Types of pile foundations with grillage

Due to the variety of construction technologies, materials used for pile-grillage foundations, there is a special terminology:

- base - a layer perceiving a vertical load, lying below the freezing mark;

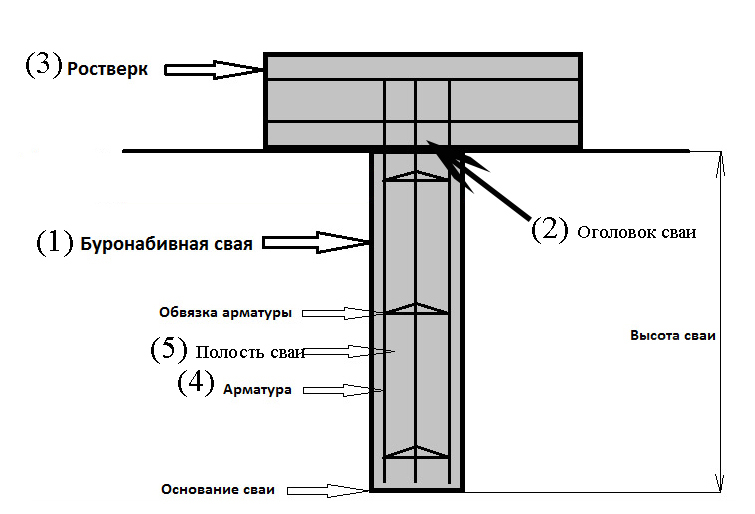

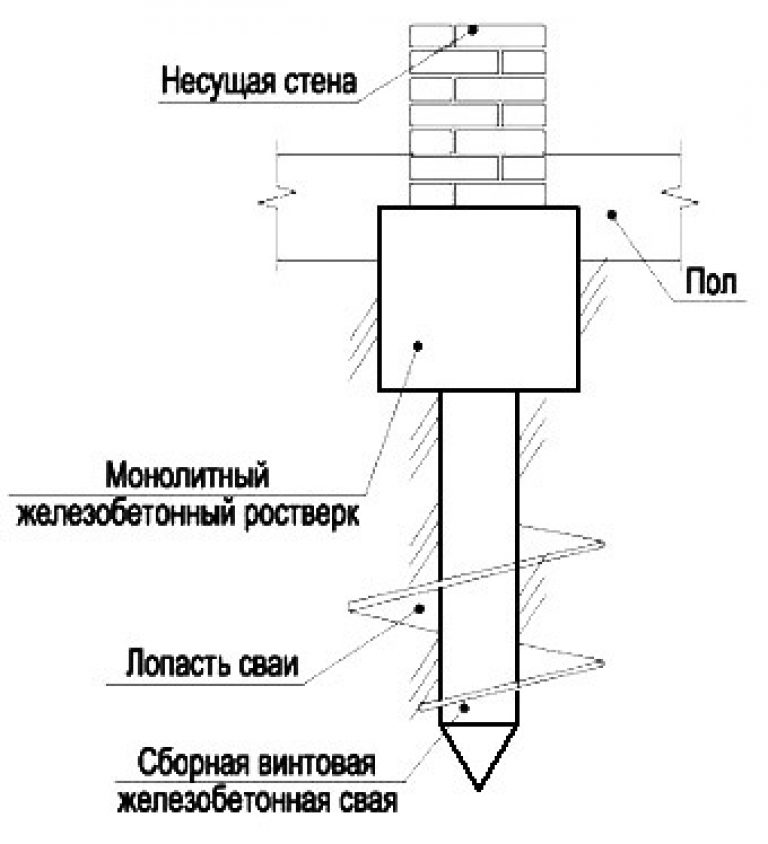

- pile - a vertical structure made in the soil or immersed in it;

- pile field - a group of piles for one structure, building;

