Disadvantages of the pile-grillage foundation

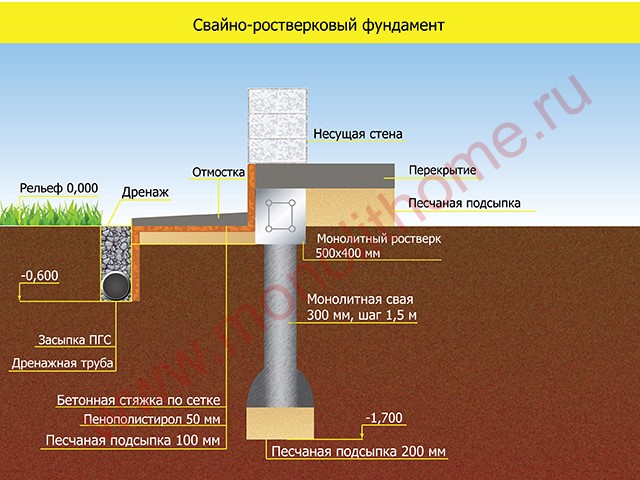

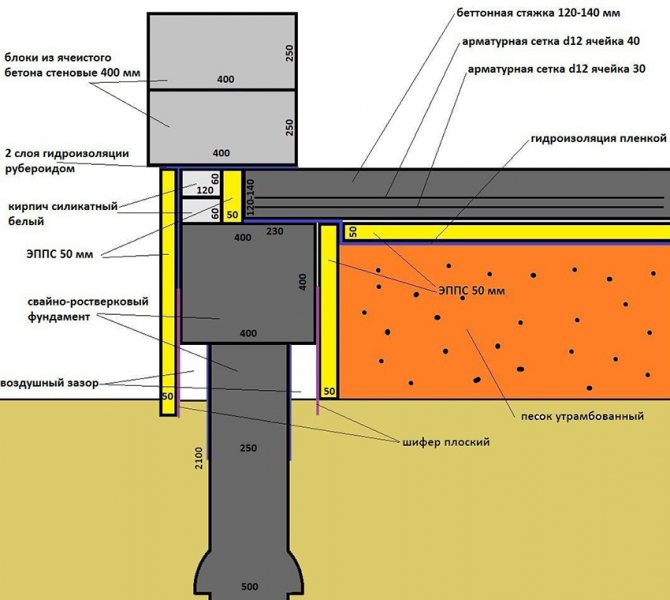

It should be noted that, despite the many advantages, this type of foundation also has its disadvantages. The main disadvantage is precisely the fact that the depth of the pile grillage, depending on the structure and properties of the soil, can contribute to difficulties in arranging the basement. This is mainly due to the fact that an empty space is formed between the soil surface and the supports. It must be filled and insulated to minimize heat loss during the cold season.

Basically, when the device of this type of foundation is carried out independently, failure to comply with the basic building codes can lead to loss of foundation properties. In order to avoid this, you should consider the most common mistakes made by developers.

- In the process of laying the foundation, a rigid connection between the grillage and the supports is not provided. This leads to the fact that in winter, when the soil begins to swell, expanding in volume, it tends to overturn the support. If the supports are poorly fixed, then the weight of the building can simply press them into the ground. Considering that with an unbound frame, the bearing loads are also not evenly distributed, the pillars can go into the ground in different parts of the structure, which will damage the building itself or even destroy it.

- For areas with particularly heaving soils, it is necessary to install expanded polystyrene plates in the formwork. in the future, they will act as shock absorbers, distributing the load and preventing the subfloor from freezing.

- The depth of the pile foundation grillage must comply with the established standards, as well as the depth of the piles themselves. If the supports are not deep enough, then in the event that the structure shrinks, the free space under the floor may disappear. And the forces arising from the freezing of the soil tend to raise the foundation. The forces of impact are uneven, so cracks and chips may appear on the walls.

- Incorrect calculation of the bearing capacity of the base. It must be performed on the value to which the soil freezes in winter, as well as on the properties of the soil itself. The lowest density is found in sandy and loamy soils. In case of errors in the calculations, there is a high probability that the future building will "walk", falling or rising, depending on the temperature difference.

If you avoid the main mistakes and take into account all the nuances when erecting a pile foundation, then as a result you can get a very solid foundation. It is possible to erect a pile foundation without spending a lot of money. But preparatory work and a thorough assessment and research of soil properties are a prerequisite for the foundation to serve for many decades.

Self-production of piles

When creating piles with your own hands, earthwork is performed using an earth drill. If necessary, drill holes over 0.3 m in diameter and 5 m in depth, use a motorized apparatus.

You can make piles yourself in the following sequence:

- Construct "glasses" from roofing material, the width of which will be equal to the diameter of the wells. They are made 25 cm longer than the immersion depth of the supports. Several layers are made from above and tightened with wire. The result is a formwork. The pipe will be installed in it.

- After installing the pipe, a reinforced frame is made. It is placed inside the support. Three rods with a diameter of 8 mm are enough. They are connected to each other with jumpers. The vertical rods should be extended 4 cm above the edge of the grillage.

- Concrete is poured into the pipes, compacting it with a vibrator.

- Equip the grillage.

When creating a feed, several recommendations are taken into account.For example, the grillage should not be crossed by pipelines. Piles are installed strictly vertically. The permissible deviation is 5 cm. Each seam and joint, which was formed during the creation of the grillage, is filled with concrete.

The grillage must be reinforced. For this, rods with a diameter of 1.4 cm are used. They must have a length equal to the length of the walls. In the absence of such rolled metal, rods of at least 60 cm are chosen.Their number is determined by diameter:

- 1 cm - 8 rods are required;

- 1.2 cm - 6;

- 1.4 cm - 5.

Before installing the walls, make sure that the grillage surface is horizontal. Flaws are corrected with concrete mortar.

After the completion of the construction of the foundation on piles with a grillage, the basement is finished. The upper edge of the finishing elements is attached to the lower part of the building wall. From above, the edge is closed with an ebb. From below, the finish does not reach the ground surface by a few centimeters. This avoids deformation of the base during frost heaving.

Important! Drainage should be provided to drain sediment. Equip and a blind area 70 cm wide

It is better to lay it with paving slabs.

If you follow all the recommendations and correctly calculate the grillage, you can create a reliable foundation with your own hands. It will not be affected by frost heaving or shrinkage forces.

Useful Tips

The pile-grillage foundation must be erected correctly, adhering to all construction technologies - this will help to increase its technical and operational characteristics.

If construction work is carried out by novice craftsmen, then they need to take into account some of the recommendations of experienced specialists.

- The installation should start with calculations. For this, the type of soil and the depth of the grillage are determined. If the support depth is insufficient, the building can shrink and crack, and then even collapse.

- A huge role is played by the study of the soil, on which the bearing capacity of the structure depends. The highest indicators are found in rocks and stony soils. If the composition of the soil is determined incorrectly, this will lead to errors in the calculations of the load of the structure, as a result of which it will sink into the ground.

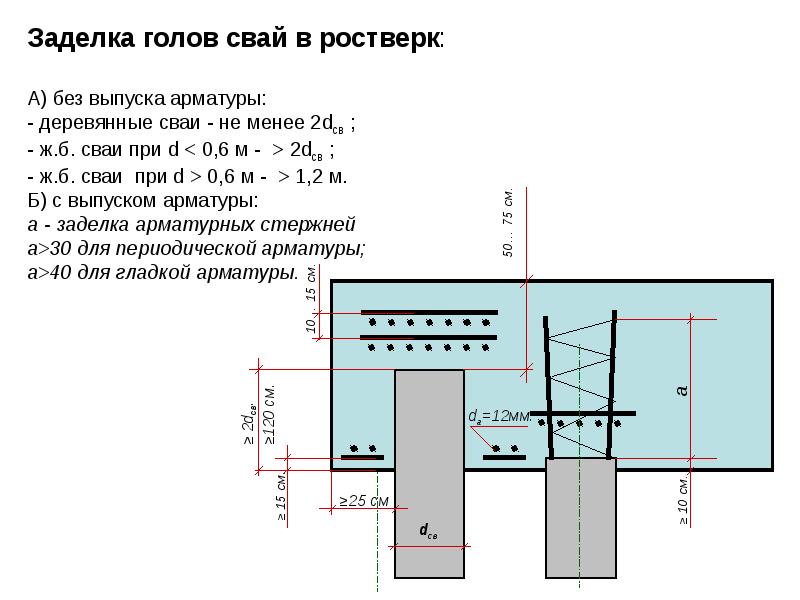

- There must be a good connection between the piles and the grillage, since the unstable structure can collapse under the influence of soil pressure.

