Create brick cladding

Before proceeding with the laying of bricks, it is necessary to mark the location of the doors, windows and other architectural details. This is necessary in order to minimize material costs. Based on these measurements, lay out the first row of bricks.

Each brick, laid with a poke, must be pinned to the desired size, since during wall cladding in a half-brick, the masonry should be carried out no more than 8-10 cm.If the overhang is more than 6 cm, the cladding and the wall are connected with nails, the length of which is 100 mm. It happens that this length is not enough, then it can be increased using a steel wire with a diameter of 2 mm.

When using silicate bricks for cladding a house, the projection should not be more than 6 cm, especially when laying the cornice. It will be correct to cover the newly laid masonry with insulating material. This will protect the seams from washing out the mortar from them in case of rain.

To create a solution with which the laying will be carried out, the following proportions must be observed: cement - 1, lime paste - 1, sand - 4. To bring the mixture to normal, add water at the end of the batch. All ingredients must be added in the following sequence:

- Water.

- Lime.

- Cement.

- Sand.

Having made the first batch, gradually adding water, you can calculate how much is needed to create the desired consistency, and next time fill the entire volume with water at once.

If it is necessary to embroider the seams, then it is important to know that the surface of the mortar dries rather quickly. The correct seam should not be thicker than 13 cm

You can check the size with a ruler.

There should be lintels on the openings of the cladding, it is best if they are made of concrete, which ideally matches the color of the silicate brick. In the absence of concrete lintels, hidden ones can be built. For their creation, steel reinforcement with a diameter of 6-8 mm is most often used. The rods are inserted into each brick row under the opening right up to the eaves.

The gap that appears can be hidden by expanded clay or other heat-insulating material. Just do not put roofing material in the gap, which will interfere with the heating of the cladding in the cold season. Cladding work has its own characteristics and rules, so if you are not sure that you can do it yourself, it is best to contact the professionals who will do it quickly and qualitatively. At the same time, your home will be reliably protected from cold, rain and other natural whims.

Cladding works

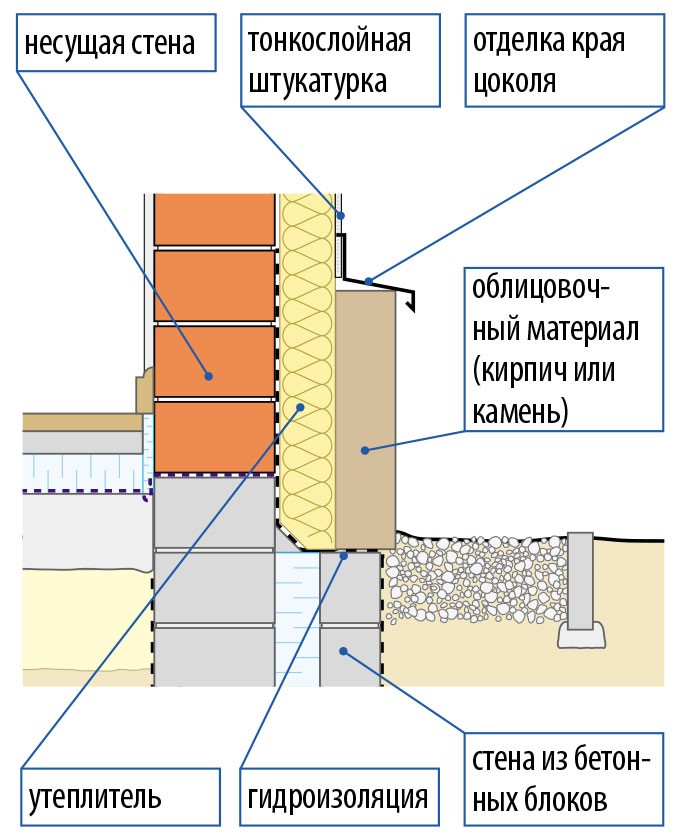

When finishing the basement, a gap of about 2-3 cm is left between the foundation and the brick for air ventilation. If necessary, fill the gap with insulation, but still leave room for ventilation to prevent moisture accumulation. In the lower (first) row of masonry, at a distance of 1 m from each other, it is recommended to leave an empty seam between the bricks. This is also done for thermoregulation.