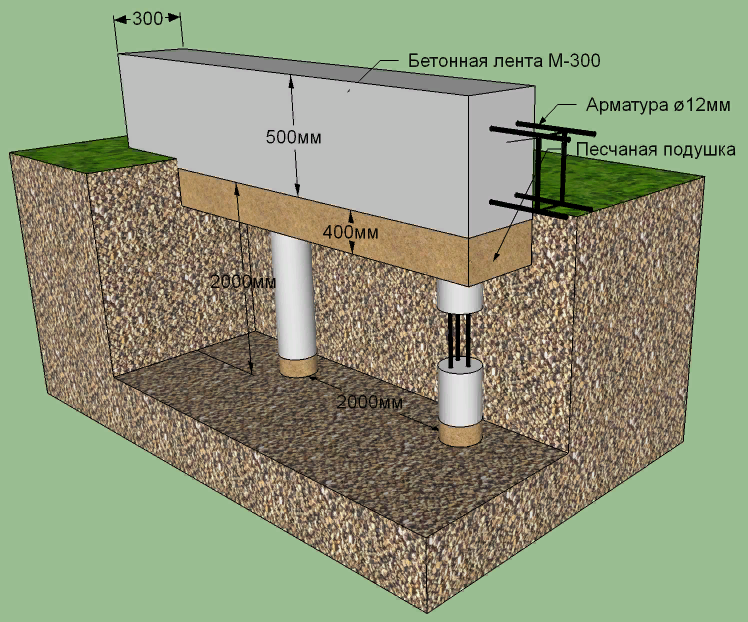

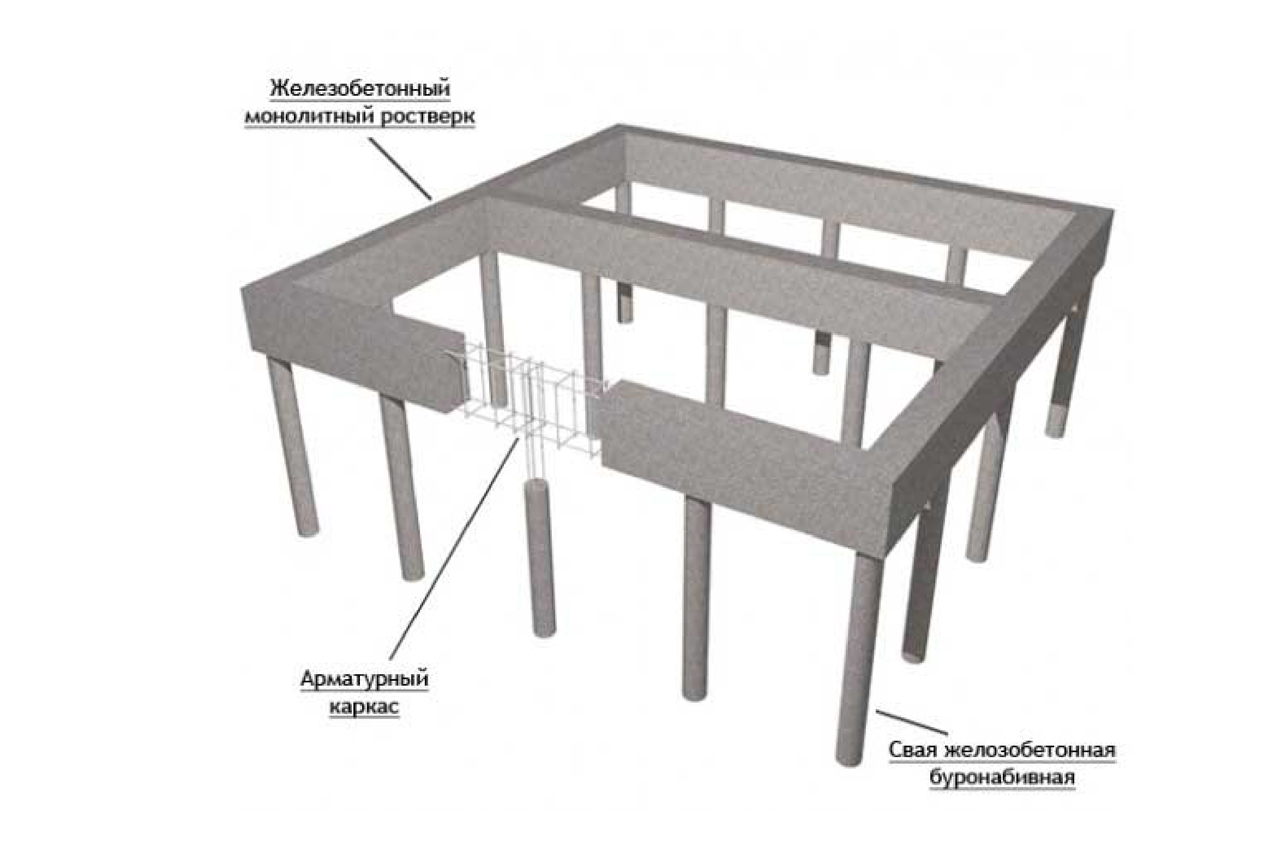

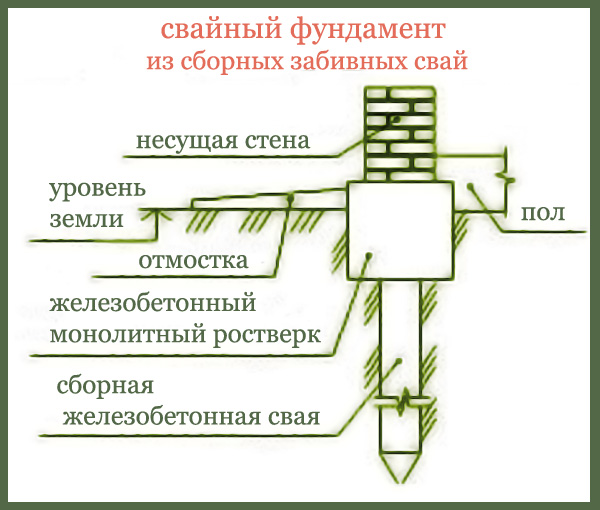

- grillage - a monolithic or beam structure along the pile heads (slab, lattice, frame or beam);

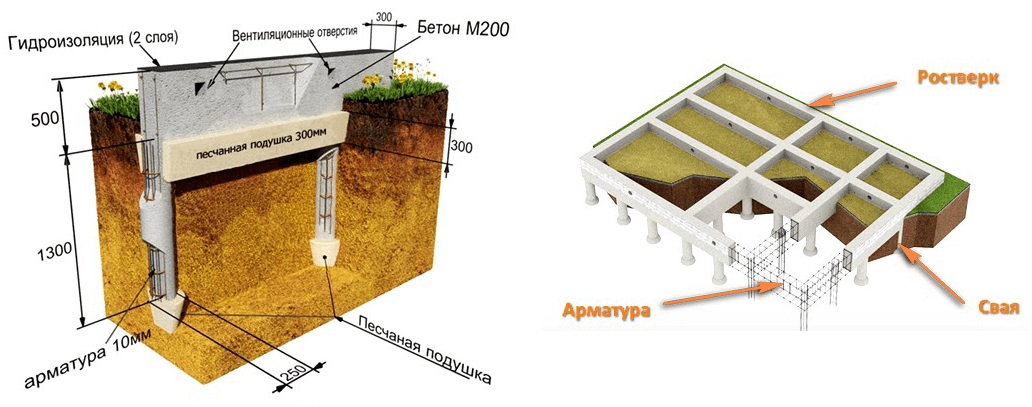

- low grillage - buried in the soil or located at the level of the zero mark;

- high (hanging) grillage - raised above ground level;

- the bearing capacity of the pile is the sum of the soil resistance on the side surfaces and under its lower end.

