The device of their sand cushion

This material is chosen if a one-story house or a house is being built from wood and other light materials. Sand bedding is good for the construction of objects in an area where groundwater occurs at great depths.

There are several ways to find out the level of the first layer of groundwater. For example, if there is a well nearby, you can find out its depth. Abundant vegetation will tell you about the proximity of the aquifer. In lowlands, groundwater approaches the surface of the earth closer than in higher elevations. But the most reliable way would be to drill an exploration well.

Preparation for the foundation requires the performance of a number of mandatory operations:

- marking the foundation on the ground;

- digging a trench;

- aligning it horizontally and vertically;

- laying an insulating layer at the bottom of the trench.

The latter is necessary so that the sand does not mix with the ground. To do this, you can take geotextiles or ordinary roofing material. Having completed this stage, they move on to the next - actually creating a gasket between the foundation and the ground. Before making a pillow, you need to choose a material. According to building standards, clean coarse sand is used for backfilling. It is forbidden to take material that is small in composition by the requirements of SNiP. The reason is that fine sand has the property of freezing, and this will lead to a violation of the shape of the foundation and the destruction of the house.

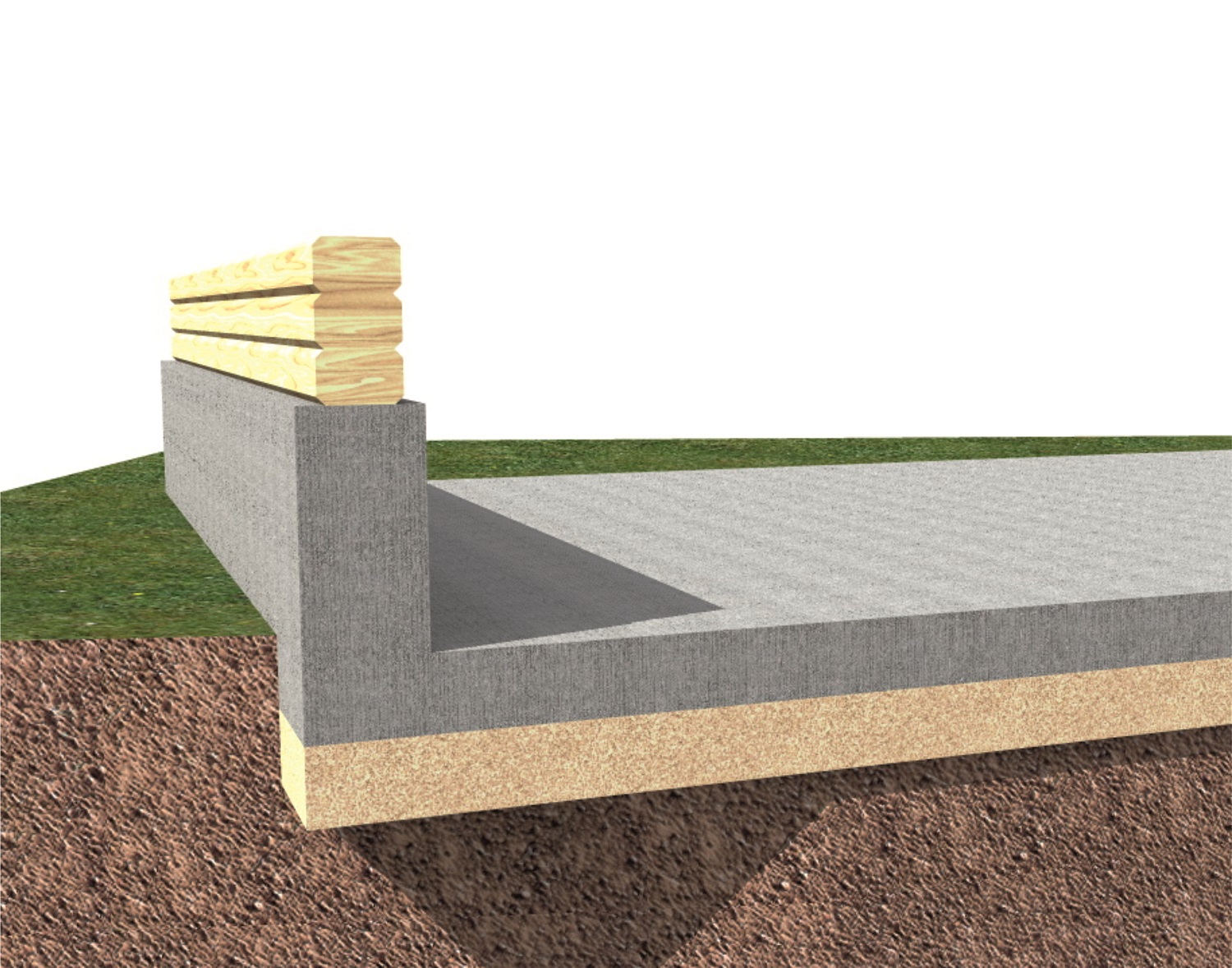

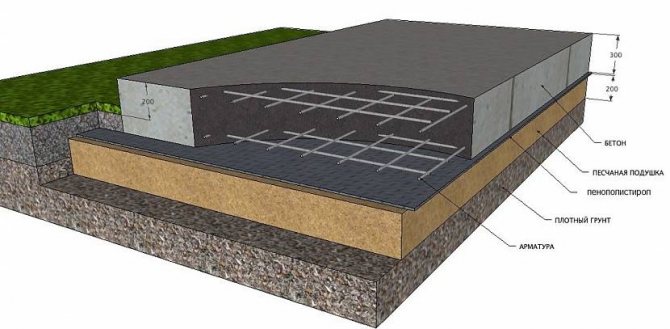

