Basement siding

A building on screw piles is the easiest and cheapest to sheathe with such material. The cladding has the following advantages:

- low cost (even taking into account the components);

- ease of do-it-yourself installation;

- durability;

- wear resistance;

- resistance to decay and mold;

- a wide range of colors;

- ease of use.

Basement siding

Basement siding

But along with the advantages, siding also has a number of disadvantages. For example, it will not work if you need to insulate the basement of the house on screw piles.

Installation technology

It is quite simple to make the cladding of a house, you just need to know the order of work and the nuances of their implementation. The base / plinth arrangement is carried out in the following order:

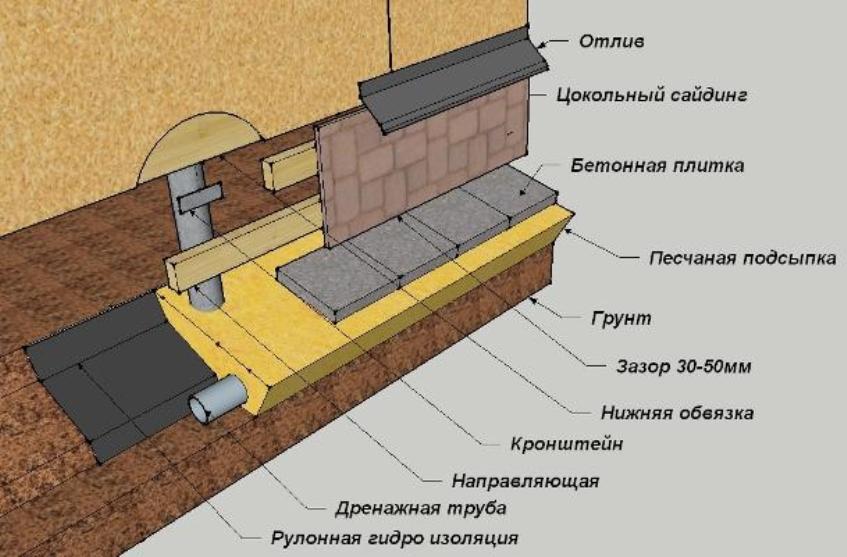

- Installation of lathing for siding. First of all, the lower bar is fixed. It is parallel to the ground. The distance from the soil surface is set equal to 150-200 mm. Such a gap is necessary to raise the skin above the ground. The distance from the panels to the ground after installation should be 50–70 mm. This layer compensates for soil swelling in winter. In warm regions or on coarse substrates, the gap can be reduced.

- Wooden boards are attached to the piles. To do this, special brackets must be welded to the heads in advance. Also, as a frame, you can use a metal profile, which is welded to the foundations without additional elements.

- Similarly to the first, a plank is fastened in the upper part of the basement of the house on a screw foundation.

- A vertical crate is sometimes made between the longitudinal guides. The need for it depends on the height of the base. With a high rise of the building from the ground, it is worthwhile to provide additional elements as reinforcement.

- Siding begins to mount from the bottom starting bar. Basement panels are installed on it. The elements are fastened to the crate using self-tapping screws. For the device of the corners, special profiles are required.

- To divert precipitation from the basement, ebb tides are installed on the siding.

- The finishing of the lower part of the house is completed after the clearance between the ground is made. The space must be closed so that there is an opportunity for air to enter, but small debris, insects and other living creatures did not have access.

All wooden elements are treated with antiseptic compounds before starting work. This is necessary to prevent damage by fungus, mold and decay. As an additional measure, fire retardant treatment can be performed.

Siding is the most common option. In this case, finishing the building is easy and fast. The device should be started after the completion of the construction of the house, when all communications have already been connected. To prevent the pipes from freezing in a ventilated underground, they are wrapped in heat-insulating material. Most often, mineral wool is used for these purposes. You can use ready-made elements of thermal insulation for pipes, or you can make insulation using mineral wool mats (wrapped in rolls).

Pay attention to the soft waterproofing of the blind area

Siding is a great option to close the space under the house. To fasten the panels to the crate, it is necessary to prepare self-tapping screws.

How to sheathe the plinth of a pile-screw foundation with your own hands

For cladding a pile-screw foundation with your own hands, you must:

- Fasten the starting siding strip to the bottom rail of the frame with a 30 cm pitch of self-tapping screws.

