In what situations is it recommended to use a pile strip foundation

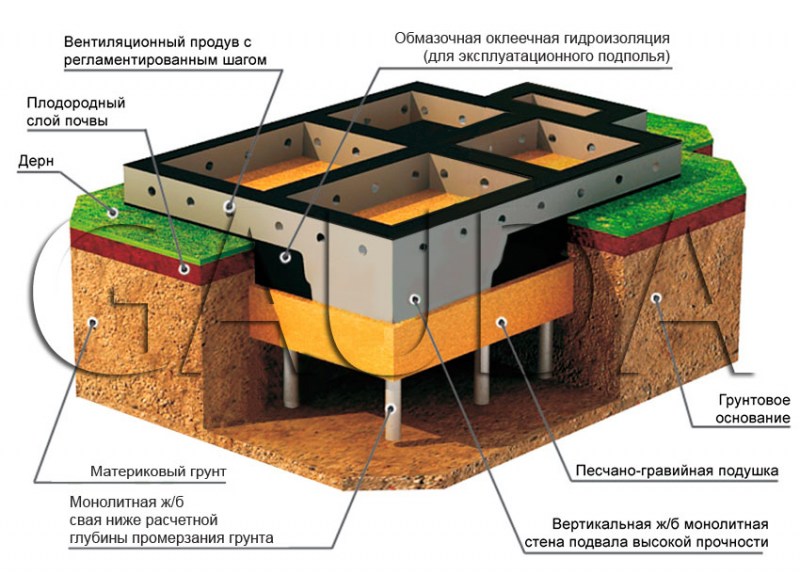

The tape foundation provides for the maximum deepening of the base deep into the soil with the help of a grillage, which will represent the level of the basement. This type of foundation is used in such cases:

- If the plot allocated for construction has a slope or relief terrain.

- The proximity to the surface of the earth of groundwater, which makes the base of the foundation weaker.

- The presence of heaving soils.

- If the weight of the future building will be very significant (use of brick and stone).

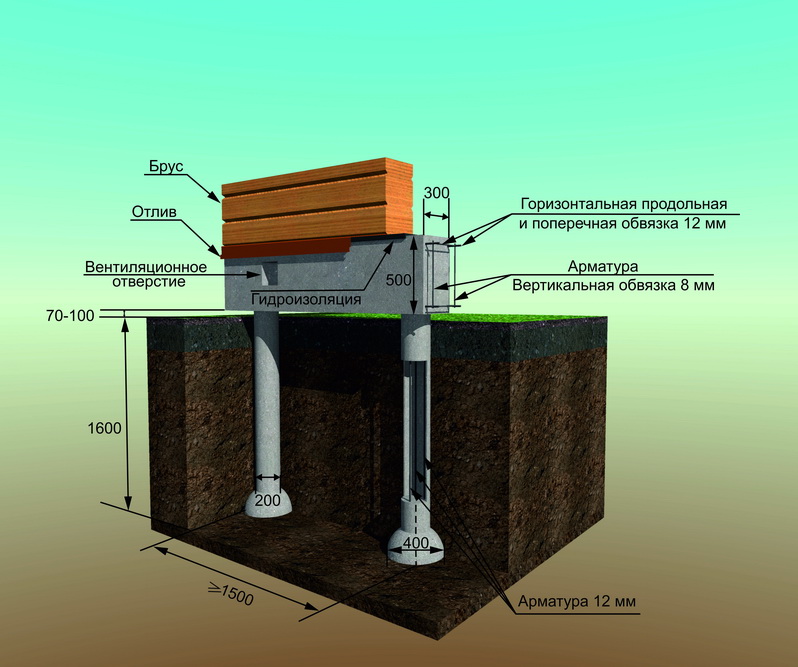

The depth of the piles is one and a half to two meters, which makes it possible to exclude the slightest inclination of the structure in the future when weather conditions change. The calculations made will help determine the amount of material required.

Types of piles used for the foundation

Today, there are several types of piles that can be used for the construction of a pile foundation. Among them:

- Driven piles.

- Screw piles.

- Bored piles.

Let's consider each of these types in more detail.

Driven piles

This type of pile gives the foundation the greatest stability. The thing is that during the design of the future structure, the designers calculate the future weight of the building and divide it between all the piles. During their installation, such a force acts on each pile, which then it will have to withstand. When the pile stops sinking into the ground, this may mean that it has reached the ground on which the structure can already withstand.

The compacted soil around it gives additional stability to the pile. It is possible to hammer such piles only with the use of a special pneumatic hammer, which is very expensive to use in private housing construction. That is why this type of pile is not recommended for self-erection of such a foundation.

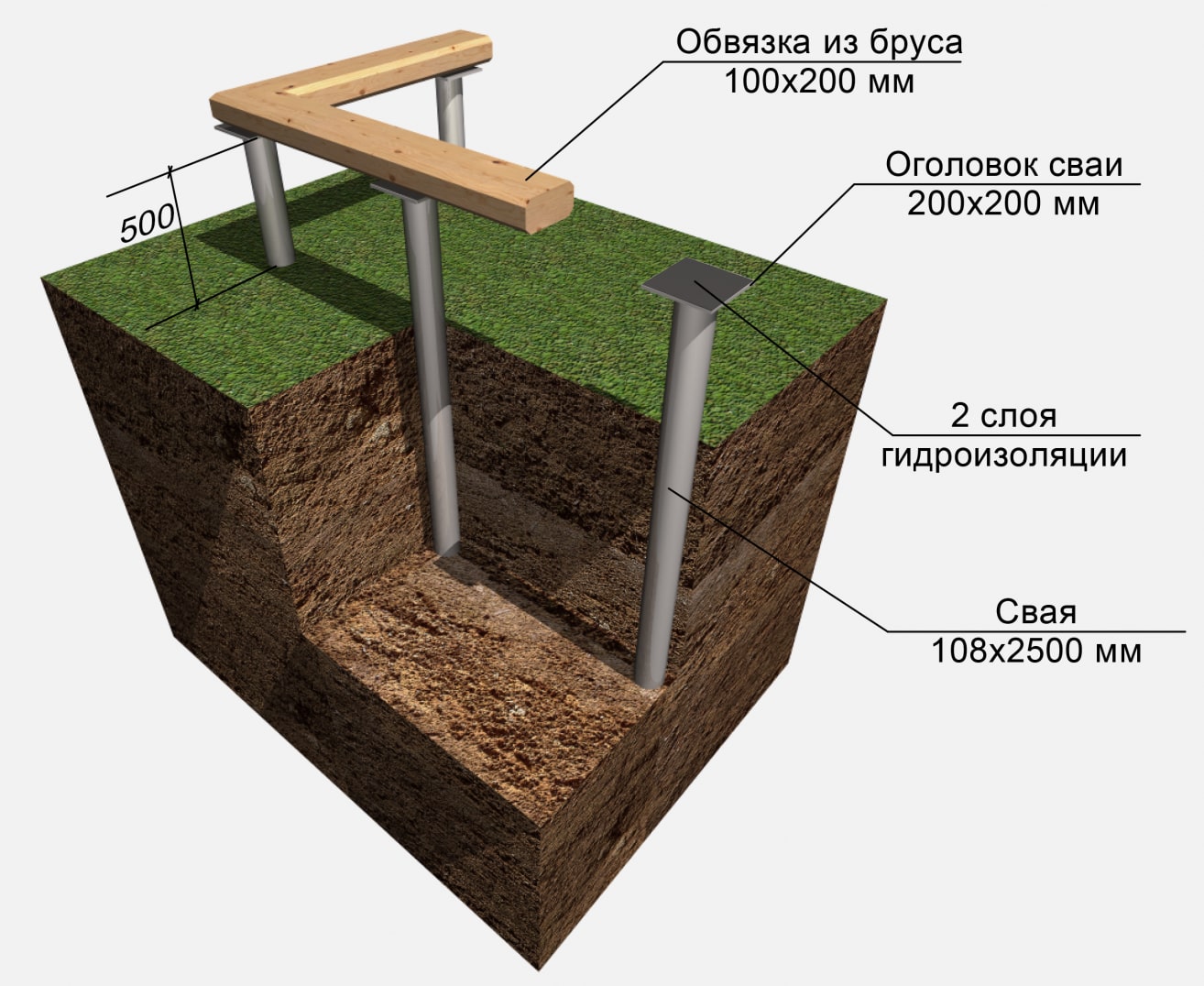

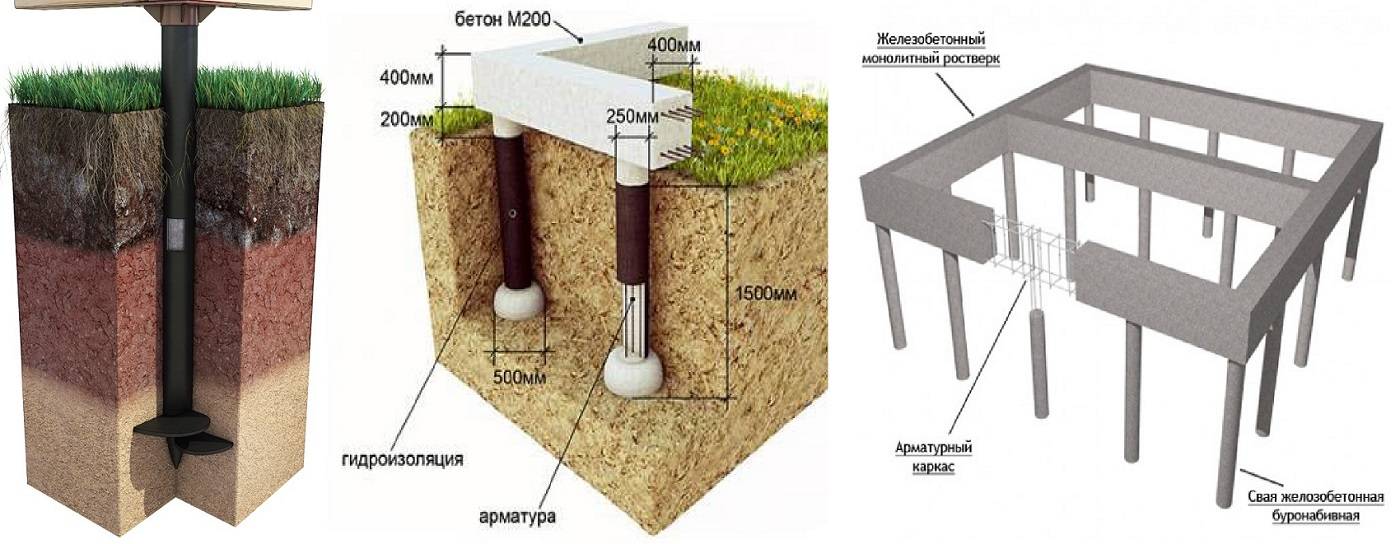

Screw piles

This type of pile is an ordinary steel pipe, at the end of which elements that resemble threads are welded. In fact, this type of pile can be compared with a self-tapping screw, that is, they are screwed into the ground according to the same principle as a self-tapping screw. Thanks to its blades at the ends, the support area is increased, which in turn increases the strength and reliability of the structure. If the soil at the construction site is not dense enough and even unstable, then piles can be used, on which blades are welded along their entire length.

