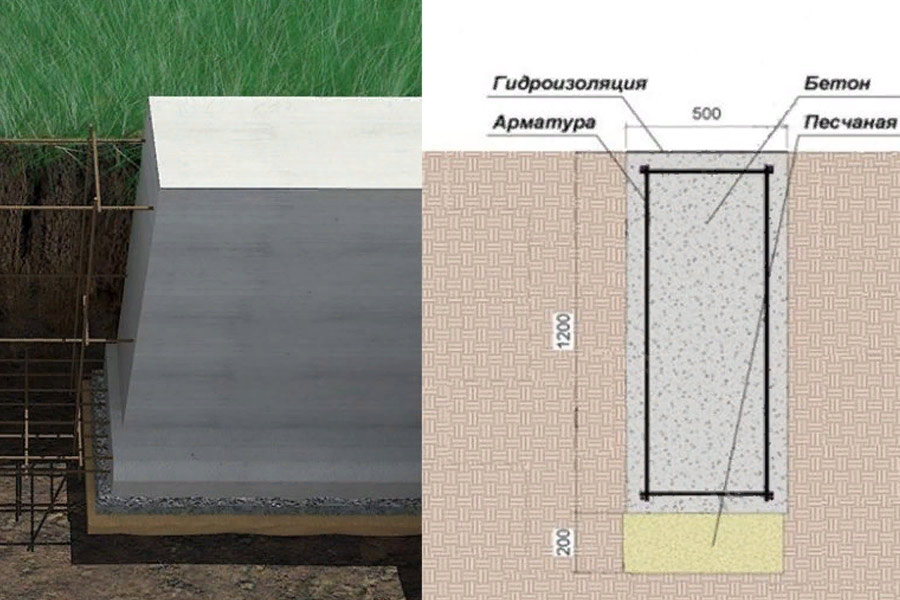

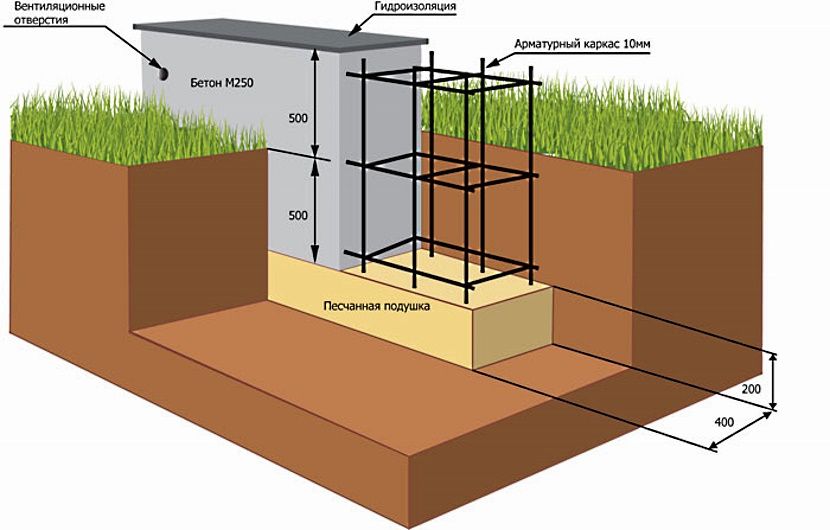

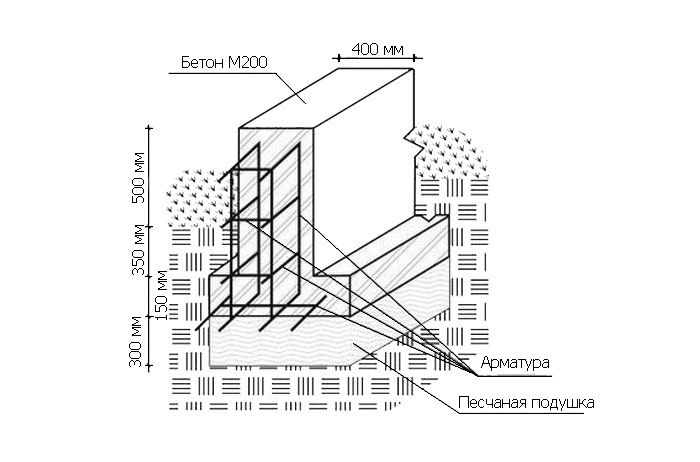

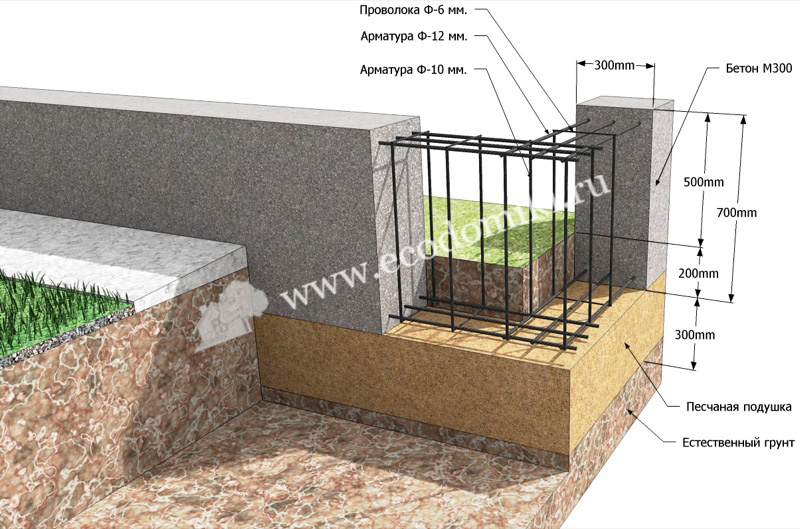

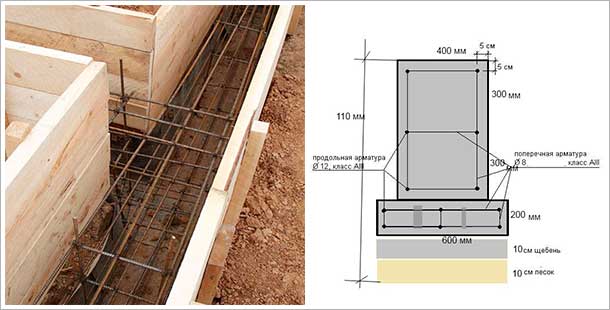

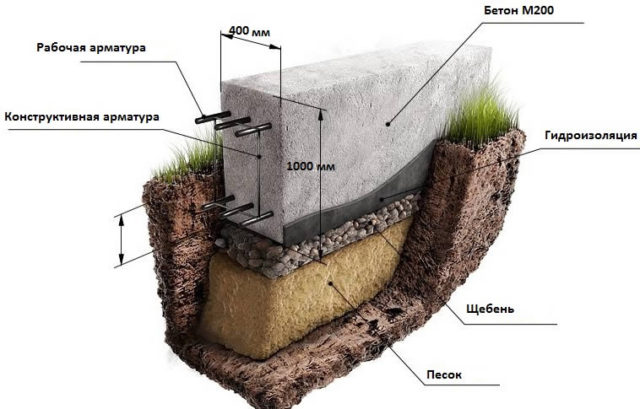

The base for the foundation is made of a layer of sand of at least 10 cm, the sand is covered with a layer of crushed stone of fraction 2-5, then the sand and crushed stone base is rammed, and only then should the reinforcement cage be laid and knitted.

