Basis creation procedure

The process of aligning the pile foundation consists of the following stages:

- Preparatory work.

- Well drilling and piling.

- Formwork creation, concrete pouring and additional procedures.

The following video will help you learn more about the procedure for creating a aligned baseline.

Preparatory stage

It is very important not to make mistakes during the markup execution. Although the preparation process is not very difficult, it is of great importance.

First of all, the working area is prepared, it is cleared of various debris, after which the top layer of soil is removed and the marking is carried out. Marking can be done by placing pegs in the corners and pulling a rope between them.

Although the preparation process is not very complex, it is of great importance. First of all, the working area is prepared, it is cleared of various debris, after which the top layer of soil is removed and the marking is carried out. Marking can be done by placing pegs in the corners and pulling a rope between them.

You will also need to determine the place where the blind area will be installed. For this, a site is created 50-80 cm wider along the entire perimeter. The future placement of each pillar is then noted. The piles must be installed in the corners, and the rest of the products can be placed at intervals of about 130 cm. After that, a trench is dug for the base tape. Its depth should not exceed 0.5 m.

To work, you will need to prepare the following set of tools:

- shovel and crowbar;

- construction trowel;

- hammer and nails;

- drill and wood screws;

- building rule;

- concrete mixer.

It may seem that the work of arranging the combined base is difficult, but in reality it is not. If you follow the instructions, even a novice builder can complete the procedure.

Installation of piles

Drilling is a tedious process, so it's best to get support.

Drilling is a tedious process, so it's best to get support.

Wells are being drilled in the marked places. This procedure can be performed in two ways:

- With the help of a special drilling rig. You can rent it and drill yourself. When using such a tool, the well will be shallow, a maximum of 1.5 m.

- For deeper drilling, you will need to call a special machine with a more powerful drilling rig.

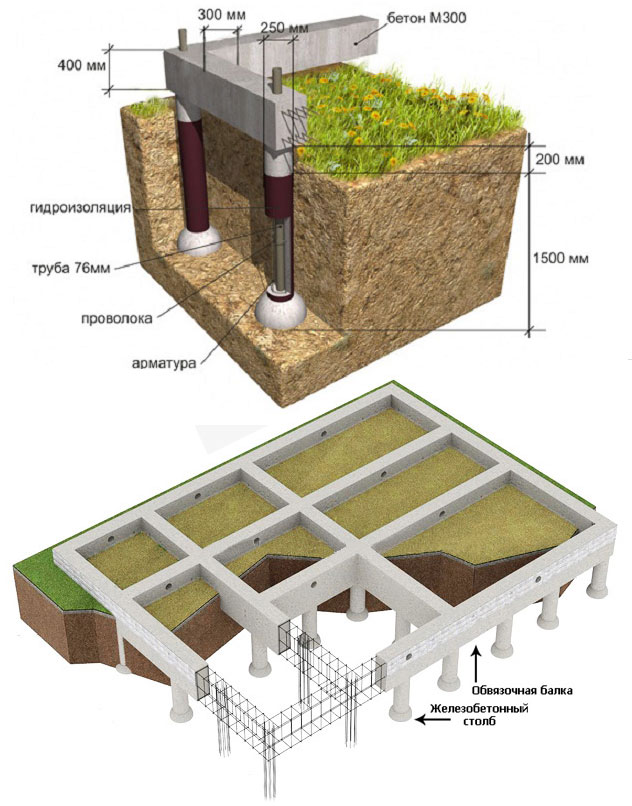

River sand is poured into the drilled wells, which will create a pillow up to 20 cm thick. The sand will need to be moistened and tamped. Then the installation of metal pipes is carried out, which are poured with concrete by about 30 cm and raised by 20 cm. The concrete will create a sole, which will provide high-quality adhesion of the piles to hard soil. Until the concrete has time to gain a foothold, the verticality of the supports is checked according to the level.

Pouring concrete mix

After pouring, it is necessary to carefully monitor the condition of the concrete.

After pouring, it is necessary to carefully monitor the condition of the concrete.

