How much is such a foundation

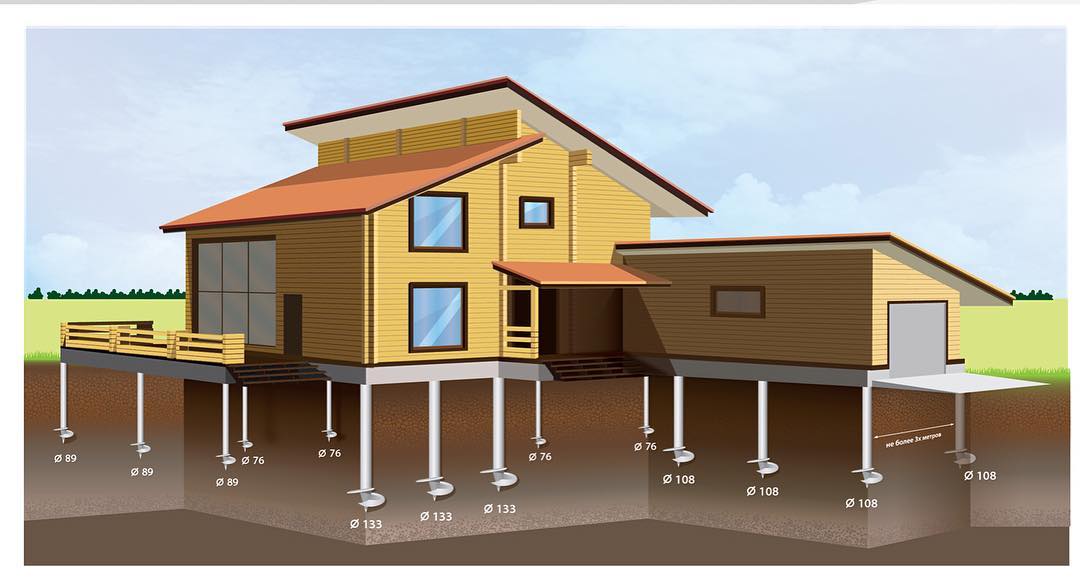

Consider the cost of a screw foundation for a small house 6: 6 m. The optimal pile field scheme consists of 9 piles.

Then the owner of the site will need to pay for the installation of 9 pieces (cost from 650 to 1100 rubles / piece) and the price of the piles themselves.

It depends on the length and diameter - for example, a VS-57 (57 mm in diameter) with a length of 3 meters costs 1100 rubles with installation or 1200 without installation.

If it is decided to use the VS-108, then the price without installation (for a 3-meter barrel) will be 1150 rubles with installation and 1350 without installation. The difference in the purchase price with and without installation is intended to stimulate the ordering of installation in this company.

As a result, the cost of the foundation will be about 20,000 rubles. But this amount does not include shipping and other overhead costs, so you need to have some reserve.

In other firms, prices may differ, this must be clarified directly on the spot.

Strip-pile foundation

This structure makes it possible to reduce the cost of construction work and increase the strength of the building.

This structure makes it possible to reduce the cost of construction work and increase the strength of the building.

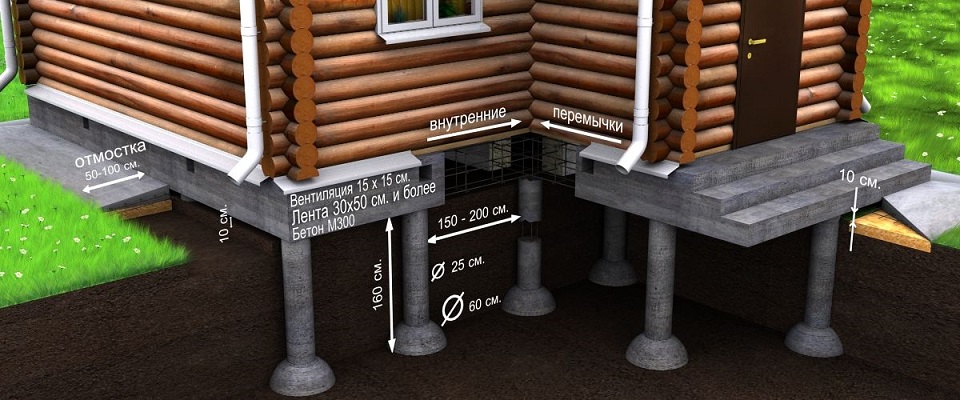

The strip pile foundation is a type of monolith that is ideal for soils such as heaving and weak. A distinctive feature is manifested in the fact that the walls press on a solid strip base, and the strength of contact with solid rocks of the earth is created by piles, which are mounted at a depth.

This structure makes it possible to reduce construction costs and increase the strength of the building.