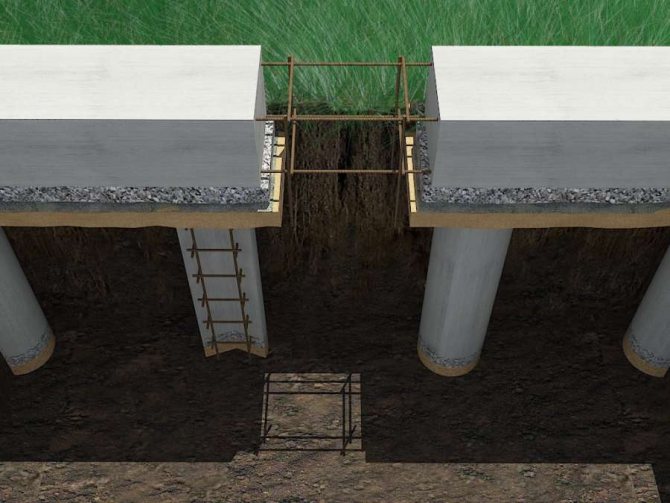

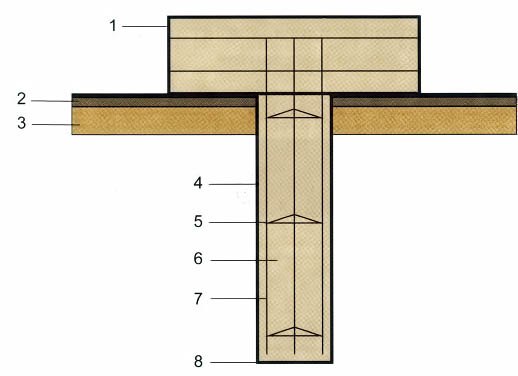

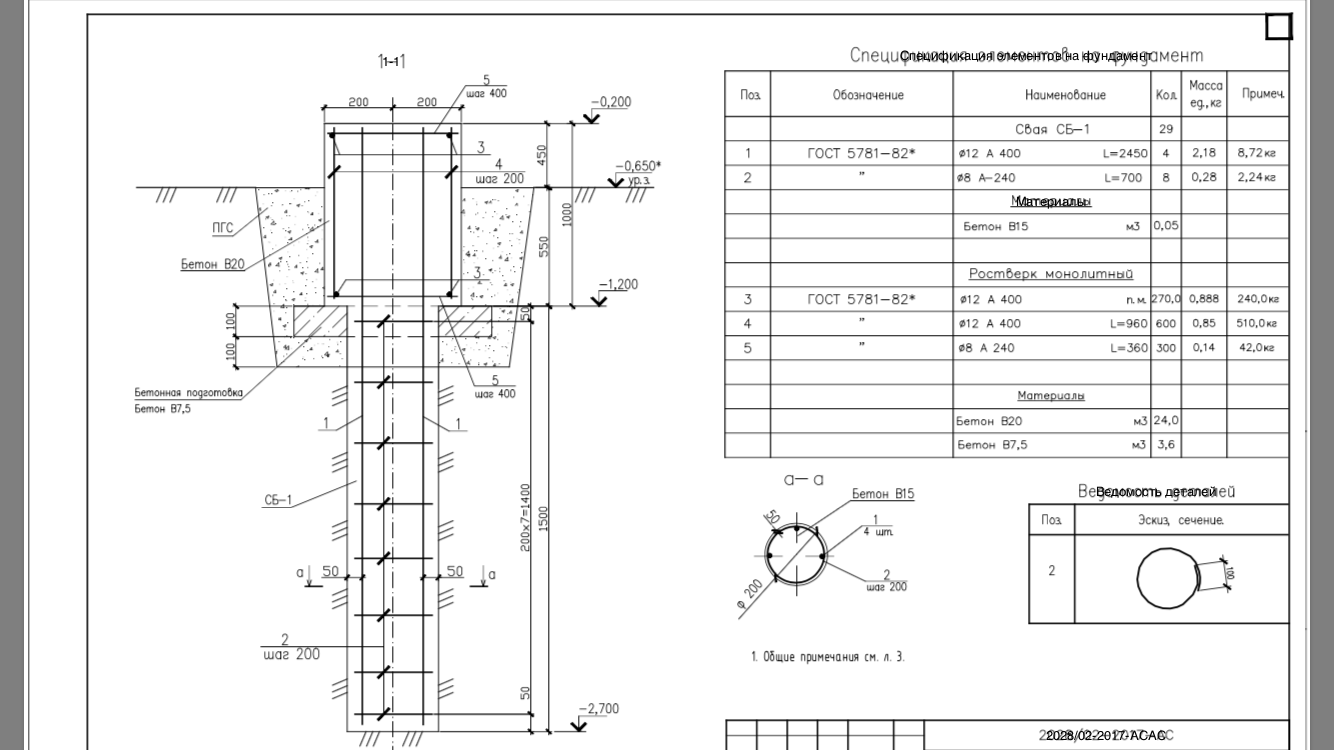

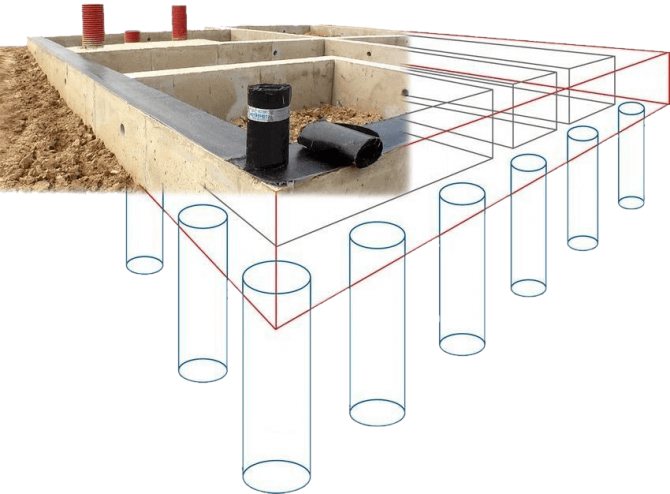

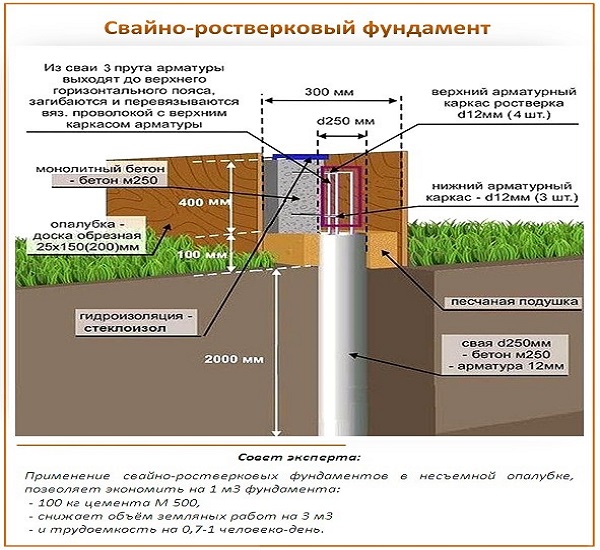

Bored foundation diagram

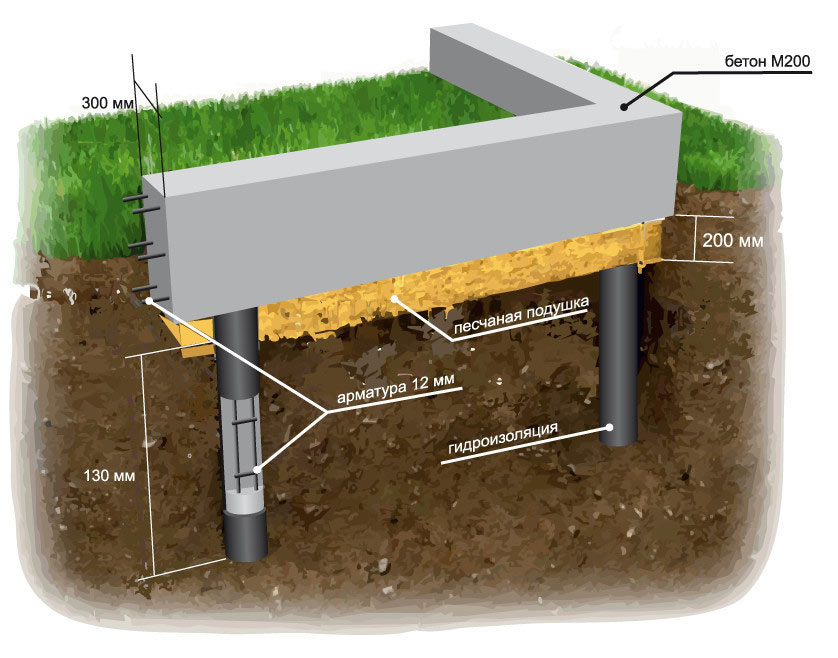

By material, bored piles are classified as follows:

- composite - reinforced concrete inside steel or polymer permanent formwork (large diameter pipe);

- rubble concrete - in the lower part of the pile, stones are sunk into concrete (maximum size 15 cm, strength not lower than the design grade of concrete), the upper part (0.5 - 0.7 m) is filled with clean concrete, reinforcement is usually along the entire length (except for backfilling);

- reinforced concrete - the pile is poured entirely of concrete with reinforcement along its entire length (usually not stressed);

- concrete - reinforcement only in the upper part for strapping with a grillage.

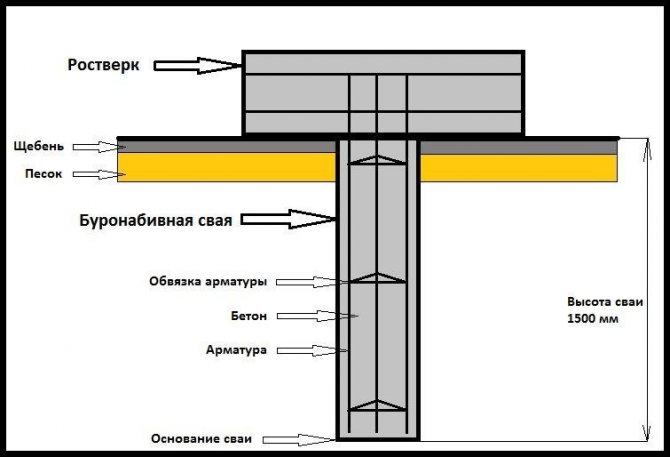

The pile shaft can be made in several ways, even when using the same materials. For example, if a hole in the ground is filled with concrete with a reinforcement cage placed inside, the pile will be shellless.

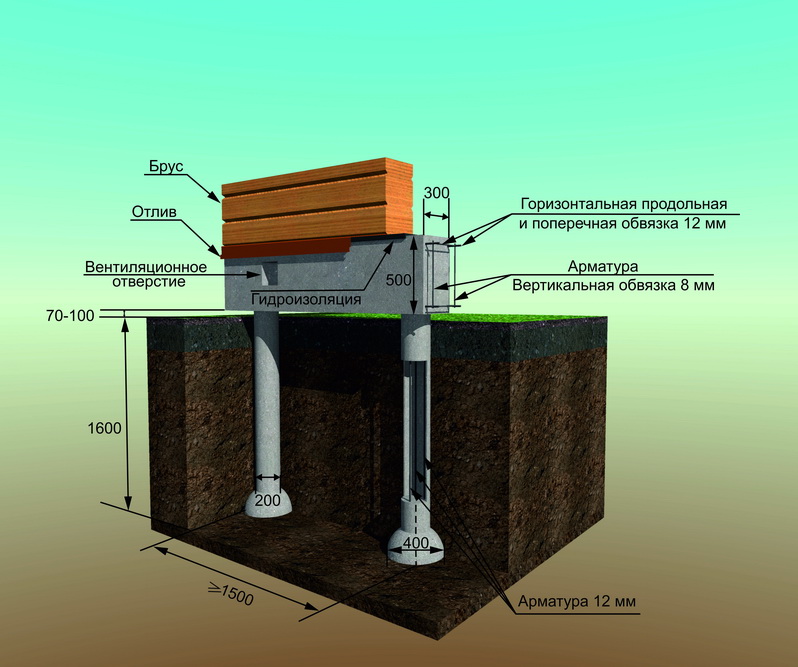

Pile scheme with expansion - TISE.

If the pile reaches the bearing layer, it is poured into a polymer or metal pipe, which does not bear loads and remains in the well for the entire period of operation (non-removable), acting as waterproofing, a pile with a shell is obtained.

If the temporary formwork is removed after pouring, the pile is called in a temporary shell, the method is a vertically movable HVDC pipe. If the formwork remains inside the well and performs load-bearing functions, the pile is called pipe-concrete.

To increase the bearing capacity, the pile base can be broadened with a monolithic base. The sole is drilled out with a special tool, an explosion or concrete piles. In the general grillage, the head of the bored pile can have a sliding interface or rigid embedment into a monolith.

If, during geological exploration of the site, the occurrence of the bearing layer deeper than 3 m is revealed, bored piles will cost an individual developer more expensive than the screw foundation of a SVF or a floating slab. In this case, hanging piles are more effective, the bearing capacity of which depends on the density and porosity of the soil. If the frictional forces on the side surfaces are insufficient, other foundation options should be considered.