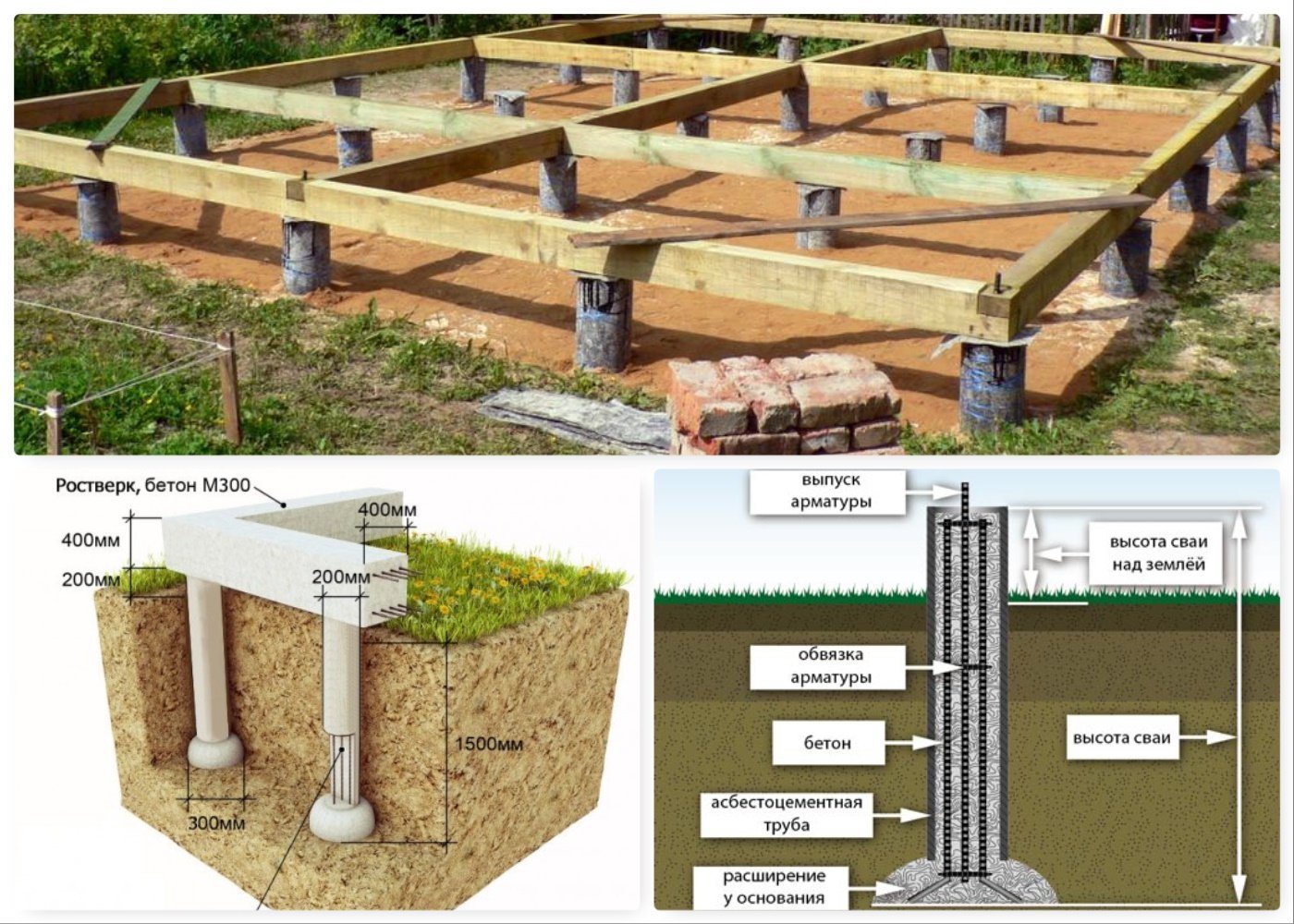

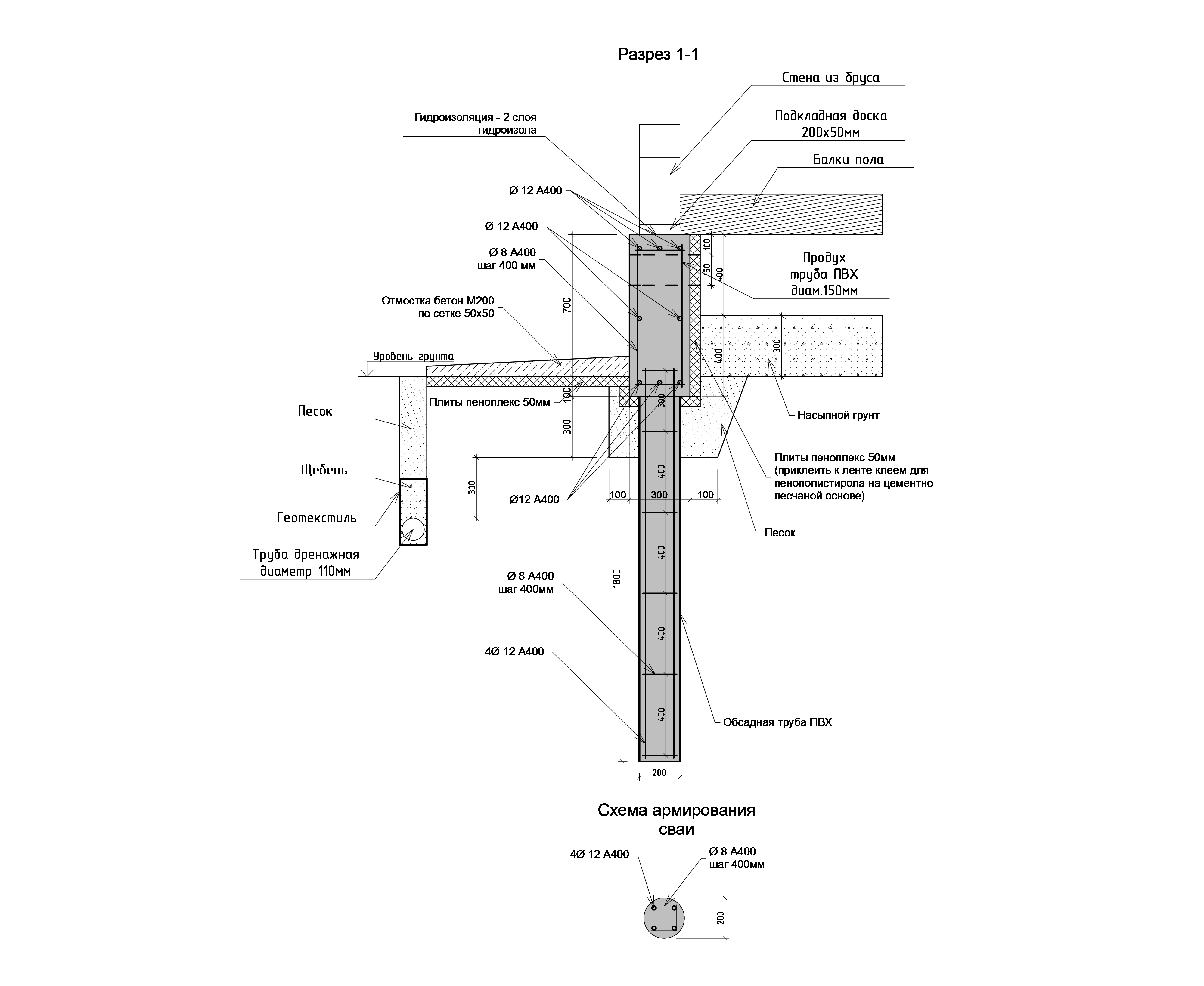

Above the soil surface, formwork is built of wood or plywood of the required height. You can build it using nails or self-tapping screws, and strengthen it with bars in the corners. All speakers elements must be placed on the outside of the structure. Reinforcement forming a grid must be laid inside the formwork.

Then you can start filling the formwork with concrete. Remnants of air from the structure must be removed, for this you can use a deep vibrator or a simple rod, which will pierce the thickness of the solution in several places. The base surface is leveled, smoothed using a building rule and covered with a protective film to provide protection from precipitation and other influences. During the drying of the mixture, you need to monitor the moisture level in order to prevent drying out.If the temperature outside is very high, the coating will need to be periodically moistened.

After the concrete has hardened and the required strength has been set, it will be necessary to carry out waterproofing and warming of the base. Concrete can disintegrate when frozen, so the waterproofing process is mandatory. To do this, you can use bitumen or polymer mastics, as well as roll coatings. The concrete surface must be pre-treated with a primer and antiseptic. After the primer has dried, waterproofing is carried out.

You can also insulate the base of the building. For this, you can use polystyrene or polyurethane foam. In the second case, you will need to rent a special device.

Using a matched base is a great solution. It allows you to save a lot, as well as speed up and simplify the process of creating a base. The main thing is to adhere to the instructions during the execution of the procedures.

Installation of a pile foundation

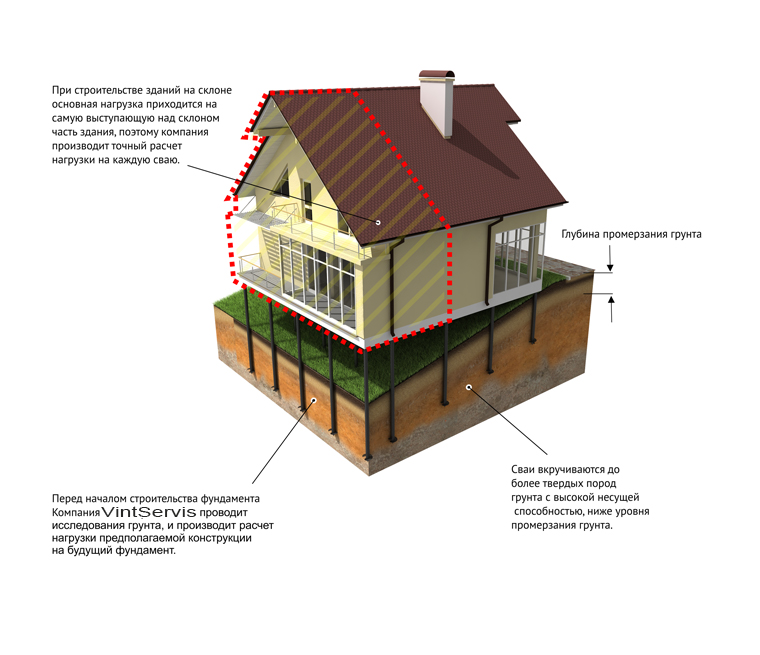

Before installing bored and screw piles, it is necessary to study the relief features of the soil and find out the lower point of its freezing in a given area.

This will give the structure of the fortress and as a result of the swelling of the soil in winter, the building will not shift, it will be densely and steadily strengthened.

That is why piles can be installed regardless of the season and weather conditions. If you do not follow the construction technology, then during the melting of the accumulated ice in the upper parts of the soil, the screw piles will dangle in the ground, and not sit tightly in it, as it should be.

In all cases, it is desirable to use industrial piles made of thick, strong steel with a blade diameter of 500 mm and more, but the cost of such piles is very high. Therefore, in the construction of summer cottages and houses, piles with a diameter of about 100 mm are used, because their price is low.

An example of a finished pile foundation

The most important condition in the construction of a pile foundation is to find a well-established manufacturer of screw piles, therefore, before buying piles from one supplier or another, you need to listen to reviews about it in advance.

You can screw piles into the ground using a special technique. But the cost of their services is quite high, so it is quite possible to install piles yourself, manually. When screwing in the pile manually, you just need to monitor the vertical level.

Piles up to 108 mm are usually screwed in manually. For thicker piles, you still have to use a special technique.