You definitely need to worry about securing the basement of a brick house with a lining. This can be done in 2 ways:

- Using anchors. They are fixed in the supporting wall with one end, and the other is placed between the cladding masonry.

- With dowels and wire. The dowel is driven into the foundation, wrapped with wire, the other end of which is fixed in the masonry.

The connecting elements should be located at a distance of 50 to 70 cm from each other horizontally, and every 4 rows - vertically. In those places where openings are located, the bundles should be placed more tightly. All work is done using cement mortar: 1 part of cement grade 500 is taken to 4 parts of sand.Or a solution with the addition of lime: 1 part cement, 8 parts sand, 2 parts lime. Having finished laying out, we must not forget about the ebb, if the base is protruding. This will prevent moisture from entering between the wall and the finish, and as a result, will prevent the destruction of the foundation.

Preparing the base for cladding

To reduce costs and time, there is an acceptable tradeoff. The foundation body can be made of any material. Most often, a reinforced concrete monolith or block structure is made, but the cladding can be made of brick. For this purpose, manufacturers have long mastered and established the production of facing stones of various types, sizes and qualities.

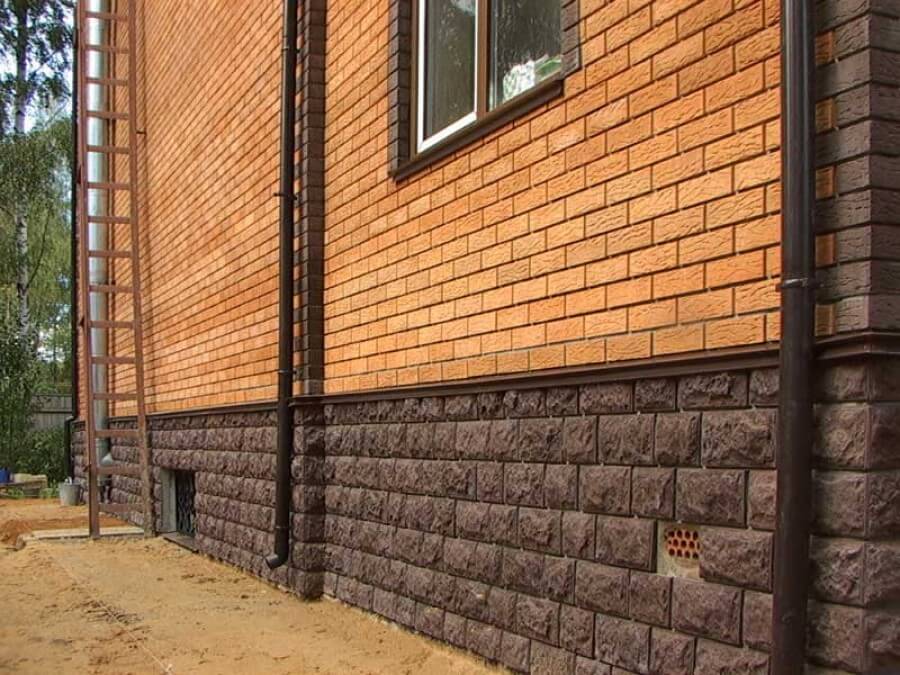

The base body can be made of any material, and the cladding can be made of decorative bricks

The base body can be made of any material, and the cladding can be made of decorative bricks

The decision to use these materials should be made at the level of foundation formation. This moment is very important, since it is not enough just to stick the stone cladding on the wall, it still needs on something lean on.

Of course, you can stuff a metal rail on the side of the foundation, but it will weaken the waterproofing and will collapse over time in wet conditions. Therefore, the surest way is to lay out a special ledge with your own hands.

When constructing the formwork for pouring the base of the house, it is necessary to correctly calculate the size of the supporting part for the cladding device. During the implementation of measures for waterproofing the foundation, the seat for the cladding cannot be missed. It must also be carefully insulated.

This process is needed both for the decoration itself and for the entire building, since it will best protect the entire structure from moisture penetration. By the way, such works are available for do-it-yourself work. Typically, vertical surfaces are waterproofed with bitumen-based mastics.

Cladding technology

The technology of forming the cladding is a little

differs and depends on the building in which it is created - in a new one or in

operated. It is worth considering each of them in more detail.