Unlike a strip foundation, the depth of the grillage does not depend in any way on the characteristics of the soil:

- the tape rests on the ground with the sole, there are lateral shear loads from the heaving forces;

- the grillage does not rest on the ground, it is created exclusively for tying piles, distributing loads, supporting wall materials (especially important for foam blocks, bricks).

After pouring a monolithic grillage, an air gap is created between the soil and its bottom to compensate for the heaving forces. In low grillages, it is protected on the sides with sheet materials in order to avoid shedding the earth, filling this space with heaving soil.

Considering the above, a monolithic grillage on the heads of bored piles is effective in the following cases:

- light buildings - budget savings of 30-50% in comparison with a slab, strip foundation for log cabins, half-timbered, frame, panel (SIP technology), panel cottages;

- difficult terrain - slopes with a height difference of more than 1.5 m in the building spot;

- high groundwater level - piles can be poured into the shell with a slight rise in water or by temporarily pumping it out of the well;

- swamp, coastal zone - excavation for other types of foundations is not possible.

Piles are economically effective in individual construction only at a depth of 3 - 5 m, which is usually sufficient for lightweight structures. With normal geology on flat areas, piles cut the budget for the construction of brick, concrete buildings in half. Only in this case, the foundation meets the requirements of SP 24.1333, which regulates the design of pile foundations.

Calculation of the pile-grillage foundation

The calculation of a combined base with a reinforced concrete grillage consists of two parts:

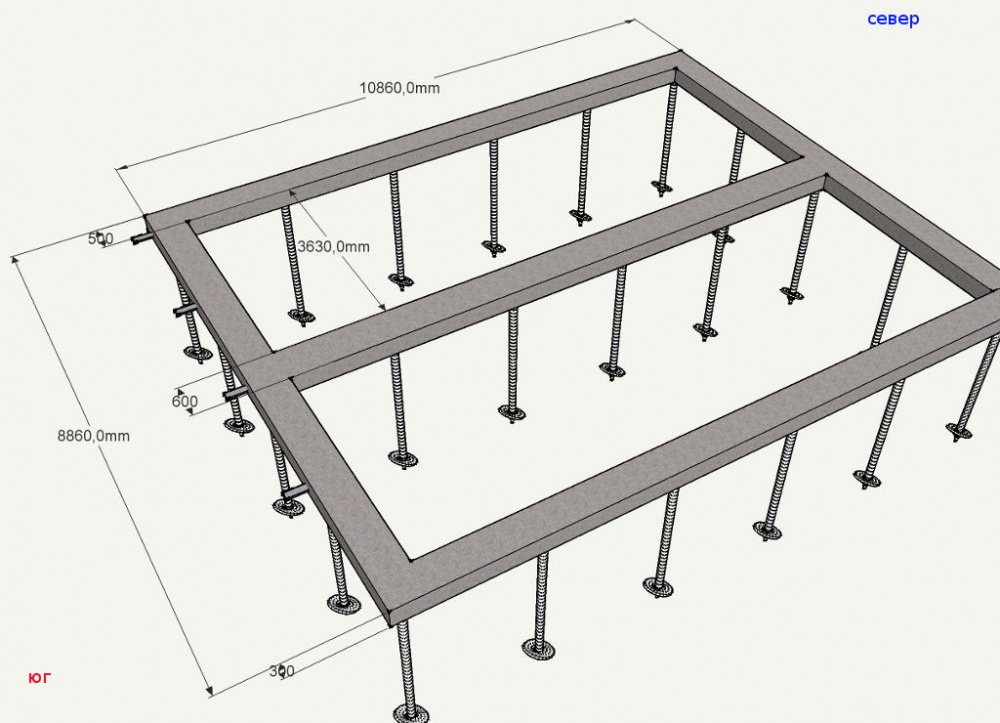

Calculation of the pile field

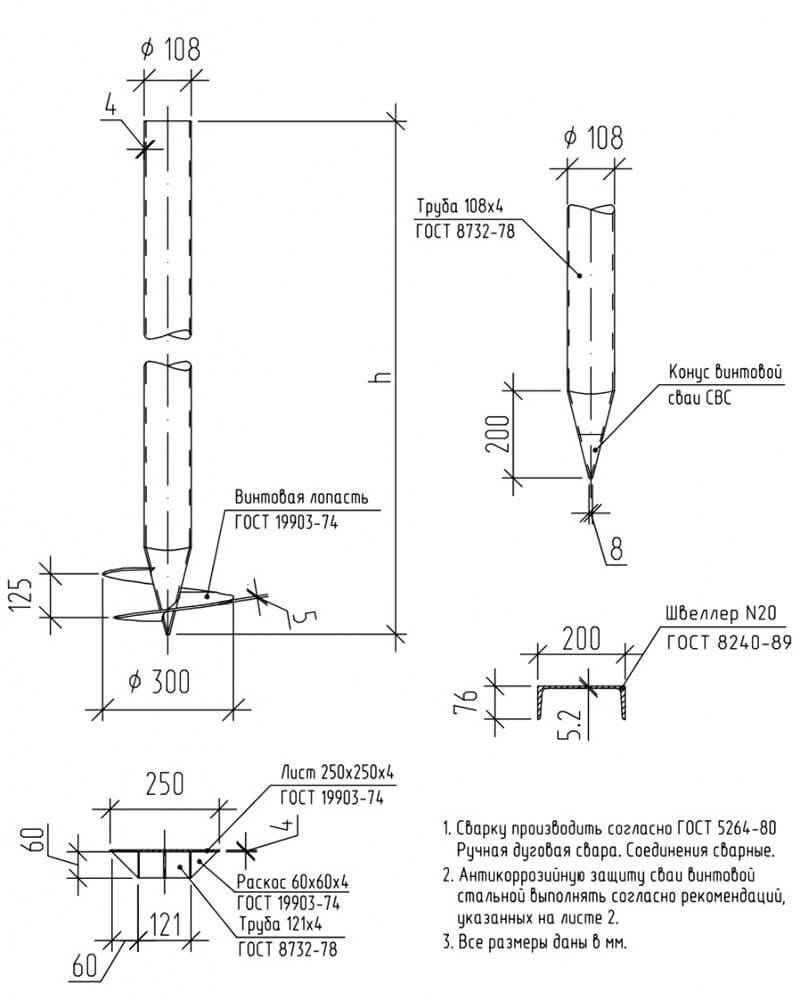

The structure and calculation principle depends on the type of supports used. For screw supports, in the calculation, their diameter, size of blades, depth of laying, distance between piles are determined. When calculating bored supports, it is necessary to determine the depth, diameter and pitch, as well as make an additional calculation of the reinforcement.