- With a gap of 10 mm, the corner strip is attached, observing the pitch of the self-tapping screws of 30 cm.

- Fasten the third panel into the groove of the starting strip and push it into the corner strip, leaving a small space for possible expansion of the material.

- Fix the bar with self-tapping screws.

- Insert the next strip into the corner strip and slide it to the lower strip, secure.

- Carry out the installation of the remaining panels. The last panel can be trimmed as needed.

- Install a second corner plank to act as the starting corner for the next wall.

- Fasten the finish bar.

All panels must be installed with small gaps of 20-30 mm and fastened with 5 self-tapping screws. The installation of the cladding should be carried out without tension, since under the influence of temperature the material can change its dimensions by 6-7 mm.

Why is it profitable to cover with corrugated board

Construction experts recommend covering the foundation with a professional sheet, based on its many advantages. First of all, these are:

-

Strength. Profiled sheets are made by cold rolling, as a result of which they acquire increased rigidity.

-

Durability. Galvanized steel does not corrode for a long time and performs its function flawlessly for up to 30 years.

-

Variety of colors. The line of modern designs includes many colors and patterns: stone, brick. The facade with a beautiful plinth becomes more decorative.

-

Ease of installation. Finishing the basement of the house with a professional sheet is easy to carry out on your own. The material is easy to cut and attach to the building.

-

Budgetary. The cost of finishing is much cheaper when compared with other facing materials (stone, tiles).

Material characteristics and dimensions

The profiled sheet is widely used in construction as a roof covering, permanent formwork for floors, a material for self-supporting and enclosing structures. Its parameters are regulated in accordance with GOST 24045-2016. Material classification is based on different criteria.

In shape, a wavy and trapezoidal profiled sheet is distinguished. In terms of thickness, the variability is within the range from 0.3 to 1.5 mm. By wave height, the material is divided into three categories:

-

For walls (corrugation height 8-21 mm);

-

For roofing (wave height over 44 mm);

-

For formwork (corrugation wave height over 57 mm).

In order to protect it from rust and destruction, the metal is coated with a special anti-corrosion compound. This could be:

-

acrylic;

-

polyvinyl chloride;

-

polyester;

-

polyvinylidene fluoride;

-

polyurethane.

Veneer care

The ease of use of a profiled sheet base is another weighty argument in favor of choosing this material. The finished finish does not need any special maintenance measures. It is enough to periodically clean the surface of the lower part of the facade from dust and dirt using a soapy solution. Every 4-5 years, the homeowner should check the quality of the basement coating for cracks or peeling of the decorative layer.

Finishing types of screw pile foundations

There are quite a few finishing options, but there are only two types:

- hinged type screen;

- shallow strip foundation.

Screw pile foundations form a basement or basement. With the help of piles, a small space is created between the soil and the lower supports of the structure.

During the construction process, the foundation is closed with a hinged or tape structure. With the help of this, a semi-basement room is obtained, which is subsequently used for its intended purpose.

Closing the plinth is necessary. Screw piles are used in three ways:

- screw compartment at the tip;

- fully screw construction;

- blade tip.

With all these options, the hinged type is more often used, which is the most popular. This is because the hinged screen is more practical and easier to install.Sometimes mixed options are used when a secondary foundation is laid between the cladding. This is especially true when insulation is required.

Also, regardless of what types of piles or the method of sheathing were chosen, to strengthen the base, a crate from a profile pipe should be used. The profile can be selected in accordance with the parameters and lower elements of the house, including pile sections. This must be done for durability.

In this video, you will learn how to close the plinth:

Finishing largely depends on the type of building and the requirements for the basement floor

The availability of materials is also important. Each type has its own characteristics due to different installation work. The hinged version aligns with the walls of the house and does not sink into the ground

Fastening occurs due to self-tapping screws and other additional elements

The hinged version aligns with the walls of the house and does not sink into the ground. Fastening occurs due to self-tapping screws and other additional elements.

The standard installation time is equal to days, installation is simple and economical. The finish can be in the form of any material, including stone or wood.

For a strip foundation, a certain set of materials will be required. Typically, such a foundation is built using masonry or brickwork in conjunction with concrete elements.

This type of finish is deepened into the ground, for this reason certain properties of the soil under the house are required, as well as a flat surface in the area where the bearing piles are installed.