Technical description

In this design, the tape is responsible for the distribution of the load evenly, which protects the building from deformation.

In this design, the tape is responsible for the distribution of the load evenly, which protects the building from deformation.

In this design, the tape is responsible for dividing the load evenly, thereby protecting the building from deformation. Piles, on the other hand, stabilize the tenacity of the building to hard soils, which protects the building from subsidence and distortions during seasonal ground shifts.

Such a combination of elements at the base makes it possible, even on a moving land plot, to erect a stable and durable building, which is not afraid of the climatic features of the soil. The most frequent use of such a foundation is observed in places of swampy soils, which are characterized by a humid climate and high groundwater.

Variety

It is the features of this combination that contribute to the high strength and protection against soil shifts.

It is the features of this combination that contribute to the high strength and protection against soil shifts.

There are three types of such a foundation:

- With a pile screw. In this case, metal piles are used, which have blades of certain sizes. They are mounted in the ground with their own hands or with specialized equipment. To extend the operational period of their life, it is recommended to treat them with a primer or special paint for protection.

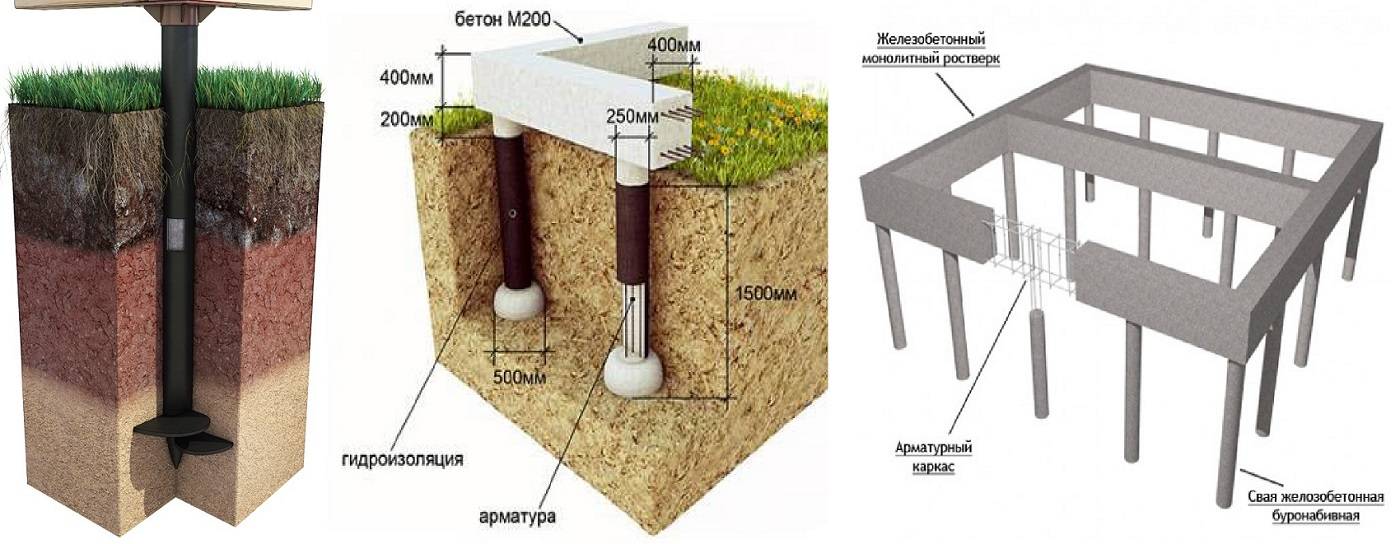

- Bored piles. They are mounted on the construction site, so their price is much lower. The first thing that these parts require is a well of a certain size, not lower than the level of soil freezing. The principle of construction consists in a reinforced water intake, which is poured with a concrete solution.

- Pile foundation made of rammed elements. Differs in its design. Its scheme consists of a monolithic reinforced concrete tape on which all the piles are installed.

Pros of founding such a combination

The pile-strip foundation has the following advantages in its functionality:

Construction speed. This foundation is being built in a matter of time. This is due to the shallow penetration of the tape and the ease of piling.

- Low cost. This base does not require special costs, for example, as a deep belt. It is worth noting that the result of the work is practically the same.

- Lack of need for correction with correct calculation. And repairs in this case will not be useful for ten years, because the device does not lend itself to the influence of water, flowability and antinodes of the soil.

Cons of the pile strip foundation

Buildings that are based on such foundations have several disadvantages. So, the cons of the designs:

- The impossibility of building a basement or basement room. For such purposes, the tape part must sink lower into the ground.

- There is an additional need to insulate the floor covering, as the ground can freeze.