This type of pile can be used for both private construction and industrial construction. Piles can be screwed in either manually or using a special technique. In the case of screwing in the pile yourself, this will require several strong people

As a rule, at the other end of the pile, there are two holes that allow you to connect them with the twisting technique, while it is very important that when the pile is twisted, it is located strictly vertically. When the pile is completely screwed in to the desired level, concrete is poured into the pile pipe and the head is welded, on which the grillage is subsequently installed

Some disadvantages of such piles should also be noted:

- A screw foundation requires an accurate calculation of the depth of solid soil, otherwise the pile will not be stable, especially during heaving of the soil.

- The piles must have high-quality welded seams, otherwise, during the screwing of the pile, the blades may come off or be damaged. This can lead to a loss of bearing capacity.

- The piles must be covered with a high-quality layer of factory paint, otherwise a poor-quality coating can lead to corrosion.

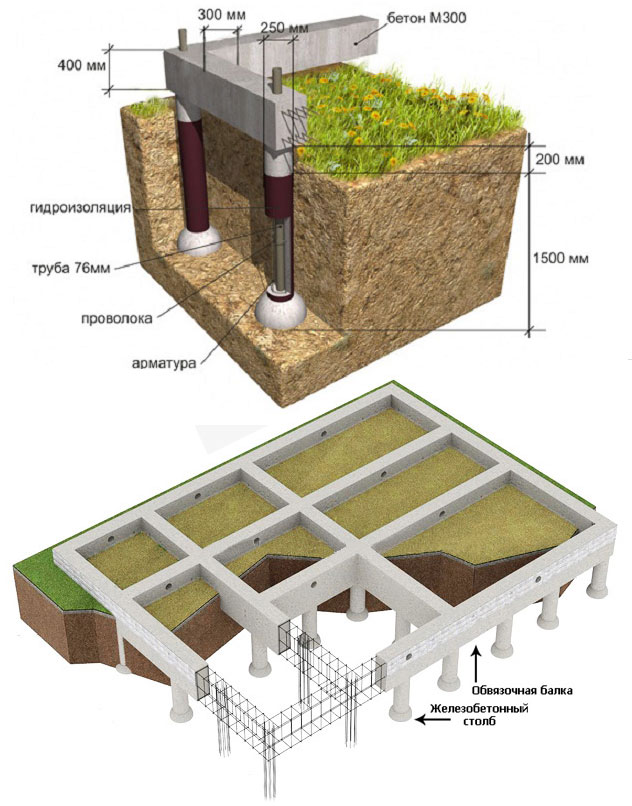

Bored piles

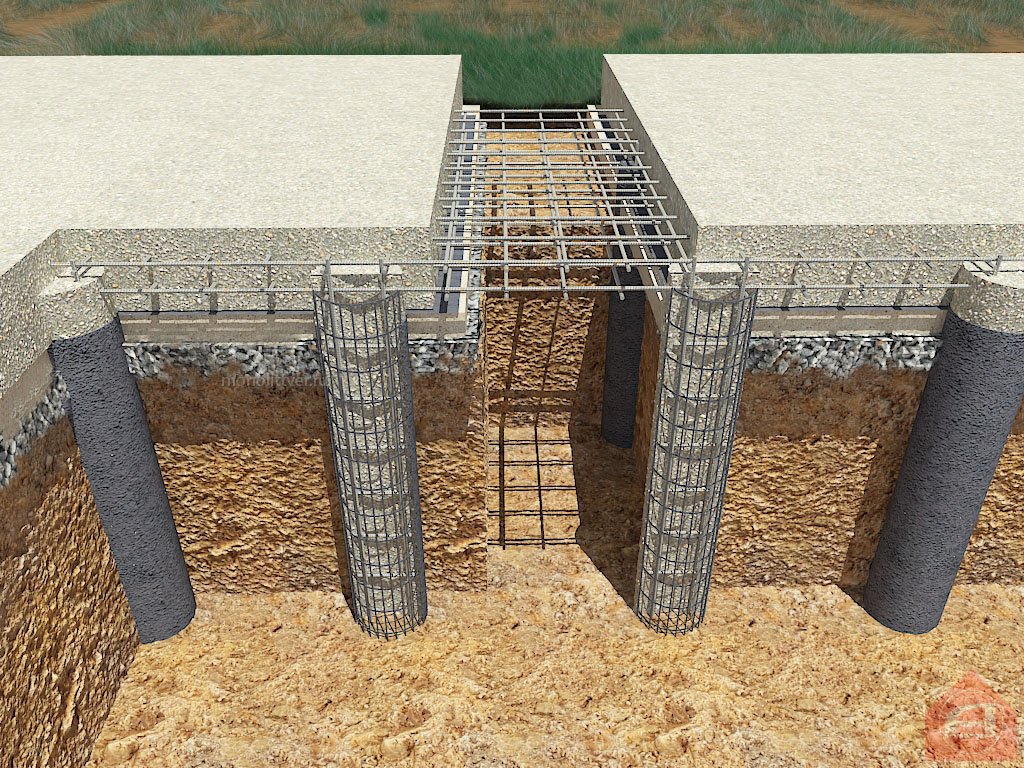

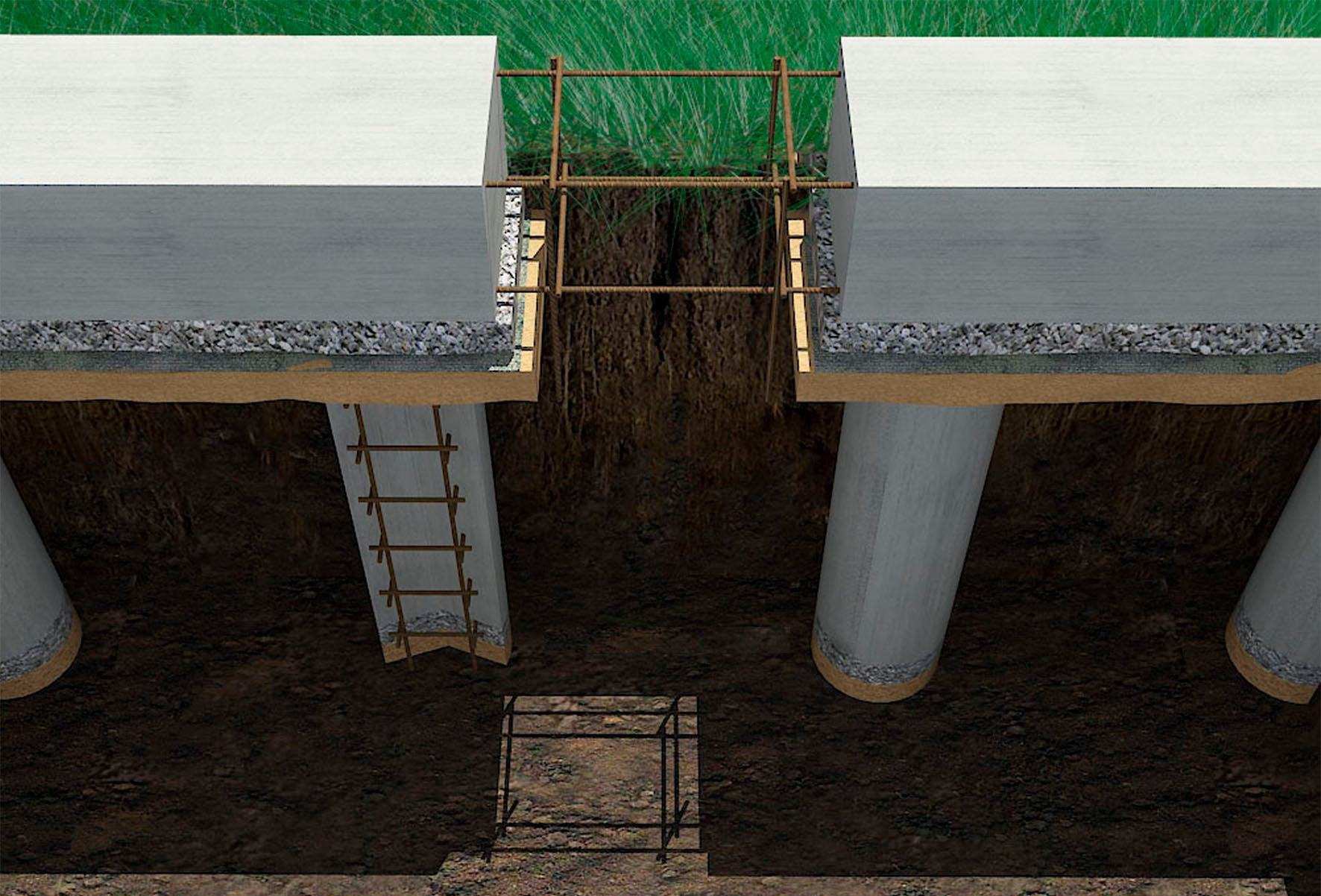

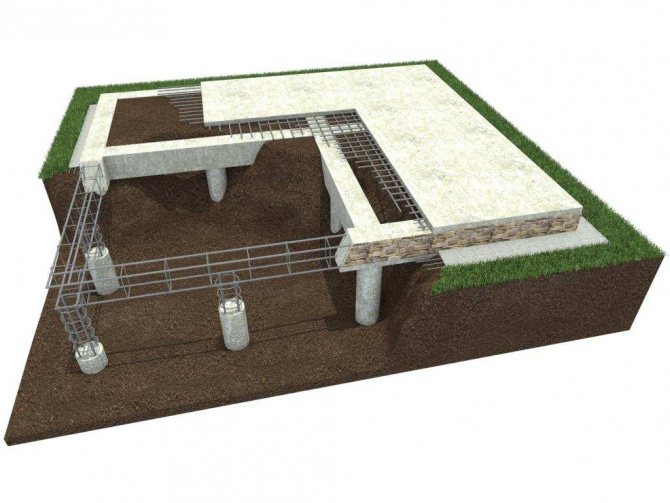

This type of pile is often used in private housing construction. In order to carry them out, it is required to make pile wells with a hand drill, after which formwork is performed in the case of loose soil that crumbles.

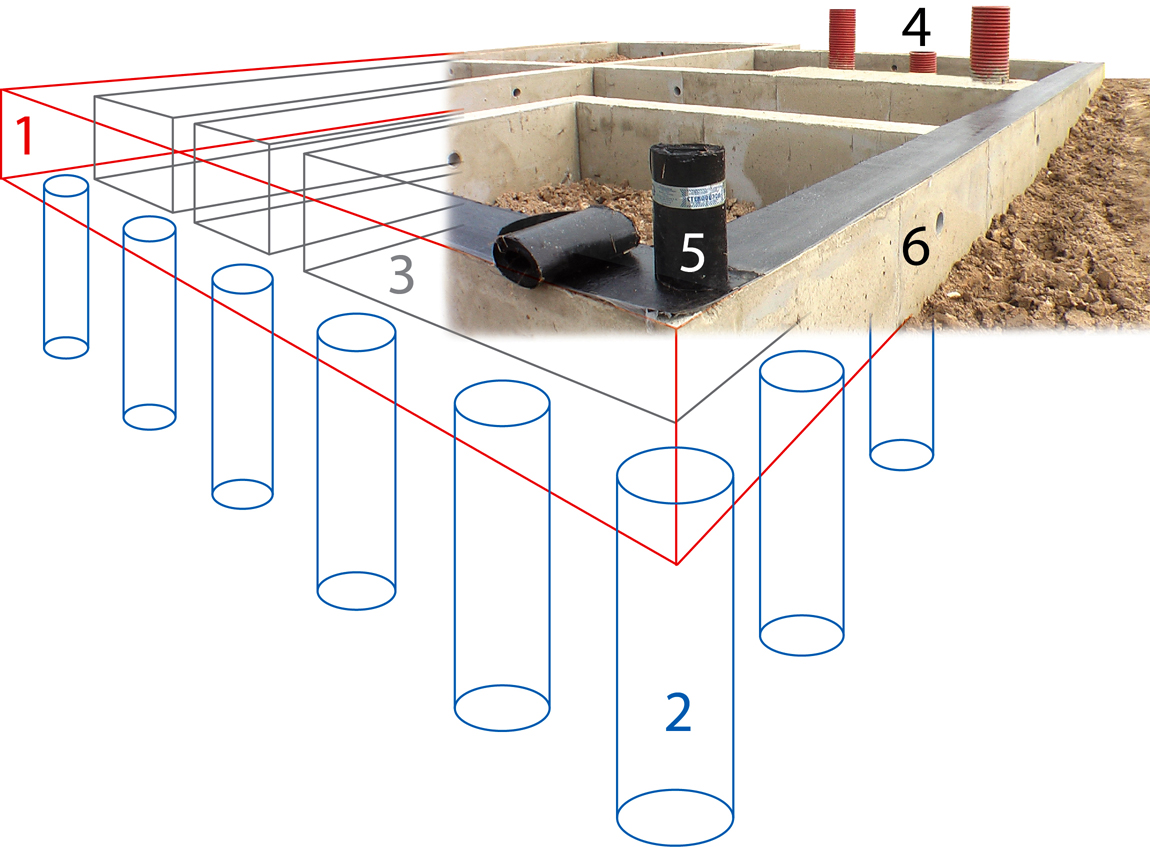

Such piles are waterproofed with roofing material or any other insulating material (asbestos-cement pipes can be used), reinforced, after which concrete is poured directly into the well. Piles are installed along the entire perimeter of the future foundation, that is, in the corners, along the outer and inner walls. The number of piles depends on the total weight of the future structure.

Among the disadvantages of these piles, it can be noted that it is impossible to accurately determine whether the pile has reached solid ground or not.

The main advantages of the pile-screw foundation

Giving our preference to one or another type of foundation, our choice is always based on its positive qualities, so let's start with them.

1. The cost of the foundation

Nobody will tell you the exact figure of how much the pile-screw foundation will cost less than other types, because many factors must be taken into account, from the depth of the foundation to the weight and size of the building itself. But, as practice shows, the benefit starts from 20-40%, compared with a columnar and shallow-buried strip foundation, and if we compare it with a buried strip or monolithic slab, then here the price may already differ several times, and in our time it is a huge plus.

2. Ease and ease of installation

Installation of the pile-screw foundation is so simple that it can be done by hand, without the use of special equipment and expensive tools, resorting only to the help of friends or relatives.

As a rule, 3 people are enough to carry out the installation without any problems.

3. Very fast installation of screw piles

A significant plus of screw piles, because in most cases, the installation of the foundation is carried out in 1-2 days. While other types of foundations, including such steps as digging, reinforcement, formwork and concrete pouring, will take much more time, effort and money.

But it is worth remembering that the installation time depends entirely on the professionalism of the workers, the soil and the depth of the screw piles.

4. The slope on the site is not an obstacle for the pile-screw foundation