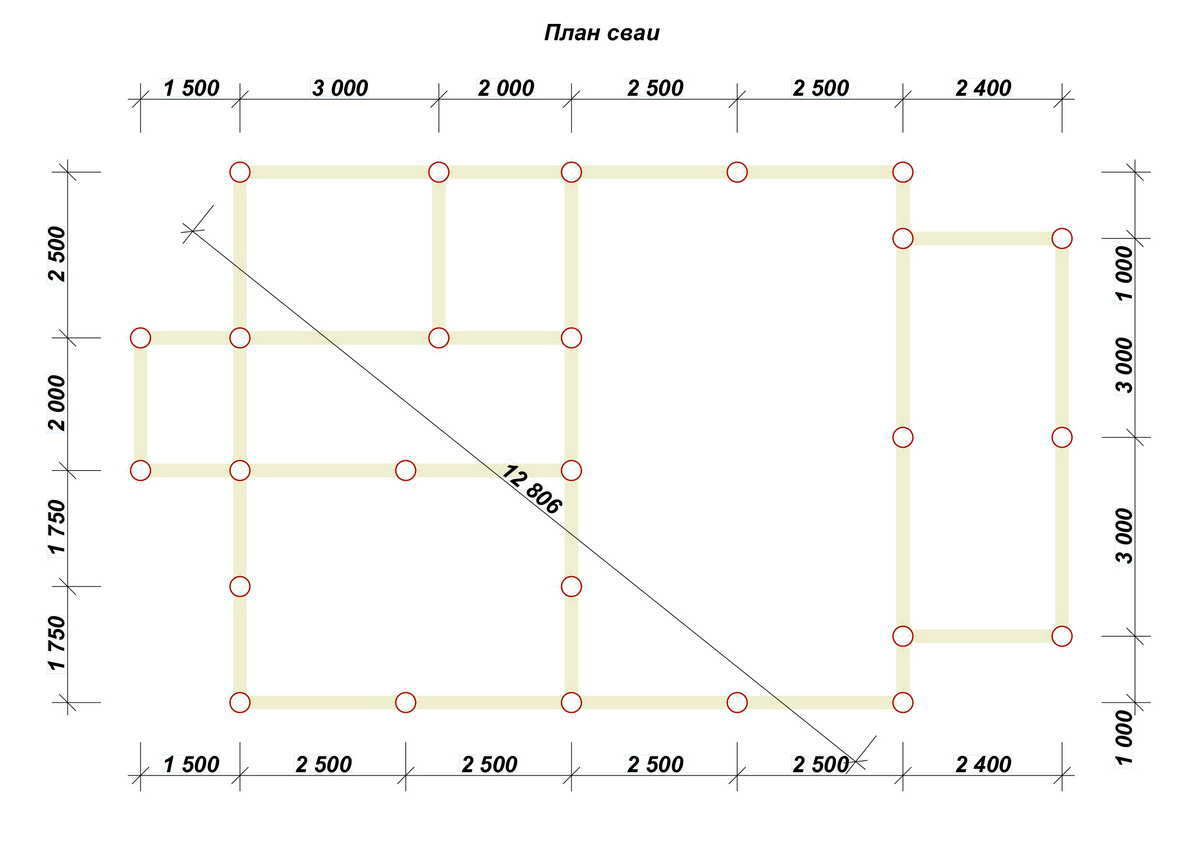

The erection of the foundation must be carried out in accordance with the norms and the screw piles must be installed at a distance of no more than three meters from each other.

A ready-made pile foundation can be used for such buildings as:

- frame house on screw piles;

- panel houses on screw piles;

- light suburban wooden house on screw piles;

- screw piles for an old house together with a different type of foundation;

- if stove heating is supposed to be in the house, then piles may well be used as a foundation for the stove.

Basic requirements for the project of this foundation

Any project must be calculated correctly.

To prevent this, it is necessary to make a high-quality project.

