Characteristic features of a foam block house

A building made of such material combines the positive features of wood and concrete structures. From concrete, the foam blocks got fire resistance and resistance to decay.

Just like wooden materials, foam blocks have high vapor permeability, creating a good microclimate in the building. At the same time, buildings made of foam blocks have a high level of environmental friendliness, good sound insulation and low cost.

I want to see everything!

I want to see everything!

The foam blocks themselves differ in density and are divided into three groups:

- Heat insulating.

- Structural and thermal insulation.

- Structural.

The first group is characterized by low density and is used to insulate existing structures and improve the sound insulation properties of partitions. Structural types of foam blocks are used for the construction of load-bearing walls, but due to their high density, they have reduced sound and thermal insulation properties.

Along with a lot of advantages, foam blocks also have disadvantages. These include the fragility of the material, the ability to absorb moisture, the presence of shrinkage before the moment of strength gain, the need for a reinforcement cage in places of point loads and the likely appearance of cracks.

Owners of foam block houses do not need to be afraid of slanting rains, but the material should be excluded from being in the water for a long time. This reduces the thermal insulation performance. Shrinkage phenomena occur only immediately after the construction of the building and are rather short-lived, and the presence of reinforcing reinforcing parts is simply a structural feature of the structure.

What cement is made of

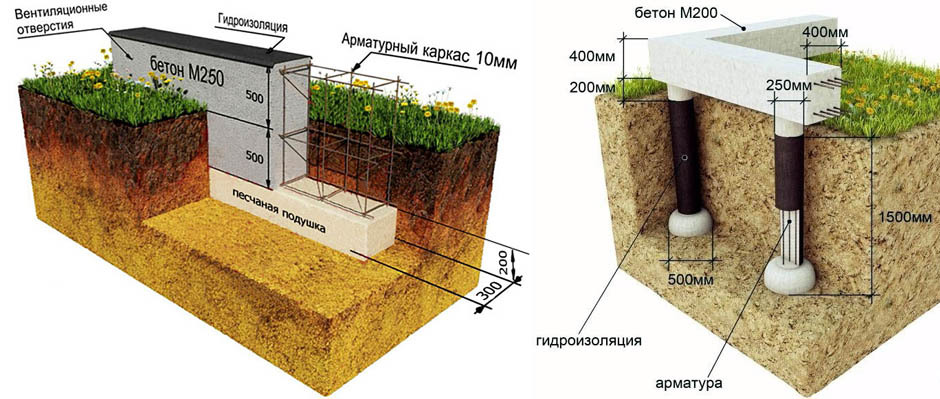

A foam block house is especially sensitive to the quality of the foundation. Due to the low density of the material, cracks can form on the building when the ground moves. At the same time, it is not worth installing excess capacity of the supporting structure. This will lead to a serious increase in the cost of the finished building.

What are foam blocks?

If you turn to the Internet, you can find out that the foam block is a specific building material, it is made from aerated concrete (foam concrete). It is made from ordinary cement mortar, a foaming agent is added to the resulting mixture (some manufacturers can mix additional ingredients with fiber, clay, ash, and so on). It meets all the standards and requirements that all building materials should have in terms of strength, susceptibility to deformation and resistance to low temperatures. Its thermal insulation characteristics are 2 - 3 times higher in comparison with traditional materials. The walls made of foam concrete create a special atmosphere and create an impeccable microclimate in the room, especially for people suffering from pulmonary and joint diseases, as well as heart diseases. Having most of the properties of wood, foam concrete is not subject to combustion and decay.

There are two types of foaming agents used to create foam concrete, synthetic and organic (protein).

Synthetic foaming agents are not of great cost and are unpretentious in manufacturing, but the foam concrete obtained with their help is not strong enough.

Organic foaming agents - made from natural raw materials and foam blocks are stronger, but its price is higher.

What are foam blocks?

If you turn to the Internet, you can find out that the foam block is a specific building material, it is made from aerated concrete (foam concrete). They make it from ordinary cement mortar, a foaming agent is added to the resulting mixture (some manufacturers can mix additional ingredients with fiber, clay, ash, and so on).It meets all the standards and requirements that all building materials should have in terms of strength, susceptibility to deformation and resistance to low temperatures. Its thermal insulation characteristics are 2 - 3 times higher in comparison with traditional materials. The walls made of foam concrete create a special atmosphere and create an impeccable microclimate in the room, especially for people suffering from pulmonary and joint diseases, as well as heart diseases. Having most of the properties of wood, foam concrete is not subject to combustion and decay.

