Pros and cons of a pile foundation

It is not recommended to arrange it only in swampy, watered areas, where excess moisture will lead to a rapid thinning of the barrel walls. Otherwise, it's just the perfect choice.

Considering the pros and cons, it is clearly seen that the advantages greatly prevail over the disadvantages. However, there is one big "BUT".

Electromechanical corrosion

The screw support must be manufactured in accordance with standards and of high quality steel. And after it is also mandatory, it is necessary to check in the Quality Control Department using ultrasound or X-ray. The main problems for developers who have opted for a pile-screw foundation usually arise precisely because of defective materials.

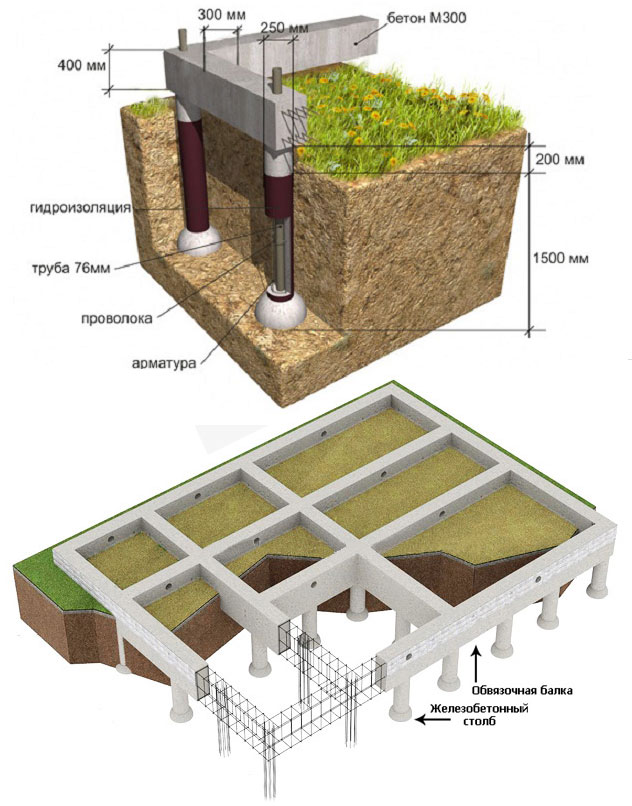

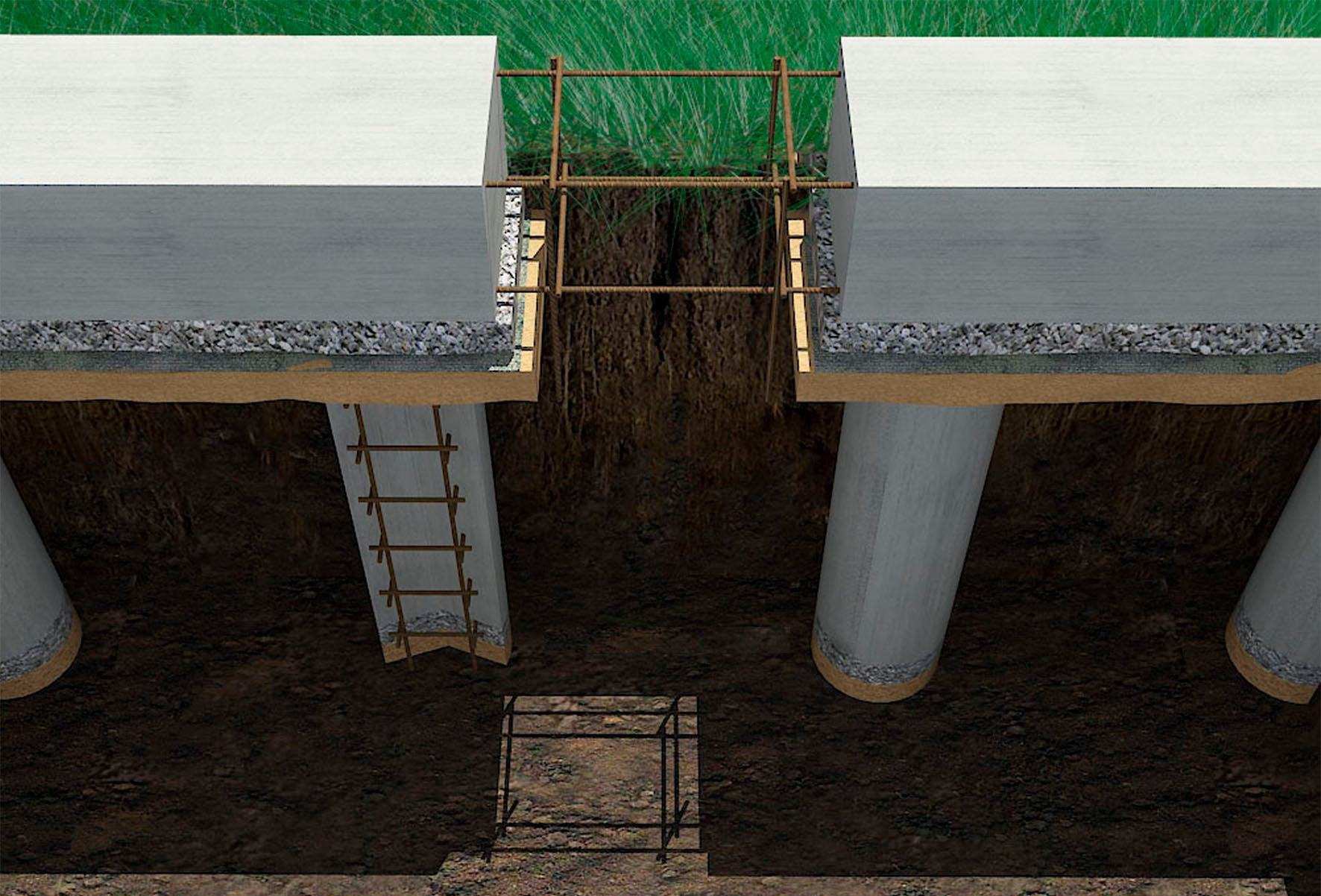

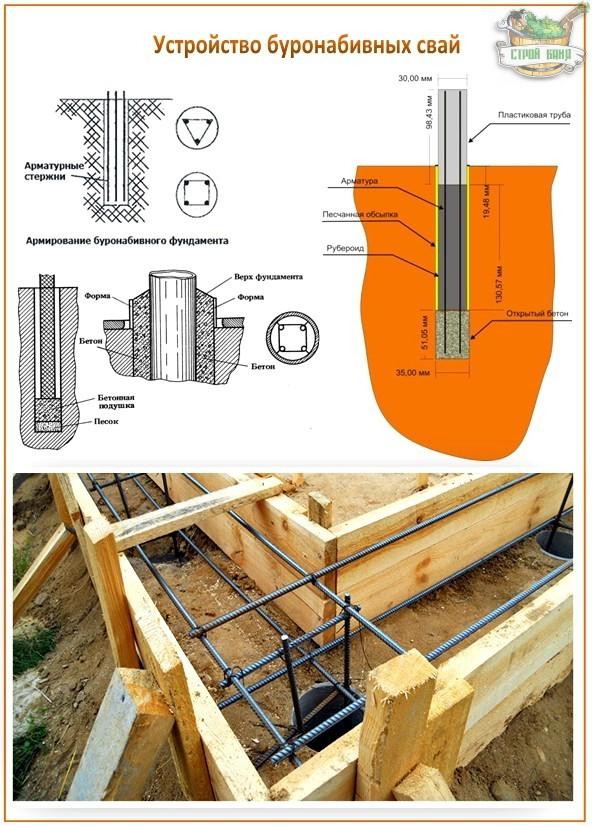

Arrangement of the reinforcing cage

For this purpose, it is necessary to stock up on some tools and materials. These include the following:

Pile frame

- 10mm reinforcing rod;

- Welding device;

- It is also recommended to prepare a grinder and a tape measure - they will also be needed.