Basic calculation rules

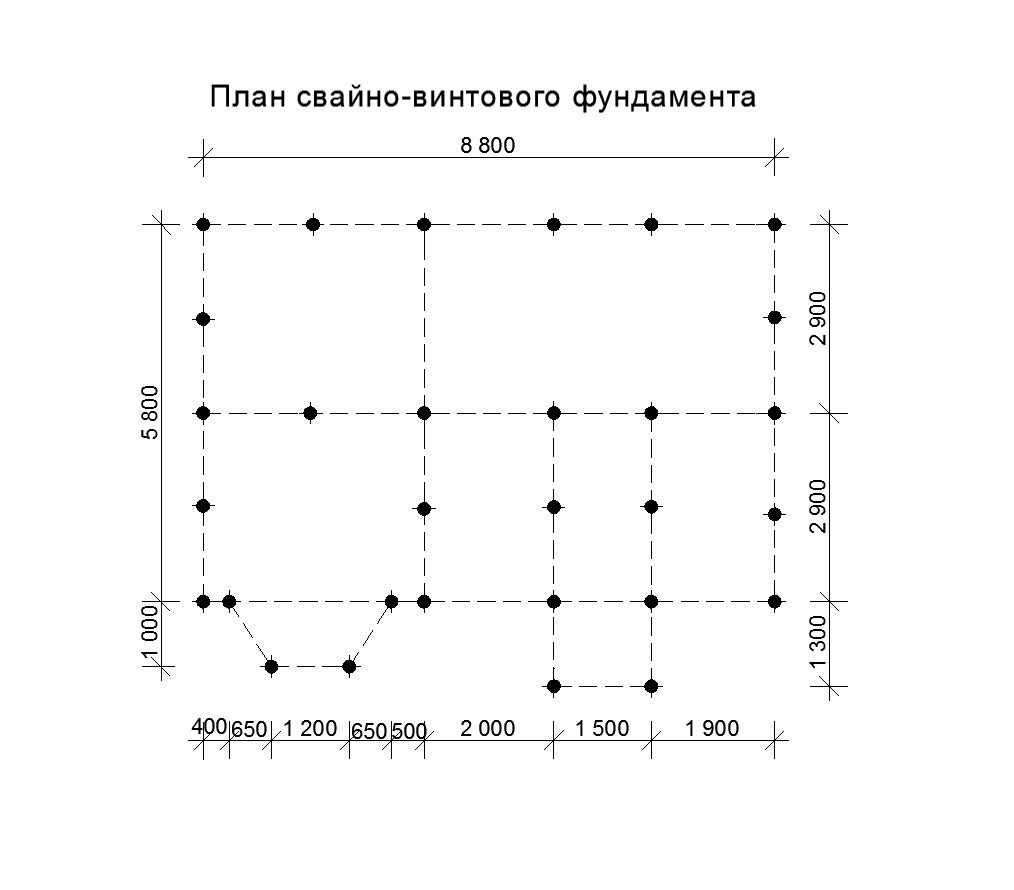

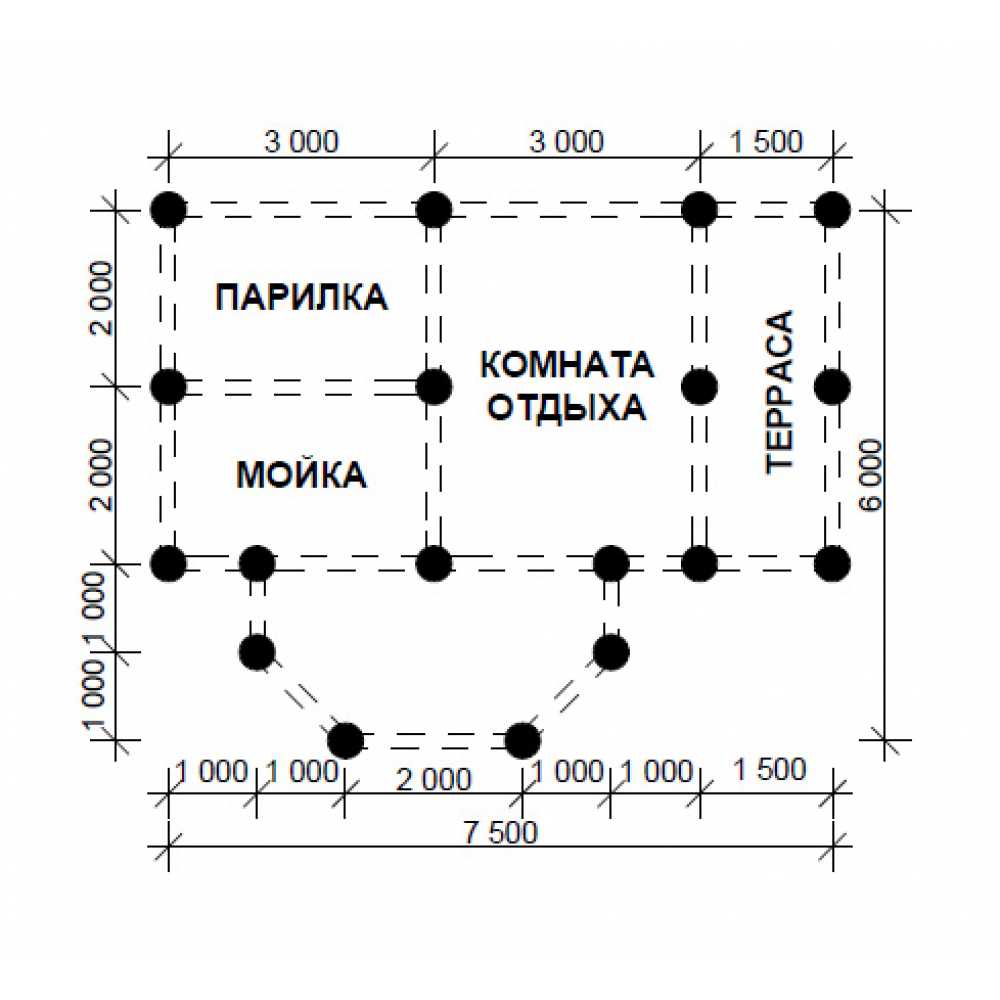

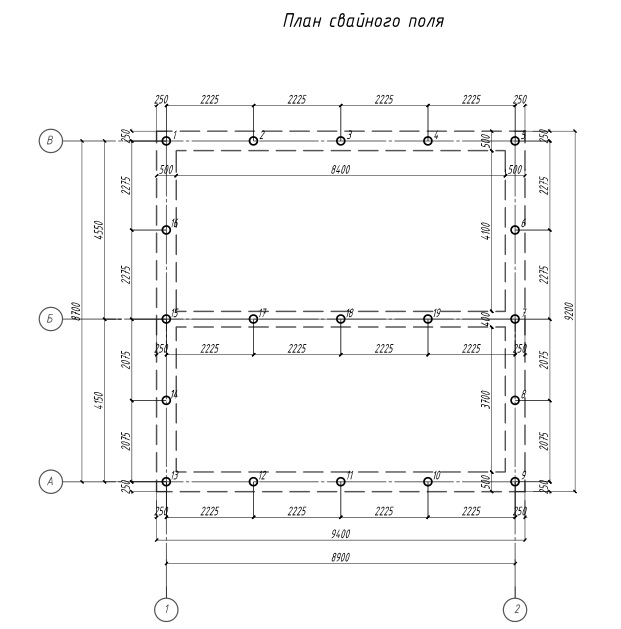

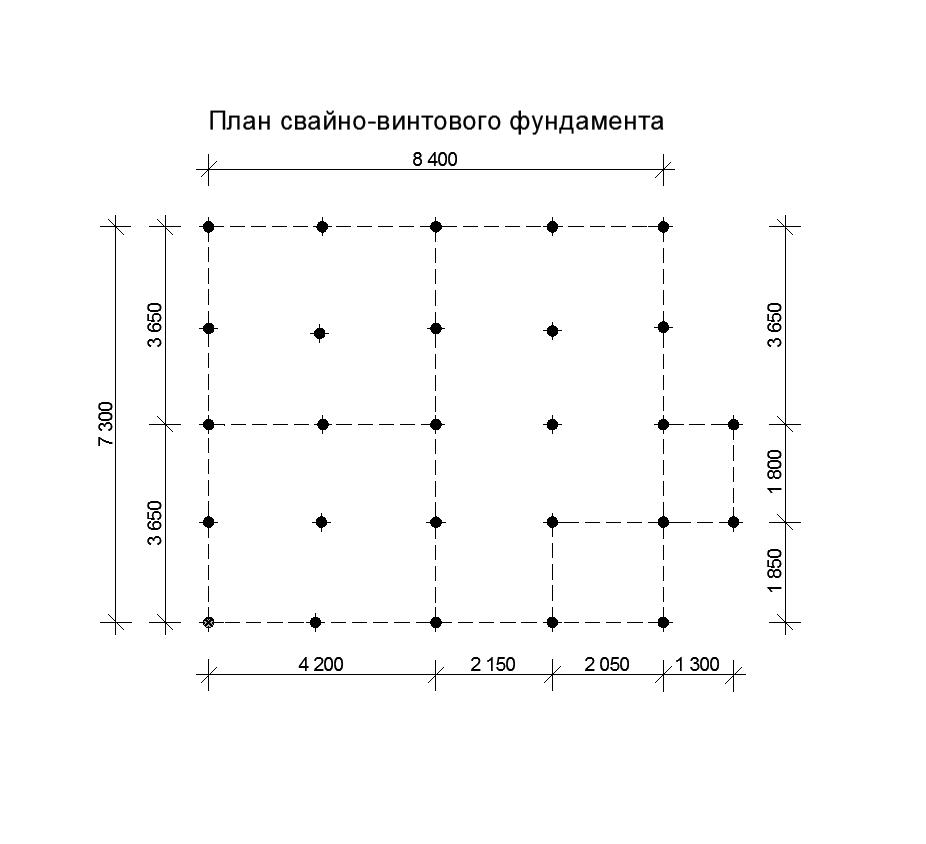

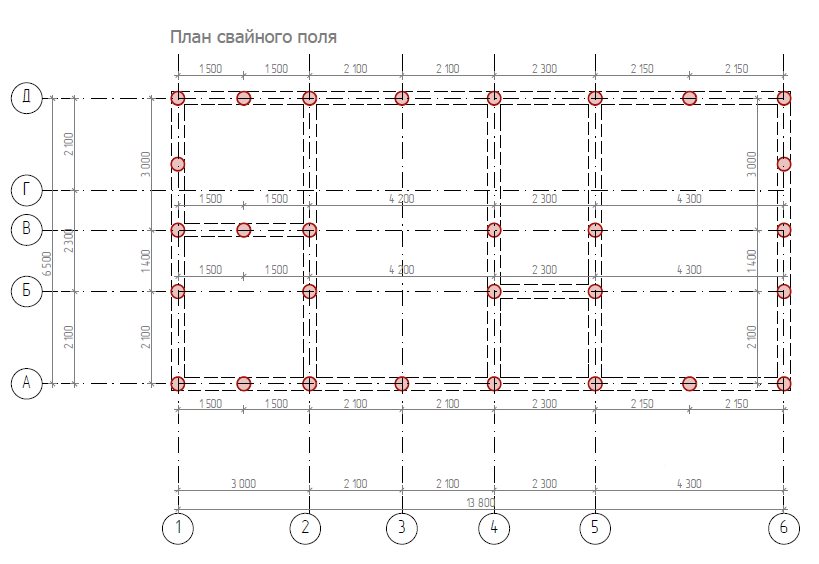

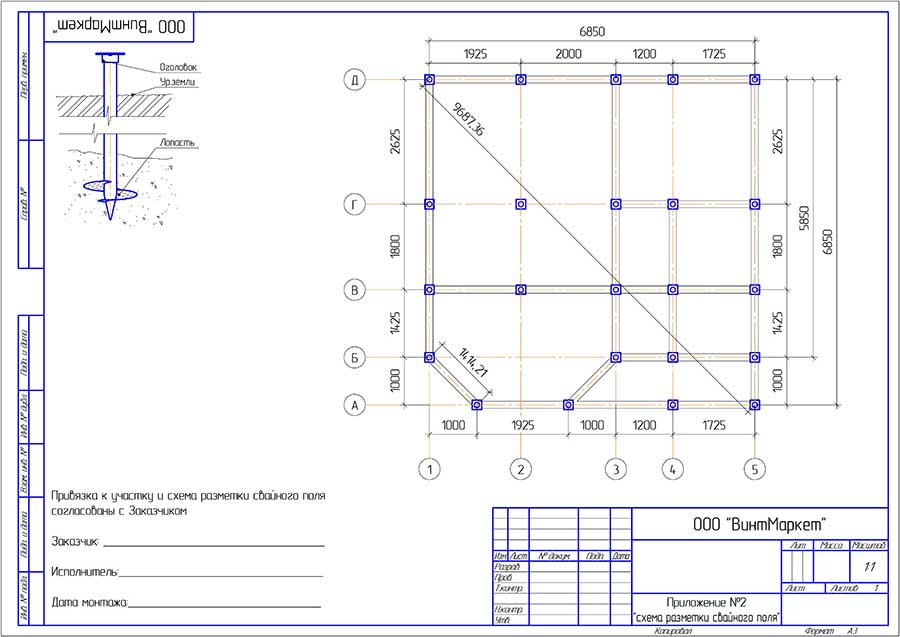

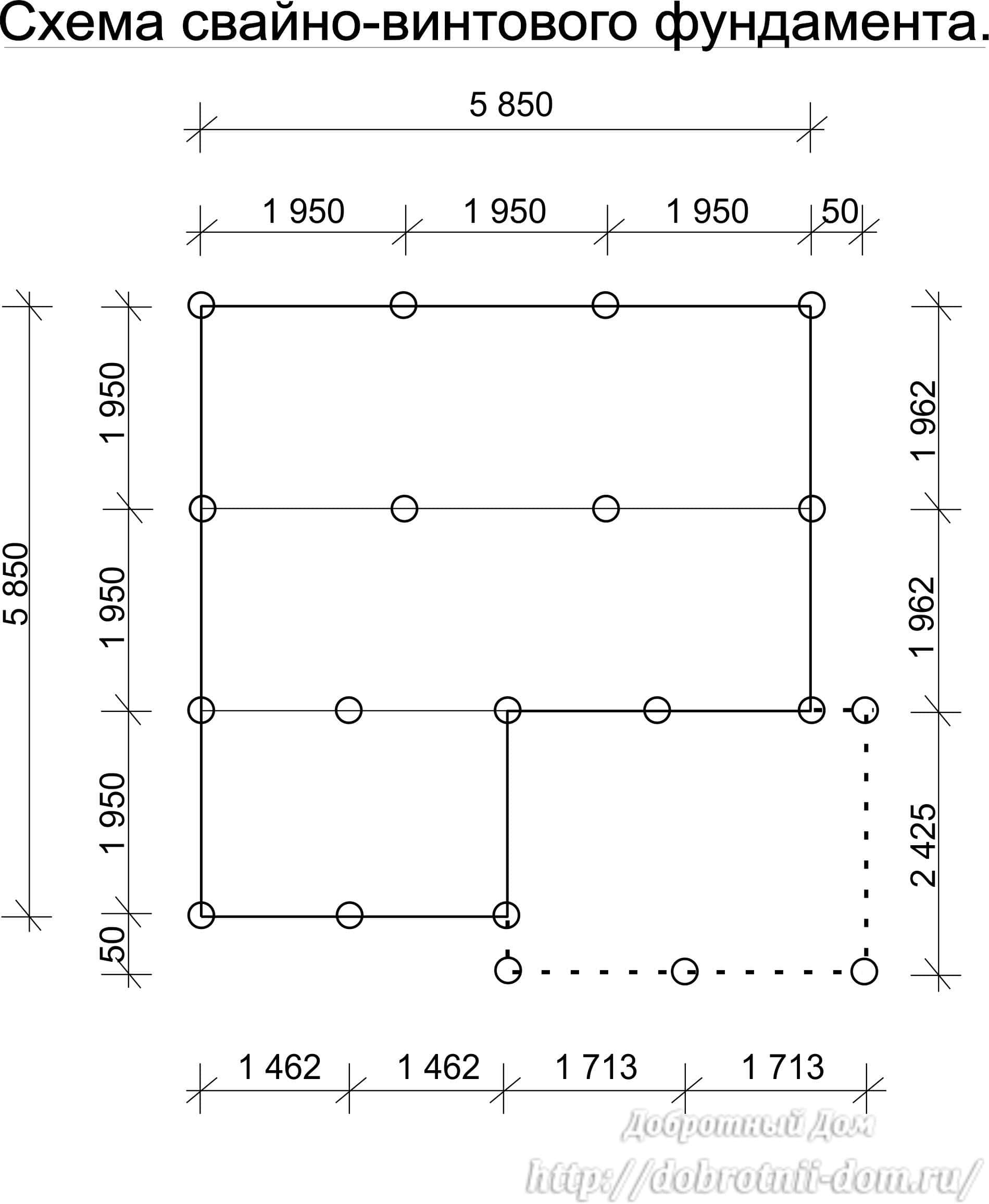

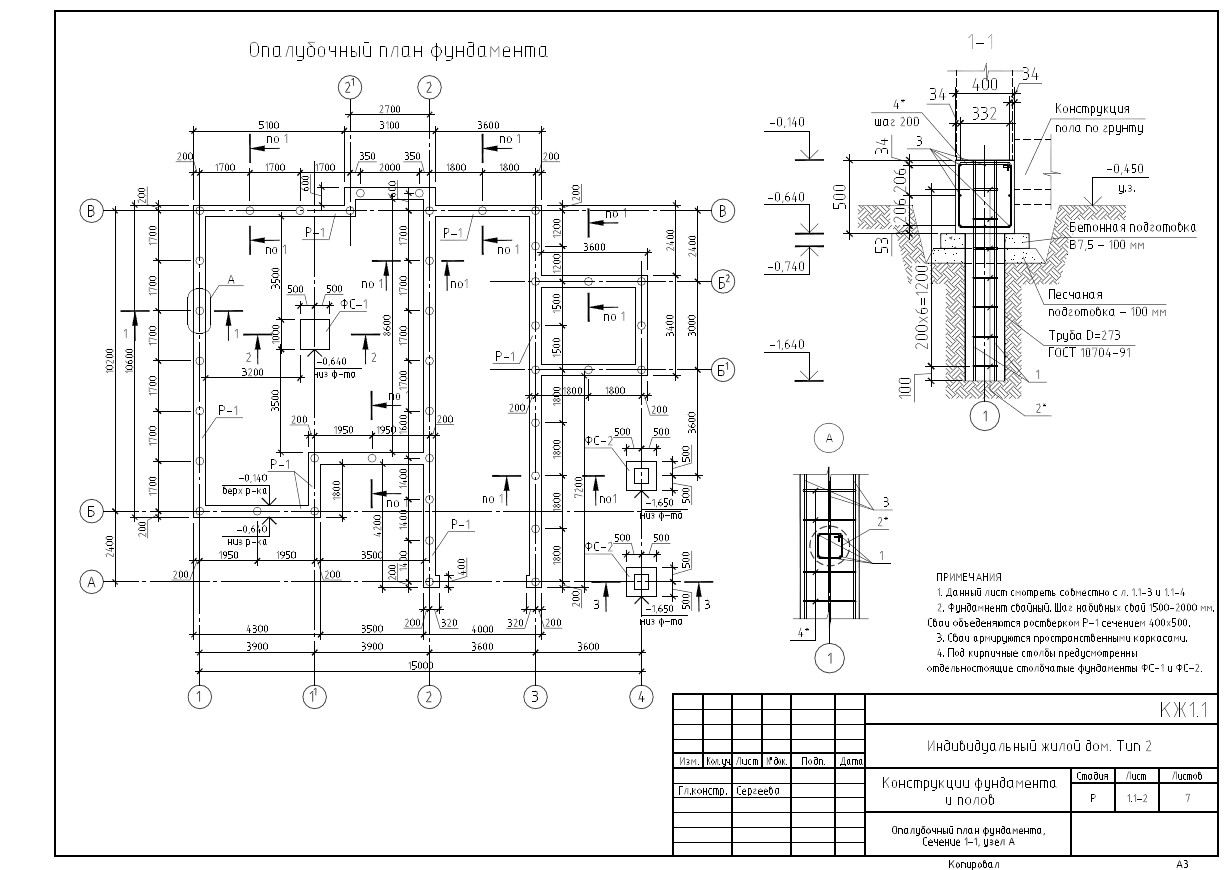

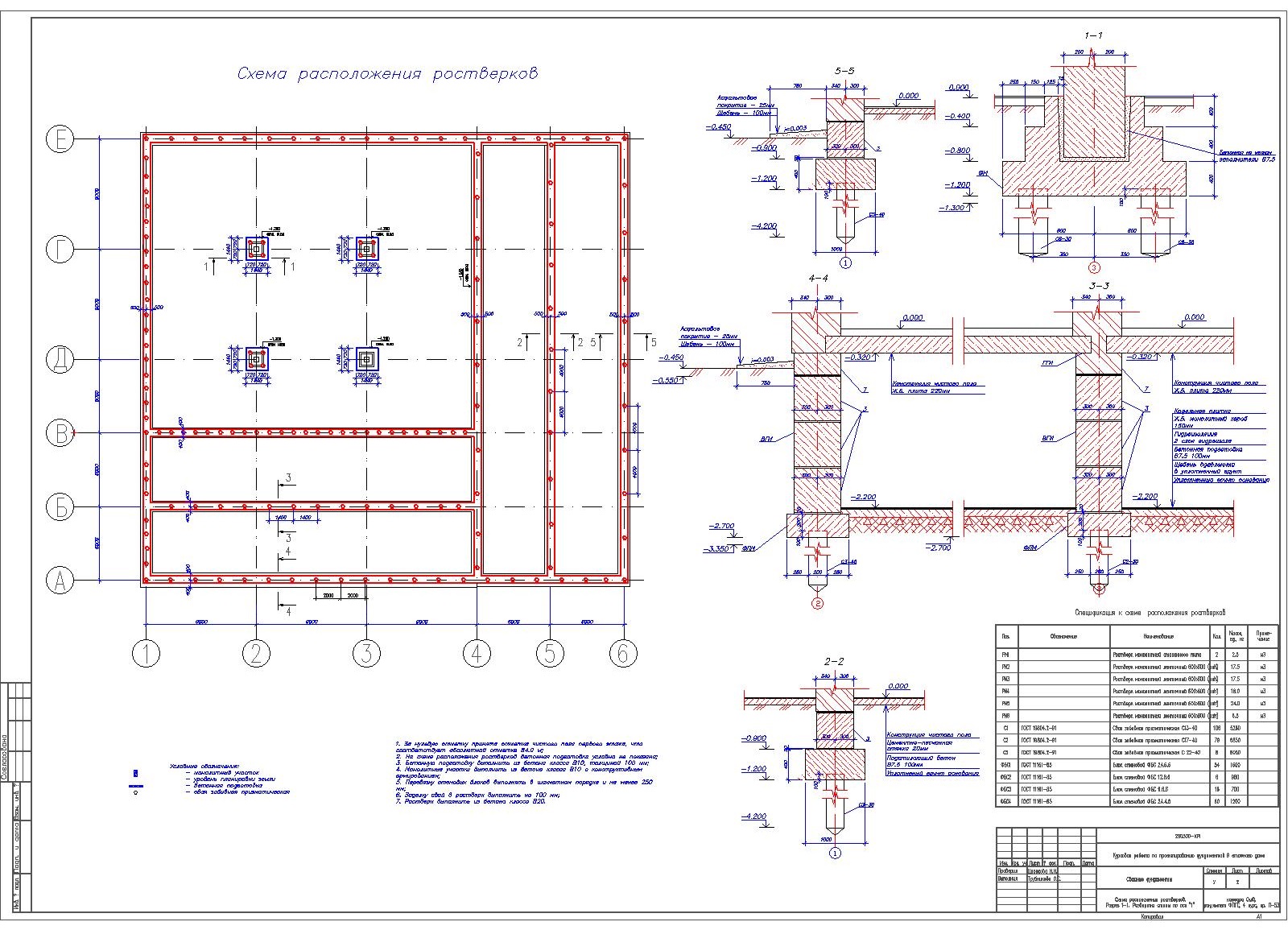

An approximate plan of the foundation of a pile for a summer garden house (wooden walls)

The very first thing you need to pay attention to is the weight of the future private house. As mentioned above, only light building materials (foam blocks, wood, aerated concrete blocks) are suitable for a foundation equipped with piles