Insulation of the basement

Before you close the foundation of the house from the outside with siding, you need to take care of its insulation

This is especially important if you will be making a warm basement. All insulation works are carried out from the outside with extruded polystyrene foam

If you have to fix the insulation to the piles, without a monolithic base, the base is first sewn up. It is most convenient to use glass-magnesium sheets - they can withstand being even in water, are frost-resistant and strong enough. They are attached to the piles, then covered with a vapor barrier and foam is attached. After that, the siding bars are installed, pulling them through with self-tapping screws through the foam to the piles, and the siding is installed.

For a monolithic base and foundation, you can simply fix the expanded polystyrene from the outside, closing it with waterproofing below the ground level. Through it, siding guides are attached to the concrete.

We recommend watching a video on how to properly insulate the base with your own hands.

Thermal insulation of the screw foundation

One of the main negative characteristics of this technology for creating a foundation for a house is that the foundation structure on screw piles has an underground space, and this, in turn, promotes the penetration of cold air from below, which will certainly affect the comfort and microclimate throughout the building.

The implementation of thermal insulation of the foundation on screw piles has its own characteristics. The first step is to create a structure like an absent base, which is subsequently insulated. Insulation must be carried out in a complex - from the inside and outside.

The scheme of thermal insulation of the foundation with expanded polystyrene.

So, the whole thermal insulation procedure is divided into the following stages:

- treatment of piles with a waterproofing agent;

- construction of a structure that will replace the capital base;

- sheathing of the constructed basement with decorative panels;

- installation of insulation plates from the inside of the base;

- foaming the joints of the insulation.

Experts recommend two ways to build an imitation basement:

- lightweight brickwork;

- the use of support bars or rails.

The first method involves digging a small depression (150-200 mm) between the support posts, then pouring a reinforced foundation in it. After it grabs, it is necessary to lay in half a brick and glue the insulation material on this wall.

The second method consists in fixing wooden beams on the piles in a horizontal position using bolts or metal guides, but then a welding machine will be needed. After that, insulation sheets are attached to the constructed structure. According to experts, the insulation can be fixed directly onto the cladding material. It is best to use penoplex or polystyrene as a material for insulation. In addition to excellent thermal insulation properties, these materials have good sound insulation.

Finishing options for the base of the pile-screw foundation

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Pile foundations are widely used. This is due to the low cost of the device and the possibility of using it even on soft soils. But during construction, a problem arises: how to close the basement of a house built on screw piles?

The buildings located on the considered supports have a ventilated underground. A grillage is provided for tying the piles. It connects free-standing elements into one system. Grillage can be made of concrete or metal... When constructing wooden or frame houses, the harness is made of wood.

The plinth cladding will be attached to the piles or walls of the house. To complete it, you will need to make a frame or crate. The most convenient way to make and fix wooden planks. Their cross-sections will depend on the pitch of the piles and the mass of the material used for sheathing.

There are several options for resolving the issue of how to close the pile foundation from the outside. The decoration of the basement of the house can be made of the following materials:

- siding;

- brick;

- plastic panels;

- metal profiled sheet.

The choice of material depends on aesthetic and economic considerations.

They are necessary for normal ventilation of the space under the building. Lack of air can lead to direct danger to human life. You can often hear about the dangers of a gas such as radon. It lies in the ground, but often rises and accumulates in the basements of buildings and underground. Constant ventilation will help to avoid the accumulation of hazardous substances. Closing the vents for the winter is highly discouraged.

How to cut corrugated board

Due to the fact that the profiled sheet has a protective anti-corrosion and decorative coating, not all cutting tools are suitable for cutting it. Some of them can be applied, but only when certain conditions are met.

Bulgarian

It is often used for cutting metal products, but it is not very suitable for profiled sheets. The explanation lies in the fact that when working with a grinder, a lot of sparks are formed and the surface heats up. This negatively affects the condition of the galvanized and polymer layers.

If, nevertheless, the grinder is chosen for cutting sheets, then it is recommended to take exceptionally thin discs with a thickness of 1-1.16 mm with carbide teeth to it. The second way out of the situation can be wetting the cutting line, followed by sticking masking tape on it.

A circular saw

This hand-held woodworking tool is suitable for this material if it is equipped with a special blade for cutting metal with fine teeth and carbide inserts.

