Impact factors

To help dry the cement and avoid various troubles, there are several factors that should be observed:

- protect concrete from direct exposure to sunlight;

- if the cement suddenly loses moisture, cracks may form; in order to avoid this, the concrete must be periodically moistened;

- in case of an unexpected cold snap, the poured concrete needs to be heated; this can be done with the help of special hothouses, steam, electricity, etc.;

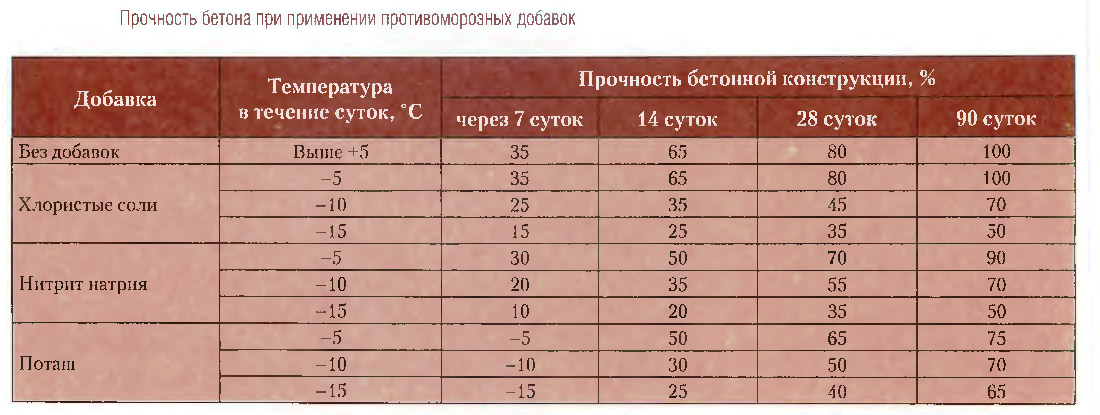

- special salt-free and salt preparations sold in hardware stores affect the drying time of cement - they significantly reduce it;

- more expensive grades of concrete harden faster than cheaper ones.

Sometimes it happens that the drying process must, on the contrary, be slowed down, if, for example, it has already been prepared, but has not been delivered to the place of construction work. In this case, use special surfactants.

In this aspect, the seasonality, the composition of the solution, the presence of auxiliary additives, the level of strength of the material matter.

If the pouring is done outdoors, and the air temperature does not exceed 5 ° C, concrete will gain strength 2 times longer than at 20 ° C. If the thermometer drops below zero, the mixture will thicken due to the freezing of water, but will not be able to achieve the desired level of integrity. Also, the hardening time depends on the proportions in which water, gravel or crushed stone filler, cement, sand were used.

Technological additives are used in cases where it is planned to subject the mixture to long-term transportation: in such conditions, a significant slowdown in the process of thickening of the solution is expected. They are also relevant if it is necessary to speed up construction work, to achieve faster drying without loss of quality and bearing capacity.

Factors related to the strength of concrete will certainly affect the rate of formation of structures from it:

- cement and water, used in certain proportions, affect the rate of the chemical reaction. If there is too much liquid, pores will appear abundantly, which will negatively affect the quality of the product;

- the larger the filler is present in the mass, the stronger it becomes when dry.

How much concrete dries depends on the toughness of the filler. Over time and as it dries, the strength characteristics of the product increase, and the temperature drops below zero to stop this progress.

To find out how much concrete dries, it is necessary to take into account a number of conditions that affect the rate of concrete hardening.

Seasonality

The key factors that determine how long concrete hardens are the environment and the period of the year when construction work is carried out. This group includes indicators of street temperature and air humidity.

If in the summer the composition can harden in a few days, then in the cold period, hardening will take more than a month. The specificity of curing under favorable conditions of concrete hardening is as follows:

- 1-3 days - no more than 30% brand strength.

- 7-14 — 60-80%.

- 28 — 100%.

If you want to make the foundation mortar quick-setting, special additives must be added to its composition.

Rammer

A dense screed does not tolerate cutting and drilling after ramming, therefore, for such work, it is necessary to use diamond drills. A simple handpiece will quickly fail.

Composition

How long the concrete hardening process can take depends on its composition.So, if it contains a large amount of porous additives, such as slag and expanded clay, water will remain in the solution for a long time. If the mixture contains sand or gravel, the liquid will come out faster.

We offer you to familiarize yourself with How to attach a cable duct to a concrete wall

To reduce the intensity of moisture evaporation and increase the strength indicators of the composition, it is diluted with additional components. It can be bentonite or soap composition. The introduction of such additives increases the overall cost of work, but prevents the problem of early drying out of the solution.