When building a new structure

The foundation is laid over the entire thickness of the wall under construction, i.e. for brick and gas block. Basement waterproofing is also done for the entire wall. Then you can start laying the walls. What to put in the first place, decide for yourself: brick, gas block, or all at the same time. But brickwork has a large number of joints in height, but you need to understand that they are noticeably thicker, but blocks can generally be laid on glue. This is how the shrinkage difference arises, but it is not significant if it is not about structures with many floors.

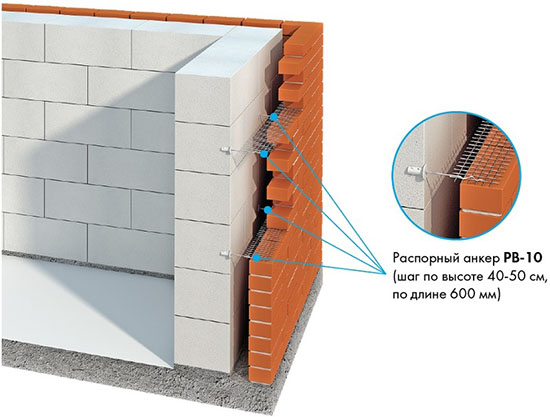

Fastening of aerated concrete and bricks when facing a new building

Fastening of facing bricks to aerated concrete is done using conventional reinforcement. You can make it yourself from a bar or wire of the required diameter. In addition, steel tape is suitable for these purposes.

But in any case, you need to pay attention to the following points:

- The sum of the values of the cross-sectional areas of the reinforcement is not more than

half a square centimeter per square meter of new masonry. - The number of reinforcement products per square meter is 3-5 pieces.

- Near corners or openings at a distance of 20-25 cm, you need to do more

row, the step of which is 25-30 cm.

Instead of connections, you can take factory products,

which at the same time provide for the fastening of the insulation.

When establishing connections, you need to ensure

high-quality anchoring - that is, they are supposed to be immersed in the solution, alternating it, approximately,

at a distance of 10 diameters.

Cladding of external walls of an operating building

In such a situation, you need to build another

foundation for masonry. It doesn't matter which type is chosen, the main thing is that it cope

with additional load, i.e. withstood walls, ceilings, roofs, etc.,

which the foundation already holds.

When forming such a cladding, ties

fixed on the dowels.It is better to make through holes in the wall and mount

rods with washers from the inside. The rods can be mounted in blind holes.

Try not to fill in the standard solution, for this case, glue on

epoxy base.

Self-anchoring bolts are suitable for fastening,

because they are fastened in blocks almost instantly and with sufficient quality

from aerated concrete and the seams located between them.

Types and characteristics

The decorative facing brick, which can be used to decorate the basement of the house, is presented in four versions. Depending on the raw materials used and the manufacturing characteristics, it can be:

- ceramic;

- clinker;

- hyper-pressed;

- silicate.

Each species has certain properties and has its own advantages and disadvantages.

Ceramic

Ceramic brick

Ceramic brick

It is produced by firing a mixture of clay with a pigment that gives the material a particular shade. Ceramic bricks for facing the foundation of a house can be either solid or contain voids. Due to the lower weight, products of the second type can reduce the load on the supporting structures of the building.

For ceramic bricks, the following is characteristic:

- resistance to fire and low temperatures;

- strength;

- the ability to maintain their parameters for a long time;

- low coefficient of thermal conductivity;

- environmental Safety.

Among the shortcomings of the material, one can single out the high cost and the tendency to form a whitish coating on the surface, which reduces the attractiveness of the building from the outside.

Hyperpressed

It can be obtained from crushed limestone with the addition of cement and dye by high pressure pressing. Brick of this type is not subject to firing, but is not inferior in strength to clinker and ceramic counterparts. It is resistant to low temperatures and can be easily machined, and the low thermal efficiency is compensated for by insulation. Thanks to an interesting texture reminiscent of natural stone, finishing the foundation with hyper-pressed bricks allows you to embody any design ideas for decorating a house.