The sand bed is mainly used for the strip foundation. But this filling is also done for other types of bases. For example, a cushion for a slab foundation can be made of coarse sand.

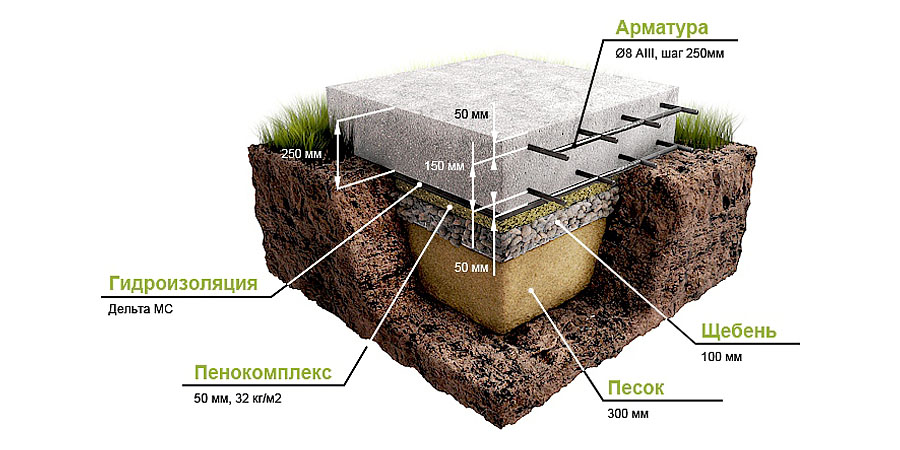

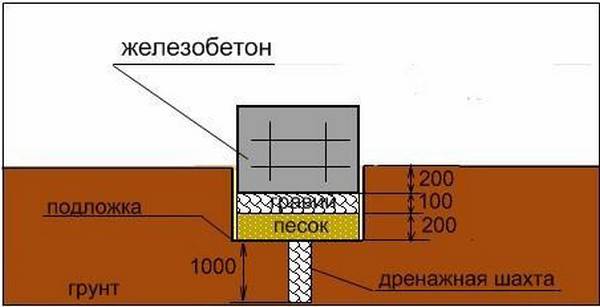

A trench is dug along the contour of the future foundation, the depth of which depends on the size of the building. On average, its depth ranges from 40-50 cm, but in some cases, builders increase this size. The standard thickness of a sand cushion is at least 20-25 cm. Professionals do not recommend making a bed less than this indicator.

A trench is dug along the contour of the future foundation, the depth of which depends on the size of the building. On average, its depth ranges from 40-50 cm, but in some cases, builders increase this size. The standard thickness of a sand cushion is at least 20-25 cm. Professionals do not recommend making a bed less than this indicator.

The sand is carefully leveled along the entire length of the trench. After that, it is necessary to abundantly moisten and tamp the sand. Water is poured into the trench, which squeezes out the air between the grains of sand and compacts it. As a result, the pillow will be denser and less prone to vibrations and movements.

Why do you need a sand pillow

At the end of the excavation work on the construction of the belt and other types of foundations, irregularities remain on the soil surface. For the reliable operation of the structures of a monolithic or prefabricated reinforced concrete foundation, it is required to make an ideal flat surface of the supporting area. The size of the thickness of the sand preparation from 100 to 200 mm will eliminate all irregularities and provide a perfectly flat support area for the building.

