Types of piles used for the foundation

Today, there are several types of piles that can be used for the construction of a pile foundation. Among them:

- Driven piles.

- Screw piles.

- Bored piles.

Let's consider each of these types in more detail.

Driven piles

This type of pile gives the foundation the greatest stability. The thing is that during the design of the future structure, the designers calculate the future weight of the building and divide it between all the piles. During their installation, such a force acts on each pile, which then it will have to withstand. When the pile stops sinking into the ground, this may mean that it has reached the ground on which the structure can already withstand.

The compacted soil around it gives additional stability to the pile. It is possible to hammer such piles only with the use of a special pneumatic hammer, which is very expensive to use in private housing construction. That is why this type of pile is not recommended for self-erection of such a foundation.

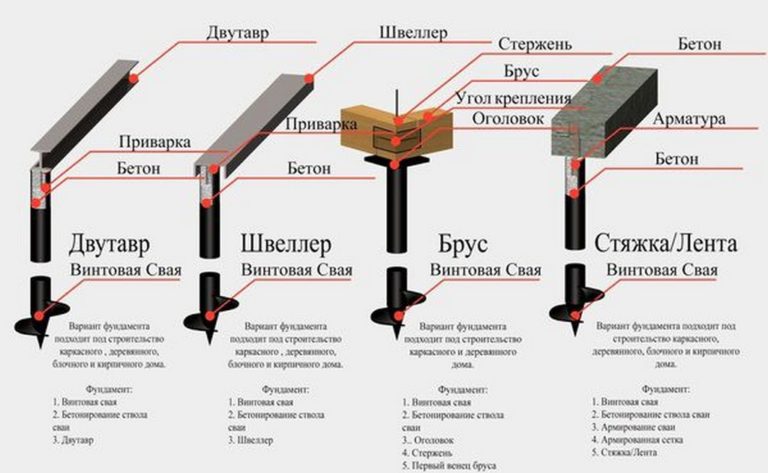

Screw piles

This type of pile is an ordinary steel pipe, at the end of which elements that resemble threads are welded. In fact, this type of pile can be compared with a self-tapping screw, that is, they are screwed into the ground according to the same principle as a self-tapping screw. Thanks to its blades at the ends, the support area is increased, which in turn increases the strength and reliability of the structure. If the soil at the construction site is not dense enough and even unstable, then piles can be used, on which blades are welded along their entire length.

This type of pile can be used for both private construction and industrial construction. Piles can be screwed in either manually or using a special technique. In the case of screwing in the pile yourself, this will require several strong people

As a rule, at the other end of the pile, there are two holes that allow you to connect them with the twisting technique, while it is very important that when the pile is twisted, it is located strictly vertically. When the pile is completely screwed in to the desired level, concrete is poured into the pile pipe and the head is welded, on which the grillage is subsequently installed

Some disadvantages of such piles should also be noted:

- A screw foundation requires an accurate calculation of the depth of solid soil, otherwise the pile will not be stable, especially during heaving of the soil.

- The piles must have high-quality welded seams, otherwise, during the screwing of the pile, the blades may come off or be damaged. This can lead to a loss of bearing capacity.

- The piles must be covered with a high-quality layer of factory paint, otherwise a poor-quality coating can lead to corrosion.

Bored piles

This type of pile is often used in private housing construction. In order to carry them out, it is required to make pile wells with a hand drill, after which formwork is performed in the case of loose soil that crumbles.

Such piles are waterproofed with roofing material or any other insulating material (asbestos-cement pipes can be used), reinforced, after which concrete is poured directly into the well. Piles are installed along the entire perimeter of the future foundation, that is, in the corners, along the outer and inner walls. The number of piles depends on the total weight of the future structure.

Among the disadvantages of these piles, it can be noted that it is impossible to accurately determine whether the pile has reached solid ground or not.

Preparatory activities

Their volume depends on the specifics of the structure, so we list everything that should be done regardless of the nuances of further work:

- disconnect the communications connected to the house. If necessary, with partial dismantling of individual sections of the routes. Cables, pipes should not interfere in the future;

- remove all unnecessary from the building, especially large and heavy things (equipment). This must be done in advance, since in the process of earthworks, spontaneous skewing and subsidence of the house cannot be ruled out, because its center of gravity is unlikely to be shifted.

Digging a trench

The task is not only to gain access to the foundation, but also to equip the place for further work. For the convenience of carrying out technological operations, the optimal width is within a meter. But the depth should be slightly more than this parameter of the tape.