-

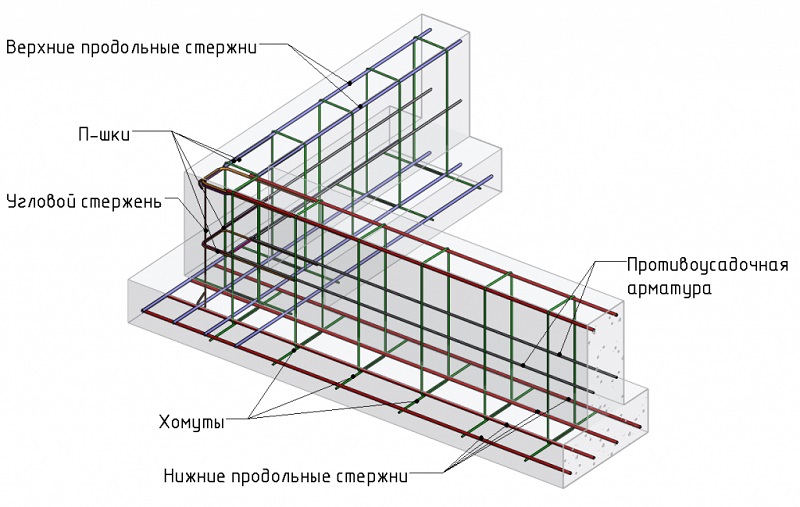

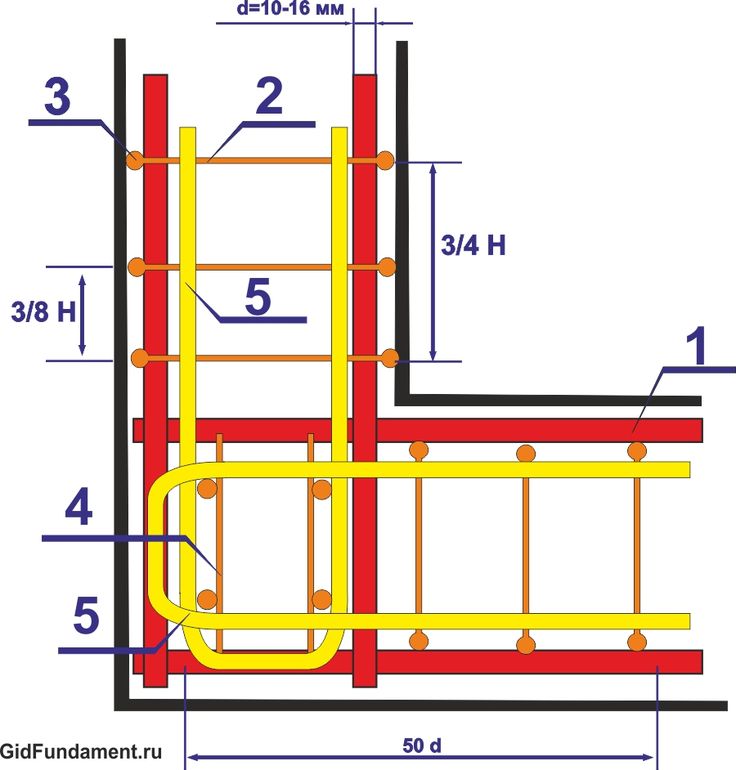

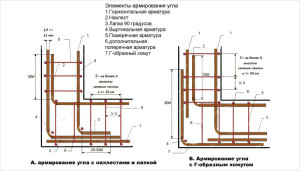

Reinforcement rods, cut along the length of the foundation tape on one side, are laid out at a distance of 20-30 cm between themselves along the bottom of the foundation. In the corners, they are screwed with a soft knitting wire to the vertical rods, as well as to each other when an overlap is formed.

-

To create vertical framing corner supports, the horizontal bottom rods of the framing are bent at 90 degrees. Can be extended by overlapping and wire fastening.

-

To facilitate the production of work on reinforcing the corners of the foundation, it is allowed to install anchors, the work is similar to the device of grillages or armored belts. At all corners of the foundation, 4 metal rods are driven into the ground, covered with bitumen resin from below for waterproofing. They act as anchors for fixing the frame. In cross-section, the driven anchor pins should form a square with sides parallel to the foundation strip.

Anchors driven into the ground, on which the frame is attached

-

Vertical reinforcing bars equal to the height of the foundation are screwed to the anchors or grabbed for fixation. All vertical bars are connected or welded to each other along the perimeter, forming the structure of the post.

-

In order to avoid contact between the metal and the sand and crushed stone base, halves of bricks are placed under it along the entire length of the rod under it with an interval of 1 m.

-

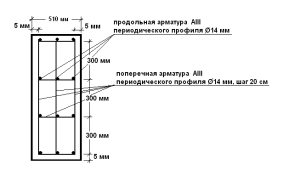

The rods are cut for the transverse laying of the reinforcement. Their length should be 10 cm less than the width of the monolithic tape, that is, the crossbars should be completely covered with poured concrete with a distance of 5 cm from the outer wall of the foundation.

-

The step of reinforcing the foundation with transverse rods is 50 cm along the entire length of the longitudinal reinforcement.

-

All reinforcement connections are twisted with knitting wire.

-

Depending on the length of the foundation side, the distance between the vertical rods ranges from 30 to 80 cm.

