Depth views

Frost heaving is the force that is taken into account in the first place when designing a columnar foundation.

Frost heaving is the force that is taken into account in the first place when designing a columnar foundation.

This is a very dangerous pressure that, if laid incorrectly, can rupture the foundation of the house.

Therefore, a large number of options for the construction of buildings are considered from the point of view of the impact on the foundation structure of frost heaving.

The basic design rule is that the foundation should be laid below the freezing depth of the soil by 30 - 50 cm.And if this indicator is, for example, 1.2 m, then the depth of the laying will be equal to 1.5 - 1.8 m.

But often a light structure cannot exert such pressure on the support racks to contain the forces of frost heaving. That is, even when laying to a great depth, the foundation will be subject to deformation. Therefore, when building a columnar foundation with your own hands, it must be borne in mind that there are two more positions: shallow and superficial.

Not buried

Shallow columnar or surface foundations are all the same racks, only their depth does not exceed 30 - 40 cm. Often they are simply built on the surface of the ground, having previously made a pillow and waterproofing. Designers attribute this variety to those foundations, the depth of which does not exceed a third of the level of soil freezing. From our example: 120: 3 = 40 cm.

The device of a columnar foundation of this type belongs to the category of the cheapest and fastest-built structures. As practice shows, they usually use block modification using blocks, stones or bricks. But since the height of the pillars is not very large, which means that their bearing capacity is also low, therefore it is recommended to increase the cross-sectional area of the supports. The minimum size is 40 x 40 cm.

Shallow

The shallow foundation from its name suggests that it goes deep into the ground, but not to a great depth. In any case, not below the level of its freezing. Designers lead the depth of their laying at the rate of 0.5 - 0.7 of the depth of freezing of the earth. Again, from our example: 120 x 0.5 = 60 cm. The main requirement for this design is not to touch groundwater.

With grillage

The node of the columnar foundation - the grillage carries one single task - to distribute the load from the house to all the pillars evenly. As mentioned above, the grillage can be built of concrete, metal (channel or I-beam), wood (timber with a section of 150 x 200 or 200 x 200 mm) or be a log of the first crown of a log house.

How to prepare for work

Prefabricated columnar foundation includes:

- Sand pillow, concrete monolith M100, up to 10 cm.

- Concrete base for pillar foundations, reinforced according to individual project requirements.

- Formwork or grillage.

- Brick or concrete base aligned horizontally.

But, before starting work on the arrangement, it is important to prepare the surface. To do this, the dimensions of the project are taken out on the plane.

Despite the fact that we do not have a monolith and not even a strip foundation, the foundations of construction still remain the same. This means that the diagonals of our base, if it is rectangular, must be equal.

Answering the question of how to dig a hole under a columnar foundation, it is worth noting two ways. This is either manually using a shovel, or using a motor drill using a nozzle of the appropriate diameter. Before drilling, you need to beat off the centers of all holes by pulling the threads and at the point of their intersection, installing pegs.

Thanks to the information received, pouring a columnar foundation will no longer seem so difficult. The main thing is to correctly mark, buy high-quality concrete M200-M300, take into account the freezing of the soil and carry out the construction work in accordance with the design requirements. This is the only way you will get a foundation that will be cheaper, but in quality it will be no worse than a tape one.

Formwork for strip and column foundations

There are many options for construction technology. One of them is the instruction we offer on how to make the formwork:

First you need to determine the size of the trench. On them, shields are hammered, for example, from edged boards. The same boards or slats are used as vertical racks. The length of the shields should be no more than 3-4 m. It is recommended to use nails for fastening.

Shields are brought into the pit and props are installed on both sides with a pitch of 50-70 mm. The lower part is fixed with pegs or spacers. The pegs are driven into the trench in the corner zones. A string stretches between them at a greater height in comparison with the ground section of the foundation.

Stakes should be driven into the bottom under the level. You can also drive in under a plumb line. In this case, the risk of horizontal movement should be excluded. Shields are placed in a row and attached for temporary fixation to vertically standing pegs. Then the shields of the second row are installed.

