Types of piles used for the foundation

Today, there are several types of piles that can be used for the construction of a pile foundation. Among them:

- Driven piles.

- Screw piles.

- Bored piles.

Let's consider each of these types in more detail.

Driven piles

This type of pile gives the foundation the greatest stability. The thing is that during the design of the future structure, the designers calculate the future weight of the building and divide it between all the piles. During their installation, such a force acts on each pile, which then it will have to withstand. When the pile stops sinking into the ground, this may mean that it has reached the ground on which the structure can already withstand.

The compacted soil around it gives additional stability to the pile. It is possible to hammer such piles only with the use of a special pneumatic hammer, which is very expensive to use in private housing construction. That's why this type of pile not recommended for self-erection of such a foundation.

Screw piles

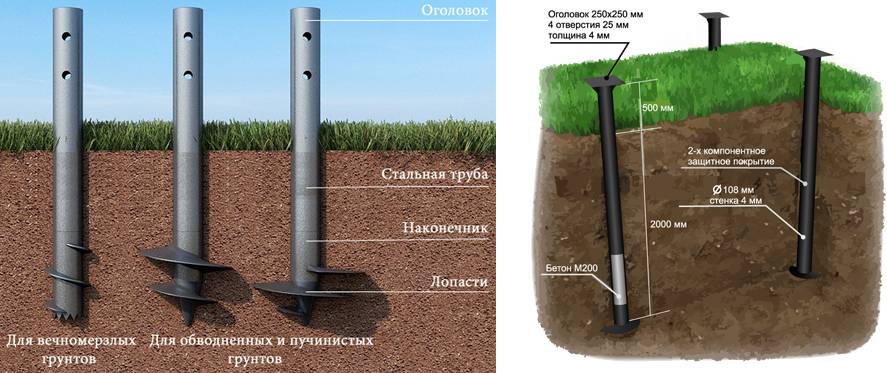

This type of pile is an ordinary steel pipe, at the end of which elements that resemble threads are welded. In fact, this type of pile can be compared with a self-tapping screw, that is, they are screwed into the ground according to the same principle as a self-tapping screw. Thanks to its blades at the ends, the support area is increased, which in turn increases the strength and reliability of the structure. If the soil at the construction site is not dense enough and even unstable, then piles can be used, on which blades are welded along their entire length.

This type of pile can be used for both private construction and industrial construction. Piles can be screwed in either manually or using a special technique. In the case of screwing in the pile yourself, this will require several strong people

As a rule, at the other end of the pile, there are two holes that allow you to connect them with the twisting technique, while it is very important that when the pile is twisted, it is located strictly vertically. When the pile is completely screwed in to the desired level, concrete is poured into the pile pipe and the head is welded, on which the grillage is subsequently installed

Some disadvantages of such piles should also be noted:

- A screw foundation requires an accurate calculation of the depth of solid soil, otherwise the pile will not be stable, especially during heaving of the soil.

- The piles must have high-quality welded seams, otherwise, during the screwing of the pile, the blades may come off or be damaged. This can lead to a loss of bearing capacity.

- The piles must be covered with a high-quality layer of factory paint, otherwise a poor-quality coating can lead to corrosion.

Bored piles

This type of pile is often used in private housing construction. In order to carry them out, it is required to make pile wells with a hand drill, after which formwork is performed in the case of loose soil that crumbles.

Such piles are waterproofed with roofing material or any other insulating material (asbestos-cement pipes can be used), reinforced, after which concrete is poured directly into the well. Piles are installed along the entire perimeter of the future foundation, that is, in the corners, along the outer and inner walls. The number of piles depends on the total weight of the future structure.

Among the disadvantages of these piles, it can be noted that it is impossible to accurately determine whether the pile has reached solid ground or not.

Advantages of the pile-screw foundation

Any design has advantages and disadvantages.Why is it worth choosing a pile-screw supporting structure for a house:

- Low cost of materials and installation work. If desired and skillful, piles can be made independently, further reducing their cost.

- Easy to install. The introduction of supports is carried out using a machine or manually, the difference between these methods lies in the speed of installation.

- Construction at any time of the year.

- There is no need for preparatory work. There is no need to dig a trench, set up formwork, or deal with groundwater. Accordingly, the site will remain clean.

- The minimum shrinkage of the house on piles allows you to start finishing work immediately after construction.