In this case, it is important to adjust the depth of the disc's entry so that it reaches the lowest layers of the sheet. To preserve the integrity of the polymer film, experienced cutters use a specially made device - a jig

It is a plate of plywood or OSB 1-2 meters long and 30-40 cm wide. Along the central axis, not reaching 10 cm to the edge, a cut is made in the jig. Align the slit with the cut line. The saw sole is installed on the jig and the metal is cut.

To preserve the integrity of the polymer film, experienced cutters use a specially made device - a jig. It is a plate of plywood or OSB 1-2 meters long and 30-40 cm wide. Along the central axis, not reaching 10 cm to the edge, a cut is made in the jig. Align the slit with the cut line. The saw sole is installed on the jig and the metal is cut.

Jigsaw

In some cases, this tool is quite suitable for cutting profiled sheets. Moreover, with its help it turns out to make curvilinear cuts, which fail when using a grinder or circular. To get a high-quality result and quickly sheathe the base, it is recommended to take a professional-grade jigsaw with a fine-toothed saw and set high speed when cutting. For long straight cuts, it is also worth using a jig.

Electric shears

It is most convenient to cut out a profiled sheet with electric shears. For any trajectory of movement, a very clean and even cut is obtained. The advantage of this tool is that it does not require an assistant to work with it. According to the principle of operation and design, there are three types of electric shears, which are used when finishing the basement:

-

Leafy. They give excellent cutting quality without waste, but they are difficult to work in a curved line.

-

Slotted. When cutting, chips are formed, and a curved cut is possible only with a large radius.

-

Nibbling. They give a lot of waste, but they allow you to cut out elements of any shape, regardless of thickness and relief.

How to close a basement in a house with a pile-screw foundation (installation technology)

Depending on the erected structure, you have to decide how to close the basement of the structure

Here you need to pay attention to a number of points:

First of all, you need to figure out for what purpose the free space under the base will be used.

It is necessary to have a general idea of the financial investments that will be required for the arrangement.

It is important to take into account the peculiarities of the soil, as well as the position of the building on the territory of the site.

You should also take into account the presence and abundance of groundwater that is present on the site.

Depending on the chosen finishing option, it may be necessary to use or mount auxiliary elements.

There are several mounting technologies

Considering all these points, you should decide in advance on the materials used for arranging the basement in your house, which is built on a pile-screw foundation. Technologically, installation includes the following processes:

- Competent selection of the necessary materials for arranging the base at the structure.

- Removing the exact dimensions, as well as the subsequent acquisition of material for facing work.

- After that, the preparation of the space for the structure is carried out, as well as the preparation of the tool.

- After that, a corresponding frame is constructed, to which the facing material will be attached.

- If a brick is used, then the base must be laid under it on the ground so that the entire base does not fall through.

- After the construction of the frame, the entire perimeter of the building is cladding on a pile-screw foundation.

- Subsequently, if necessary, work is carried out on the arrangement of external waterproofing and blind area.

After these measures, the interior decoration of the structure is started.

Currently, there are also other options for lining the basement on a pile-screw base, but not so often. It should be understood that such a foundation device is a rather complex structure that must be performed by a specialist using the appropriate technology. The same is the case with the subsequent arrangement.If the owner of the building does not have the necessary skill and experience, then it is recommended to entrust the work to specialists so that there are no difficulties and no mistakes.

Major manufacturing companies

Below is the

list of manufacturers of siding panels for the facade of private

houses.

- Grand

Line. Base / plinth siding produced by Grand Line is one

of the most common building materials for cladding serving

parts of the foundation. A wealth of colors and textures, as well as an affordable price made

its one of the market leader. - Basement

siding Canadaridge. The effectiveness of technologies used in production

basement siding Canadaridge has been successfully tested in

Canadian and Russian climate. Panels are high pressure molded and

colored during the casting process. This ensures uniformity

structure and color of products. There are about seven color options.

The surface of the panels is resistant to fading in the sun. The firm provides 30

summer quality guarantee for their products. - Basement

siding Fineber. Facade panels Feinbier has a large assortment of panels,

various colors and textures. It includes 6

types of panels for a stone and 2 types of siding for a brick. Embossed drawing, its

color and texture exactly reproduce the pattern of bricks and some natural species

stone (granite, marble). FineBer panels are resistant to mechanical stress,

precipitation, do not fade in the sun. - Facade

Tecos panels (ImaBeL). Plinth trim panels made by Tecos,

also have a high quality workmanship. The strength of the products makes it possible

use not only as a decorative element, but also to protect the most

vulnerabilities of the facade of the house. - Facade

Zodiac panels. The zodiac is a domestically produced facing material,

having a multilayer structure. Zodiac products are environmentally friendly and compliant

world quality standards. This company appeared on the building materials market

recently, but has already won high marks from builders and

designers.