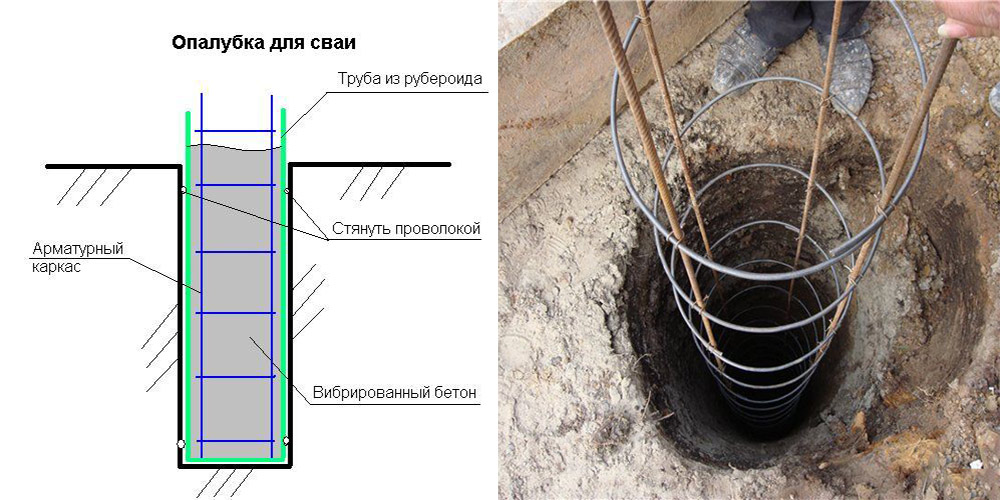

It should be noted that the reinforcement of the foundation with piles is always accompanied by the reinforcement of the latter. There are two ways in which this operation can be performed. The main thing is to know that the outgoing rods should be slightly higher than the top of the surface, which is planned to be poured in the future. This is done in such a way that the location of the reinforcing rods begins at a five-centimeter height above the ground.

So, let's start looking at the first, simple way. To implement it, you need to stock up on two rods, the length of which should exceed the value required for pouring by ten centimeters. As for such an indicator as the distance between the foundation piles, it is also equal to ten centimeters. The following steps are related to welding the rods. For this, a step of ten centimeters is used.

After that, one more such strip should be produced, the cells within which they are located similarly. At the end it is necessary to place the jumpers opposite each other. After connecting them, we get a long square frame, the edge of which will be ten centimeters.

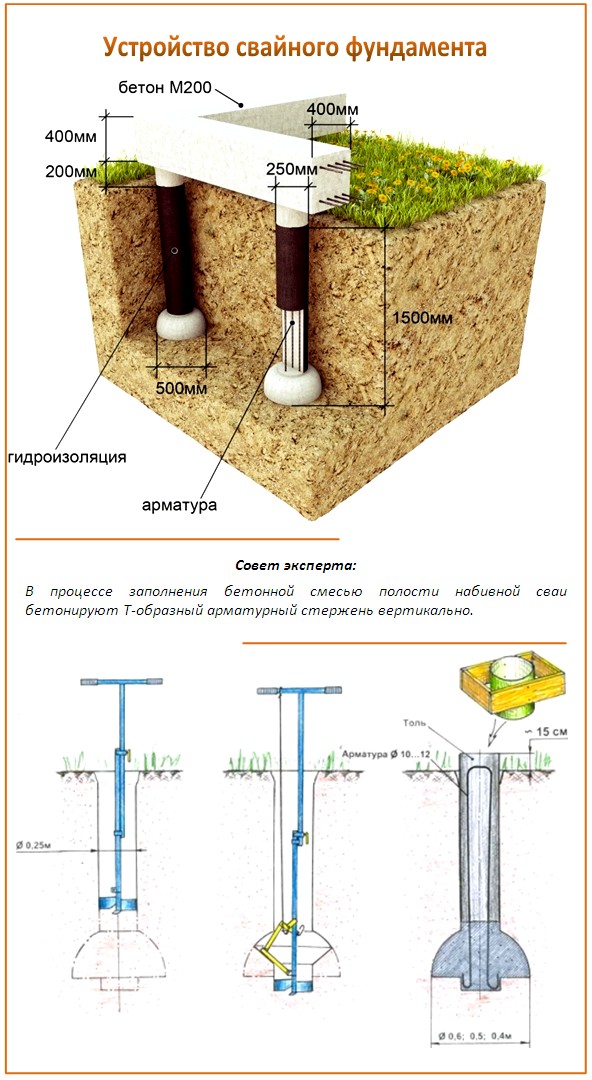

Pouring concrete piles

There is another way, which is much more complicated and much more expensive. But, at the same time, such a solution can be called much more reliable. Its use cannot be called quite frequent, since for it you will have to bend reinforcing bars into rings, the diameter of which ranges from twelve to fifteen centimeters. In this case, the ends of the circles must be welded together. The number of rings is determined based on length calculations. So, for example, you need one piece for every fifteen centimeters. The same should be done when there is a foundation on bored piles.

After finishing the production of the required number of rings, you can start pulling them onto the frame structure. To this end, you should take rods of the required length and weld them to each of the rings in a circle. In this case, a three-centimeter step is taken. In cases where there are not so high influencing forces, the step can be increased to four centimeters. In order to fix the reinforcement at the required level, it is necessary to hold two horizontal rods at the top, after which the formwork structure is laid on them. And only then the main frame is welded.

Types of screw foundations

According to the configuration and purpose of the blades, there are:

- Broad-bladed - a typical variant with one blade in 1–1.5 passes.

- Multi-bladed - with multiple blades.

- Narrow-bladed - with a tip in the form of a screw for 5–8 screw turns.

Various types depending on the soil

The first option is intended for light buildings and stable soils. The second type of screw piles is used when it is necessary to improve the bearing capacity of the support with compensation for its vertical movements, as well as for high and heavy cottages with a total weight of 2-3 floors.

The third type is for foundations on soils with an abundance of stones. For permafrost conditions, it is also recommended to take a narrow-bladed analogue, only having not a pointed end, but an open cut with teeth along the perimeter.

The pile tip can be cast (VSL) or welded (SHS). The first is more expensive. However, it is more durable and able to withstand heavy loads than a welded analogue. If the soils at the construction site are dense or the foundation needs to be made for a large house, then it is better to spend money and take it with a cast tip.

Pouring concrete mortar

During the implementation of all stages of construction work, you can immediately notice that screw piles under the foundation are a complete exception from all other bases. The pouring process also differs from standard technologies. So, for example, instead of the traditional mixture of concrete grade M300, M500 should be used, which is distinguished by its strength characteristics. As a result, you will be dealing with a rather thick solution. And it can take about six minutes to knead one batch. If possible, it is preferable to order a ready-made mixture.

In the course of filling, you must be extremely careful and approach this matter with utmost care. So, for example, try to touch the reinforcement as little as possible, as this often leads to its displacement. Then, when the mixture is poured, it must be covered with plastic wrap. In this form, the structure should be left for about one month. Then it will be possible to remove the plastic foil and the formwork. At this point, the construction of the structure can be considered completed.

How to make a false plinth

False plinth is designed to protect the space of the pile field under the house from the entry of animals or birds, snow cover in winter, from wind and moisture. Various materials are used to create such a base.

The most budgetary and aesthetically attractive option is a strip along the outer perimeter of corrugated board. It is attached with its upper part to a special wooden board installed along the perimeter of the grillage.

The lower part is attached to a wooden beam laid on supports made of bricks, cinder blocks, etc. to cut off contact with the ground.

A concrete ebb is arranged along the lower edge, and an ebb should be mounted on the upper border to drain rainwater.

Useful tips for installing screw piles

- The pile will not enter the ground strictly vertically, it will be necessary to constantly level it and return it to the design position, therefore it is better that at least three people carry out the work: two act on the lever and one checks the accuracy. In order to prevent it from shifting, special devices are sometimes used to fix it.

- If an obstacle or a layer of dense soil is found in the path of the pile as it is screwed in, the depth of entry and location are analyzed. If it is not located at the corners of the house and it turned out to enter its soil by a meter or more, it is allowed to simply cut off the top and leave everything as it is. With a depth of less than a meter, there is a possibility of skewing the house. At the corners, piles should be installed at full length as these are the most critical areas.

- The final stage of the installation can be concreting. It will provide additional reliability, but this process is not necessary in the case of screw foundations.