- The walls are protected from getting wet by groundwater - they just don't touch.

- Underfloor heating on the first floor, provided that the space between the ceiling and the ground is carefully insulated.

- The foundation adapts to the relief of any complexity due to the regulation of the pile height.

- Optimal load distribution over a large pile area.

- Installation is carried out without vibration, therefore construction can be carried out next to existing facilities without the risk of violating their integrity.

- The supports can be reused after dismantling the temporary structure if their condition is satisfactory.

Comparison of two foundations

Which foundation is better, tape or pile-screw? To be honest, strip foundations are used in the construction of buildings as a traditional structure that has shown good results for a long time.

However, practice shows that pile supports have a higher bearing capacity. Let's try to compare these two designs in terms of indicators such as:

- financial expenses;

- construction time and labor costs during construction;

- possibility of application;

- manufacturability and seasonality.

Financial expenses

Which foundation is cheaper than a strip or pile foundation? During the construction of a strip base, there are costs that are not required for pile structures:

- excavation and leveling, storage and removal;

- transportation costs for the delivery of tooling, reinforcement and concrete mix;

- backfilling of sand and gravel cushion and its compaction;

- concreting or installation of blocks using lifting equipment.

In total, the strip foundation is much more expensive.

Construction time and labor costs

The design of the strip foundation is much more complicated in its structure. When erecting it, it will take time to carry out earthworks, install the formwork and reinforcing cage, install the underlying cushion, and pour concrete. After that, you will have to wait until the concrete mix sets properly and start waterproofing work.

In the pile foundation, it is enough to screw in, drive in or install piles and tie them with a grillage. The work is performed several times faster.

Possibility of application

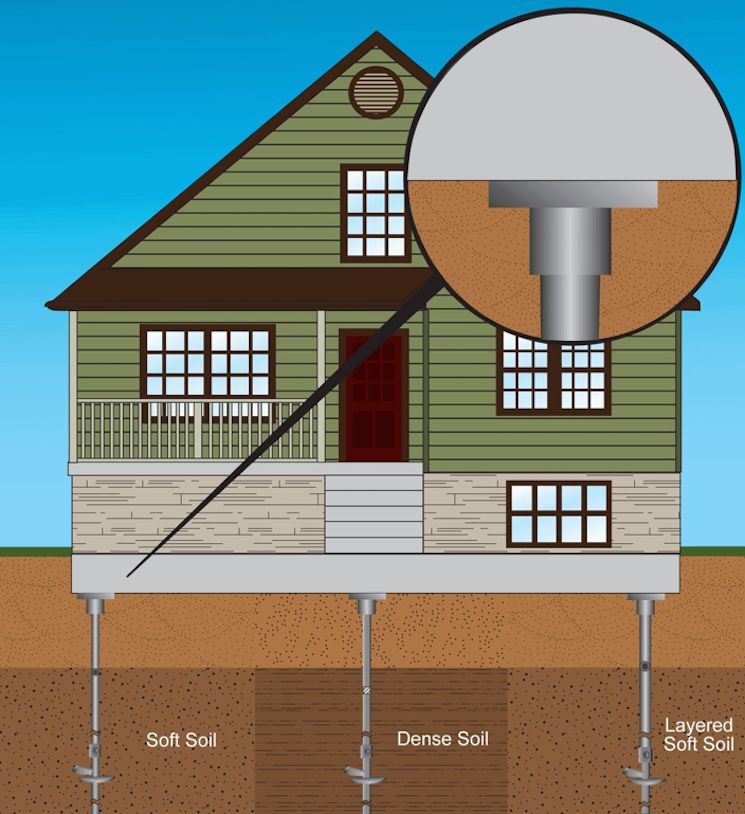

For pile foundations, there are practically no restrictions on use depending on the type of soil. The exception is peat bogs, on which no one usually builds anything. But the use of tape depends on the depth of its inception.

If the sole of the structure rests on dense soil layers below the freezing point, then only lateral loads act on the tape and its stability depends on the degree of reinforcement, that is, the strength of reinforced concrete. Shallow foundations can only be used on stable, dense soil with a shallow depth of freezing and deep groundwater.

In the presence of a complex relief of the site, with a slope or elevation differences, the cost of the strip foundation increases sharply, while the pile foundation allows you to solve the issue without any special problems.