Pros and cons of shallow foundations

In order to understand the main difference between pile and non-pile types of foundations in order to determine the pros and cons of each of them, we will determine in which cases shallow foundations are used. The latter include columnar foundations, strip and slabs. Such foundations may have a mark of the inception at the level of the depth of soil freezing, and, provided that the basement part is insulated, they can be located even higher.

The pluses of shallow foundations include the simplicity of their construction, their cheapness in comparison with the classic pile foundation (driven square piles driven by a diesel hammer), a fairly high bearing capacity (especially in the slab version). But their disadvantages are not always obvious. The main one is vulnerability to seasonal flooding. Surface groundwater, called "verkhovodka", can significantly reduce the bearing capacity of the insulated shallow foundation.

The scheme of the formation of a soil verkhovodka.

Drainage is used to combat this problem. But it cannot work on its own, the drained water needs to be diverted somewhere. The construction of the foundation at the marks of the freezing depth is also not always possible, for example, if the level of "ordinary" groundwater is above the freezing depth, for the foundation it will be necessary to perform dewatering - do not pour concrete directly into the water. Construction dewatering is a rather expensive undertaking.

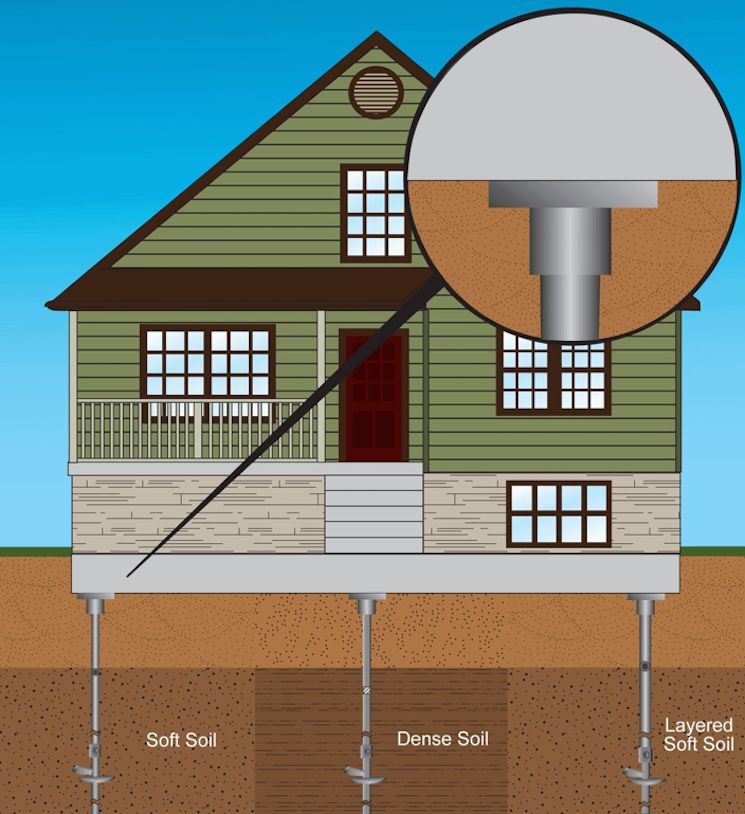

In cases where the construction site is seasonally flooded, and the drainage device does not make sense due to the absence of storm sewers or other unloading zones, it is advisable to consider the option of a pile foundation with a high grillage.