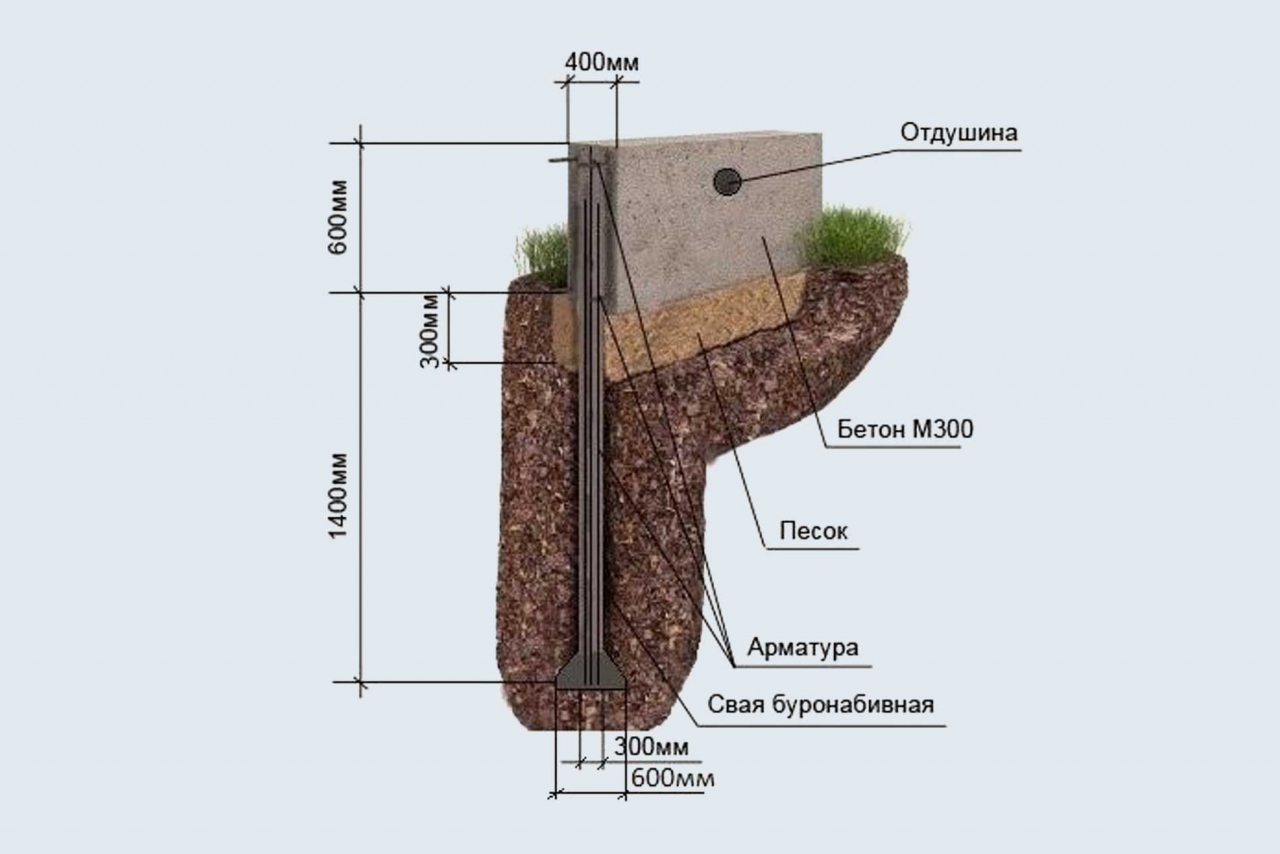

- Regardless of the type of foundation, it is imperative to lay a sand cushion at the depth of freezing - this is especially true for the operation of the foundation in winter. Frozen ground can expand and cause the grillage to break.

- The grillage should not touch the surface of the ground or be buried in it. It is necessary to remove a small layer of soil around the entire perimeter of the site, then install the formwork, fill in the sand and pour concrete.

- The step between the piles should be accurately calculated. This indicator is determined in accordance with the load on the foundation, the diameter and the number of reinforcement.

- During the reinforcement, it is worthwhile to provide for the required amount of ventilation ducts. All internal compartments must be connected to outside exits.

- Insulation and waterproofing play a huge role in the construction of the base. They should be laid before the foundation is poured with concrete.

- The bottom of the pit or trench must be tamped down and not loosened. It should not be allowed that earth from the walls crumbled onto the base. In addition, sedimentary water must flow away from the trench or foundation pit, otherwise the bottom will get wet and be unsuitable for filling with a solution. Excessive slope steepness is also unacceptable in trenches.

- Weak soil requires reinforcement with piles and good backfill.

- The sand that is used to fill the air cushion must be moistened and the cushion must be distributed under the contour to the edge at an angle of 45 degrees.

- The formwork must be securely fastened, since when poured with concrete, it may not withstand the load and collapse.The deviation of the formwork from the vertical by more than 5 mm is not allowed.

- The height of the foundation is made with a small margin of 5-7 cm from the height indicated in the project.

- When reinforcing the frame, it is recommended to use rods with a total cross-sectional area of at least 0.1% of the area of the concrete element. In this case, it is best to choose smooth fittings that do not have traces of rust, dirt and paint.

- It is undesirable to fasten the reinforcement by welding - this can violate its strength at the joints.

- The grade of concrete for pouring should be chosen depending on the construction of the base and the climatic conditions of the region.

For information on the design features of the pile-grillage foundation, see the following video:

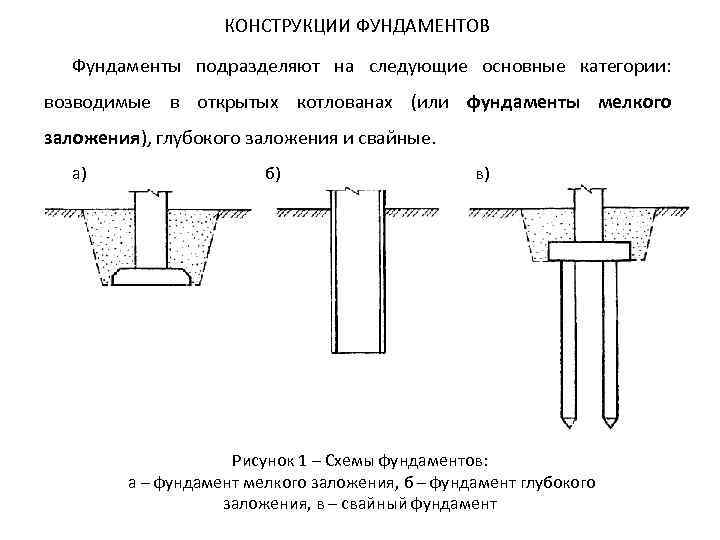

Peculiarities

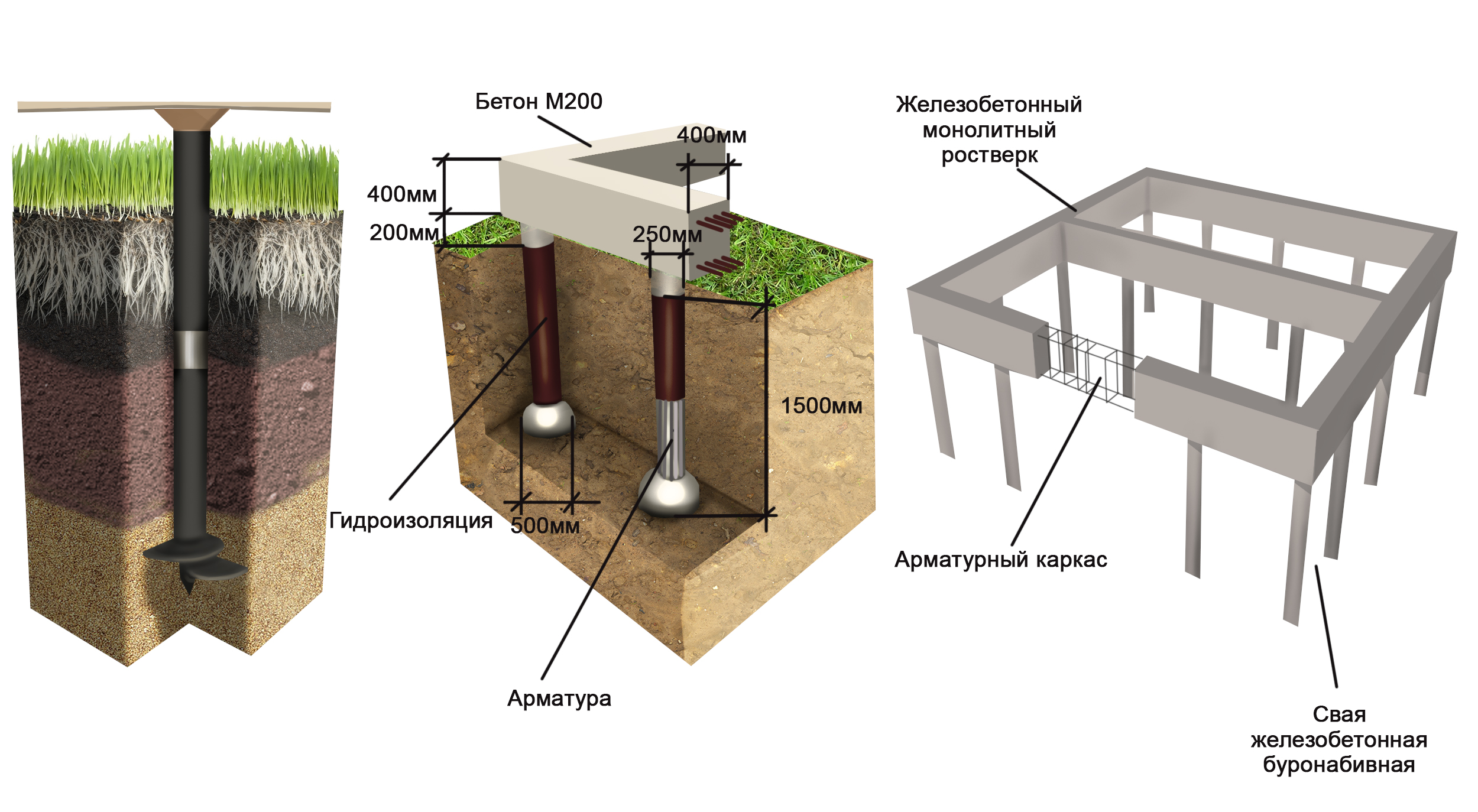

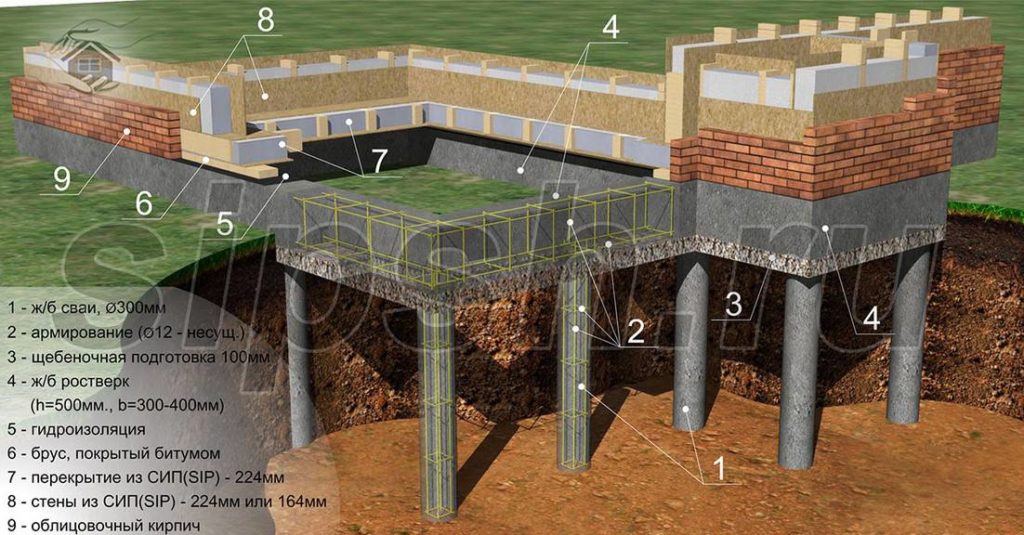

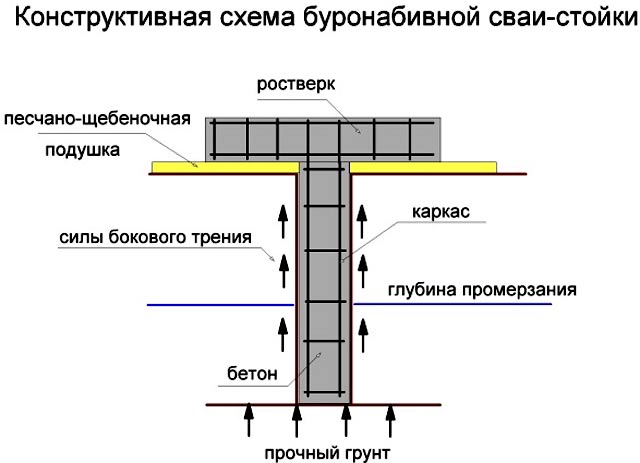

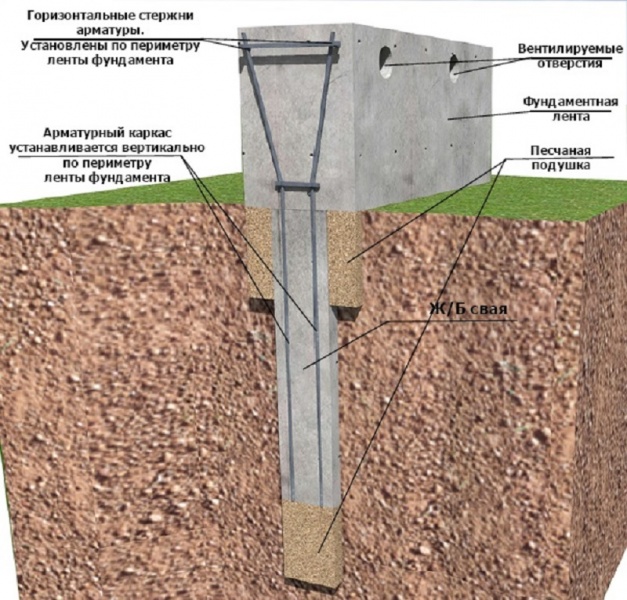

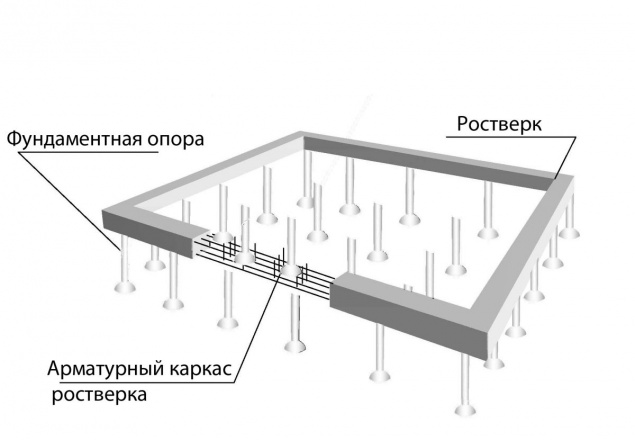

The technology provides for the presence of free-standing supports and a connecting element - a grillage. The pile depth depends on the geological conditions on the site and the structural features of the building. Drilling wells over a long distance allows you to increase the contact area of the building support with the ground. This increases the friction. Such foundations are capable of withstanding heavy loads.