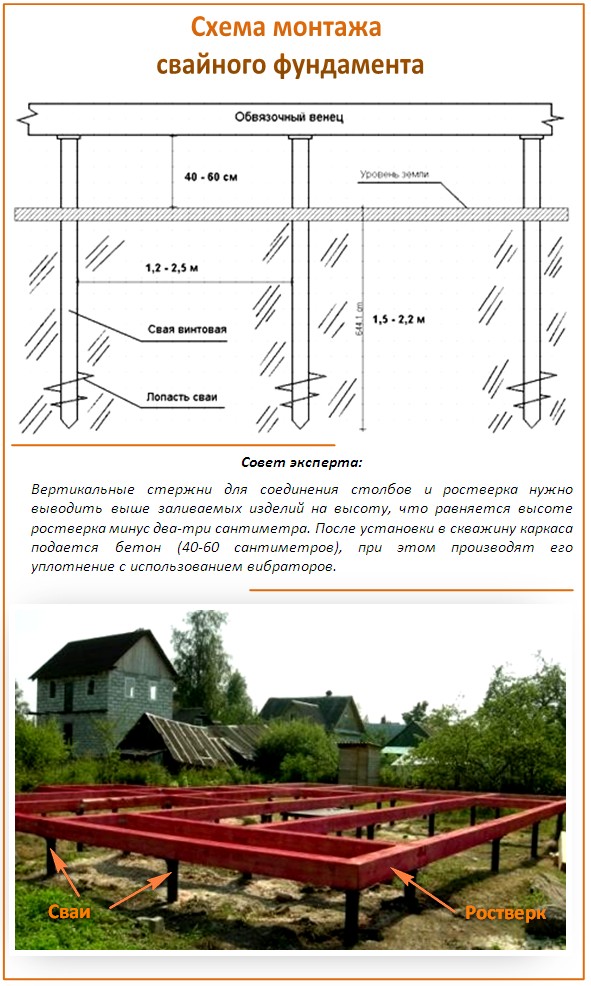

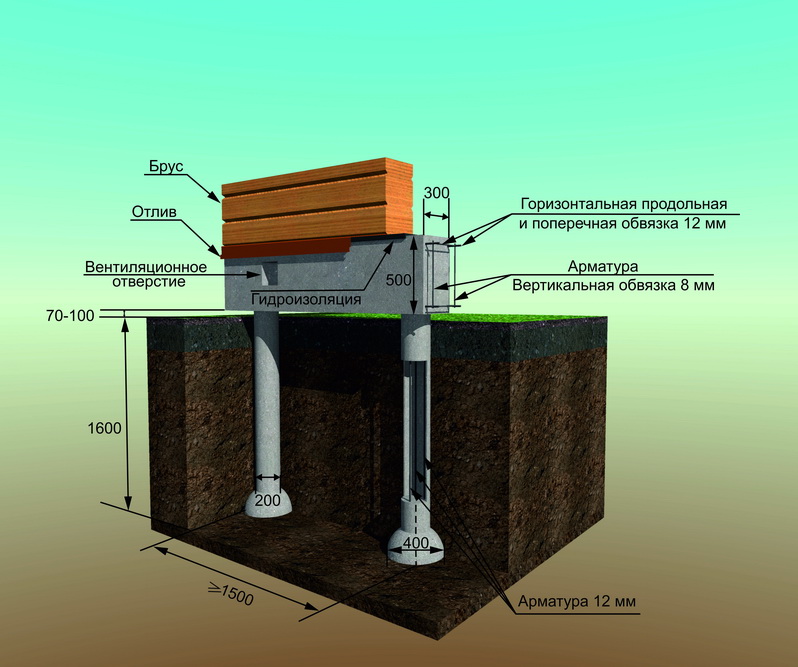

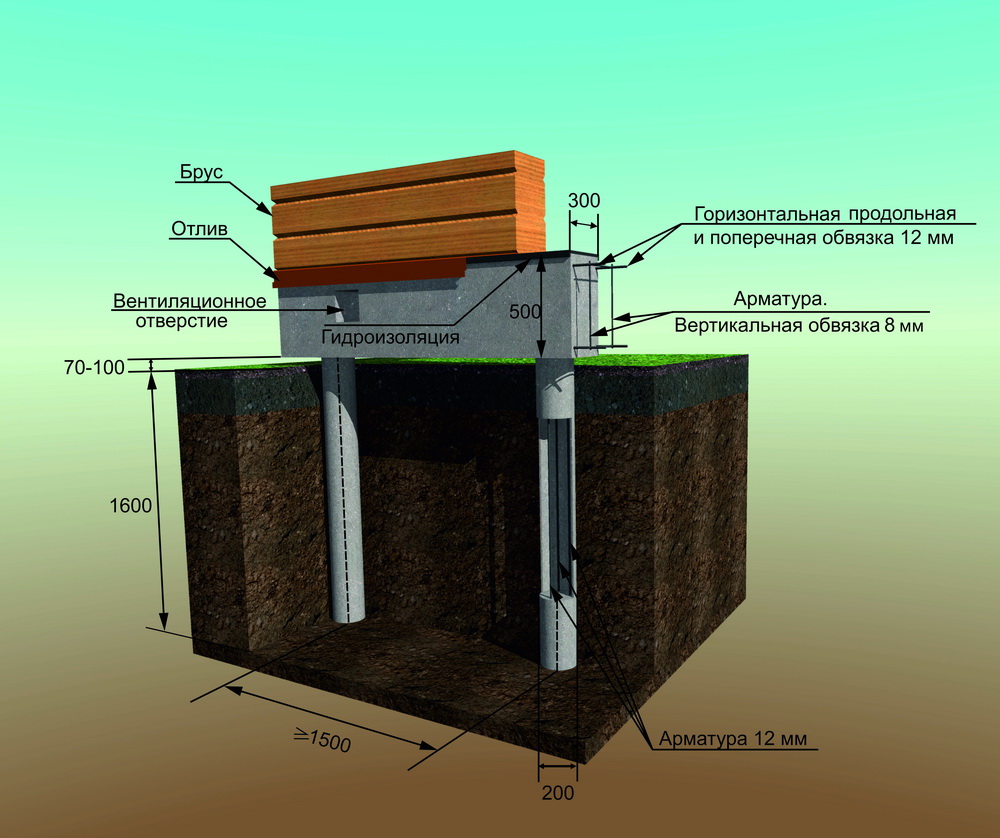

Reinforced concrete and prefabricated types of grillages

If the pile foundation is being erected in an area with strong winds and snows, then the construction of a grillage is mandatory

If the pile foundation is being erected in an area with strong winds and snows, then the construction of a grillage is mandatory

Foundation elements that are placed on top of the pile structure are called grillage. It is necessary in particular for connecting the supports located around the perimeter of the building. He also takes over most of the mass from the residential building.

If the building has a large weight, taking into account the impact of temporary loads from wind and snow in the winter, then the device for the structure of the grillage is simply necessary. If the house is small, the additional grillage structure is not used. In this situation, the entire load is transferred to the ground through the supports.

Grillage device

Grillage device

The grillage can be of several types, for example, such as: prefabricated metal or monolithic. The reinforced concrete type of structure is considered more reliable than the prefabricated one, since in the first case there are no abutment seams, and the second method is connected by welding. Therefore, in the case of a massive structure, it is better to use a monolithic grillage.

The disadvantage of this method is the high cost and long installation time. Prefabricated grillages due to quick installation and low cost are used in small construction of country houses much more often

But it is important at the time of the device of such a structure to comply with all the requirements, otherwise the bearing capacity of the foundation will be reduced

Types of screw foundations

According to the configuration and purpose of the blades, there are:

-

Broad-bladed - a typical variant with one blade in 1–1.5 passes.

-

Multi-bladed - with multiple blades.

-

Narrow-bladed - with a tip in the form of a screw for 5–8 screw turns.

Various types depending on the soil

The first option is intended for light buildings and stable soils. The second type of screw piles is used when it is necessary to improve the bearing capacity of the support with compensation for its vertical movements, as well as for high and heavy cottages with a total weight of 2-3 floors.

The third type is for foundations on soils with an abundance of stones. For permafrost conditions, it is also recommended to take a narrow-bladed analogue, only having not a pointed end, but an open cut with teeth along the perimeter.

The pile tip can be cast (VSL) or welded (SHS). The first is more expensive. However, it is more durable and able to withstand heavy loads than a welded analogue. If the soils at the construction site are dense or the foundation needs to be made for a large house, then it is better to spend money and take it with a cast tip.

Pile foundations yesterday, today, tomorrow

The technology of manufacturing buildings for various purposes on free-standing supports has been known to mankind for thousands of years. And today it retains its relevance and is being improved. The very first pile foundation consisted of hewn round pillars driven into the ground, which were cuttings of tree trunks. The installation process was quite complicated and time-consuming, but found wide application, especially in the area of frequent flooding.

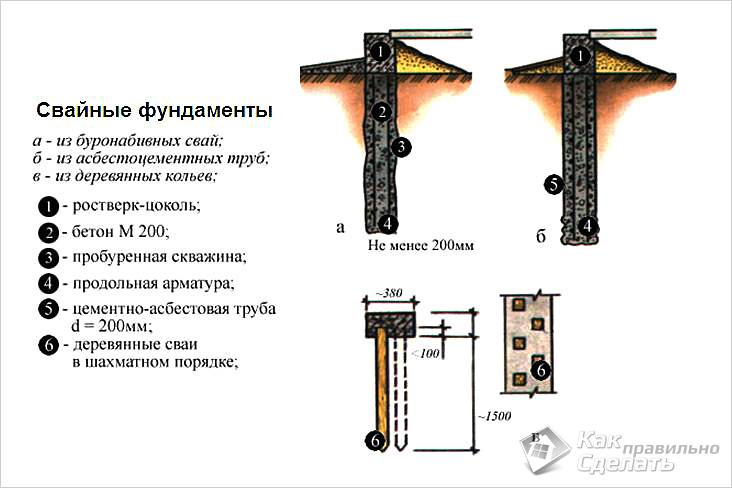

Currently, this technology has practically disappeared, since it is unreasonably expensive and physically costly to make a pile foundation for a house with your own hands from logs. Already in the last century, reinforced concrete piles began to be widely used as supports vertically installed in the soil, which were also driven into the ground with the help of various mechanical devices. This version of the supports had a number of advantages:

Pile foundation technologies

- The strength of the rods was incomparably higher in comparison with the wooden ones, which preserved them during installation and further operation;

- Reinforced concrete supports made it possible to significantly increase the total load on the foundation, which made it possible to safely build multi-storey structures on such foundations;

According to the cross-sectional shape, such piles were mainly produced in three types - round, rectangular and hexagonal. Each of them was justified for certain specific soil and climatic conditions in the construction zone.