Whatever the slope on your site, it will not be a problem for the installation of the pile-screw foundation. A large difference in height (5-8 meters) can become an almost insurmountable obstacle for reinforced concrete types of foundation, and pile-screw can cope with this task.

It is worth noting here that another type of foundation, for example, a tape foundation, can also cope with this task, but it will cost you several times more.

5. Clean area after laying the foundation

In the process of laying the foundation, there will be no unnecessary waste and dirt on the site, such as excavated soil, spilled concrete, traces of equipment on the lawn, etc. Although not so significant, but still a plus.

When laying the foundation on screw piles, you do not have to think about where to put excess soil, how to clean the area

6. Installation at any time of the year

Unlike concrete and reinforced concrete foundations, the construction of which in winter provides for additional costs for heating concrete, antifreeze additives, etc., the installation of screw piles can be carried out at almost any air temperature and without additional costs. Moreover, everyone knows that construction in winter is much cheaper.

7. Warm floor in the house

The peculiarity of this foundation is such that there is a decent layer of air between the ground and the floor of the house, and as you know, air is a good heat insulator.Thus, if we compare the floors on the ground, and the floors "hanging in the air," then the second will be warmer, at the same cost. And this is already a significant plus in favor of screw piles.

8. Fast availability

If the concrete foundations provide for hardening within 28 days, as well as the time for shrinkage, before the installation of the walls begins, then the pile-screw foundation is ready for the design loads immediately after installation.

9. Ease of building up the foundation

In the case when you need, for any reason, after the installation of screw piles, to slightly change the project of the house, the layout, or simply attach something, it will not be difficult to build up the pile-screw foundation. Which is not always possible to do without significant costs with other types of foundations.

10. Simple repair of the foundation

No one is insured against low-quality materials, improper installation, and generally unskilled specialists. So, if, for any reason, the screw pile bursts, then it will be easy to replace it, even if the house has already been built. But if a strip or slab foundation bursts, then the repair will cost you a very large amount.

11. Does not pull moisture from the ground

Due to the fact that the connection of the house with the ground is carried out only through metal piles, moisture located in the ground can in no way penetrate either the walls or the floor of your house.

So we examined all the main advantages of pile-screw foundations. As you can see, there are a huge number of them, most of which can become a weighty argument in favor of screw piles when choosing a foundation for a house.

Application area

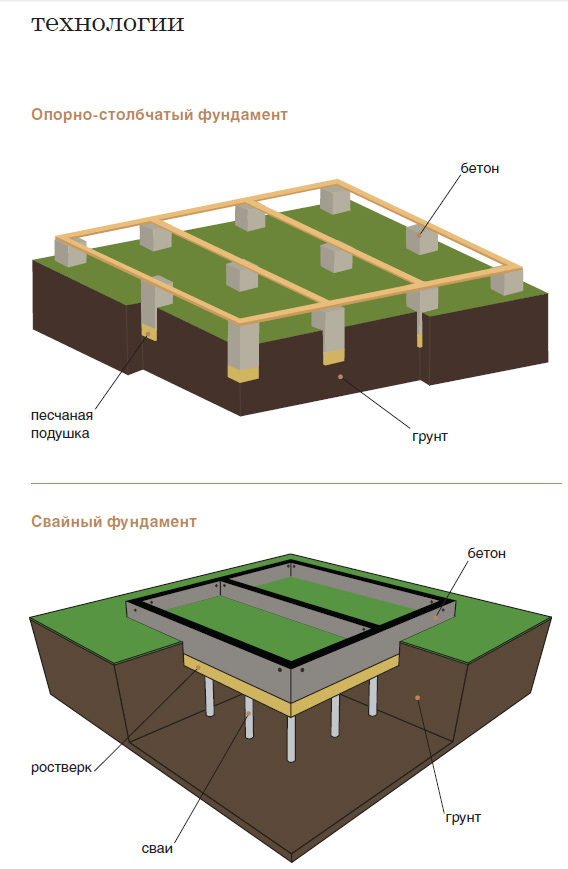

Piles are a budget solution for small architectural forms (LFA), outbuildings and fences. The choice of a strip foundation (grillage) on bored or screw structures is economically justified in the following cases:

- high ground level - the grillage is raised above the ground, the heaving forces are practically absent, the piles rest on the supporting layer;

- wooden houses - the optimal solution is a pile-screw foundation with a grillage from a channel;

- brick, foam, aerated concrete walls - bored piles with a monolithic grillage can withstand the prefabricated loads of two-story mansions.

