The main enemy of the basement is water

In some cases, building a house with a basement with your own hands is impossible without additional measures that will protect the foundation from soil moisture. Before starting the construction of a house, you need to do detailed geological research with the involvement of specialists. They will allow you to identify the exact level of the location of groundwater, the likelihood and frequency of their rise.

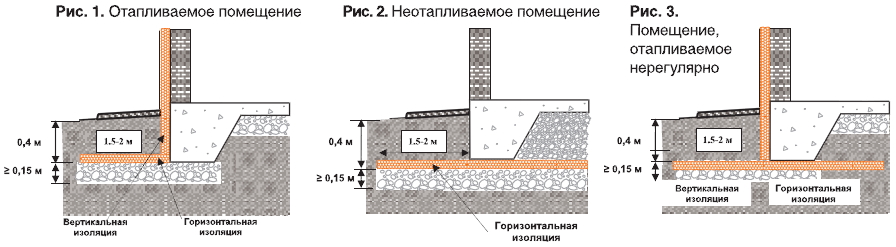

If the groundwater level (GWL) is located far from the earth's surface, it is sufficient to provide the following types of moisture protection:

- vertical (coating, pasting with protection from damage);

- horizontal at the level of the basement floor (closed with the vertical);

- horizontal along the edge of the foundation.

To protect the supporting part of the building from moisture at a high ground level, the following measures are envisaged:

- Gravity drainage is suitable for eliminating the upper water in elevated areas. It is laid at the level of the sole or below and is diverted to the nearest body of water or to an open area.

- Forced drainage is used if it is necessary to make dewatering for flat or lowland areas. In this case, the system is equipped with a well with two pumps (one main and one backup in case of emergency). A device of this type of dewatering requires constant additional costs during the operation of the house.

- External insulation with a pressure wall. It is a system of a vertical layer and a horizontal one located in the basement or basement floor structure. The technology requires that the system be closed, that is, the horizontal waterproofing is connected to the vertical one.

Important! The device of any type of drainage makes sense if the water rises during the period of heavy rains or floods. With a constantly high level of moisture, the drainage system will not cope with the load

Foundation insulation methods

Warming the foundation with expanded clay.

The methods of warming the foundation directly follow from the selected material for insulation.

When choosing soil as thermal insulation, it must be remembered that all the necessary measures will need to be carried out even before the start of the construction itself. In addition, the structure will need a ventilation shaft to evaporate excess moisture from the basement. Further, a certain amount of soil and sand must be leveled between the supports of the structure, compacted.

There is no need to use expanded clay on your own. It is often added to concrete solutions or when insulating with soil. Expanded clay is in the form of balls with internal pores, due to which it retains heat. The technology for using it in construction is also quite simple. After the formwork has been prepared, it is necessary to prepare a mixture of concrete and expanded clay. Then pour it into the equipped formwork, allow time to dry.

Polyurethane foam (PPU) is applied to the walls of the foundation using a special spray technique under high pressure. For sufficient insulation, several layers must be sprayed, the total thickness of which should be no more than 5 cm. All work must be carried out by specially trained people.

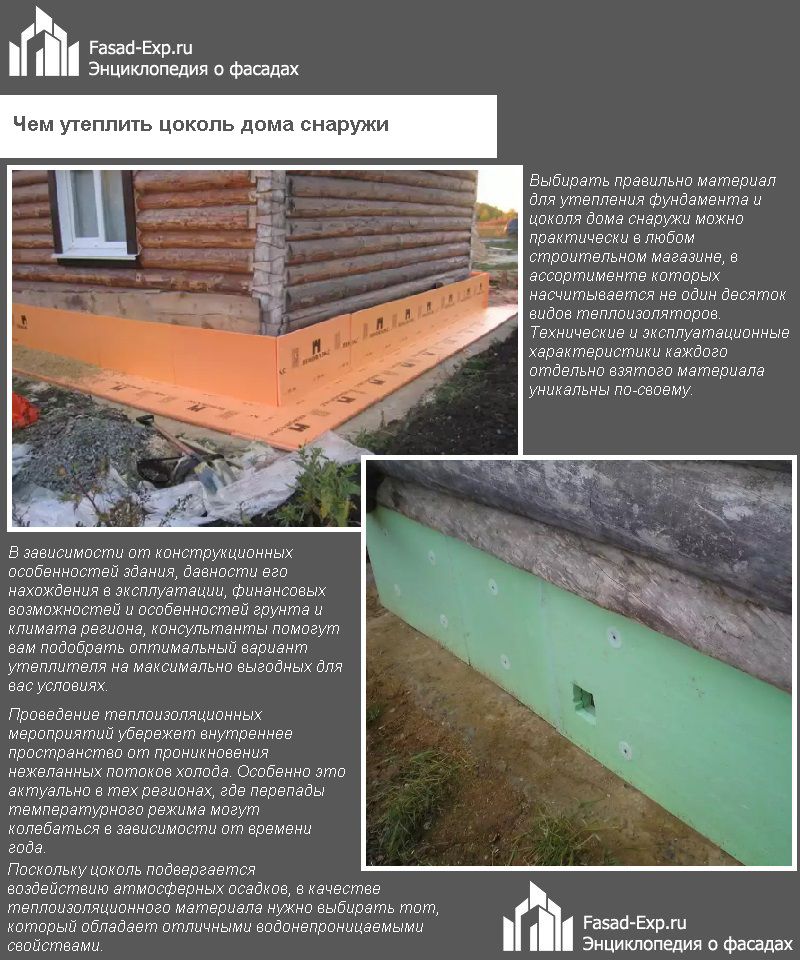

Expanded polystyrene is produced in the form of already frozen sheet foam. The total thickness of the material for good protection from the cold should be at least 12 cm. For the installation of expanded polystyrene sheets, additional parts will be needed - guides, which are used as fasteners. As a result, the total cost of installation is slightly higher.