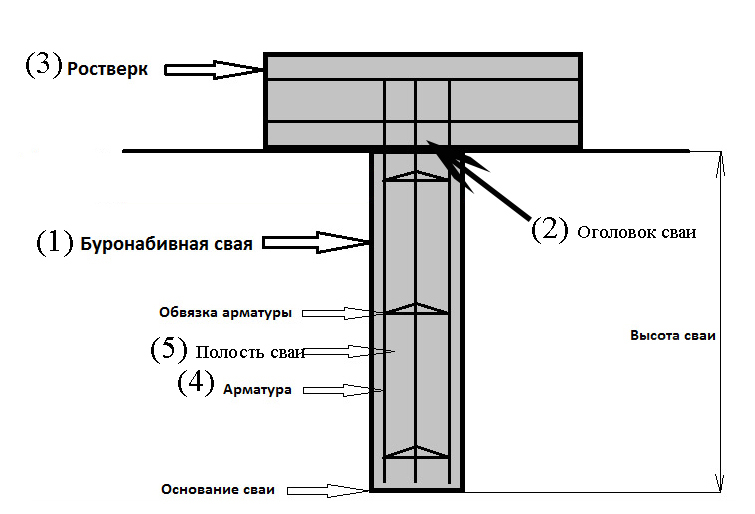

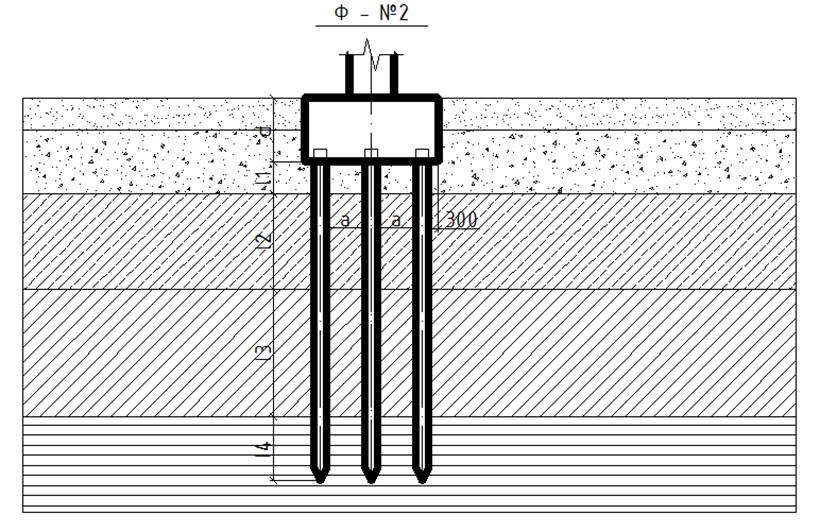

Device diagram

Device diagram

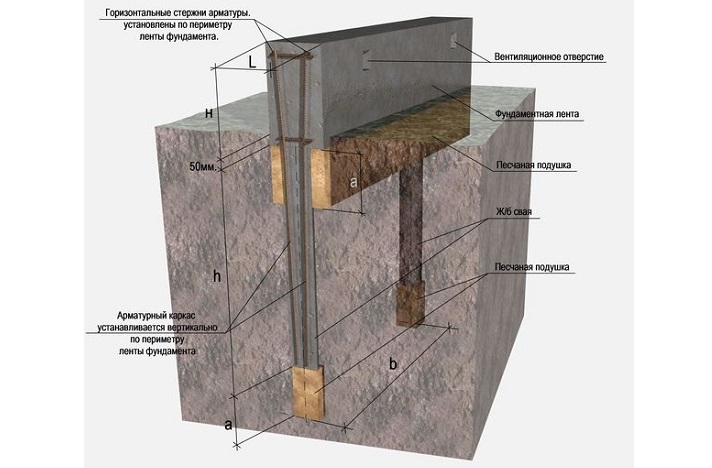

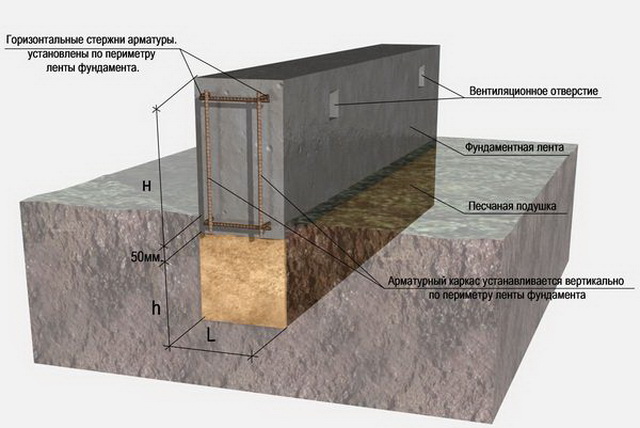

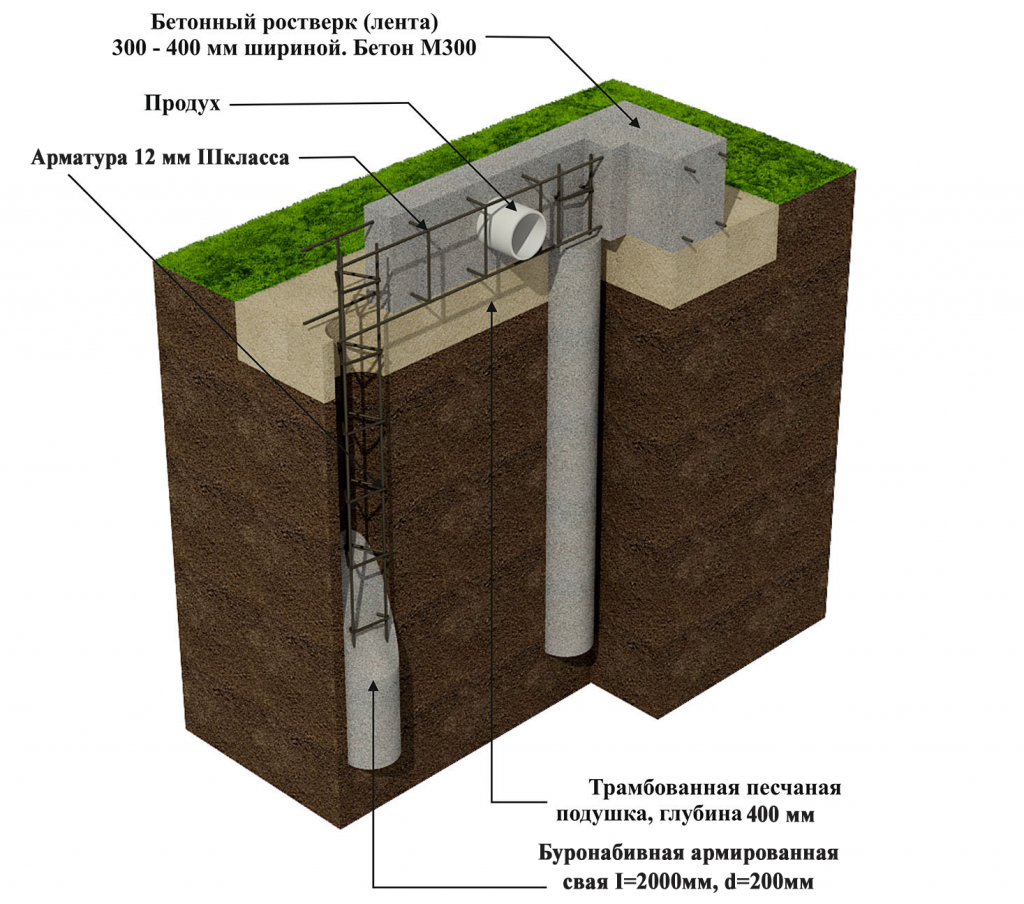

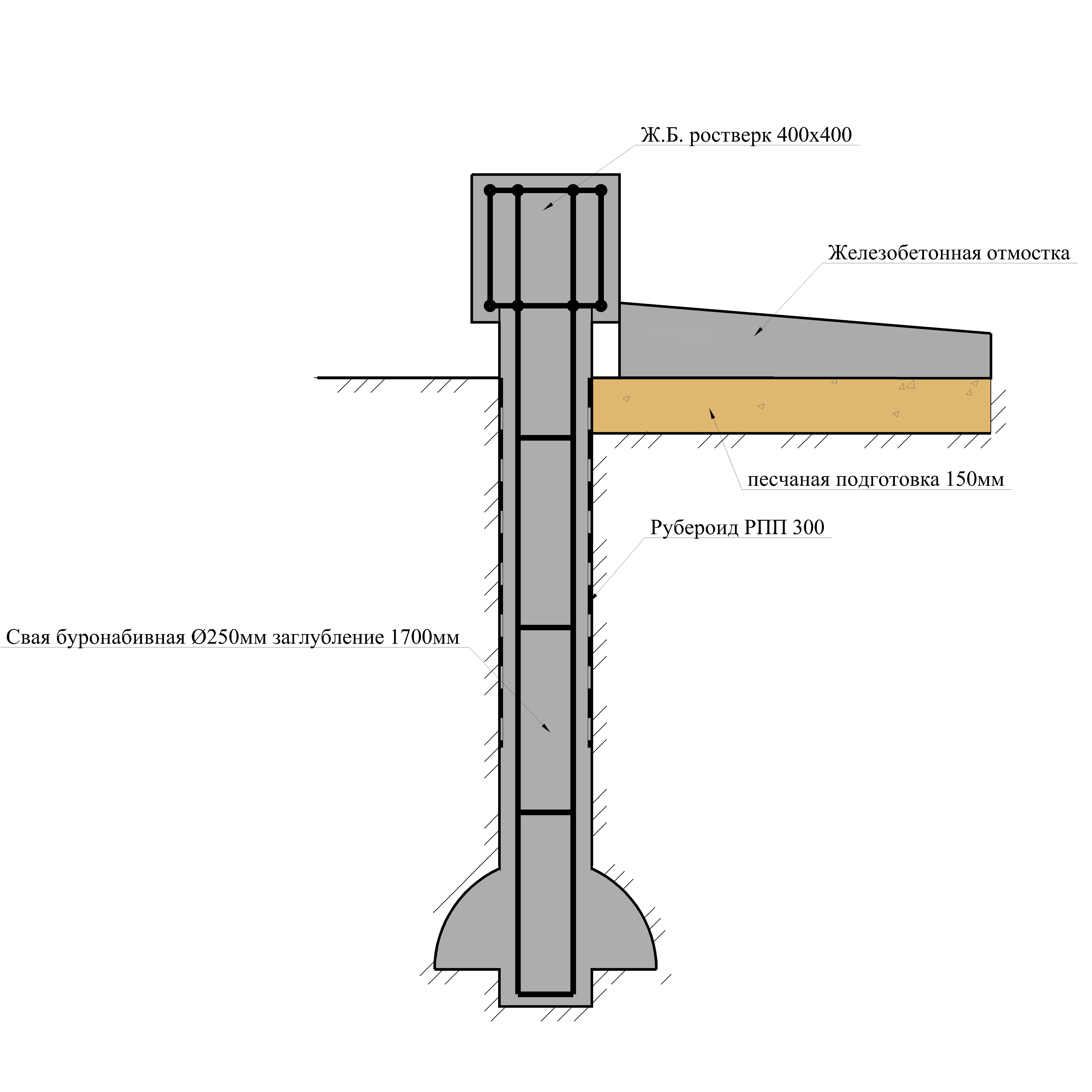

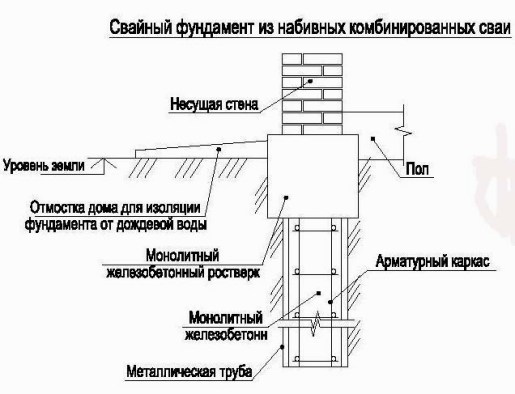

The device of bored piles has one serious drawback: all supports work separately. This option increases the likelihood of uneven precipitation, which is dangerous for almost all types of buildings. To prevent the destruction of the walls, a reinforced concrete tape grillage is provided. Its reinforcement allows it to take bending loads well and unite all the supports into one foundation. The manufacturing technology of the grillage can be different depending on the geological conditions.

Design advantages

A foundation with bored piles and a monolithic grillage is the best option for combining two technologies (concrete armored belt and pile foundation), which in tandem provide the best performance characteristics. Before equipping a foundation of this type, it is necessary to study its features.

The main advantages of a pile foundation with a grillage:

- High load-bearing capacity - the structure can withstand the loads of a building made of any material, and the laid waterproofing makes the structure practically invulnerable to external negative factors.

- No destructive effect of the construction process on neighboring buildings - you can even build a house next to other structures.

- The ability to build a reliable durable house in difficult geological conditions - in swampy areas, in places where groundwater is high, in heaving soil.

- Simplicity of technology, minimum amount of earthwork.

- No need to attract qualified specialists (subject to the ability to perform calculations, think over everything), heavy equipment - all work is carried out directly at the construction site.

- Strength - ensured by the fact that the piles are driven deep, below the depth of soil freezing.

