Horizontal waterproofing

It is almost always used. The layer is needed so that moisture from the foundation does not rise up the wall. The work is carried out at the construction stage, when the foundation has already been poured and the time comes for laying the walls. In this case, roofing material is laid on the foundation under a beam, brick or other material. Horizontal waterproofing is:

- pasting;

- painting (coating).

We are interested in precisely glued waterproofing, since roofing material can be laid on the foundation in this way. Bitumen is applied to the surface of the base, and roll material is glued on top. Instead of roofing material, other roll materials, such as waterproofing, brizol or izol, can be glued to the foundation.

Note! As for the paint protection against moisture, it is carried out by applying bituminous mastic and synthetic materials.

In addition, there is a weldable roofing material on sale. How to glue roofing material to the foundation? This requires a burner. With its help, you need to slightly melt the lower layer of roofing material and gradually glue it to the base. You will learn how to put an ordinary roofing material on the foundation from this video.

Here are some of the benefits of using roofing material for this job:

- If the work is done correctly, then the material will last up to 50 years.

- The products are cheap.

- The material is durable and elastic.

- Resistant to oxidation.

- It is not afraid of salts contained in the soil and in groundwater.

- A versatile material that is easy to lay.

Laying of welded roofing material

There is a film on the welded roofing material from the heated side, it turns white and burns out with sufficient heat for gluing. It is impossible to overheat the sheets, they are easily melted through.

There is a film on the welded roofing material from the heated side, it turns white and burns out with sufficient heat for gluing. It is impossible to overheat the sheets, they are easily melted through.

The preparation of the base is the same.

Step-by-step instructions for laying the welded roofing material

A roll of roofing material is placed in front of you so that, rolling it forward and gluing it, go on it.

They hold a burner in their hands, warming up part of the surface of the roll and the mastic in front of it for 20-30 cm.

Then the heated sheet of roofing material with a burnt film (the adhesive base “boils”) is rolled out and glued for about half a turn, trampled down, while all the folds and swellings must be straightened out.

It is better if the glued roofing material is rolled with a heavy roller. Then the next section heats up.

So gradually, heating and rolling, and glue the entire roll

It is important to roll, press the glued roofing material.

The second sheet is glued with an overlap (5 cm) after it has completely cooled down and the first is glued.

Why use roofing material for waterproofing foundations?

- It has excellent water resistance;

- Waterproofing the base of load-bearing walls and foundations is economically beneficial because the material is inexpensive and you can choose its various types;

- High durability in the absence of direct sunlight;

- Small weight;

- It is an environmentally friendly material;

- You do not need to have special knowledge for styling;

- The quality of the coating does not depend on the material, but solely on the laying technology.

- It has insufficient elasticity, fragile structure;

- This is a combustible material, because the composition contains bitumen, rubber and polyethylene (or cardboard);

- When exposed to ultraviolet light, the roofing material loses its waterproofing qualities, and the service life of the coating sharply decreases. This problem occurs especially often when waterproofing the outer surface of load-bearing walls.

- Such a base has better water-repellent properties than bitumen;

- No need to heat roofing material;

- Significantly lower consumption;

- Roofing material adheres better to rubber;

- The quality of the base is higher than in the case of bitumen;

- Great durability of the base;

- Provides reliable protection for all types of strip foundations.

Advantages and disadvantages

Insulation of the foundation with roofing material is reliable and durable, and it is easy to do it yourself. Roofing material provides not only hydro, but also vapor barrier. However, at the same time, it has low elasticity, therefore, it can tear when the ground or foundation moves.

Since roofing material is a material that is afraid of exposure to sunlight, it is covered with plaster on top. To protect the roofing material in the ground, sheets of asbestos cement are used.

If the waterproofing is performed poorly, the life of the building can be significantly reduced. As a result of moisture ingress, basements and cellars become unusable, and the microclimate in residential premises is disturbed.

The figure shows a diagram of the correct waterproofing of the foundation of a house without a basement

And in this diagram - options for waterproofing the foundation of a house with a basement

And subscribe to site updates in Contact, Odnoklassniki,, Google Plus or.

Other methods of waterproofing with roofing material

The scheme of waterproofing the foundation of the house.

Laying the material on a base covered with liquid rubber. It is rarely used, but it has advantages over the bitumen method:

- Liquid rubber has better water-repellent properties than bitumen.

- There is no need to heat the adhesive and roofing material.

- Consumption is 2 times less than bitumen.

- Roofing material is much better glued with rubber.

- The durability of the coating is higher than that of bitumen.

Roofing material with a clay castle.