Insulation of the foundation without a basement

Let's start with a wooden house. Insulation of the foundation of a wooden house is best done during the construction phase. Alas, many recollect when the building has already been erected.In this case, you should hurry up before the onset of cold weather, otherwise you will have to heat the stove almost all the time. But, even if the cold has already hit the house, the point in thermal protection of the base still remains.

So, how to insulate the foundation of a wooden house? Many private buildings do not have basements. In this case, the empty space in the box (of which there is quite a lot) is better than falling asleep. Soil is also suitable as a material. On the one hand, this seems to be a simple task, because after digging a pit there is quite a lot of soil left, and it will definitely be enough for such work. But the problem is that the volume of soil that needs to be filled is very large, and you will most likely have to do it all manually.

If you need filling material (as in this case), it is better to opt for expanded clay, especially since only 40 cm from the walls of the foundation from the inside are covered with it.

What other insulation materials are suitable for the foundations of wooden houses? As in any case, the choice depends on many factors. But most opt for materials such as:

- Penoplex.

- Polyurethane foam.

- Expanded clay.

Any of these heaters will cope with the protection the foundation of the old house made of wood (however, new too). You just need to accurately calculate their number, thickness, and also carry out the work correctly.

Now let's talk about whether it is necessary to insulate the foundation of a house without a basement. Disputes about this need continue to this day. But it is still better to protect the base from the cold and here's why:

- Without thermal insulation, you will experience heat loss, even if you take care of the insulation of walls and windows.

- The structure will be exposed to temperature effects and may simply collapse along with the house.

It is quite possible to insulate the foundation with your own hands, especially during the construction phase. Then it’s better to do it. The point is not only that at this stage the work is easier. It so happens that in an already erected house, access to the foundation is only from the inside. But internal insulation gives a good effect just in buildings with basements.

The materials are the same as in the previous cases. It can be the same foam or polyurethane foam. In the first case, you can insulate the foundation with your own hands, in the other, although you have to pay a large amount and invite specialists, the result will be more effective, since all cracks and seams will be sealed.

A bit of theory

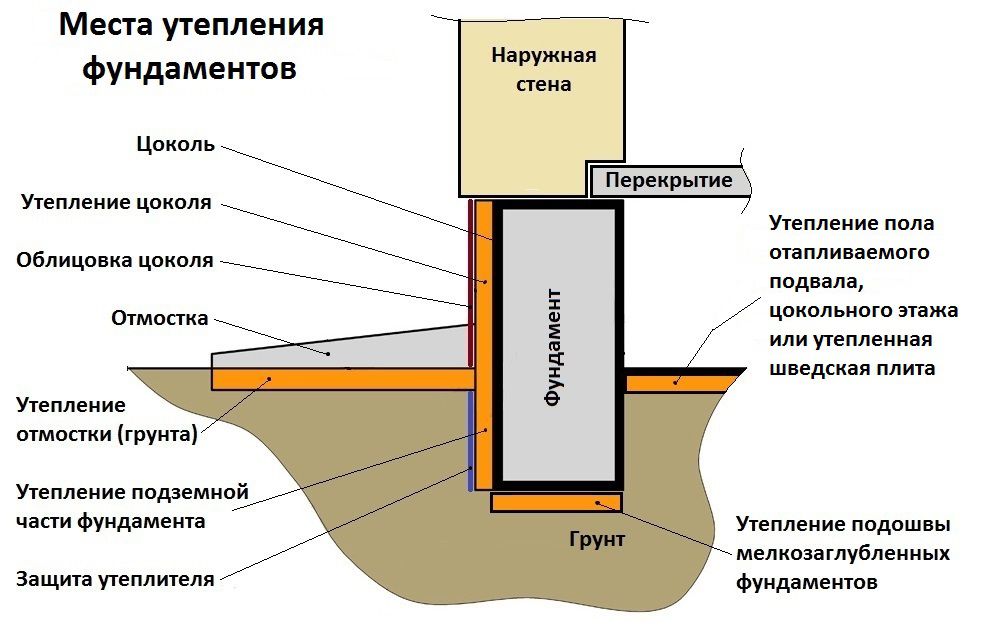

Thermal insulation of the underground part has several main goals.

Most residents of southern and central Russia build cottages on concrete foundations and are not particularly worried about this. They live for many years, quite happily and comfortably, without additional insulation of the buried part, although for most inhabitants of the northern lands, this approach to business seems frivolous and wasteful. First, you need to figure out why people insulate the foundation.

Thermal insulation of the underground part pursues several main goals, the main of which is to reduce the depth of freezing and heaving of the soil adjacent to the building. This allows you to protect communications, equip a cellar or living quarters in the basement. But the main function of thermal insulation is to protect structures with uneven heaving. The soil may rise higher at one corner of the house than at another. The foundation is deformed and cracked, which is already bad. That is why the base of the house is insulated. It is now much easier to talk about when you shouldn't. About why you should not do the insulation of the foundation from the inside, read on the page / pochemu-ne-stoit-delat-uteplenie-fundamenta-iznutri /.

How is the polyurethane foam insulation of a multi-storey building carried out?