There are two types of foaming agents used to create foam concrete, synthetic and organic (protein).

Synthetic foaming agents are not of great cost and are unpretentious in manufacturing, but the foam concrete obtained with their help is not strong enough.

Organic foaming agents - made from natural raw materials and foam blocks are stronger, but its price is higher.

This is interesting: Wallpaper options for the living room and hall

Combination options

There is no single formula for combining different materials, since developers pursue different goals. Some want to minimize costs while keeping costs down. Others consider this method a promising investment in an elite mansion with unusual architecture.

Be that as it may, such construction solves a set of tasks. Combination options:

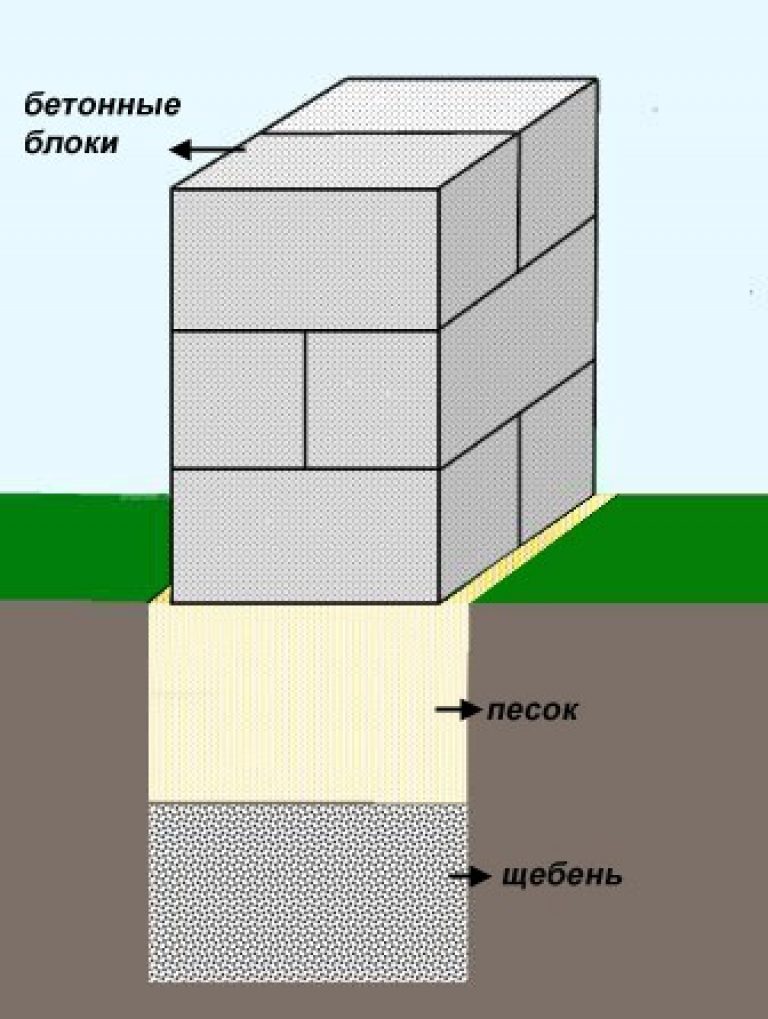

- Wood-stone. The option is suitable for creating durable housing. Includes a strip foundation, lined with natural stone on top. Handcrafted log house. Moss serves as a sealant (it also serves as an antiseptic). Stone, excellent protection from groundwater, strong winds.

- Wood-brick. The foundation is tape, rubble concrete. If the soil is dense, you can skip the formwork. Walls made of silicate or ceramic bricks are protection against moisture, fire, pests.

- Wood and concrete. The base is made of concrete blocks. They save time on construction, but have low sound insulation properties. Heat is retained worse than brick.

- Wood-foam blocks. A high level of thermal insulation, serious insulation is not necessary. But, given the fragility of the blocks, the correct reinforcement should be performed when laying.

Brick (stone) and wood: advantages and disadvantages

The combination of these two materials helps to compensate for the disadvantages of one with the advantages of the other.