-

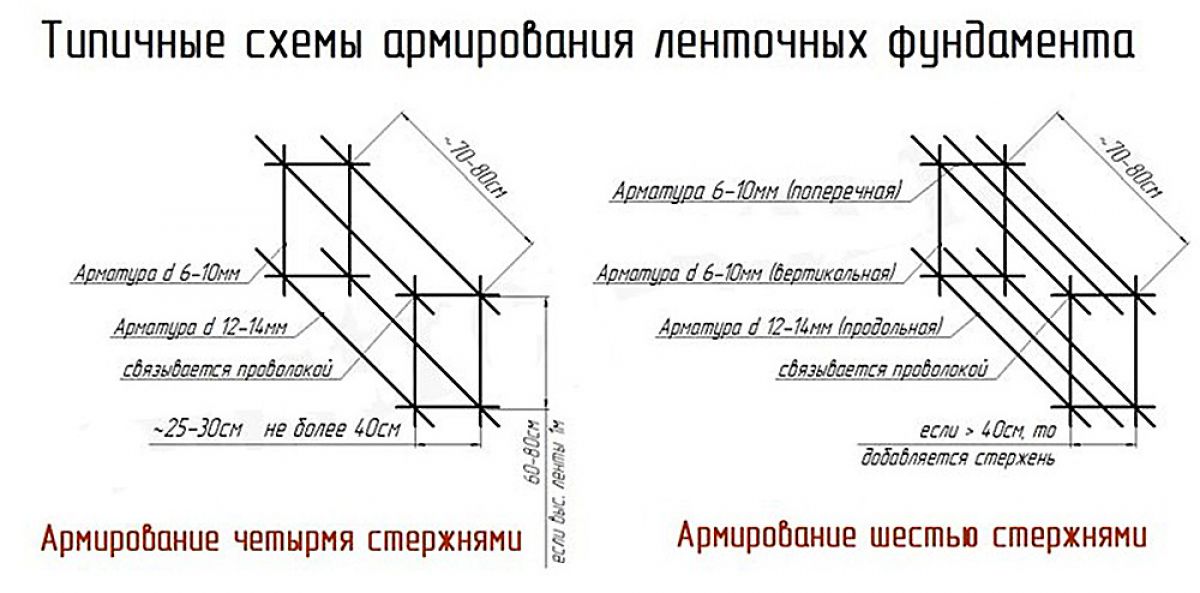

There can be only two longitudinal rows: an upper and a lower one.

-

Each horizontal row is parallel and similar to the bottom row.

It is quite permissible to assemble the frame close to the foundation, and then simply lower it into a trench or formwork.

The frame does not have to be assembled inside a pit prepared for the foundation - installation can be done outside, and then lower the entire structure down

Of course, this method is only possible if there is a flat area for assembly, otherwise it is difficult to achieve accurate work.

What is important to know

The foundation during the operation of any structure is regularly tested for strength with various loads - from the weight of the house to the movement of the soil. Therefore, an incorrect calculation and careless reinforcement of the strip foundation can lead to the destruction of the building.

When purchasing reinforcement for strip foundations, pay attention to the marking:

- index C denotes welded reinforcing bars;

- K index - the material is resistant to corrosion cracks that occur under high pressure.

If there are no indices, the material is not suitable.A pragmatic calculation in order to save on reinforcement entails low quality reinforcement, therefore, the regular occurrence of cracks in the winter. Experienced builders, when working, follow the requirements of SNiP, where the reinforcement scheme for the strip foundation (including the step between the longitudinal bars and the step of the transverse reinforcement) is presented in detail.

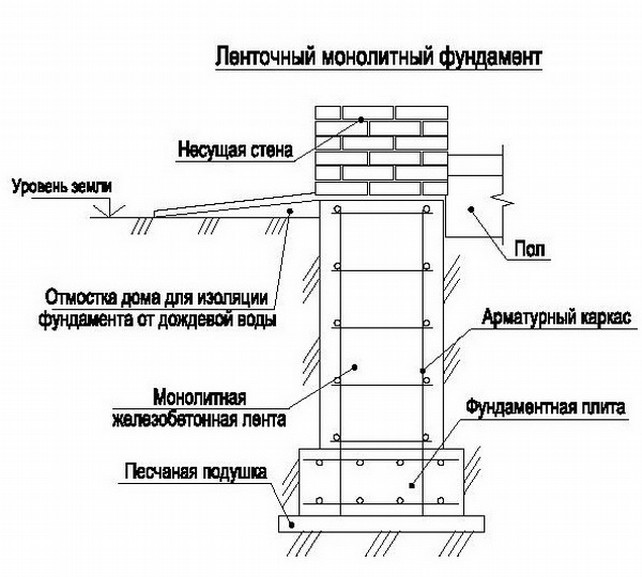

To know how to properly reinforce a strip foundation, you need to arm yourself with some theoretical knowledge. When arranging the frame of the strip foundation, reinforcement is used, which is mounted at the stage of installing the formwork, and then poured with concrete mixture (layers), and at the end waterproofing work is performed using roofing material and mastic.

Before work, the calculation of the reinforcement is performed, where the maximum load on the foundation will be taken into account. The stability of the entire construction object depends on how correctly the calculation is made, therefore it is advisable to entrust the calculation to professionals in this area, which is carried out in accordance with the individual characteristics of each structure.

The calculation includes factors such as:

- configuration of the structure;

- soil type;

- wall construction technology;

- number of floors;

- type of floors, etc.

Some construction companies make the calculation free of charge, subject to the order and subsequent payment for reinforcement work from them.