According to the required width, both rows of panels are connected by rails in the upper part of the structure. The gaps between the slats are up to 50 cm. With a higher above-ground part of the foundation (over 50 cm), the boards are fastened with a wire in two steps, which must be fixed to the cross-beams of the vertical placement.

Supports for shields are placed in series. From below they are fixed with pegs, and from below - by a wooden stop nailed to the shield. To equip ventilation ducts and holes in the foundation, plastic pipe cuttings are inserted on top of the formwork structure.

After construction, it is necessary to check the structure and make corrections. As a result, it is necessary to obtain a system of panels, as can be seen in the photo of the formwork for the foundation.

Features of filling

If panel formwork is installed, it is recommended to apply the concrete solution with a concrete pump. But since renting special equipment seems to be an expensive pleasure to many, such work is done manually. The mortar will have to be fed into the pipe formwork through a special funnel made of scrap sheet materials.

The concrete is laid in layers, and compaction is performed every forty to sixty centimeters. The correctness of the work will be confirmed by the appearance of cement milk, the rapid closure of the trail from the extracted funnel tip, and the absence of air bubbles.

Do-it-yourself technology for making formwork from roofing material for a columnar foundation

Before making the formwork for a columnar foundation with your own hands, you should discuss the technology in detail with an experienced architect and builder. Each object has its own characteristics, which impose restrictions on the production of work and make their own adjustments. The popular version of the foundation requires a careful approach to the preparatory work.

Formwork made of roofing material for a columnar foundation has a low cost and at the same time provides high reliability and strength of the structure.

Before starting work, you need to decide exactly what to make the formwork for the columnar foundation. If a decision is made to use roofing material, then the order of work is as follows.

Preparation of materials. At this stage, it is necessary to choose a durable and whole sheet of roofing material. The length should be about 2 meters, because about 25% of the roll will end up underground. After that, the sheet is rolled up to a diameter of 200 mm. When unwinding, the thickness should be at least 2 sheets of roofing material.Wire is used to fasten the roll.

The lower part of the twisted roofing material is closed with an insulation bag. Thus, the roll is protected from the penetration of water from the pit or pit. Also, the bag serves as a separation between mortar and earth.

If the structure being erected provides for an expansion in the lower part of the trunk, then it is necessary to prepare 4 reinforcement bars with a length of about 2.5 meters. For correct and accurate reinforcement, bend the bottom edge of the bar at a right angle.

The diameter of the intended expansion should be taken into account to determine the size of the edge fold. After that, each rod, which has been prepared accordingly, is sewn into a combined frame for concreting. In this case, tying wires must be used because welding is not permitted. The strength of the knitting should be moderate so that when the frame is installed in the roofing material, its configuration can be corrected.

The resulting reinforced frame is lowered into a roofing felt roll to the very bottom so that it rests against the base. The concrete mix is poured in several stages to obtain an optimal and lasting result.

First, the heel of the support is formed. For this, a small amount of concrete is poured into the pile shaft. It is necessary to pour the mixture slowly so as not to damage the roofing material and not to displace the location of the formwork trunk.

After the first stage of pouring is completed, you need to slightly raise the roofing material. Thus, the solution will fill the base of the column and create a reliable stop for subsequent work.

The roofing material pipe is lowered down. After that, the reinforcing frame is gradually lowered into place and fixed

It is important to achieve the specified shrinkage depth of the reinforcement into the concrete mix.

Next, pour the base and wait for the allotted time for the mixture to harden. After that, you can proceed to the next stage of construction.

An important parameter when creating a columnar foundation is the correct adherence to technology. Features begin with the site preparation stage. Builders need to make an accurate breakdown of the projected foundation on the building site. After that, holes of the required dimensions are dug at the indicated points.

At the bottom of the pit, tamped pillows are arranged with a capacity of 150 mm. The materials are crushed stone and gravel.