After laying the sheets on bitumen or liquid rubber, the surface of the roofing material is coated with clay mortar. This provides additional, inexpensive and reliable moisture protection. For any method of waterproofing based on this material, safety precautions should be observed. Hot bitumen can severely damage the skin and cause burns. During the heat treatment of roofing material, you also need to be careful not to overheat it. All actions must be carried out with gloves.

If everything is done in accordance with the rules of work, then such a basement waterproofing will last for decades.

Features of choosing the type of foundation

The support must be strong enough to withstand significant loads. The type of soil on which the structure is erected is of great importance. To begin with, you need to collect the most complete information about the soil and the level of occurrence of groundwater

It is important to know the level of the peak rise of groundwater, the soil composition. Exploration drilling will provide the most complete data, but this is a laborious activity.

The easiest way to collect information is to interview future neighbors or contact land administration authorities. The information received will help you choose the right:

- Structural type of support structure

- Define its parameters

- Pick up the necessary materials

- Choose a time for work.

Instagram ssi56ru

Instagram ssi56ru

In any case, effective waterproofing will become a mandatory stage in the construction of a building. But depending on the type of support system, the method of its implementation will be slightly different.

Types of foundation insulation

Even if a concrete mixture with waterproofing additives was used at the stage of construction of the supporting base of the house, there is still a problem of creating additional insulation of the base of the house from the effects of a humid environment. Such a protective durable structure, which does not require repair during long-term operation, will be the horizontal and vertical insulation of the foundation. The protective insulating layer can be applied in the form of a coating layer for vertical waterproofing or made of cushioning insulating material for horizontal insulation.

Foundation horizontal waterproofing scheme

Foundation horizontal waterproofing scheme

Horizontal insulation

The very name "horizontal waterproofing" indicates a method of protection against moisture ingress on load-bearing structures. It fits on critical sections of the foundation in the horizontal plane. To counteract the ingress of groundwater, protective insulation is placed under the sole of the supporting structure of the base.

To protect the load-bearing walls of the house from the ingress of capillary moisture, waterproofing protection is laid at the junction of the walls and foundation. Typically, the cross-section of the foundation is usually rectangular or square, so a dense roofing roll material is ideal for installing an interlayer waterproofing. The most optimal type for horizontal insulation will be laying roofing material under the foundation.

Insulation of the foundation surface with roofing material

Insulation of the foundation surface with roofing material

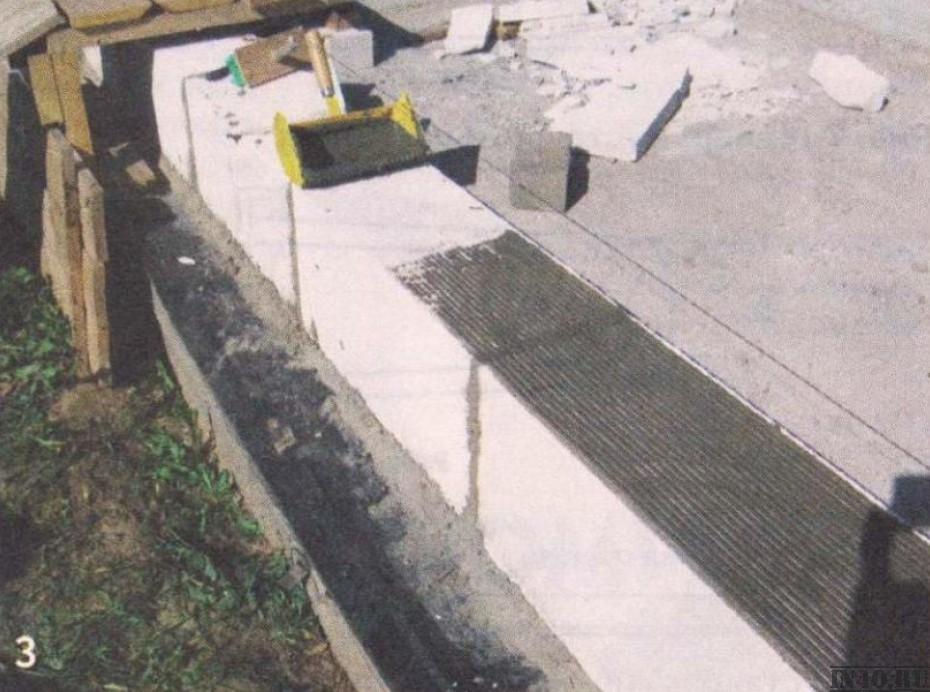

Sequence of horizontal insulation work

Laying of the pasting insulating waterproof horizontal layer is carried out in the following sequence:

- The horizontal surface of the foundation is carefully leveled with a cement-sand mixture and, after drying, a primer layer is applied with a wide brush, which is called a primer. It is a ready-made bituminous mastic, which is commercially available in any hardware store.