Therefore, knowing the parameters of the structure, and the weight of one of the blocks, which has a standard width, length and weight (since they are made industrially), you can accurately calculate the weight of the entire structure. This also applies to foam blocks and wooden beams.

You also need to pay attention to the weight of the future roof, as well as the amount of precipitation that falls in this area.Such calculations will lead to the fact that knowing the distance between the piles, you can accurately calculate their number

The next point is that it is necessary to conduct a study of the soil where the construction of a private house will take place. On the territory of our country, in different zones, the soil has different properties, heaving, freezing depth and composition. There are special reference books according to which you can find out the properties of the soil in a specific area of construction and the depth of groundwater. Thanks to this knowledge, it is possible to determine the required pile length.

Installation of various grillages for foundation on screw piles

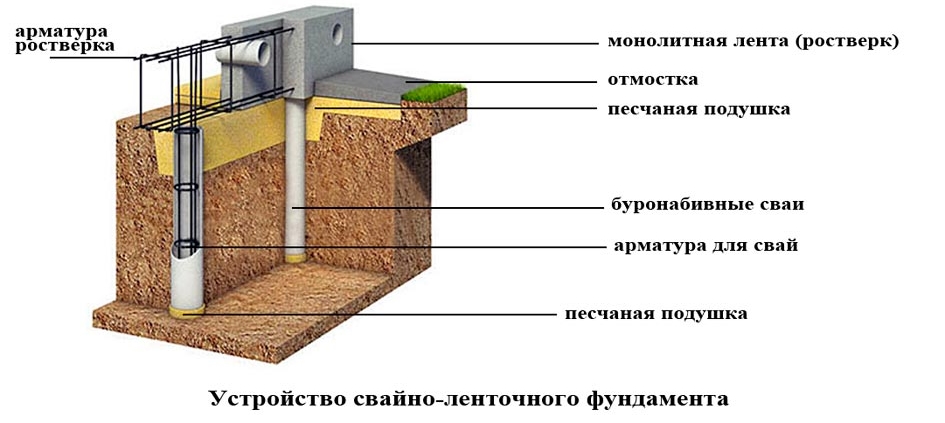

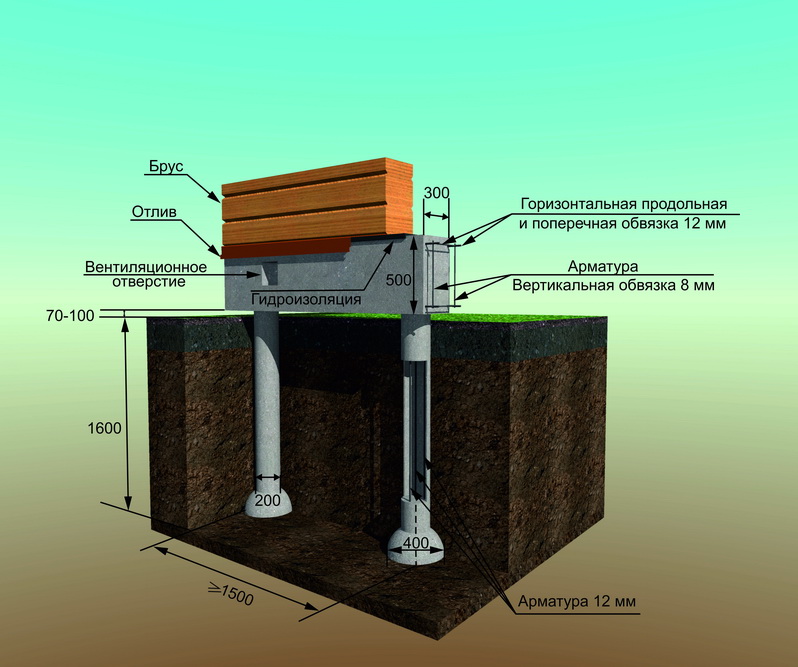

The next element is the grillage. It can be made of wood, reinforced concrete, or concrete. His duties include the adhesion of all piles into one whole, and serves so that load-bearing walls and internal partitions can be placed on it.