Roofing material is often used for waterproofing concrete. The formwork assembled with its use will automatically be reliably protected from moisture.

Do-it-yourself formwork for a columnar foundation made in accordance with all the rules is able to guarantee the strength of the structure and its durability. At the same time, builders reduce the financial costs of construction and speed up the process of erecting the foundation.

A columnar foundation made of roofing material may be an unexpected solution, but in practice this option is an excellent solution for organizing construction. Removable formwork for a columnar foundation allows you to reduce the cost of building the base of the house, while ensuring the strength and durability of the structure.

What is formwork for?

It is impossible to pour concrete without installing the formwork, if you carry out the work yourself, you will have to figure out the issue. Decide what size should be, prepare everything you need. The design has the following features:

- Sets the shape of the future foundation. Do it only if you have a project with all sizes on hand. The parameters depend on the type of soil on which the building is placed, as well as the weight, the heavier the structure, the stronger the foundation must be.

- Collected from different materials. Private developers mainly use wood, but if you have durable plywood on hand, you can use it. It is allowed to put chipboards, plastic boards or metal structures.

- Can be collapsible or non-collapsible.In the first case, you first need to build a structure according to the specified dimensions, and after the concrete has hardened, carefully remove it. In the second, special elements made of expanded polystyrene are used, which give shape, plus they provide insulation.

- Designed for heavy loads. If you assemble shields from a thin or fragile board, then under the weight of the concrete, the surface will swell or the elements will simply break, and the solution will flow out. Therefore, they take only reliable lumber, plus they are additionally reinforced with braces and thrust elements.

- Should not pass the solution at the joints. Due to leaks, the appearance deteriorates, as well as the strength of the concrete, as it dries unevenly. If the boards do not fit tightly, it is better to cover the surface from the inside with construction plastic wrap.

The easiest way to make a structure is from a board with a thickness of 25 mm or more. Usually, about 20% of the funds spent on the foundation are spent on formwork, it should be well calculated how much lumber is needed in order to reduce costs. Strengthen better, it will not hurt, but it will eliminate problems during pouring.

Varieties of construction

Depending on the features of the constructive solution, you can build a removable and non-removable formwork with your own hands.

The structure of the first type is disassembled after the concrete has frozen and acquired a level of strength above the critical - from 50%. In the future, it is used to build a foundation on a new site. Taking into account the materials used, such formwork can withstand up to 4-8 fillings.

Non-removable formwork is an integral part of the foundation being built. She doesn't understand. The material can be used:

- blocks of extruded polystyrene foam, connected by locks and metal pins;

- concrete blocks with a hollow structure;

- wooden sheets, if they are not removed, for example, when building shallow foundations for baths.

Material classification

Like any foundation for a house, a columnar foundation must be strong and reliable. Therefore, for its construction, building materials are used that can provide the necessary strength and reliability. These include concrete, concrete blocks, bricks, stone, metal and some types of wood, which are used in the form of logs or beams installed vertically.

The choice of material is actually a crucial moment, on which the quality of the final result depends. And if the task is to build a columnar foundation with your own hands, then you need to choose the right material for its construction. For example, it is believed that it is better to erect monolithic structures on water-unsaturated soils, and prefabricated prefabricated ones on damp ones.

Monolithic reinforced concrete pillars

This is the most durable and reliable design. Such a foundation for pillars has high tensile and compressive strength. Of course, if you take into account the correct reinforcement.

Moreover, if you correctly distribute the racks around the entire perimeter of the house, taking into account the required cross-section of the supports, then multi-storey buildings can be erected on such a foundation.

We add that a columnar reinforced concrete foundation is constructed in cases where it is necessary to fill it to a sufficient depth, and more often below the level of soil freezing. It perfectly withstands soil swelling, but is afraid of contact with groundwater. Therefore, it is necessary to take care of the waterproofing of the supports.

Asbestos-cement pillars

Asbestos-cement pipes for the construction of foundation pillars are not often used.