What is a pile foundation

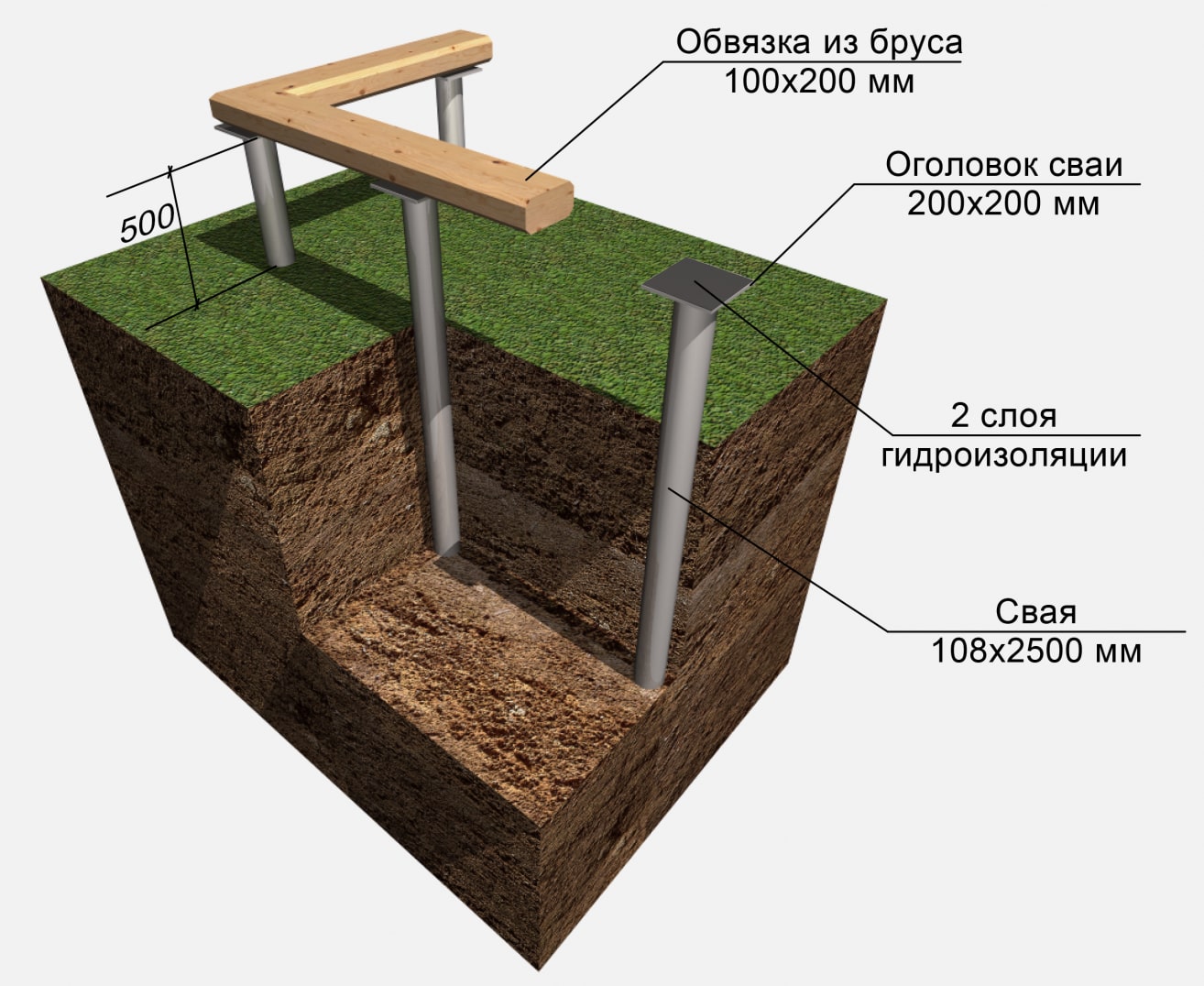

A pile foundation is a type of structure, the main element of which is piles. It is through this structural element that the load distribution is carried out. The pile-screw type of structure differs in that the supporting part of the structure is not driven in, but screwed in. As for the option with a grillage, in this case, the individual piles are combined with each other using a bar.

Thus, we can say that the pile foundation is the foundation that can be erected for structures of the most varied purposes.

Pile types

It is not difficult to guess that it is the piles that are the main structural element. According to the established norms of SP 2024-13330.2011, they are classified as follows:

- Driven in or pressed in. In the manufacture of piles of this group, steel or wood, as well as concrete and reinforced concrete, can be used. In this case, the immersion of the structure is carried out without creating a trench, but when using percussion or vibration-impact machines. It should be borne in mind that this type of pile is rarely used.

- Vibro-submersible, made of reinforced concrete and presented by a shell. This type of structure is immersed in the ground using special equipment. After the pile is in the ground, the internal space is freed from the soil, and then poured with concrete. This type of construction is suitable for a wide variety of structures.

- Rammed, made of concrete or reinforced concrete.In this case, first, work is performed to form a cavity in the soil, after which it is poured with concrete. Rammed piles are suitable for capital construction.

- Drilling rigs of reinforced concrete type. A similar structure is obtained by forming a special trench, into which concrete is poured, having previously installed a metal structure. Such piles are most often created during the construction of residential buildings.

- Screw made of steel. It should be borne in mind that some companies are engaged in the production of steel screw piles with heads. The cavity of this structure is filled with concrete. This type of pile is most often used in the construction of residential buildings.

The above information determines that in most cases it is concrete reinforced with a metal structure that will take the main load. Most piles can significantly simplify the work of forming the required trench for the concrete mix.

Advantages and disadvantages of a pile foundation

The main advantage of a pile-type foundation is the possibility of using it on almost any terrain. Other pluses include:

• tight deadlines for the construction of the base of the structure;

• the ability to install on any type of soil (swampy soil, clay, sand, etc.);

• simple installation (with careful preparation!), The screwing of structures is performed manually and using special equipment;

• long service life (more than 30-50 years);

• if necessary, damaged piles can be replaced;

• during the demolition of a building, the pile elements are easily unscrewed from the ground, which allows them to be reused.