Many individual developers confuse strip foundations on piles with a grillage. With external similarity, the grillage rests on the pile heads and does not have contact with the ground. It serves solely for the redistribution of loads. The tape rests on the ground completely, the piles only increase the bearing capacity with insufficient bearing capacity of the upper soils.

The pile-grillage foundation is the only solution for operating conditions:

- coastal zone - unlike the strip foundation, you do not need to tear off trenches, pump out water;

- hilly area - with elevation differences of more than 2 m in the building spot, the strip foundation or slab will be too expensive, the pillars will overturn the heaving forces.

Piles are used in the repair of strip, slab and columnar foundations of frame, log, panel and panel houses. Thus, the advantages of spatial structures with rigidly fixed beams at the heads of bored or screw piles outweigh the disadvantages.

In addition, the shortcomings indicated in the aggressive advertising of the opponents of the pile-screw foundations are not substantiated and are not supported by facts. During the Soviet era, for the needs of the army, screw piles covered with hot zinc were produced. The buildings on these pile fields are currently in operation, so the real resource is still unknown.

Errors and recommendations in the construction of pile-grillage foundations

- Lack of a reliable connection between the piles and the grillage itself. In winter, through the freezing of the soil, an additional force arises, which tends to overturn the piles. This is due to the natural expansion of moisture as it turns into ice.If the pillars are not fixed or the reinforcement is broken, then in the place of the greatest impact, the pillar will shift horizontally. As a result, the design load from the building will no longer act on one or more pillars and it will sag in that place.

- There is no air gap under the grillage. This layer plays an important role precisely in winter, because the frozen ground expands in different directions, right up to the vertical. As a result, there is excessive pressure on the bottom of the grillage. Pile breakage is possible. To protect the slab from pushing through, it is recommended to glue several balls of polystyrene foam from below, which will act as insulation and artificial shock absorption.

- Calculation errors. Inattention, lack of experience, or just a thirst to save money can go badly. If the loads are incorrectly calculated, then the subsidence of the foundation will begin, which cannot be stopped. Therefore, it is immediately necessary to take into account the peculiarities of each type of soil and obtain a detailed map of the soil at the construction site from the surveyors.

- Incorrectly installed piles or shallow depth. If this happens, then due to the free space under the pile, additional shrinkage of the base will occur, respectively, the air gap under the grillage will decrease. To prevent this from happening, the piles are installed below the freezing depth.

Pile foundation

This type of foundation has been widely used in construction recently.

This type of foundation has been widely used in construction in recent years. The supports are special screw piles made of durable carbon steel that does not corrode. By their design, screw piles resemble auger drill, only several times larger.

There are two types of foundation piles:

Cast supports. These are made by casting on the right in a special collapsible mold. As a result, the supports are monolithic without seams and joints. The strength of such an element is several times higher.

Welded piles. This type of construction support is made by casting a steel base pipe and then welding steel blades to it. Due to the presence of welded seams, the strength and reliability of the support is reduced

But if a decision is made to use cheaper welded screw piles, it is worth paying attention to the evenness of the seam and the presence of a protective bitumen coating on it.

The thickness of the steel walls for both types of piles varies from 4 to 6.5 mm, which makes it possible to use such supports not only in private construction, but also in the construction of industrial buildings. In this case, it is always better to choose piles with thicker walls.

The advantages of a pile foundation are:

- The possibility of building a house on complex heaving soils with the presence of clay, loam, peat or a large amount of water in the composition.

- Favorable cost of the finished structure. The foundation on piles will cost several times less than the construction of the tape contour. This is due to the smaller volume of required materials and less laboriousness of the work.

- High speed of installation. With a competent approach, a pile foundation can be ready within 3-5 days. Moreover, in this case, there is no need to wait for its shrinkage.

- The ability to perform work in any weather. The piles are perfectly embedded in the ground at any temperature.

However, the foundation on piles also has disadvantages:

- It is categorically impossible to mount the pile foundation in rocky ground. And in order to avoid gross design mistakes, it is better to immediately conduct a soil analysis. Here there is a risk of breaking the support vanes.

- Do not discount the possibility of pile roll in a horizontal or vertical position. For careful calculations of the possible risk in this case, it is better to conduct a detailed analysis of the soil at the design stage of the house.

- The need to install concrete piping for the reliability of the structure.

- The absence of a basement or basement floor, which reduces the heat loss of the finished house and requires additional thermal insulation of the space under the floor. In addition, for the same reason, you will have to reliably hide in the ground and insulate all plumbing communications coming from an individual source of water supply. And decorating the space between the floor and the ground will not be superfluous. And this is also a cost.

Cons and pros of a pile foundation

Now let's talk in more detail about the advantages and disadvantages of the pile foundation. The indisputable advantages include the following aspects:

- The possibility of erecting a foundation in areas with difficult terrain and a large slope. Where, for other types of foundations, one would have to splurge on concrete, or spend a lot of money on earthworks, leveling the site, piles beat their competitors on the head, since the pile foundation has practically no restrictions on height differences.

- The ability to use piles on almost any soil - it will be stable both on wetlands and on clayey soils. Laying the foundation on piles is advisable when the topsoil has a low bearing capacity and significant thickness:

- On black earth, fertile and silted lands, next to forest lands.

- In swampy areas, on peat bogs, sandy-clayey quicksands, clays and loams in a plastic state.

- On salt marshes, subsidence soils.

- In regions with permafrost, with a significant freezing depth.

- In areas with a high GWL (groundwater level), with the threat of flooding.

- On forest soils that lose strength when saturated with water.

In all these cases, the load from the house must be transferred to dense layers of soil. Strip foundations or insulated Swedish slabs at such a depth become economically unprofitable, and simply, such foundations may be fragile.

- Low labor intensity of work. If we consider screw piles, then the installation process consists in screwing the piles into the ground. As a rule, two people can cope with this work without the use of special equipment. This implies another plus - the ability to carry out work with your own hands without the involvement of hired specialists.

- High speed of work. The foundation of screw piles can be erected in one day, and the next day further work on the construction of the house can be carried out.

- Low cost. A ready-made foundation made of bored or screw piles will cost orders of magnitude cheaper than other types of foundation.

There are also disadvantages to this type of foundation:

Reduced bearing capacity of piles compared to other types of foundations. If the load on the piles is incorrectly calculated, they can sag, damaging the frame of the structure.

Therefore, before choosing the type of foundation, it is important to make all the necessary calculations and make sure that the future foundation will be able to bear the loads from the structure.

If screw piles are chosen for the construction, but at the same time you plan to build a heavy house, then the way out of this situation will be to use screw piles with a diameter of more than 133 mm (standard screw pile diameter). At the same time, the problem is that many companies operating on the market do not have the ability and special equipment for the installation of such piles.

No basement

In houses on pile foundations, it is not possible to organize a full-fledged basement, since during the installation of the foundation there is no excavation under the house. However, when the houses are located on a large slope, it will be possible to organize utility rooms in the resulting space.

The need for additional insulation of the basement of the building. The disadvantages of pile foundations is the ventilated basement of the structure. This creates an obligatory need (as opposed to concrete foundations) for insulation.

Comparison of two foundations

Which foundation is better, tape or pile-screw? To be honest, strip foundations are used in the construction of buildings as a traditional structure that has shown good results for a long time.

However, practice shows that pile supports have a higher bearing capacity. Let's try to compare these two designs in terms of indicators such as:

- financial expenses;

- construction time and labor costs during construction;

- possibility of application;

- manufacturability and seasonality.

Financial expenses

Which foundation is cheaper than a strip or pile foundation? During the construction of a strip base, there are costs that are not required for pile structures:

- excavation and leveling, storage and removal;

- transportation costs for the delivery of tooling, reinforcement and concrete mix;

- backfilling of sand and gravel cushion and its compaction;

- concreting or installation of blocks using lifting equipment.

In total, the strip foundation is much more expensive.

Construction time and labor costs

The design of the strip foundation is much more complicated in its structure. When erecting it, it will take time to carry out earthworks, install the formwork and reinforcing cage, install the underlying cushion, and pour concrete. After that, you will have to wait until the concrete mix sets properly and start waterproofing work.

In the pile foundation, it is enough to screw in, drive in or install piles and tie them with a grillage. The work is performed several times faster.

Possibility of application

For pile foundations, there are practically no restrictions on use depending on the type of soil. The exception is peat bogs, on which no one usually builds anything. But the use of tape depends on the depth of its inception.

If the sole of the structure rests on dense soil layers below the freezing point, then only lateral loads act on the tape and its stability depends on the degree of reinforcement, that is, the strength of reinforced concrete. Shallow foundations can only be used on stable, dense soil with a shallow depth of freezing and deep groundwater.

In the presence of a complex relief of the site, with a slope or elevation differences, the cost of the strip foundation increases sharply, while the pile foundation allows you to solve the issue without any special problems.