Their bearing capacity is not high, but it is not required either, because the pipes in the foundation structure perform the functions of formwork.

For light structures, it is recommended to use pipes with a diameter of up to 150 mm. For heavy buildings not less than 250 mm.

Plastic pipe poles

Here the situation is the same as with asbestos-cement. That is, plastic pipes act as formwork.They do not corrode, do not deteriorate under the influence of water, so they do not need waterproofing. The only thing is that it is necessary to properly fill the support under the foundation. Namely: install a reinforcing frame in them and pour concrete mortar.

Of bricks or blocks

Until now, brick pillars stand under huge buildings, and, as you can see, they will stand for more than one century.

Because the attitude towards the choice of bricks in those ancient times was serious. Burnt bricks of the highest quality were necessarily used. Therefore, when building a house on a columnar foundation, this requirement must be taken into account.

As for the block pillars, they are not inferior in strength to brick ones, of course, depending on the material from which the blocks are made. It is better to give preference to concrete blocks, a cinder block in this regard cannot bear heavy loads, although they are used for light buildings such as a veranda, a bathhouse, and so on.

Block structures include pillars built of stone. Not a bad option, strong enough, but such supports cannot withstand the exploits of the soil. Therefore, when a house is being built on a slope, it is better to refuse stone racks. As a replacement for them - foundations from rubble concrete. This is when stones are poured into the prepared formwork, and then they are poured with concrete mortar.

Wooden pillars

Such a columnar foundation, like a brick one, has been used in Russia for a long time.

Today it is not so in demand, but, for example, for baths installed by a river or lake, they are often found.

We must pay tribute to the correct choice of wood. The stronger it is, the longer the service life of the poles. In this case, it is necessary to very carefully carry out protective measures.

- Treatment of the entire column with antiseptic compounds.

- Treatment of the part deepened into the ground with bituminous mastics with gluing a layer or two roofing material.

Doing all this yourself is not a problem. The main thing is not only to make protection, but also to install wooden supports under the posts. They are made of a board with a thickness of at least 50 mm and a width over the entire area twice as large as the cross-section of the column. The supporting boards must also be protected from moisture and the negative effects of the soil.

Basically, wooden posts are used for light structures, although a hundred years ago boyar mansions were built on them several floors.

Important notes

The work should be done reliably, it is impossible to save on strength, since if the formwork breaks or deforms, a lot of additional work will have to be done. And sometimes it is necessary to fill the foundation again. Remember simple guidelines:

- If the dimensions are large, install the structure in parts. Limit in length, in this case the ends are closed, but the bars of the reinforcing belt should stick out on both sides by at least 50 cm, so that after pouring the new part, the structure is firmly connected. If the base is high, it is poured in layers, rearranging the formwork higher and higher.

- Strengthen as best you can. If the boards or plywood begin to bend, move the mortar with a shovel, quickly push the surface into place and put a couple of braces. Sometimes the next day it is found that the bearing part has moved, in this case it cannot be touched, only after removing the elements, level the surface with a puncher or a gas cutter.

- If one side falls, then the work will have to be redone. First, fill in the rest, and leave this, then make it securely.

To make it easier to separate the boards after the concrete has dried, it is not necessary to cover the surface with a film. Regular painting will also make it easier to remove, apply it in 2-3 coats to saturate the wood.

You can make a formwork for the foundation with your own hands from different materials, first choose the best option for construction, then figure out the features of each of them. Assemble in parts, connect with nails or self-tapping screws, level, secure with jumpers, braces, and also threaded rods.

Varieties of columnar foundation

The main principle by which a columnar foundation is selected is the low weight of the building object. Therefore, on a columnar basis, houses made of wood, baths, gazebos, structures from SIP panels are often placed. Depending on the developer's budget, on the loading capacity of the foundation, on the type of soil, general preferences and aesthetics, the columnar foundation is divided into the following types:

- Reinforced concrete pillars. This option is the most common. It requires the use of formwork to raise the future home to the desired height. The resulting monolith has high strength, is resistant to soil heaving and can withstand the loads of even two-story wooden houses.