Dependence of the holding time of the foundation on its type

The insinuations that the finished foundation, after the set of the normalized strength of its constituent concrete components, must stand for a year or a winter, are absolutely not consistent. The widespread misconception about the need to withstand the structure until the end of the ongoing sedimentary-shrinkage processes arose as a result of the substitution of concepts. The fully erected building must be maintained before the start of finishing. This is explained simply by the example of existing varieties of the structural structure of foundations.

Video on how to accelerate the hardening of concrete

Columnar foundations

A columnar foundation is a series of individual pillars, for the arrangement of which brick or masonry is used, often the foundation pillars are made of concrete or reinforced concrete. To give the foundation elements additional stability, a grillage is set up - a reinforced concrete tape connecting the headbands of the pillars.

This type of foundation is classified as a light variety, therefore, the foundation base, unloaded by the weight of the building, is subject to increased mobility during soil movements with a heterogeneous morphology, and can be easily deformed as a result of frost heaving. The foundation of a columnar structure cannot be defended by definition, and it is necessary to start erecting walls immediately after the end of the setting of the masonry mortar or the curing of concrete.

Belt type foundations

Reinforced concrete strip foundations can be equipped in two types:

- shallow foundations are equipped for the construction of light buildings and with their soles rest on soil horizons located above the freezing level;

- deeply buried options involve the erection of bulk structures on them with a large weight, the level of occurrence of their soles exceeds the depth of freezing of the soil.

A shallow strip foundation undergoes loads that are similar in tension and strength to the impact on columnar options with a grillage. If such a foundation is allowed to stand during the period when the active heaving of soils occurs under the influence of freezing and thawing of ground moisture, the possibility of its deformation is very likely.

The foundations of the strip type of deep bedding are supported by their soles on dense horizons, are not subject to the influence of ground shifts. The shrinkage processes in the concrete mass are completely completed after reaching the standard strength, and the structure's settlement under the action of its own mass, without taking into account the weight of the building, is completely leveled by expansion joints.

Plate varieties

Monolithic foundations are easy to calculate and equip, they provide the foundation for the building being erected with sufficient strength characteristics. The even distribution of the load on the soil base due to the large supporting surface determines the minimum value of the specific pressure on the soil. Competently prepared sand or sand-crushed stone cushion under the foundation slab prevents its significant sedimentary movements.

The stability of the building erected on a slab foundation directly depends on how carefully the preliminary earthworks were carried out.The amount of time that a monolithic foundation must be defended is, again, determined only by the period necessary for concrete to cure.

Pile foundations

The foundations of buildings on piles, with any technology for their arrangement, ensure the transfer of load to deep, often primary, horizons of soil and rocks. This type of foundation construction completely eliminates the possibility of deformation of the building, regardless of how much time is allotted for their standing after the end of installation.

The determination of the time for how long the foundation should stand after pouring should be correlated with the time period for which the ready-mixed concrete will gain the strength specified by SP 70.13330.2012. Additional curing is not advisable, and in cases of using columnar structures and shallow strip foundations, it is even contraindicated.

Construction requirements

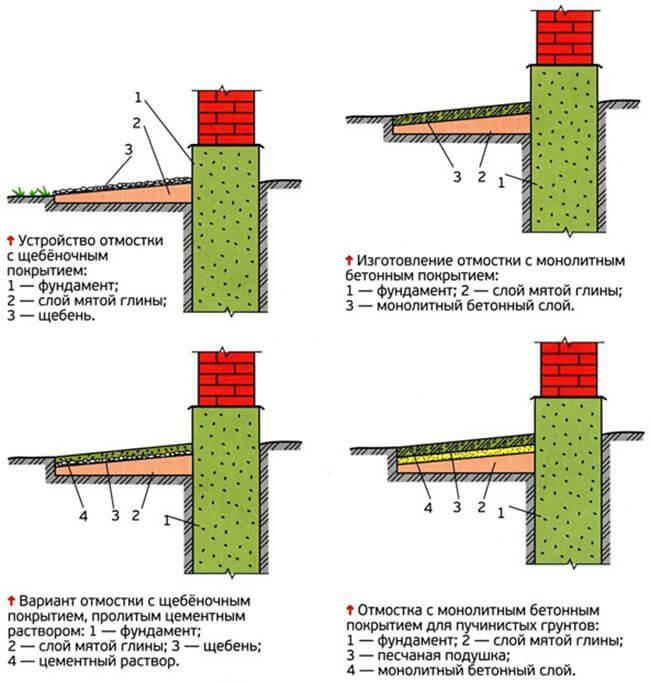

The concrete blind area has a fairly simple design, for the preparation of which the following materials will be required:

- Padding (pillow). It is performed before pouring the solution. A variety of materials are used as bedding: coarse or medium sand, sand and gravel mixture, crushed stone, fine gravel. The foundation blind area does not fit onto fine sand due to the likelihood of shrinkage, since in this case there is a risk that the base will crack. It is best to prepare a two-layer cushion: first lay gravel or crushed stone, which will compact the soil, and then the sand.