Its width will depend on the width of the gas silicate blocks or foam blocks from which the house will be built. If it is made of wood, then wooden beams will go under the grillage. To make a high-quality grillage, it is necessary to clearly imagine the house standing on such a foundation, as well as all its features.

And the last thing to consider is the property of the pile foundation and grillage, the ability to repair some piles or individual blocks from the structure of the house. A house that stands cannot maintain its strength forever. It requires periodic repair of load-bearing parts, which consist of blocks or beams.

The pile foundation, as mentioned above, due to its peculiarity, allows repairing individual blocks or piles without disturbing the entire structure. But in order for this to be possible, it is necessary to clearly work out all the smallest details of such a foundation.

This table will help you determine the number and diameter of piles.

And the last thing is the choice of the diameter of the future piles. To do this, it is enough to have information about the weight of the entire structure. It must be remembered that the piles have a cavity into which concrete must be poured. It is needed in order to further strengthen the piles and give them better rigidity.

As you can see, the pile foundation requires a careful approach. This is due to the fact that such a foundation requires a special approach to it. Despite its reliability, its design must be approached with great care.

If the future home owner does not have some knowledge in the field of civil engineering, then in order to prepare a high-quality project, it is necessary to invite a specialist who will take into account all the features and provide them in the project.

The pile foundation plan for any structure is very complex calculations, so it must be approached with special care. If this is not done, then you can count on the fact that sooner or later the walls of the house will begin to crack, or the structure itself will shrink and squint.

To prevent this from happening, you need to take care of a high-quality pile foundation, which will be made in accordance with all the requirements and rules. This is also necessary in order not to start doing the first major overhaul of the house in a few years.

We calculate the grillage

The pile foundation can be constructed from one of the supports, along which the lower piping of the structure is laid.

A grillage is a beam or reinforced concrete slab that horizontally connects the tops of each screw element. Pile-grillage bases are equally well suited for the construction of wooden and foam block buildings. The tape grillage can be monolithic or prefabricated, the main thing is that it is poured from concrete, the grade of which is not lower than 150.

In order for the grillage to be correctly constructed and create a strong bond between the screw elements, you need to correctly calculate its dimensions. There are a number of special calculations, but we will restrict ourselves to the minimum dimensions of the binding tape:

Foundation with reinforced concrete grillage

Foundation with reinforced concrete grillage

- Height - 30 cm.

- Width - 40 cm.

To give the grillage the necessary rigidity, it must be reinforced with longitudinal and transverse reinforcement (10-12 mm in diameter). The rods are connected using wire according to the armored belt principle. The distance from the reinforcement to the edge of the grillage should be at least 2.5 cm so that the metal rods are completely sealed with concrete mortar and do not undergo corrosive processes.

The connection of the grillage with the supports can be rigid, when its reinforcement is connected to the pile rods, or free, when the grillage lies on the foundation supports without additional garters. In both cases, the load is evenly distributed between the piles.

What nuances should be considered when performing calculations?

To create a reliable and durable supporting structure, the developer must know how to correctly calculate the distance between the piles and the depth of their burial. As for the immersion depth of the supports, then to calculate it, you should take into account the type and complexity of the soil. The developer must take into account one important nuance. The lower part of each pile should be immersed 30 cm deeper than the standard depth of soil freezing determined for the region in which construction work is being carried out.

To calculate the pile-grillage foundation, the following characteristics should be taken into account:

- The degree to which the supports will shrink when subjected to a vertical load.

- Strength characteristics of materials that will be used in the manufacture of grillage and piles.

- The bearing capacity of the foundations of the supports (if there are significant differences in the relief on the site).

- The bearing capacity of the soil (the developer must take into account the compaction of the soil, which will occur during the immersion of the piles).

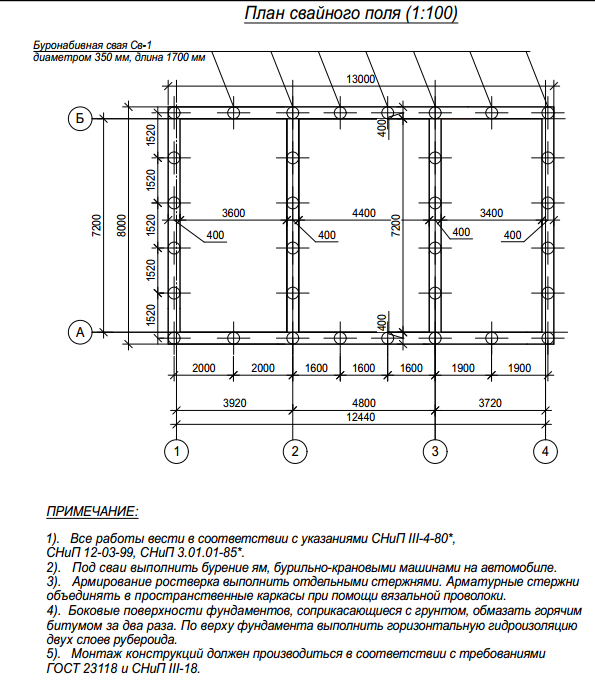

Bored pile structures

When creating a pile foundation of this type, pile structures from monolithic concrete are made and applied.

When creating a pile foundation of this type, pile structures from monolithic concrete are made and applied.

When creating a pile foundation of this type, pile structures from monolithic concrete, combined, prefabricated (from reinforced concrete) are made and used. The latter are often made with a widening of the heel - the option is shown for construction in problem soils, where the main composition is clay and loam. The broadening of the heel makes it possible to enhance the bearing capacity of the pile element, but this technique is not used in rocky soils.

When determining the types of bored piles, it is necessary to be guided by GOST 19804.2-79; GOST 10060.0-95. The most used are bored, bore-section, bore-tangent piles. Drilling foundations also include downhole structures: wells filled with crushed stone filling with layer-by-layer compaction, supports with a widened heel, for the manufacture of which blasting operations are used and hollow supports made by using a core.

Bored piles

These are structures, including reinforced concrete ones, which are widespread due to the simplicity of arrangement.

These are structures, including reinforced concrete ones, which are widespread due to the simplicity of arrangement.

These are structures, including reinforced concrete ones, which have become widespread, due to the simplicity of arrangement, the possibility of using them to strengthen the existing foundation and the construction of foundations in a limited space. The advantage is the minimum dynamic load on neighboring buildings, the absence of destructive effects on the routes, underground communications. In addition, the technology for manufacturing the foundation allows the object to operate in a normal mode during restoration work.

Wells are carried out by means of drilling tools, when the required depth is reached, the drill is removed and the well is reinforced with a pre-fabricated frame, after which it is filled with a mixture of concrete. The production of bored piles can be carried out using the following technologies:

- With the use of a casing;

- Using a clay talker;

- Through the use of a through-feed auger;

- Using a double rotator;

- By compaction of the soil.

Drilling piles advantages:

- Possibility of manufacturing at the building site;

- Long service life;

- Relative cheapness of the project;

- High bearing capacity of the foundation;

- Thickness variability;

- Minimum requirements for the use of heavy equipment (sometimes you can do without it altogether);

- Wide range of applications.

However, there are also disadvantages:

- Compared to strip and slab foundations, the bearing capacity is low;

- Increased labor costs;

- The complexity of the manufacture of piles on water-saturated soils.

