Carrying out work on laying a columnar foundation

The site for the foundation of the house is prepared according to a pre-developed plan. The perimeter of the building is outlined, the places of future supports are piled up with pegs. Remove the fertile soil layer and level the surface.

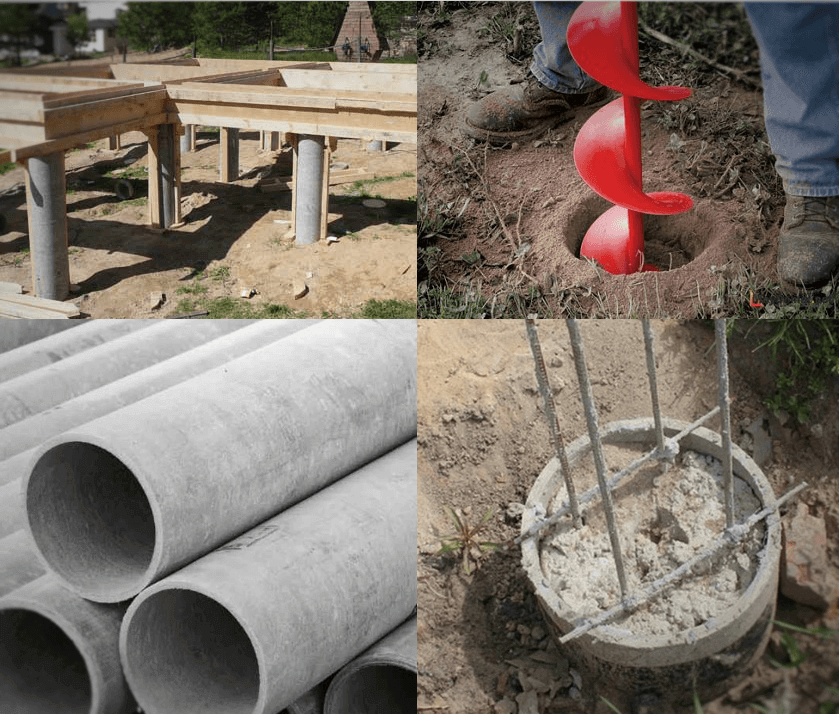

Wells are drilled with a hand drill. The depth of the pit depends on the chosen method of laying the pillars. The hole diameter should slightly exceed the size of the fixed formwork. For the construction of residential buildings, steel pipes with a diameter of over 250 mm are chosen as load-bearing supports.

Concrete is prepared in a mechanical or manual mixer. For 1 part of M500 cement, 6 parts of a sand and gravel mixture are added.

Technology for installing pillars of a buried foundation:

- At the bottom of the well, a sand cushion is tamped tightly;

- The body of the metal support is insulated with bitumen mastic;

- The pipe is buried in a sand cushion and fixed vertically;

- Pour the solution so that it saturates the sand pillow;

- The formwork is fixed in a vertical position and kept for a while so that the base hardens;

- To increase the strength of the base, a reinforcement rod is inserted into the pipe, which must pass the concrete base;

- The metal body is filled with concrete up to the upper edge;

- The space around the post is compacted with sand and soil.

In the process of carrying out work on the construction of a foundation from metal pipes, the same level of the entire supporting system is monitored. The height of the above-ground part of the supports should be 40-50 cm. After the concrete has hardened, you can proceed to the construction of the grillage.

Areas of use

Plastic pipes are superior to metal counterparts in many respects, which are important for any field of application.

Main areas of use:

- Transportation of aggressive chemical liquids. Plastic does not react with many chemicals.

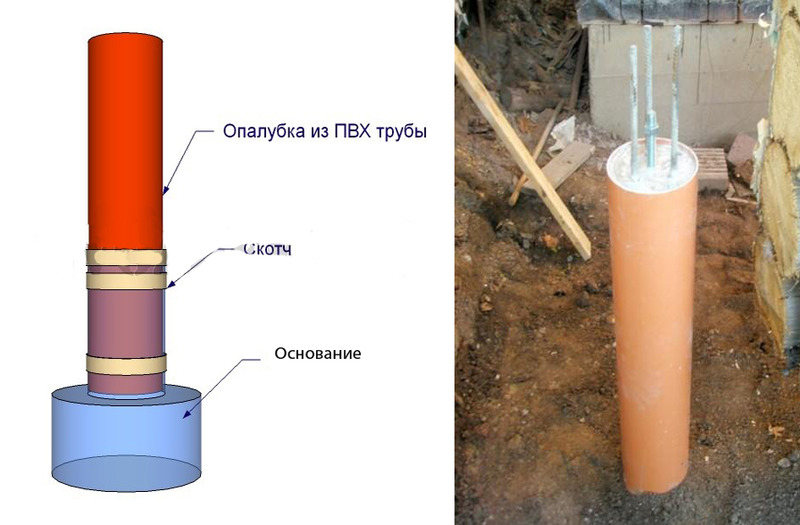

- In monolithic construction, PVC pipes are used for formwork in order to protect sheet screeds from concrete penetration during foundation pouring.