Calculation of reinforced concrete monolithic grillage

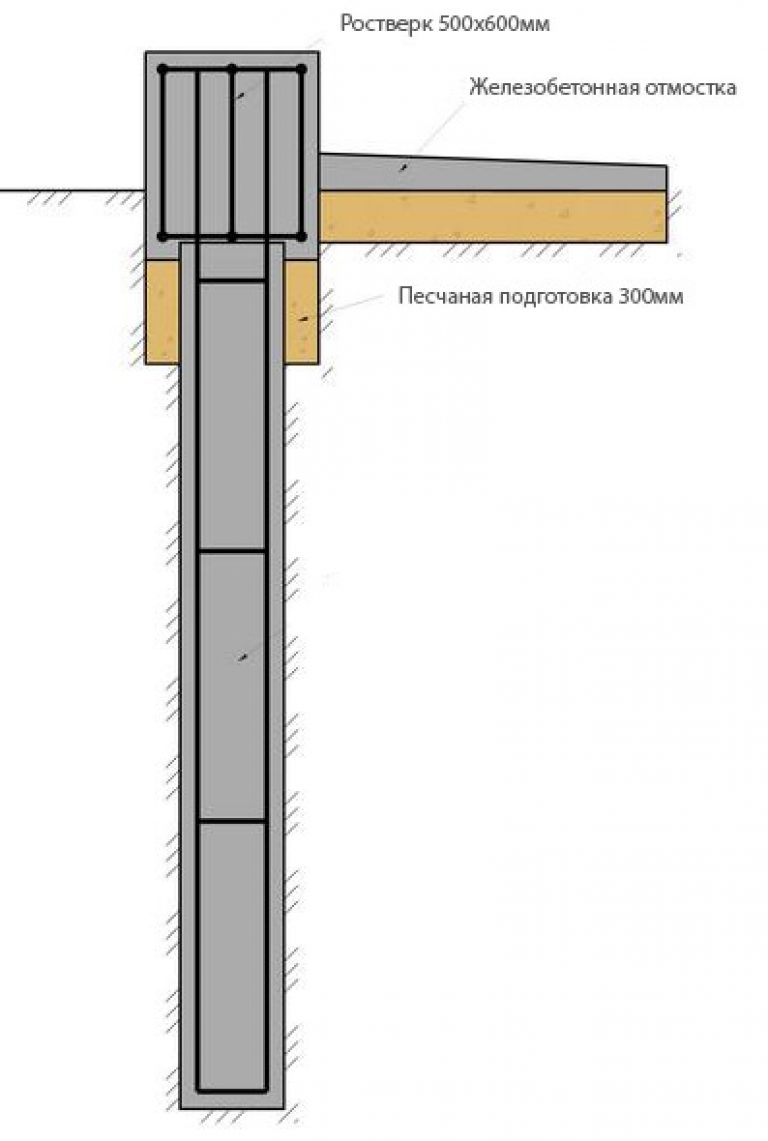

The purpose of calculating a monolithic grillage of a pile foundation is to calculate the punching shear of the structure, its ability to withstand bending loads and to determine the strength of the section when exposed to shear forces. The calculation process is described in detail in SNiP 3.03.01-87, JV "Design and construction of pile foundations" and GOST R 52086-2003. In the field of private housing construction, it is not advisable to make these complex calculations. It is enough to determine the main dimensions of the strapping for the pile foundation:

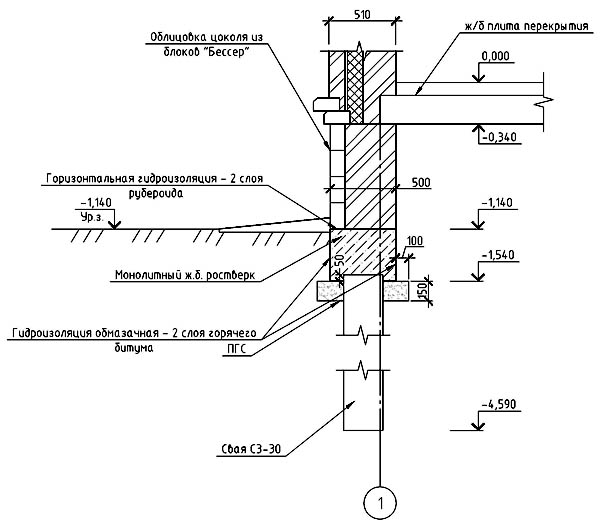

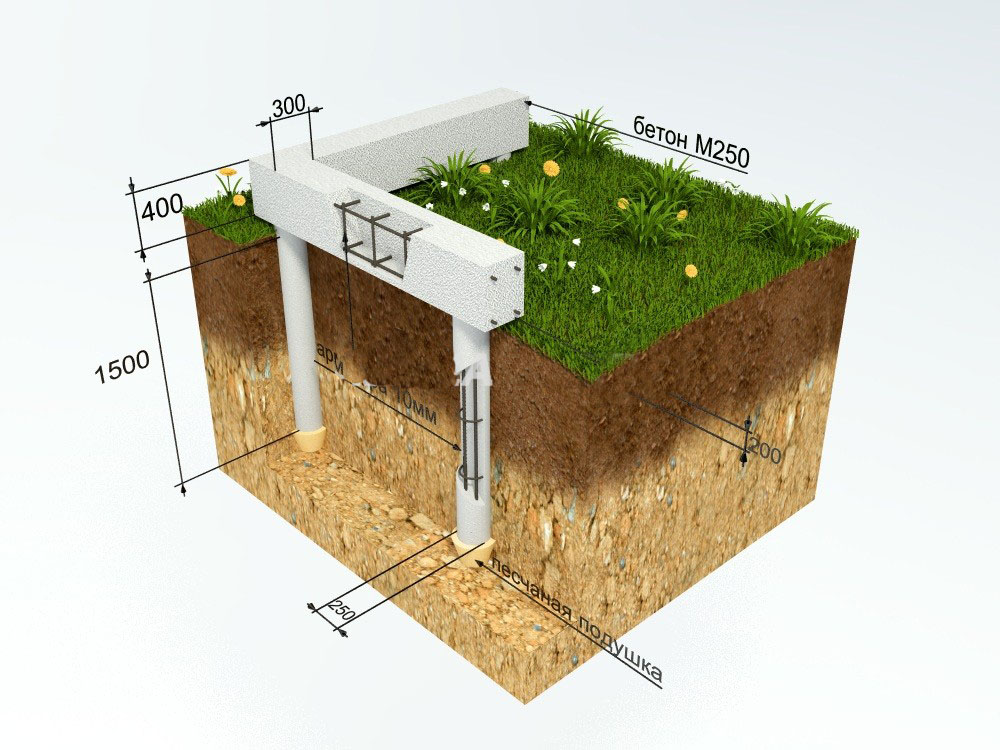

The depth of the grillage

The depth of the laying directly depends on what type of foundation was chosen. Recall that relative to the ground level, the pile-grillage foundation can be hanging, elevated, shallow and deeply buried. The pile part of the combined pile-grillage foundation is laid at least to the depth of soil freezing. The optimum depth of the grillage is 10-30 cm below the zero level. The heavier the mass of the house, the deeper the grillage should be.

If the grillage is not deep enough, then the foundation can shrink, which will lead to the disappearance of the air gap between the soil and the monolithic tape.

Width of the grillage of the pile foundation

The width of the strapping monolithic tape is determined by the formula:

B = M / L * R

where: B is the width of the tape;

M is the mass of the house (materials + loads);

L is the length of the grillage;

R is the coefficient of the bearing capacity of the soil, determined according to the tables in SNiP.

Height of the pile foundation grillage

The height depends on the type of building material from which the house will be built. For aerated concrete, a height of 40 cm is sufficient, for silicate blocks - 50 cm, for heavier materials - 60 cm. In relation to the width, the height of the grillage should be 90-110%.

If the grillage is at the same time the basement of the house, then it should be made higher - 50-60 cm. This is necessary for the device of vents, which are located at a height of 30-40 cm from the zero mark.

An example of calculating a grillage for a pile foundation: a house is being built from aerated concrete with a bearing wall length of 100 m on dense sands using screw supports with a diameter of 108 mm. The mass of the house is 55 tons. The deepening of the grillage, taking into account the mass of the structure, is taken as 0.2 m. We calculate the width: B = 55 t / 100 m * 75. The width is 41 cm (according to another calculation, 10.8 cm + 30 cm = 40, 8 cm). The height of the grillage will be 40 cm, of which 20 cm will be buried underground.

Payment

The process of installing any foundation is based on clear and dry numbers.No matter how much you would like to think otherwise, the slightest mistake in installing the foundation - and you can provide yourself and your structure with constant repairs with earthworks and a lot of financial costs. Avoiding this is simple - just take into account the widest possible range of factors that can affect the reliability of your foundation. This, of course, also applies to the foundation on bored piles.

Here is a complete list of parameters that, in one way or another, affect the safety of installing a bored foundation:

- the area and length of the foundation / grillage, as well as its height, the area of the lateral surface and the foot - this way you can calculate the average pressure from the building on a separate part of the foundation and the pile (do not forget to take into account the parameters of the internal partitions);

- average costs of concrete or rubble elements - this will allow you to calculate the possibilities of rigidity and strength of an individual pile - here it is worth taking into account the presence or absence of siege pipes, formwork, waterproofing elements (do not forget that the initial planned costs of concrete are almost 100% slightly lower than the volume spent in the result);

- load and pressure on an individual pile, and load on rock from the weight of the building and foundation;

- the requirements and recommendations for the reinforced frame must be observed - this is a diameter of 1 cm, the number, length and weight of reinforcing bars, the diameter and pitch of the fastening clamps according to SNiP for your building;

- the characteristics of the formwork (depending on the material used for the formwork, these values according to GOST vary greatly);

- in addition to all this, take into account the external climatic conditions, which have already been mentioned above.