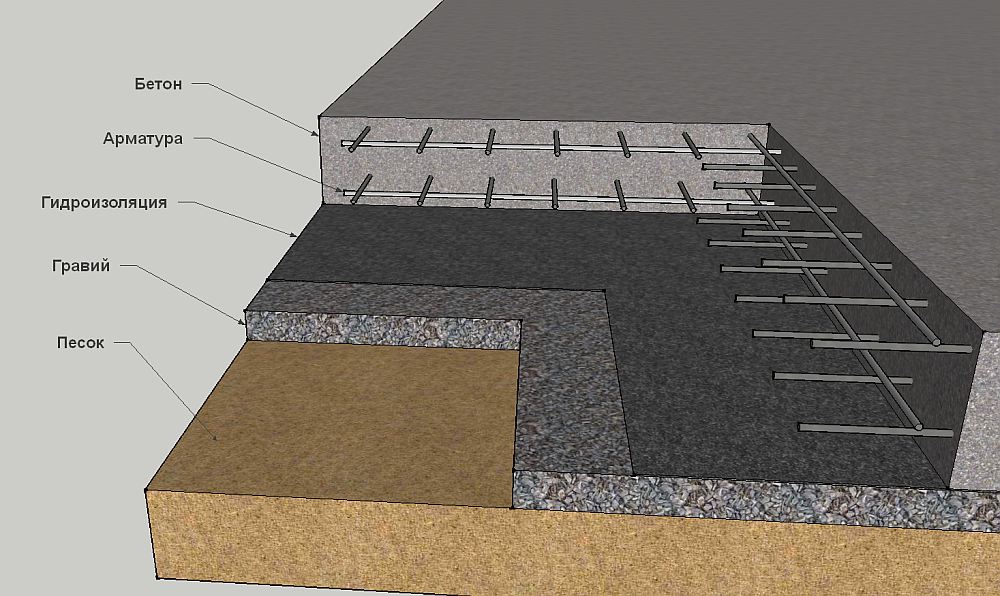

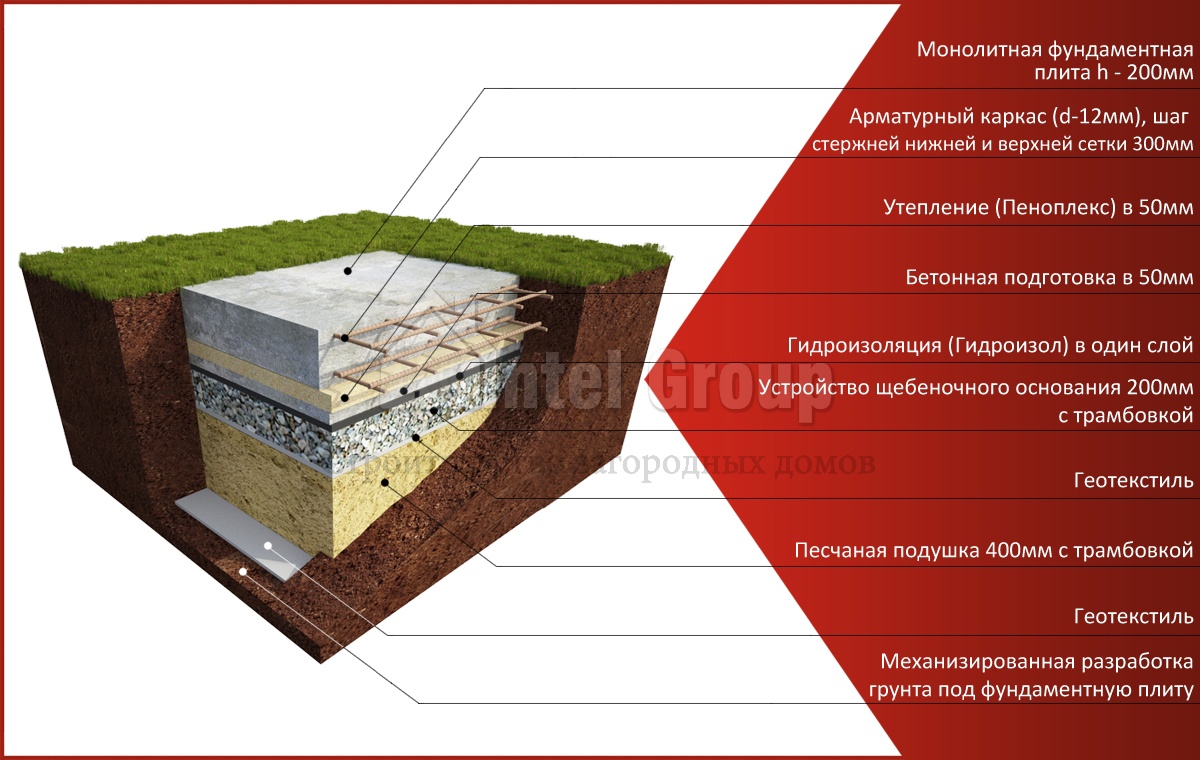

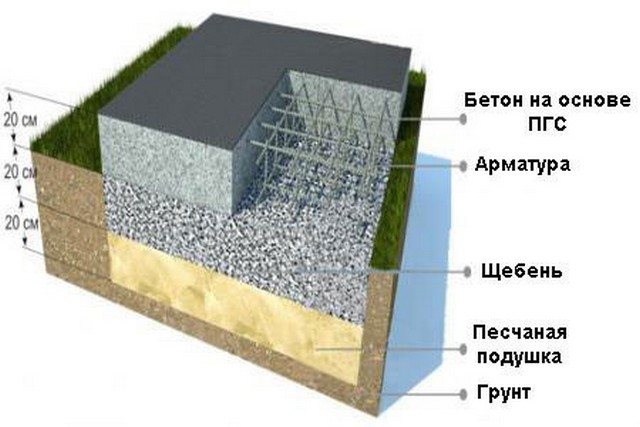