When choosing piles as the main elements of the foundation structure, it is worth considering that the installation technology requires careful preparation (including accurate calculations) and correct work. This will help to avoid skewing of the structure as a result of shrinkage of the supports and premature wear of the building. During the study of the soil, all kinds of risks are identified, which makes it possible to create fortifications in vulnerable areas of construction.

Disadvantages of using piles:

• heavy weight of structures, which provides for the attraction of special equipment for delivery to the construction site (it will be necessary to attract special equipment even with complex soils of a dense structure, when manual force for installation is not enough);

• the quality of the metal, along with the observance of the technology, determines the life of the foundation;

• impossibility of using near existing buildings (for screwing in pile elements, a space with a radius of at least 2-3 m is required).

Piles from tubing

A separate category is welded-type screw piles made of tubing. For their manufacture, a thick-walled pipe (6.5-7.5 mm) made of corrosion-resistant steel is used. The welded blade is made of high strength structural steel.

The construction of the foundation using screw supports from tubing at a cost is close to the arrangement of foundations on reinforced concrete bored piles. However, a significant advantage is the ability to perform foundation work in a short time, including on difficult soils.

Pros and cons of a pile foundation

Any construction - pile foundations are no exception - they have both their pros and cons.

pros

Advantages of pile foundations made of reinforced concrete piles for use in private construction:

- Resistant to all kinds of loads.

- The existing chemical inertness of the concrete mixture is very important when arranging foundations in those soils that are chemically active.

- Durability.

- High safety margin. This makes it possible to complete the second floor (if necessary).

Minuses

Available disadvantages:

- The need to use special equipment.

- If copra is used in the installation, then there is a high probability of destruction of dilapidated buildings due to strong ground vibrations.

- If special equipment is used, then on a cramped construction site there may not be enough room to maneuver the first one.

Considering all the pros and cons, reinforced concrete piles are the best and most reliable solution for building a country house. Since it is such a foundation that is the strongest and most durable.

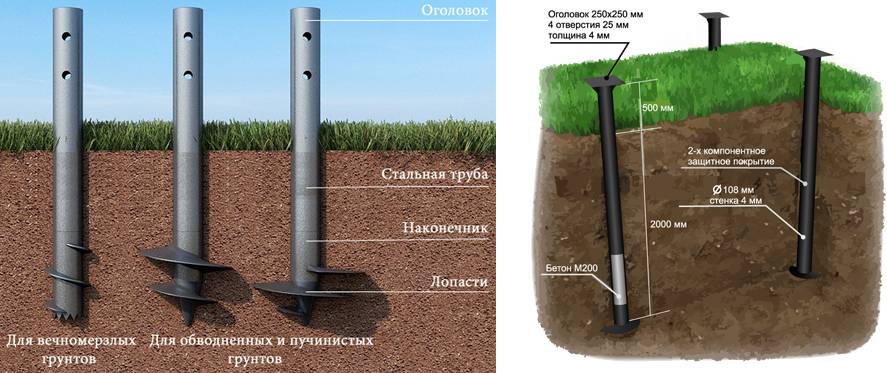

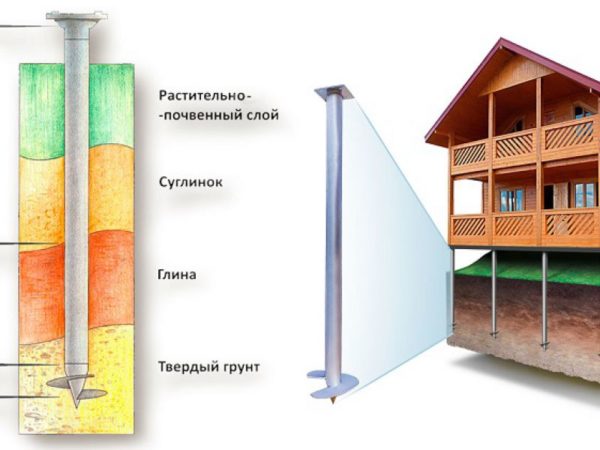

What is a screw pile

This is a steel pipe, in the lower part of which spiral blades are welded, and in the upper part there is a retainer or holes for fixing the pivoting levers. The installation of piles is carried out by simply screwing them into the ground, like an ordinary self-tapping screw, until solid soil layers are reached below the freezing point.

Possible execution options

The simplest products have an oblique cut in the lower part and two short blades covering no more than one revolution of the pipe surface. In such models, during screwing in, the earth gets inside the pipe and subsequently does not allow concrete to be poured into the cavity. The disadvantages of a screw foundation of this design are that it can only be used for the construction of temporary buildings and structures.

More expensive models are made in the form of large screws. Their lower edge is sharpened, and the guide vanes reach up to one meter along the length of the pipe.

a - the most common, wide-blade piles; b - piles with increased bearing capacity; c - narrow-blade piles for stony soils; d - special piles for use in permafrost conditions.

a - the most common, wide-blade piles; b - piles with increased bearing capacity; c - narrow-blade piles for stony soils; d - special piles for use in permafrost conditions.