It often happens that some of the types of calculations cannot be applied to buildings erected by private developers, this can be justified by such factors as the installation of additional structures and elements on the territory (to which accurate calculation operations cannot be applied before construction), the use of an individual type foundation (foreign, unpopular or not so widely known types of foundation) and some others. This is a common situation today, as the number of individual projects is increasing, and there are more and more bold design solutions in the construction of buildings. In this case, the developer must use the norms, rules and tables with data in SNiP 2.02.03-85, SNiP 3.03.01-87, SNiP 52-01-2003 and GOST R 52086-2003. Studying these documents will allow you to determine the optimal number of pile elements, calculate the depth of piling, the load on the soil and foundation in your area, and will certainly be useful for novice builders.

The process of calculating a bored foundation is simple. First, you need to calculate the weight of all foundation structures, take into account the approximate weight of furniture, people, wall barriers, stairs, superstructures, loads from snow or rain. The next step will be to determine the bearing capacity of an individual pile, it will depend on such parameters as the diameter and length of the pile, the characteristics of the reinforcing cage, the loads of soil and their properties. You can calculate the bearing capacity of the piles from the data obtained from the die tests

After the calculated measures, the builder carries out corrective work, which includes optimizing the number of piles (if the number is odd, it is usually rounded to an even number) and checking the entire structure for damage and cracks. The number of piles, as well as the distance between them, is determined by the weight of the building and the diameter of the piles themselves. When placing piles, keep in mind that their installation in the corners and at the junction of the walls near the building is required. Otherwise, the load and pressure on certain sections of the foundation may be close to the critical value.

Advantages and disadvantages of pile foundations

It is most advisable to build such a foundation on problem soils. These include:

- clayey;

- peat;

- loamy;

- swampy.

The construction of a reinforced concrete structure on these soils will be expensive. The foundation on piles is capable of providing decent strength parameters and inexpensive cost in such conditions.

The main advantages of the foundation on piles:

- The service period can be up to 140 years. This is due to the fact that each pile is made of high-alloy metal and treated with special compounds for protection.

- The cost of building a structure can be more than 30% cheaper than building a reinforced concrete foundation, provided that loose and unstable soils lie on the territory.

- The installation of supports can be carried out at any time of the year.

- Possibility of installation in the shortest possible time.

- There is no need to use large equipment. Piles can be installed manually.

- An excellent option for making buildings in swamps, loose or unstable soil.

- Safety and long service life.

- There is no need to carry out preparatory work, which consists in digging trenches.

- The best option for setting up a private house with large differences in elevation in the territory.

Despite the many significant advantages, the base on the piles also has disadvantages:

- There is no way to build a basement.

- Large labor costs for warming free space under the floor base and finishing the basement.

- Water and sewer pipes will need to be buried and insulated, since due to the lack of a basement, the soil can freeze under a private house.

- If the soil is rocky, then the foundation on piles will not work. During installation, the blades may burst, and therefore it will not be possible to mount the supports to the required depth. The result is an unstable, shallow foundation that is not suitable for erecting a building on it.

- The quality of the materials to be used. If you do not have the appropriate knowledge, you can buy poor quality products. In this case, the foundation will be short-lived. The disadvantage of metal is that it corrodes if it interacts with water. Therefore, each support must be treated with a protective mixture and made exclusively of high quality steel.

Particular attention in the pile selection process should be paid to the welding points. The joints must be neat, they must be treated with mastic. bitumen based in order to protect them from corrosion