- Brick-monolithic option. This variety has been used for a long time, which proves the durability of the chosen base. The columnar foundation, the dimensions of which must correspond to the design documentation, is a monolithic foundation, poured with concrete M200-M300 at ground level. Next, the base is laid out from ordinary red brick, leveling the plane for the future house. Brick is often changed to a block. It is more convenient and faster to work with it.

- The base is in the form of piles. Metal piles, which are screwed into the ground, act as reference points here. The depth of the columnar foundation can be different, since the piles can be docked.

When choosing an asbestos pipe as a formwork, keep an eye on its diameter. For example, a diameter of 150 mm is suitable for gazebos and utility trailers. Option 250 - 400 mm is suitable for single-storey houses.

The process of building a columnar-strip foundation

This process consists of two main stages:

Create a support structure from pillars.

The first step is to choose the right foundation depth. This must be done taking into account the structure of the soil, the degree of freezing of the earth and the depth of the groundwater. As the immersion proceeds, the foundation is divided into two types: shallow and buried. The deepened columnar-strip foundation is immersed approximately half a meter below the freezing level of the soil.

It is necessary to pay attention to the fact that the poles must be installed at a distance of one to two meters from each other. A greater distance can lead to the structure being not very strong.

The installation of foundation supports must be started from the preparatory stage, which consists in preparing the site for construction. The first step is to remove the excess soil layer, making the area even. If the soil at the construction site is clayey, then you need to remove most of it and fill the area with sand.

Then we mark our place for construction. To do this, you need to use a special thread used in construction. We stretch it in the form of two non-intersecting strips, the distance between which is equal to the thickness of our strip foundation.

Do not forget to keep an eye on the angle of intersection of the threads, it should be equal to 90⁰. Also, do not forget to mark the intersection of the wall surfaces and the corners of the building.

The next step is to dig trenches in the places where the strip structure of our foundation is located. The depth of the trenches should be approximately 40 cm, and the width should be made in such a way that there is still about 10 cm left for the placement of the formwork.

Next, we drill holes with a hand drill at the locations of the support structures. We pre-fill the wells with 8-10 cm of river sand.

We use a concrete mixture to install the pillars, but do not forget about creating a waterproofing layer. For him, using a roofing material twisted in a couple of layers, we make a pipe. We connect it with tape and insert this structure into the ground until it stops.

Before making a columnar-strip foundation, you need to take care of creating a frame from reinforcement and wire, and then insert it into the drilled hole so that the reinforcement protrudes outward by about 15-20 cm.

Next, let's start pouring the resulting support with concrete. To begin with, we fill in a layer of concrete mixture with a thickness of about 20 cm into the well. Then we lift the pipe made of roofing material to allow the mixture to form a sole. The next step is to fill the well completely and leave the concrete to dry.

Creation of the strip part of the foundation.

First of all, we knit the reinforcing frame again.Then we weld it and attach it to the reinforcement sticking out of the concrete pillars.

Having completed all the above described stages of the construction of the columnar-strip foundation, we will be engaged in the installation of the formwork, which is part of the strip foundation. To do this, take several boards, the width of which is 10 cm, and knock down the formwork from them. Then we lay waterproofing inside the formwork, which can be a polyethylene film.

After carrying out these manipulations, we will fill the formwork with concrete. You can do it manually, or you can use a special mixer machine. It will be possible to remove the formwork after three weeks, when the concrete is solid.

After the concrete has hardened, a coating layer of waterproofing must be applied to the foundation. You need to process the side parts of the tape structure. For this purpose, heated bitumen can be used. It is best to do this procedure a couple of times.

It is better to remove the sand poured under the tape element, since otherwise the structure will stand on an unburied structure. This should result in a trench about two centimeters deep. After the concrete is poured, the mixture that has entered this trench will create a ledge that will help secure the structure in place.

