Correct ventilation

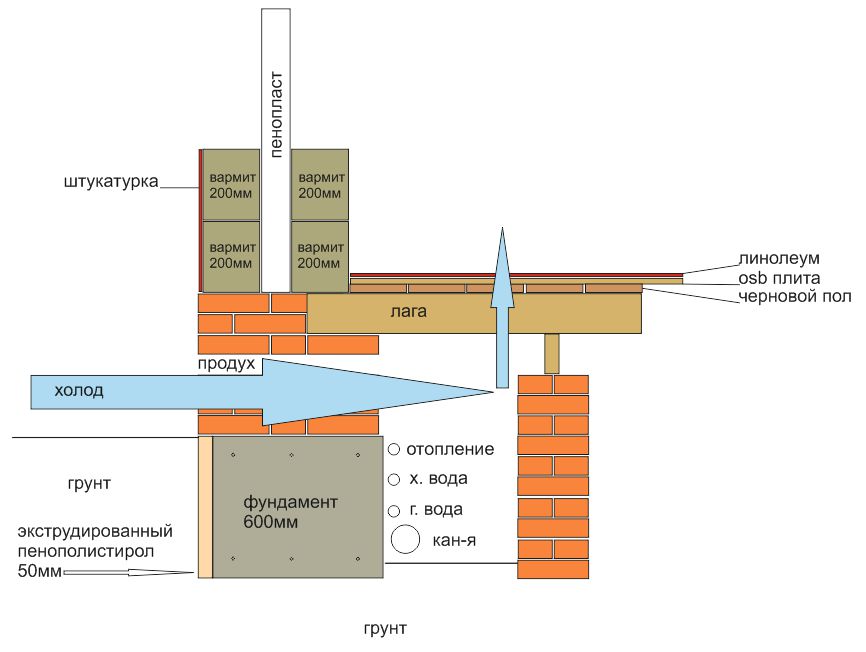

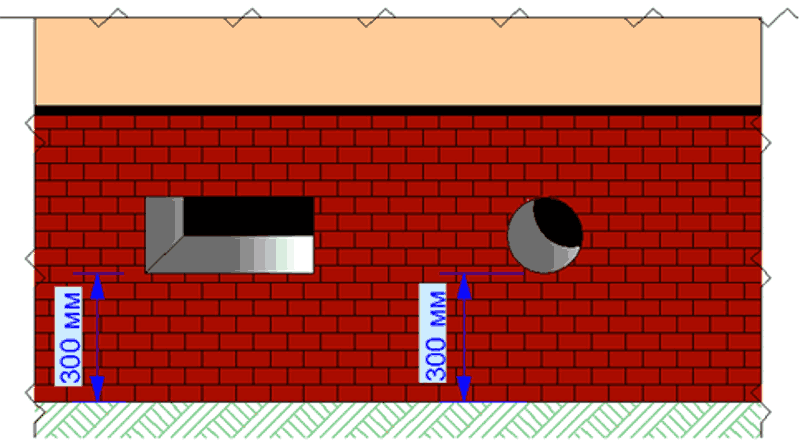

Good ventilation is essential to get a dry basement. Such ventilation in the foundations is included in the project when organizing the formwork. For the organization of vents, it is necessary to take into account their location above the earth's surface. The height of the vents from the surface should not be less than 30 cm so that melt or rainwater does not leak through them in spring.

Probably, in some cases, the ventilation holes will need to be made higher if the height of the foundation allows. It all depends on the climate and the amount of snow. Note that wooden beams cannot be used to organize ventilation. For airflows, it is better to use plastic or asbestos pieces of pipes with a diameter of 110-130 mm, mounted in concrete (at the stage of pouring it).

The boxes and beams are pulled out of the foundation no earlier than a month after its laying. During this time, they "stick" to the concrete, and it is difficult to knock them out of there. For such an operation, you need to perform the following steps:

- After the concrete has dried, a metal drill is taken and a block is drilled on both sides, in the center or around.

- Then a drill for wood is taken, a hole is drilled through, and the drill should not be more than 2.5 cm.

- Having made a through hole, you need to expand the hole from the center to any side with a semicircular chisel.

- Then, with the help of a straight chisel, the stuck side is beaten off.

The procedure for removing the beams hammered in this way is quite time consuming. Therefore, it is better to use other methods, for example, vents can be made using metal boxes instead of bars, since it is easier to knock it out of the foundation. You can also use sewer pipes for this. In this case, the ventilation vents are placed strictly one against the other.