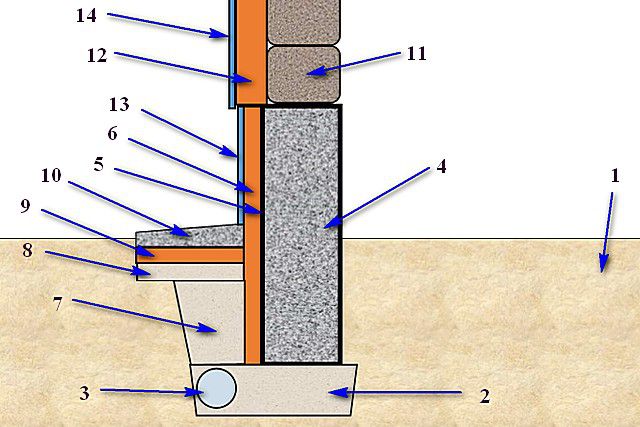

First, the building is dug in to a depth of 50-60 cm. The walls are cleared of earth and dried. Sand is poured at the bottom of the formed trench. After that, PPU is sprayed on the entire surface of the foundation, capturing about half a meter above ground level.The dried foam is cut off and plastered. You can use special finishing boards instead of plaster. The polymer, which is above ground level, is trimmed with cladding.

Around the house, a concrete blind area is organized with drainage channels, ebb and flow. After such work, the basement of the house becomes dry and warm, and the cost of heating is reduced by 15%. In addition, cracks on the foundation and facade of the house cease to appear, and the basements are not flooded with melt water.

Having insulated the foundation, you don't have to worry about its durability and strength, especially if you have chosen reliable and durable waterproof polyurethane foam as insulation. Since this material is not cheap, for work you need to contact firms that cooperate directly with manufacturers of PU foam components. In such companies, fairly reasonable prices are offered, they have modern equipment and experienced specialists.

Varieties of foundations and features of their insulation

Belt at the stage of formwork

If you take care of thermal insulation in advance, during design, you will get a thoughtful, energy efficient and economical solution.

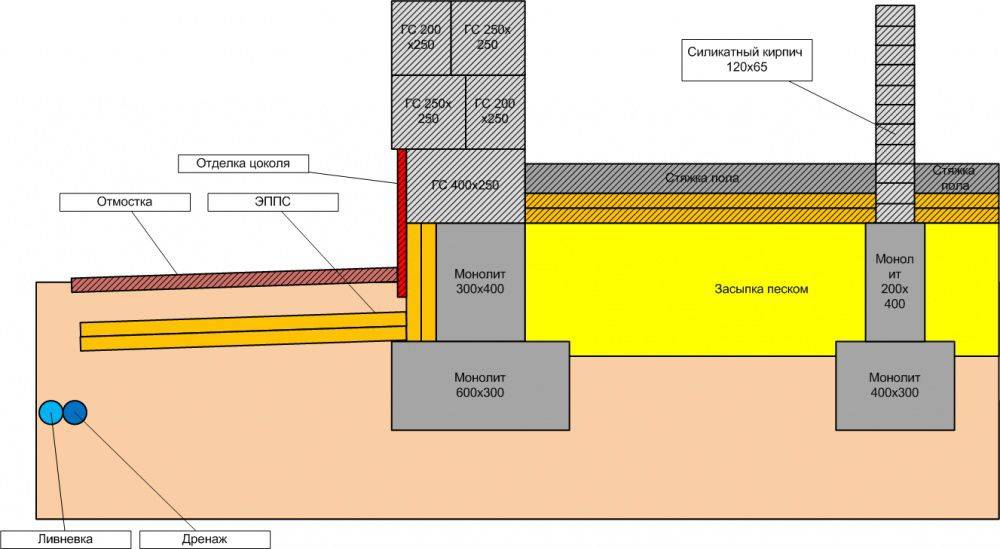

After the trench has been dug, it should be covered with sand and formwork made of expanded polystyrene sheet. Such formwork must be protected from bursting with concrete poured by installing supports made of boards or thick-walled plywood.

There are also special polystyrene foam blocks with cavities on sale. They are used for masonry, like bricks or foam blocks, connecting with glue. In the cavity of such masonry, reinforcement is mounted, concrete mortar is poured and vibration compaction is carried out.

Permanent foundation formwork

Permanent foundation formwork

Formwork of this kind will be non-removable and, remaining on the foundation structures, will serve as excellent thermal insulation