- Reinforcement. The presence of a reinforcing mesh for the concrete blind area will give the structure more strength. The mesh size of this product is usually 30 x 30 or 50 x 50 cm. The mesh diameter should be about 6-8 mm, but it all depends on the type of soil.

- Formwork. Wooden guides located around the perimeter of the pavement are required, as they will prevent spreading of the concrete mixture. The width of the formwork boards is usually 20-25 mm.

- Concrete mortar. Pouring the blind area is performed using a specific composition of the concrete mixture.

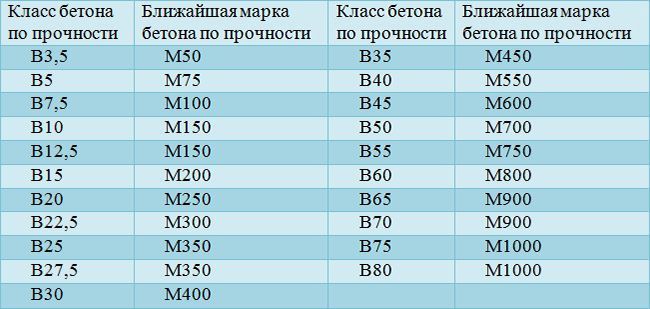

Concrete classes, depending on the strength of the composition

Concrete classes, depending on the strength of the composition

To get a high-quality coating, it is most profitable to make a concrete mixture on your own.

To fill the blind area of the house with concrete, you must familiarize yourself with the regulations and recommendations of SNiP:

- The width of the blind area should be 20 cm larger than the overhang of the roof (SNiP 2.02.01-83). If a drain is provided in the structure, then its indicators are also taken into account. The optimal value is 1 meter. In this case, you can lay out a tile path around the house.

- The length of the self-made blind area around the house should correspond to the perimeter of the building. However, if you plan to install a concrete porch, then a "break" is allowed.

- Depth. The level of deepening of the "tape" is half the estimated depth of freezing of the earth.

- The thickness of the concrete blind area is also regulated by SNiP and, according to these requirements, should be at least 7-10 cm for the top layer. However, many make concreted parking spaces for private cars along with the blind area. In this case, the operational load increases, and the thickness of the concrete blind area can reach up to 15 cm.

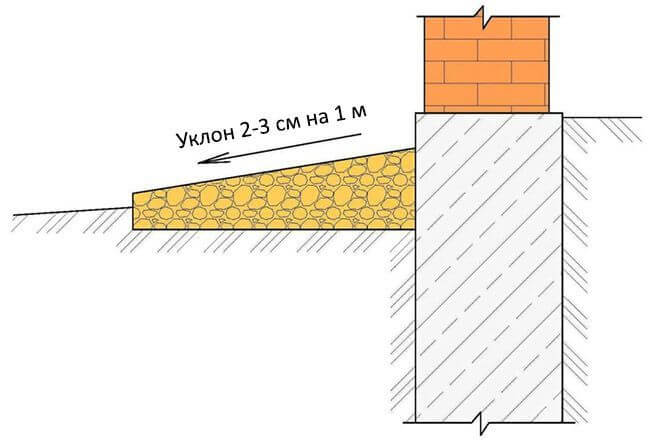

The blind area must be built with a slope of 2-3 degrees

The blind area must be built with a slope of 2-3 degrees

- Bias. According to SNiP III-10-75, the slope should be from 1 to 10 cm for each meter of width. Most often it is 2-3 cm per meter - this is approximately 2-3 degrees. The angle of inclination must be directed in the direction opposite to the foundation. It is not recommended to increase the slope, as in this case it will be difficult to walk along such a path in winter, when ice forms on the surface.

- Border. The device of the blind area of the house does not include the obligatory production of a border, therefore, in this case, the decision is made by the owners of suburban real estate.However, experts recommend installing such "limiters" if trees and shrubs with an "aggressive" root system grow next to the foundation (blackberries, raspberries, sycamores, poplar and others).

- Base height. For hard cover (concrete), the plinth must be at least 50 cm.

- The recommended height of the blind area above ground level is 5 cm or more.

There are also several schemes according to which a crushed stone blind area can be erected, in the form of a monolithic concrete coating, both for the usual type of soil and for the "problem" one.

Types of blind area, based on the characteristics of the soil

Types of blind area, based on the characteristics of the soil

Knowing the requirements of SNiP and the features of a suburban area, you can make a blind area with your own hands using the step-by-step instructions given below.

Impact factors

Before starting construction work, it is necessary to take into account all factors that can somehow affect the drying time of concrete.

Seasonality

Of course, the environment has a major impact on the drying process. Depending on the temperature and atmospheric humidity, the period for setting and full drying may be limited to a couple of days in the summer (but the strength will be low), or the structure will retain a large amount of water for more than 30 days during the cold season.