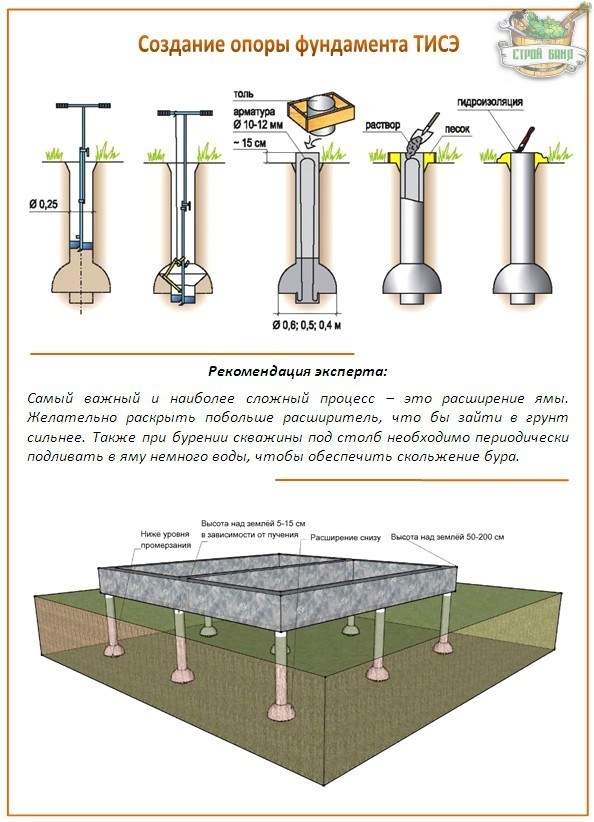

Gradually, the technology of the pile foundation was adjusted and changed significantly. Instead of using ready-made reinforced concrete supports driven into the soil, they began to be made directly in the construction zone, having previously drilled wells of a suitable diameter and depth. This technology has received the name pile-rammed foundation, which has become possible to produce even by non-professional builders.

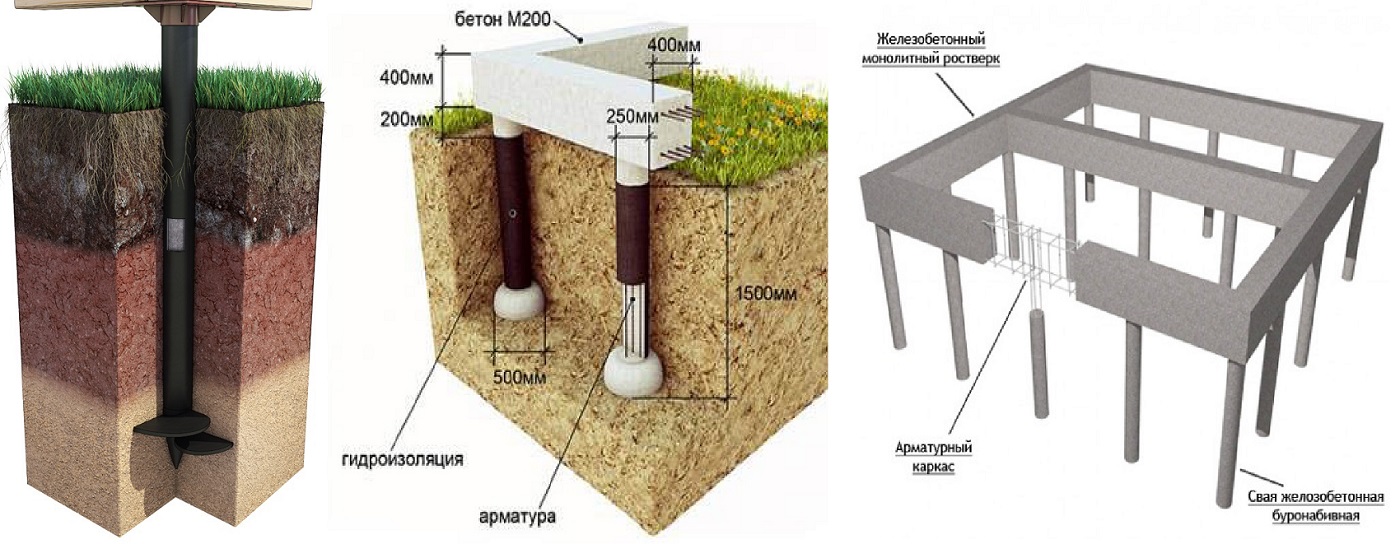

Varieties of piles

Another fairly young type of pile foundation was the foundations of a house on screw supports. They are steel pointed pipes equipped with helical blades from the lower working end, following the example of a screw. In contrast to this fastener, one or two threads are mainly used. The technology for installing a pile foundation on piles in the form of screws is similar to the process of screwing in a self-tapping screw. There are also multi-turn piles.

As noted above, building a foundation for a house on piles with your own hands or by the forces of professional workers is advisable for sufficiently loose, unreliable soils. The pile penetrates to the depth of the strong geological layer and rests on it, thus transferring the entire load from the structure. In a similar way, the rods work with their entire lateral surface, using the friction force.

Limitation of pile foundations

The limitation for the use of pile foundations are rocky soils, as well as those with a high level of rock outcrops. In this case, the introduction of supports of any kind will be complicated, and the design depth may not be achieved.

Preliminary work

Before making piles for the foundation, some preliminary work must be done. As part of this stage, some materials should be prepared, among which the following can be noted:

- It is necessary to stock up on material from which the formwork structure will be created in the future;

- You should also prepare a tape measure;

- A drill with nozzles for volume and length.

Jellied pile

In the process of preparatory work, it is necessary to make a clear marking of the perimeter, as well as calculate the required number of pile supports. Further, earthworks are carried out, which are performed using a hand drill. This is not the easiest of the stages, but it can be done with your own hands. A drill should be installed on the selected area, and without haste with rotational movements, they plunge into the depths of the soil.

It is worth noting that it is necessary to get the drill out of the ground every thirty centimeters, after which it is shaken off nearby. In the event that this condition is neglected, then after just one meter the drill will be simply impossible to reach. This is explained by the adhesion of too heavy soil mass. When the drill is fully inserted into the soil, you should take out and put one nozzle. In the future, the manufacture of piles for the foundation involves repeating such actions until the drill goes to the required depth. Before completing such work, you should put on specialized nozzles on the drill, which make it possible to expand the installation platform. By using this option, it becomes possible to achieve the greatest weight gain, which contributes to a tremendous increase in bearing capacity.

If the choice fell on a non-removable formwork structure, then a metal profile is perfect for this purpose. In addition, thanks to its design features, it is possible to achieve a significant extension of the life of the columns. In this case, only one drawback is noticed - the relatively high cost.

Another solution is an insulating box made of expanded polystyrene. This option is quite relevant in the northern regions. To equip the formwork under the piles for the foundation with your own hands, in any case, you can do it yourself. The height of the resulting structure should be approximately twenty centimeters. In cases where there are significant irregularities in the surface of the earth, then this value is taken as the nominal value. In other words, it is to this height that the rest of the pile supports are raised.

Scope of the foundation on piles

The use of a pile foundation is associated with the peculiarities of the area where construction work is supposed to be carried out. Most often, piles are used under the following conditions:

- The presence of weak soil, which is prevalent in peatlands and wetlands. Weak or unstable soil can be called a soil that loses its stability when penetrated by water. When building on such soil, it is necessary to transfer the load of the structure to a denser layer located deeper.

- High location of groundwater, which has a detrimental effect on the traditional foundations.

- Rough terrain on the site.

- Moving soil, which also negatively affects many types of substrates.

- Construction in regions with a predominance of constant low temperatures. The construction of buried types of foundations in such an area is simply impossible. The pile foundation reduces the amount of earthmoving work, such as digging pits or trenches, removing the released soil.

- The close location of any water bodies.

- The small construction budget does not allow to attract hired workers for the construction of the traditional base. The pile foundation is erected quickly and at minimal cost.

Foundation piles on problem soils ensure the reliability and strength of the structure. However, it is not recommended to build large objects on such a foundation. This is explained by the fact that the base on piles has a small bearing capacity.