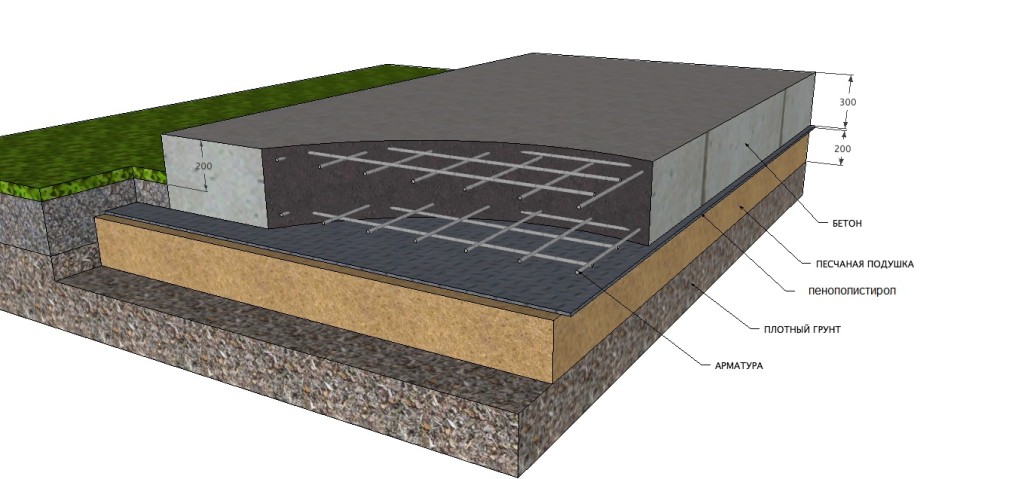

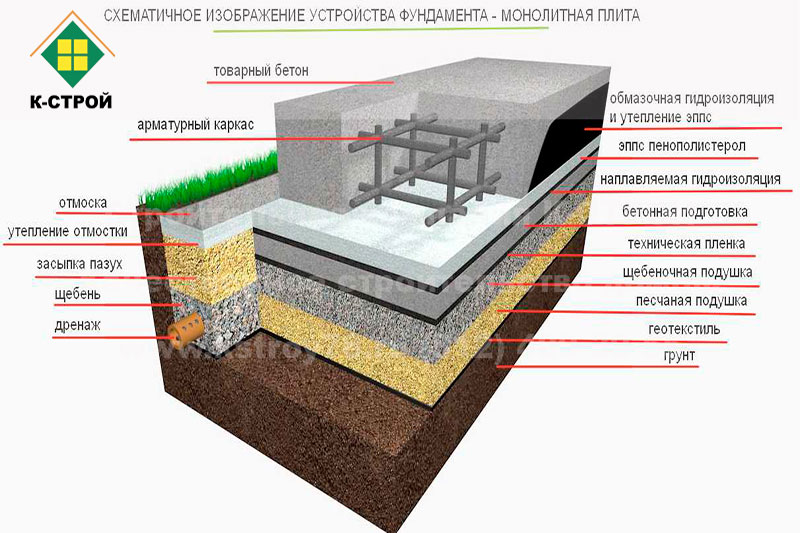

When installing the base, the order of layers must be carefully observed.