These are the most popular

basement panel brands. However, do not forget about local producers.

various building materials. They are lesser known, but their products may not be

less quality. It should be borne in mind that the quality of the plinth plating is not affected

only the quality of the panels, as well as other building materials that

used during installation. The strength of the lathing depends on their quality and

fastenings. If they are of poor quality, the skin may fall off.

Mounting surface

Oil impregnation of wood

Depending on the base: wood, concrete or metal, they choose how to close the foundation. If everything is clear with concrete, then the metal, due to its technical characteristics, should be ventilated. This also applies to wood, in a damp place their service life is noticeably reduced.

Special attention is paid to the preparation of such foundations. For example, a tree is impregnated with a special compound that protects it from rotting, fire

GF-021 - anti-corrosion primer

Biosecurity measures are also carried out, since untreated pillars are an excellent breeding ground for insects, which will render the entire wooden structure unusable in a couple of years.

Metal, processed with red lead compounds and special anti-corrosive primers. For such purposes, you can use a conventional compressor with a spray gun. It is not difficult to do this with your own hands. Having diluted the soil to the required consistency, for example GF-021, you can carry out all the preparatory work on metal in one day.

Stages of work on finishing the basement of a frame house on screw piles

We had sheets of 1200 mm by 1800 mm in size (you can also take 2000 mm), the gap between the ground and the house is standard for a dry area of 500 mm. Therefore, it was very convenient to cut one sheet across the stiffeners into 4 equal parts of 1200 mm by 450 mm (just the ventilation gap remains) using metal scissors. The cost is 475 rubles. per sheet, thus, a running meter of our basement costs only 99 rubles, while the cheapest basement siding will come out 480 rubles. per running meter, excluding the cost of the required crate.

This is how the gap between the frame house on screw piles and the ground looked like before installing the homemade basement panels.

The cut parts of the profiled sheet were screwed with self-tapping screws directly to the wooden trim of our foundation.

Fastening sheets of corrugated board.

In order not to need to make an ebb from the basement, it was decided to place the corrugated board under the level of the main siding, i.e. it was necessary that the corrugated board was located on the same level with the still unfinished wall. In some places, it was necessary to put "inserts" on the OSB sheets so that it was flush with the wall.

The lower edge of the sheets was tied with a bar with self-tapping screws. The result was a fairly stable structure that did not require anchoring to the piles themselves.

Theoretically, in the future, it can be fixed to the piles.

At the corners, the sheets are bent, this gives additional rigidity. It is necessary to bend in certain places so that the corner profile stands, not on the stiffener.

On top of the sheets, the starting strips of the main facade siding are already attached.

As a result, it turned out like this:

How to close the pile foundation from the outside - photo.

In our opinion, it is beautiful. It remains only to make a blind area.

Materials (edit)

The hinged plinth is lightweight and does not require any excavation work

Consider how to close the pile foundation from the outside

It is important that the material used for finishing is durable and frost-resistant, does not lose its qualities under the influence of temperature extremes and ultraviolet radiation.

More reliable is the finishing of the basement of the pile foundation with stone, brick, cinder block, concrete. This will require the implementation of earthworks like the device of a shallow foundation.

The hinged structure is lightweight and does not require excavation work. Polymer, wood and composite materials are used, which are quick and easy to assemble.

Basement siding

The most commonly used for finishing a screw foundation is basement siding.

It is produced in the form of decorative panels with a thickness of 1 to 2.5 mm.

Advantages:

- the ability to use in any climatic zone, including in the north;

- resistance to mechanical stress;

- light weight, ease of installation;

- has low thermal conductivity, retains heat;

- durability 40-50 years;

- does not collapse under the influence of moisture, ultraviolet radiation.

The possibility of facing the foundation of a house with semicircular shapes is provided. For this, a technology was launched into production, thanks to which the material is easily bent. The panels are produced with a small thickness (1.1 mm) with the addition of synthetic threads.