Design features of the pile foundation

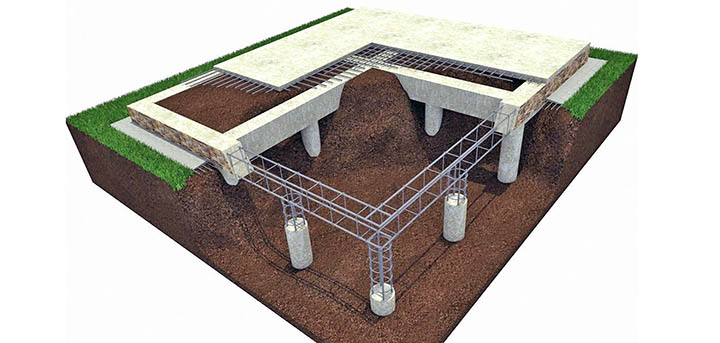

From a technological point of view, a pile foundation is a pile system that must evenly distribute the weight of a building onto the ground.At the same time, the load of the structure itself is transferred to the piles using various types of grillage.

Even a separate type of foundation can serve as a grillage, for example, a strip or slab, but this will already be a combined type of foundation.

A grillage of a purely pile type, usually represents a beam floor, some kind of frame, or the very base of the structure frame.

From this it follows that, by default, the pile foundation is limited to use only for light and non-massive structures, while the combination of piles with other types of foundations allows you to create very strong foundations, with huge bearing capacities - for the construction of large and heavy houses.

The methods of placing piles can also be different, they can be placed both along the perimeter of the future structure, under load-bearing walls, corners, and whole pile fields can be created, where the piles are installed over the entire area of the building. The distance between the piles is also different.

In addition, in the presence of a horizontal load on the foundation, an inclined type of pile is used.

How foundation piles differ

The main difference in piles is the method of making the tip blade, depending on its type, there are pros and cons of screw piles. There are 2 types:

The main difference in piles is the method of making the tip blade, depending on its type, there are pros and cons of screw piles. There are 2 types:

- Welded tip. The economical version of the pile is a pipe with a welded blade. As a rule, of very low quality and small diameters. There is a possibility of inaccurate welding, due to which, when screwing in, labor will leave the vertical level. In case of weak welding, the blade may come off during drilling. And you're in luck if the blade breaks off during the foundation process. It is worse when a poorly welded blade comes off after a couple of years after the start of operation at home. In this case, the load on adjacent piles increases greatly and the integrity of the structure is called into question. The only advantage is the low price.

- Cast blade. Solid construction of the drill, made by precision casting in a vacuum environment from steel grades ST-25, ST-35. They are distinguished by ideal drill geometry and high bearing capacity (up to 6 tons). The price tag for cast piles is on average 25% higher than for welded piles, and the risks of damage are much lower. Piles with a cast drill are screwed even into soil with stone inclusions. And the term of responsible service for such bases is more than a century.

When choosing piles, pay attention to the quality of the pipe and its coating

Also, when choosing piles, you should pay attention to the quality of the pipe. Ideally, this is a galvanized pipe with a polymer powder coating.

Ideally, this is a galvanized pipe with a polymer powder coating.

But the anti-corrosion treatment of the drill does not really matter.

Firstly, when screwing in, this layer will be erased, and secondly, there is little free oxygen in the soil and the oxidation processes are slow.