The most expensive, but also the highest quality, piles have a screw head in the form of a cast in the form of a monolithic product. They have increased strength and resistance to rust.

For the manufacture of piles, ordinary water and gas pipes or rolled alloy and stainless steel can be used. Depending on the materials used for the manufacture, the market value of the products is determined.

Corrosion protection

To provide protection against rust, the pipe surface is coated with zinc or other protective material. However, in most cases, during the installation of the pile by screwing it into the ground, this coating is damaged, which is why the corrosion process will be inevitable. In order to increase the durability of the structure, steel reinforcement is installed in the inner cavity of the pipe and a concrete mixture is poured.

Screw piles made of alloyed stainless steels do not need additional protection against corrosion, but they are also much more expensive.

Pile installation options.

Pile installation options.

The main criteria for the selection of piles

When determining the optimal pile design option, consider:

- soil types in a horizontal section based on the results of engineering and geodetic surveys or control drilling;

- the level of groundwater, taking into account seasonal fluctuations;

- the possible depth of soil freezing;

- constant and seasonal soil moisture;

- the total weight of the building structures of the building being erected;

- a margin of pile length for the possibility of horizontal alignment in one reference plane.

Determination of these parameters allows you to determine the advantages and disadvantages of the material in each case and make the right choice regarding the length of the pipe, the design of the blades, the presence of a pointed head and the grade of steel from which the pile is made.

Types of pile foundations

The development of pile foundation projects, taking into account all of the above features, is often based on data from engineering and geological exploration of soil, requirements for bearing capacity, and also depends on the type of pile used.

Only experienced professionals can correctly calculate the structure of the pile foundation, which will provide the necessary bearing capacity in the off-season and will be rational in terms of its cost.

According to the material used for piles, there are 3 main types:

- Wooden piles - used only for very light, wooden structures and do not differ in durability;

- Metal piles - have a huge list of subspecies, both in design and in the method of installation, due to which they are widely and universally used in modern construction;

- Reinforced concrete / concrete piles are perhaps the most common, due to their affordability, installation method (special equipment is not always used) and cost.

Metal pile foundation

According to the method of installation, piles are also divided into three main subspecies:

- Bored piles - are installed in a pre-prepared well, which is usually done by drilling with a screw or casing, both manually and with special equipment, the shock-rope method can also be used. Such piles are usually poured from concrete, have a heel, and a reinforced frame;

- Driven piles - during installation, the earth is not extracted for them, they are driven into the soil with the help of various hammers, vibrators or indents. They are usually square in cross section and have a sharp lower end. The heel is missing;

- With a shell structure - they are introduced into soil masses with the help of vibratory drivers and are subsequently filled with concrete;

- Screw - have metal elements with a screw or variable section and deepen by screwing into the soil. There are broad-bladed and vice versa with narrow blades. In the latter case, usually on frozen soils, a well is prepared only for the width of the main pile rod.

Foundation on bored piles

By the nature of the performance of their functions, piles are divided:

- Stand piles or support piles - it is assumed that with the heel part they will rest on solid, lower soil layers, and the upper heaving layers of the soil, when moved, will not affect the piles themselves and the entire structure;

- Hanging piles - they provide their bearing capacity and stability due to the friction of their side walls, if literally - due to the lateral area of the piles and the quality of the soil. The larger the area and the denser the soil, the greater the friction, the higher the bearing capacity. This type of installation is used in places where it is difficult or impossible to reach dense soil layers. Calculating the frictional force to bearing capacity is not an easy task; it is better to entrust such work to experienced professionals.

Screw piles and their location

You can also consider the types of piles according to the shape of the profile, for example: square, round, or from more complex geometric shapes. By the presence of voids along the axis, they can also be divided into hollow and solid piles.

When considering a pile foundation, classification can be applied by the type of grillage used, its height or depth, etc.

Foundation on reinforced concrete (reinforced concrete) driven piles

Advantages and disadvantages of the strip foundation

Such a base is considered by many to be one of the most reliable types of construction. The following advantages of strip foundations are known:

- the possibility of building a house with weighted floors and walls;

- ease of construction and no need to use heavy equipment;

- reliability;

- the possibility of construction with uneven soil density;

- it is possible to use the walls of the structure as basement walls.

Disadvantages of strip foundations:

- the need to use a large number of materials;

- the need for waterproofing work.

Many find it difficult to answer the question of which foundation to choose. The technology for erecting a belt-type base is simpler than a pile one, while much less money will be spent on construction, but more consumables are used

It is important for the strip base that all work is carried out in warm conditions. Often the tape type of base acts as an alternative to other types of structures.