The advantages of a house where the first floor is brick (or stone) and the second is made of wood (logs or beams) include:

- stone walls will protect from the spread of fire in case of fire, from subsidence of the second tier ;;

- the upper floor will not be affected by fungus in high humidity;

- the service life of such a combination is longer than that of a wooden building (more than 100 years);

- saving on finishing, wall insulation;

- wood retains heat, energy is saved, less natural gas is used for heating;

- the weight of the finished structure is not large;

- does not require the construction of a solid foundation;

- presentable appearance.

The disadvantages include:

- different service life of building materials (in order to extend the service life, you need to choose dry, high-quality processed wood);

- the tree needs time to shrink (up to a year);

- additional care for the drainage system for the walls of the second tier.

Wood and foam blocks or aerated concrete: advantages and disadvantages

The use of block materials in the construction of the first floor is preferred by economical developers. Simple, fast construction, affordable price are the main factors of popularity.

The positive characteristics of this type of construction include:

- both building materials are light, the construction of a strong foundation is not necessary;

- the construction of the first floor is accelerated due to the large size of the blocks;

- work with the material is not difficult, foam blocks are easily processed, cut;

- the structure does not shrink, the facade can be finished immediately after installation;

- decorating is not difficult, this is facilitated by a flat surface (siding, stone, decorative panels, plaster);

- aesthetic appearance, allows you to fit into any landscape;

- the combination of wood-block increases the service life (up to 100 years and more);

- an optimal microclimate is created, wood regulates humidity, provides air exchange.

Cons of combining:

- the thoroughness of finishing the first tier, taking into account the implementation of the waterproofing layer;

- it is necessary to fill in a reinforcing belt for fastening a wooden structure;

- periodic processing of wood, care to extend the service life.

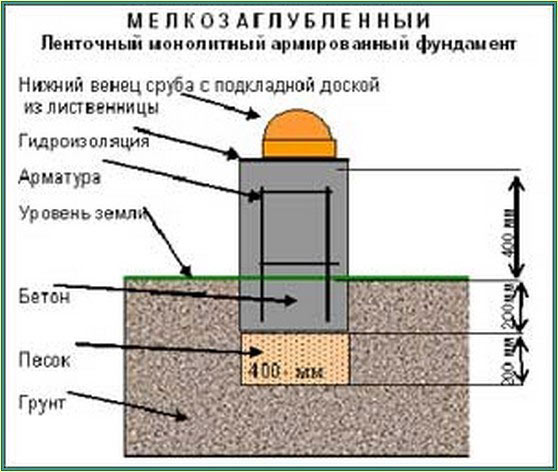

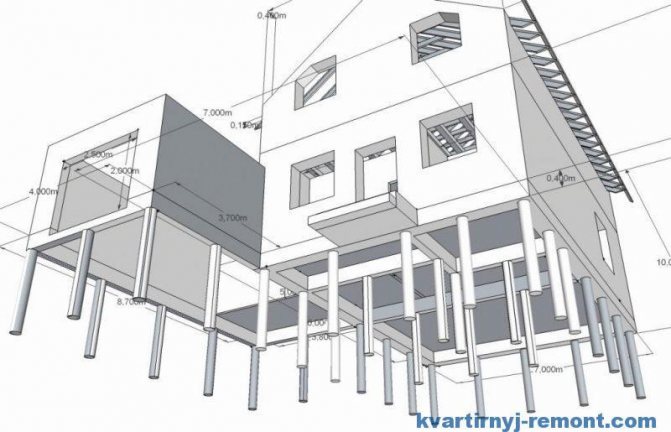

Advantages and disadvantages of tape structures on piles

Before settling on a tape-based pile, it is worth weighing the pros and cons. This type of basis has many positive qualities, among which are:

- Possibility of filling in any weather conditions and at any time of the year;

- Resistance to heaving and soil movements;

- Ability to bookmark in hilly areas;

- Ease of construction - the foundation can be done with your own hands, without resorting to the help of professionals and without involving construction equipment;

- Minimum time spent on work (the foundation device will take a maximum of 3 days);

- Low consumption of materials;

- Acceptable price: it is not as cheap as a pile or strip foundation for a house made of foam blocks, but at the same time its cost differs pleasantly from the cost of a buried or slab foundation;

- Possibility of installation in areas with high soil water disposal.