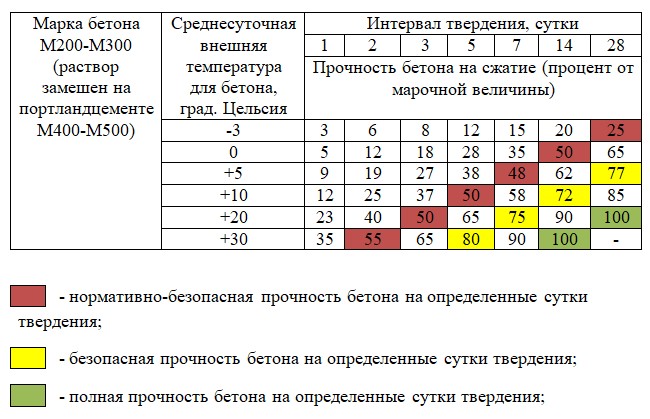

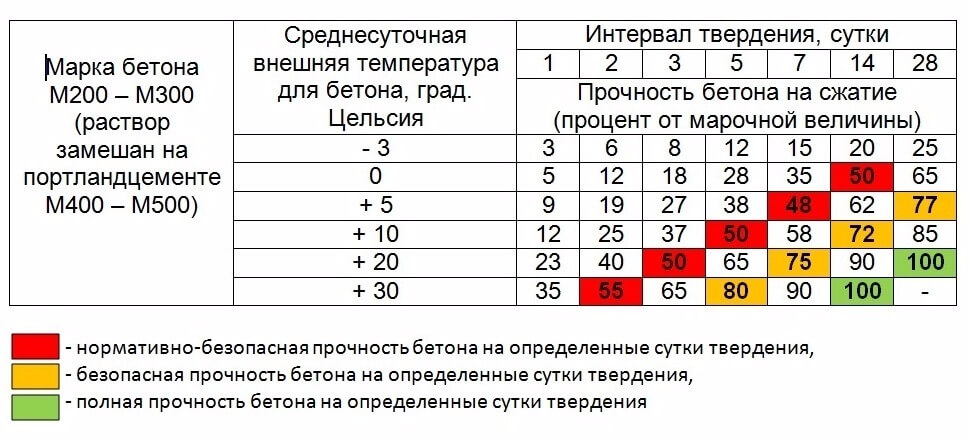

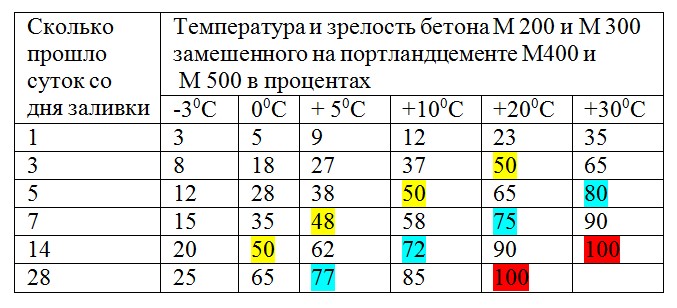

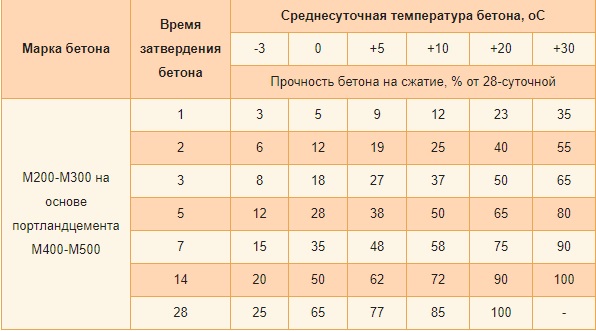

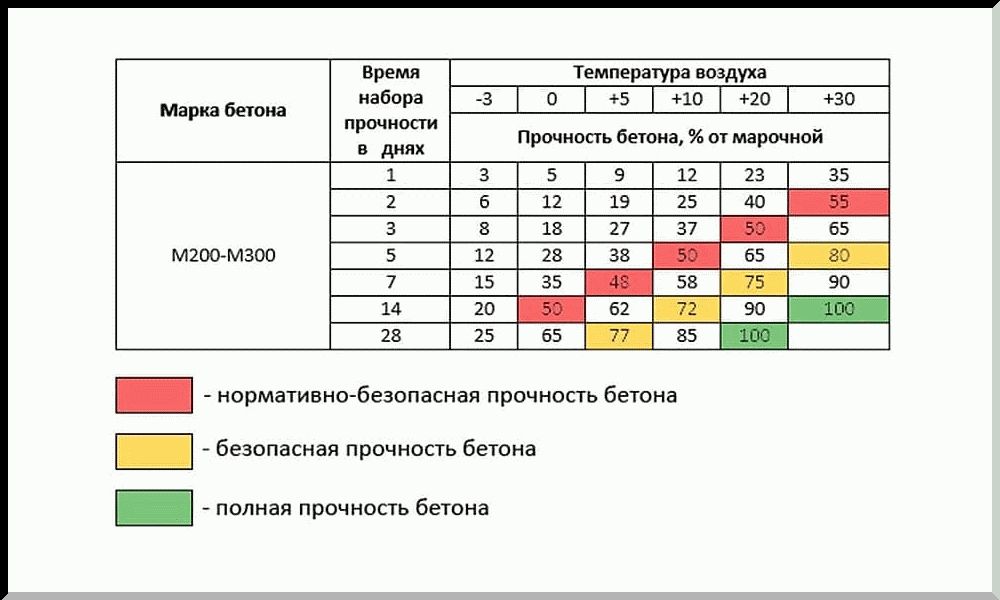

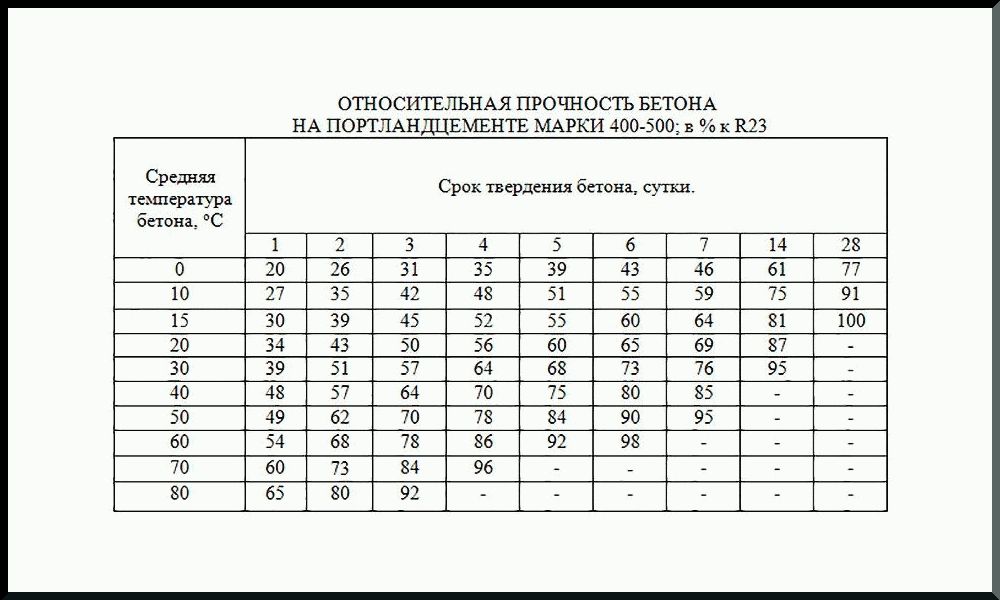

The hardening of concrete under normal temperature conditions is best described in a special table, which indicates how long it will take to achieve the maximum effect.

| Time, day | Brand strength,% |

| 1-3 | no more than 30 |

| 7-14 | 60-80 |

| 28 | 100 |

Rammer

Also, a lot depends on the density of the laying of the building mixture. Naturally, the higher it is, the slower moisture leaves the structure and the better the cement hydration indicators will be. In industrial construction, this problem is solved with the help of vibration treatment, and at home, they usually do with bayonetting.

It is worth remembering that a dense screed is more difficult to cut and drill after tamping. In such cases, diamond burs are used. Drills with a conventional tip fail instantly.

Composition

The presence of various components in the building mixture also affects the setting process. The more porous materials (expanded clay, slag) in the composition of the solution, the slower the dehydration of the structure will occur. In the case of sand or gravel, on the contrary, the liquid will come out of the solution faster.

To slow down the evaporation of moisture from concrete (especially at high temperatures) and improve its strength, they resort to the use of special additives (bentonite, soap composition). This will somewhat affect the cost of the mass for pouring, but will eliminate premature drying out.

How long does it take to build a strip base for a house

Why is it necessary to calculate the drying time of concrete during the construction of the foundation supports of a residential building? It's simple - if the work was started at the end of summer, this process (the strength gain of the support tape) may shift to mid-autumn, which will affect the drying rate of the structure in the formwork.

Usually, the mixture in the formwork dries up in the summer in 28 days, gaining the required strength at an average t 20 C, humidity within 68%. With a decrease in temperature in the autumn period, the drying time of concrete in the foundation belt of the house increases from 1.5 to 2 months.

Therefore, for winter work with concrete, special formulations have been developed for the preparation of compositions for pouring building structures. In severe cold weather, a special formwork (warm) may be required, otherwise the solution will not only not begin to gain the necessary strength, but will not even grab.