Clinker

Clinker brick is beautiful and reliable at the same time

Clinker brick is beautiful and reliable at the same time

It is a modified version of ordinary brick, which is made from a special type of clay by processing at a high temperature. As a result, a material of increased strength with a dense structure is obtained.

It absorbs a minimum amount of water, withstands heavy use and is used as a base / plinth finish, as well as for paving paths and framing window and door openings. The main disadvantage of clinker is its high thermal conductivity.

The use of silicate bricks is impractical, since, along with low cost, it is characterized by increased moisture absorption and poor resistance to low temperatures.

Ways to expand the foundations

Each type of foundation has its own ways of expanding. But they all have a common approach - there must be a rigid connection between the old and the new base using metal anchors and embedded elements.

Expansion of the slab foundation

To "top up" the foundation for facing a house with a brick, which stands on a slab, there is only one way of increment - driving anchors along the end of the slab.

Although there is a "classic" method, when concrete is broken along the perimeter of the base, choosing a "quarter" of 20-30 cm in size. In this way, the reinforcement is exposed in order to weld a new frame to it. But in this case it is not suitable.

The technology for expanding the slab with anchors looks like this:

- At the end of the slab, markings are made for anchors in two or three levels - it depends on the number of meshes of the reinforcing cage. To prevent the anchors from falling into the reinforcement, they make indents from the upper, lower and side edges by an amount slightly larger than the protective layer of concrete - about 6-7 cm.The distance between the anchors depends on the thickness of the bar and the size of the cells of the slab's reinforcing cage. In low-rise construction, with a rod thickness of 12 mm, a cell size of 200 mm is usually made, the same is done for an anchor layout.

- According to the marking, holes are drilled with a length equal to 35 diameters of the reinforcing bar (for 12 mm - at least 400 mm). The diameter of the drill should be 2-4 mm larger than the diameter of the bar. It is necessary to drill at a slight slope to the horizon and in different directions - in this form, the anchors are better wedged under load.

- The rods are cut to the required size - the length of the anchoring plus the width of the foundation ledge for facing the house with bricks.

- Holes are cleaned of crumbs and dust - they are cleaned with a metal brush and blown out with a compressor.

- The holes are filled with a solution based on polymer-cement compositions or epoxy resins (chemical anchoring).

- Bars are inserted, to which the new reinforcing cage will be attached in the future.

Expansion of the strip foundation

The monolithic strip foundation is expanded using the same technology as the slab. But if two or three rows of anchors are enough for a shallow foundation, there will be more of them for a deep foundation.

The prefabricated strip foundation of blocks or rubble stone is also expanded by pouring a monolithic strip around the perimeter of the house. Prefabricated foundations have a shorter service life and withstand lower loads, so this method of expansion allows you to strengthen the foundation and improve its bearing capacity. A monolithic tape around the perimeter is akin to a reinforced concrete cage, with the help of which old foundations are reinforced.

Expansion of the pile foundation grillage

If a brick house stands on piles, then the solution to the problem of how to brick the house with a brick, if there is no place on the foundation, can be done in two ways:

- Additionally, equip a bored pile foundation around the perimeter, and rigidly tie the grillages together. Steel beams - with welded rolled ties. Drill holes in reinforced concrete beams, install embedded elements (reinforcement outlets, dowels, anchors) and weld together.

- Reinforce each support and expand the existing grillage.

The second method is suitable only for a shallow bored pile foundation, and it is akin to the method of strengthening the pile foundation with a reinforced concrete clip:

- for the duration of the work, a jack is installed near the pile, which must take the load;

- around the pile, soil is taken out of greater depth than the heel of the pillar (by the thickness of the crushed stone-sand preparation);

- in the section, the pit must have a margin of at least 40 cm than the corresponding pile size;

- a layer of rubble and sand is poured onto the bottom;

- the support is drilled in several places;

- an anchor is inserted and jammed into the holes;

- install the formwork;

- mount the reinforcing cage, tie it to the outlets of the anchors;

- concrete is poured and compacted.

The order of work

In order for the work to take place as soon as possible, you should calculate and prepare consumables, prepare access roads, clear the working area and prepare tools.