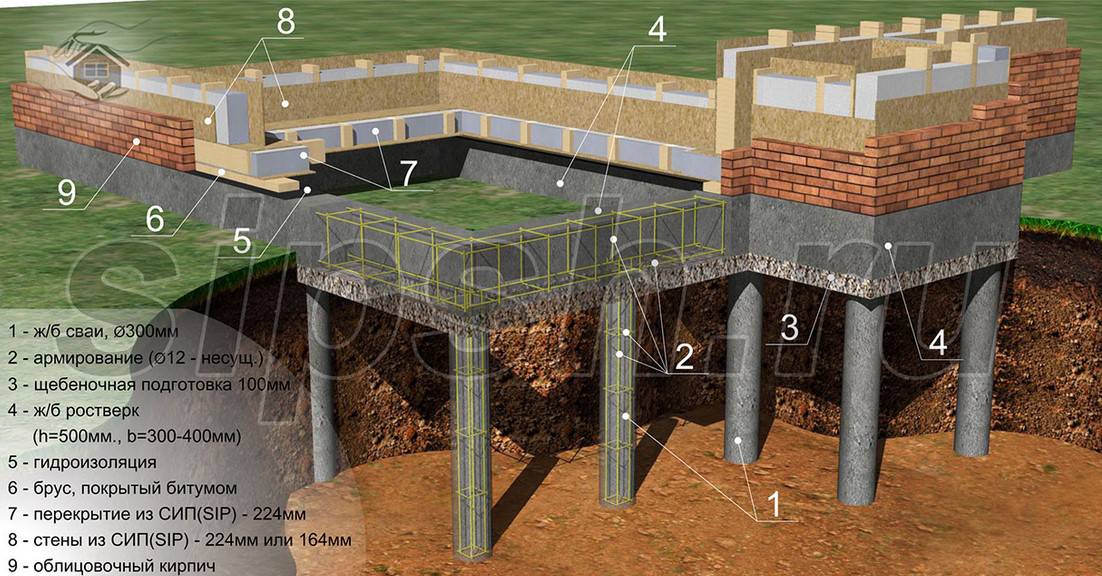

Types of strip foundations on piles

- Screw piles. Most often, hollow metal piles with blades of fixed length and thickness are used here. They are screwed into the ground using a special technique or manually, in the case of a small deepening into the ground. To prolong the service life of metal pile structures, you need to use a special primer and protective paint.