The foundation on piles often attracts with its price and ease of installation.Also, the base allows you to erect a structure on soft soil or on slopes, and it is better to refuse the tape type of base under such conditions. Before choosing a tape or pile type of structure, it is necessary to weigh all the information regarding the features of the structure, the characteristics of the soil, the funds that can be spent on materials and construction of the structure. It does not matter whether a pile or strip foundation was chosen, it is recommended not to save on materials and the quality of work, since the features of the operation of the structure depend on this.

Sometimes builders decide to create a combined type of foundation when a strip type of foundation is used in conjunction with reinforced concrete piles. It is recommended to build it in difficult terrain, as well as on sloping terrain.

The advantages of this foundation

Types of pile foundations: a - rack piles; b - hanging driven piles; в - hanging rammed piles; 1 - driven piles; 2 - grillage; 3 - rammed piles

Types of pile foundations: a - rack piles; b - hanging driven piles; в - hanging rammed piles; 1 - driven piles; 2 - grillage; 3 - rammed piles

Of course, such a foundation has pluses that need to be discussed, and they are as follows:

- Such bases are ideal for any type of terrain, and especially their advantages are manifested when the terrain is not even, or is generally located at a slope;

- The next advantages are the ability to immerse them in any soil. Therefore, they are indispensable on swampy soils, on that soil that has a large freezing depth, and is also difficult from the side of special indicators (the presence of groundwater, clay, sand, and other poor soil indicators). Due to these features, pile construction is especially popular in the north and permafrost conditions.

- The next advantages of such foundations are that they are easy to assemble. If we compare tape and monolithic bases, then their construction and manufacture takes not only a lot of time (digging trenches, preparing concrete, a reinforcing layer, waiting until the concrete dries and hardens), but also financial resources (the cost of tape and monolithic structures in some cases is one third of the price of the house). The base is on piles; it can be mounted under any structure within one day.

- Their service life is more than 30 years, but these are guarantees from the manufacturers. In practice, this time can be much longer. This is due to the fact that the metal undergoes a special treatment and is covered with a layer of zinc. In addition, there are special cavities in the metal piles, into which the cement-sand mortar is poured. It gives additional rigidity to them, and of course increases the service life.

- The next advantages are that, subject to the installation technology, the piles will never shrink. Before installing them, you do not need to carry out preparatory work, that is, to clear the entire area of various debris, to remove the top layer of the soil. Therefore, they are also environmentally friendly, as they make it possible to preserve a unique landscape and vegetation on the construction site. This cannot be attributed to structures on concrete piles. But as mentioned above, they are used in large-scale construction and will not fit a private house or summer cottage.

- The next advantages of this building material are the possibility of their reuse, as well as the possibility of their easy replacement. Metal piles can be easily screwed into the ground, and can be easily unscrewed. This property makes it possible to reuse them (the only exception can be piles, where concrete was poured into the cavity during their installation). If it is necessary to add an extension to the house, and if it has the above basis, then this is very easy to do, since you just need to add a few piles for the extension. And the last advantage is that damaged elements can be easily replaced, or new ones can be screwed in next to them.

As you can see, there are many positive characteristics, therefore, recently, an increasing number of builders are paying attention to this type of foundation, and having carefully studied its properties, they give preference to it. But behind the positive sides there are also some problems with the use of piles in construction.

Of course, these problems are not significant, but you also need to be aware of them.

But behind the positive sides there are some problems with the use of piles in construction. Of course, these problems are not significant, but you also need to be aware of them.

Characteristics of the main elements of the pile-screw foundation

Screw pile installation

The screw pile is a steel pipe with a sharp, closed tip and blades. In fact, this is a drill screwed into the ground. The screw tip is the main working element, which acts as a functional part, support and anchor. Heads are sold in addition to the piles. They cover the upper part of the structure and serve as a platform for further strapping work. Also, the head is used for screwing, clinging to it, and not to the base of the pile. The blades hold the building under the influence of frost heaving forces.

Pile-screw foundation

Pile-screw foundation

In winter, swelling on clayey water-saturated soils, especially for light timber structures, can lead to squeezing out of the foundation. The problem cannot be solved by deepening the supports below the freezing zone due to the forces acting on the side part. But if you lower the support below the freezing level, with an anchor, then a layer of solid soil will hold the foundation.

Screw piles are designed to erect a lightweight and inexpensive foundation. Moreover, each building has its own standard size, shown in the table.

| Type / size | Application area | Bearing capacity (kg) |

|---|---|---|

| SV76X122 | The most lightweight structures are fences, sheds and utility blocks, playgrounds. | 350 |

| SV89X250 | Non-residential premises - garden houses, arbours (gazebos), lightweight berths and piers | 1450 |

| SV108X300 | Residential buildings of light weight - houses made of timber, logs and SIP panels. | 2200 |

| SV133H350 | The heaviest of the possible structures made of foam concrete, expanded clay concrete blocks. | 2900 |

Pile types

There are two main types of supports, they are distinguished by the way the tip is created:

- Welded tip.