Peculiarities

For a high-quality arrangement of the ventilation subfloor, the windows are closed with special lattice covers (made by hand from nets or lattices). This is done to prevent animals from entering the house through the vents. The diameter of the boxes is selected in proportion to the ventilation covers. If the air vents are not made in advance, they are drilled with diamond core bits.

The shape of the holes can be very different: square, round, triangular. But, as a rule, they are made rectangular. It is necessary to position the vents evenly, at equal distances from one another. If the house is cold, then it is better to close the holes. But in wooden houses they are not closed under any circumstances, especially if the house is new.

In the absence of ventilation or closed openings, you can incur costs associated with repairing the foundation or cleaning the walls from the resulting rot and mold.

A little about the positive aspects

Unlike other methods of organizing ventilation, air vents have much more advantages. The main ones are:

- long service life;

- low price;

- reduction of heat loss;

- ecological cleanliness;

- practicality.

None of the other ventilation methods compare in efficiency and practicality with air vents.

Why is ventilation in the plinth so necessary?

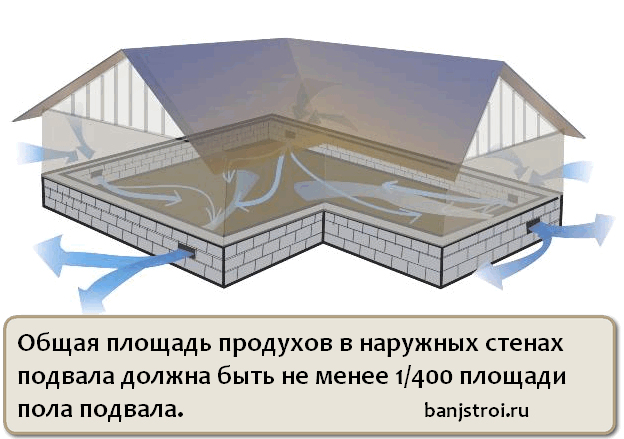

The construction of any private house requires the fulfillment of all norms and rules, which later will leave their influence on the comfort and coziness of its residents. But, some builders often forget that some works also concern the "underground". After the builders have built the foundation, it is necessary to make ventilation holes in it. In addition, they are made according to certain rules that will make it possible to make it as warm and dry as possible when operating a house. A ventilated foundation allows you to get rid of condensation, which is the main enemy of any building.It is because of its effect that small drops of moisture appear on concrete, metal and wooden surfaces.

Having decided to make a monolithic foundation, the need for ventilation will be even greater. In an enclosed space, due to the temperature difference in the house, outdoors and underground, the condensation process is accelerated. Building materials that are in such an environment quickly lose their strength properties. Mold forms on the walls of the basement in a private house, which can very quickly spread to the walls of rooms. Fungal growths are harmful to human health. Inhaling them, his body succumbs to the threat of asthmatic and allergic diseases.

The need for ventilation is also caused by the slow but dangerous accumulation of radon gas in the basement space. Even in small quantities, this radioactive gas poses a great threat to the human body. There is a theory that radionuclides show their activity when interacting with metals, as well as with moisture. It is the lack of ventilation in heated houses that leads to the negative manifestation of radioactive gas. In addition, if the construction of a dwelling is planned on the territory of metal deposits, ventilation of the foundation is indispensable.