Pile-grillage foundation

As soon as the piles are installed, they are connected with a monolithic grillage, on which the entire building is subsequently erected. This structure evenly distributes the load on the foundation supports and is the basis of the basement of the house.

The grillage is made in a strip or monolithic way and is made of wooden beams or reinforced concrete slabs that unite the foundation supports. Depending on the location, the pile foundation with a monolithic grillage is divided into: high, intermediate and buried.

The grillage is the basis of the basement of the house Important! Due to the natural drop in soil temperature in the cold season, a phenomenon occurs inside the soil, called frost heaving of soil by geologists. The moisture in the soil freezes in winter and increases in volume

This can lead to the extrusion of the foundation, and therefore the house. To counter this phenomenon, the piles are united with a high grillage at a height of 0.1 - 0.15 m above ground level. Typically, such a grillage is installed under buildings that are lightweight.

The moisture in the soil freezes in winter and increases in volume. This can lead to the extrusion of the foundation, and therefore the house. To counter this phenomenon, the piles are united with a high grillage at a height of 0.1 - 0.15 m above ground level. Typically, such a grillage is installed under buildings that are lightweight.

To build a foundation from piles, you do not need to dig trenches and pits

The intermediate grillage is placed at ground level using a sand or gravel pad. The disadvantage of this type of grillage is that it is not protected from frost heaving of the soil, which can pull out piles and damage the masonry.

The low grillage is located below ground level. It is lowered to a depth of freezing in heaving soils; on slightly heaving soils, the structure is laid 0.2-0.3 m below ground level.

When building a private house, a high pile foundation with a monolithic grillage is most often used. When arranging the foundation on screw piles, a wooden beam can serve as a grillage, which is fixed with anchor bolts.

Pile foundation with timber grillage

The pros and cons of the pile-grillage foundation are as follows:

Advantages of the pile-grillage foundation:

- affordable price;

- the ability to do it yourself;

- quick installation;

- reliability - almost no shrinkage.

Cons of the design:

- strict calculation of the pile foundation grillage;

- used only for light buildings;

- the effect of corrosion on the steel part.

Screw piles for different types of soil

DIY pile foundation foundation

The first thing to start with pile foundation foundation Is the preparation of the necessary tools.

Instruments

To carry out the marking and installation of the screw foundation, you must have:

- A tape measure of at least 20 m, it will be needed when marking.

- Building level, it is advisable to stock up on a tool equipped with magnets, since in the process of carrying out work it can be fixed to the base of the pile, which will significantly add comfort.

- The hydraulic level will make it possible to almost ideally mark the plane that the heads of the products should form for laying the grillage on them.

- A drill for the earth is necessary for preparing holes for the installation of screw supports.

Tip: The drill should be smaller in diameter than the pile. This is necessary so that the pile fits snugly into the ground.

- Scrap metal.

- Two pieces of metal pipe with a diameter of 45-50 mm and a length of 2.5 meters for screwing in supports.

- Rope or construction cord for marking.

Payment

In order to calculate as accurately as possible the required number of supports for building a bath, it is convenient to use an online calculator. If there is no access to the World Wide Web, and the calculation is necessary, you need to adhere to the following principles:

- All corners of the foundation must be piled.

- The maximum distance between piles in the foundation should not exceed three meters.

- If the walls have partitions, then in the place where they intersect with the main wall, a support must be installed without fail.

Adhering to these simple rules, you can easily calculate the required number of products for the manufacture of a reliable and stable structure.

Site preparation and marking

Immediately before marking, it is necessary to clean the perimeter of the site. Make sure that nothing interferes with the markup and further installation.

After that, you can designate the place of installation of the first pile and proceed with further marking. First, the locations for the installation of corner piles are marked. This should be done as carefully as possible, while be sure to check the diagonals.

Important: The maximum divergence of the diagonals should not exceed 4 cm.

After the corners are marked and marked with stakes, a rope or construction cord is pulled between them. Then pegs are installed in those places where the rest of the piles should be located. Do not forget about how the calculation was carried out and where the lintels of the walls will be located, everything must be done according to a pre-planned plan. After the marking has been carried out, you can start drilling and installing piles.

Mounting

Immediately before screwing in the product, it is necessary to prepare a guide hole for it. This can be done with a drill, but do not forget that the diameter of the drill should be slightly less than the diameter of the pile.