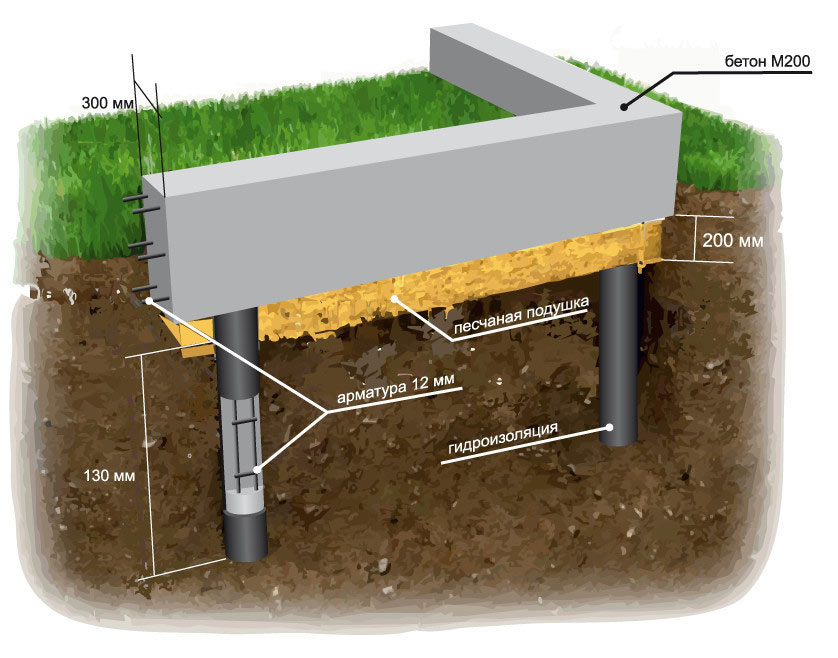

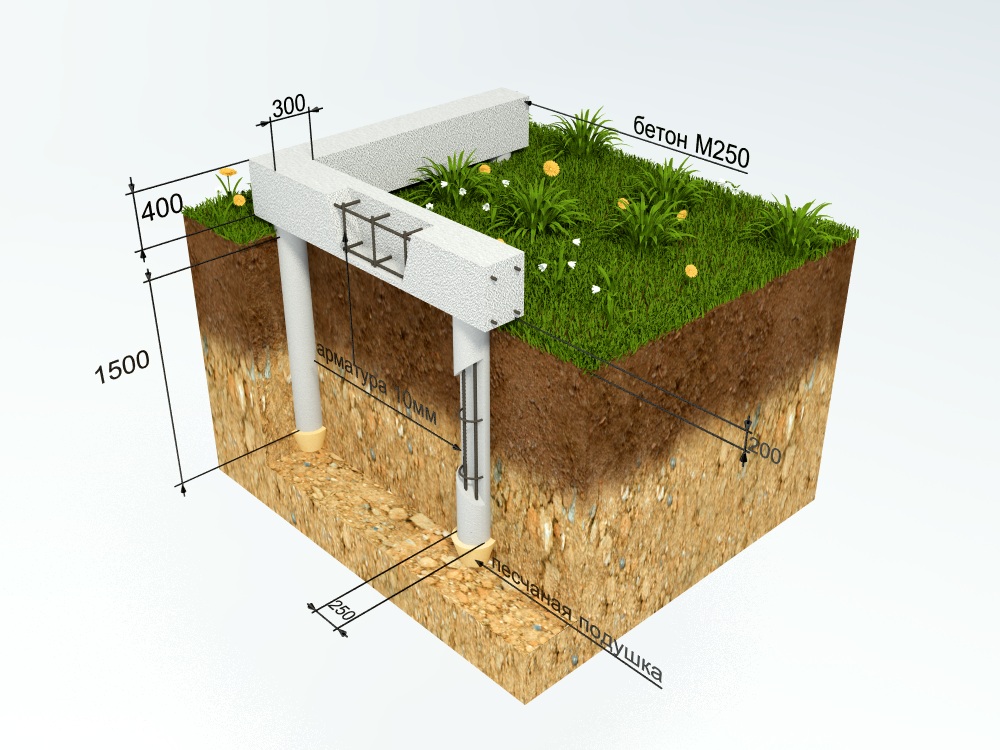

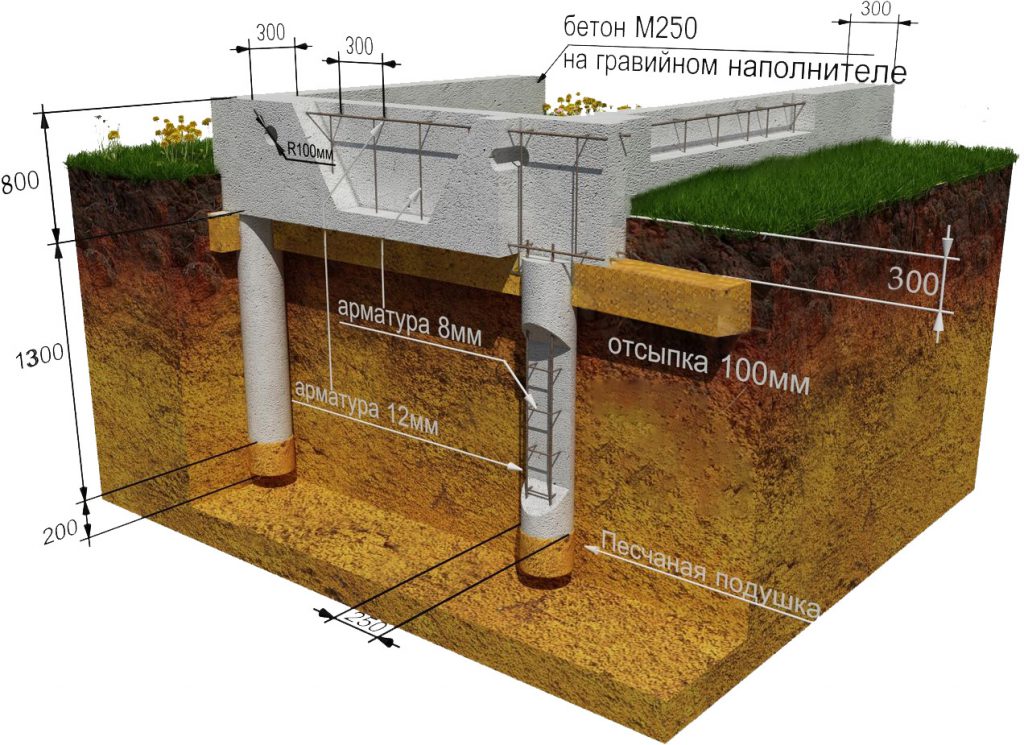

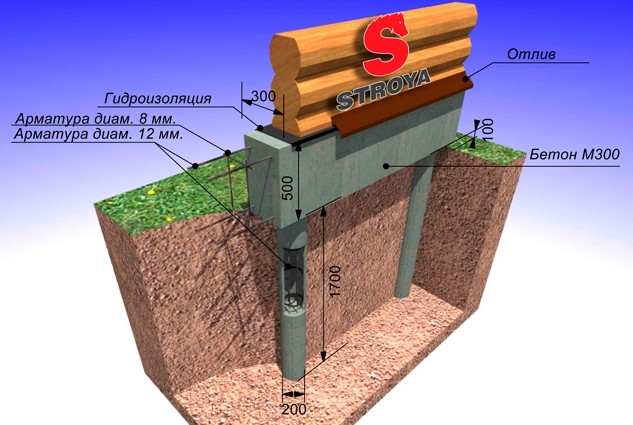

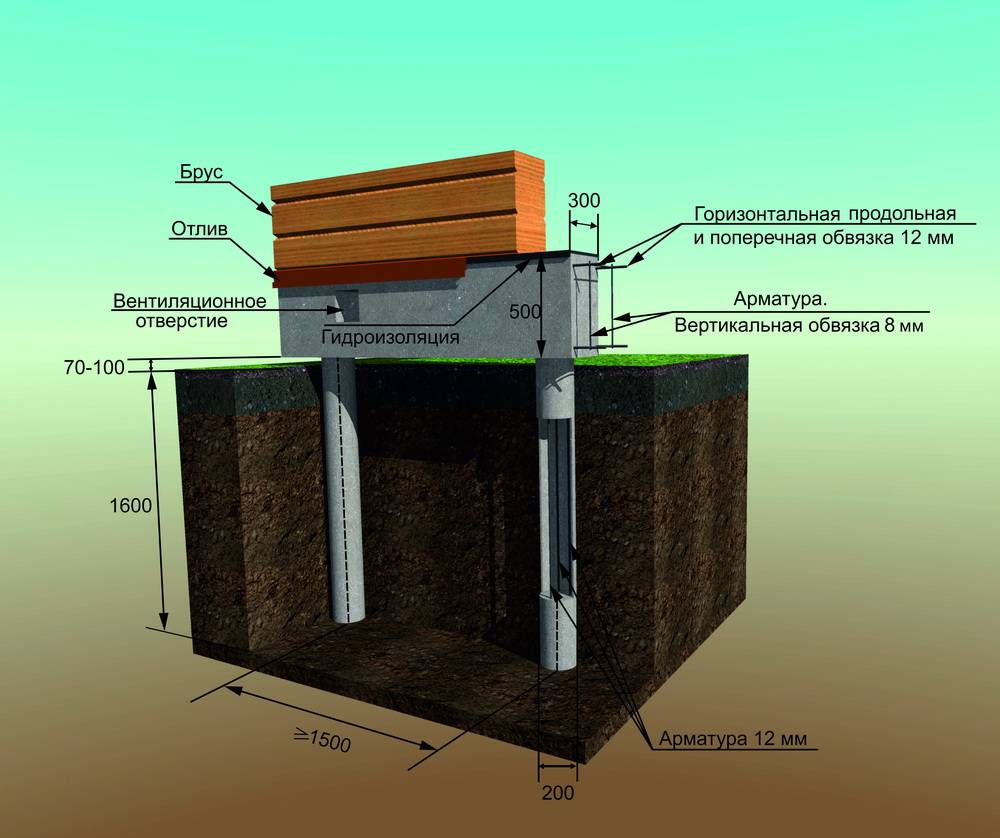

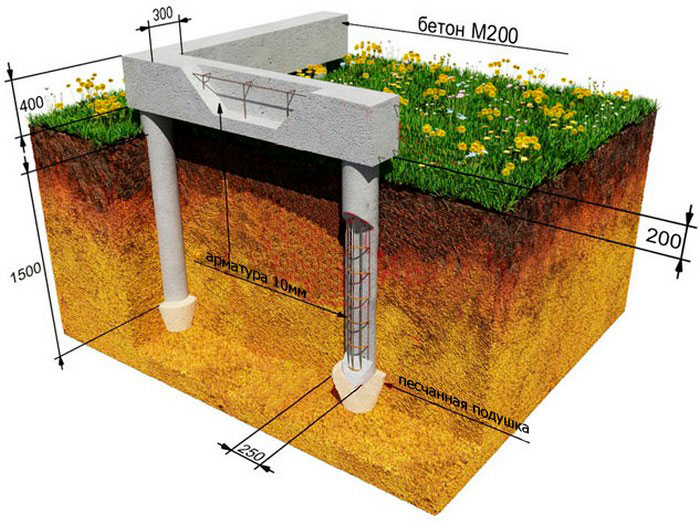

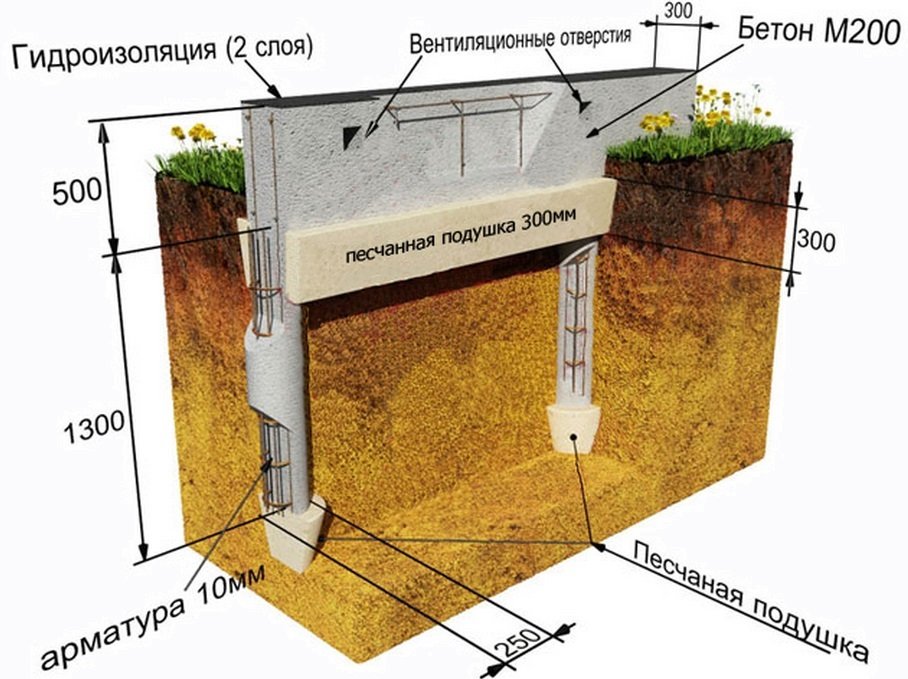

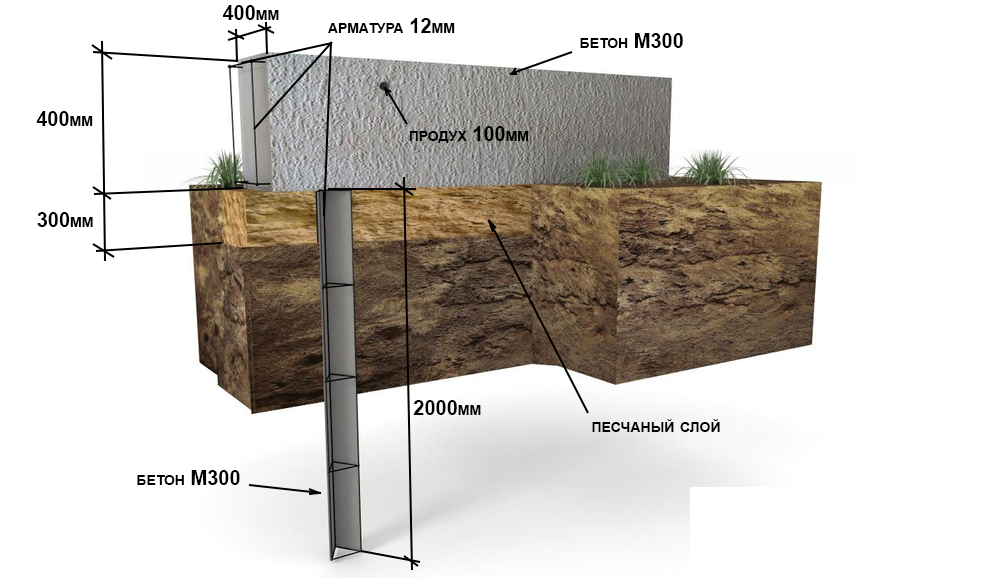

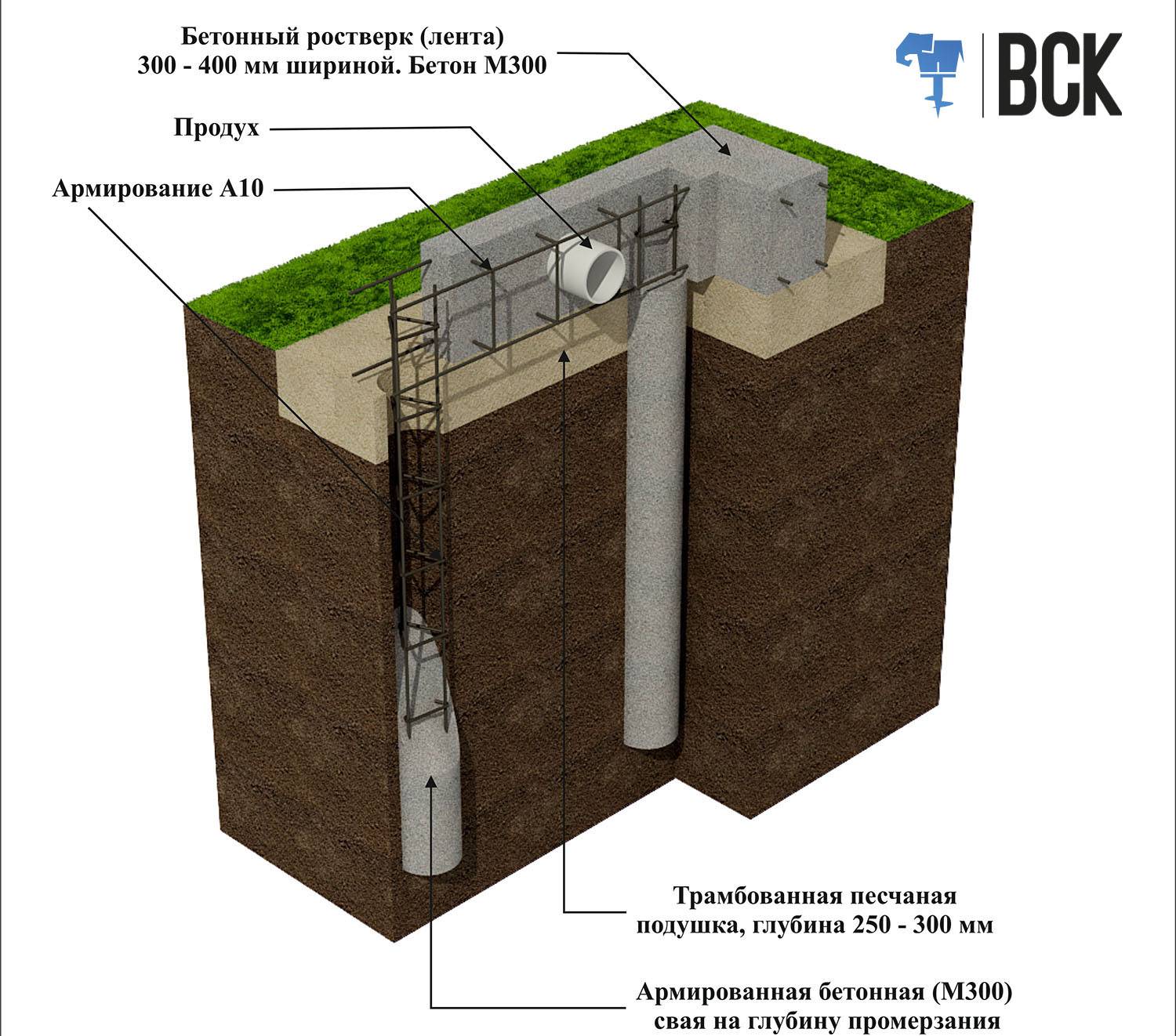

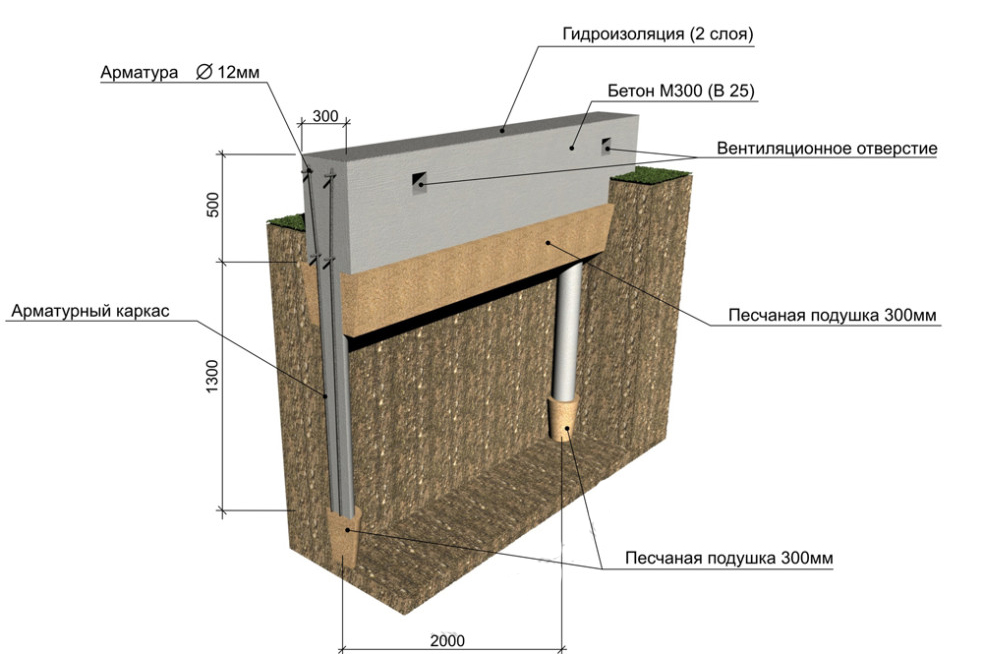

- Bored piles. Manufactured locally, and therefore cost significantly less. The first step is to prepare a well of a fixed depth, to the level of soil freezing or until it rests on solid ground. Then the bottom of the well is covered with a sand and gravel pad and rammed. The essence of bored piles is that the well itself is reinforced and poured with ready-made concrete mortar, and the soil surface inside and a hollow asbestos pipe above the well are used as formwork.