2> How to properly close the vents

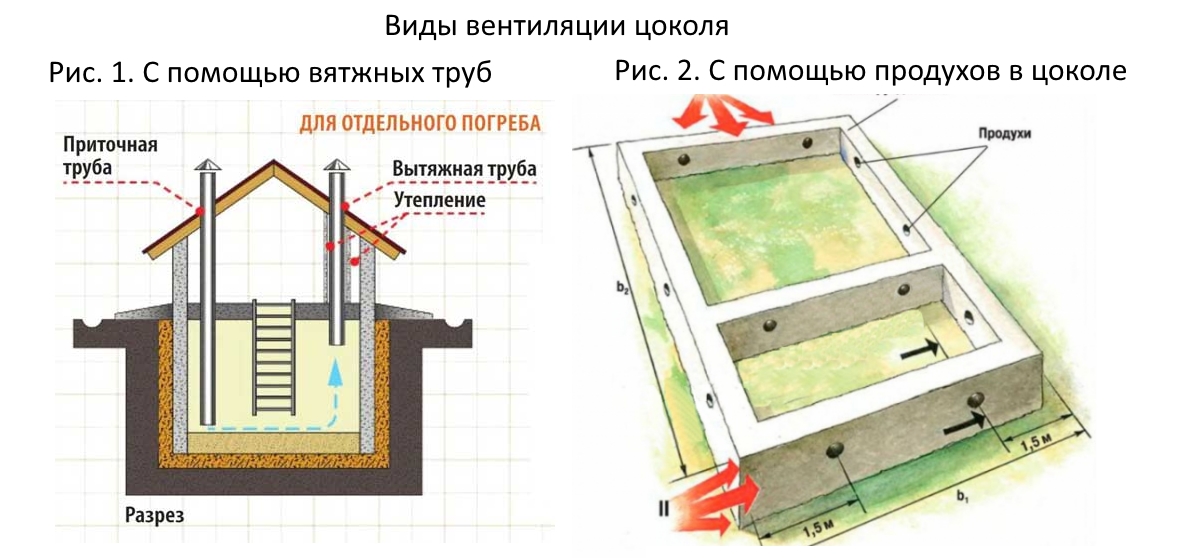

To begin with, you need to understand what vents are and what they are for. Air is a small hole in the foundation that opens out onto the street and allows air to circulate in the basement or basement. They can be made in the form of a pipe extending from the basement up to the roof. The essence of the pipe is the same - the organization of air circulation.

Ventilation of the walls and subfloor is very important for a private house.

Ventilation of the basement and subfloor is necessary for several reasons:

- Firstly, no matter how well the waterproofing of the concrete foundation is done, it still absorbs moisture. This is the physical property of concrete. And from the water, it begins to rapidly collapse, as a result, the house can be skewed to one side, which is why it can simply collapse. Thus, constant ventilation is a must for a basement.

- Secondly, airing helps to remove harmful fumes from the soil from the basement. For example, it is considered extremely dangerous to breathe in radon vapor. You also need to remember that mold and other types of fungi that destroy concrete quickly develop in the stale air.

- Thirdly, ventilation allows you to maintain the recommended temperature in the subfield - more than 0 degrees. This is necessary for the preservation of concrete and wooden floor elements.

You can buy special plugs at a hardware store for the required diameter. They have adjustable valves and, having installed them once, there will be no need to return to this issue.

In general, there are no specific rules for closing the air vents. The main thing is to do it so that no water gets into it. If snow or even more rain can flow into the air, then it threatens with a flood. Therefore, you need to dig a drainage groove that diverts water from the wall where the ventilation is made. It is advisable to make a shield over the hole, covering it from rain.

Ventilation location

Airflow arrangement diagram

Building codes and regulations (SNiP) in order to ensure the most effective ventilation and protection from radon coming from the ground, it is recommended to place ventilation openings at least 0.7 m from the ground level; however, it is not always possible, due to the structural features of the building, to fully comply with these recommendations. Therefore, you should be guided by practical considerations:

- in order to prevent flooding of the underground space, the height of the vent in the strip foundation from the ground level should be located at a height not less than the level flooded by melt water (in most regions it is no more than 30 cm);

- to avoid getting debris and dust into the vents, it is necessary to make them as high as possible from the ground level, as far as the foundation structure and floor level allows;

If the basement of the foundation of the house is low and the ventilation holes, if they are made in the body of the foundation, will be too close to the ground, they can be made along the edge of the foundation, or between the first and second crowns of the outer wall.

How to fix the situation

What to do if there is a foundation, but they forgot to make the air vents or their sizes are insufficient for normal ventilation - fungus, high humidity and other "delights" began to multiply in the subfield. There are several ways to solve the problem:

-

Increase the dimensions of the existing ones or drill new ones. Drilling a monolithic foundation is not an easy task. This is done either with a crown of a suitable size. If there is no crown, you can take a long drill with a large diameter, drilling many small holes with it around the perimeter of the vent. Then the remaining gaps are drilled, and the uneven surface is then either sanded or simply closed with a grid. Another way is to order diamond drilling. In this case, special equipment is used, holes are drilled much softer, without shock loads.

- If there is no possibility or desire to make new or expand old vents, you can improve traction by bringing one or more pipes from the vents to the roof. Due to the pressure drop, the thrust will be better, the humidity will decrease.

- Make forced ventilation. In order not to turn it on / off manually, you can put a timer or a differential thermometer. It will turn on the fan when the temperature in the underground is higher than outside (condition for condensation).