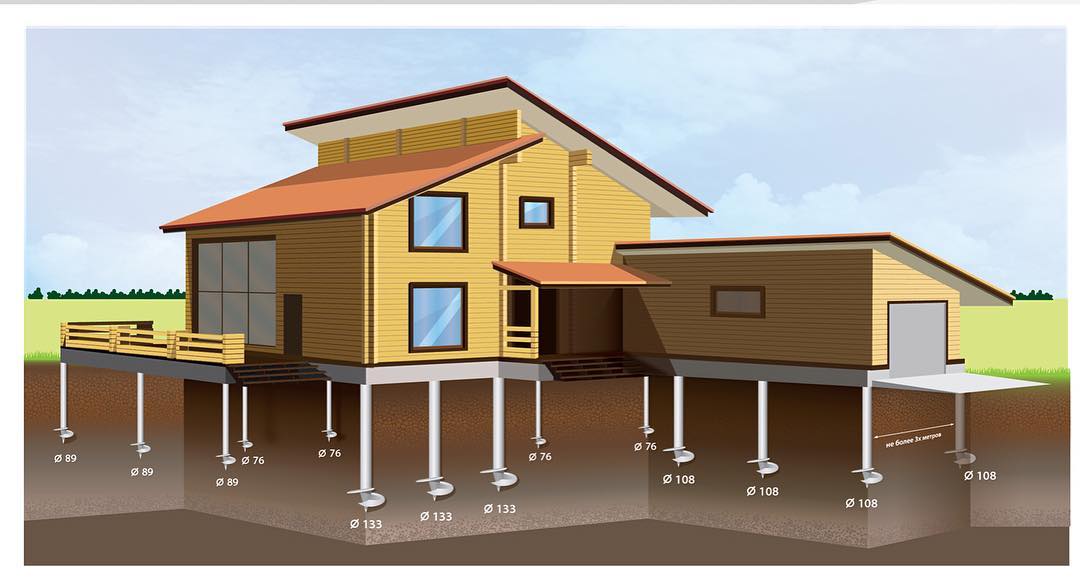

| Designation | Pipe diameter (mm) | Blade diameter (mm) | Application area |

|---|---|---|---|

| SV89x250 | 89 | 250 | verandas, terraces, gazebos, fence posts; |

| SV108x300 | 108 | 300 | small frame houses and buildings made of profiled or solid timber; |

| SV133x350 | 133 | 350 | Solid wood buildings and buildings made of foam or aerated concrete blocks |

There is a type of welded piles that are not inferior in their characteristics to cast ones. These are piles made of thick-walled tubing.

The pipe wall thickness must be at least 6.5 cm

The pipe wall thickness must be at least 6.5 cm

In the process of their production, pipes with a wall of 6.5 - 7.5 mm are used, made for high-pressure pipelines and used in the gas and oil industry. Such pipes are designed to work in aggressive environments. The blades in such piles are made of structural steel. At the same time, the strength of the drill increases by a third.

It should be noted that the cost of high-quality screw piles is often in the same plane with bored reinforced concrete products. In such situations, the choice of a screw foundation is justified only by time constraints, weather conditions or difficult soils.

Advantages of a foundation on screw piles

Installation speed

The high speed of installation is perhaps the most important advantage of screw piles, because in the construction business, time is valued like nothing else. The screw pile is ready for use immediately after installation. Even the concreting of the inner lumen of the pile shaft does not lead to forced downtime at the construction site: there is no need to wait for the concrete to gain grade strength, since the load on the pile is primarily taken up by its steel shell.

Low noise level when arranging the foundation

Low noise level during installation is the main advantage of screw piles over driven ones. The process of driving the latter into the ground is accompanied not only by noise, but also by vibrations. Vibration effects on the ground can harm various structures in the immediate vicinity of the work site.

Low price

The low cost of the foundation on screw piles in comparison with the cost of all kinds of reinforced concrete foundations is achieved primarily due to a significant reduction in the amount of land work.

Ability to withstand various pulling loads

This ability is due to the presence of blades in screw piles. It is thanks to their blades that these piles can be installed on uneven ground (which means they are great for buildings located on slopes) and at any angle to the vertical.

No need to pull out a lot of soil

An insignificant amount of soil displaced during the installation of screw piles allows work to be carried out close to existing buildings.

Can be used in various conditions

The weather and climatic unpretentiousness of screw piles is expressed in the fact that they can be operated in a fairly wide temperature range, are not afraid of groundwater rise and soil swelling, which means that they do not require mandatory drainage of the site where construction is underway.

Reusability

One of the areas of application of screw piles is the construction of temporary structures. After such a building finishes performing its functions and is dismantled, the screw piles can be removed from the ground and reused, if necessary.

It is worth noting that all these advantages are possessed only by industrially produced screw piles, the quality of which complies with the International Building Standard ICC AC358 Helical Foundation Acceptance Criteria.

Characteristics of the main elements of the pile-screw foundation

Screw pile installation

The screw pile is a steel pipe with a sharp, closed tip and blades. In fact, this is a drill screwed into the ground. The screw tip is the main working element, which acts as a functional part, support and anchor. Heads are sold in addition to the piles. They cover the upper part of the structure and serve as a platform for further strapping work. Also, the head is used for screwing, clinging to it, and not to the base of the pile. The blades hold the building under the influence of frost heaving forces.