- Use in the channels of compressed air transportation up to 30 atm.

- In the process of laying the wiring, plastic products are used to protect communications from possible mechanical deformations.

- In melioration, irrigation and drainage systems.

- Poles for billboards are made of a smooth pipe, taking into account the customer's sketches.

- Heating systems and plumbing.

- Plastic pipes are often used in furniture making.

- Corrugated electrical pipes are used to protect products by cable and conductors when laying by any means.

DIY installation of a columnar foundation

Anyone can build a columnar foundation from sewer pipes

a person, subject to the construction technology:

- Design. At this stage, the number of supports, their location is calculated, the depth of immersion of the pillars is determined, and the site is marked.

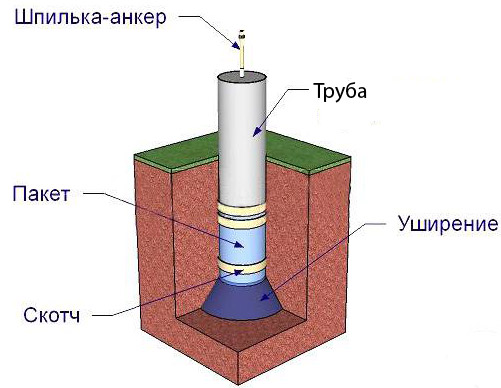

- Preparation for work. First, you need to cut the blanks into pieces of the required length, prepare the lower part of each blank for concreting the heel. It is also necessary to prepare anchor studs, which will be poured into the upper part of the support to connect the foundation with the grillage.

- Frame fabrication. To increase the bearing capacity of the pillars, it is necessary to make a reinforcing cage, for which ribbed reinforcement bars are used. To reinforce the expansion, the rods are bent in the shape of the letter "L".

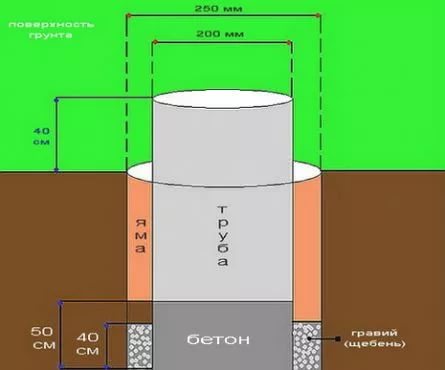

- Well drilling. With the help of a hand drill, it is necessary to drill wells in accordance with the diameter of the sewer pipe. The depth of the well depends on the level of freezing of the soil, it is necessary to go down below this mark by 20-25 cm.

- Expansion at the bottom of the wells. Using special nozzles for a hand drill, an expansion is made at the bottom of each recess. This increases the stability of the posts.

- Prepared products are inserted into the well and an expansion is formed. To do this, concrete mortar is poured into the pipe and the future support is slightly raised. Before fastening, each plastic post is vertically aligned using a building level. After that, from the outside, they are covered with sand, crushed stone and earth.

- Aligning the supports. All sewer piles must be of the same height. To do this, they beat off the horizontal using a laser level, pull the construction cord and cut each support at the level with a grinder.

Reinforcement and concreting

Reinforcement. The prepared frame made of reinforcing rods is inserted into the pipe. The bent rods are turned to the sides to strengthen the expanded base of the pillar.

Concreting. The prepared post must be filled with concrete mortar. Concrete is fed in small portions, constantly piercing the mixture with a thin rod to compact

In doing so, care should be taken to avoid damaging the plastic product. In the upper part of each support, an anchor pin is installed to secure the grillage.

It is very important to build a foundation from sewer pipes with your own hands in accordance with construction technology. Its violation can lead to negative consequences:

- Exceeding the permissible load on plastic supports leads to their destruction. Additional strengthening of the pillars helps to solve the problem.

- Under heavy load, the pillars can fall into the ground. In this case, the pipe supports are raised to the desired level and fastened to each other with reinforcing rods.

How to make a pile foundation with your own hands

The first step is to create a project. It is possible to make a simple plan on paper without any special experience. It is necessary to correctly determine the number of pillars, the optimal installation depth for future piles. For this purpose, you can use online calculators and instructions for marking and design. If you are not sure of your actions, use the services of qualified specialists.