When installing the base, the order of layers must be carefully observed.

In the construction of small houses, the thickness of the sand cushion under the foundation is sufficient in size 150 mm. A sand cushion for a strip, slab and columnar foundation resists soil compression, evenly distributes the load from the total weight of the structure.

The pillow prevents capillary penetration of moisture from the ground up into the building structure. The preparation device on the ground base prevents the occurrence of negative temperatures in the base of the building.

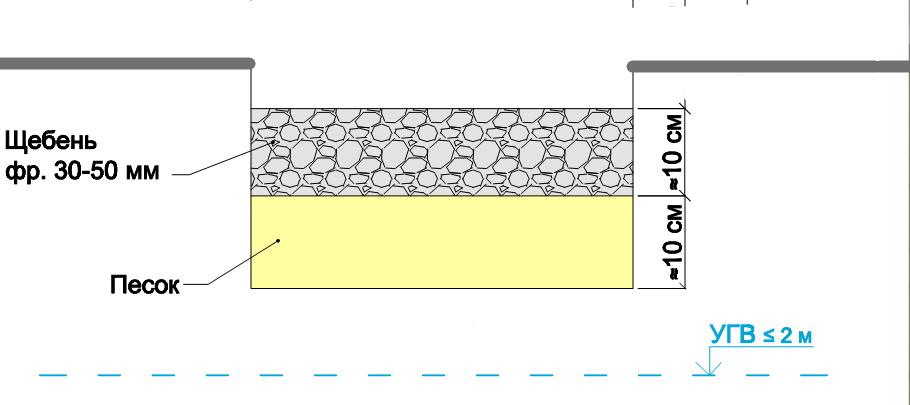

Preparation of sand and crushed stone at the bottom of trenches, pits and pits, as drainage drains rain, melt water away from the construction of the foundation of the house.