Concrete or stone tape

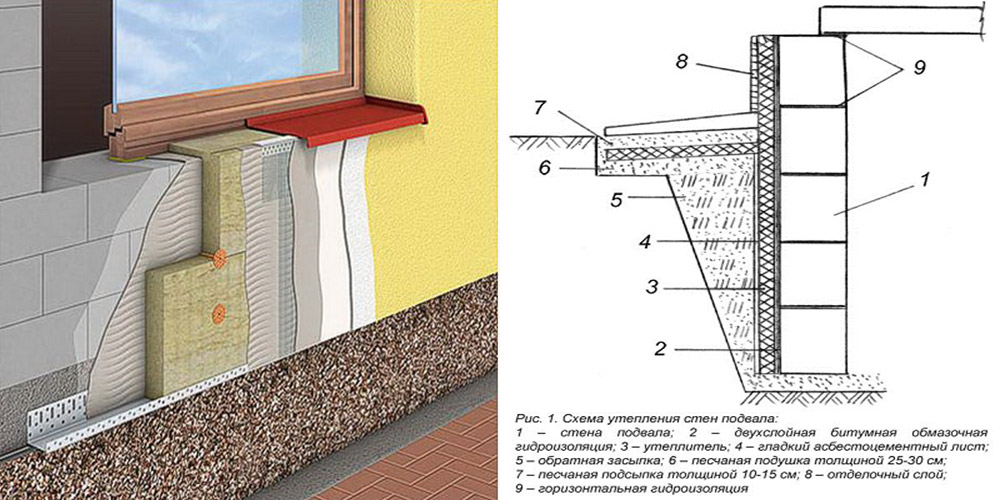

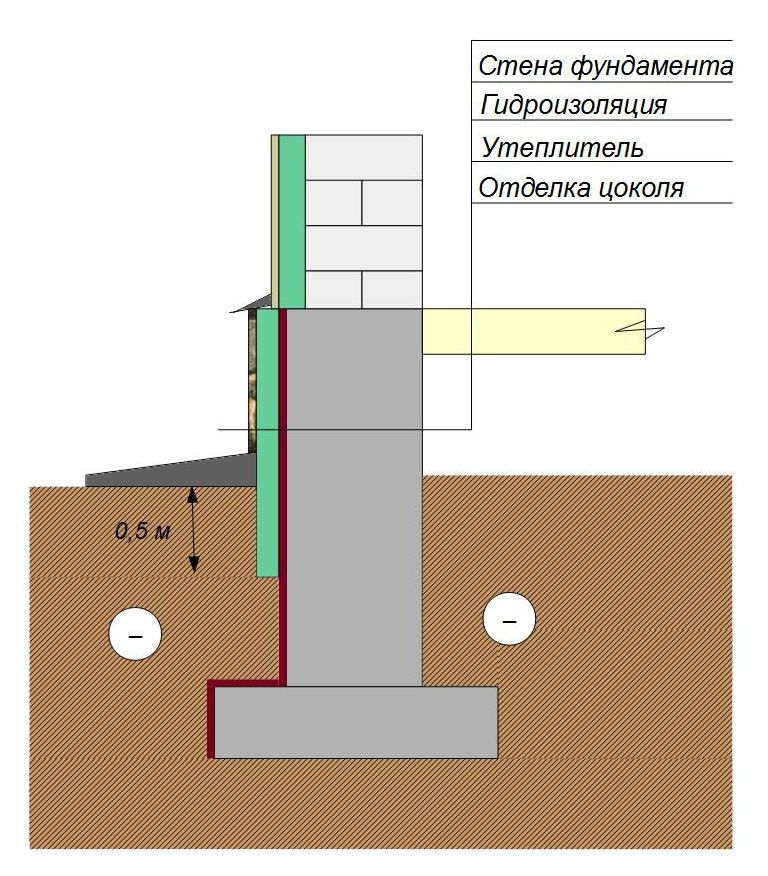

The insulated monolithic strip foundation will last much longer. First, the structure poured or folded from the foundation blocks should be waterproofed. For this, special bituminous mastics are used. The waterproofing layer must be allowed to dry until the solvents are completely weathered. It takes three days to a week.

Foamed plastic is glued to concrete with adhesives. Acetone based glue should be avoided - it dissolves the foam.

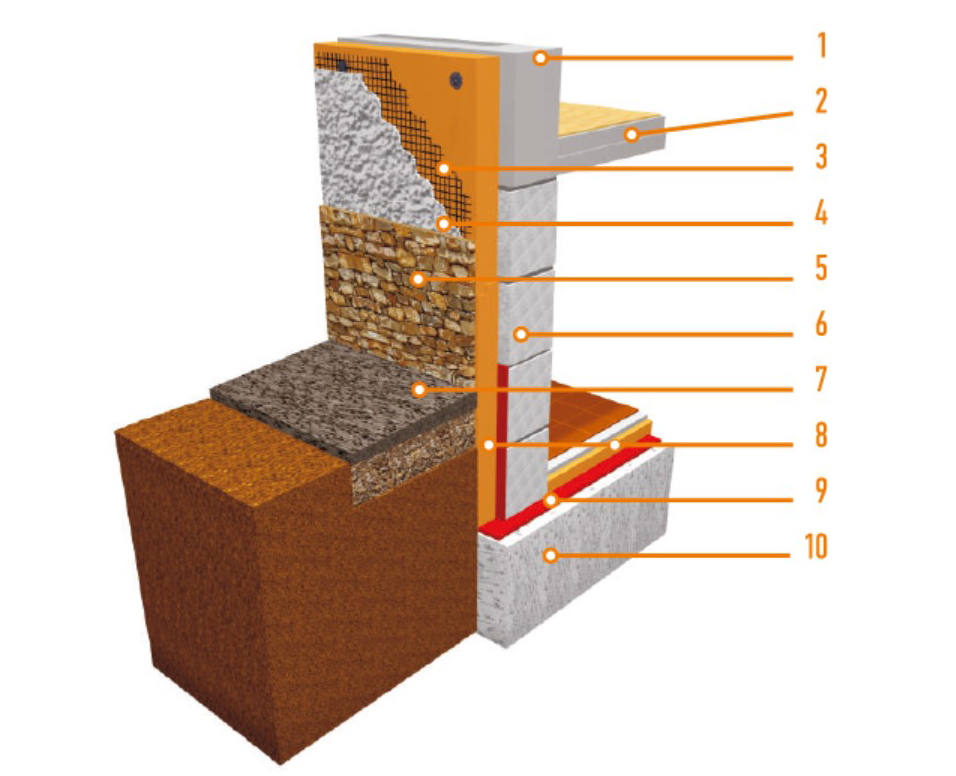

Thermal insulation of strip plinth

Thermal insulation of strip plinth

On top of the foam, protective sheets of asbestos cement can be installed or a layer of plaster can be applied, reinforced with a pre-installed support mesh.