In addition to a significant number of advantages, the foundation also has negative features:

- Designing the base and drawing up a detailed drawing is a very complex and painstaking work that is almost impossible to do on your own. Therefore, the calculations will have to be left on the shoulders of specialists;

- The impossibility of arranging a basement in the house;

- Not suitable for building too heavy buildings.

Taking into account all the advantages and disadvantages of a belt base on piles, we can come to the conclusion that in many cases such a base is a real salvation. This is especially true for the construction of simple lightweight buildings from blocks on areas with difficult terrain.

It is interesting: DIY pile-screw foundation + video: consider all the nuances

What factors influence the choice of the type of foundation

First, the characteristics of the soil at the construction site are taken into account. To determine them, several holes should be dug. However, you can simply find out from the nearest residents the results of their geological surveys.

Table 1. Types of soil.

| Soil types | Peculiarities |

|---|---|

| Rocky and stony | By themselves, they are a good foundation and do not change properties under any seasonal climatic phenomena. |

| Cartilaginous | High-strength soil from stone fragments. When calculating the depth of foundations on such soil, you can not take into account the depth of freezing |

| Sandy | Weakly freezing to a depth of no more than a meter maximum |

| Clayey | They puff up strongly, as they keep moisture perfectly. Less compacted clay swells |

| Loam and sandy loam | Mixes in different ratios of clay and sand. Their properties depend on what prevails in the composition |

| Peat | Drained soils, which are characterized by high GWL |

Impact of frost heaving forces

Since rocky and semi-rocky soils have a high bearing capacity, any foundations can be arranged on them, except for pile foundations, which is almost impossible to make on rocky ground. The rest of the soil types are heaving and the choice of base design for them depends on various factors:

the depth of the layer: this can be found out by drilling several holes at different points of the proposed construction;

GWL: the closer the moisture is to the surface, the more the choice of the base design is limited.If it is located at a depth of about one meter, it is worth giving preference to a slab or piles

If the waters are lower, shallow belts can be taken into account;

depth of soil freezing.

In freezing temperatures, the water in the soil freezes and becomes ice. At the same time, it grows significantly in volume. This process is called frost heaving. Heaving causes the movement of soils and their strongest effect on the structural elements of the house, leading to their deformation and gradual destruction. The following factors influence the depth of soil freezing:

- type of soil: sandy ones freeze more and faster than, for example, clayey;

- climate: the colder, the more the ground freezes;

- GWL: the higher this indicator, the stronger the impact.

The main types of soils

The choice of the type of building is also influenced by the total load exerted by the proposed structure on the future sole of the base. The calculation of the calculation of the sole area is carried out taking into account all types of loads:

- the weight of the structure, including the weight of walls, floors, roofs, stairs, fireplaces, etc. All these data, taking into account the building material, can be found in specialized sources;

- the weights of the estimated maximum number of people who will be in the house;

- the weight of furniture and equipment, if it will also be placed within the house;

- snow load typical for the region. For the middle lane, 100kg per sq.m. is taken. roof area, for the south - 50 kg, but for the north - already 190 kg.

The value obtained as a result of these calculations is used when drawing up a project: for a tape - to select its width, for a columnar and pile - for a shoe area.

However, all these calculations can be avoided by building the most expensive type of foundation - a slab. This solution cannot be called economical, since the slab base is quite expensive, however, the soles of the filled-in for the entire area of the house are enough to solve all the problems that may ever arise with this house.

Specific gravity of some building materials

The question of the economy of building a base for a house is important. The foundation is a rather expensive construction. If you have a choice between several options, it is worth calculating the costs of building materials (concrete, pipes, fittings, etc.) and directly for the work process: you may have to order a concrete mixer, a team of workers, take a vibrator and a vibropress for rent. Any financial overspending in this area is not justified.

This is interesting: How to make a floor on the veranda with your own hands

Material features

Gas blocks are less dense than ordinary bricks

Gas blocks are less dense than ordinary bricks

Aerated concrete has a number of technical features that distinguish it from other building materials. In this regard, the entire technology of construction from aerated concrete has its own nuances. The method of choosing and laying the foundation for a house made of aerated concrete is no exception.