Execution order:

- do the markup. Here you will need to mark the location of the future pillars. Set up an obstruction, pull the string over the circle crosswise. Place pegs at the point where the threads intersect - they will become the center of the pile;

- well drilling. For the base to stand securely, the hole must be lower than the freezing depth of the soil. Accordingly, in the northern regions it is necessary to carry out construction with the creation of a deeper pile foundation. The borehole diameter must match the pipe diameter;

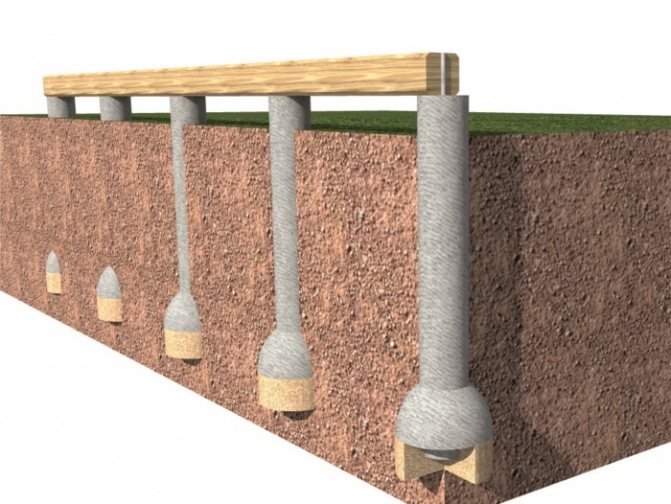

- at the bottom, expansion is performed. For this purpose, you can use a TISE drill or a cut-off bayonet shovel;

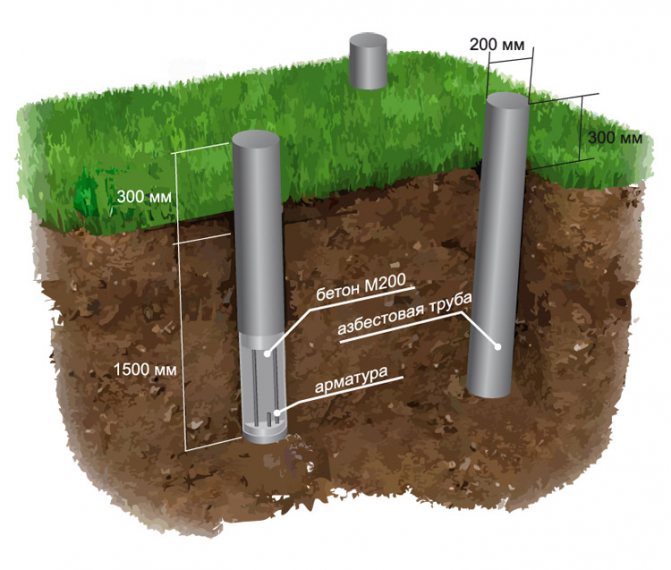

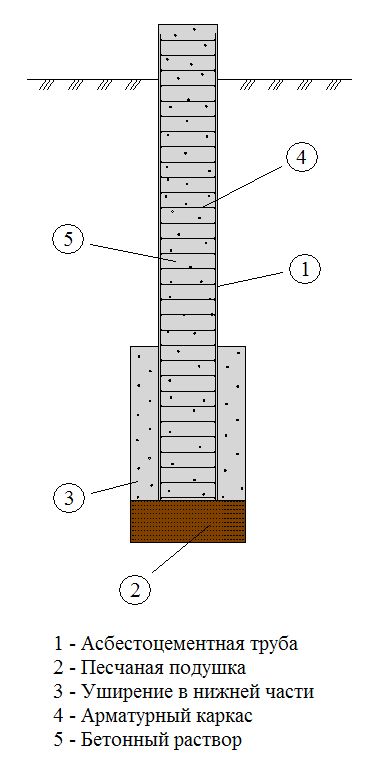

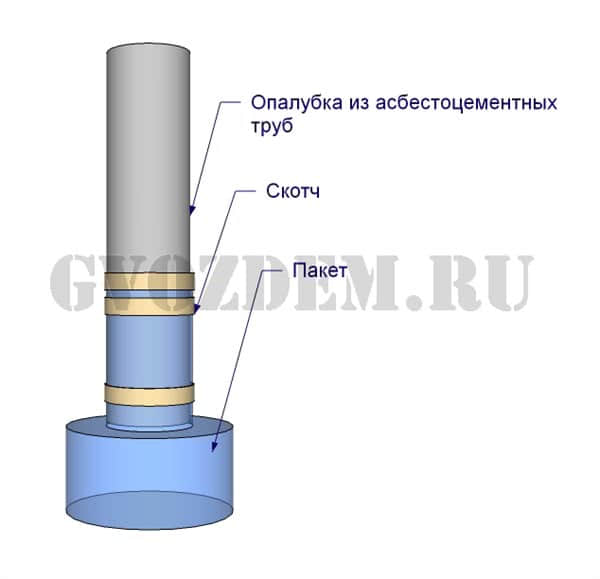

- cut the asbestos-cement pipe to the required length, including aboveground and underground parts. At the bottom of the pipe, secure a plastic bag with tape. It will not allow the broadening of the pile to be poured with concrete mixture and, with nearby groundwater, will not allow the pipe to pass inside from below;