- The ability to equip the foundation on bored piles with a grillage in difficult areas - where there are slopes, when you do not want to spoil the surrounding relief.

- The choice of any material for the construction of a building - even the most massive one.

- Low cost in comparison with other types of foundations with similar properties and parameters.

- High construction speed - the foundation is built in 4-7 days.

Installation technology for bored piles: step by step instructions

Before starting work, they carefully study the soils, perform all important calculations, purchase material, think over all the stages and only after that they begin to build a bored foundation with a concrete grillage.

Site preparation and marking of the future foundation

First, you need to clear the area of debris and all unnecessary, remove the fertile layer of earth, carry out a cast-off so that the markings do not interfere with the excavation work.The cast-off is made of wood, installed with racks and lintels around the perimeter of the structure at a certain distance so that wells can be drilled freely.

Nails are attached to the planks, and a cord is tied to them, which indicates the axes of the future building. All lines must be strictly parallel and perpendicular, the evenness is checked with a level.

Well drilling

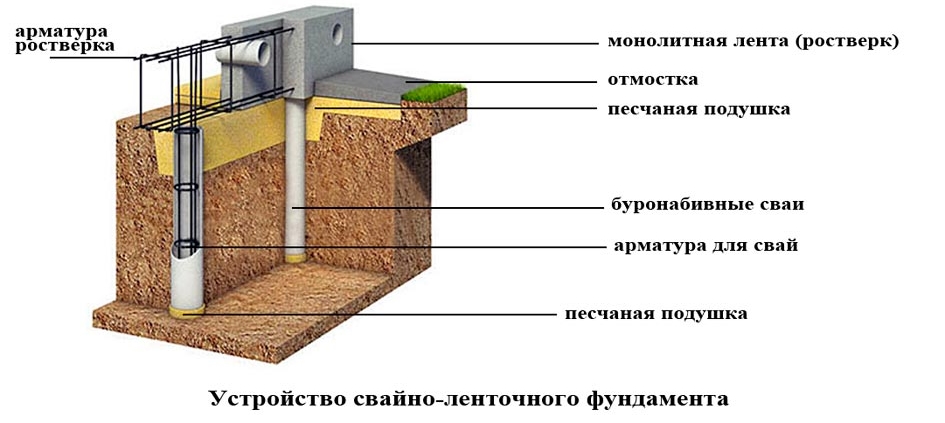

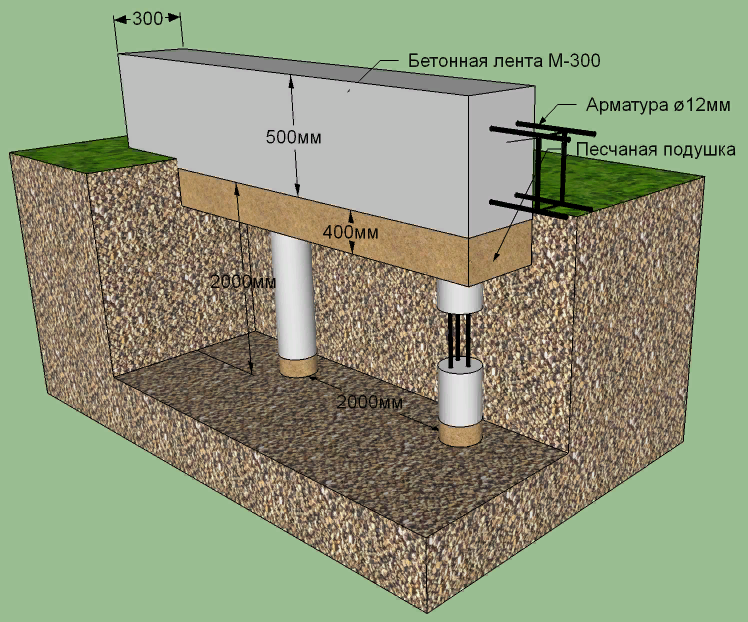

Wells are drilled according to the markings to the depth calculated by the formula. The borehole diameter corresponds to the diameter of the supports. When the drill reaches the required depth, it is pulled out, loose soil is removed from the well, the support part is rammed, and the sand cushion is covered with a layer of 30-50 centimeters.

Installation of casing pipes

The casing pipes do not allow the walls of the well to crumble and guarantee the safety of the work. On loams and dense clay soils, pipes can be dispensed with, but if work is carried out in swampy areas or all stages are carried out by hand, it is better to install pipes. Inside them, it is easier to create reinforcement, which is determined by the bearing capacity of the pile.