Columnar foundation - features and varieties

The formwork of a columnar foundation is determined by the specific type of foundation, because the supports can be erected in various ways:

A kind of columnar foundation

Wooden columnar foundation. This type of construction is an outdated method, although it is now often used for the construction of temporary and utility structures. It has a short service life and reduced strength, and is also susceptible to destruction under the influence of external factors.

Brick type. It uses bricks that have undergone heat treatment. The cross-sectional diameter of the pillars to be installed must be at least 400 mm.

Reinforced concrete piles. In this type of foundation, the diameter of the piles can vary widely. Simple and affordable in production

An important component is the choice of material and type of formwork. For example, you can use several layers of dense roofing material, which are tied with wire, and the cavity inside is reinforced with reinforcement.

Metal (or asbestos) pipe

This type of foundation uses a permanent formwork, which is concreted and secured for the entire duration of the building's operation.

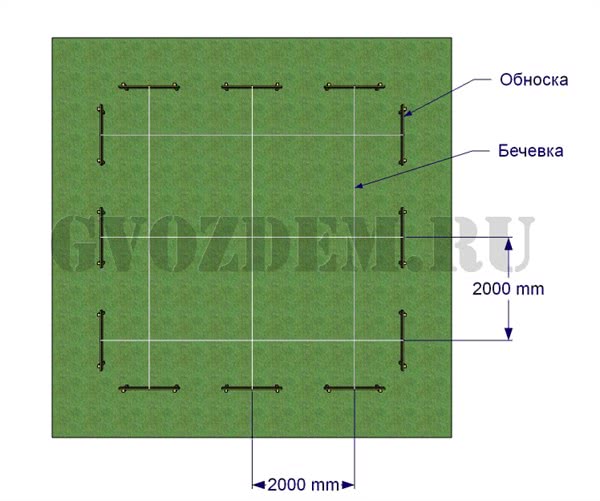

Installation of the manufactured formwork on the construction site is carried out in accordance with the project. It is installed in key places of the future building or structure - the corners of the house, the joints of the partitions. For additional reinforcement, auxiliary supports are installed between the nodes. The distance between the posts should not be more than 2 meters. When designing the location of the foundation pillars, many indicators are taken into account, such as soil properties, the load created by the house, and so on. Therefore, when taking out and erecting pillars, one must not deviate from the project, so as not to reduce the reliability of the foundation.

Features of the construction of a columnar foundation

The diameter of the pillar to be erected can be different, but the most popular is 200 mm. This diameter allows you to guarantee the strength of the structure at a minimum cost.

An important parameter when erecting a columnar foundation is the depth mark to which the support should go. There are 2 ways to identify this value:

If the soil is located to heaving, then it is necessary to go below the depth of soil freezing.

If the ground is unstable, it is important to get to the supporting ground.

What is the basic option for a columnar foundation

Like any other technology, foundation pillars have a basic set-up sequence from which they are repelled during construction. This sequence of work performed is conventionally divided into stages:

- Equipment of depressions in the soil, which depends on the design strength, the depth of freezing and the type of soil.

- Arrangement of a pillow. It is advisable to pour 10 cm of concrete under the pillow. There is no such possibility, then fill in the sand 10-20 cm in the depth of the hole, which will create a drainage that repels water. It is thanks to the pillow that the columnar foundation, the technology of which has been actively used in the last 10 years, is resistant to heaving of the soil.

- Formwork arrangement. This option is considered the most time consuming at the beginning of work. At this stage, boards are assembled from boards, the geometry of which should be close to a rectangle. This will allow the pillars to be solid and aesthetically pleasing. The construction of a columnar foundation involves the alignment of the general plane of the house along the lace and level.

- Reinforcement. Each post needs to be reinforced. To do this, a frame is welded from reinforcement to individual sizes, in 4 or 6 rods. It is lowered to the bottom.

On this topic:

BACK

FORWARD

1 of 3

If they work without formwork, assuming to remove the pillars from the brick, then between the first row and the base, they must put waterproofing so that the pillars do not absorb moisture and do not collapse.