Materials and tools

The set of tools and materials needed to expand the foundation are practically no different from those that are needed when carrying out standard concrete work to fill the main foundation. You should prepare:

- shovels (bayonet and pick-up), trowel;

- measuring instruments (tape measure, level, water level) and marking devices (pegs, construction cord);

- electrical tools (grinder and hammer drill);

- ax, hammer, hacksaw for wood;

- cement, sand, crushed stone, rebar, formwork boards, knitting wire.

Foundation making

The place for the additional foundation is thoroughly cleaned, the formwork, if any, is dismantled, only the cleaned soil is left, marking is carried out.20 cm is added to the width of the future additional foundation - this will provide space for formwork and simplify the work in the trench. With the help of pegs and a cord, the building is striped, focusing on the width.

A trench is dug to a depth of 0.5 m, this should be done carefully, trying not to "wound" the soil at a given depth, since the loosened earth, even carefully compacted, subsequently gives rise to a draft.

In the old foundation, at a distance of 10 - 15 cm from the upper border, holes for reinforcement are drilled with a puncher. The pitch between the holes is 50 cm, the depth is 15 - 20 cm, the diameter corresponds to the reinforcement (10 -12 mm). The reinforcement is cut into lengths of 30 - 35 cm and hammered into the holes, leaving 15 cm outside. This reinforcement will serve as a kind of anchorage, providing a rigid adhesion of the old and new foundations. After that, the trench is cleared of crumbling earth, a sand cushion is poured onto the bottom, which is spilled and rammed.

Reinforcement cage preparation

Reinforcement cage preparation

The formwork is made of jointed boards and installed at a predetermined distance (30 cm), securing it with struts. Then they begin to reinforce the future foundation. You can knit reinforcement directly into the trench, but given its small width, it is wiser to prepare sections of the reinforcement cage at the top, and then fix them in the trench.

After that, you can start pouring concrete, which is better to order at a specialized enterprise.

After 2 - 4 weeks, when the concrete has completely set, the formwork is dismantled. Then the foundation is protected with waterproofing, the remaining ditch is filled with earth, after which you can begin to veneer the house.

Fill the foundation

When all the measurements have already been made, then you can proceed to how to fill the foundation itself. To make it durable, the sequence of actions should be as follows:

The foundation is made of bricks on a concrete strip base.

- First you need to make the formwork and install it in the right places. You can use planed boards. It is necessary to calculate the level of the foundation, and the formwork itself should be located about 30 cm higher. Check that the boards are wet. If this is not possible, then it is recommended to use a polyethylene film. The edges need to be secured on the outside.

- Next, you should prepare the fittings. It must be laid in the very foundation. The metal pins should be installed about 4 cm from the base of the building. This distance should be also to the formwork. It is necessary to make a distance of 60 cm between the reinforcement bars. It is recommended to tie the rods together. This will increase the strength of the frame.

- Now you need to start preparing the concrete. With this solution, the formwork is poured. Experts do not recommend filling the entire depth with the solution at once. This is required to be done in several passes - 2-3.

- The layer should be approximately 20 cm thick. After each layer, you need to wait 2 days. If this procedure takes place in rather hot weather, then the layer must be covered with an additional pillow. This will work as a waterproofing so that moisture in the concrete will be retained and the setting will be much more effective.

- You also need to think about the communications that will be displayed through the foundation layer. For example, sewer and water pipes may come out. Experts advise against wiring such structures directly into a concrete wall. It is better to make a special belt for them, or to wrap certain areas on the pipe with a film, so that in the process of pouring the foundation itself, they do not violate their integrity.

There are times when the house, which is planned to be faced with bricks, does not have a foundation. Then it is required to arrange the base on which the finishing will be carried out.

After such preparatory work, you can start the process of facing the walls with bricks.

Facing the basement level with bricks

Facing the basement with bricks is an excellent solution if the building is built from a similar material. So it acquires integrity and solidity. For work, decorative or red fired bricks can be used. It is not recommended to use silicate products due to their insufficient resistance to moisture and unpresentable appearance.

The scheme for finishing the basement with brick or stone.

Clay brick for a plinth itself is an excellent insulation material. It can be fixed directly to the foundation or by building a wall next to it to create a ventilation opening.

The gap is filled with insulation or left empty, since air is an excellent heat insulator. The finished design looks very nice and solid. It does not need any care or maintenance. But finishing the basement with bricks creates an additional load on the building structure. Such a solution should be envisaged even at the design stage.