- After the priming layer has dried, roll roofing material is laid. Currently, for these purposes, a weld-on euroruberoid is used, which must be heated with a gas (propane) burner from the back side and glued to the prepared base.

- The second layer of waterproofing is glued in the same way.

- After curing the roll coating for one day, further construction work on the construction of walls can be carried out.

When laying horizontal waterproofing under the base of the strip foundation, roofing material in two layers is glued to the concrete preparation under the base of the building. When performing reinforcement work, you should carefully monitor so as not to damage the waterproofing layer.

Advantages of roofing felt protection

At present, pasting insulation of the foundation with roofing felt belongs to the most common type of protection of load-bearing structures from moisture ingress. The following indicators can be attributed to the positive characteristics of roofing material as insulation:

- The service life of a roofing material waterproofing, if properly installed, reaches 50 years.

- Relatively cheap and affordable material.

- Elasticity and high strength.

- Versatility and economy.

- Resistance to aggressive environmental influences.

- Ease of installation.

The disadvantages of roofing material waterproofing include the flammability and fragility of the material.

The choice of roofing material for pasting insulation of the foundation

In order to better understand which roofing material for waterproofing the foundation will correspond to the existing construction conditions, it is necessary to familiarize yourself with its technical characteristics and indicators. Roll insulation material can be divided into two categories:

- Roofing.

- Interlining.

Horizontal foundation insulation

Horizontal foundation insulation

To reduce the cost of horizontal waterproofing of the basement and foundation, you can use a dense roofing felt with a density of 350 g / m2 for the top layer, and use a cushioning insulating material with a lower density of 200 - 300 g / m2 for the lower layer.

During the installation of waterproofing pasting of the foundation and the basement of the building, roofing material of the RKP-350 brand is most often used, which means: roofing felt roofing with dressing and a density of 350 g / m2.

Technology of arrangement of a waterproof layer

The least effective method of waterproofing is mechanical fastening of roofing material using nails or slats.However, currently existing materials in the form of mastics make it possible to effectively solve the problem of fixing sheet materials with their use.

Preparatory activities

This work consists in leveling the surface of the foundation with a cement-sand mortar. It is used to cover up chips, cracks, shrinkage cavities and other surface defects that could subsequently cause mechanical damage to the insulating layer.

It might be interesting

Formation of a protective layer with roofing material

To fix the roofing material, the surface of the foundation is covered with bitumen heated to a fluid state, at the same time placing a rolled sheet of material on it. Hot bitumen is applied by brush or roller. Rows of roofing material are laid with an overlap of 7 - 12 centimeters. The edges of the material along the entire perimeter are folded and covered with vertical waterproofing. For complete reliability, 2 layers of protection should be arranged.

Laying roofing material with heating

Roofing material laying technology

Foundation waterproofing works are carried out in the following order:

- Sealing cracks and defects with cement-sand mortar. After it has solidified, the surface is treated with a primer.

- Application of mastic in several layers.

- Heat the sheet of roofing material with a blowtorch and lay it with an overlap, while the joints are heated especially carefully and additionally glued with mastic.

- On top of the first layer of waterproofing in the same order (except for point 1), the second layer is laid, and, if necessary, the subsequent ones.

Roofing - rubber insulation

This method of waterproofing is used quite rarely, but it gives an excellent result. In this case, a special rubber in a liquefied state is used as a binding agent between concrete and roofing material. In this case, the protective layer turns into almost a monolith endowed with elasticity.

This achieves the following advantages:

- the consumption of rubber is significantly reduced in comparison with the technology of pure rubber insulation;

- there is no need to apply heating of roofing material, rubber provides high adhesion to roofing material, acting as glue;

- in terms of durability, such waterproofing is comparable to the limiting life of the structure itself.

Additional protection

A natural moisture-proof material is ordinary clay, which is still widely used today for clay gates of the upper structure of water intake devices:

- To prepare such a material, the clay must be soaked for a day with a small amount of water, and then stirred until it becomes thick sour cream. To improve the quality of the composition, fiber shavings are added to it as a reinforcing element. When dry, it prevents the formation of cracks in the monolithic clay layer.

- The foundation around the perimeter must be poured with such a solution to the level of the ground surface and left to dry in an open state.