Thermal insulation coated with a layer of plaster

Thermal insulation coated with a layer of plaster

For thermal insulation of the above-ground part, it is recommended to use sheets with a thickness of 100 mm.

How to insulate a foundation made of rubble stone? Before thermal insulation, it should also be leveled with a layer of plaster mesh.

Columnar

How and why to insulate a columnar foundation? Its thermal insulation is more difficult than tape, since there is no closed loop. Insulating each pillar will have less effect than insulating the closed outer contour formed by the tape. Most often, the insulated circuit begins with a log and a rough floor.

In order for the columnar foundation not to act as a conductor of cold into the house, it is necessary to arrange a thermal break between the top of the column and the floor structures. The material for such a gasket should:

- have low thermal conductivity;

- be strong enough - through this gasket, the weight load of the house will be transferred to the foundation.

For this, special finely granular high-strength foams are suitable.

Platen

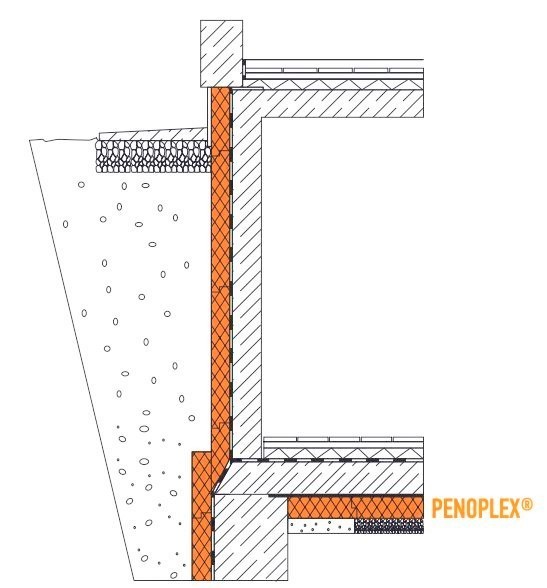

Foundation slabs are the most advanced type of support structure. The insulated Swedish plate, as it is called in everyday life, ensures the maximum strength of the structure and its resistance to seasonal fluctuations in the soil. Thermal insulation is carried out before casting, both from the bottom and from the ends of the slab, in order to exclude the formation of so-called. "Cold bridges".

A layer of rolled waterproofing material is unfolded on a leveled and tamped sand cushion, then expanded polystyrene plates are laid out. A reinforcement system is mounted on top of them, after which the slab can be poured. From the ends, sheets cut through the thickness of the slab are fixed, which will serve as permanent formwork. From spacing, they are fastened with special squares.

Insulation of the Swedish plate

Insulation of the Swedish plate

Just in case, experienced builders for insurance put external supports of the end part of the formwork from boards and thrust beams.

The thickness of the plates in Russian sources ranges between 60 and 100 mm, Western recommendations say from 200-300 mm.

Pile-screw

The problems of insulating the pile-screw foundation of a house are the same as in the case of a columnar foundation. Theoretically, it is possible to dig the soil to the depth of freezing and make an insulated contour around the outer piles.

Insulation of piles

Insulation of piles

However, at the same time, the whole main advantage of screw piles is lost - the almost complete absence of earthworks and the installation of the foundation of a wooden house in one day.

Most experts agree that the piles themselves do not need insulation, and it is worth focusing your attention and efforts on insulating the walls, floor and contact points of the logs and the tops of the piles and strapping in order to exclude the transfer of cold through them. And the piles will have to freeze

Why do you need to insulate the foundation

In an ordinary private house without thermal insulation, of which a great many have been built, in winter there is almost always a coolness in the lower area of the premises. No matter how well the heating system inside a residential building works, this coolness in the legs remains and causes discomfort for the people living in it. You will say - you just need to insulate the floors, and everything will be fine. But in fact, this is not enough, because there are several reasons why it is worthwhile to warm up the foundation:

- as noted above, the loss of heat through the floors causes significant inconvenience to people;

- the amount of lost heat is quite significant, which increases the cost of heating a private house;

- the foundation and its aboveground part - the basement without insulation is exposed to moisture and freezing, which contributes to the slow destruction of the structure;

- in areas with heaving soils saturated with moisture, the effect of frost swelling may appear. It exerts additional stress on the base, up to and including cracking.

If everything is clear with the first item of the list, then the rest require clarification. The fact is that the share of heat losses through cold floors reaches 20% of the total amount of heat lost by the building. Therefore, all attempts to save energy resources by performing thermal insulation of all structures of the house, except for the foundation, will not achieve their goal.