- Reduce the amount of moisture entering the subfloor. The most common source is soil, especially when the water table is high. It is closed with a vapor barrier. A thick plastic film (from 150 microns thick) is suitable. It is laid so that one canvas overlaps another by 10-15 cm. The joints are glued with double-sided tape (you can do it twice - at the beginning of the "overlap" and at the end "). The film is put on the walls by 20-30 cm, fixed with a bar. So that during further operation the film is not damaged, a layer of sand is poured on it or a skinny screed 3 cm thick is made. If the foundation, blind area and basement are insulated, this gives a good effect - in combination with a vent pipe brought to the roof. If there is no insulation, condensation will form on the film. Having made a slope in one direction, it will be possible to collect moisture and remove it outside the subfloor. This option, although worse, works.

-

For ventilation of the subfloor in a bath (heated) or houses with stove flooding, there is another solution - to put the stove so that the air is drawn from under the floor (make a blower below the level of the finished floor).

- No subfloor - no ventilation needed. To realize this axiom, the entire space from the ground to the subfloor is filled up. The most available material with good thermal insulation properties is used. Usually it is expanded clay. Its disadvantage is that it is hygroscopic and capable of "pulling" water from the ground. With a high level of groundwater, if you do not make high-quality waterproofing on the ground (film with an approach to the walls), you can only make it worse. There is a second suitable material with the best thermal insulation characteristics and completely non-hygroscopic - granular foam glass or its fight. This material appeared relatively recently and very few people know about it. For this case, it is an excellent choice. It is, however, more expensive than expanded clay, but several times warmer and safer (expanded clay is often environmentally unsafe).

How to choose a ventilation scheme?

So, we figured out whether an underfloor ventilation system is needed, and now it remains to decide which scheme to choose for specific conditions. There are several important points to consider when choosing a system.The operation of ventilation largely depends on the type of climate in a particular area, the average outside temperature, etc.

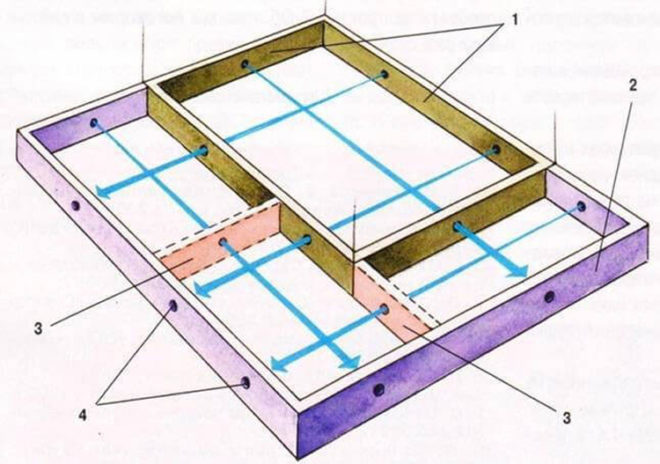

In a natural ventilation device, the main rule must be observed: the supply openings are located below the exhaust openings. The greater the altitude distance between them, the more efficiently the system operates.

Natural ventilation is more effective in winter, since it is at this time that a large difference between the temperature inside the subfloor and outside is recorded, due to which good circulation of air masses is ensured.

However, with an even greater decrease in temperature, there is a possibility of an excessive increase in air exchange, which is also not particularly good, since it can lead to freezing of structures. Therefore, with a significant decrease in temperature, the air vents must be closed.

If the house has a supply and exhaust ventilation, it makes sense to connect the hood from the basement to the general scheme. So the air outflow will be stimulated in any weather.

To equip a combined ventilation system for a small underground floor, it will be enough to install one pipe. In order for it to provide both output and reception of air masses, it must be divided vertically into 2 channels.

These ventilation pipes are sold in hardware stores. Each channel has its own valve to adjust the flow rate. The functioning of such ventilation is checked quite simply: you need to attach a sheet of paper to the outlets in turn.

Features of laying holes for ventilation

Ventilation for a particular house begins to be calculated during the design of the structure. In order to answer for yourself the question of how to make ventilation of the foundation of a particular structure, a number of important factors should be taken into account. These include the following points:

- location of the future structure;

- how much the house is protected by adjacent houses;

- Rose of Wind.