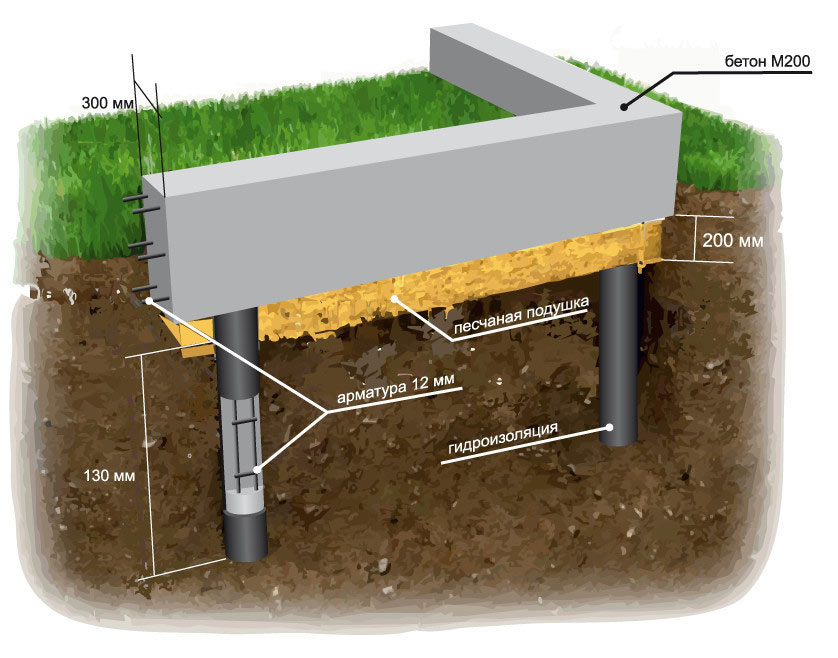

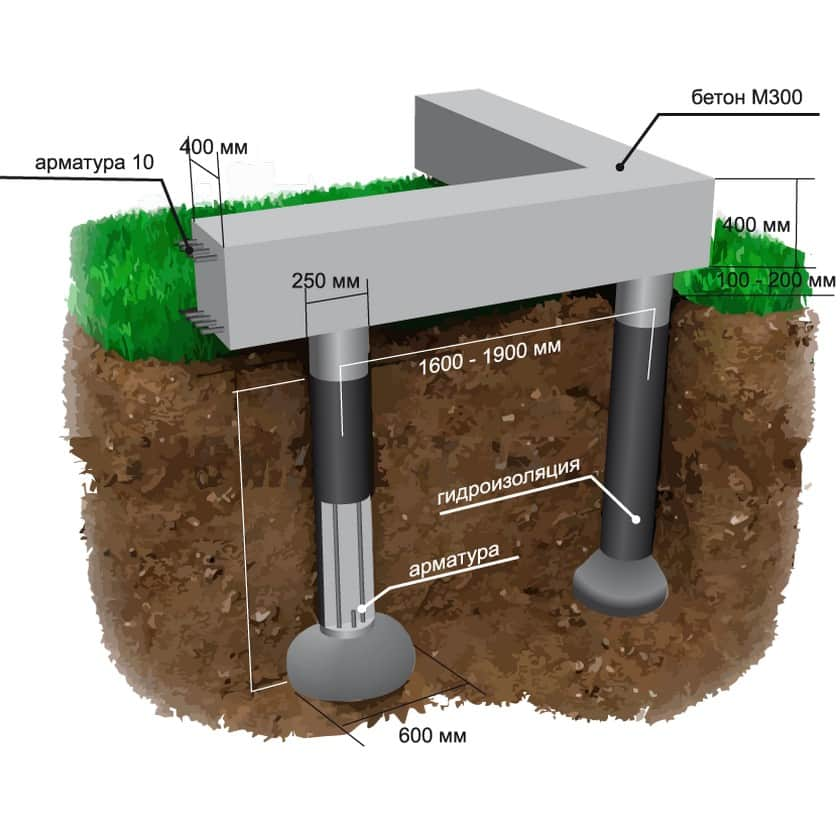

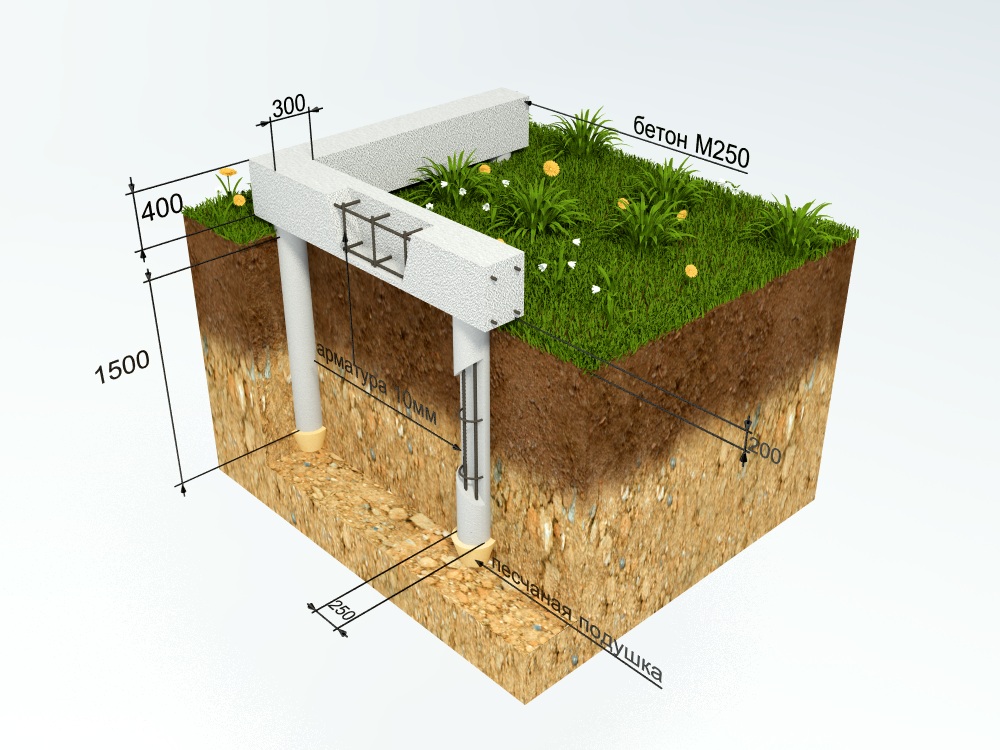

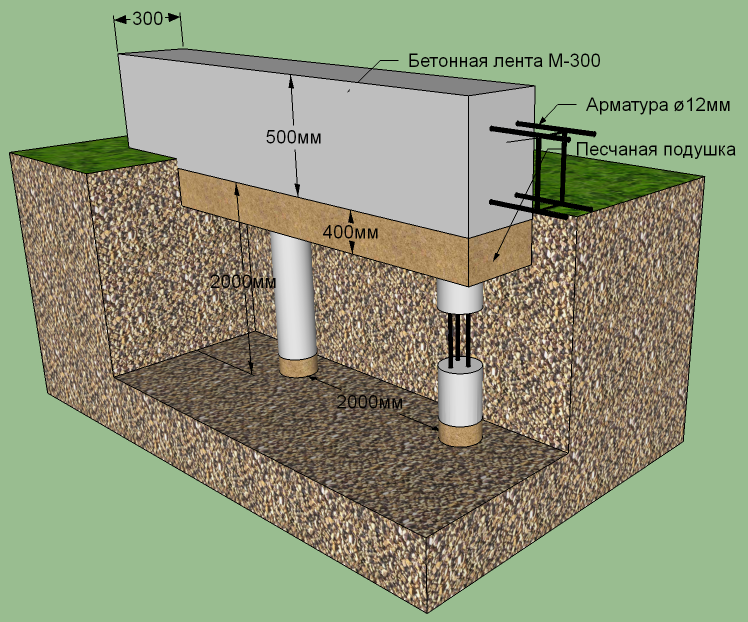

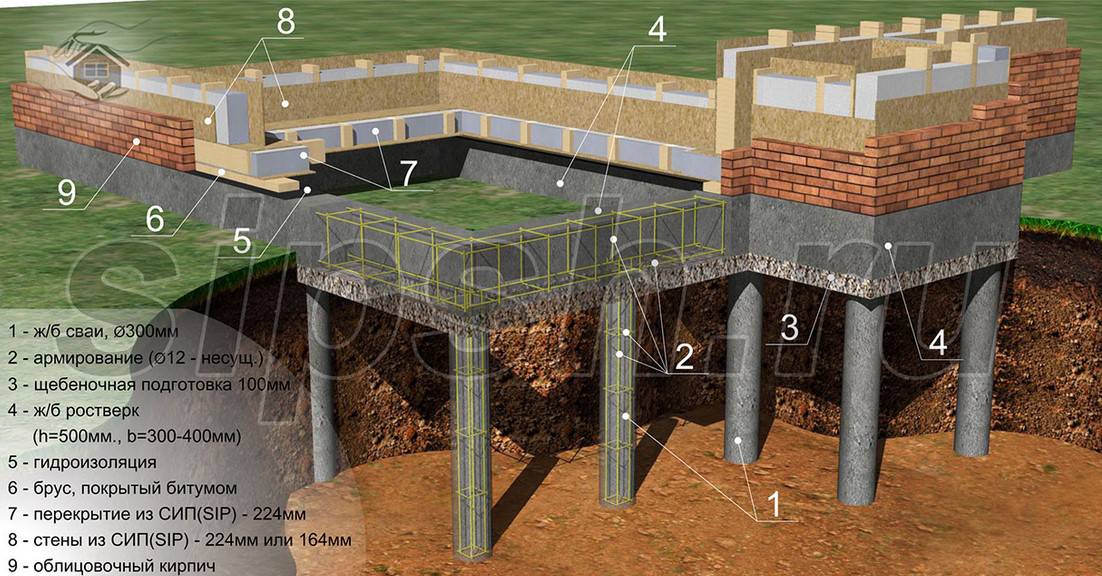

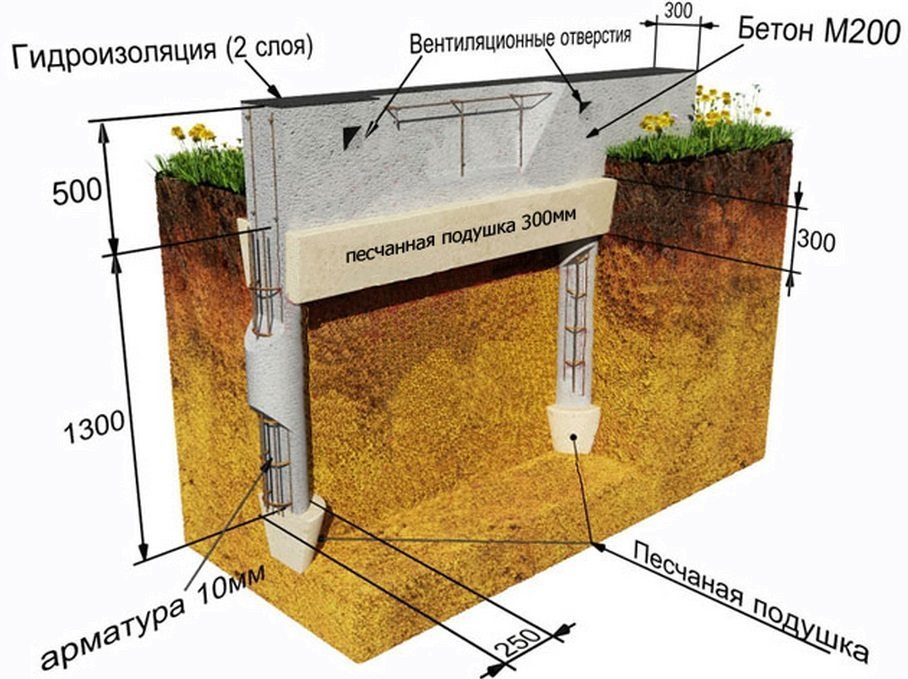

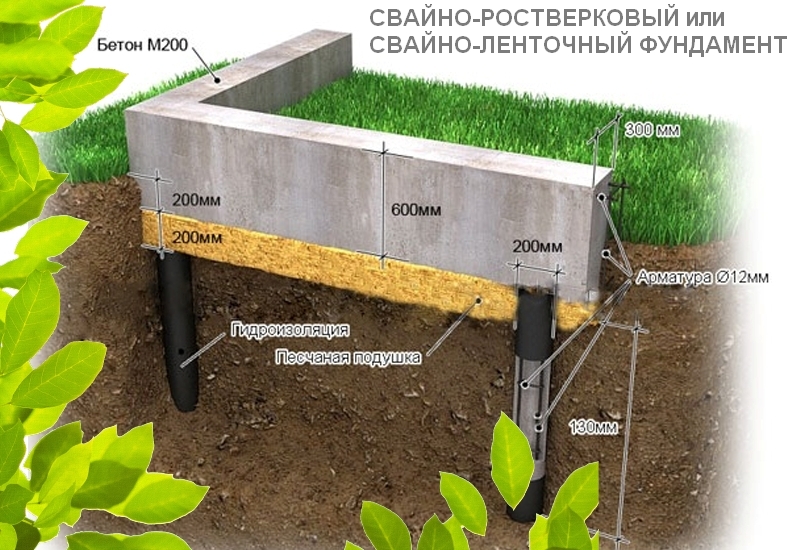

What is a strip foundation on piles?

The strip pile foundation combines the advantages of two types - column and flat strip foundations. The first one performs the main work on interaction with the ground, and the second one ensures the distribution of the load of the walls of the structure.

At the same time, the material requirement for materials for the construction of the foundation is significantly reduced and labor costs are reduced.

Application area

Piles and strip foundations are suitable for the construction of a wide variety of buildings, from fences to brick houses, wooden beams and more modern materials such as aerated concrete, foam blocks, etc.

When using logs, they themselves can act as a pile-based grinder. If the structure consists of small elements, a rover is necessary.

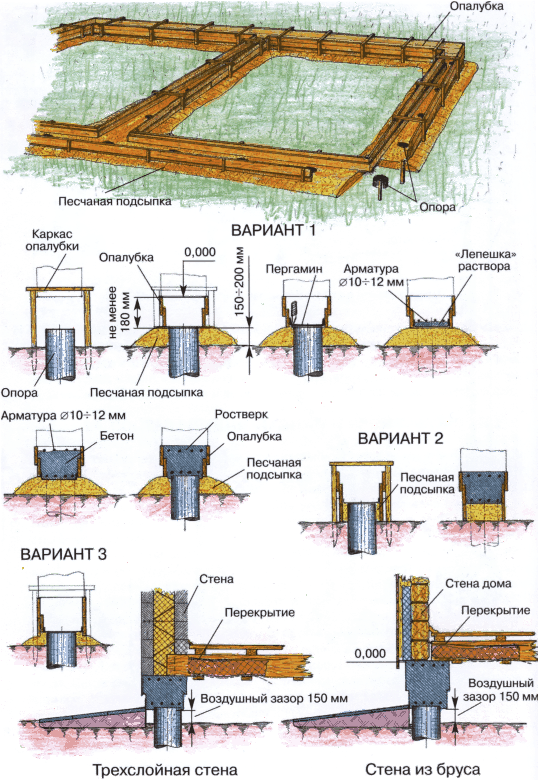

There are several options for pile and strip foundations. The differences lie in the design of the lattice and the manufacture of the piles. In the simplest case, protocols can be used as such.

It's a short-lived material, but it's cheap. Usually coniferous wood is used and impregnation with mixtures is mandatory to protect against mold, fungi, etc.

Piles are not installed without the use of special equipment, so there is no need to talk about their use in independent work. And delivering them is not easy. ...

Monolithic

The monolithic foundation includes the manufacture of a monolithic reinforced concrete tap of the coupler, regardless of the type of pile.

This allows you to build almost any building from any modern material.

The load from such a foundation can be very high, although the load is slightly higher than with simpler options.

Screw

Another possibility is the use of prefabricated auger piles.

These are iron structures with threaded blades at the end.They will remind someone of a screw, a drill, but they are really screwed into the ground.

This type of pile is produced with a diameter of 57 mm and a length of 1650 mm. Given the corrosion resistance of the material from which the piles are made, it is not recommended to use them on soils with a high acid content (pH less than 5.5).

It turns out that attention to the acid-base balance is also important when building a pile foundation. For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows you to go below the soil freezing line

For building a house, the optimal stack size is 108 or 133 mm in diameter and 2500 mm in length. After all, it is easier to cut off the surplus than to weld the missing one, especially since this length in most cases allows it to fall below the soil freezing line.

The benefits of this type of pile include, but are not limited to, the following benefits

- A minimum amount of excavation is required.

- This is a little time consuming.

- High speed when performing work.

- High "stability" in the ground due to the narrow entrance to the ground.

The disadvantage of piles is that the piles require a place for screwing in, which makes them difficult to install near other buildings, as well as low corrosion resistance.