Pile-screw foundation

In winter, swelling on clayey water-saturated soils, especially for light timber structures, can lead to squeezing out of the foundation. The problem cannot be solved by deepening the supports below the freezing zone due to the forces acting on the side part. But if you lower the support below the freezing level, with an anchor, then a layer of solid soil will hold the foundation.

Screw piles are designed to erect a lightweight and inexpensive foundation. Moreover, each building has its own standard size, shown in the table.

| Type / size | Application area | Bearing capacity (kg) |

|---|---|---|

| SV76X122 | The most lightweight structures are fences, sheds and utility blocks, playgrounds. | 350 |

| SV89X250 | Non-residential premises - garden houses, arbours (gazebos), lightweight berths and piers | 1450 |

| SV108X300 | Residential buildings of light weight - houses made of timber, logs and SIP panels. | 2200 |

| SV133H350 | The heaviest of the possible structures made of foam concrete, expanded clay concrete blocks. | 2900 |

Pile types

There are two main types of supports, they are distinguished by the way the tip is created:

- Welded tip.

- Molded tip.

The first option is cheap, for which you have to pay for reliability. The disadvantage is that the blades are welded to the tip without observing technological standards, using a handicraft method. As a result, when screwing in, the pile can move away from the vertical. The blade may break off, this is noticeable by the decrease in resistance when screwing in. Such a pile can no longer fulfill the role of a full-fledged support, some of its load-bearing duties are assumed by neighboring points, as a result of which their wear is accelerated. The worst option is the breakage of the pile after the construction of the house. The foundation grillage is deformed, and the structure becomes emergency.

Cast head for screw pile

More reliable lugs made by precision casting are more reliable. They are more expensive, but durable and can withstand up to 6 tons of load.

Separately, it is worth considering piles from a tubing with an increased wall thickness. Their reliability is comparable to cast ones, thanks to the thick-walled pipe. Special steel can withstand aggressive environments without a protective coating up to 7 times longer. The use of such piles allows you to get rid of their main drawback - metal corrosion in the soil.

Important pile parameters

When choosing screw piles, one should be guided by the type of tip and a number of auxiliary parameters:

- wall thickness is an individual parameter, depending on the type of soil, the weight of the structure, and a number of other requirements;

- characteristics of steel - each alloy has a number of operational parameters that should be considered when purchasing piles;

- type of strapping - strong, steel foundation strapping distributes the loads between the supports better than its counterparts from a bar;

- methods of anti-corrosion treatment - there is a choice between galvanized metal and polymer coating; if the processing is done according to the requirements, the polymer will be preferred.

When buying piles, ask the seller for all the necessary regulatory documents. They will be a guarantee that, under the guise of reliable supports, the handicraft product has not been sold to you. Otherwise, there is a risk of collapse of the building in the first years of operation.

Stilt house

Applications

Steel pipe columns allow the construction of 4 types of foundations:

- installation of pile supports for each load-bearing element of the frame building;

- the device of the pile tape in the form of a steel or reinforced concrete grillage;

- pile field for pouring a reinforced concrete slab;

- single supports for the construction of an extension or individual building elements.

The intended use of metal piles is determined by the diameter of the pipe and the size of the blades. In the product marking, the first number indicates the size of the pipe string, the second indicates the blade. Depending on these indicators, it is recommended to use:

- 76 mm pipe for light fences and individual posts;

- 89 mm for awnings, verandas, gazebos and reinforcement of brick columns;

- 108 mm for frame-type buildings and light timber houses;

- 133 mm for structures made of logs or foam blocks.

At the same time, twin-screw piles with a lower cast tip have the best bearing capacity. After screwing in the supports, their inner cavity must be filled with concrete without reinforcement.

Cons and pros of a pile foundation

Now let's talk in more detail about the advantages and disadvantages of the pile foundation. The indisputable advantages include the following aspects:

- The possibility of erecting a foundation in areas with difficult terrain and a large slope.Where, for other types of foundations, one would have to splurge on concrete, or spend a lot of money on earthworks, leveling the site, piles beat their competitors on the head, since the pile foundation has practically no restrictions on height differences.

- The ability to use piles on almost any soil - it will be stable both on wetlands and on clayey soils. Laying the foundation on piles is advisable when the topsoil has a low bearing capacity and significant thickness:

- On black earth, fertile and silted lands, next to forest lands.

- In swampy areas, on peat bogs, sandy-clayey quicksands, clays and loams in a plastic state.