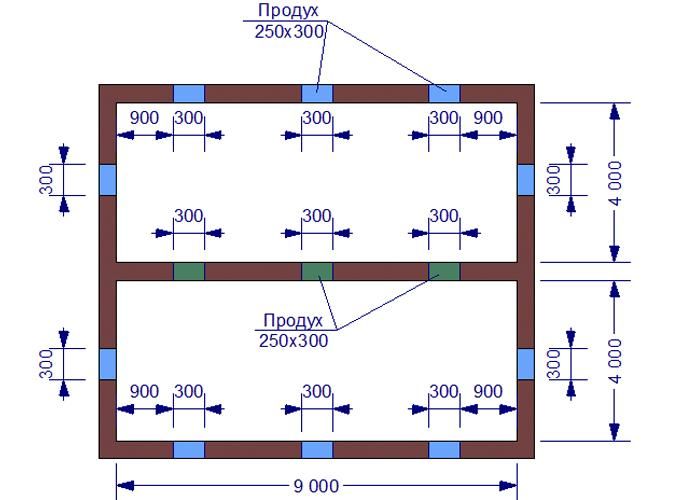

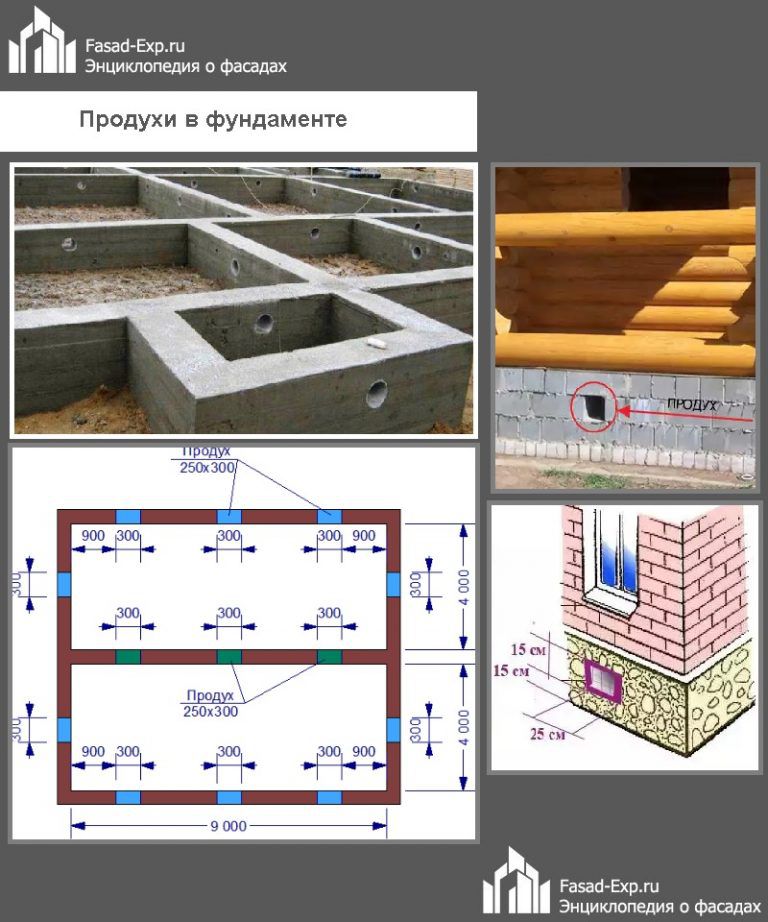

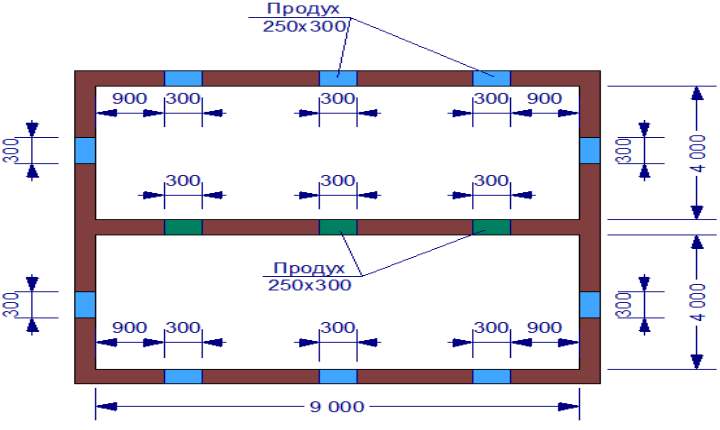

Usually, in order to organize a ventilation system in any private house or bath, it is enough to provide for the presence of two through holes in the foundation. However, there are exceptions to the rules, and in order to make sure of your choice, you should accurately calculate their number depending on the location of the future home. To do this, at the design stage of the holes, it is necessary to build on the known building codes. According to them, the holes in the foundation for ventilation should have a size equal to 1/400 of the total area of the basement room.