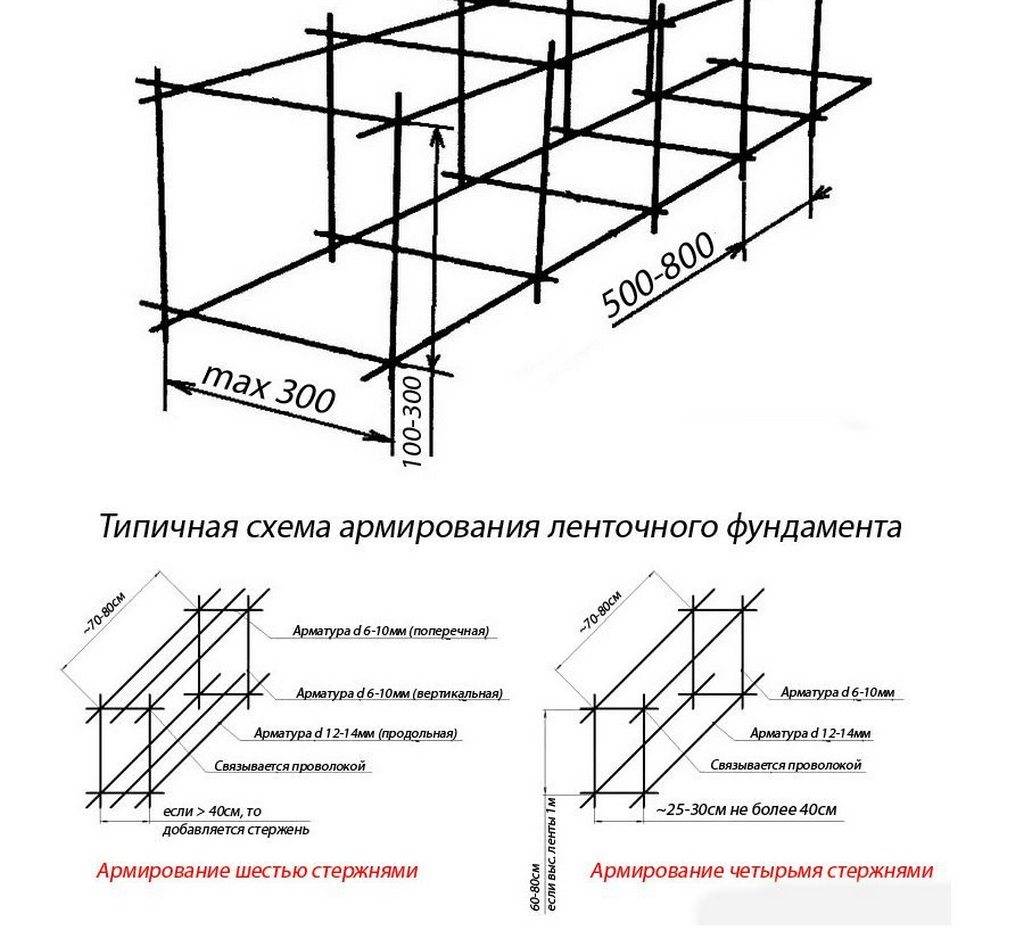

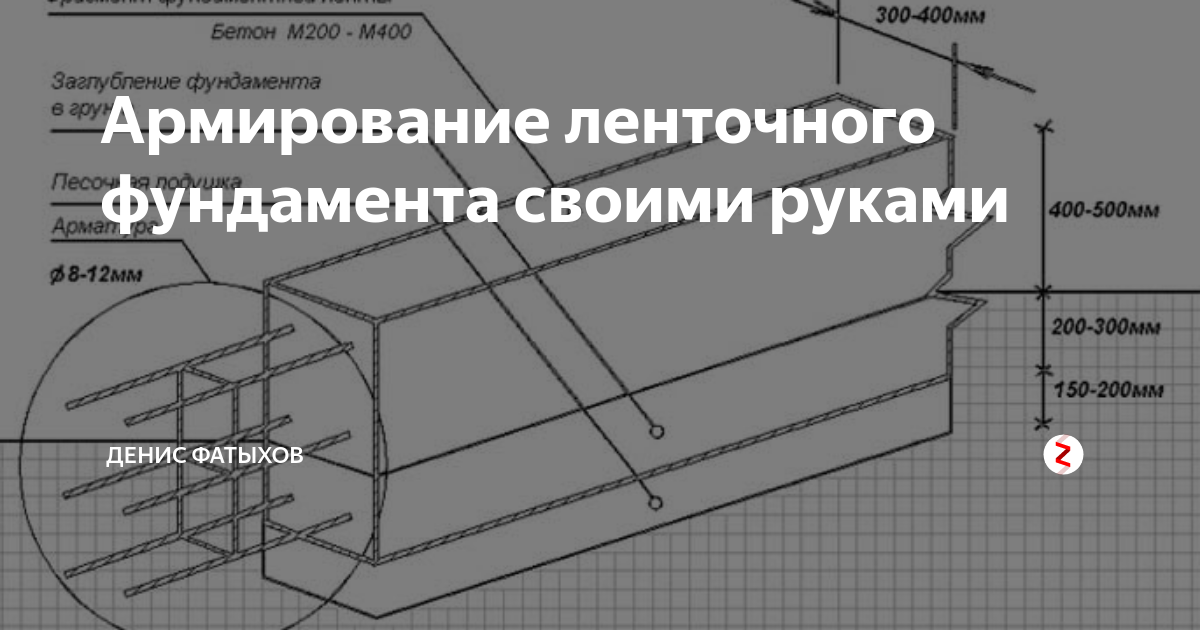

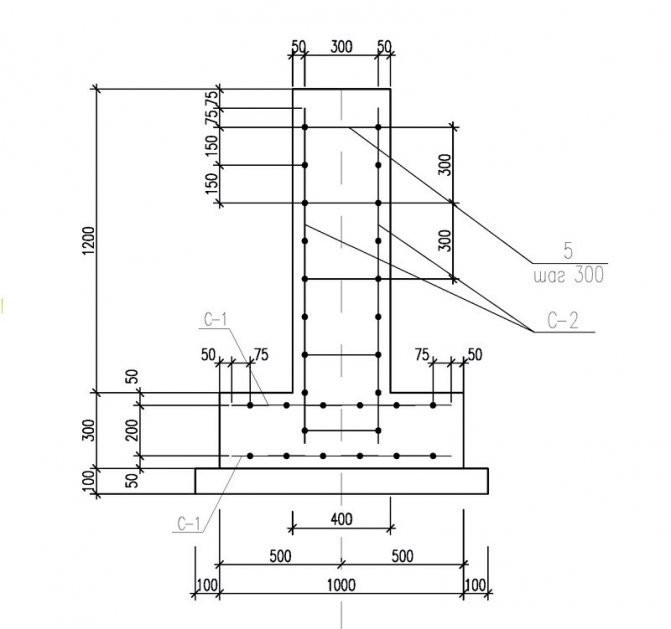

Reinforcement calculation scheme for strip foundations

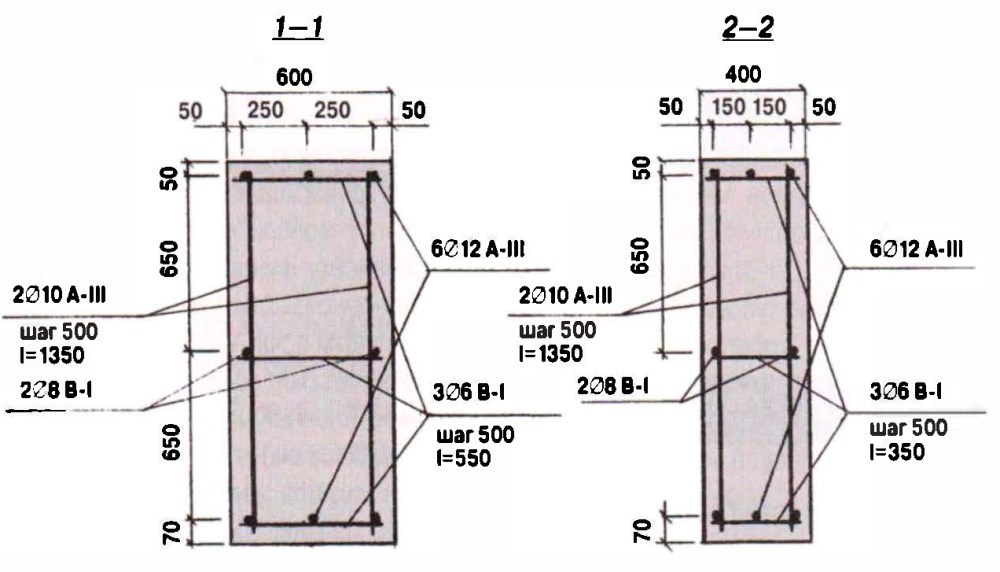

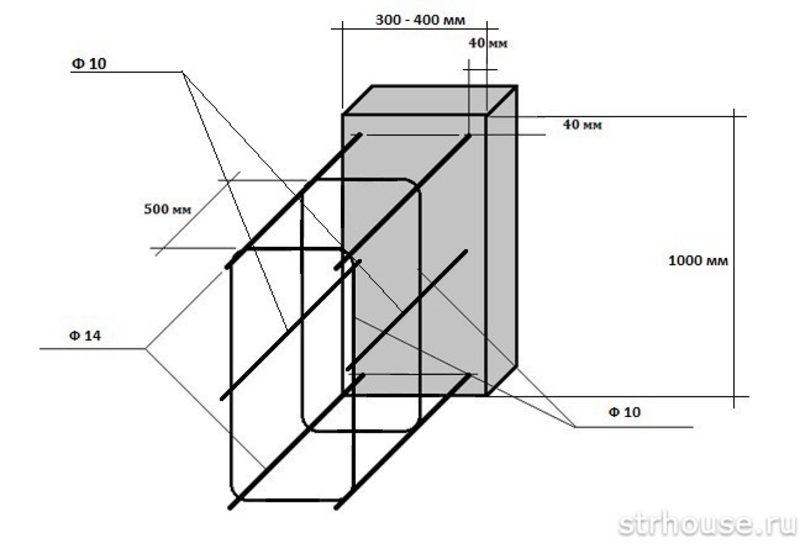

Reinforcing the strip foundation with your own hands requires not only the correct calculation, but also the correct choice of the size of the rods. It is recommended to choose a rod made of A-III steel with a periodic profile and a diameter of 10 to 22 millimeters. The permissible size of additional rods is from 4 to 10 mm. They run vertically to support the bottom and top in the rows of reinforcement and provide strength. The installation pitch of vertical rods should be 0.5 - 0.8 m.

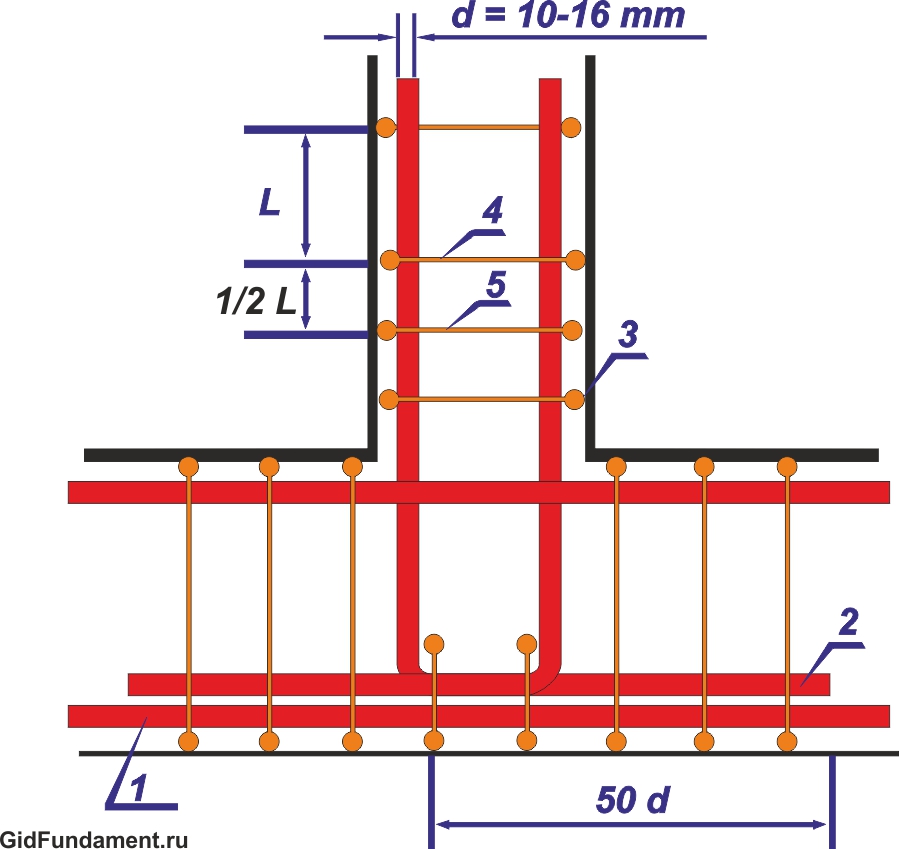

The metal frame is immersed in the concrete mixture for the following distance:

- the upper tier - 50-60 mm;

- lower - 70 mm or more.

The distance between the horizontal rows is at least 30 cm. If the frame is set up in a deepened foundation, you need to use two or four rods in a row.

The minimum spacing between the reinforcing bars in the clear is taken taking into account the diameter of the reinforcing material, the location of the reinforcement, the method of laying and compaction of the concrete composition. Step between the rods should not less than the diameter of the material, but not more than 25 cm. The pitch when arranging the bars of the longitudinal working reinforcement is set taking into account the characteristics of the reinforced concrete element, while the pitch should not exceed 400 mm.

Strip foundation reinforcement technology

Rebar is one of the most common materials. When preparing the site for construction, it is necessary to clear the construction site and dig a ditch along the perimeter of the base. This can be done by hand or with the help of special equipment. For the evenness of the walls, formwork is used. The reinforcement frame is installed at the same time as the formwork. Then concrete layers are poured, and waterproofing is also done using bituminous mastics and roofing material.

Rebar is one of the most common materials. When preparing the site for construction, it is necessary to clear the construction site and dig a ditch along the perimeter of the base. This can be done by hand or with the help of special equipment. For the evenness of the walls, formwork is used. The reinforcement frame is installed at the same time as the formwork. Then concrete layers are poured, and waterproofing is also done using bituminous mastics and roofing material.

Reinforcement of the bases can be done with your own hands. You should be aware that after the completion of the waterproofing of the base, sand is poured into the cavity. For areas with a cold climate, it is preferable to additionally insulate the strip foundation, and for this you can use foam. If reinforced correctly, this foundation will be durable.

It is necessary to highlight several points of reinforcement of the strip foundation:

- There is a situation when there is no construction project. In this case, you can resort to the personal experience of the builders.