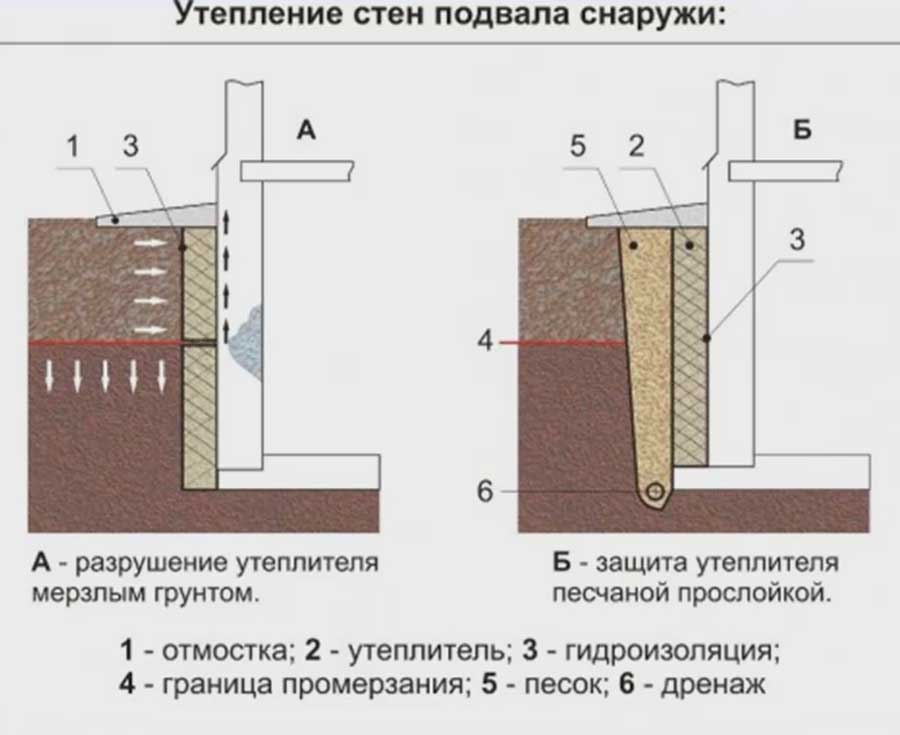

Imagine that the cold penetrates inside over the entire area, and the insulation of the floors from the inside does not fundamentally solve the issue, for this it is necessary to insulate the foundation from the outside.

Concrete, from which the vast majority of foundations are arranged, has a very low resistance to heat transfer. During cold weather, the concrete wall freezes, which is why condensate forms from its inner side, which is absorbed into the thickness of the material. With increasing frost, this moisture turns into ice crystals and leads to the destruction of the structure. That is why you should not insulate the foundations of private houses from the inside, this will help protect from the cold, but will not protect the structural elements from destruction.

The same freezing moisture with which loess soils are saturated, when freezing, makes them swell, exerting shock loads on the base. As a result, cracks can appear in the concrete, which is at least unpleasant. All of these reasons are equally relevant for all types of houses, including wooden ones, where it is also necessary to insulate the foundation. The exceptions are structures on screw piles, which will be discussed below.

Types of insulation used

Among the thermal insulation materials that meet the above requirements and have an affordable cost, you can name:

- sprayed polyurethane foam;

- sheet expanded polystyrene;

- extruded polystyrene foam;

- expanded clay.

Each of the listed types of thermal insulation has its own characteristics associated with the installation technology, the efficiency of the insulation layer and the cost of purchasing the material.

Polyurethane foam (PPU)

Of all the insulation materials listed, sprayed polyurethane foam is the most expensive material that requires the use of special equipment for its application to the surface. However, it is also the most effective insulation of all existing polymeric materials.

Its main feature is that the polyurethane foam coating does not have connecting seams, being a single continuous layer. This material for insulating the foundation of a house from the outside:

- has excellent adhesion and adheres perfectly even to dirty surfaces;

- has one of the lowest thermal conductivity coefficients;

- after complete curing, it becomes waterproof;

- has good hardness combined with high ductility;

- absolutely unattractive to rodents and insects.

The waterproofness of polyurethane foam makes it possible to abandon the installation of a waterproofing layer. This significantly reduces the time required to insulate the foundation of the house from the outside, reducing the overall cost.

Conventional Styrofoam Boards

This material is made by heating the raw material, poured into a mold, with hot steam. Under the influence of temperature, expanded polystyrene granules expand, forming a porous mass that occupies the entire volume of the mold. This technology is used for the manufacture of most soft foams.

PPP is supplied to the market in the form of flat slabs with a locking recess at all ends. This shape allows for partial overlapping of the joints at the junction of adjacent slabs and avoids the formation of cold bridges.

The material is cheaper than polyurethane foam, but the presence of connecting joints cannot guarantee the surface protection from moisture. Therefore, before installing the thermal insulation layer, a mandatory waterproofing device is required.

Extruded polystyrene foam

This material differs from the previous version in the manufacturing technology and quality of the plates. Forming of plates provides for the supply of ready-made molten polymer mixture through a special extrusion machine. In this case, the foaming of the composition occurs by filling it with neutral or carbon dioxide. Regular air is not used for this, because this will affect the fire hazard.

Extruded polystyrene foam is somewhat more expensive than usual, but, thanks to this method of molding, it does not have a single open pore on a smooth and even surface. This means a longer service life and improved thermal insulation properties.

Expanded clay

The main advantage of expanded clay granules is the lowest cost among all heaters used for foundations. In terms of other technical indicators, expanded clay, frankly, loses to foamed polymers. The use of new modern technologies for thermal insulation of building structures has made this material poorly demanded, its use is now rare.

The ability of expanded clay to partially absorb water over time increases its thermal conductivity by 25-30%. Therefore, ensuring the effectiveness of the bulk heat-insulating layer requires a large thickness, and, therefore, a significant consumption of material. This, in turn, leads to an increase in costs and, as a consequence, a complete leveling of the previously mentioned main advantage of expanded clay.

Base insulation technology

The basement insulation technology differs depending on the type of base and the heat-saving materials used.