The diameter of such holes directly depends on the area of the perimeter of the future private building. A hole of 25 cm is considered ideal, but this is not always feasible. In this case, it can be made smaller, but it is not recommended to lay holes with a diameter of less than 11 cm. It is better to make these holes slightly larger than necessary. This is easy to fix with special plugs that reliably protect against the through-flow of air.

To avoid the formation of air pockets, the first hole near the blind corner should be placed at a distance of about 90-100 cm. If the foundation provides for the presence of overlaps, then similar holes are also made in them. They should be laid in an even number and placed in pairs in the foundation. The outside of the duct should be approximately 10 to 15 centimeters from the ground cover. The finished openings do not need to be closed as this will impede normal air flow. Next, you should decide where you need to place them.

If a private house under construction is located in a depression (lowland), there are other buildings nearby or there are natural obstacles to the movement of air, then they must be installed along the entire foundation. Thus, the most effective ventilation of the foundation in a private house is ensured. In cold winter seasons, the owners, due to their illiteracy, try to completely close these holes with some material, thinking that all the heat leaves through them.This should never be done. Since then moisture and harmful radon begin to accumulate in the basement, which simply poison the inhabitants of this private house.

That is why you should strive for the ventilation system in the house to function all year round, especially in winter. There is no need to harm your health and your home, it is quite easy to shorten its service life, and it is very difficult to restore it. And so that it is not cold, first of all, before frost, you need to close up all the cracks and gaps in the house.

Payment

Schematic display of location and size The optimal number of air vents should be one per 2-3 meters. It is worth considering where the wooden house is located, if it stands on a hill, then two air vents will be enough, for a house in the lowland from four. It is advisable for homeowners who are building a house to find out the diagram of the local wind rose (diagram of the wind regime in a certain place according to long-term observations) so that the ratio of airflows on each side is not a problem. Let's look at an example of how to make a calculation.

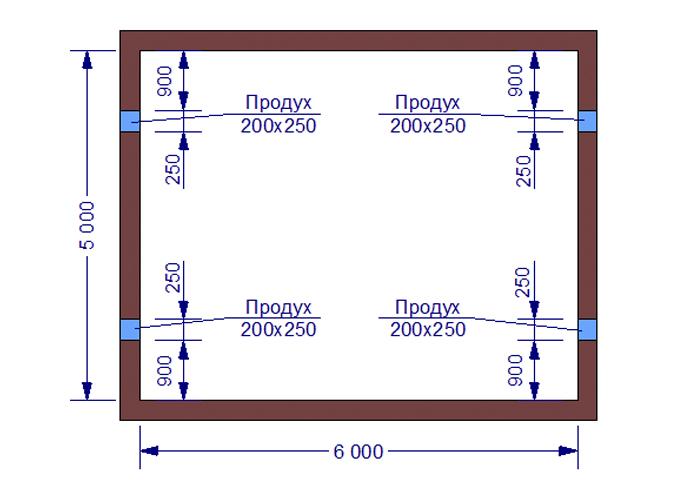

Let's say the dimensions of the foundation are 5 by 6 meters. The planned dimensions of the vents having a rectangular section of 20 by 25 cm. It is necessary to calculate the minimum permissible number of windows and place them correctly along the walls.

The required air area is determined by the formula:

S = F / 400 = 30/400 = 0.075 m2,

where: F - basement area.

The required number of airflows is determined as follows:

N = S / P = 0.075 / 0.05 = 1.5 ≈ 2 pcs,

where: P = 0.2x0.25 = 0.5 is the area of one air passage.

It turns out that you need 4 holes to avoid non-blown "bags". They can be placed on the short or long side of the house. But the best ventilation will be when the vents are located on the short sides. Height above the ground not less than 30 cm from the ground.

Algorithm for arranging ventilation holes in the foundation

Tools required for work: hammer, sledgehammer, shovel, drill or puncher.

In order to make vents, you need to prepare the following tools and materials:

- shovel;

- hammer;

- sledgehammer;

- drill or hammer drill;

- wood drill with a diameter of 2.5 cm;

- drill for metal with a diameter of 1.4 cm;

- straight and semicircular chisel;

- plastic or asbestos-cement pipes of circular cross-section with a diameter of 11 to 13 cm (timber timber);

- sand.