To understand what requirements are imposed on load-bearing bases and how to choose the right foundation for a house made of gas blocks, you need to familiarize yourself in more detail with the technical and operational characteristics of the material.

| № | Specifications | Indicators |

|---|---|---|

| 1 | Density | 300 - 1000 kg / m³ |

| 2 | Linear compressive strength class | B-2.5 ... B-3 |

| 3 | Moisture resistance | Low |

| 4 | Fire resistance | Not flammable |

Mass and density

Due to their low density, the blocks are lighter and place less stress on the base

Due to their low density, the blocks are lighter and place less stress on the base

The density of gas silicates is much lower than that of building bricks or cinder blocks. For comparison: if this indicator for a baked clay brick is about 1.5 tons per cubic meter, then the density of gas silicate blocks varies from 0.3 to 1 ton per m³.

That is, their density indicators are comparable to the density of wood.This greatly lightens the load on the supporting base of the building, so the foundation for a house from gas silicate blocks can be erected using lightweight technologies, which speeds up the construction process, and also reduces estimated costs.

Vapor permeability

Blocks absorb moisture well, and therefore require additional external finishing

Blocks absorb moisture well, and therefore require additional external finishing

Aerated concrete does not interfere with free gas exchange between the interior and the atmosphere. This allows you to create and maintain a comfortable microclimate inside the building, with a natural moisture and oxygen content. This is due to the high porosity of the material.

But, on the other hand, high porosity also determines the greater hygroscopicity of gas silicates - the ability to absorb moisture from the environment and keep it inside.

That is why the gas blocks must be carefully sheltered from dampness: a block that has absorbed water can collapse at sub-zero temperatures: water frozen inside will simply split it.

That is why the gas blocks must be carefully sheltered from dampness: a block that has absorbed water can collapse at sub-zero temperatures: water frozen inside will simply split it.

To avoid wall blocks getting wet, the height foundation for the house from aerated concrete should be at least 40 cm. This will protect the walls from rain streams and splashes from the water flowing from the roof during bad weather.

Strength

Very often inexperienced builders complain about the low strength of the gas silicate material, but this should not be attributed to the disadvantages, but rather to its operational features. It requires special conditions during transportation and storage due to its fragility.

Very often inexperienced builders complain about the low strength of the gas silicate material, but this should not be attributed to the disadvantages, but rather to its operational features. It requires special conditions during transportation and storage due to its fragility.

But due to the low strength in comparison with concrete and brick, gas blocks can be processed with ordinary carpentry tools: sawing with a hacksaw, planing with a plane, processing with a chisel.

Foam concrete is easy to saw with an improvised tool

Foam concrete is easy to saw with an improvised tool

Among the disadvantages of low strength, one should point out the tendency of aerated-block walls to cracking when the base is deformed. This imposes special requirements on the foundation for an aerated concrete house.

The foundation for gas silicate blocks, despite its lightness, must have maximum strength and stability. The foundation for a gas silicate house should be selected and installed in such a way as to minimize any movement and deformation during operation.

So, the forces of frost heaving, acting on an improperly constructed foundation for an aerated concrete house, can lead to its curvature and cracking, and this, in turn, will cause a violation of the integrity of the masonry of the walls.

Foam blocks

Foam concrete is a relatively new building masonry material. Foam blocks are made from it for the construction of walls. Foam concrete blocks (PB) have gained great popularity due to their quality characteristics.

Sizes of foam blocks

Sizes of foam blocks

PB are manufactured at the factory using special equipment. Foamed cement-sand mortar is treated with hot steam under high pressure. The resulting mass is poured into molds, which are sent to the drying chamber for 2 hours. Then the process of final solidification of the foamed mass takes place in the open air.

For the construction of external walls of buildings, PB of standard dimensions are used 390x188x190 mm. Blocks 90 mm thick are used for masonry partitions. There are varieties of foam blocks with lateral locking systems - "thorn-groove". Sometimes the horizontal surfaces of the masonry elements are also made in the form of locks, which provide an almost seamless PB connection.

Cutting the block with a saw

In terms of their quality characteristics, foam concrete blocks surpass many of their counterparts. Foam concrete blocks are used for laying external fences of multi-storey buildings, where the structural function of the building is performed by the frame of the structure (columns + floors). The porous structure of the material gives the blocks high thermal insulation qualities. In winter, the wall masonry does not let the cold through, and in hot weather it keeps the interior cool.

The main disadvantage of the material is its low bearing capacity, therefore, as external enclosing structures, foam block masonry is made in houses with a height of no more than 2 floors.