- After the asbestos-cement pipe is inserted into the well, create a reinforcement cage to strengthen the foundation. For this, reinforcement of 10 or 12 mm is used. Depending on the diameter of the pipes used, 3-4 rods with their bundle are used. The expansion at the bottom of the piles can also be reinforced, for this you need rods bent at the bottom in an “L” shape. After lowering into the pipe, the bends are turned to the extreme points of expansion. When creating a pile-grillage, you need to remove the frame from the reinforcement a few centimeters up. If the supports are connected with a bar, then the reinforcement should be located just below the upper end of the asbestos-cement pipes;

- the pile widening is being poured.Concrete mixed with cement grade M300 or higher is poured in sufficient quantity to fill the expansion zone. Lift the post up - as a result, the concrete will enter the attached bag, filling it and the widening itself. Next, you need to push the pipe down. Provide vibration and bayonet so that there are no air pockets left in the formwork, and the mixture lies as tightly as possible;

- fill. The mixture should fill all the internal space in the pipe, also bayonet to eliminate voids. At this stage, fix the stud anchor, with which it will be possible to tie the post to the timber strapping.

The concrete will fully harden within 28 days, after which you can start building the house. After pouring, cover the top of the pile with plastic wrap to protect the mixture from the environment and speed up its hardening. During construction, make sure that all the pillars remain at the same level - this way the foundation will more securely support the building.

The exact implementation of these instructions will allow you to build a reliable foundation for an outbuilding or even a small wooden cottage.

All work can be done independently, it is only important to select high quality materials and take into account the characteristics of the soil and the region in which the construction is underway

Preparatory work

The main stage of preparation consists in calculating the expected load on the base and studying the bearing capacity of the soil. The first task is solved by carrying out engineering calculations based on the building design and the building materials used. The second task requires a thorough analysis of the soil composition at the site and the determination of the occurrence of groundwater.

To analyze the soil requires the involvement of specialists who can reliably determine its composition and the location of dense rocks. The depth of the foundation pipes and the reliability of the facility being built will depend on the result.

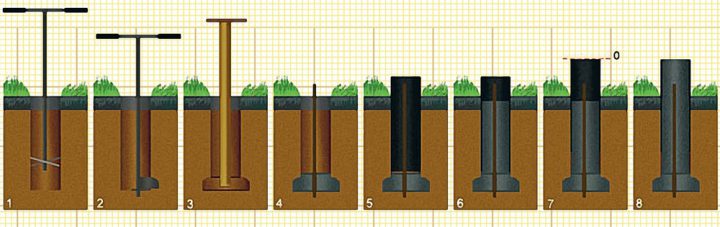

There are three types of columnar bases:

- Not buried. They are used for the construction of auxiliary or auxiliary facilities. The depth of the bookmark is up to 0.5 m.

- Shallow. The depth of the filling is up to 1 m, which is half the level of soil freezing in the middle lane. They are used for the construction of frame houses on dense soils.

- Recessed. They are laid to a depth below the freezing level (from 1.5 m). They are used for the construction of low-rise buildings on weak or flooded soils.

After choosing the type of base, they proceed to preparing the site for building with their own hands. Wooden or steel pegs are driven in at the corners of the building being erected and a rope is pulled around them around the perimeter. From the corners of the marking, they retreat 0.5 m along the lines, drive in pegs and pull ropes on them to form the perimeter of the building being erected. The pegs driven into the corners are removed. This solution will allow you to accurately drill wells under the pillars without disturbing the marking.

Use a tape measure to mark the places for the pillars, remove the fertile soil layer to a depth of 30 cm and drill holes along the pipe diameter

It is important to provide a 10 cm margin for alignment of the posts. It is allowed not to remove the surface layer on the building site if the plot is flat

The spacing between the posts should be 1-2.5 m, depending on the load of the building and the type of soil.

At the bottom of the wells, widening is drilled with special equipment for the bottom of the piles. The diameter of the used PVC pipes is from 150 to 250 mm. Consequently, the diameter of the wells to be drilled will be from 160 to 260 mm.

Diy bored pile foundation

The step-by-step instructions presented below provide for the independent construction of a pile foundation in a bored version with a grillage on top. This is the most popular option among private traders, since it is not difficult to implement it.For work, only asbestos-cement pipes, concrete mortar and steel or fiberglass reinforcement are needed.

The device is performed in five stages:

-

Excavation.

-

Installation of asbestos-cement pipes and laying fittings in them.

-

Pouring concrete.

-

Grillage device.

-

Closing the plinth.