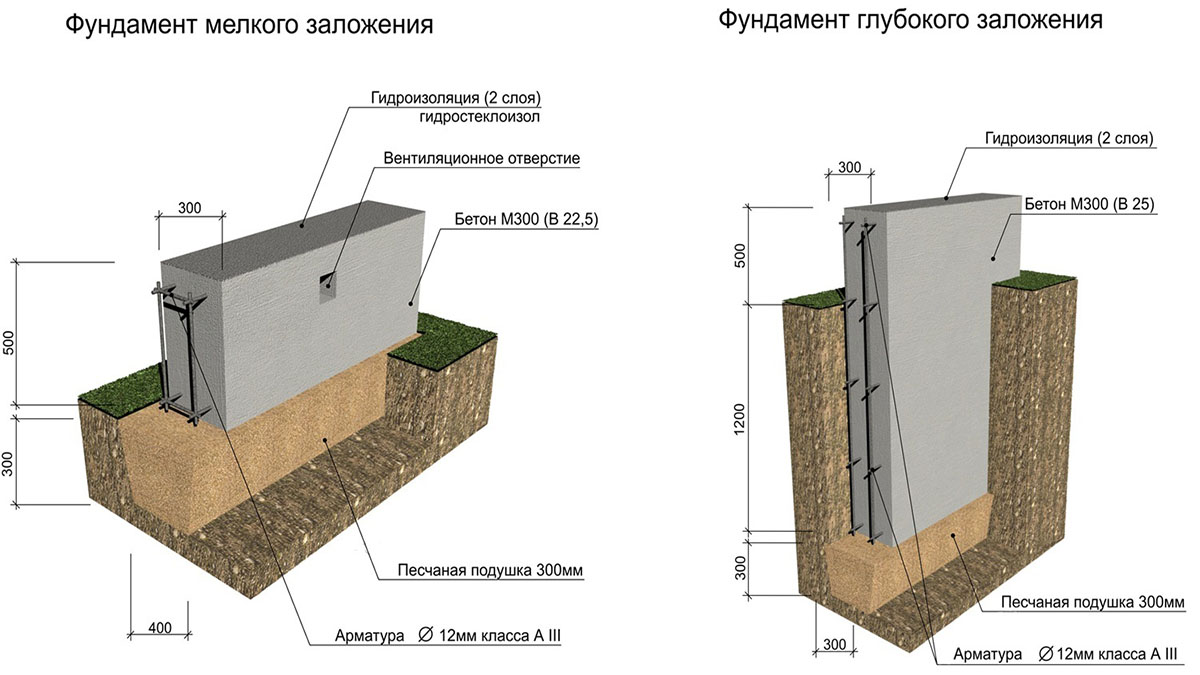

- The reinforcement cage must contain two vertical rows of rods, and the number of longitudinal ones must be calculated according to the depth of the underlying foundation. Foundations are:

- poorly buried;

- strongly recessed.

They have different base heights. In addition, in deeply buried foundations, the side walls and the bottom are more developed.

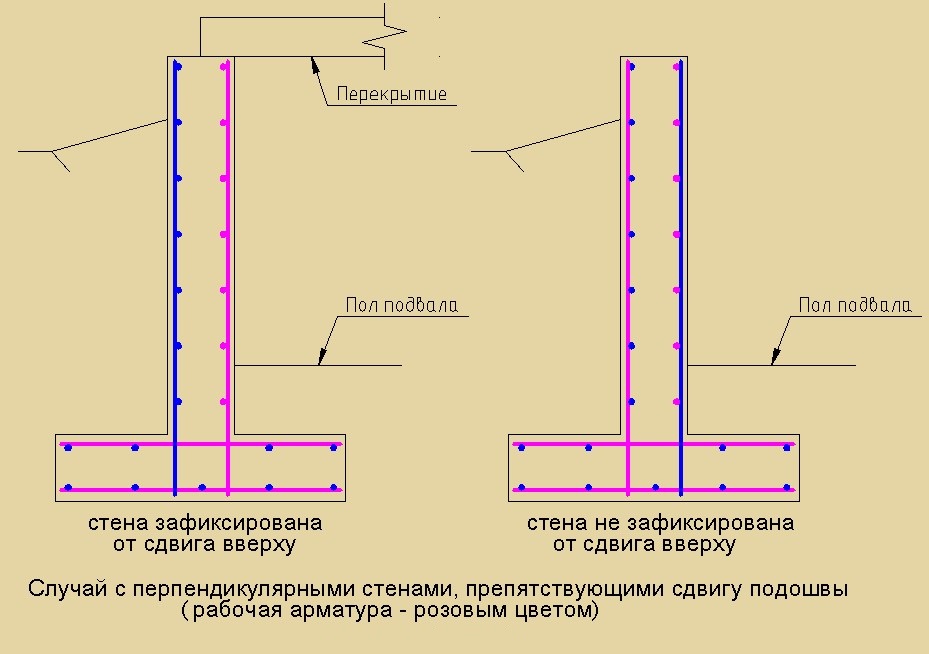

- Considering this fact, in weakly buried foundations, reinforcement of only the bottom is allowed, and in deeply buried foundations, there is a need to strengthen the outer part.

To strengthen the shallow foundation, an additional 10 × 10 cm wire mesh can be attached.

When erecting the foundation, it is necessary to carry out a financial calculation of costs and draw up a certain scheme for yourself. Usually, the main expenses are for building material and the construction work itself. They include digging a ditch, installing formwork, preparing a concrete solution, processing the finished base, filling sand into the ditch, which will act as a cushion for the bottom.

When erecting the foundation, it is necessary to carry out a financial calculation of costs and draw up a certain scheme for yourself. Usually, the main expenses are for building material and the construction work itself. They include digging a ditch, installing formwork, preparing a concrete solution, processing the finished base, filling sand into the ditch, which will act as a cushion for the bottom.

For buildings with a simplified shape, it is preferable to use reinforcement of a monolithic tape type in the form of some geometric shapes: a square or a rectangle. In this way, the base will be solid and the axles will be in the correct position. To reinforce a tape monolithic type of base, it is necessary to adhere to the correct thickness of the cushion in the trench. Waterproofing should be done with high quality, because when filling sand in a trench, the foam waterproofing can be damaged. It is better to entrust these works to a professional.

Among the existing types of bases, tape is one of the most popular, especially for private housing construction. Its advantage lies in the low cost of materials. It is necessary to correctly calculate the costs of raw materials and construction.

Since concrete is low-plastic and does not tolerate tension well, it can crack when exposed to cold or when deformed. To avoid them, it is necessary to properly reinforce the base.