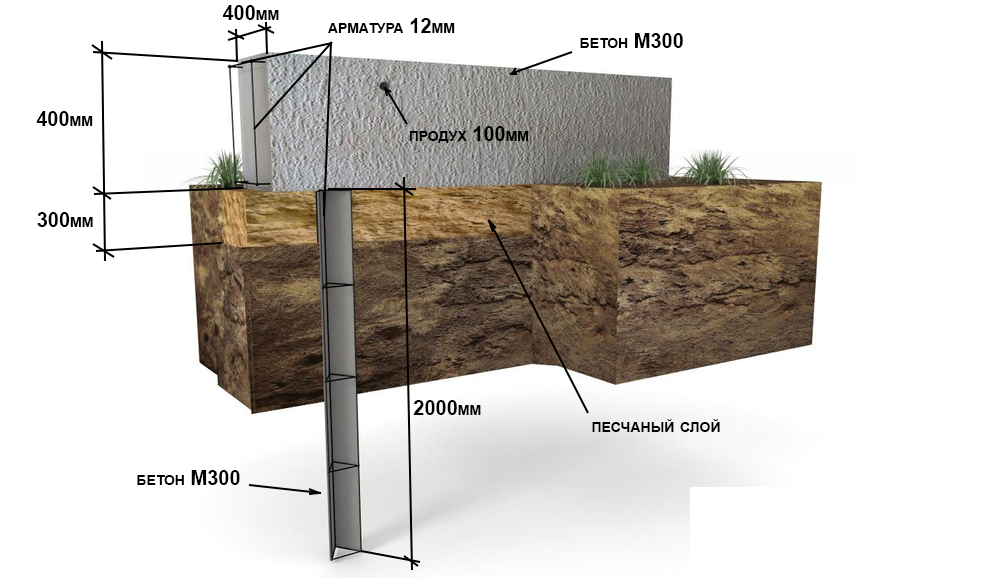

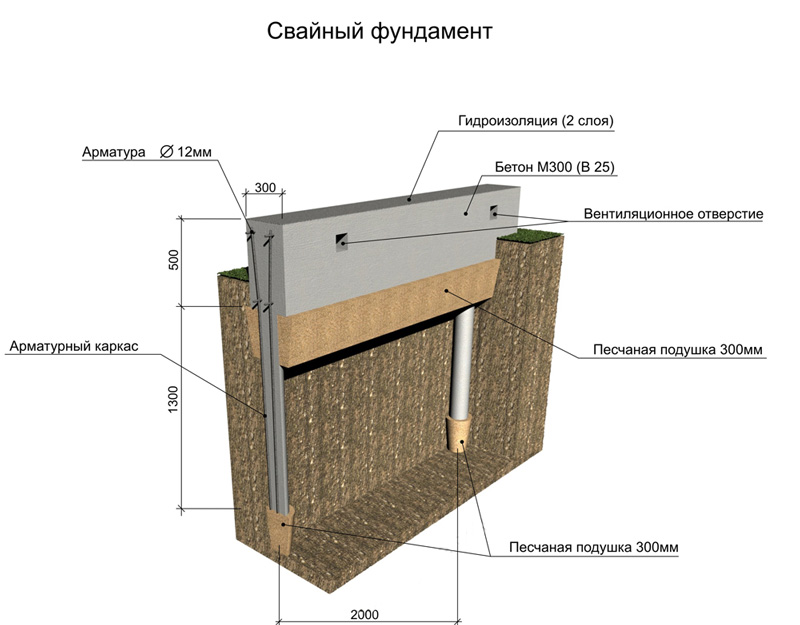

With bored piles

These piles are manufactured locally. A hole is drilled in the pile, formwork is installed, reinforcement is installed, if necessary, and concrete is poured.

This option applies to almost all soil types. The main thing is that the depth of the piles should be greater than the depth of soil freezing in the area.

The benefits of this type of fund include, but are not limited to, the following benefits

- Low cost.

- Simplicity and speed of installation.

- You can do without special construction equipment.

Among the disadvantages, it is especially difficult to maintain the required accuracy when drilling and aligning the upper pile belt.

Regardless of the pile depth, approximately 10 cm of sand should be poured into the ground as a cushion.

Finishing

The installation of the foundation can be combined with insulation. This will improve the insulation parameters of the building and help reduce the cost of maintaining comfortable temperature conditions.

First, the crate is fixed between the piles. It can be made from galvanized metal profiles, wooden beams. For cladding, basement siding, profiled sheet is suitable. The insulation layer is fixed from the inside.

Artificial stone finishing

Artificial stone finishing If you build a brick wall, the cladding can be made from plaster

If you build a brick wall, the cladding can be made from plaster

When studying the question of how to finish the basement, remember to maintain good waterproofing between the base and the building. If concrete, other heavy materials are used for the construction of the wall, it is necessary to add the appropriate weight to the calculation of the loads. If necessary, increase the diameter of the pillars, or reduce the step of their installation.

What soils are they suitable for?

The immersion of screw piles is carried out to a sufficient depth to exclude the effect of vertical loads of frost heaving. Only lateral impacts remain, which, due to the small contact area, are not capable of exerting a decisive effect on the supports.

Therefore, when determining the suitability of the soil, it is customary to consider only the mechanical properties.

The most suitable types are the following types of soil (in descending order of suitability):

- Sandy.

- Sandy loam.

- Loams.

- Clay.

Rocky and rocky-clastic species are absolutely unsuitable soils. In addition, biogenic types are contraindicated - peat bogs, or loose subsidence soils.

Care must be taken when dealing with heavily watered areas subject to strong seasonal fluctuations in groundwater levels. During construction in such areas, it is necessary to carry out test drilling and increase the immersion depth to the maximum.

During construction in such areas, it is necessary to carry out test drilling and increase the immersion depth to the maximum.

Advantages and disadvantages of the pile screw foundation

Screw piles are now widely used in the construction of private houses, but before choosing a house on a screw pile foundation, it is necessary to study their positive and negative sides. The pluses include:

- strength due to the use of steel as raw material;

- durability, the service life of such a base can reach 150 years, subject to the manufacturing and installation technology;

- low cost of the product itself and its installation;

- simplicity and high speed of installation;

- the ability to use on terrain with difficult terrain, for example, on slopes;

- ensuring reliable operation on poor soils, such as sedimentary rocks, swampy areas;

- the ability to reuse if necessary.

Simplicity and speed of installation is possible due to the fact that:

- lack of preliminary soil development (digging trenches or pits);

- there is no need for complex special equipment;

- simplicity of technology does not require special skills and knowledge;

- unlike concrete foundations, you do not need to wait 4 weeks until the structure is fully ready.

All these positive characteristics made it possible to obtain mass distribution of screw piles, but do not forget about the negative aspects. Especially if you can prevent their consequences in time.

Pile screw foundation video

Pile screw foundation cons:

- corrosion of metal;

- limited bearing capacity;

- impossibility of installation close to the walls of an existing structure;

- the impossibility of arranging a basement in the house.

Corrosion can be avoided by treating the material with special compounds. With individual construction, there are no large loads on the foundation, so the second point does not become essential. With an impressive list of advantages, not a small number of disadvantages, which are rather operational features and are completely preventable, screw piles become an excellent support option for a private house.