Upsetting pipes can be any product of the desired section made of plastic, metal, asbestos cement. It is possible to purchase special casing pipes specifically for wells. Pipes are installed in prepared wells strictly vertically, the gaps are covered with earth and compacted.

Reinforcement

To create a reinforcing frame, corrugated rods of the required diameter are used. The technology is simple: inside the support, 4-6 rods are installed around the circumference 3-5 centimeters less than the pipe. The rods are knitted with wire, fastened with clamps. The finished reinforcing cage is mounted in a well inside the pipe and buried in the soil (for this, the length of the rods should be 30 centimeters longer than the length of the pipes).

Pouring concrete mix

For a minimum strength of class B12.5, it is optimal to take B15. For pouring, a funnel is installed at the wellhead, which prevents the appearance of voids. The mixture is poured slowly, in layers 50 centimeters thick, compacting for 10 minutes. After 5-7 days, the installation of the grillage can be started.

Making a pile foundation with your own hands

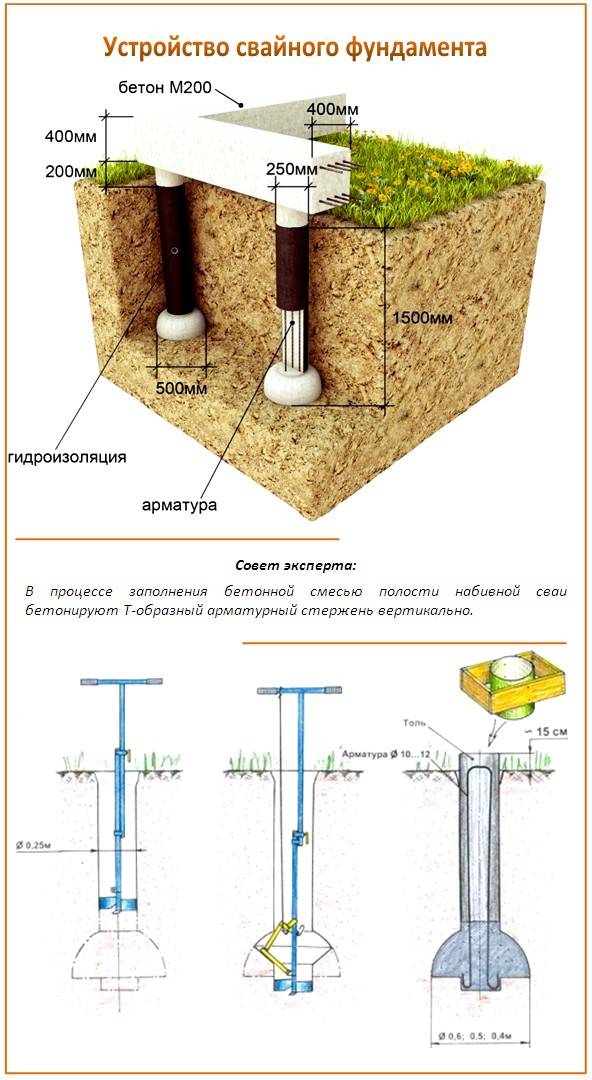

The sequence of actions for the construction of the pile foundation:

First of all, you need to mark the contour of the base.

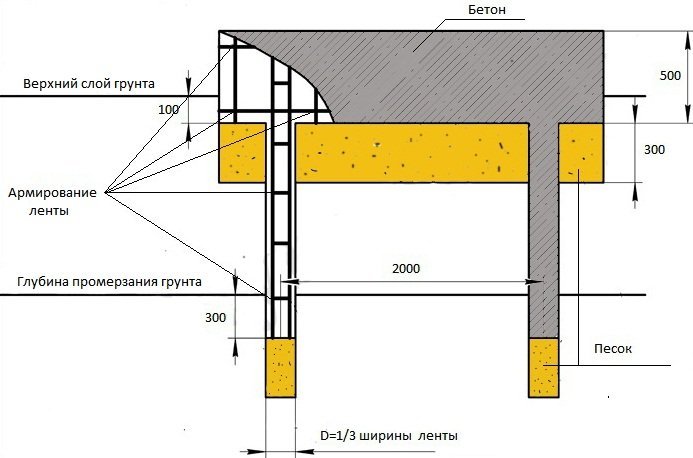

Next, you need to remove the fertile layer and soil from the trench to a depth that corresponds to the thickness of the grillage.

Formwork is being constructed.

Along the perimeter of the structure, with a step of 2 m, you need to make holes with the help of a garden drill. The diameter of the wells is 120-150 mm. The depth of the hole should be greater than the level of freezing of the ground. The minimum value is 1500 mm. In the lower part, the borehole should be expanded to 350 mm in diameter. Expansion height - 300 mm.

After that, sand must be poured into the pit. The height of the layer is 5 cm. Further, the backfill must be tamped.

In the resulting recess, you will need to insert a roofing material shell according to a given thickness of the support before the expansion begins.

The frame is being assembled from rods. It can be constructed from reinforcing steel rods. The parts should be fastened to each other using a welding device, plastic clamps or steel wire

It is important to ensure that the power rods protrude beyond the top of the post. After that, the grillage frame will need to be connected to the base supports.

After that, concrete solution is poured

The mixture can be ready-made or you can prepare it yourself. Water in the composition should be no more than 70% of the mass of cement.

The concrete solution must be compacted with an electric vibrator. If it is not there, you can use an iron bar or a ram made of wood, the diameter of which should not exceed the dimensions of the metal frame.

2.5 hours after the completion of the work, the open surface of the mortar and the grillage formwork must be spilled with water. In order for the concrete to harden gradually, it must be covered with a polyethylene film.

After that, you will need to build and install the grillage.

Installation of grillage

The structure must be raised above the ground. This will eliminate heat leakage from the premises through the ground. On the supports, you can build a monolithic grillage. The method of its construction is similar to the strip base device.

Step by step guide:

-

First of all, you need to form the formwork. Shields made of wood or chipboard sheets must be firmly fastened together.

- It is allowed to use permanent formwork, which will also serve as a layer for thermal insulation.

-

Inside the formwork, you will need to make a metal reinforcing structure. The frame is made of rods. You will need to make 2 horizontal tiers, and then strengthen them inside with jumpers horizontally. The parts are fastened to each other using vertical jumpers.

-

When the formwork and the load-bearing frame are formed, it will be necessary to pour the concrete mixture. During the pouring process, the concrete must be compacted with a vibrator or a simple rammer.

The pile foundation will be ready in approximately 15-30 days.

After stripping, you will need to waterproof the base. This can be done in several ways:

- impregnation with a penetrating agent (the service life is the same as that of concrete structures);

- the use of bituminous mastic (the option is budgetary, the service life is 15-30 years);

- installation of rolled materials in several layers with sealing of joints (service life - 30-50 years).

It is recommended to use impregnating waterproofing or a set of measures consisting of coating with mastic and installing materials in rolls.

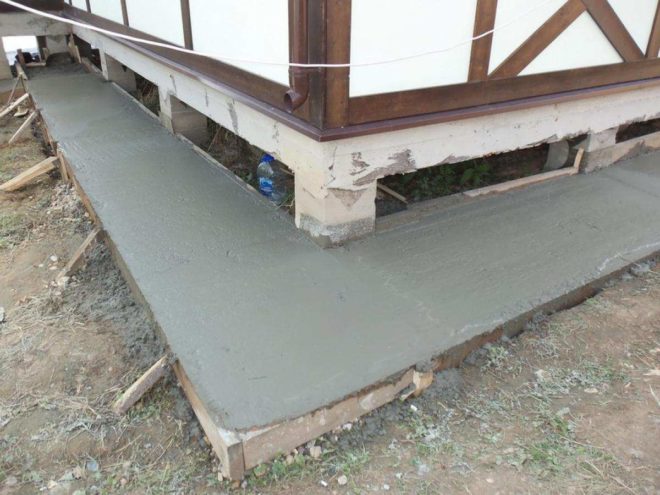

Blind area

Any foundation requires a blind area with a slope of 4-7 ° from a private house to the outside. The design allows you to drain water after rain or melted snow under the grillage. To prevent drains from damaging the soil adjacent to the blind area, it is necessary to integrate storm water inlets and trays into its outer perimeter, which will move the liquid into a container underground.

To reduce the heaving forces under the grillage, which exert pulling loads on the supports, the blind area must be insulated at a depth of 50–60 cm. For this, expanded polystyrene must be laid at the bottom of the pit. The blind area should be 7–9 cm wider than the roof slopes, so that in the event of an overflow of the roof drainage tanks, the liquid does not destroy the fertile layer.