Profile decking

One sheet of corrugated board will cover a significant space

Sometimes the question arises of how to close the screw piles so that the work can be done during the day.

In 4-7 hours, you can close the pile foundation with profile sheets.

The width is available from 1 to 4 m, due to this, a significant space can be covered with one sheet.

Advantages:

- polymer coated sheet has a service life of 30-50 years, galvanized sheet serves for 10-15 years;

- available in various shades and sizes;

- a light weight.

The disadvantages include:

- in places where the coating is damaged, the sheet is subject to corrosion;

- the zinc coating gradually evaporates.

Flat slate

Asbestos boards are not environmentally friendly material

Every year this material loses its popularity, it is being replaced by modern, environmentally friendly materials.

Advantages:

- resistant to atmospheric influences;

- durable.

Disadvantages:

- asbestos is dangerous to human health and pollutes the environment;

- fragile;

- unattractive appearance.

Frame system

It is a budget option. For the installation of the battens, we use vertical racks made of timber (metal) with horizontal rails and metal profiles attached between them. We attach the acrylic and vinyl siding to the prefabricated frame. For more information on how to close the basement space in a house on screw piles, see this video:

Leaf system

Tiles can be laid on the mounted profile

It is cost effective to use a sheet system.

Stages of the device:

- we fix vertically a metal profile (corner, pipe) or a wooden bar;

- we fix cement-bonded or asbestos-cement slabs;

- we lay tiles, porcelain stoneware, bituminous tiles on the slab.

Composite materials

We use as a composite material:

- lightweight polymer-sand panels reinforced with cellulose threads;

- fiber cement sheets have great strength, reliability;

Facing brick

Facing brick

Brickwork is a reliable but costly and time-consuming method of finishing a foundation on screw piles. To correctly and evenly lay the cladding, you need to have construction skills.

Advantages:

- durability, strength, reliability;

- high thermal insulation qualities;

- additional support for housing construction;

- aesthetic appearance.

Disadvantages:

- high price;

- labor intensity.

How to close the basement space with a brick:

- remove the fertile layer by 30-40 cm;

- we fall asleep a pillow of sand, crushed stone, ram;

- we insulate the sole;

- we put a brick.

The masonry should be connected with piles by means of metal pins. The metal is welded to the lathing, adhered to the brick by means of cement mortar.

Basement siding: practical, fast, aesthetically pleasing

If the design should only perform the function of decoration without additional insulation, then siding panels are quite suitable. A variety of textures, colors of material can transform an unfinished open area of work into a neat pedestal on which the building rises. They can be brickwork, tile or ceramic tiles, decorative stone.

Siding will be the perfect solution to the problem:

- It is very simple to solve a problem like: how to close the basement of a house on stilts, using this simple and understandable material. For independent work, you will need the following tools and devices: a cord, a building meter or tape measure, a set of wooden pegs, a plumb line, a building level, boards, a shovel, roll-type waterproofing.

- Before the start of work, the site between the piles and around them is freed from vegetation and debris.

- The soil is selected along the outer perimeter of the house near the walls. A trench with a depth of up to half a meter and a width of 0.3-0.4 m is being formed. At the same time, its inner border should be located, slightly going under the walls, and the excavation itself should be carried out with the formation of a slight slope in the direction from the walls: for every 2 m, 1-5 cm.

- The entire excavated pit, including the walls, is covered with a layer of roll waterproofing.

- A drainage perforated polyvinyl chloride pipe is laid on a small layer of crushed stone along the perimeter.

- In several places, drainage wells are brought to the surface - "ambulance" when silting up the system to flush it.

- The pipes are covered with a layer of 0.1 m of fine gravel. The trench is completely filled with sand along the upper border, which is well tamped, performing a slope from the walls.

- A blind area is being formed. Alternatively, it can be paving slabs, paving stones or concrete screed.

- Holders are welded onto the piles, onto which the guides will be attached through the holes.

- The frame is made of wooden (40x100 mm) or metal elements. To prevent wood from rotting, it is pre-treated with an antiseptic agent.

- Siding panels are installed using the J-profile, external and internal corners with fasteners. At the same time, a compensation gap of 3-5 cm is maintained for possible expansion when the temperature changes between the panels and the blind area.

- On top of the finished structure, an ebb is installed, along which precipitation is diverted from the base.