The drilling depth is chosen depending on how far the pile needs to be buried, but it is several tens of centimeters less, since it is necessary that the pile travels some distance on its own. So it will stick much better in the soil.

The next stage is directly screwing in the pile. This operation will require at least three people. One is located near the pile and tries to keep it strictly vertical, and the other two, with the help of metal scrap threaded into the technological hole in the upper part of the pile, and two pieces of metal pipes, dressed on the edges of the scrap from different sides, are gradually twisted and thereby screwed into the pile. the ground.

This method of installation, although it does not differ in speed, allows you to mount screw piles without the use of technology without any problems.

The first piles are installed in the corners, this is necessary so that in the future it is possible to control the installation of intermediate products using laces.

Advice: of course, the quality of manual installation differs markedly from installation using special equipment and supports in some cases can be installed a little crooked.To avoid this, at the moment of twisting the pile, you can tilt it slightly in the opposite direction from the place where the propeller blade hits the ground. It is quite difficult to explain in words, but when the work begins, it will not be difficult to understand in which direction to tilt.

The mounted pipes are leveled using a hydraulic level, after which heads are welded onto them, on which the grillage will be installed. Heads allow to partially compensate for inaccuracies in the installation of piles.

Stage two. Reinforcement of corner modules with "bulls"

One should start by strengthening those sections of the foundation that account for the bulk of the distributed mass. The corner parts of the building support are subject to the greatest load, which comes from the geometry of the structure. Often, only strengthening the corners of the foundation is enough to prevent further destruction and reduce the degree of natural deformation.

Preparation of the object. We expose the foundation

In order to gain access to the concrete base, it is required to dig a pit, taking into account the following features:

- Dimensions not less than 100x100 centimeters and deepening below the level of the foundation.

- The fourth part of the pit should fall directly on the corner of the concrete structure.

- The ditch for the foundation should not be too large: it is enough to provide a gap of 10 centimeters.

- When the foundation is opened, dirt should be washed off from it and allowed to dry for a day.

Screwing in piles

The immersion of corner piles can, if necessary, be done manually: the dimensions of the pit and the absence of restrictions on the side of the walls make it possible for the knob to move freely. The piles must be immersed to a depth determined by the features of the existing structure so that the flat head is on the same level with the bottom edge of the foundation. The pile insertion point should be located as close to the corner of the building as possible. The project may provide for the use of two piles on opposite sides of the corner of the foundation.

Reinforcement and pouring

A concrete block called "bull" must be poured into the excavated pit. To do this, you need to assemble a frame from steel reinforcement:

- Under the foundation, profile reinforcement rods with a diameter of 12 mm or more are brought up and do not reach the digging border by 5–10 cm. The best option would be to prop the reinforcement to the foundation with stones or broken bricks.

- The outward-facing ends of the reinforcement should cover at least half of the excavation area. In general, 6–7 rods are enough, which are laid flat on the pile head and welded to it. After fixing the reinforcement to the heads, the fixing stones should be removed.

- Several reinforcement rods are vertically welded to the pile head.

- In accordance with the specified parameters, a frame is formed from the reinforcing rods and the reinforcing mesh.

Pouring concrete should be done in two stages. At the first stage, the concrete mixture is poured to a level not lower than the middle of the existing foundation and subjected to vibration compaction. At the second stage, it is possible to reduce the consumption of concrete mix by reducing the size of the pit by 30–40% using external formwork.

Note: if additional filling is not provided by the project, an angle bracket is used as a head and additional reinforcement is not performed.

Important points in pile installation

As "pluses" can be called

The design can be formed at any time of the year

- Saving money for the preliminary arrangement of the site, access roads to it.

- Lack of excavation work for the arrangement of the pit or trenches, wet operations associated with the installation of formwork followed by concreting, etc.

- The ability to perform work at any time of the year under any weather conditions.

- Leveling problems associated with flooding and rising groundwater levels.

- The possibility of arranging a pile field in swampy areas and in areas with soil freezing, permafrost (those areas that were previously considered unsuitable for construction).

- The durability and strength of the building, which is not afraid of force majeure (sudden mudflows, landslides, floods): they do not affect the deep layers of soil into which the blades are screwed.

- Execution of work by a minimum number of people in optimal terms: for a small private house, one day is enough, with a larger construction it takes 3-4 days to erect a pile field.

- Simple technology: piles are simply screwed into the ground with a certain effort.