The recommended width of the blind area is 0.8–1 m.

The blind area of the pile foundation can be made of concrete

It can be made from the following waterproof materials:

- paving slabs;

- concrete screed 6 cm thick;

- PVC tiles.

If you want to save money, you can use a dry mix of asphalt concrete. It should be compacted with a rammer.

DIY step-by-step instructions for building a foundation

It is best to entrust the calculation and preparation of the project of the foundation for the house, whether it is a pile-strip foundation, to a professional designer. If the piles are incorrect in height and thickness, then the reinforced concrete support and the building on it will not serve for a long time.

Marking on the site

At the same time, it is also not worth laying the parameters "in reserve", this will only lead to an increase in the cost of work. As such, a do-it-yourself foundation device of the type in question should not cause difficulties. Below is a short step-by-step guide to quickly understand all the nuances of this process.

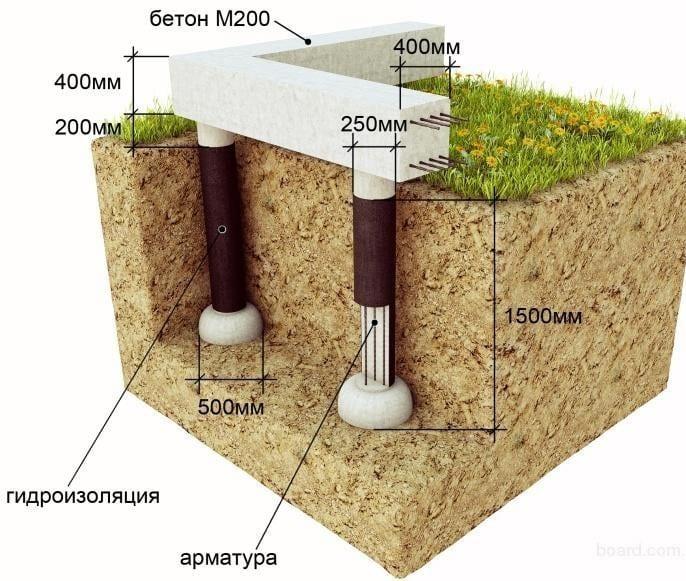

To make a foundation from bored piles and a monolithic grillage, you must:

-

Drill out or dig holes under the support pillars according to the scheme "in the corners of the house and with a step of 1–2 meters under the tape."

-

Pour and tamp at the bottom of the “wells” a 30-centimeter sandy one, and then pour concrete on it for the support pillars with a thickness of another 20 cm.

-

Lower asbestos-cement pipes into the ground, reinforce them with rods with a cross section of 10–12 mm and fill them with concrete.

-

Make a formwork for the tape.

-

Lay the grillage reinforcement and fill it with concrete.

-

Perform waterproofing.

The lower edge of the supports should be below the freezing point of the ground.In this case, wells for piles are made 10–15 cm wider than the asbestos-cement pipes taken. To keep the pillars stronger in place, an expanding concrete sole is arranged in their lower part. Pits in the ground for supports in width are made just for its dimensions.

Waterproofing of concrete is carried out with roofing material or mastic. Even modified bitumen shingles will do. True, it will cost more than the usual roofing felts.

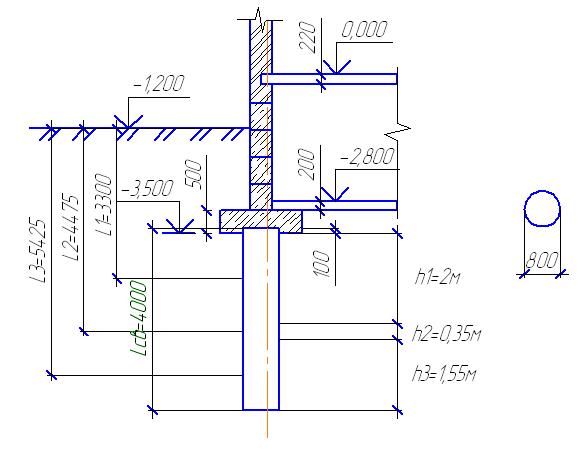

Calculation of a bored foundation with a grillage

Before starting to mount the foundation of bored piles with a grillage, everything must be very carefully calculated. Only the correct parameters and numbers will allow you to achieve the desired result and ensure the strength, reliability, long service life of the future building.

Calculation of bored piles

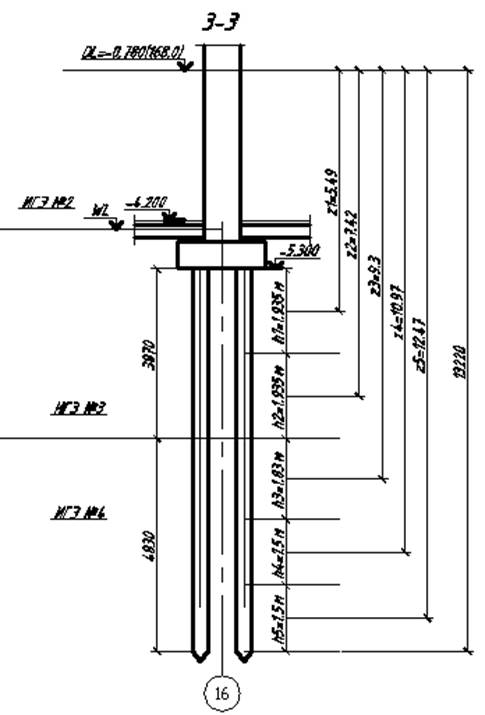

In the process of calculating the piles, the following values are determined: the length of the supports, the diameter, the number and the layout. The diameter is usually taken in the range of 15-40 centimeters, a section of 20 centimeters is considered optimal. For more accurate calculations, you can use special tables indicating the diameter of the supports and their bearing capacity, which is relevant for different materials.

If there is a value for the bearing capacity of an individual pile, the distance between them is calculated using the formula:

l = P / Q - here:

- l - optimal distance between supports

- P - indicator of the bearing capacity of the pile

- Q is the load per linear meter of the base (the mass of the building is divided by the length of the grillage itself)

So, for a house weighing 50 tons, which is being built on clay soil on supports with a cross section of 20 centimeters, 27 supports are needed (50,000 kilograms / 1884 kilograms = 26.53). They also remember the rule: the distance between the piles must be equal to at least three of their diameters. That is, if piles are taken with a cross section of 20 centimeters, the distance between them should be at least 60 centimeters. For dense soil, the figure is increased by a quarter.

It is necessary to mount the base under the house according to a previously drawn up scheme, which is based on SNiP, which requires the implementation of such rules: the piles must be in the corners of the building, along the load-bearing walls and under the entrance group.

It is also advisable to install supports under heavy elements (stove, fireplace, boiler room, etc.). The drilling depth depends on the depth at which the bearing soils are found, on the level of soil freezing in the region. Usually drilled to a depth of 1.5-3 meters.

Calculation of a monolithic grillage

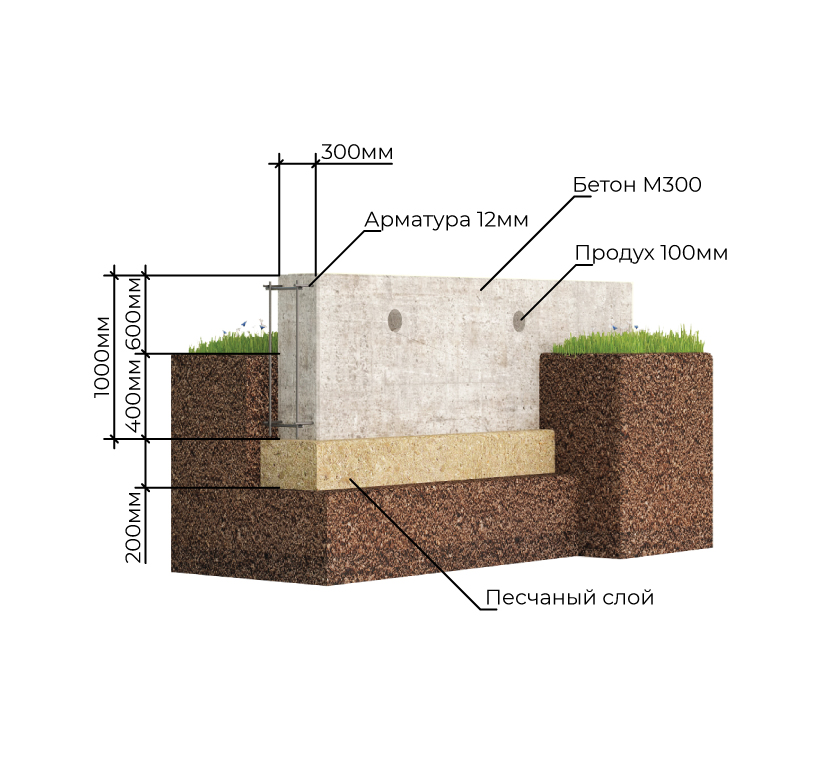

When it is created with a grillage, the technology assumes an accurate calculation of the very: its height and width. To get the width value, use the formula:

B = M / L * R - here:

- B - belt width

- M - building weight

- L - indicator of the length of the grillage

- R - the exact value of the bearing capacity of the topsoil

The formula is used for both a shallow foundation and a zero-height grillage. The hanging grillage is considered according to a different technology, rather complicated - in this case, it is better to leave the calculations to professionals.