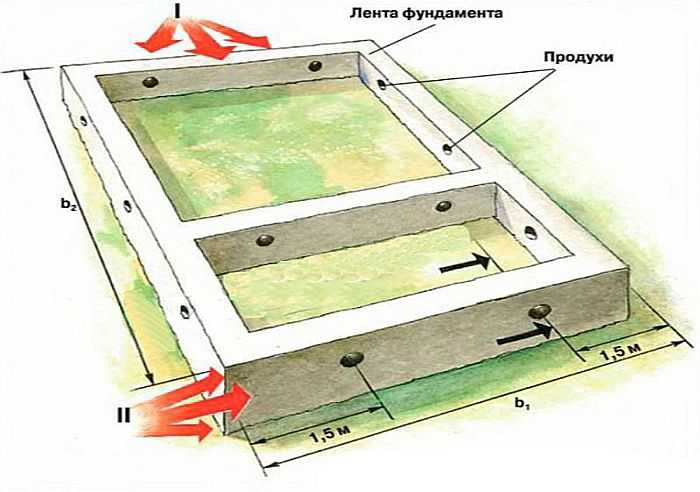

It is necessary to take care of how to make the vents even during the construction of the foundation. If we talk about the strip foundation, then each vent is laid at the stage for pouring the concrete mixture. It should be remembered that the height from the soil level to the outlet must be 30 cm or more. If this condition is not observed, moisture generated during the melting of snow in spring can enter the underground and flood it.

The diameter of the holes depends on the size of the foundation perimeter. The longer it is, the larger the diameter of the ducts should be. Most often, ventilation openings with a diameter of 10 to 15 cm are equipped. It is also necessary to remember the basic rule: all vents should be located parallel to each other in parallel walls.

Typically, air vents are made from circular pipes of a certain diameter. You can also use a wooden beam, but experts do not recommend doing this. This explains all the difficulties that can arise when removing a bar from hardened concrete. For a month, while the concrete solution is drying, the timber will firmly adhere to it, and it will be quite difficult to remove it.

In the event that pipes are used to make an outlet in the foundation, the process is greatly facilitated. First of all, it is necessary to cut the pipes into pieces, the length of which will be equal to the width of the formwork and, accordingly, the width of the future base. Then sand is poured into each piece, while both ends must be plugged with unnecessary rags or paper to avoid sand spilling and concrete penetration into the pipe. After that, the pieces of pipes are placed in the marked places of the formwork in such a way that they abut closely against the parallel sides of the form. After placement, future ventilation openings are filled with concrete.

How to remove timber from hardened concrete

The device of the strip foundation.

If beams were laid in concrete, then to remove them, it will be necessary to carry out a number of the following measures:

- Using a metal drill, make 2 holes parallel to each other or 1 hole in the center around the perimeter of the bar. Then drill through the hole with a wood drill.

- With a semicircular chisel, expand the hole to one of the sides of the bar, and with a straight chisel, beat off this part from the hardened concrete. Thus, it is necessary to remove 2 corners of the timber.

- After that, the remaining 2 corners are knocked out with a sledgehammer.

When the concrete slurry of the strip foundation has dried up, both ends of the air vents are freed of paper and sand. After that, each ventilation hole must be equipped with a grill, which will not only provide a constant flow of fresh air into the underground room, but also protect it from the invasion of rats, mice and insects.

By learning how to make ventilation holes in, you will extend its life and save yourself from the need for repairs in the basement.

The ventilated underground room will remain dry throughout the year, regardless of weather conditions and the level of melt water. And this, in turn, will protect it from dampness, mold and mildew.

Calculation of airflow

Indeed, construction according to a plan verified by the design calculation makes it possible to do without errors and subsequent alterations, and this is a guarantee of saving both time and financial resources. But the preliminary calculation of air vents in the foundation, which is carried out at the design stage, has only an approximate, estimated nature of the number and location of air vents.

The calculation of airflows in the basis, which is carried out even at the design stage of the house, is only an estimate.

There is no universal formula or algorithm here, there are only recommendations prepared on the basis of standards. The fact is that before the foundation of a building appears, it is impossible to predict in advance exactly how the drafts under it will manifest themselves.

There are the following general rules regarding how to make air vents in the foundation (their dimensions, location and arrangement of holes are taken into account):

- A full-fledged and functional device of air vents in the basement is impossible without free movement of air under the floor, therefore the logs should be located at least 25 cm above ground level. And the distance between them is taken on the order of 55–65 cm. If the floor is low, then no pluses from the presence of air vents are out of the question.

- The airs are made strictly opposite each other, that is, they are placed on one line perpendicular to the walls.

- The distance between the vents is chosen to be no more than 3 meters, the height from ground level to their base should be at least 15 cm, to the upper edge of the basement - 15–20 cm. A rectangular opening with a side width of at least 14 cm has sufficient dimensions for ventilation tasks. Thus, the number of air vents in the foundation of average private houses will be no more than 8 pieces, that is, two in each wall.