- There is no need to wait for the time required for foundation shrinkage.

- Piles are ideal for lightweight, one-story construction.

- The admissibility of building up supports depending on the depth of their laying.

- Gentle conditions for the foundation of the main building in the event of the need for an extension.

- the possibility of construction work in close proximity to the functioning or planned ground and underground communications;

- A relatively inexpensive method (compared to driving reinforced concrete pile structures).

- Repeated use of piles during re-erection of a building.

- A feature of construction, in which it is possible at any time to replace or additionally install screw-in elements with a preliminary recalculation of loads without dismantling the building structure.

- Preservation of natural or artificially created landscapes: screw drilling is possible directly in the forest zone, near trees without damaging their root system, ornamental forms.

- High seismic resistance and, practically, a century-long service life.

What is in the "cons"?

Piles are afraid of corrosion

- Mandatory execution of an individual construction project, because there are no standard options.

- There is a high probability of destruction of the building, its distortion, subsidence of the foundation due to the slightest violations in the calculations of the base and the weight of the building being erected. The accuracy of the calculation allows you to evenly distribute the total estimated load between all piles.

- The susceptibility to corrosion destruction, both of the external and internal surfaces of piles, without preliminary repeated processing with a special compound before immersion in the ground.

- Problematic observance of vertical, as well as minimal deviations from the axis when screwing in the blades.

- Interaction with chemical compounds in aggressive soils, which reduce the service life of piles.

- Impossibility of mounting on rocks, characterized by special hardness, due to the high probability of damage to the screw during rotation.

- Restrictions on the number of storeys of capital construction buildings under construction.

- Selective approach to wall material (brickwork on piles is not recommended).

- Contraindications for the construction of a basement: the formation of wells under the piles violates the structure and integrity of the soil.

- The need for additional thermal insulation of the floor on the ground floor, which is in direct contact with cold air in winter.

- Sensitivity to bending loads.

A screw foundation, of course, is not a panacea for all the risks that arise when building a house. This is evidenced by the list of shortcomings limiting its construction. But in cases of work on difficult soils, problematic terrain, limited construction time, it is screw piles that can be the only solution to the problem. You just need to take a responsible attitude to the calculations, not to save on the quality of the materials and piles used.

Installation of a new structure

These are the main stages of work, although for a better understanding of the technique, some nuances should be noted:

- The piles do not have to be screwed in to their full length.With optimal deepening, it is easy to cut off the excess with a "grinder".

- If the supports need to be additionally strengthened, then a concrete solution is poured inside (with a filler of fine fractions, for example, pebbles).

- In case of partial destruction of the base, the structure does not need to be raised. To do this, piles are installed in the foundation from opposite sides, "windows" are cut into the tape, into which the channels are inserted. They are attached to the pole heads and become part of the old structure. Here, an accurate calculation of the height of their installation is especially necessary. You can just "prop" the tape on one side.

The drawings illustrate well all the points, and it is not difficult to understand the meaning of the work from them. And which method is more convenient is decided on the spot.

In fairness, it should be noted that such options for reconstruction of the foundation are suitable only for relatively light buildings - houses made of wood, prefabricated panels, frame, that is, those that are easy to lift from at least one side (with the exception of the latter, with partial damage).

For those readers who are interested in other techniques, here is a small list of them, and information on the topic "how ... with your own hands" on our site is easy to find.

- Cementation.

- Installation of reinforced concrete "shirt" (or "clip").

- Installation of so-called unloading elements (beams, frames, braces, racks, etc.).

- Reinforcement with reinforcing bars.

It is worth noting that such methods do not completely solve the problem, but only allow you to postpone the time for starting the overhaul of the foundation. From the point of view of complexity, labor costs, financial investments, practical feasibility, the above technique with the use of piles is still the most preferable.

Pile - screw foundation: pros and cons

Having dealt with the types, we will consider the pros and cons of the foundation on screw piles, as the supporting base of the building.

Having dealt with the types, we will consider the pros and cons of the foundation on screw piles, as the supporting base of the building.

Positive sides:

- Price. In practice, a device of this type of base is, on average, 30% more economical compared to a shallow reinforced tape.

- Timing. In most cases, the installation of the base on piles takes no more than a couple of days. At the same time, it is ready for supporting loads immediately after installation. There is no need to wait to grab.

- Ease of installation. Everything is relative, and the work of screwing in piles requires certain skills. But in comparison with other types of bases, their installation is simple and does not require the use of heavy special equipment. A brigade of 3-4 people is enough.