- On salt marshes, subsidence soils.

- In regions with permafrost, with a significant freezing depth.

- In areas with a high GWL (groundwater level), with the threat of flooding.

- On forest soils that lose strength when saturated with water.

In all these cases, the load from the house must be transferred to dense layers of soil. Strip foundations or insulated Swedish slabs at such a depth become economically unprofitable, and simply, such foundations may be fragile.

- Low labor intensity of work. If we consider screw piles, then the installation process consists in screwing the piles into the ground. As a rule, two people can cope with this work without the use of special equipment. This implies another plus - the ability to carry out work with your own hands without the involvement of hired specialists.

- High speed of work. The foundation of screw piles can be erected in one day, and the next day further work on the construction of the house can be carried out.

- Low cost. A ready-made foundation made of bored or screw piles will cost orders of magnitude cheaper than other types of foundation.

There are also disadvantages to this type of foundation:

Reduced bearing capacity of piles compared to other types of foundations. If the load on the piles is incorrectly calculated, they can sag, damaging the frame of the structure.

Therefore, before choosing the type of foundation, it is important to make all the necessary calculations and make sure that the future foundation will be able to bear the loads from the structure.

If screw piles are chosen for the construction, but at the same time you plan to build a heavy house, then the way out of this situation will be to use screw piles with a diameter of more than 133 mm (standard screw pile diameter). At the same time, the problem is that many companies operating on the market do not have the ability and special equipment for the installation of such piles.

No basement

In houses on pile foundations, it is not possible to organize a full-fledged basement, since during the installation of the foundation there is no excavation under the house. However, when the houses are located on a large slope, it will be possible to organize utility rooms in the resulting space.

The need for additional insulation of the basement of the building. The disadvantages of pile foundations is the ventilated basement of the structure. This creates an obligatory need (as opposed to concrete foundations) for insulation.

Advantages and disadvantages

So, the advantages of screw piles are as follows:

- The cost of erecting a pile foundation can be at least 30% cheaper than installing a foundation made of reinforced concrete (in conditions of occurrence of loose and unstable soils on the construction site);

- Short installation times. In this case, it is not at all necessary to use specialized equipment. To build an individual residential building, you can install piles manually;

- Ideal for erecting buildings in swamps, loose and unstable soils;

- Durability and safety;

- Considering that each support is made of high-alloy steel and treated with special protective equipment, it can last up to 150 years;

- When installing piles, there is no need to carry out preliminary work on digging trenches, which significantly reduces the time for erecting the foundation for the house;

- Installation of supports can be carried out at any time of the year;

- The ideal solution for the construction of the foundation with a large difference in height on the site.

But you must agree that any type of foundation also has a number of certain disadvantages.

Supports from piles are no exception, of course, the list of disadvantages when constructing this foundation is completely insignificant, but nevertheless, you should pay close attention to the disadvantages of screw piles when choosing the type of foundation for future construction

So, the disadvantages include the following:

- The quality of the material used. This is perhaps the most important thing. Without the necessary knowledge, you can purchase low quality products. In this case, you can forget about the durability of the foundation on the piles. The main disadvantage of metal is its susceptibility to corrosion when interacting with water, therefore, each support must be treated with a special protective compound and made only of high-quality steel.

- Rocky ground is not the best option for installing supports. As a rule, during installation, the blades break, and it is impossible to install the supports to the required depth. The result is an unstable, shallow pile foundation that is not suitable for the construction of a building on it.

- Well, and, probably, the biggest disadvantage is the lack of a basement and large labor costs for insulating free space under the floor and decorating the basement. In addition, all water supply and sewerage systems must be buried and thoroughly insulated, since the absence of a basement contributes to the freezing of the soil under the house.

It should be added that when choosing piles, special attention should be paid to the welding places. The weld seam must be neat and surely processed bituminous mastic for corrosion protection or other special compounds

Installation of screw piles

And so, all the calculations were performed, and you found out, for example, how many and which screw piles will be needed for a house made of aerated concrete in accordance with the soil conditions on your site. The purchase is complete. Now you can proceed to the construction of the foundation.

In the photo, the marking of the site

Markup

An equally important process than calculating the foundation is the marking of the building area in accordance with the project. Naturally, you must first prepare the site, remove all unnecessary and provide an entrance, if equipment is used.