Drying process of the mixture in the formwork

The initial stage of concrete drying is setting

The initial stage of concrete drying is setting

When filling the foundation formwork for a house with a concrete composition (take, for example, a tape belt), there are two stages of hardening:

Setting - the concrete mix quickly loses its mobility and plasticity, which is why when pouring the structures of the house, it is recommended to perform all the laying work very quickly, avoiding the formation of dried layers in the formwork in order to avoid the formation of "cold bridges" inside the structure.

Concrete is transported to the place of placement with constant mixing of the mixture. All technological operations for laying the mixture into the formwork (leveling the surface, compaction) should be performed without downtime and random interruptions. "Cold bridges" that appear when the layers of the laid mixture dry out can affect the strength and durability of the house support.

Correctly prepared concrete dries within standard times

Correctly prepared concrete dries within standard times

But the hardening time of concrete in the foundation depends not only on weather conditions. The quality of the cement binder from which the mortar is mixed has a great influence on the hardening time of the mixture.

Equally important is the ratio of water to cement when mixing a solution.

It is very important to observe the recommended proportions if the concrete mixture for pouring the foundation of the house is prepared directly at the construction site with your own hands. It is worth noting that the drying time of the foundations from the monolith depends on the composition of the soil at the building site, because the hardening of the mixture during concreting is a chemical process that takes place depending on the combination of components

It is worth noting that the drying time of the foundations from the monolith depends on the composition of the soil at the building site, because the hardening of the mixture during concreting is a chemical process that takes place depending on the set of components.

How to correctly calculate the hardening time of the composition

Whether a monolithic strip foundation is worth a house or a bathhouse, the concrete mixture, on average, reaches full hardening in 28 days, but the strength gain does not stop there

For a long time, the foundation foundation will continue to gain strength, therefore it is very important to observe the technology of placing the concrete mixture in the formwork and maintaining it

The drying process of concrete must be carefully monitored, taking all measures so as not to disturb it ahead of time. The mixture laid in the formwork must be carefully looked after - moisten the surface of the structure, and protect the surface of the foundation from the sun's rays.

Watch the video with expert commentary on how to properly care for your flooded base.

Concrete hardening period

The overwhelming majority of amateur builders believe, for reasons that are not entirely clear, that after the end of laying in the formwork or the completion of work on leveling the screed, the concreting process is complete. Meanwhile, the setting time of concrete is much longer than the time it takes to place it. A concrete mixture is a living organism, in which, upon completion of the laying work, complex and lengthy physical and chemical processes occur, associated with the transformation of the solution into a reliable basis for building structures.

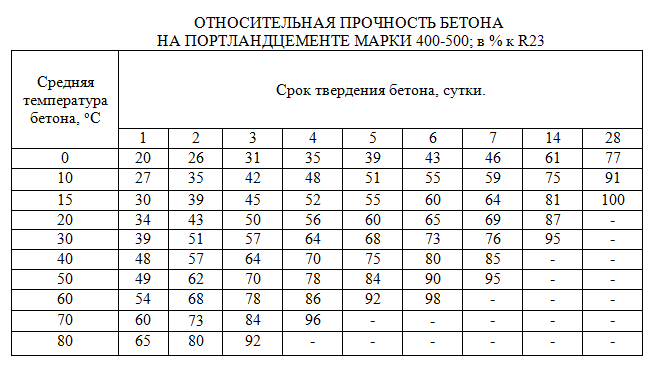

Before stripping and enjoying the results of the applied efforts, it is necessary to create the most comfortable conditions for the maturation and optimal hydration of concrete, without which it is impossible to achieve the required brand strength of the monolith. Building codes and regulations contain verified data, which are given in tables of concrete setting times.

| Concrete temperature, С | Concrete hardening period, days | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 14 | 28 | |

| Concrete strength,% | |||||||||

| 20 | 26 | 31 | 35 | 39 | 43 | 46 | 61 | 77 | |

| 10 | 27 | 35 | 42 | 48 | 51 | 55 | 59 | 75 | 91 |

| 15 | 30 | 39 | 45 | 52 | 55 | 60 | 64 | 81 | 100 |

| 20 | 34 | 43 | 50 | 56 | 60 | 65 | 69 | 87 | — |

| 30 | 39 | 51 | 57 | 64 | 68 | 73 | 76 | 95 | — |

| 40 | 48 | 57 | 64 | 70 | 75 | 80 | 85 | — | — |

| 50 | 49 | 62 | 70 | 78 | 84 | 90 | 95 | — | — |

| 60 | 54 | 68 | 78 | 86 | 92 | 98 | — | — | — |

| 70 | 60 | 73 | 84 | 96 | — | — | — | — | — |

| 80 | 65 | 80 | 92 | — | — | — | — | — | — |

The data contained in the official tables, of course, should serve as a guideline for the independent arrangement of concrete or reinforced concrete structures. But the application of such data should take place in close practical connection with the real conditions of construction.