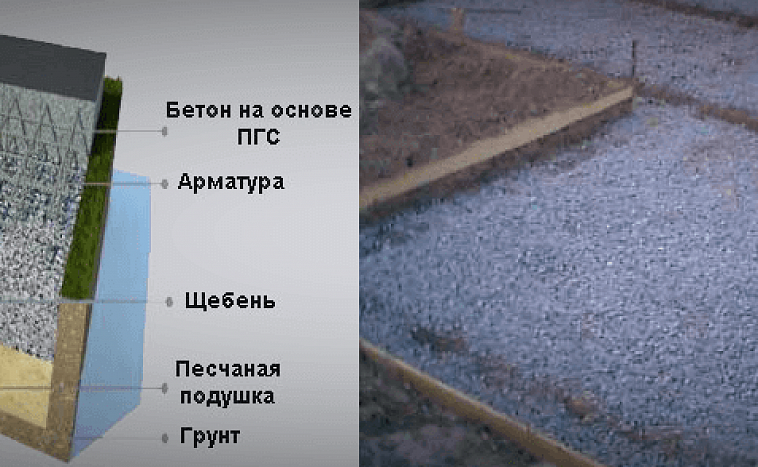

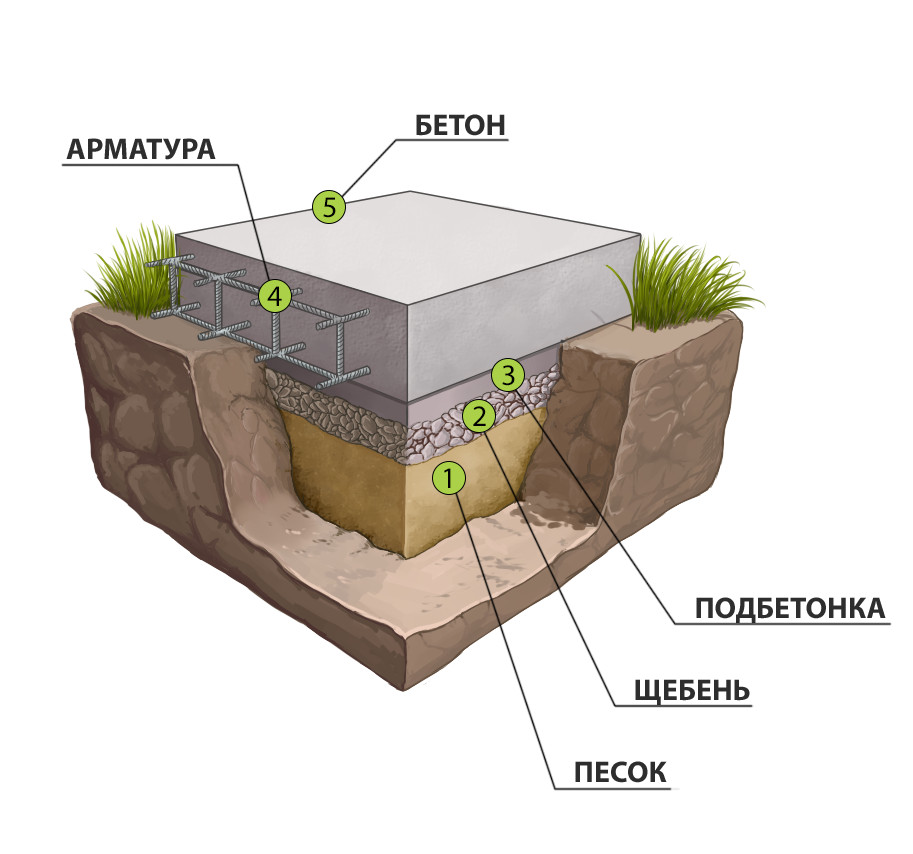

It is necessary to pour a layer of crushed stone on top of the sand preparation, and not vice versa. Why do you need to do this? Due to its fine-grained structure, the rock can penetrate deep into the crushed stone layer. As a result, two dissimilar layers of base preparation are mixed.This will adversely affect the properties of the sand cushion.

Geotextiles will help to further protect the future foundation of the house

Geotextiles will help to further protect the future foundation of the house

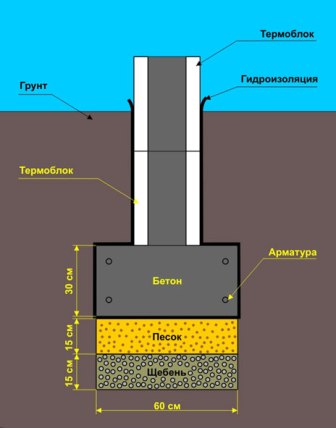

There are exceptions, though. At the bottom of the pits of the columnar supports, crushed stone or gravel is poured, then sand. Due to the small size of the support area, slight mixing of the layers does not affect the quality of the sub-base.

A waterproofing material (polymer film, geotextile, etc.) is laid between the soil and sand, sand and crushed stone. This will protect against moisture penetration from the seasonal rise of groundwater.

Varieties of foundation pillows

To begin with, the ideal option for a pillow is a poured concrete layer. Sand, crushed stone and other materials indicated above are just an opportunity to reduce the cost of building a house. But among them the best is compacted sand. And there are several reasons for this:

- A well-compacted sand cushion has the same strength characteristics as dense soil.

- It evens out the uneven bottom of the foundation pit or trench more easily than other materials.

- Sand is an excellent drainage material that helps to drain melt and rainwater from the foundation structure.

- The formation of the pillow itself does not require the use of special equipment.

But it should be noted that the sandy layer has its drawbacks. First, the material is quickly washed away by groundwater. Second, it has poor transverse strength, especially if the load is pointwise.

For backfilling, it is better to use coarse-grained or medium-sized sand. A prerequisite is the minimum amount of clay inclusions. The thickness of the layer is 10-70 cm. It is possible to tamp in one pass a layer up to 5 cm thick, therefore the process of forming a sand cushion is long and laborious.

Tamping a sand cushion with a vibrating plate

Sand ramming is carried out with moistening

And here it is very important to catch the amount of water. If you overdo it with this, then the sand will begin to disperse from the place of ramming.

That is, there will be a decrease in the thickness of the layer and a decrease in its density, which cannot be allowed.

The easiest way to determine the exact amount of water is to prevent it from appearing on the surface of the pad as it is tamped. And the required density of the compacted sand is determined by walking on it. There should simply be no traces on the surface.

So, having figured out why a sand cushion is needed for the foundation, as well as with the technical characteristics of the layer, we turn to crushed stone.

Sand pillow under the foundation

Rubble pillow

More recently, in private housing construction, one method was used to form a cushion from rubble. It was simply interfered with the bottom of a foundation pit or trench, and then rammed. It turned out a good quality pillow, which had one serious drawback - under the influence of groundwater, the earth was gradually washed away, only rubble remained. That is, the strength of the layer itself decreased.