- The normal drying time for a clay seal is about 30 days, but work can be continued after 7 to 10 days. If the weather is dry and hot, the pouring surface should be covered with a film and sprinkled daily with water, ensuring uniform drying of the layer. Otherwise, it may undergo cracking.

The creation of a clay seal will protect the roofing material waterproofing layer from mechanical damage, since the seal layer is not tamped during the laying process.

Installation of protective flashing

The main purpose of the ebb is to prevent the appearance of moisture at the junction of the wall and the part of the foundation protruding outward. They are made of metal or plastic.

Plastic sills are lighter and are not afraid of corrosion, but they are easily damaged during operation. Metallic ones require control over the state of the protective paint, but in the case of complex geometry of the foundation, it is easier for them to give the required shape.

There are a number of points to consider when installing basement sills.

- The installation must be done before the external wall cladding.

- The presence of slopes helps to maintain tightness. They are created from a cement mixture. The optimum slope of the slope surface is 15 degrees.

- It is possible to attach the ebb to the wall and to the guides made of a galvanized profile or bar. They are nailed to the wooden base with ordinary nails, the material is fixed to the profile with self-tapping screws.

To ensure tightness, the drips should be overlapped. The inner and outer corners can be made from the scraps of the sills themselves.

Tasks of horizontal waterproofing

Waterproofing is considered a troublesome undertaking, but not a single house will stand for a long time without it, even if it is built on a mountain, and the groundwater lies at great depths. There are always reasons for the appearance of condensation and moisture penetration into the structural elements. Indeed, in addition to underground waters, there are also rain and melt waters, which have an equally destructive effect on the foundation and walls of the structure.

Horizontal waterproofing is arranged between the brickwork and the foundation during the construction phase. Of course, there are ways to do it after the walls have been built, but they are either too laborious or too expensive.

The decision to save on materials or the elementary forgetfulness of the "masters" can lead to significant problems and difficulties in the future, therefore, the importance of the moisture-protective layer should not be ignored

The lower horizontal waterproofing is laid at the level of the base of the foundation, but this article is not talking about it, but about the upper insulating layer. When installing it, roll materials are used, such as roofing material, roofing felt, glass-insol, hydro-insol, rubemast, etc. To create a waterproof carpet between foundation and brickwork or blocks you need:

- level the upper surface of the foundation with mortar;

- lay the waterproofing material in two layers.

For reliability, it is allowed to fix roofing material with hot bitumen. In this case, it is recommended to apply the mastic directly to the prepared canvases, and after installation, press it with a semi-rigid roller. If there are crumbs on the rolls, the surface should be pre-cleaned, otherwise the joining will be of poor quality.

In the absence of a basement, double horizontal waterproofing of the walls is performed:

- the first layer - between the foundation part and the basement masonry;

- the second layer is in a brick or block wall, not reaching the lower level of the first floor overlap or a lag of about 10-15 cm.

Strips of roofing material or other roll material are laid flush with the masonry, but they may protrude somewhat beyond the walls. To achieve a neat appearance, it is recommended to orient the straight edges of the cut along the canvases outward, and the "torn" side to turn inward. In addition, it should be borne in mind that the material must be overlapped along the length.

The successful combination of vertical and horizontal waterproofing of the house ensures maximum tightness of the structures. And the absence of moisture in them can guarantee a long service life of the house and the impossibility of the appearance of dampness and fungus in the interior of the building.

Installation technology

If waterproofing is carried out in an already operated house, at the first stage, the outer wall of the foundation is dug to the full height, cleaned of earth and dirt, the cracks are closed and the surface is leveled. Then the sequence of actions is as follows:

1. Prime the concrete with a bituminous primer.

2. Put on a layer of mastic. Cold applied bitumen mastic can be used.

3. Stick a sheet of roofing material on the mastic. It is recommended to heat the material with a gas burner. The overlap of adjacent strips is up to 15 cm.

4.Put the mastic and the second layer of roofing material again, observing the gap between the seams in relation to the first layer.

5. If insulation is not carried out simultaneously with waterproofing, the wall is covered with plywood sheets. Otherwise, PPS plates are glued over the roofing material, fixed with dowels.

Insulation is protected from external mechanical factors - with plywood sheets, asbestos-cement or reinforced concrete slabs. For the exterior of the base / plinth, a durable cladding material (eg porcelain stoneware tiles) is suitable as a protective coating.

Horizontal waterproofing with roofing felt is done in the same way, only there can be more than two layers.