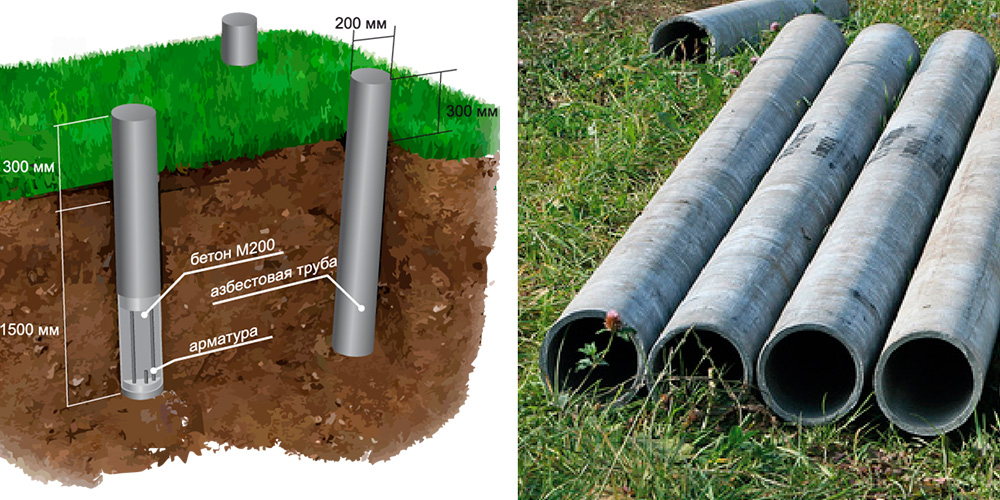

For the manufacture of bored piles, asbestos-cement pipes with a diameter of 300–400 mm are required. They will serve as a guarantee that the foundation will have a good bearing capacity both vertically and horizontally. And unlike the steel version, asbestos cement will not rust in the ground.

The wells for the supports are easiest to make with a hand drill with a gasoline or electric motor. The depth of these holes should end up being 30–40 cm below the freezing point of the soil.

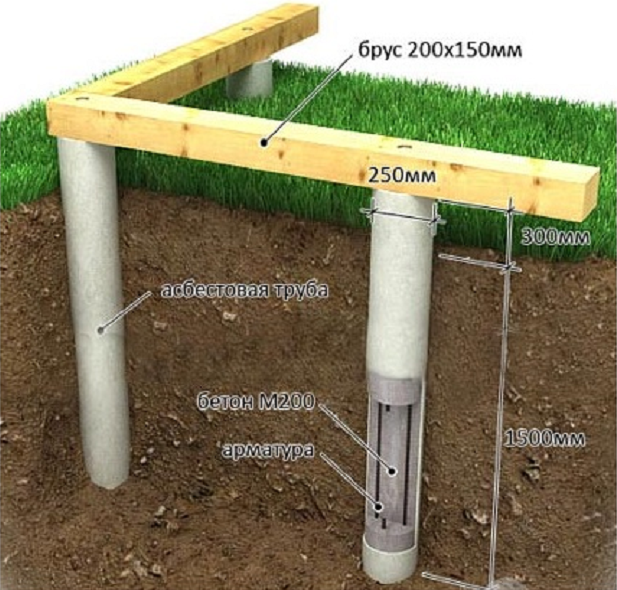

Pile pillars are located along the perimeter of the building and under the load-bearing walls inside with a step of up to two meters. After drilling the wells, a sand cushion 10–15 cm thick is poured on their bottom. Then concrete is poured another 25–30 cm from above as a support under the piles. And already in this not frozen solution, pipes made of asbestos cement are installed. Moreover, they should protrude at least 30 cm above the ground.

In order for the pipes to remain strictly in an upright position, they are sprinkled with sand, which is thrown in the process of compaction. Next, the support pillars are reinforced. For this, 3-4 rods of steel or fiberglass with a cross section of 10-12 mm are used.

Reinforcement rods must be placed in the center of the pipe at an equal distance from each other. To simplify installation, they can be tied with wire crossbars while still on the ground. In height, these vertical rods should be higher than the upper edge of the pipe, protruding from the latter by 15–20 cm. After reinforcement, this fixed formwork should only be poured with concrete, making sure that no voids are formed inside the solution.

Already after 3-4 days on the resulting supports, you can mount a grillage made of reinforced concrete (with the laying of formwork, reinforcement and pouring a concrete mixture), a steel channel or a bar. As a result, there should be a gap of 25-30 cm between it and the ground. It is impossible to lay the grillage directly on the ground, it can simply be squeezed up when heaving and demolished along with the building.

At the end of the arrangement, it is best after the construction of the walls, the supports and the grillage structure should be closed with cladding on the sides. Corrugated roof or facade sheeting or decorative brick is perfect here. Only first you need to lay down all communications. Fortunately, water supply and sewerage in the house on piles are carried out between the supports without additional tweaks and drilling in concrete.