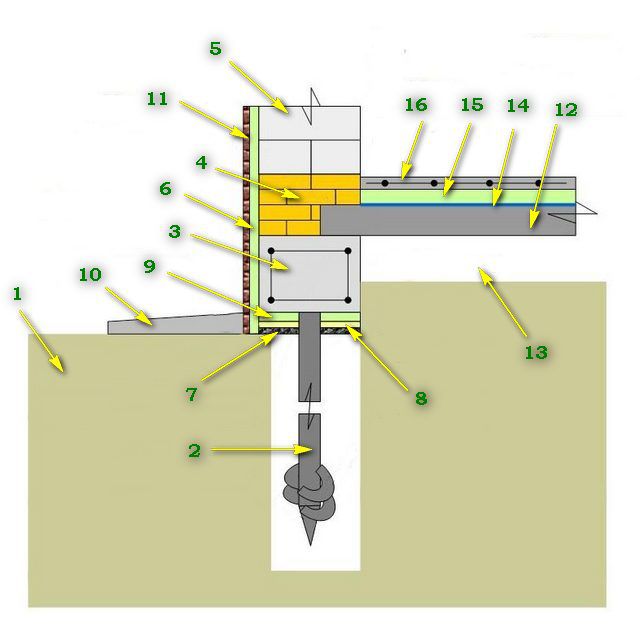

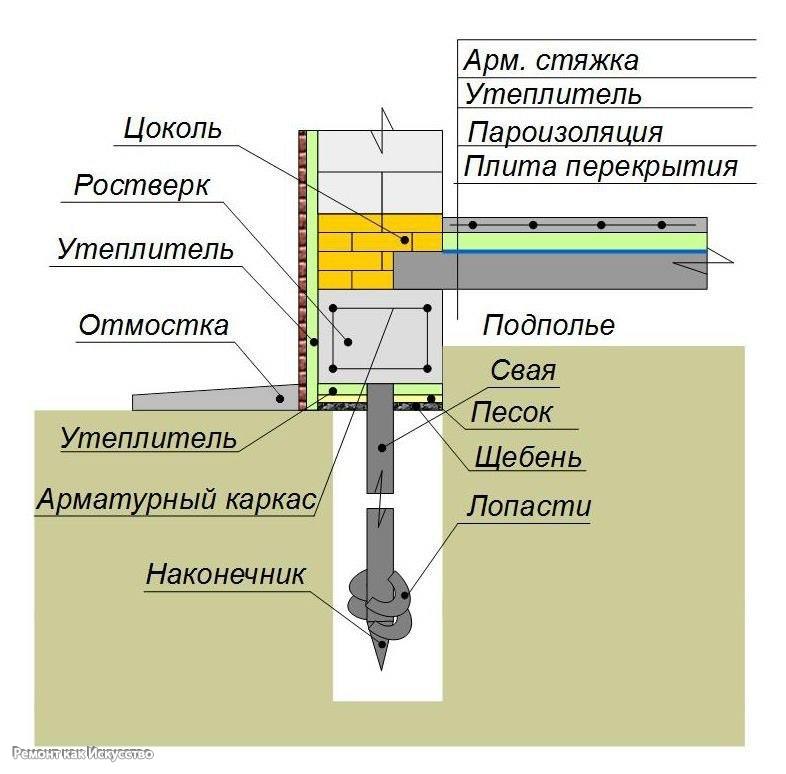

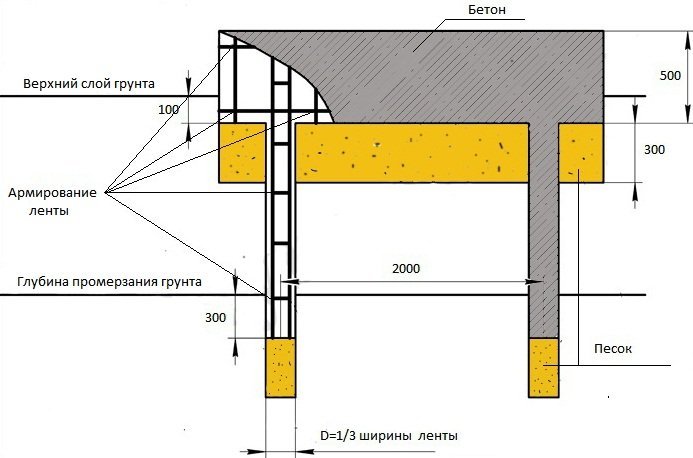

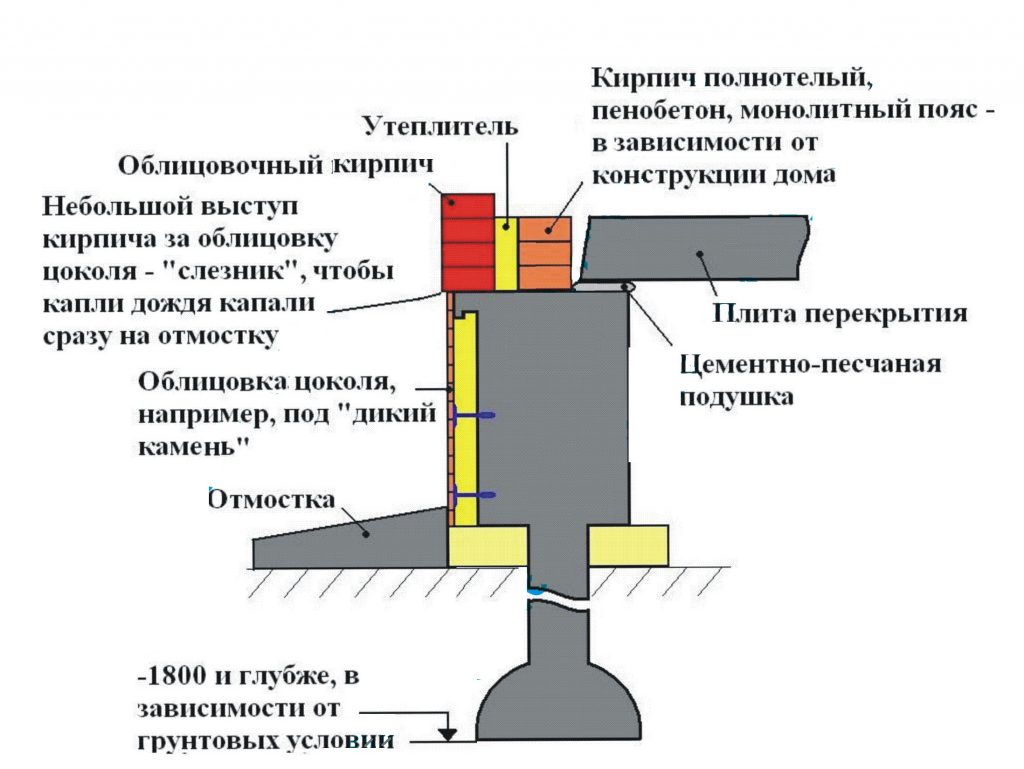

Column foundation with low grillage

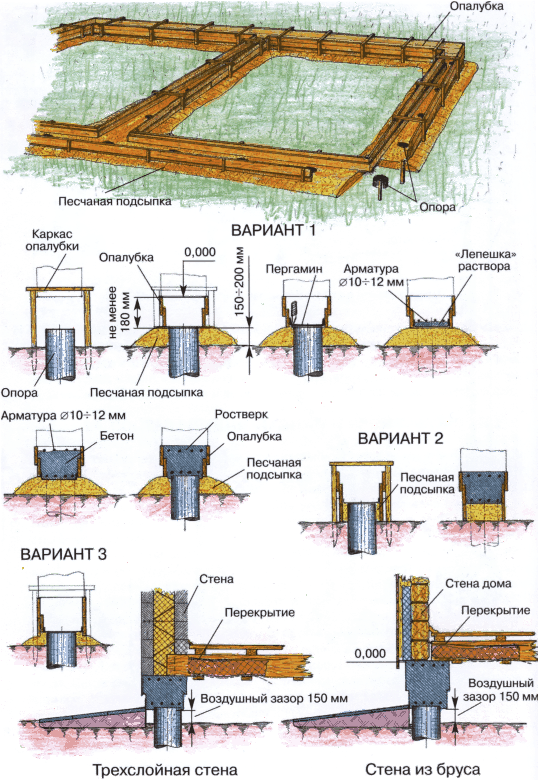

This scheme has been used quite often lately, but its use is associated with a certain risk. The thing is that many developers make the mistake of trying to combine two in one foundation at once - a columnar and a shallow (not deepened) tape one. But the principles of operation of these two types of foundation are absolutely opposite to each other.

A shallow strip foundation is made in the form of a single rigid frame, which, under the influence of frost heaving forces, has the ability to slightly rise and fall along with the ground. The columnar foundation is deliberately deepened below the freezing depth in order to exclude its rise in the winter season.

Now let's imagine a situation: we poured the pillars, dug a small trench, made, as it should be for shallow foundations, a sand cushion and poured the tape. In winter, severe frosts come, little snow has fallen, the ground begins to freeze and rise. At the same time, it also lifts our shallow tape and the pillow does not save here (as some think), because sand is an incompressible material, it just plays the role of a rigid pad that improves the bearing properties of the soil.

As it rises, the tape drags the pillars along with it.An empty space appears below them. Due to the elasticity of the soil, this space does not retain its diameter throughout the winter, the cross section decreases somewhat (especially with wet or sandy soil). That is, in the spring, when the ground begins to thaw on the surface, the pillars will not sink to their original depth. And this process can be repeated more than once.

It is even more interesting when a shallow foundation is made on TISE pillars (with an extension at the bottom), without even paying attention to the fact that the creator of this technology Yakovlev in his book “Universal foundation. TISE technology ”writes in black and white and justifies why this should not be done. On heaving soils, this can lead either to a break in the tape between the posts, or to its separation from the posts.

And yet it is possible to make a low grillage for a columnar foundation. Consider the following scheme:

This design is suitable for those who want to make flooring in the house on the ground. In addition, there is no need to think about arranging a pick-up, which is necessary with a high grillage.

Instead of sand, a simple foam plastic with a minimum density of PSB-S-15 with a thickness of 10 cm is used. It has a certain elasticity and can, if necessary, absorb soil swelling. To reduce heaving, a blind area is made insulated with extruded polystyrene foam (EPS).

The principles for choosing the dimensions of the section of a low grillage, its reinforcement and filling are the same as for a high one. We will not repeat ourselves.

Concreting of the pile foundation grillage

We make an armopoyas

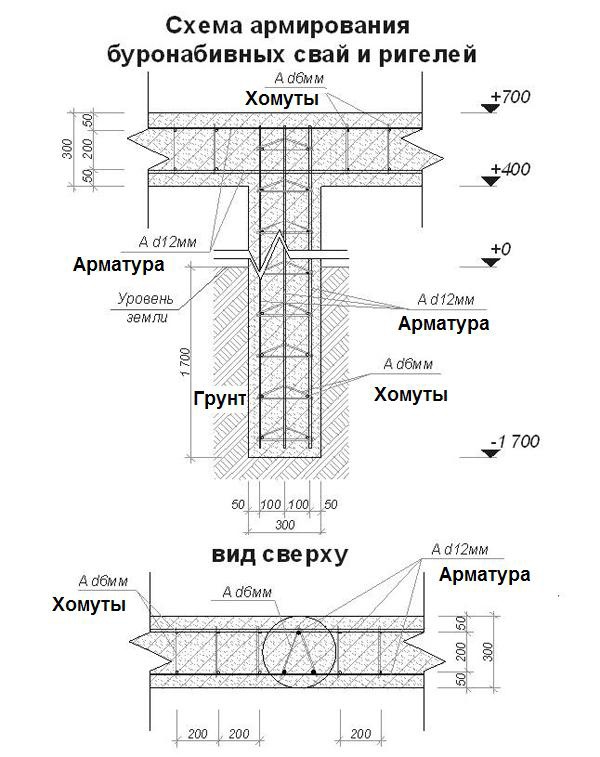

After making and installing the formwork for the grillage with your own hands, you can start making it. This will require several tens of meters of steel or plastic reinforcement and a few cubic meters of concrete. We knit an armored belt from the rods, which is subsequently buried in the foundation and will provide it with the necessary strength characteristics.