- Molded tip.

The first option is cheap, for which you have to pay for reliability. The disadvantage is that the blades are welded to the tip without observing technological standards, using a handicraft method. As a result, when screwing in, the pile can move away from the vertical. The blade may break off, this is noticeable by the decrease in resistance when screwing in. Such a pile can no longer fulfill the role of a full-fledged support, some of its load-bearing duties are assumed by neighboring points, as a result of which their wear is accelerated. The worst option is the breakage of the pile after the construction of the house. The foundation grillage is deformed, and the structure becomes emergency.

Cast head for screw pile

Cast head for screw pile

More reliable lugs made by precision casting are more reliable. They are more expensive, but durable and can withstand up to 6 tons of load.

Separately, it is worth considering piles from a tubing with an increased wall thickness. Their reliability is comparable to cast ones, thanks to the thick-walled pipe. Special steel can withstand aggressive environments without a protective coating up to 7 times longer. The use of such piles allows you to get rid of their main drawback - metal corrosion in the soil.

Important pile parameters

When choosing screw piles, one should be guided by the type of tip and a number of auxiliary parameters:

- wall thickness is an individual parameter, depending on the type of soil, the weight of the structure, and a number of other requirements;

- characteristics of steel - each alloy has a number of operational parameters that should be considered when purchasing piles;

- type of strapping - strong, steel foundation strapping distributes the loads between the supports better than its counterparts from a bar;

- methods of anti-corrosion treatment - there is a choice between galvanized metal and polymer coating; if the processing is done according to the requirements, the polymer will be preferred.

When buying piles, ask the seller for all the necessary regulatory documents. They will be a guarantee that, under the guise of reliable supports, the handicraft product has not been sold to you. Otherwise, there is a risk of collapse of the building in the first years of operation.

Stilt house

Stilt house

Stages of construction and installation of a screw foundation

The technology for arranging such a base is simple and does not require digging trenches. Step by step:

- Work begins with marking the land plot, installing pegs around the perimeter - these will be the places for screwing in the supports.

- Next, they pull the cord between them - this is the outline of the future foundation of the house.

- Next, the soil is removed by 10-15 centimeters under each support, based on the diameter of the blades.

- According to the markings, you need to screw the supports into the ground. For this purpose, holes are made in the upper part of the pile - scrap or pipes are inserted into them (depending on the diameter of the piles), they will be levers for twisting.

- The pile must be screwed in strictly perpendicular to the soil surface. The pile is not completely screwed in - some margin remains.

- The supports are made the same in length - the excess is cut off with a grinder.

Expert opinion

Sergey Yurievich

Construction of houses, outbuildings, terraces and verandas

Ask a Question

During work, it is very important to check the perpendicularity with a level. After the performed actions, the support must be filled with concrete to exclude moisture ingress, increase the strength of the product and the rigidity of the entire structure

After the performed actions, the support must be filled with concrete to exclude moisture ingress, increase the strength of the product and the rigidity of the entire structure.

Further, an additional element is welded - the head. It is on it that the slab or grillage beam will be installed. In this case, any distortions are unacceptable!

After that, the strapping is already made, which is done on wooden or metal jumpers. In one case or another, treatment with an antiseptic or anti-corrosion agent, respectively, is necessary.

With some experience, you can not resort to the services of special teams, but do the work yourself - just look at how it is done correctly at least once, and also have at least minimal construction skills.

Welded tip

Support elements with a welded tip are cheap products of low quality, especially if they are made in a handicraft way. A drill blade is welded to the bottom of the pointed steel pipe. If the blade is positioned incorrectly, such a pile cannot be vertically immersed in the ground - it will "go" to the side.

Another problem with welded tips is the poor quality of welding and the metal itself from which the blade is made. For such products, the blades are easily deformed and even come off if, during the immersion process, the support bumps into stones in the ground. Blade separation can be felt during installation - the pipe will turn too easily.

If, due to the poor quality of welding and anti-corrosion treatment, the seam collapses a few years after the foundation foundation, the pile will lose its support. This threatens with uneven subsidence of the foundation under loads, destruction of the grillage, and then wall structures. The building in a short time comes into disrepair.

Critical reviews of screw pile foundations are primarily based on the experience of building underground foundations using low-quality supporting elements with a welded screw tip.

Inexpensive products of this type are suitable for the construction of temporary light buildings, various kinds of fences and sheds. For housing construction, it is risky to use supports with a welded blade.