- Extension. Due to the ease of installation, in the case when it is necessary to change the configuration or increase the area of the room, it is quite easy to build up the foundation.

- Ease of repair work. Again in comparison with other types of foundations. Replacing a pile is easier and cheaper than repairing a pole or base band.

- Terrain independent. The difference in height on the site can be a problem for any type of foundation, except for piles.

- Purity. At the end of construction work on the construction of the pile foundation, there is no need to remove garbage or take out the soil, the site will be clean. For more information about piles, in particular about screw, see this video tutorial:

As you can see, there are quite a few advantages to such a foundation, there are fewer negative points, but they do exist.

As you can see, there are quite a few advantages to such a foundation, there are fewer negative points, but they do exist.

Cons of screw piles:

- Building weight restrictions. The pile-screw foundation is used only for light structures: wooden or frame and the like. Sometimes, in an attempt to save money, such a base is brought under a brick structure. But even with the accuracy of the load calculations, no one is safe from a change in its vector due to the failure of one of the pipes. Of course, you can use reinforced cast piles, but then you will not be able to save money, the price tag will be similar to other types of foundations.

- Rocks and mountains. This type of foundation cannot be built in rocky soil. Although in the mountains, any foundation with deepening is a problem.

- To organize the basement, you will have to carry out a lot of additional work, which will negate all the advantages from savings. Therefore, if you need a basement or basement, it is better to choose another base.

When considering the pros and cons of a pile foundation, it is worth considering the entire set of criteria. It is necessary to study the soil, landscape and the possibility of constructing a different foundation for your home. And only on the basis of in-depth analysis to make a decision on the construction of a foundation of this type.

Advantages and disadvantages of the pile type of foundation

The main advantages of a pile foundation:

- the possibility of using in unstable soil;

- the reliability of the building erected on the slope;

- installation in any weather conditions;

- the settlement of the building is minimized;

- relatively low construction cost;

- great reliability with correct calculation and construction.

The main disadvantages of the pile foundation:

- For the construction of this structure, you will need special equipment;

- such a design is not recommended for use with horizontally moving soil;

- complications in the construction of a basement or underground garage;

- impossibility of calculating pile damage;

- the need to use heavy equipment.

Piles during construction

Dignity

This type of foundation pouring easily competes with conventional standard methods and has a number of advantages.

- does not require the use of heavy types of construction equipment and various works related to the extraction of problem soil and leveling the surface.

- the choice of a site for construction is not limited to the presence of difficult sites. Such as, for example, large trees growing near the object or finding it on different slopes.

- the ability to attach additional buildings to the main building of various types.

- it will take several days to bookmark, which is very convenient. Often the efficiency of the project depends on the speed of the work.

- work on this technology can be carried out at any temperature and does not depend on precipitation.

Calculation of the foundation on piles

The construction of any foundation always begins with a calculation. First of all, it is necessary to carry out engineering and geological surveys at a depth of at least 5 meters below the projected depth of the lower part of the pile. This condition is mandatory, however, not everyone adheres to it.

Such geodetic "reconnaissance" can be ordered from a specialized firm. True, it will most likely cost not cheap. If you can't find specialists or can't afford it, then you can ask how many and what kind of screw piles the neighbors used for the house on their plots, since the composition of the soil there is about the same as on your site. For specialists, the screwing process itself will tell a lot about the soil.

Modern two-story aerated concrete house on screw piles

Calculation and design of screw foundations should be carried out in accordance with SP 50-102-2003 "Design and construction of pile foundations". Specialists must calculate the bearing capacity of the foundation in relation to the main combinations of loads and actions. As a result, you will know, for example, how many screw piles are needed for a 6x8 house made of certain materials.

It should be borne in mind that the formula for calculating bearing capacity of the screw piles in accordance with the parameters of the soil, from SP 50-102-2003, gives a fairly underestimated value. As a result, the number of piles, which is obtained in the calculations, is several times higher than what is actually required. Designers do not care about this fact, but for the customer it is unacceptable for financial reasons.

Therefore, the calculation of the foundation is often done by a simplified method, based on approximate soil data, the approximate weight of the structure and the characteristics of screw piles.So in the diagram below you can see how many screw piles are needed for a 6x6 house made of wood.