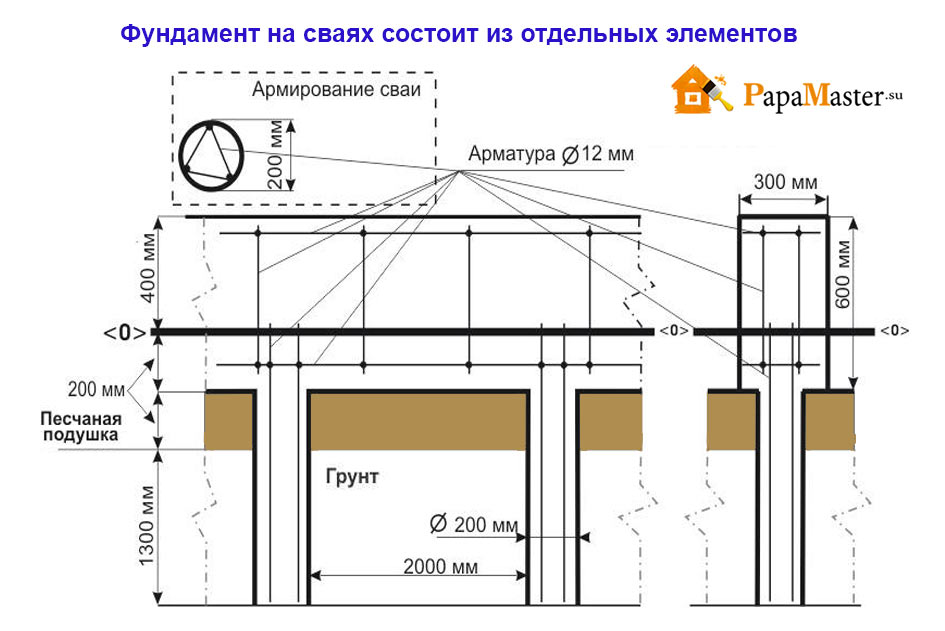

We cut the reinforcement into pieces or use the full length of the rods if the grillage length exceeds 12 meters (the standard length of the reinforcement). The rods should be located at a distance of at least 10 cm from the formwork in two rows of 2-3 pieces each. Short cuts welded or tied with a special knitting wire vertically and horizontally will help to fix the reinforcement in the desired position.

Reinforcement of the grillage

Achieving maximum strength is facilitated by a high-quality connection of reinforcement at the corners. To achieve this, professionals recommend laying reinforcement bent at an angle of 90o at the joints of the grillage walls. In the absence of a welding machine, the rods are securely connected with twists of steel wire.

Filling the grillage with concrete

An important stage of construction is filling the grillage with concrete. It can be purchased at the nearest factory ready-made or made by hand. To do this, you need to purchase concrete components - cement, sand and crushed stone. An electric concrete mixer - home-made or factory-made - will be a good mechanical assistant.

When buying concrete, its delivery is carried out by automatic mixers. Not all novice builders know how to fill the grillage with their own hands. If special equipment can drive directly to the formwork, concrete is poured directly from the container. Otherwise, a tray is made from edged boards of the required length and the formwork is filled.

Making concrete with small fixtures does not allow large volumes of mix to be obtained. In this case, the grillage is filled in parts. Lintels of edged boards are installed inside the formwork, dividing the internal volume into parts. After filling the confined space on the previous day, the concrete is allowed to harden and work continues the next day, having previously removed the lintel.

Filling the inter-formwork space with concrete does not end the process of making the concrete tape, since pouring the grillage with your own hands is half the battle.It is necessary to know how long the concrete foundation hardens and to perform a number of works that allow it to achieve maximum strength. The concrete is covered with damp burlap and is not allowed to dry out for one to two weeks, periodically moistened. The curing time of the grillage is 1.5-2 months.

Insulation of the grillage

During the construction of residential and public buildings, it is important to carry out work on the heat saving of the building. In the case of using a pile-grillage or strip foundation, the insulation of the concrete base will help to increase the temperature in the premises.

You will need to purchase liquid bitumen mastic and plate insulation - expanded polystyrene or polyurethane foam. The process technology is not complicated. Previously, the entire surface of the monolithic grillage is coated with mastic. It can be applied with brushes, rollers, with a low viscosity - by spraying. Then let the mass dry.

Insulation of the foundation with foam

We insulate the treated surface with insulation plates. They can be fixed to concrete with special adhesives or mechanically. In the latter case, you will need a carbide-tipped drill and many special plastic fasteners - fungi with large flat caps.

Calculation of the reinforcement of the band grillage

To calculate the reinforcement of the tape grillage, we use the "Arbat" SCAD Office application.

After starting, select the tab "Selection of reinforcement in the beam", since the strip foundation on the piles is nothing more than a multi-span beam supported on the piles.

In the main window for the selection of reinforcement in the beam, we indicate the number of spans between the piles and their spacing. The number of spans is defined as the wall length divided by the pile spacing. That is, for a wall of 10m with a pile step of 2m, we get 5 spans.

Specify rigid clamping on the left and right, set the binding of the center of the reinforcing bars in the corners equal to the cover 40mm plus half the diameter of the bar. Previously, you can set approximately 16-28mm, then the binding will turn out in the range of 48-54mm. In this example, 55mm is taken into the stock.

Working condition factor and other data can be left unchanged.

Next, we proceed to the formation of loadings.

According to the rules, constant, long-term and short-term loads should be separated. But the calculation can be simplified by conventionally accepting all loads as constant, forming one single load by pressing the "Create" button. Then, one by one, we select the span number from the first to the fifth, and set each of them with the “add” button to the previously obtained load on the grillage.

In the process of adding loads, the program will display in real time the diagrams of internal forces - this is a kind of graph that displays the typology of the distribution of internal forces over our grillage beam.

If everything is done correctly, a diagram of internal forces will appear within each span.

Then we move on to the assignment of the concrete class. We figured out how to define it earlier.

Specify the class in the "Concrete" tab. For grillages, a concrete class lower than B15 is not used. Most often, the B25 class will be optimal.

After pressing the "Calculate" button, the "Results" tab will appear.

The results will be the cross-sectional area of the required reinforcing bars. The "S1 and S2 Areas" row can be expanded to display different reinforcement options - symmetric, non-symmetric, and transverse reinforcement data. Non-symmetrical reinforcement is rarely used in private construction due to its higher complexity.

The calculated values of the transverse reinforcement are extremely important for a strip foundation on piles (grillage)

This type of building structures experiences significant loads, as a result of which, in order to avoid the appearance of oblique cracks, one should pay direct attention to the transverse reinforcement, it should be no less than the calculated one.

It is convenient to perform the final analysis of the calculation results by pressing the "Report" button followed by studying the table "Results of the selection of reinforcement". The report is generated in Microsoft Word format.

To determine the required diameter of the reinforcement, it is necessary to constructively set the number of frames. For small buildings, three are usually taken. Further, the values of the total reinforcement are divided by the number of frames. The resulting figure is the calculated cross-sectional area of the bar.

We determine the diameter through the cross-sectional area according to the table.

Correspondence table of cross-sectional area and diameters.

In this example, 3.549 / 3 = 1.183, which corresponds to a diameter of 14mm (a diameter of 12mm is a little insufficient). Similarly, we determine the diameter of the transverse reinforcement - 6mm with a step of 100mm will be enough.

The scheme of reinforcement of a strip foundation on piles is in many ways similar to the reinforcement of a conventional strip foundation.

Of the differences, it is worth mentioning the importance of transverse reinforcement, it is not advisable to use a step of such reinforcement of more than 200 mm without additional calculations and the advisability of reducing the step to 100 mm in the support area on each of the piles in an area of 50-100 cm in each side of the pile along the grillage

Choosing piles

There is always a choice: buy finished products, or make piles with your own hands. The first option, like the second, implies many sub-options, and the quality of the material plays an important role here. When buying screw supports, ask for a certificate of quality for piles; when making yourself, check the quality of steel. You shouldn't take our word for it - your house will be renovated by you, and not by the seller of low-quality products. In addition, in order to tie a group of piles with a grillage, you need to choose a suitable type of supports.

Standard screw metal piles have a length of 2.5 m, since the minimum depth of immersion in the ground below the freezing point is 1.5 m.Based on these dimensions, it becomes clear that for steep sections, piles need greater length, since for arranging a grillage and leveling the building horizontally, only 1 m above the ground level remains.

Drawing of a standard screw pile

Advantages of pile foundations with grillage

The advantages of the foundation on piles with a grillage include the increased strength of the structure. The house erected on it will be durable and stable. Other advantages of such foundations:

- Minimum excavation work.

- Low consumption of materials. Less concrete is required than when building a traditional strip base.

- Possibility to work in winter. Piles are installed even at temperatures of -10 degrees.

- The soil does not sink during flooding or during frost heaving.

- Reducing heat loss - the area of contact between the foundation and the ground is small.

- Reducing foundation construction costs by 20%.

- Acceleration of work.

A bored foundation with a grillage takes its rightful place among other types of bases. It is a reliable structure with a large margin of safety. Since the endurance of a monolithic structure is much higher, it is necessary to equip the grillage as a single tape. Such a foundation on reinforced concrete piles is reliable, easy to build and inexpensive.