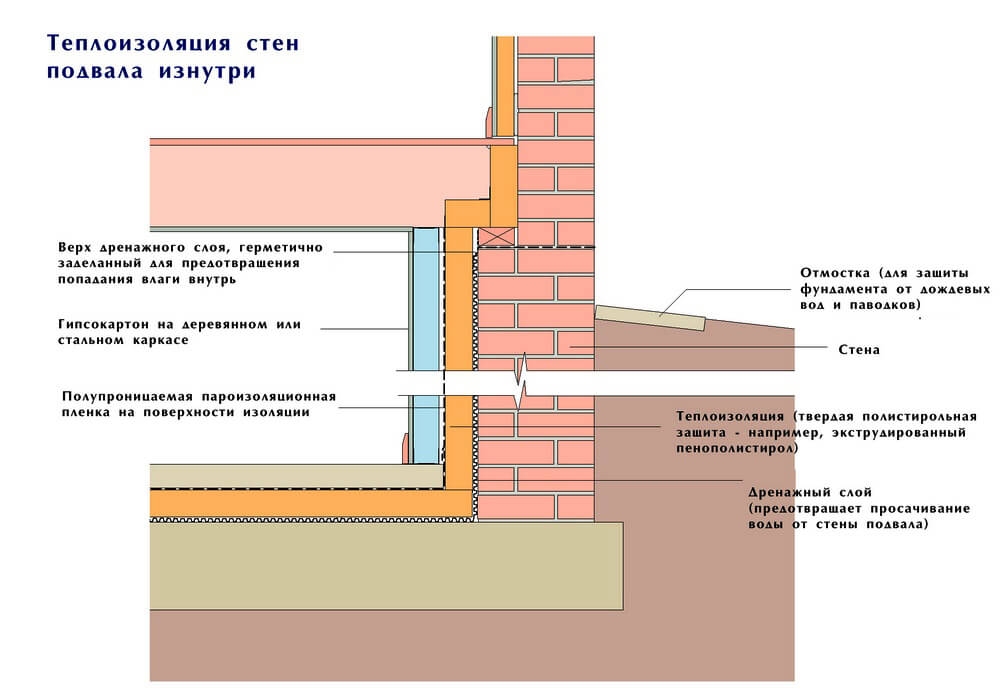

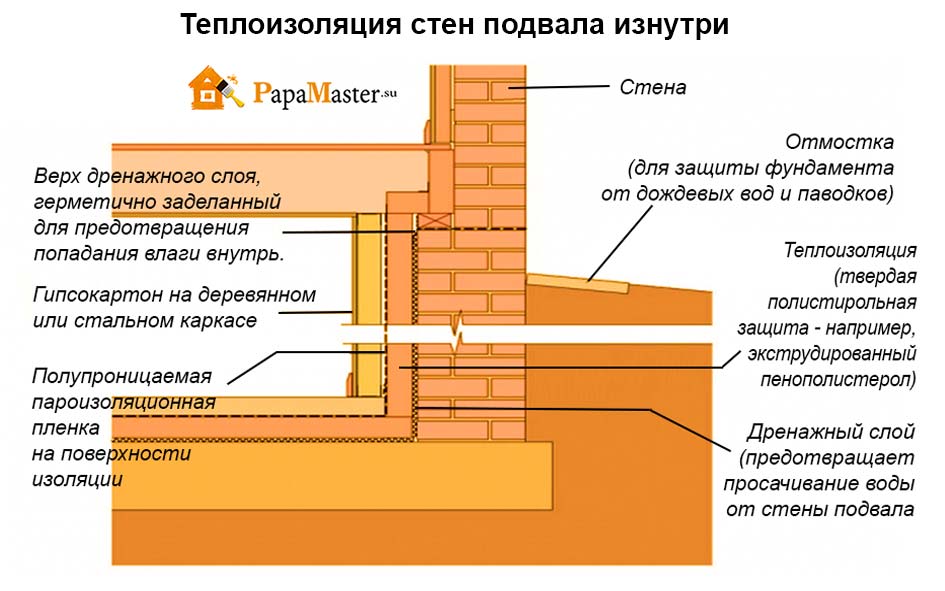

Insulation of the foundation is divided into external and internal. It is necessary to insulate the outer part of the base before the construction of the basement and walls.

If at the construction stage the measures for thermal insulation were omitted, they are insulated from the inside.

Thermal insulation of the strip base

Many people ask the question, why insulate the foundation in the house, if there is no basement there. Moisture, penetrating through the pores of concrete, increases in size during freezing, this often leads to the formation of cracks.