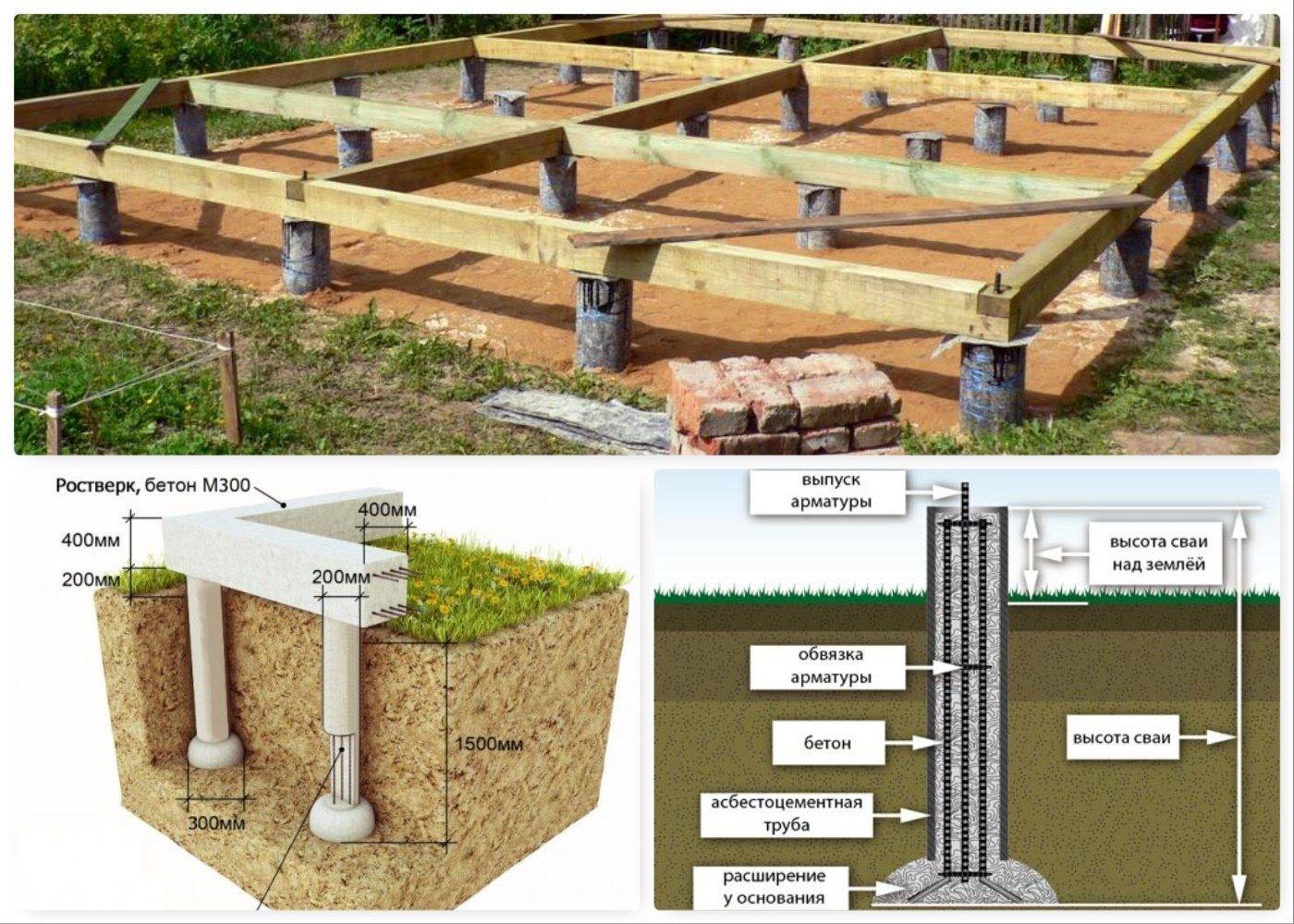

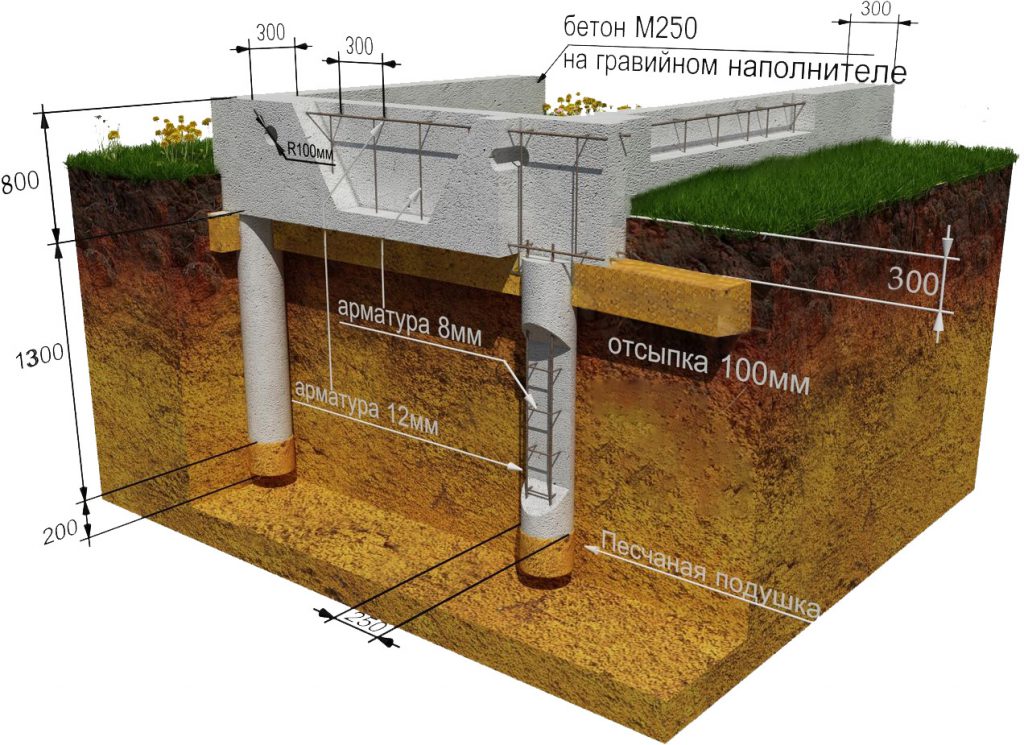

How to pour piles under the foundation

To carry out high-quality pouring of piles under the base of the house, it is necessary to follow a certain procedure:

Filling piles with concrete

Prepare the site and mark it. The construction site is leveled using a level. The places where the installation of piles is planned is marked. It is obligatory to have a support at the corners of the house, at the points of attachment of load-bearing walls and partitions.

Holes with a diameter of about 30 cm are made with a manual or mechanical drill for pouring future piles. The depth of the holes is selected in accordance with the type of foundation and the condition of the soil

It is important that the bottom of the hole is below the level of soil freezing.

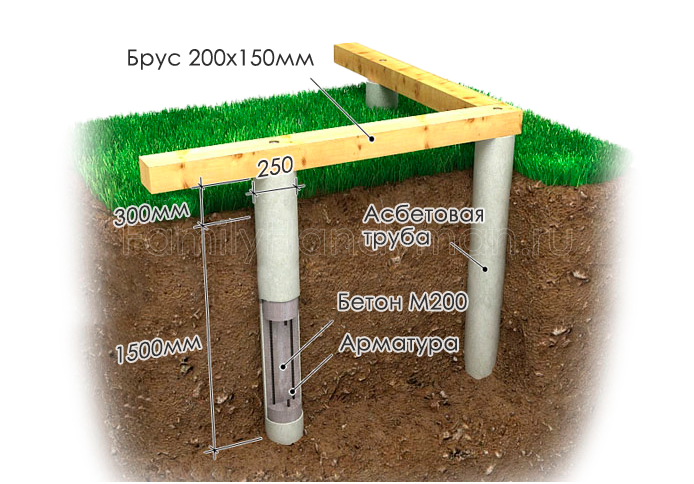

Non-removable formwork is being installed. With a sufficient construction budget, you can use asbestos-cement or steel pipes

To save money, you can build a formwork from roofing material. To do this, the material must be rolled into a pipe of a given diameter. The prepared formwork is lowered into the hole so that it rests against the sand cushion. The shell formed in this way prevents the soil and piles from freezing in the cold season. In addition, the structure prevents moisture from entering the concrete. When using metal and asbestos-cement pipes, treatment with a waterproofing solution is required.

The installed formwork is filled with a small amount of liquid concrete and raised slightly. As a result, a cavity is formed under the pipe, into which liquid concrete penetrates.After the mixture hardens at the bottom of the hole, a kind of pillow is obtained. It multiplies the bearing capacity of the foundation.

The frame is installed from the reinforcement. For its manufacture, steel rods with a cross section of 8-10 mm are used. Their number directly depends on the pile thickness. Most often, 3-4 rods of reinforcement are tied together with soft wire, installing transverse jumpers along the entire length of the frame. The frame is also lowered into the hole. Reinforcement of the well allows you to protect the future pile from the impact of the soil from the sides, which can lead to the fracture of the pile.

The prepared well is filled with high-quality concrete mortar. The concrete must be periodically compacted using a special vibrator. You can use a crowbar or a piece of reinforcement for these purposes. In both cases, the mixture is compacted by removing air. It is best to fill the piles with concrete in one go, this will make the pile a solid monolith.

Strapping functions

The piles themselves are pillars built into the ground, which, without additional strapping manipulations, do not exclude the appearance of deformations. So that during operation there are no problems in the floor of the house, be sure to use a strapping of screw piles with a bar. The pillars are connected to each other and receive a solid and reliable foundation that can withstand the planned load. Pile strapping is called a grillage.

The screw elements of the pile foundation are hollow tubes made of high quality steel. The ends of the pillar have conical blades with which the product is screwed into the soil. The pile has special holes. Before the construction of the wall, it is imperative to perform a strapping from a bar on screw piles. Then the entire foundation structure is transformed into a single solid system that can withstand the load intended for the foundation.

The screw elements of the pile foundation are hollow tubes made of high quality steel. The ends of the pillar have conical blades with which the product is screwed into the soil. The pile has special holes. Before the construction of the wall, it is imperative to perform a strapping from a bar on screw piles. Then the entire foundation structure is transformed into a single solid system that can withstand the load intended for the foundation.

Types of piles

By screwing the piles into the soil much easier

By screwing the piles into the soil much easier

Pile-based foundations are classified into several basic types that are considered to be widely used. To have an idea of each of the types, you should read in more detail:

- The base of the pile-screw type is installed under the influence of screwing into the soil structure. Installation can be carried out on almost any soil. This pile - screw type of construction has many positive characteristics, due to which it is widely used in practice. For a full-fledged device with your own hands of a screw foundation, step-by-step instructions will be useful. The process of installing the pile - screw base can be performed using construction equipment or manually. The second option is the most budgetary, so for private suburban buildings you will need an additional pair of hands.

- The construction of a pile-driven type of foundation in private construction can be found quite rarely, since the cost of installation is expensive. Such a basis requires the obligatory involvement of large construction equipment; not every owner can afford this action. But, despite its high cost, this type of foundation has many advantages, and the service life is quite long.

- The pile-bored type of foundation is one of the budget options. According to experts, it is much easier to do such a foundation on piles with your own hands than the above options. Due to the fact that the installation of piles is carried out directly on the construction site, all costs for transportation and use of large construction equipment are deducted. Based on the facts, you can easily make your choice of a base for a residential building.