Boring piles

Cutting elements are mounted with a step "to zero", that is, they represent a solid wall of structural bodies

Cutting elements are mounted with a step "to zero", that is, they represent a solid wall of structural bodies

These are structures, the installation technology of which repeats the bored pile elements. The difference is that the bore-section elements are mounted with a step "to zero", that is, they represent a solid wall of structural bodies, which serves to equip a full-fledged support of the soil. They are used for the construction of underground parking lots, tunnels, crossings. Construction according to SNiP 2.02.01-83 of this type is permitted at shallow depths - no more than 30 meters.

Tangent piles

A foundation of this type is used in the case of vertical and horizontal load on the elements from the nearest buildings.

A foundation of this type is used in the case of vertical and horizontal load on the elements from the nearest buildings.

A foundation of this type is used in the case of vertical and horizontal load on the elements from the nearest buildings, groundwater. As a rule, this method is used in construction in a confined space, as well as for fencing very deep pits, for cutting embankments in soils with solid coarse-grained inclusions.

The advantages of the technology are the following indicators:

- The ability to carry out work in a dense building;

- There is no need to arrange additional drainage, drainage;

- It is not difficult to make bore tangent piles both in terms of labor costs and promptly in time.

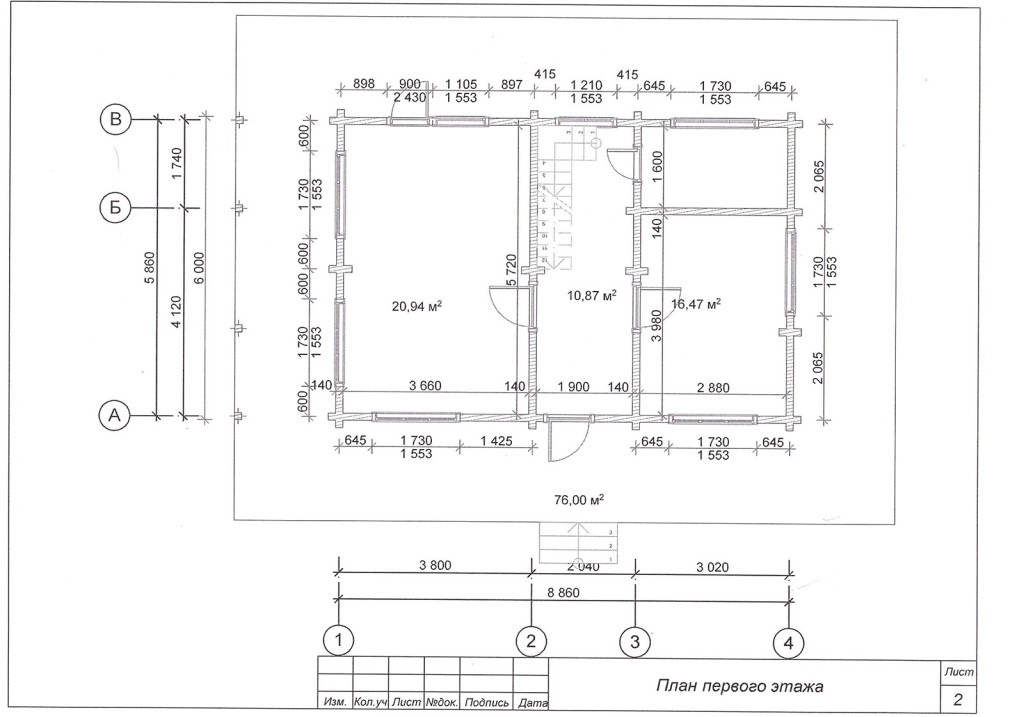

An example of calculation for a frame house

To consider in more detail how to calculate the foundation on screw piles, we will give an example for a one-story frame house with an attic. The roof of the building is metal hip, so all external walls have the same height (no gables). Internal partitions made of plasterboard 80 mm thick without insulation, walls with insulation 150 mm thick. Overlapping wooden beams. The height of the floor is 3 m, the height of the room is 2.7 m. The dimensions of the house in the plan are 6 by 6 meters. The height of the outer walls of the attic floor is 1.5 m. One inner wall is 6 m long, the total length of the partitions on both floors is 25 m.

Clay soils are located at a distance of 3 m from the surface of the earth, there are no significant differences in elevation on the site. Snow standard load is 180 kg per square meter.

We accept pile-screw products with a diameter of 108 mm and a length of 3.5 m (it is necessary to provide for an additional margin, therefore it is better to buy piles with a length of 4 m). In the calculation of loads, we take an approximate amount of 9 pieces (in all corners + the middle of the walls).

The calculation begins with the collection of loads. Let's execute it in tabular form.

| Load type | Reliability coefficient | Calculation |

| From outside walls | 1,1 | Wall length * wall height * mass = 4pcs * 6m * 4.5m * 50 kg * 1.1 = 6600 kg |

| From the inner walls | 1,1 | 2pcs (for two floors) * 3m (floor height) * 6m (length) * 50 kg * 1.1 = 1980 kg |

| From partitions | 1,2 | 25m * 2.7m (floor height) * 27.2 kg * 1.2 = 2204 kg |

| From overlaps | 1,1 | 2 pcs (ground floor and attic floor) * 6m * 6m * 150kg * 1.1 = 11880 kg |

| From the roof | 1,2 | (6m * 6m * 60kg * 1.2) / cos45ᵒ (roof slope) = 3702 kg |

| From foundations (preliminary) | 1,05 | 9pcs * 40kg (weight of one pile) * 1.05 = 378 kg |

| Useful | 1,2 | 2 floors * (150kg * 6m * 6m) * 1.2 = 12960 kg |

| Snowy | 1,4 | 180kg * 36m * 1.4 = 9072 kg |

The sum of all loads on the pile-screw foundation is 48776 kg. We take into account the rounded value of 48.8 tonnes. Next, the number of supports is calculated. The bearing capacity of one product of the accepted diameter is 5-7 tons. We take a value of 6 tons.

Number of supports required = 48.8t / 6t = 8.13 pcs.Round up to the nearest whole. The value corresponds to the preliminary one - 9 pieces, we finally accept it. Supports are installed at the corners and midpoints of external and internal walls.

The above calculations will allow you not to make mistakes during construction and to rationally use resources. They will not take a lot of time, but they will solve many problems that may arise in the future.

Good publicity

Calculation of the bearing characteristics of the pile

The bearing characteristics of a pile in a particular type of soil are important, since if they are neglected, a situation may arise when the characteristics of the pile exceed the capacity of the soil and shrinkage will appear. Due to the negative impact of soil subsidence, the weight of the building will be unevenly distributed and unwanted deformations or partial destruction of the object may occur.

It is possible to determine the bearing capacity of the soil only after conducting surveys. Then, knowing the composition of the underlying layers and using tables from regulatory documents, you can calculate the bearing capacity of the soil. Table 1 shows values for typical soil formulations.

The bearing capacity of the soil, depending on its composition

The bearing capacity of the soil, depending on its composition

After that, the bearing characteristics of one pile are determined. For these purposes, it is also necessary to use reference data for a specific type of pile or data from manufacturers of pile elements for bored or screw piles. As an example, Table 2 shows the data on determining the bearing capacity of the 89x300 (T) screw pile.

Influence of soil density on the bearing capacity of piles 89x300 (T)

Influence of soil density on the bearing capacity of piles 89x300 (T)

The calculation of the number of screw or bored piles for the foundation is made by the usual division of the total load of the object by the bearing capacity of one support.

What should be the pitch of the piles?

The obtained value of the number of piles is insufficient for calculating the foundation, since they can be placed only in a certain way, observing a certain step, so as not to disturb the density of the soil and not to worsen its bearing capacity.

We recommend watching a video on the placement of supports at the required distance.

The maximum step for houses made of different materials is:

- For timber based on ready-made frames, logs or beams, the permissible spacing between piles is 3 m.

- For houses based on foam concrete blocks or cinder block, the step between the piles should be up to 2 meters.

The minimum pitch of the foundation piles is limited by the bearing capacity of the soil. When installing bored piles or twisting screw piles, the soil layers are compacted. Therefore, being too close is not only technically inappropriate, but also financially.