For what?

A columnar foundation made of asbestos pipes is considered the main component of any building, and the strength and durability of the building will depend on how well it is made by hand. Therefore, it is necessary to choose the base carefully, taking into account the type of object being built, the materials used for the construction, the geological and climatic features of the area.

Features of the installation of asbestos pipes

Features of the installation of asbestos pipes

Specifications

It's no secret that aggressive environmental conditions negatively affect such indicators of building materials as their main characteristics and operational features. So, for example, for construction in an area where the depth of groundwater is shallow and flooding is characteristic, a columnar foundation made of asbestos pipes is perfect. It is he, thanks to its structure, that will allow the finished structure to more firmly gain a foothold in the desired area and withstand the onslaught of natural influences.

The part of the asbestos pipe, which is in the ground, is practically not subject to corrosion and decay

The part of the asbestos pipe, which is in the ground, is practically not subject to corrosion and decay

Advantages

Everyone knows that not only an asbestos pipe, but also a metal one can be used as the main axis for a columnar foundation.However, in the modern world, preference is given to the first component. Such a clear advantage of such a building material as an asbestos pipe received due to its special properties, namely: • high resistance to corrosion; • minimum rate of thermal expansion: • ease of machining; • the shortest construction time; • affordable price. The first characteristic means the resistance of asbestos pipes to aggressive environments. The second feature implies the ability of the material to maintain its structure regardless of sudden temperature changes. The next indicator means that you can choose the required length of the product right on the construction site by sawing off the pipe.

Installation of a foundation made of asbestos pipes

Installation of a foundation made of asbestos pipes

Peculiarities

The main distinguishing feature of the columnar foundation is the way it was laid during construction. The concrete solution is poured not with a solid frame around the entire perimeter of the object under construction, but certain structures are formed that are located in certain places, which are maximally affected by the finished system. When choosing a columnar foundation made of asbestos pipes, it is worth considering the need for preliminary calculations regarding the number of pillars, the depth of their immersion in the ground, the thickness of the pipes used, which are necessary to form a more reliable support for the structure under construction.

Installation of an asbestos pipe

Installation of an asbestos pipe

What to look for

It's no secret that such calculations are made even at the stage of design documentation. Thus, to create a durable building of your dreams with a solid foundation that can withstand the negative effects of the environment, you need to know: • climatic features of the area; • geological features of the selected area; • weight of the finished structure; • the depth of soil freezing. These and other indicators contribute to the presentation of a clear picture. Consequently, on the basis of the data obtained, the engineer is able to design the correct arrangement of the pillars, which will allow obtaining a solid foundation for future construction.

asbestos pipes for foundation

asbestos pipes for foundation

Timber fastening armature

The strapping of the posts (or the formation of the grillage) is necessary in order to evenly distribute the load on the posts. In addition, the grillage is a support for future walls. Therefore, this design must be performed efficiently, following the instructions:

- On the pipes, make a formwork from boards.

- Pour sand at the bottom of the formwork.

- Install fittings on the sand by connecting it to the fittings that come out of the pipes.

- Pour concrete mixture.

- After the concrete has set, remove the formwork.

Step-by-step instructions, starting from drilling wells, ending with the formation of a grillage, are presented in this video

Installation of a columnar foundation made of plastic pipes

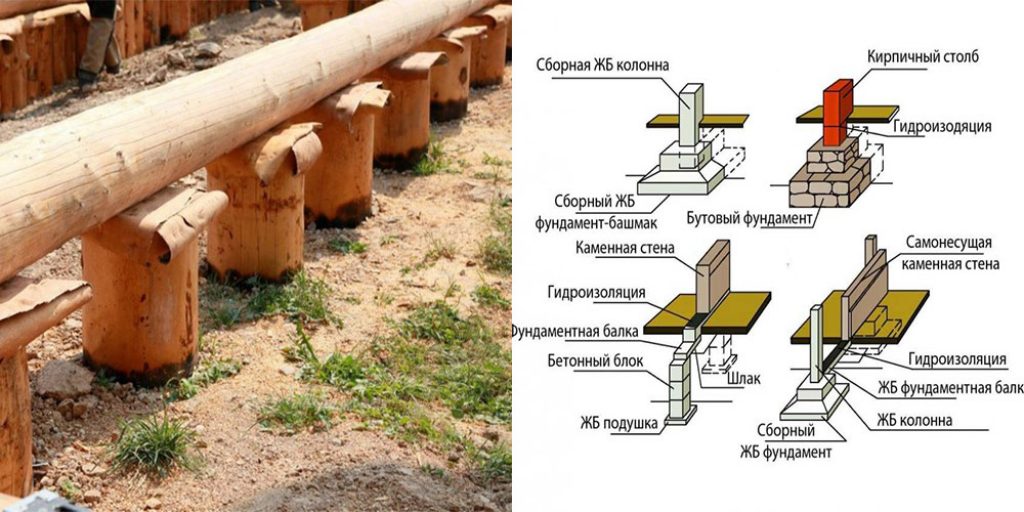

Columnar foundations come with different grillages:

• high (the base of the grillage is located above the ground level);

• low (the sole is flush with the ground);

• deepened (the sole sinks below the surface of the ground).