Which crushed stone is better to use for the foundation cushion. To form this element at home today, crushed stone of a large and medium fraction is used. But this building material is used only if it is necessary to ensure the maximum possible throughput of the layer in terms of its drainage characteristics. At the same time, a drainage system must be formed around the house, and under it.

Large fraction crushed stone Source shcheben.store

In all other cases, either a lean concrete solution is laid using crushed stone, or a mixture of sand and crushed stone. The latter, while seemingly inconsistent in terms of strength, has its own advantages over other materials:

- high drainage qualities that do not allow water to accumulate in the pillow;

- sufficient strength to speak of the ability to withstand the loads of a house of three floors;

- resistance to erosion.

Of course, even a mixture of two materials is a layer that absorbs water well.Therefore, there is a high probability that the cement milk, which is part of the concrete solution poured into the formwork, will leave the concrete, weakening it.

What the builders offer in this case. There is only one way out - to waterproof the bottom of the trench or foundation pit. But, as practice shows, it is often more expensive than pouring lean concrete.

What is the function of a crushed stone pillow

The soil cannot replace the pillow. The tight fit of the foundation and the soil to each other leads to many problems with the building being erected. Even structures built in accordance with all building codes and standards can give significant shrinkage, create a load on the base that does not correspond to the design data.

The crushed stone pillow takes on the following functions:

- evenly distributes the load on a given area of the soil;

- reduces point load - the pressure exerted by the building;

- significantly reduces the negative impact of negative temperatures;

- minimizes the likelihood that the building will shrink;

- removes moisture from the base and prevents the onset of processes destroying the foundation;

- reduces the level of groundwater flow;

- makes it possible to place the sole of the base in a horizontal position;

- levels the bottom of the foundation pit dug under the foundation.

The absence of crushed stone bedding does not allow obtaining the above advantages in the construction of a particular type of building. This makes the arrangement of the pillow an important stage in the construction of a capital structure.

Calculation of the amount of material for arranging a crushed stone pillow

To determine the consumption of bulk material, it is necessary to know the volume of the substrate and the weight of the fraction involved. This indicator can be viewed either in the certificate of quality, or use the overall average value. The latter is 1,450 kilograms per cubic meter. One ton of crushed stone fills a volume equal to 0.67 cubic meters. It is enough to divide the volume of the pillow by this parameter. The result is the right amount of crushed stone.

If it is possible to find out the exact weight of the fraction, the calculations will be more accurate. In addition, it is necessary to take into account the fact that the pillow is most often equipped with a combined one, which means that part of the volume will be occupied by river sand. Its consumption will increase when replacing the top layers of problem soil. It is better to order bulk materials with a margin of 10-20 percent. Otherwise, you will have to make an additional purchase later. We should not forget that crushed stone is also used for the foundation, so it will be required more than just for a pillow.

Crushed stone classification

Depending on the size, crushed stone is divided into fractions. In this case, the fraction is understood as the maximum permissible size of a single stone (grain). Thus, two groups of factions are distinguished:

- main fractions of crushed stone (0.5-1.0 cm, 0.5-2.0 cm, 1.0-2.0 cm, 2.0-4.0 cm, 2.0-6.5 cm, 2 , 5-6.0 cm, 4.0-7.0 cm.);

- associated fractions of crushed stone (0-0.2 cm, 0-0.5 cm, 0-1.5 cm, 0-2.0 cm, 0-4.0 cm, 0-6.0 cm, 0.2- 0.5 cm.)

As a decoration option or in the construction of dams and reservoirs, the so-called rubble fractions of 7.0-12.0 cm and 12.0-15.0 cm are used.

The greatest demand in the sales market is noted for granite crushed stone ufraction 0.5-2.0 cm, less often 0.5-1.5 cm. This crushed stone is used in the production of asphalt, concrete and reinforced concrete structures. Fractions of crushed granite 2.0-4.0 cm, 2.0-6.5 cm, 2.5-6.0 cm, 4.0-7.0 cm the same are in the list of demanded ones, finding their use in repair and construction of tram lines, embankments for railways, "pillows" of autobahns, in the construction of buildings in the laying of foundations. Smaller fractions are also obtained from these fractions by crushing them. It should be noted that of all natural materials used in construction, crushed stone from granite is undoubtedly among the main ones.

Tamping accessories

1. Manual.

Made of metal, it weighs from 5 to 10 kg.It consists of a handle and a base ("paw") - a plate approximately 20 x 25 cm in size or a channel (the smaller the dimensions of this part of the device, the greater the impact force). The handle of the tool is straight (in the form of a tube) or T-shaped, with two handles on the sides. If necessary, the manual rammer with a channel can be made heavier by filling it with cement.