Typical mistakes

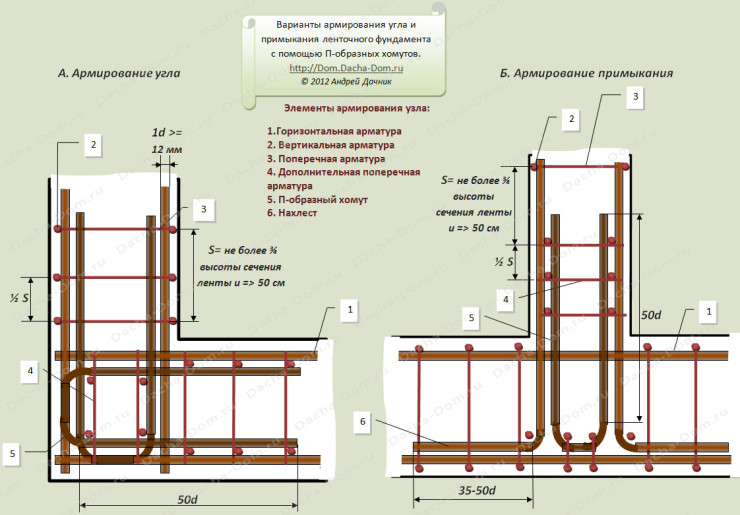

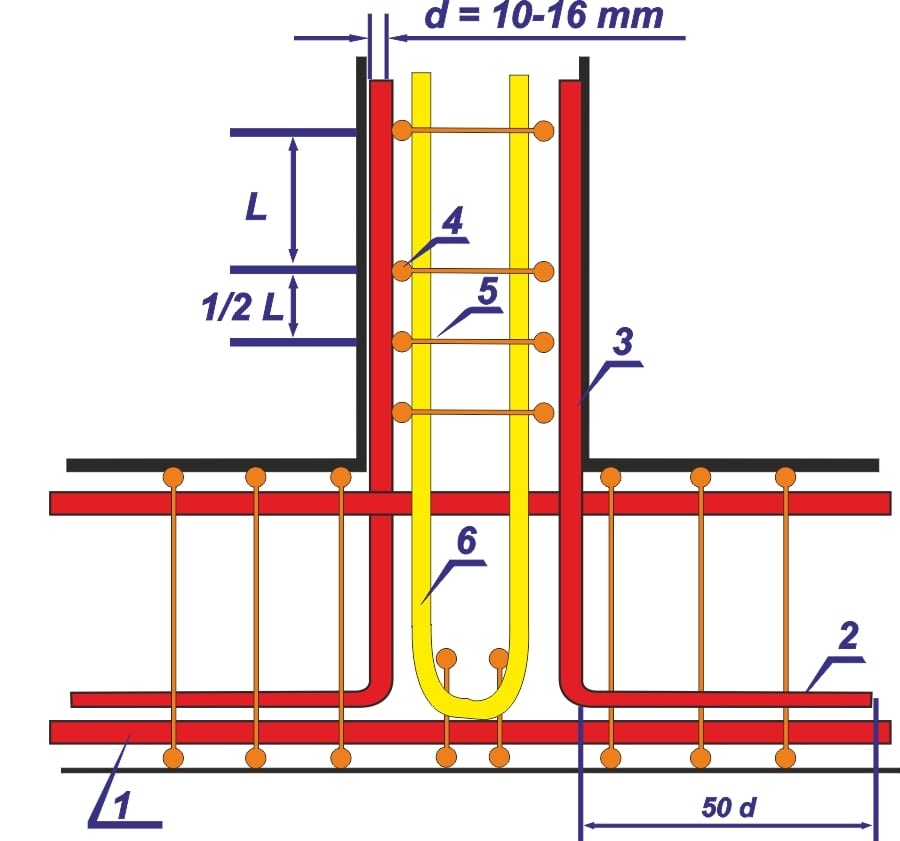

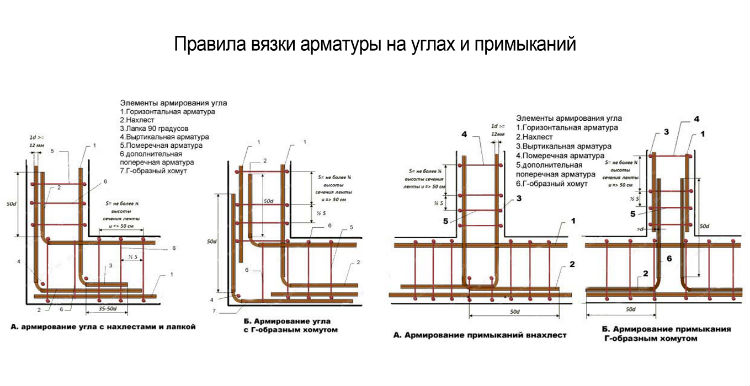

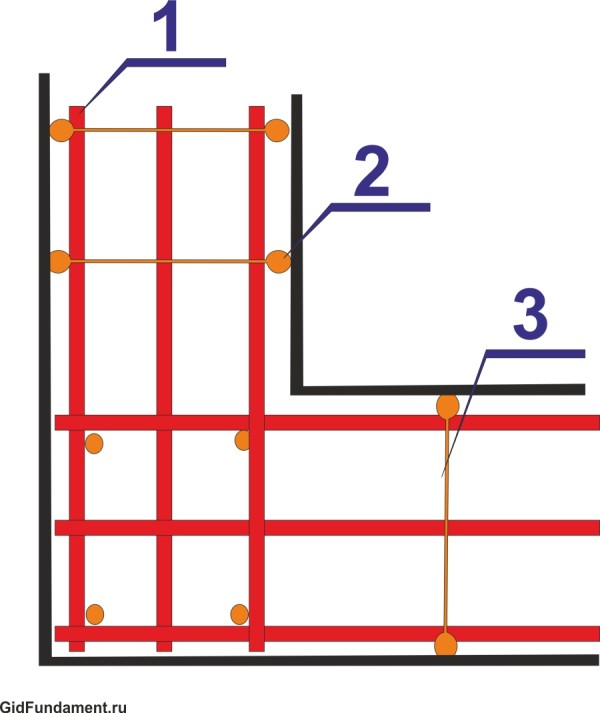

All methods of corner and adjacent reinforcement joints are aimed at maintaining the integrity of the reinforcement cage, regardless of its configuration. The strength of the strip foundation depends on the correct anchoring of the end pieces of the longitudinal reinforcement. The following schemes lead to incorrect reinforcement of the corners of the strip foundation:

1. Reinforcement of the corner zones of the strip foundation with reinforcing crosses with viscous longitudinal reinforcement bars at right angles.

2. Installation in corner and adjacent zones of bent longitudinal reinforcement without anchoring.

These errors are the most common and can lead to the destruction of the foundation in the places of corner joints and abutments.

Corner and adjoining joints made by knitting the crosshairs of longitudinal reinforcement bars

A typical mistake in reinforcing corners and junctions is the connection of longitudinal reinforcement using the crosshair knitting method. Such a reinforcing connection without proper anchoring of the rods can lead to the destruction of the concrete monolith due to multidirectional loads arising at the corners of the strip foundation.

Rice. 9. A common mistake when reinforcing corners

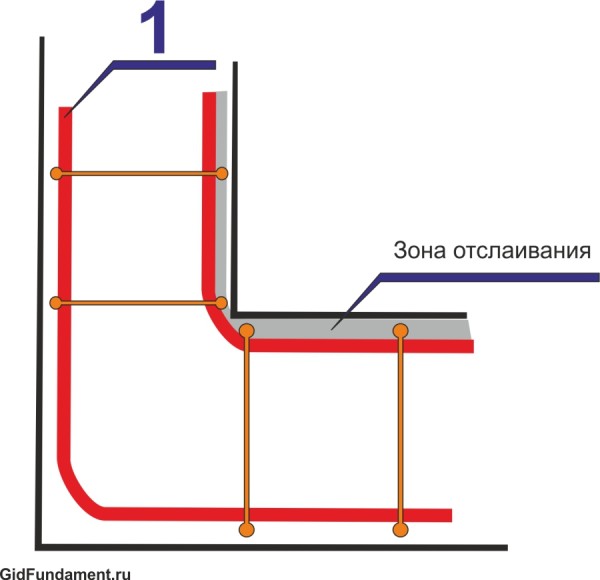

The use of bent longitudinal reinforcement for the reinforcement of corner joints and abutments

1. Corner joints without a bundle of internal and external longitudinal reinforcement (1) do not provide rigid bar fixation.

2. The destruction of the foundation can occur not only due to the formation of transverse cracks, but also due to the flaking of the inner corners.