Updated: 21.02.2017

Waterproofing the foundation with roofing material - features

To determine what complex of measures is needed, the following factors should be taken into account:

- The presence of groundwater and their level of occurrence.

- The heterogeneity of the soil and the amount of precipitation in the region.

- Terms of use of the building.

Perform waterproofing work on the foundation when the groundwater level is below 1 m from the bottom of the base. Protection is carried out with vertical coating waterproofing, this will be enough. In the event that the groundwater is at a distance of less than 1 m from the bottom of the base, full protection from moisture is carried out. In this case, resort to the use of vertical penetrating waterproofing and horizontal gluing method.

Note! When the groundwater level is at the same level with the basement, horizontal and vertical waterproofing is performed, as well as the creation of a drainage system around the building.

Now with regard to the heterogeneity of the soil and precipitation. If the soil is dense, then it does not allow moisture to pass through so well, which means that it will accumulate on the surface. In this case, there is a risk of flooding the basement. Inhomogeneity is directly related to the property of surface water to quickly sink into the ground during heavy rain, snow and other atmospheric precipitation. Loose soil, which contains gravel, pebbles and sand, has excellent water permeability. With them, water quickly goes into the soil. But sandy loam, loam and clay are waterproof soil.

But the operating conditions also play an important role when it comes to the degree of protection of the building. For damp and humid rooms (saunas, baths, pool complex, etc.), high-quality waterproofing is needed. Also, the degree of protection, the amount of consumable materials, the procedure for performing work and their number is played by the presence in the building of heating, residential premises and the area of \ u200b \ u200bthe structure.

The process of waterproofing the foundation with roofing material

Before starting work on waterproofing the foundation, it is necessary to prepare the surface. To do this, perform the following actions:

Foundation waterproofing stages

- They inspect the surface, identify damage and determine ways to eliminate them.

- The grinder rounds off sharp corners and protrusions that can cause damage to the sheets of waterproofing material.

- The surface is cleaned from dust and other contaminants.

High-quality protection involves the processing of all sides of the foundation, therefore, vertical and horizontal waterproofing is performed.

Protection of vertical foundation surfaces

Waterproofing of the side parts of the foundation is carried out according to the following scheme:

Vertical waterproofing

- Using a brush, apply one layer of deep penetration primer to the surface and wait for it to dry.

- Bitumen is melted to a liquid state and applied with a brush to the side parts of the foundation. In this case, the movements must be vertical, and each next layer must be superimposed on the previous layer.

- The roll is applied to the surface with the side on which there is no sprinkling, heated with a torch or blowtorch, rolled out and pressed against the wall.

- The edges of each next strip are additionally coated with mastic, applied to the wall, making an overlap on the adjacent canvas, and pressed tightly.

- After pasting all the vertical surfaces of the foundation, the roofing material is covered with some dense material and backfill is performed. Read more in our previous article on the rules for backfilling a foundation.

Horizontal waterproofing

If vertical protection of the foundation from moisture can be performed at any stage of construction, then horizontal waterproofing is carried out in the process of laying the foundation. In this case, the protection is supposed to be double: the first layer is laid between the soil and the foundation, the second - between the foundation and the walls of the house.

The waterproofing of the lower level is carried out in the following order:

- The bottom of the pit is covered with a layer of fatty clay and carefully tamped.

- Concrete made from high quality cement is poured on top. The surface is aligned horizontally.

- After the screed is dry, it is coated with molten bitumen. Find out how and how you can dilute bitumen for the foundation.

- Roofing material is immediately laid with an overlap on adjacent sheets of 15-20 cm. The joints of the strips are heated with a blowtorch or gas torch and pressed tightly. The edges of the canvas should have a protrusion of up to 20 cm.

- Roofing material is again coated with bitumen mastic and another row of waterproofing material is glued. In this case, the canvases should be located perpendicular to the first row.

- After the bitumen hardens, another layer of concrete screed is poured.

To waterproof the foundation on the second level, you must perform the following steps:

- The horizontal surfaces of the foundation are poured with a cement screed for complete leveling. See details on how to properly align the top of the foundation and side faces.

- After the cement hardens, the surface is coated with bitumen mastic and a layer of roofing material is laid. In this case, it is necessary that some part of the laid canvases hang from the wall.

- Another layer of mastic is applied to the roofing material and covered with a sheet of waterproofing material.

Waterproofing the foundation with roofing felt belongs to the category of simple processes available for independent execution. The main thing is to choose the right material and apply it in accordance with the waterproofing technology.

This can be helpful:

- Roll waterproofing for foundation

Additionally, we recommend reading:

Tags: Waterproofing