Several factors regarding concrete

To answer this question, you should again return to the correct use of concrete itself.

When concrete is just poured, it is necessary to leave a small distance (about 0.5 m), which is filled with sand - this is what will prevent excess liquid from accumulating and destroying the concrete structure. Plus, in winter, when water turns into ice, moisture remaining inside the foundation can simply destroy or severely deform the entire structure when expanding.

When it’s not about building a country house or a bathhouse, but about important military-industrial facilities, then concrete is given an extremely long period of time, during which it must fully gain strength and density.

This applies to various bridges, dams, embankments, breakwaters, dams - all this requires an extremely massive foundation, and rush in the construction of such facilities is simply unacceptable due to their importance.

The concrete continues to gain strength even after it has completely hardened and dries up - moreover, even after the resumption of construction work. Of course, such a process is going on at times slower than usual and in construction it is no longer taken into account.

However, this provides additional security when it comes to reinforced concrete or just concrete structures.

As in many other cases, temperature serves by all faith and truth as a reliable catalyst for ongoing reactions - that is, at an elevated temperature, the reaction proceeds much faster. But to abuse this knowledge is by no means worth it, during the time the foundation dries under the house, water and concrete manage to react successfully. When heated, the water simply evaporates - and the mixture dries out, but, nevertheless, does not harden, and the bearing capacity of the entire foundation is strongly questioned. Therefore, it is necessary to allow the chemical reaction to take its course, without trying to interfere with this natural and entirely natural course of events.

How do you know that the screed is ready?

The screed is the base for the floor. Depending on the different species, it dries for about 27-28 days. After that, they start laying the flooring. Since the prescribed drying time is not always the same as indicated by the manufacturer, you need to make sure that it is ready. This question is especially relevant if a concrete screed is being made in an apartment when the heating season has not yet begun.

If you install a moisture-proof floor covering on top of a not dried base, the remaining moisture will create conditions for the formation of mildew and mildew. Concrete under its influence will begin to collapse, thermal insulation will be broken. In the future, the finishing flooring will also suffer.

To determine the readiness of the screed, you can use two methods:

- The answer may be given by visual inspection. The screed must be uniform, with a uniform color and structure over the entire surface. There should be no cracks on it.

- You can use a large size plastic wrap and attach it to the screed using duct tape. After a day, the film must be removed and inspected. If there are no traces of fogging on it, you can continue the flooring work.

Setting time of concrete in the formwork

Formwork is a special structure designed to create various monolithic concrete products, including the foundation. During construction, wooden or metal formwork can be used.

Formwork for concrete foundation

When creating the foundation of houses, wooden demountable formwork is most often used.

After pouring concrete and initial setting, the formwork is not disassembled for at least a week. In rare cases, the formwork is retained for most of the curing time of the concrete. After 7-10 days, the formwork is usually dismantled. Dismantling is carried out in such a way as not to violate the integrity of the structure. If the structure was assembled taking into account all the rules and regulations, then there will be no problems with dismantling.

Before assembling the formwork, preparatory work is required, including digging a trench (if you plan to create a strip foundation). The preparation of the mixture is carried out immediately before pouring, when the formwork is already assembled.

How long does it take to set and how much does a concrete foundation dry?

Strength of concrete for days goes by the following scheme:

- initial setting (the process starts in 10-20 minutes and ends within 24 hours);

- hardening (this stage takes about 1 month).

At temperatures above 20 degrees, the strength of the foundation for 3 days is about 50%.

Leveling is performed while the mixture is still liquid. The builders act quickly, as the signs of setting become noticeable already in the first hour after pouring.

How long does concrete harden?

Nowadays, concrete has become the main material for construction. Most often it is used for the construction of residential buildings, production facilities, because it is the most affordable and practical. However, when you start "cooperation" with this material, the time of concrete hardening is a question more urgent than ever.

What does it depend on?

The concrete hardening process lasts from one to twenty-eight calendar days. Much depends on the cement used in the work. The chemical process looks like this: the minerals in the concrete are converted into potassium hydrosilicate. In order for the material to be durable, not crumble, not break, it must be systematically impregnated with water. Hardening concrete is "capricious". Fast setting is due to several factors: temperature, humidity, layer thickness (tamping), etc.

Solidification stage (for example, foundation)

Concrete strength table.

The period of complete solidification and setting of the cement is not so long. One day after pouring is enough, and the material hardens completely. However, the main role is still played by the air temperature at which the foundation is poured. Two hours later, the concrete hardens after mixing the cement mixture with water at a temperature of twenty degrees Celsius. The end of drying occurs after three hours. Special additives will help to reduce the setting by fifteen, twenty minutes.

The hardening period of several grades of concrete:

- Curing time M 200 = two to two and a half hours.

- Curing time M 300 = one and a half to two hours.

- Curing time M 400 = one to two hours.