The width of the grillage is usually 35-50 centimeters. For a medium-sized cottage, a width of 40 centimeters and a height of 30-50 centimeters will be sufficient, depending on the expected depth.

Reinforcement calculation

When the foundation is being created, the bored piles with the grillage must necessarily be combined with a reinforced frame. Reinforce with corrugated steel rods with a diameter of 10-12 millimeters, knit with a smooth knitting wire with a cross section of 6 millimeters.

The provisions of SNiP are dictated by the following rules:

- The number of rods in the longitudinal belt - at least 4 with a distance of up to 10 centimeters

- The step between the transverse jumpers in the longitudinal belt is up to 30 centimeters, between the connecting vertical ones - up to 40 centimeters

- The concrete cover is at least 5 centimeters thick on all sides to avoid metal corrosion.

To understand how to calculate the amount of reinforcement, you can take a simple example.So, if a monolithic grillage is created with a perimeter of 9x7 meters, and the conditional dimensions of the strapping are 40x40 centimeters, two longitudinal belts with three rods with a diameter of 14 millimeters each are used for reinforcement. The value of the step between the rods is 10 centimeters, the belts are united by jumpers made of rods with a diameter of 11 millimeters with a step of 20 centimeters.

Calculation:

- Determination of the total length of the rods in the upper longitudinal chord: 9 + 9 + 7 + 7 = 32 meters (perimeter of the grillage), 32x3 = 96 (length of three rods) 96 x 2 = 192 (length required for two chords).

- The jumpers are used with a length of 30 centimeters, located at a distance of 20 centimeters. For both grillage belts you need: 2x (32 / 0.2) = 320 pieces of 30 centimeters each = 96 meters.

- Length of vertical bridges connecting both frames. Their length is the same, 30 centimeters, for a square grillage = 96 meters.

It turns out that in this case it is necessary to purchase 192 meters of reinforcement with a cross section of 14 millimeters and 96 + 96 = 192 meters with a cross section of 11 millimeters for lintels.

The knitting wire is calculated as follows: 40 centimeters of material is spent on one connection. The number of connections is: 4x (32 / 0.2) = 640 pieces of 40 centimeters each = 256 meters.

Dimensions of piles of different types

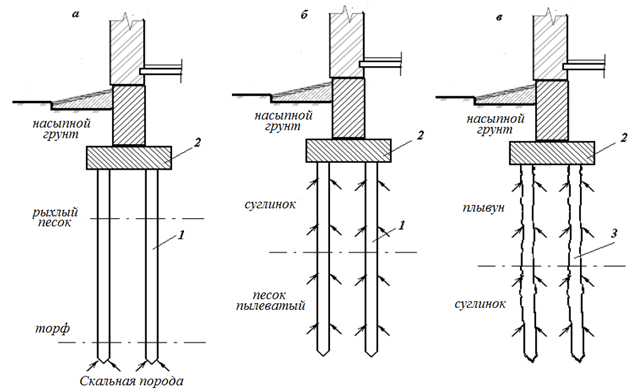

In addition to the geological conditions and design features of the buildings being erected, the depth of the pile foundation also depends on the type of supports.

Screw

Screw piles

Screw piles

To determine the parameters of foundation supports for light buildings of small sizes, a surface analysis on the site is sometimes sufficient. If clay or sandy soil of increased density is found at the lowest point of the construction site at a depth of 50 cm, then the length of the screw piles should be at least 2 m. In other conditions, the calculation is made taking into account the level of soil freezing.

For example, for the construction of various objects in the Moscow region, screw piles with a length of 2-3 m are most often used.Constructive elements of small diameter are in demand when erecting fences and gazebos, and similar products of a significant section are used for the construction of a private house with several floors.

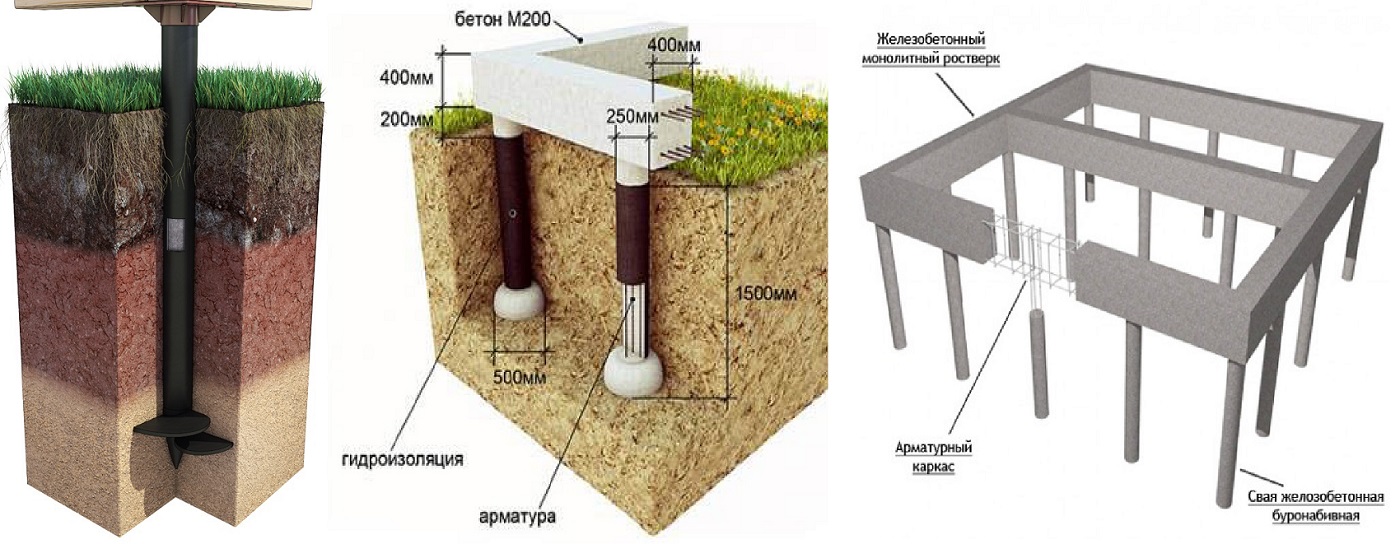

Bored

They are poured into pre-prepared wells, the number and location of which is determined by the building design and technical documentation. The drilling depth depends on the type of supports, which can be without broadening, with a tapered base or a broadened heel. When choosing a structure of a certain type, the characteristics of the soil and the loads acting on the foundation are taken into account.

Bored piles

Bored piles

The length of the bored pile in the ground must be at least 3 m from the base of the grillage or the surface of the earth. If structures without broadening are used, then they are buried in the support layer by at least 1 m. The immersion of supports in cohesive soil with a broadened heel cannot be less than 2 m or the value of its diameter. If the construction is carried out on areas with a buried layer of peat, then the end of the piles is placed 2 m lower.

The diameter of the trunks of bored supports is determined by their length and height of the house, and is:

- for structures up to 10 m - 400 mm;

- for structures up to 15 m - 500 mm.

The strength of piles from 15 to 30 m in size is ensured by means of shafts with a diameter of 600 mm.

Hammered

Depending on the type of materials used, driven piles are made of wood, metal or reinforced concrete. Wood or metal structures are treated with protective compounds before immersion. Watch the video on how the driven piles are mounted.

The minimum length of reinforced concrete supports does not exceed:

- for hollow - 4 m;

- for solid - 3 m.

The standard size can be from 3 to 16 m. If the installation depth of reinforced concrete supports involves a significant distance from the surface to the support point, then composite piles and a combined installation method are used.