Since brickwork cannot simply hang on a plinth, proceed as follows:

- A separate strip foundation is made for brickwork in close proximity to the existing one. It is possible to foresee a small ledge on the foundation even at the design and pouring stage. This will significantly save time and effort when carrying out finishing work.

- Bricks are glued to the plinth using temporary supports made of timber or cement blocks. The supports are removed immediately before the installation of the blind area. It is made from asphalt or concrete. After hardening, the blind area takes on part of the weight of the brick cladding.

It is somewhat easier to work with decorative material. The facing brick is lightweight, which does not significantly affect the structure. In addition, there is a huge variety of models of this material.

Today, you can buy facing tiles in the form of individual strips or in the form of basement panels that imitate part of the brickwork. Lightweight materials based on polystyrene or polyurethane foam are used as the basis for facing tiles. It is fixed to the foundation with polymer glue, which creates an excellent protective layer for concrete.

Plinth trim panels

Siding has a number of advantages that must be used during construction. As a rule, the panels are mounted on a steel or timber frame, which creates additional volume. It is advisable to fill the empty space between panels and concrete with insulation. For this, foam or basalt wool is used.

Decorative siding is made from metal, polyvinyl chloride, cement-based mixtures and composite materials. The front layer of the panels can be imitation of stone, natural wood or colored fabric. The resulting surface is characterized by sufficient strength and presentable appearance. The brick building takes on a whole new style with siding trim.

The scheme of finishing the basement with panels.

The sequence of cladding with panels is as follows:

- Marking. For this, a tape measure, a level and a marker are used. The size of the frame mesh should be adapted to the parameters of the insulation material.

- Drilling holes in concrete. Installation of plastic dowels in them. A punch and hammer are used.

- Assembling the frame. This will require a screwdriver, hammer, level and steel profile. It is impractical to use a tree, since it has a limited service life.

- Insulation installation. The best option is to stick it to concrete. To increase the reliability of fastening the insulation, anchor bolts with wide heads are used.

- Docking panels. This is quite simple to do, since all siding models have a system for fixing parts to each other.

You can cover the base / plinth with panels in just 1 working day. This construction is lightweight and does not weigh down the foundation at all.

Why is it important to trim the base

It is wrong to think that

this kind of finish is just a design decision. She performs some

other functions:

- Despite the fact that the foundation is the strongest part of the house, it also needs protection from external factors. Finishing minimizes the influence of precipitation, sudden changes in temperature and high humidity, direct rays of the sun;

- Since the foundation is closest to the ground level, it is most susceptible to pollution, and not only dust and soil residues, which are harmless, but also various aggressive substances that cause the destruction of concrete joints. The plinth finish not only prevents this process, but also cleans well;

- This material also protects the base from biological life forms: mosses, fungus, mold;

- The basement finish should also include insulation under the outer layer of the material;

Insulation of the foundation is

an important point. On the one hand, the entire internal space of the building is located

above, and it does not need to be insulated. But this is not the case. The foundation is a kind

cold accumulator. Even a well-insulated floor will not prevent penetration

low temperature from the side of the foundation. A significant part of the heating

spend money just like that. But this is not the worst thing. In winter, because of the strong

freezing the foundation collapses regardless of the material, whether it is stone,

concrete or brick.

Markup

Wall marking with water level

Wall marking with water level

Brickworking skills are pretty simple. The more thoroughly the preparation for the process goes, the better the result will be. You will have to do several stages of marking and verification.

The first stage includes checking the perimeter and levels. A simple tool is required:

- Hydro level, tube with flasks, 10-20 meters long, filled with water. Before use in the work area, it must be in a filled state for at least 12 hours.

- Rule 2.5 meters in length, measure individual areas of the bed (masonry sites).

- Roulette, marker, pencil.

- Construction cord, fishing line. Consider line slack in hot weather.

- A hammer drill with a drill and dowels come in handy when pulling ordinary cords.

Second step, check the right angles. You can check the angle using a construction square or the "Egyptian triangle" method. On one cord with a marker, mark 3 meters, on the perpendicular 4 meters, the distance from point to point should be exactly 5 m. We make adjustments before starting the first and main row.