Types of structures

One of two types of formwork is used: removable or non-removable. Each with its own advantages, it is worth disassembling them and deciding which option to put. Sometimes you can combine different types, but this greatly complicates the project, it is easier to choose one.

Removable options

They are assembled at the place of work, sometimes ready-made elements are installed, if it is necessary to make structures not in one, but in several places. Even old boards are used if they are still strong and can withstand the pressure of concrete from the inside. Remember the main features:

They are assembled at the place of work, sometimes ready-made elements are installed, if it is necessary to make structures not in one, but in several places. Even old boards are used if they are still strong and can withstand the pressure of concrete from the inside. Remember the main features:

- The structure is easy to assemble and then disassemble after the concrete has set. For it, either ready-made boards, or improvised options, old lumber, pieces of plywood, chipboard are used. Adapt different residues if strength permits.

- It is convenient to build from ready-made elements because then it is much easier to disassemble the formwork for the strip foundation. If you just knock down the boards, then when dismantling them it is easy to spoil them.

- By adapting what is at hand, the savings are significant. When buying lumber, the costs will be higher, but if you set them carefully, protect the surface with construction film, then you can use them for other purposes.

- It is necessary to strengthen the boards well, then they will not be bent under the mass of the mortar. To do this, the easiest way is to reinforce the elements with additional cross-members, as well as to put braces, resting them on the ground.

- It is possible to carry out work even in winter. It is necessary to include special heating systems so that the moisture in the material does not freeze before it hardens. There are even ready-made formworks for monolithic construction and foundations with built-in heating elements.

- After pouring the mortar, maintain the structure for at least 4 weeks. Such a period is needed for a set of strength, at which work continues further. Previously, you cannot start laying walls.

Tip: In many cities, removable formwork can be rented. It is inexpensive, but the work will take no more than a day, and the concrete surface will turn out to be perfectly flat.

During construction, pay special attention to the exact breakdown of the site, the leveling. It is imperative to measure the sides, diagonals so as not to fill the curved foundation, then redo the work, while ensuring strength, it will be very difficult

Fixed formwork

They are used most often on buildings that are completely made of hollow elements. But you can only build a foundation using ready-made blocks. They are made of concrete or polystyrene. The main features are:

They are used most often on buildings that are completely made of hollow elements. But you can only build a foundation using ready-made blocks. They are made of concrete or polystyrene. The main features are:

- There is no need to wait 4 weeks, as when using the removable version. It is allowed to continue construction in a few days.

- The structure is immediately insulated.This applies to the use of foam blocks or extruded polystyrene foam. In addition to good heat retention performance, the base acquires good sound and heat insulation performance.

- The foundation can be made very quickly. But the preparation will take more time, since you will have to prepare the base, expose the elements, and control the correct position.

- Due to the reinforcement, the structure is easy to strengthen. Reinforcement will increase the strength indicators at times, make it easy, the rods are simply inserted into the internal cavities.

Beautiful gazebos for a summer residence: how to do it yourself, a photo of the best design ideas

This option will cost more, but the foundation will be immediately insulated on both sides. The surfaces will turn out to be smooth, which will simplify finishing work. It is impossible to fill such bases in winter, therefore, work should be carried out only at above-zero temperatures.