Solidification stage

In other words, the stage of hydration is during the period when the action of setting the foundation is active (evaporation of moisture from cement concrete). The hydration process ends prematurely with too active moisture evaporation, which, in turn, negatively affects the quality and strength of the material. The ideal time interval for the solidification of the foundation with the required volume of water will be one and a half to two weeks.

The period of complete hardening of some concrete brands:

- M 200 = fourteen to eighteen days.

- M 400 = seven to fourteen days.

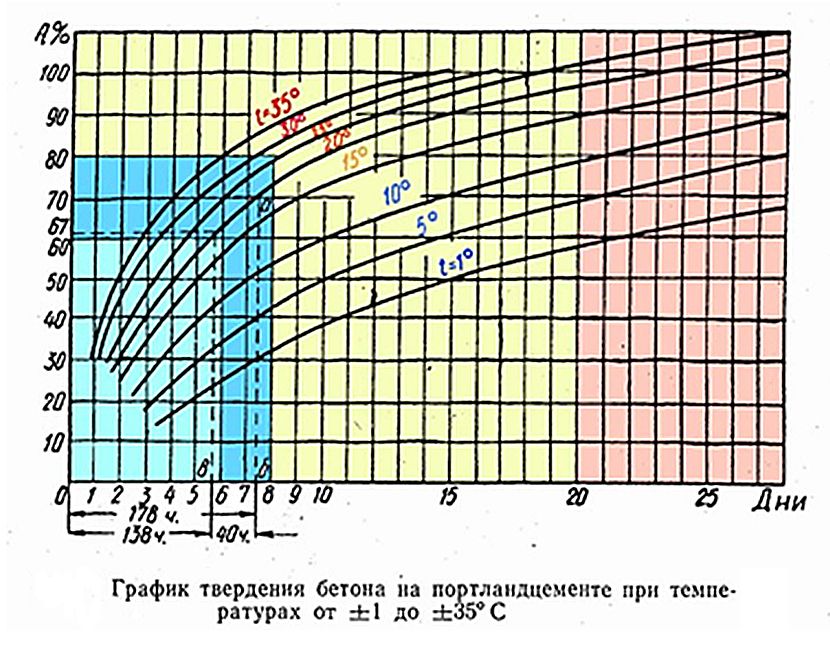

It is important to know that the duration of concrete hardening in the formwork must last at least a week before it is allowed to be removed without disturbing the structure. But do not forget that the drying period depends on the brand of cement. To figure out how long the concrete will set (taking into account the temperature), a graph or table will help

The graph and table clearly describe the temperature, material grade and drying time. A table or graph will become indispensable helpers in this difficult task.

Seasonality of work

A new method of thermal influence in construction in winter is the use of thermomats.

How long does it take to dry at low temperature? During cold weather, when working with concrete, the ability to isolate the cement-concrete structure from water and low temperature must be taken into account.

Negative conditions, like retarders, affect how long the hydration period lasts, create problems with drying, thereby reducing the durability of structures

It is important to observe the time required to build up the material's safe stability.

At five degrees of heat, the quality of concrete curing increases five or even seven times compared to twenty degrees of heat.

How long does it take to harden at thirty degrees of heat? Naturally, due to high temperatures, the cement mixture sets faster, but this can negatively affect the strength. Intense evaporation of moisture from concrete causes hydration to stop and also reduces durability

Basically, at 30 degrees of heat, cement concrete will harden an hour after pouring. In hot weather, when the air temperature reaches 30-40 degrees Celsius, builders use special retardants. They are necessary in order for the mixture to dry evenly. Retarders allow you to reach the highest point in material strength.

Concrete is the most affordable and practical material. Grasping will take place quickly and efficiently, depending on weather conditions. Novice specialists need to know the answers to two questions: how long does it take for the cement mixture to dry; how many and what additives should be used to make the material last longer.

Effect on drying rate

The transformation of the mortar into a solid monolith depends on weather conditions, the size of the structure, and the composition of the concrete.

Optimal air parameters:

- Temperature - 15-20 degrees;

- Humidity - 75%.

It is difficult to guess a day with such characteristics, usually the best time to create a foundation is late summer and early autumn.

In dry hot weather, the drying process is accelerated, which is bad for concrete. Rapid evaporation of moisture prevents the cement from completely crystallizing, the foundation becomes brittle, and cracks form on the surface. Grasping takes place in 1 hour.

Low temperatures also adversely affect the quality of the foundation. Hydration slows down significantly, and at zero and below moisture remains in the solution, when it freezes, it expands and has a destructive effect on the structure. The critical threshold of hardening is 10 degrees Celsius, setting lasts 6-12 hours.

The duration of curing depends on the composition of the concrete. M200 concrete hardens within 14-18 days, M400 - in 7-14 days. The rammer used when pouring prolongs the drying time.

Setting too fast can be slowed down with water and foil. A completely different technology is used to speed up the process.