The entire load of the erected structure is distributed evenly on the foundation pillars, even if the sole is buried in the ground.

The columnar structure is arranged quite simply: a bed of sand and crushed stone is made into the prepared pit, after which an expanded sole for the pipe is created in various ways (concrete, metal frame). Next, the pipe is installed and filled with concrete and reinforcement. The final touch is filling the space between the polymer formwork and the pit walls.

Columnar foundation manufacturing technology

Further work will be divided into two stages, each of which requires responsible and step-by-step execution.

Well drilling and piling

- According to the markings, wells are made using a drill. The depth of the well should be 25 cm deeper than the level of soil freezing, and the width should be 7 cm more than the diameter of PVC pipes.Due to possible collapses, it is not worth drilling all the wells at once, it is better to make them sequentially;

- Using a shovel or a special drill nozzle, an expansion is made at the bottom of the well with a height of 25 cm and a diameter of 12 cm;

- A pillow is made at the bottom of the well from a mixture of sand and gravel 20 cm thick;

- The pipe is inserted so that its surface practically coincides with the lower plane of the grillage.

- Using a level, mark the location of the lower part of the grillage on the pillars and, if necessary, cut off the piles according to the markings;

Concreting pipes

For convenience, pour the ready-made concrete solution into a container and pour 20 liters into the pipe cavity, it is necessary to raise it by 20 cm. The concrete, spreading along the expansion, forms a heel. Fill the remaining space around the support with soil and tamp it thoroughly; Insert a pre-welded frame of three fittings into the pipe so that their edge is 25 cm higher than the plastic pipe, if a reinforced concrete frame is planned. If the bundle will be carried out with a tree, then the reinforcement should be installed 5-7 cm below the edge of the plastic pipes. Pouring of concrete should be carried out in portions, with careful compaction of each layer using a vibrator or a metal rod

In the latter case, it is necessary to act with utmost care so as not to violate the integrity of the plastic pillars; Pour the concrete solution until it reaches the level of the pipe; Fill the pipes completely with mortar, tamp them, install a 10-12 mm diameter stud in the pile (for a wooden grillage) and leave until completely solidified. So that the solution does not dry out, raw sawdust is laid on the surface of the pillars and covered with polyethylene until the concrete has completely set.

So that the solution does not dry out, raw sawdust is laid on the surface of the pillars and covered with polyethylene until the concrete has completely set.

Video: Foundation for a utility room

What is the cost of a columnar foundation?

First of all, it is necessary to summarize the cost for all types of pipes.

Scheme of the reinforcement cage of the support.

- Cement. The basis of such a foundation is cement. For small buildings, in order to save money, you can use cement grade M400, and for capital and large structures - M500. The average cost on the construction market of the Russian Federation fluctuates for m400 in the region of 180-200 rubles per 50 kg, and for m500 from 250 to 300 rubles (depending on the manufacturer). Sand can cost another 350-400 rubles per 1 ton. The cost of crushed stone ranges from 480 to 520 rubles per 1 ton. The total volume of the required concrete mixture will need to be calculated individually. It will depend on the diameter and depth that the hole has, as well as the use of fittings and the type of pipes.

- Pipes. The most economical are plastic pipes. Depending on the diameter, they can cost from 50 to 200 rubles per 1 m. It should be noted that due to their ease, transportation can be carried out manually, without ordering a truck. Asbestos pipes will cost an average of 450-750 rubles per 1 piece. It should be noted that it is best to purchase long pipes, and then just saw them into 2 halves. For both types of pipes, which were listed above, the price of fittings must be added to the cost. Based on the diameter and prices for 1 m of the product, the average cost will range from 200-300 rubles per 1 m.

- Metal pipes are quite expensive. Depending on the pipe wall thickness and diameter, their cost ranges from 650 to 800 rubles per 1 m. For metal pipes there is no need to purchase fittings separately, but they will require additional costs for special anti-corrosion agents. In this case, there are 2 small nuances: you can buy pipes that are resistant to a hostile environment, or you can save a little by purchasing used pipes.

- Land work.In this case, everything will depend on the owner of the site on which it is planned to repair a brick bath or other building. If time permits, wells can be prepared (in this case, they are called a pit) with their own hands, without the involvement of outside specialists. The only expense item in this case is the cost of purchasing a drill so that a hole can be drilled (manual can cost about 1300-1500 rubles). It is recommended to purchase a special drilling rig, which can greatly speed up the process.