The marking begins with the designation of the corners, after which the position of the remaining structures on the site is marked. In the places where the piles are installed, holes should be made, which will simplify the installation and make it more accurate. All distances must be rechecked several times so that the dimension is respected.

Immersion structures

,

Installation of piles

Before proceeding with the installation, you should decide in what way the piles will be installed - mechanized or manually. The second method is less fast and requires the physical efforts of several people, but at the same time it is more accurate and less costly.

Also, before installation, you need to take care of the anti-corrosion coating of the supports, since the durability of the foundation will depend on this. If the soil is abrasive, i.e. has inclusions of small stones, sand, etc., then even a two-layer anti-corrosion coating will not be enough.

If you decide not to resort to the help of specialized equipment, then for the installation of piles with your own hands you will need a simple device in the form of a scrap and two pipes at least two and a half meters long, which can be put on scrap.

The installation instructions are as follows:

- The pile fits into the prepared hole.

- A scrap is threaded into the hole located in the upper part of the pile, after which pipes are put on both ends.Thus, levers for screwing in the product are created on both sides.

- Several people, holding the pipes, walk in a circle, screwing in the pile. It is imperative for one person to observe the observance of the vertical position of the trunk and correct its direction.

Mechanized mounting of supports

The structure should be screwed into the ground until the helical blade, which takes the main load, enters the frost-free soil layer. To do this, it is necessary to determine the depth of soil freezing, and also take into account the dimensions of the blade part of the structure. In most cases, it is enough to immerse the post 30 cm in the supporting layer of the soil.

It is forbidden to unscrew the support and submerge it again in the ground in the same place. The reason is that a change in soil parameters will affect the bearing capacity of the pillar. Piles should be started from the corners of the foundation, this will ensure high accuracy of installation of all intermediate supports.

Sometimes, in the process of immersion, the propeller blades or the lower part of the barrel may bump into some kind of obstacle. If this happened below the level of soil freezing, then the structure can be left as it is. A large rock in the path of the pile will make it stronger by distributing the load evenly over the ground.

Also, a good indicator is the achievement of the blades of such a hard soil that several people are not able to turn the structure. This also indicates strength, provided that the blades are submerged below the freezing level of the soil.

Concreting pillars

Concreting

Since the stem of the screw pile is, in fact, a pipe, after installation, it must be filled with concrete. Firstly, it will add weight to the structure, and thereby make it more durable, and secondly, it will protect against corrosion.

If the barrel is not filled with concrete, then over time it can collect water, which, with the onset of frost, will lead to its rupture. Cement-sand mortar is made in a ratio of 1: 4. Under no circumstances should it be possible to cement the outer part of the post.

Marking heights and clipping

After immersing the supports, they begin to mark the heights of the pillars. For these purposes, an optical rangefinder is usually used. If the pillars are installed in plastic soil, then the alignment is carried out by screwing in the structures. If this is difficult, then the upper part of the supports is cut off with a grinder at the set level.

On top of each pile trunk, it is necessary to install and weld a head, i.e. steel plate It is needed to evenly distribute the load over the entire cross-sectional area of the structure barrel.

disadvantages

The main disadvantage is the corrosion of the metal base

Therefore, special attention should be paid to the quality of the metal from which the pile is made. Since, in order to save money, many companies use low-quality material for the production of screw piles

Therefore, you should pay attention to the main characteristics of screw piles:

- the stem of the screw pile is made from a new one-piece pipe i.e. piles should not have welded seams;

- with a pile diameter of 108 mm, the wall metal thickness should not be less than 4 mm, and the propeller blade thickness should be at least 5 mm, and the blade dimameter itself should be at least 300 mm;

- the blades of the screw pile must be of the correct shape;

- the propeller blade must be well welded to the pipe, otherwise, under load during twisting, it may break off or be damaged;

- piles must be sandblasted (surface preparation process before applying a special anti-corrosion coating). Companies that make piles “handicraft” do not sandblast;

- quality of anti-corrosion coating. The service life of the pile-screw foundation depends on it.

Conclusion: the screw method of bookmarking is a quick and practical option, which is increasingly being used by specialists.In addition to the above positive points, it has a high bearing capacity. When screwing piles, the soil is not loosened, but compacted in the screw grooves, which increases the stability and endurance of the foundation part. Professionals have long appreciated the advantages of this method and use it for various types of objects for any purpose.