Instructions for the construction of a bored pile foundation with widening

Site marking

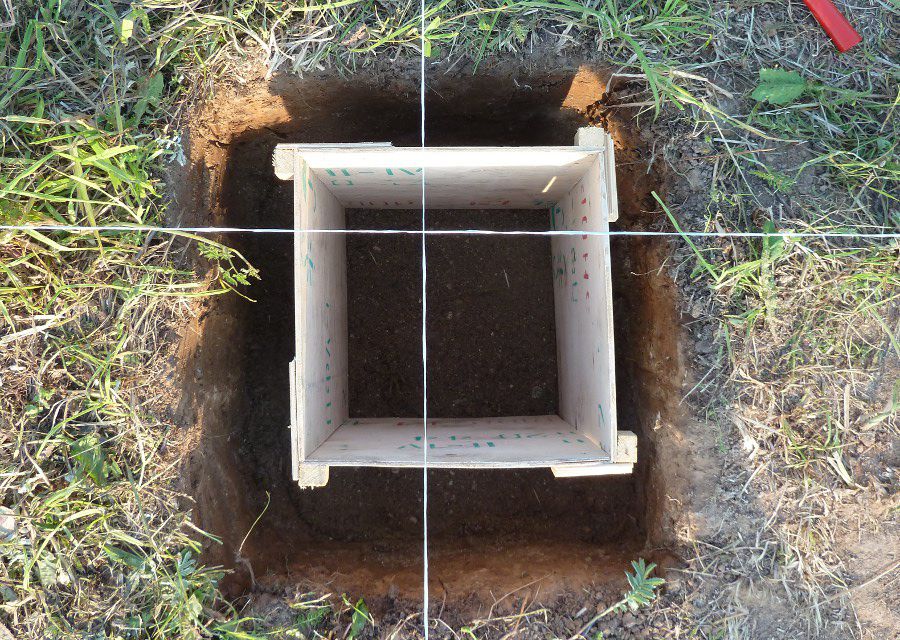

1. Install a strip for pulling the twine, along which we will mark the location of the pillars (piles). Instead of cast-off, you can simply use pegs or reinforcement that is firmly anchored in the soil. Before placing the castoffs, we must have drawn up a project for the number and location of pillars.

We pull the twine (cord, thick thread, or any analogue) to mark the location of future piles. The points of intersection of the twine will be the centers of the wells. In our example, the distance between the centers of the pillars will be 2m. Provided that the diameter of the bored pile is 25 cm, therefore, the distance between the piles will be 1.75 m.

2. We outline the centers of future wells. For this task, we will use a plumb line, which will be lowered from the intersection of the twine.

3. Drive in the peg exactly along the plumb line. Instead of a peg, you can use anything you like, the main thing is to keep it securely in the ground and be noticeable so as not to accidentally knock it down.

As a result, we get a marked area for future pillars. We remove the cast-off so that it does not interfere with us. Only the pegs remain.

More detailed instructions on marking the foundation can be found in the article: Marking for the foundation. Rules for constructing a rectangular foundation. For a columnar foundation: Marking for a columnar foundation with a grillage.

The nuances of formwork for different types of foundations

In low-rise private construction, a strip base is the most common option. However, he is not the only one. Slab and columnar foundations are also used.

Formwork for a columnar foundation

In this case, in addition to the common trench, deep holes are dug for columnar supports. They are located along the perimeter of the future building so that there is a support at each corner or intersection of the walls.

The formwork itself is also made of boards, plywood or other sheet materials according to the technology described above. The difference is the arrangement of the limiting elements in the form of a vertically located tetrahedral prism (a column of rectangular or square section) or a cylinder. Filling is done from the top. Reinforcement of the columnar foundation goes separately for each support, followed by strapping.

In this case, the pillar has either the same cross-section over the entire height, or an increased lower step.

It is obligatory to fill the cushion under the foundation supports, the lower step can be poured into the ground without formwork, but at the same time reinforced. For the upper part of the support, the formwork is mounted, the reinforcement of the upper and lower parts is connected. Simple in form, with limited load, supports can be concreted without reinforcement.

If it is planned to arrange a monolithic grillage over the columnar foundation, the formwork for it is performed separately, in the form of a box.

Formwork for foundation slab

The main difference between this type of limiters is one-sided arrangement: the shields outline the shape of the future slab on the outer sides.

Important: when arranging this type of formwork, you should pay more attention to the calculation of the strength of the structure, since the load on the shield stops increases in proportion to the size of the slab.

Foam blocks are not used as permanent formwork for slab foundations. If it is necessary to make the stoppers non-removable and at the same time use them to insulate the base, use flat sheets of foam or polystyrene.