Foundation scheme on piles

Peculiarities

The pile-strip foundation is a strip base on supports (piles), due to which a stable structure with a high margin of safety is achieved. In most cases, such a foundation is created for large low-rise buildings on "problem" soils (clay, organic, uneven relief, water-saturated).

In other words, the strength of the structure is provided by a strip (usually shallow) foundation on which the walls rest, and strong adhesion to the soil is provided by piles driven below the freezing level of the soil.

This type of foundation is not designed for multi-storey construction. Usually, private houses of no more than 2 floors in height are erected on such a foundation using lightweight materials - wood, cellular concrete blocks (aerated concrete and foam blocks), hollow stone, as well as sandwich panels.

For the first time, the technology was applied in Finland, where mainly wooden houses are being built. That is why a combined foundation is optimal for wooden houses or frame structures. Heavier materials will require an increase in the number of grounds, and sometimes search for other solutions.

The pile depth is usually determined by the depth of the hard soil layers. A monolithic concrete foundation is poured into a formwork located in a trench 50-70 cm deep. Before starting work, they carry out a study of the soil and punching a test well. Based on the data obtained, a diagram of the occurrence of soil layers is drawn up.

The use of a strip foundation on piles can significantly increase the operational characteristics of the facility under construction.

Among the advantages of the system, some positions can be distinguished.

- The possibility of capital construction on "capricious" soils - where it is impossible to use a strip base. However, due to the heavy load of the facility, it will not be possible to use only piles.

- In the considered type of foundation, it is possible to reduce the sensitivity of the strip base to heaving soils and groundwater.

- The ability to protect the strip foundation from flooding, as well as transfer most of the weight of the foundation to harder soil layers to a depth of 1.5-2 m.

- Such a foundation is also suitable for strong soils subject to seasonal deformations.

- Faster construction speed than deep foundation construction.

- Possibility to get an object with a basement, which can serve as a useful or technical room.

- The availability of the use of materials used both for the organization of the foundation and for the construction of wall structures.

- Reducing the cost and labor intensity of the process in comparison with the organization of the strip foundation.

There are also disadvantages to such a foundation.

- An increase in the number of manual operations when pouring the foundation. This is due to the inability to use excavators and other equipment for digging trenches due to the driven piles.

- The inability to use the resulting semi-basement room as a full-fledged room (pool, rest room), as is possible when installing a strip foundation. This disadvantage can be leveled by digging a foundation pit, but the cost and labor intensity of the process increases. In addition, this approach is not possible on every type of soil, even in the presence of piles.

- The need for a thorough analysis of the soil, the preparation of voluminous design documentation. As a rule, this work is entrusted to specialists in order to avoid inaccuracies and errors in calculations.

- A rather limited choice of building materials for walls - this must necessarily be a lightweight structure (for example, made of wood, aerated concrete, hollow stone, frame house).

Foundation restoration

Screw piles can be used not only in the construction of new houses, but also in the restoration of old foundations.

To lift a house onto screw piles, you must do the following:

- First of all, the feasibility and possibility of installing the pile foundation are assessed. If the lower rims of the log house have rotted, then it will not work to lift the building onto the piles.

- At the second stage, the quality of the soil is assessed, the mass of the building is calculated and the required immersion depth of the supports is determined.

- Then piles are mounted along the walls of the house on both sides, at the closest possible distance.

- The house is raised on jacks to the required height, after which I-beams are brought under it.

This method is applicable only to light buildings. Installing screw piles under a brick house will not work

It is necessary to lift the structure extremely carefully so that the corner joints do not chip off, it is also possible to displace the entire structure

In the process of lifting one side, the other may tilt. This moment must be controlled especially carefully.

Carelessness can lead to cracks on the walls.

Scope of application

The main area of use of screw piles is the arrangement of economical foundations for household buildings and private wooden houses, the construction of enclosing structures.

Product marking indicates the standard size of the screw piles. The first number is the diameter of the barrel in millimeters, the second is the diameter of the helical blade. When choosing a standard size, the operational loads on the foundation are taken into account:

- diameter 76 mm - for lightweight enclosing structures;

- diameter 89 mm - for verandas, awnings, gazebos, brick posts;

- diameter 108 mm - light timber houses, logs, frame buildings;

- diameter 133 mm - heavy log houses, buildings made of foam concrete and aerated concrete blocks.

A screw pile is a supporting element of a foundation base, its main functional part is a screw (tip with a blade). The operational properties of the foundation depend on its parameters. Manufacturers offer two types of screw piles: with a welded or cast tip.