- If the house has internal load-bearing walls supported by the base on transverse foundations, then such walls create an obstacle to the free movement of air through the underground. Therefore, the placement of vents in the basement of the internal load-bearing wall must also be planned. Their size is made slightly larger than those of the vents under the outer walls in order to provide more freedom for air flow and improve its circulation in the space between the logs. A good solution would be to plan, instead of an outlet, a non-closing technical opening for access to the underground parts of the communications.

- To protect small pets and rodent pests from crawling into the underground, a fine mesh or decorative lattice is inserted into the air vents.

It is easier to foresee and exclude a cubic cavity from the concrete poured in advance, rather than to think about how to make air vents in the finished foundation.

To do this, a so-called lug is laid in the place of the intended location of the airway - an easy-to-remove cut of a log or several bricks with wedges laid between them.

Wedges are needed so that the bricks can be easily removed from the finished base. Instead of a lug, you can use a short piece of large diameter pipe with sand filled in and plugged ends. This is done so that the pipe is not flattened by the impressive mass of concrete of the strip foundation. After demolding, they can not be removed.

Airflows in a wooden house are made much easier. To obtain a hole of the required size, it is enough to make a notch between the pickup logs.

4 How and why to close the vents

For the winter, if the building during this period will not be used for housing and will not be heated, the air vents in the basement can be closed. In spring, however, this will cause increased humidity in the basement, but otherwise the house may freeze

There is another danger that should be paid attention to - the entry of rodents into the house.

There are several ways to close the vents:

- Hammer in with a rag. There will be no draft, air access, albeit limited, will remain.

- Close the holes with special removable covers. Now there are closing blocks. Some have mini ventilation. A homemade lid is easy to make out of wood or plastic.

- Fill with polyurethane foam. This is a reliable, but too radical way: in the spring you will have to tinker with its removal.

- From rats and mice (regardless of the season), install the lattice inside the channels. The nets should be metal and not the thinnest, otherwise they will not become a serious obstacle to rodents. It is better to do this on the basis of anti-vandal considerations.

Installing gratings and closing channels can interfere with each other. It will be convenient to mount the grate from the outside, and push the rags from the inside of the basement. A long metal hook can be made for spring canal cleaning.

Hole closure

Often home owners are interested in the following question - is it necessary to close the holes in the cold season?

If the room is heated, and people constantly live in it, then it is not recommended to close the vents. If the holes are closed, then the resulting temperature difference will contribute to the appearance of rot, the release of condensate. This will lead to general destruction of the building.

If the building is operated only in the warm season, the openings should be closed at subzero ambient temperatures.

The vents must provide a constant flow and ventilation of air. For this, the holes can be closed partially, not completely.

Answering the question of how to close the vents in the foundation, many experts advise using a special plastic mesh to protect against rodents. When covering openings during the cold winter season, it is recommended to use breathable material to maintain minimum ventilation. You should not use the means at hand to close it. This can lead to malfunctioning of the ventilation system and subsequent destruction of the entire building.

There is no need to avoid the issue of installing airflows. This uncomplicated work guarantees the correct operation of the building. Air ducts will provide clean, ventilated air in the room, relieve the house from the growth of fungi and bacteria.

Recently, many have begun to neglect the construction of air vents, justifying this with the European construction system. The fact is that vents are not really used there during construction. However, there is a completely different technology. Construction work in our country is carried out according to domestic technology using the foundation, basement. In this case, it is extremely necessary to arrange them at the base.

Do it yourself

I will say right away that it is quite difficult to make airflows in the foundation with your own hands, since the thickness of the tape fluctuates between 40-60 cm.And drilling reinforced concrete of this thickness is long and costly.

There are several ways to make holes in the foundation:

- Basement superstructure made of brick and with pre-drilled holes. This method is the most correct and quite simple, but it is applicable in all cases. So, for example, if the walls have already been erected, then, of course, it will not work to build on the basement.

- Making holes with a puncher is the most popular and affordable way among private developers. Depending on the grade of concrete and the degree of its reinforcement, it will take from several hours to one full working day to make one blow. In this case, you will have to spend several concrete drills. Holes are drilled around the perimeter of the vent hole, you need to work with a perforator not at full power and periodically wet the drill with water to avoid overheating.

- Use the crowns on the bud and drill out the concrete piece by piece, step by step, and then knock out the concrete with a punch with a lance. Also a difficult and not fast way.