In view of the design features, another point is the need to sprinkle the soil under the bathhouse with crushed stone or slag. This is necessary in order to prevent the growth of all kinds of grasses and plants.

Therefore, with a little skill and a reasonable approach using this method, it is possible to repair the site, build and make the floor with your own hands in the shortest possible time, while spending a small amount of money. The dream of a country house, a small summer cottage or a private bathhouse will become one step closer to the owner of the site who is repairing it.

disadvantages

Composition and varieties of a / c pipes

Composition of a / c pipes: asbestos (15%) + Portland cement (85%) + water.

Varieties: Asbestos pipes are produced in 2 types: pressure and non-pressure.

Non-pressure a / c pipes are designed to create networks of free-flow sewerage, ventilation, etc., where the transported medium is supplied without pressure. They are marked with BNT.

Pressure a / c pipes are more durable and are used in conditions of increased pressure (6-9 atm). VT marking.

Average prices for asbestos-cement pipes (St. Petersburg)

Non-pressure asbestos-cement pipes

| Asbestos-cement gravity pipe | Length, mm | Outside diameter D, mm | Inner diameter d, mm | Weight, kg | Price, rub / piece |

|---|---|---|---|---|---|

| A / c pipe BNT-100 | 3950 | 118 | 100 | 24 | 360 |

| A / c pipe BNT-150 | 3950 | 161 | 141 | 37 | 580 |

| A / c pipe BNT-200 | 3950 | 211 | 189 | 64 | 1210 |

| A / c pipe BNT-200 | 5000 | 204 | 184 | 74 | 1310 |

| A / c pipe BNT-250 | 5000 | 252 | 228 | 94 | 1780 |

| A / c pipe BNT-300 | 5000 | 295 | 269 | 121 | 2560 |

| A / c pipe BNT-400 | 5000 | 388 | 356 | 199 | 4000 |

| A / c pipe BNT-500 | 5000 | 508 | 454 | 359 | 7600 |

Asbestos-cement pressure pipes

| Asbestos-cement gravity pipe | Length, mm | Outside diameter D, mm | Inner diameter d, mm | Weight, kg | Price, rub / piece |

|---|---|---|---|---|---|

| A / c pipe d 100 VT-9 | 3950 | 122 | 100 | 45 | 760 |

| A / c pipe d 150 VT9 | 3950 | 168 | 141 | 67 | 1110 |

| A / c pipe d 200 VT-6 | 5000 | 224 | 200 | 123 | 1670 |

| A / c pipe d 200 VT-9 | 5000 | 224 | 196 | 142 | 2010 |

| A / c pipe d 300 VT-6 | 5000 | 324 | 292 | 199 | 3190 |

| A / c pipe d 300 VT-9 | 5000 | 324 | 286 | 217 | 3970 |

| A / c pipe d 400 VT-6 | 5000 | 427 | 385 | 333 | 5310 |

| A / c pipe d 400 VT-9 | 5000 | 427 | 377 | 390 | 6570 |

| A / c pipe d 500 VT-9 | 5000 | 528 | 466 | 637 | 7550 |

Varieties of columnar base

The pile can be made from various types of products. The following are actively used in construction:

- asbestos-cement;

- wooden;

- concrete;

- metal;

- plastic.

The base, made on piles of asbestos-cement pipes, is considered the most durable. In addition, such a base has a number of other advantages:

The base, made on piles of asbestos-cement pipes, is considered the most durable. In addition, such a base has a number of other advantages:

- Asbestos products have a low cost, which reduces the final cost of all work.

- To equip a foundation of this type, it is not required to additionally build a formwork for pouring concrete mortar.

- No special equipment is needed to install asbestos products.

- Before installing the supports, it is not required to create a special cushion of sand and gravel.

In addition to asbestos products, other types of supports and technologies are used in the construction of the foundation. For example, it is quite common to make supports and piles from steel pipes. In addition, for the construction of small light buildings, the use of plastic pipe piles is common.

Recommendations for erecting a base from pipes

Works can be performed in all weather conditions

But it is very important to do everything right.

Key recommendations:

- The metal body is protected from corrosion with bitumen mastic or several layers of roofing material;

- In the absence of pipes of the required diameter, several smaller pipes can be laid in one well;

- In the upper part of the post, before the concrete hardens, a threaded pin is laid for convenient fastening of the grillage elements;

- After pouring concrete, construction continues after 7 days;

- As a strapping of the supports, you can use a wooden beam, a steel channel, an angle or pipes;

- Ready-made supports must be loaded before the soil freezes;

- Do not install additional supports for safety factors. With a low weight of the structure and heaving soil, the increased base area contributes to the extrusion of the underground structure.