Rice. 10. Another example of incorrect corner reinforcement

Be sure to read: Is it possible to reinforce a strip foundation with fiberglass reinforcement, if you are going to use it.

In order to prevent the formation of cracks, spalling and delamination at the corners and abutments of the strip foundation, it is necessary to correctly tie the end rods of the longitudinal reinforcement and perform their reliable anchoring. Correct reinforcement of the corners of the strip foundation is the key to the reliability and durability of the building.

Good publicity

The procedure for performing the reinforcement of the strip foundation

The existing scheme for reinforcing the strip base for building a house implies following several mandatory rules:

- Application when carrying out reinforcement of bars of class A400

- Minimization of the use of welding when joining the rods, as this technology contributes to the weakening of the sections

- At the corners, the frame can only be tied, the use of welding at the corners is not recommended

- The protective laid layer of concrete used in a particular situation must be at least 4 centimeters to protect metal elements from negative environmental influences, corrosion

- The use of smooth reinforcement is not recommended.

- When laying concrete, it must not be able to get stuck between the rods, which will eliminate control over failure, for too frequent arrangement of metal rods

Detailed step-by-step instructions with photos and videos given for clarity will help to create a reinforcing cage. A significant advantage of reinforced strip foundations is the combination of high reliability and affordable cost. Steel and concrete are high strength materials.

This is important for creating a foundation for construction on any soil, except for the already naturally stable and reliable rocks. In other situations, any foundation reinforcement will save you from damage caused by stress.

How is formed

When carrying out work such as strip foundation reinforcement, drawings include three groups of rods:

- Used for laying along the belt, used working rods

- Horizontal elements located transversely

- Vertical options, transverse

The task of the transverse reinforcement is to connect all working elements into a stable in use, a single unit of reliable, innovative working rods. They are often called clamps.

The task of the transverse reinforcement is to connect all working elements into a stable in use, a single unit of reliable, innovative working rods. They are often called clamps.

An important feature of the work is the use of SNIP and other regulatory specialized documents in activities such as reinforcement of the strip foundation. The calculation uses SNiP 52-01-2203

In this regulatory document, it is easy to find all the necessary calculations to create the reinforcement of the strip foundation of a small country house.

What are the requirements for concrete determined by regulatory documents?

If you maintain the order of creating reinforcement, it is important to comply with the mandatory requirements for the concrete used in a particular job. When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is an indicator of resistance to axial compression, readiness to resist stretching and not respond to transverse fracture

Correction factors for reliability can vary from 1 to 1.5

When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is the indicator of resistance to axial compression, the readiness to resist stretching and not respond to transverse fracture. Correction factors for reliability can vary from 1 to 1.5.

Requirements for fittings

These indicators are determined by regulations and standards. Reliable foundation reinforcement uses bar-based:

- hot-rolled rebars,

- mechanically hardened fittings

- heat treated reinforcement

It is GOST that allows you to calculate the indices of the limiting submerged states, which are strictly divided into groups in it. Indicators are determined on the basis of the requirements specified in state standards, which are determined on test benches.Any regulatory and technical documentation that is used to determine the reliability of reinforcement must be approved by the official regulatory authorities.

What basic rules are important to consider when performing work?

As a rule, reinforcement during suburban and construction is carried out independently. In this case, the requirements of SNiP and GOST are not always followed so carefully.

For this reason, when considering how to reinforce a strip foundation with your own hands, it is important to adhere to some mandatory rules:

- When performing the reinforcement of the strip foundation of the future structure, including 1-2 floors, rods with a diameter of 10-24 mm are used.

- The use of welded joints is not recommended

- When creating a strip foundation with your rivers, it will be necessary to create a formwork

The procedure for performing the reinforcement of the strip foundation

The existing scheme for reinforcing the strip base for building a house implies following several mandatory rules:

- Application when carrying out reinforcement of bars of class A400

- Minimization of the use of welding when joining the rods, as this technology contributes to the weakening of the sections

- At the corners, the frame can only be tied, the use of welding at the corners is not recommended

- The protective laid layer of concrete used in a particular situation must be at least 4 centimeters to protect metal elements from negative environmental influences, corrosion

- The use of smooth reinforcement is not recommended.

- When laying concrete, it must not be able to get stuck between the rods, which will eliminate control over failure, for too frequent arrangement of metal rods

Detailed step-by-step instructions with photos and videos given for clarity will help to create a reinforcing cage. A significant advantage of reinforced strip foundations is the combination of high reliability and affordable cost. Steel and concrete are high strength materials.

This is important for creating a foundation for construction on any soil, except for the already naturally stable and reliable rocks. In other situations, any foundation reinforcement will save you from damage caused by stress.

How is formed

When carrying out work such as strip foundation reinforcement, drawings include three groups of rods:

- Used for laying along the belt, used working rods

- Horizontal elements located transversely

- Vertical options, transverse

The task of the transverse reinforcement is to connect all working elements into a stable in use, a single unit of reliable, innovative working rods. They are often called clamps.

The task of the transverse reinforcement is to connect all working elements into a stable in use, a single unit of reliable, innovative working rods. They are often called clamps.

An important feature of the work is the use of SNIP and other regulatory specialized documents in activities such as reinforcement of the strip foundation. The calculation uses SNiP 52-01-2203

In this regulatory document, it is easy to find all the necessary calculations to create the reinforcement of the strip foundation of a small country house.

What are the requirements for concrete determined by regulatory documents?

If you maintain the order of creating reinforcement, it is important to comply with the mandatory requirements for the concrete used in a particular job. When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is an indicator of resistance to axial compression, readiness to resist stretching and not respond to transverse fracture

Correction factors for reliability can vary from 1 to 1.5

When creating a strip foundation with your own hands at the site of future construction, it should be borne in mind that among the main characteristics of the strength of concrete structures is the indicator of resistance to axial compression, the readiness to resist stretching and not respond to transverse fracture. Correction factors for reliability can vary from 1 to 1.5.

Requirements for fittings

These indicators are determined by regulations and standards. Reliable foundation reinforcement uses bar-based:

- hot-rolled rebars,

- mechanically hardened fittings

- heat treated reinforcement

It is GOST that allows you to calculate the indices of the limiting submerged states, which are strictly divided into groups in it. Indicators are determined on the basis of the requirements specified in state standards, which are determined on test benches. Any regulatory and technical documentation that is used to determine the reliability of reinforcement must be approved by the official regulatory authorities.

What basic rules are important to consider when performing work?

As a rule, reinforcement during suburban and construction is carried out independently. In this case, the requirements of SNiP and GOST are not always followed so carefully.

For this reason, when considering how to reinforce a strip foundation with your own hands, it is important to adhere to some mandatory rules:

- When performing the reinforcement of the strip foundation of the future structure, including 1-2 floors, rods with a diameter of 10-24 mm are used.

- The use of welded joints is not recommended

- When creating a strip foundation with your rivers, it will be necessary to create a formwork