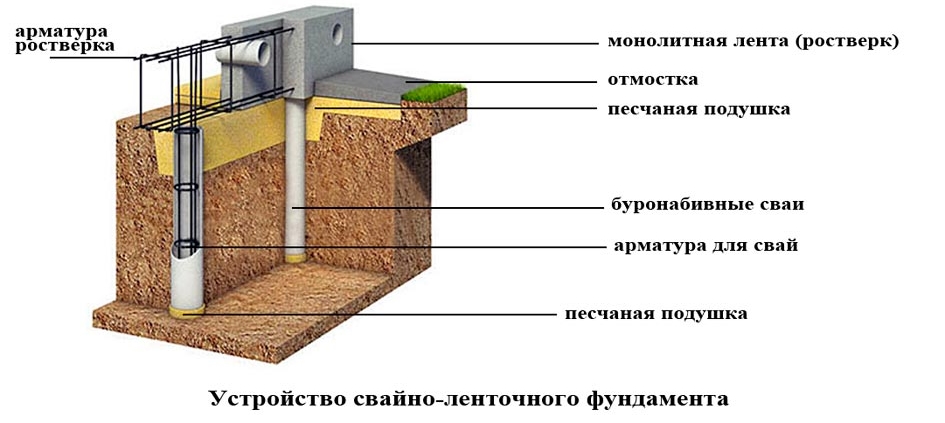

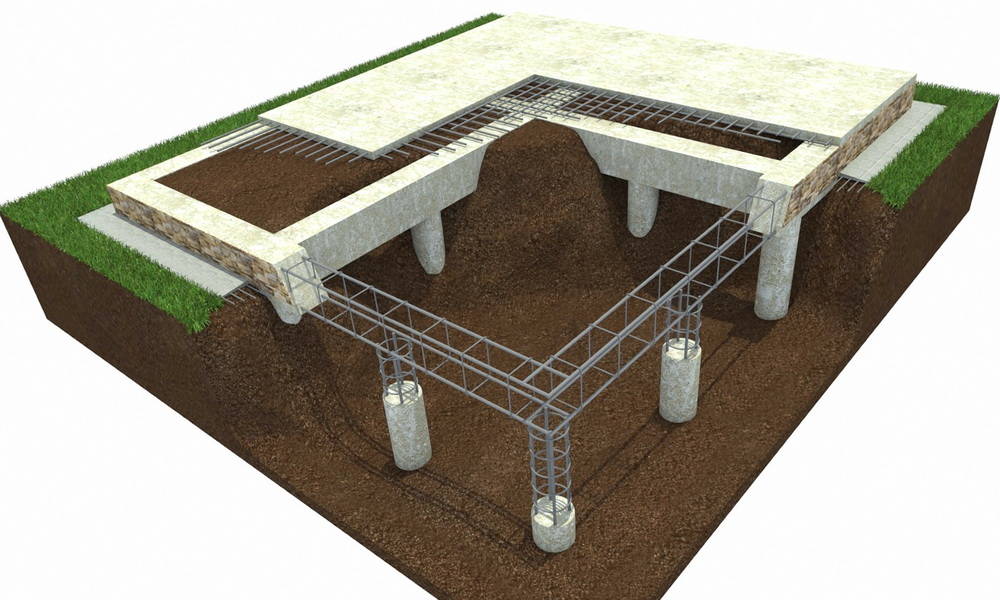

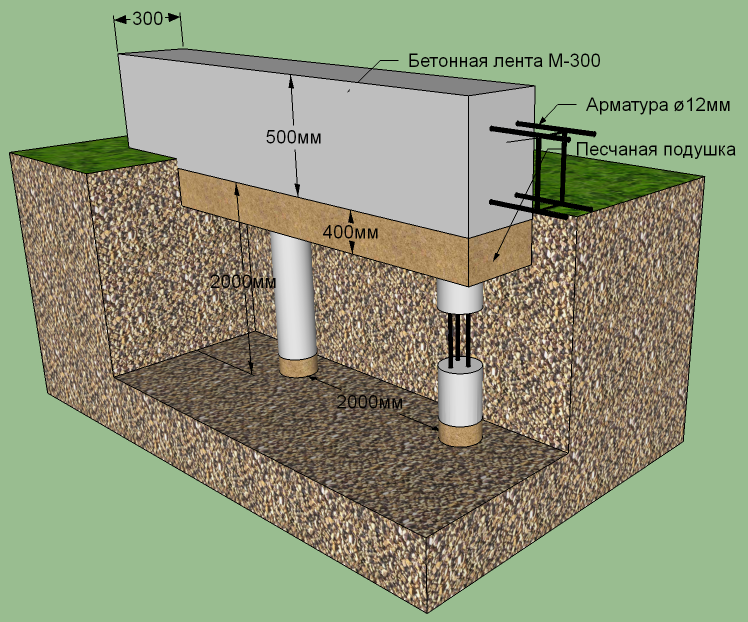

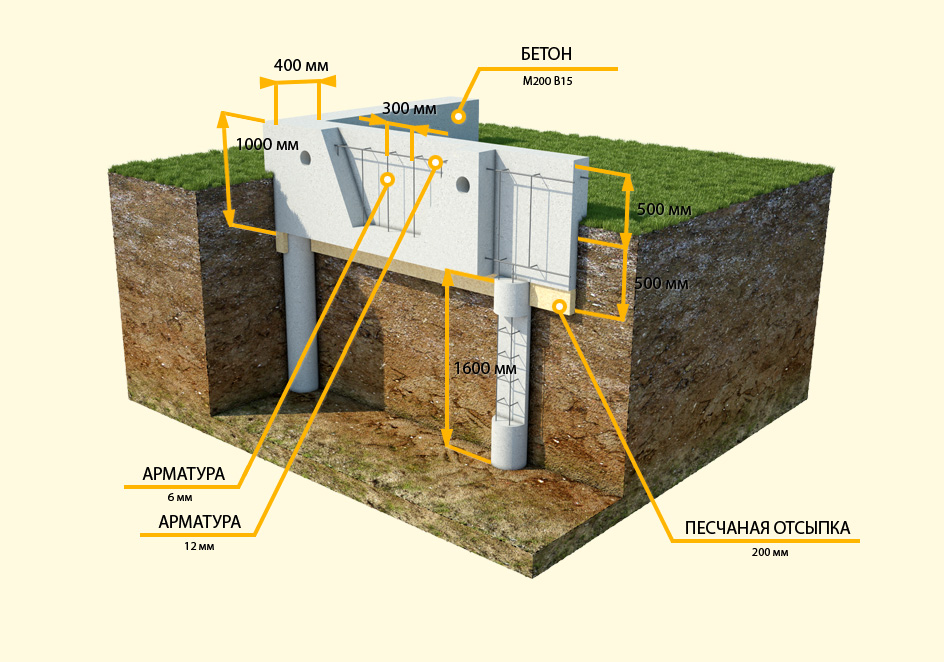

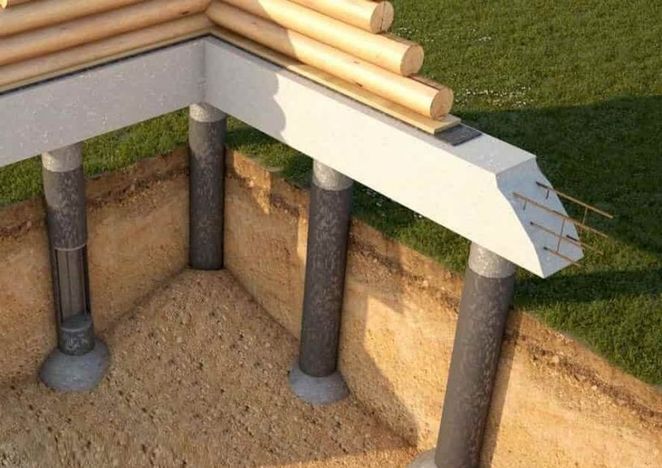

Within the framework of the foundation, a monolithic reinforced concrete tape of various thicknesses and widths (according to load calculations) is prepared from rammed piles, on which the supporting structures of the building are already mounted.

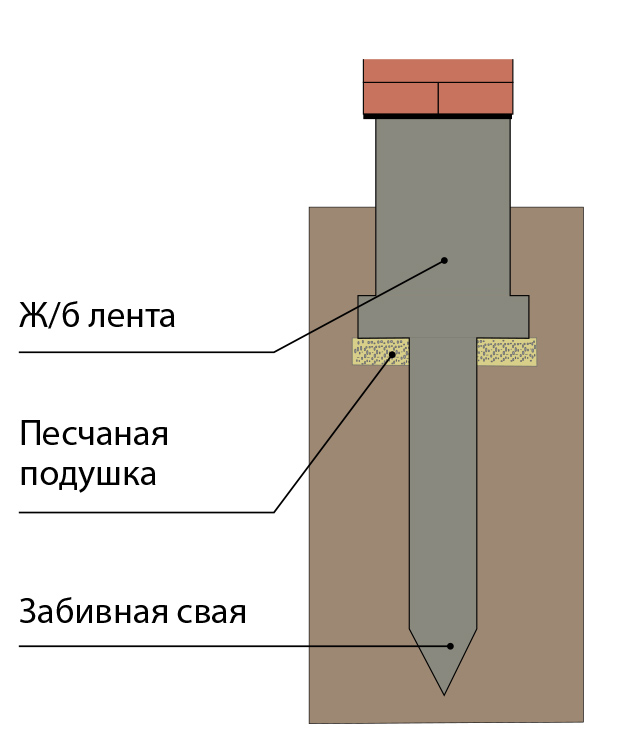

The strip base above the piles is made shallow, i.e. reinforced concrete tape should be buried to a depth of 40 cm and installed on a sand and gravel pad. Under the pillow, at the same time, driven reinforced concrete piles are installed. Piles and grillage are connected with reinforcement. This ensures sufficient structural strength and resistance to ground movements.

The main types of pile foundations

The foundation for a house made of aerated concrete, foam concrete or foam blocks belongs to the category of lightweight structures, while it is still recommended to consider the possibility of installing piles.

The main types include:

- Installation of bored piles, which are manufactured on site, which significantly affects their cost. To begin with, you should take care of a well of a certain depth, depending on the level of freezing or finding more durable soil rocks. A cushion of gravel and sand is placed on the bottom, which is carefully compacted. The advantage of a screw well is that it is poured and reinforced with a ready-made solution. The soil (its top layer) will act as formwork, as will the hollow pipe, which will be visible above the well.

- Foundations to be placed on screw piles. For this, it is customary to use metal structures that are equipped with special blades of a certain thickness and length. They are hollow inside. If the pile-strip foundation for the house is screwed in shallowly, then such manipulations are carried out manually. If we are talking about several meters, then it is better to use special equipment or equipment. It is recommended to use a protective paint and primer to prolong the life of the main elements.

It differs from the tape belt in its design, because it uses monolithic reinforced concrete belts, which serve as a support for the supporting structure of future buildings. In the strip, the piles are made finely cut (the slab level will reach no more than half a meter).

You will need a gravel or sand pad for installation. Under it, reinforced concrete piles are installed, which makes it possible to achieve the most durable connection between the grillage and the reinforcement used. Thanks to this, it is possible to achieve such a high level of efficiency and stability of the entire structure.

Pile strip foundation with their own hands step by step instructions:

First of all, the necessary marking is made, which is required if the strip foundation is reinforced. This will require calculations regarding the used area of the base of the foundation.

And only after that, the arrangement of future trenches should begin, the depth of which will be at least half a meter. This indicator will directly depend on the area of the base of the foundation.

Wells are being drilled for a pile foundation with a step of two meters

Compliance with this step is extremely important. The depth of the hole must be at least the level of soil freezing in this region

The construction of the pile-strip foundation also implies the arrangement of a cushion at the bottom of the well. Its thickness will be approximately 30 cm. The remaining space is filled with reinforced concrete.

After the grillage layer is ready, you can proceed with the installation of the waterproofing layer. In this case, you will need a sheet roofing material, which rolls up with a tube and is placed in the well. It would be good if the pipe will rise above the bottom of the trench by at least 30 cm. This will eliminate the possibility that sand did not clog the wells during backfilling.

The bottom of the trench should be covered with sand. The layer will be about 30 cm, after which you can begin to install the formwork.

It is rather difficult to determine which foundation is better than pile or tape, but in any case, one of the main stages will be reinforcement. If you make a foundation for a house from foam blocks, you will also need both reinforcement of the tape itself and the installation of an additional belt under them. All of them are hidden with a wire for tying reinforcement.

With the correct implementation of the previous steps, no difficulties should arise, after which you can proceed directly to pouring the main part of the foundation.To begin with, wells are poured, while every 10-15 cm is compacted and compacted, which will reduce the risk of voids in the concrete. Before pouring the next layer, you should check for foreign objects (pebbles and debris).

What is a strip pile foundation?

The use of such a foundation makes it possible to erect a building, despite the complexity of the relief and unfavorable soil for the tape option. A reinforced concrete base is used as a tape or grillage, but the pile part can be different.

Piles can be made of metal, wood, reinforced concrete. The most disadvantages are piles made of wood. More often, ready-made metal piles screwed into the ground and rammed ones installed in special wells are used.

When constructing a pile-strip foundation, two methods of installing piles are used:

- Screw.

- Bored.

With the screw installation method, special metal piles are screwed into the ground until stable layers are reached. The installation of such metal supports can be carried out using special equipment or manually, depending on the depth of screwing in and the financial capabilities of the developer.

With the bored method of installing pile supports, at the first stage, a well of the corresponding diameter is drilled to a given depth. After that, a cushion of sand and gravel is formed at the bottom of the well, tamped, reinforcement is installed and the structure thus obtained is poured with concrete.

After the supports are installed and aligned, using a special technology, they are connected with a grillage to evenly distribute the load between all piles. With the correct installation of the reinforced concrete tape, further construction is provided with sufficient strength and reliability of the foundation. It is also desirable to provide a 200-300 mm sand cushion under the reinforced concrete tape.

In addition, it is necessary to waterproof the grillage by analogy with a simple tape base. The advantages and disadvantages of the pile-strip foundation are of particular importance when constructing buildings on difficult terrain; it is necessary to install them in compliance with all technological standards.

Let's sum up - which one is better

If we compare the characteristics of both foundations, we can conclude that they are equally acceptable in the construction of buildings. The choice of this or that design depends on the conditions of the land plot and the type of building.

The strip base is used on stony soils, the pile analogue is used on swamp soils. A pile field is mounted on uneven terrain. If you need to equip the basement, pour concrete tape. A monolithic base is required for brick and block houses so that the masonry does not crumble from uneven shrinkage of the foundation.

If it is possible to choose any type of foundation, it is advisable to compare the performance characteristics of these structures and the forthcoming financial costs. It will be possible to reduce the cost of the tape option only by saving on materials (the grade of concrete or the thickness of the reinforcement), which will lead to a decrease in the strength of the building.

The reinforced concrete base will be ready within 20 days after pouring, which is explained by the need for strength gain. If the regime is violated, the surface of the foundation will crack, and it will have to be reinstalled. The field on piles can be put into operation after the completion of the installation of the supports.

The service life of concrete structures is at least 50 years. The same period of operation is typical for screw piles with wall thickness 6 mm provided that the elements are made of high-quality metal with reliable welded joints.

The choice is also influenced by factors such as:

- Freezing of the floor. It is difficult to arrange ventilation holes in a concrete base. This should be taken care of when installing the formwork.At the structure on piles, the gap between it and the soil is revetted with siding or profiled sheet. Ventilation openings are also designed here. In addition, unlike a tape base, such a base does not lead to condensation.

- Freezing of the basement and technical communications. When laying pipes and installing a basement, thermal insulation is used regardless of the type of structure.

The tape-screw foundation will allow to speed up installation work and reduce construction costs. When installing it, the pillars are connected using a monolithic reinforced concrete grillage. Such a design is chosen for the construction of houses on areas with a complex type of soil and relief.