If there is a need to save money, then it is easy to make the device yourself. Two manufacturing options:

- Make a handle from a heavy wooden bar about 1 m long and nail a "paw" from a solid board to it from below.

- Buy a separate ready-made plate (it costs about 1000 rubles) and put it on a shovel handle or a metal stick.

2. Vibratory rammer.

For compaction of soil and bulk materials, including sand, in a confined space, use a "vibro-leg". The engine of this device runs on gasoline or diesel fuel. At the base of the apparatus there is a “heel” plate with a width of 15 to 30 cm and a length of about 33 cm. Vibratory rammers also differ in power. The principle of operation is based on vertically directed force, like a hand-held device, but the efficiency is much greater. This type of equipment is used on sites where operation of large-sized equipment is impossible: vibratory plates and vibratory rollers.

2.1. Vibratory plate.

For work on a large area, subject to the possibility of free movement, a rammer using a vibrating plate is suitable. This apparatus consists of a motor, a basket with or "shoe" and a guide handle. The unit moves back and forth, transmitting strong mechanical vibration (vibration) to the sand particles, due to which compaction occurs.

Types of equipment for soil and bulk materials with a slab base:

- gasoline;

- diesel;

- hydraulic;

- electrical;

- with remote control.

Vibratory plates vary in weight. The lightest are suitable for sand.

2.2. Vibratory roller.

For the largest volumes of work, vibratory rollers are used. Their types:

- with manual control due to the guiding handle;

- self-propelled with a cab for the operator single-drum (rear wheel-mounted);

- with two-drum cab;

- trench with remote control.

The device of a high-quality vibratory roller allows compaction along the edges of the site, that is, the use of additional equipment (manual or vibratory ramming) is not required.

Price

The price of the services of professional builders for compaction of sandy soil or sand bedding is from 90 to 600 rubles per m2. If the area that needs to be tamped is large, or we are talking about permanent work, then you need to compare these prices with the cost of equipment. In many cases, it is advisable to purchase a device or rent it and do it yourself.

Depending on the type of equipment, either a vertically directed force of impacts or vibration transmitted from the roller shaft or the base of the plate acts. In any case, the technology does not include any secrets and complexities.

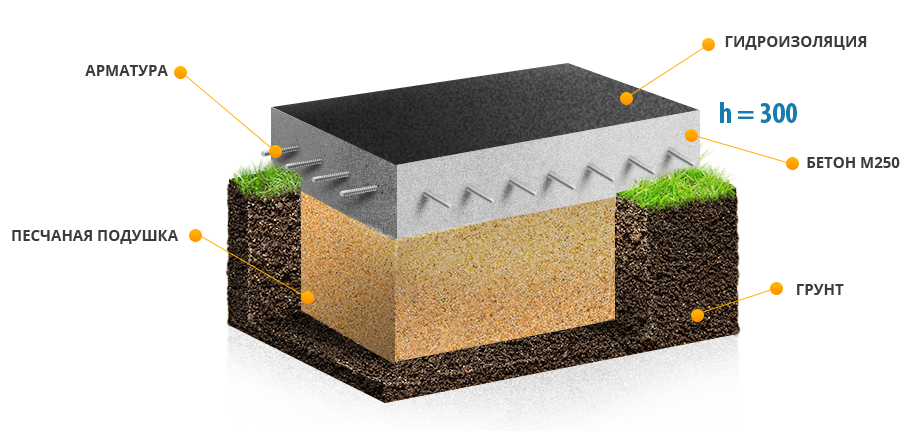

A foundation cushion is a layer of sand, gravel or crushed stone that is poured in before starting construction of the foundation. It is mainly used for the tape type, especially if the foundation is being erected on unstable ground. The most common and cheapest is considered to be a sand cushion, since this material is good at softening the load of a building on the soil, and its deposits can be found in almost any area.

Arrangement of a pillow and tamping sand under the foundation is used in the following cases:

- On problem ground. Erected on heaving, mobile soil or peat, the strip base warps quickly enough, which leads to its destruction. A sand cushion allows you to increase the strength of the soil, preserve the integrity of the foundation and its stability;

- For leveling the base.Sand poured in a thin layer helps to hide all the unevenness of the soil before pouring the foundation;

- To prevent shrinkage of buildings and structures. Due to its qualities, the compacted sand is not subject to compression and stretching;

- To prevent the negative effects of moisture on the foundation. Since the sand cushion prevents water from contacting the substrate, its lifespan is greatly increased.