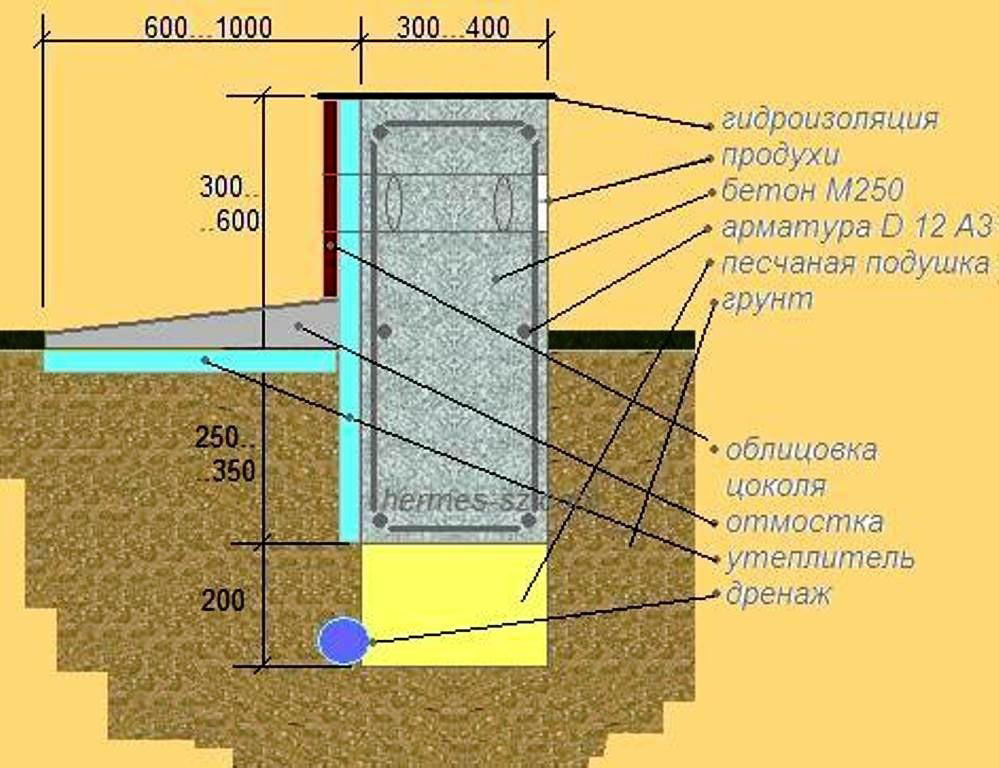

The strip foundation is insulated with a uniform layer along the entire perimeter.

Step-by-step instruction:

- A trench is dug along the entire length of the foundation. Its dimensions should be: in depth, like a foundation, in width 80-100 cm.

- They clean the concrete tape from dirt, earth and dust.

- If necessary, the surface is leveled by making a concrete screed.

- Laying waterproofing from roll materials or treating the surface with bitumen-based mastics.

- The slab insulation is fixed to a special glue.

When insulating the foundation with expanded clay, it is necessary to provide for a drainage system to drain water from the base of the house. Expanded clay due to its porous structure is characterized by high moisture absorption, while it loses its thermal insulation qualities.

For a drainage device, a trench is dug at a short distance from the base of the house. The bottom of the pit should be located deeper than the base of the foundation. The bottom is covered with geotextiles so that its edges go over the walls of the trench. Crushed stone is poured, pipes are laid, with a section of 10-20 mm. From above they are covered with rubble. The protruding edges of the geotextile are wrapped so that they cover the drainage structure. A layer of sand is poured on top.

Expanded clay is filled up to ground level. It must be dry and clean, free of foreign matter.

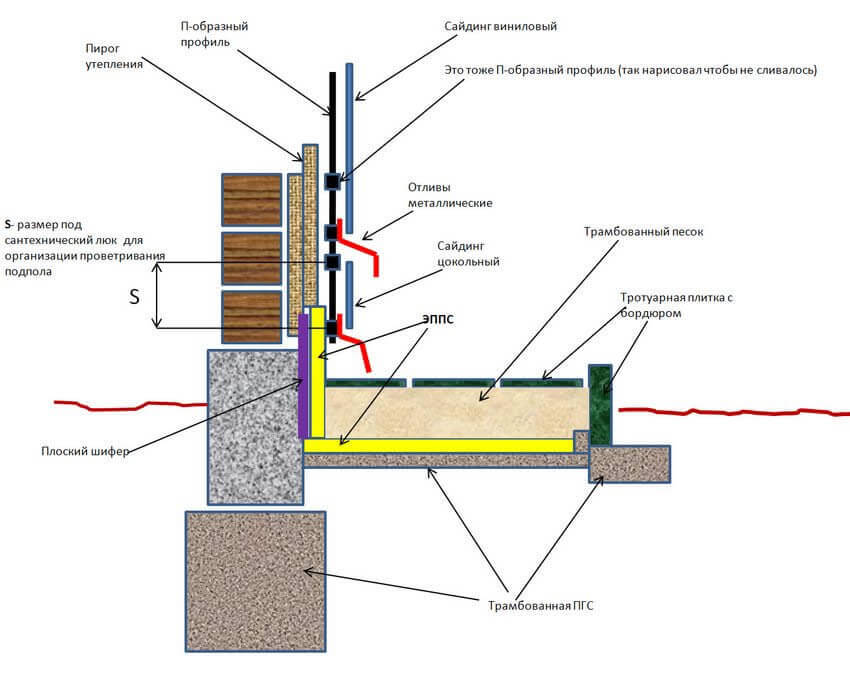

Pile base thermal insulation scheme

When using a material prone to increased moisture absorption as a heater, it is necessary to make a blind area. It will protect expanded clay from getting wet during rain or melting snow.

Thermal insulation of the pile foundation

In order to significantly reduce heat loss during the operation of the house, it is necessary to provide measures for its insulation at the stage of construction of the pile-grillage base.

This type of foundation is characterized by the fact that there is a gap between the ground level and the floor of the house. In winter, the floor in such a house will be cold and heating will be expensive. To reduce costs and create a favorable microclimate in the house, it is necessary to insulate the grillage.

The grillage is a structure made in the form of a tape, which unites the piles. It takes on the bearing load from the house and distributes it evenly through the piles to the dense layers of soil.

At the stage of installation of piles, they are isolated from moisture. Roofing material or other material rolled into a pipe (rough side inward) is laid in the well. After that, the reinforcement is laid and the well is poured with concrete.

After installation of the grillage, it is waterproofed and insulated. Most often, sheet polystyrene foam or polystyrene foam is used as heat-saving materials.

Insulation of the slab foundation

The slab foundation has a large area, so its insulation is quite expensive. There is a lot of controversy about whether it is necessary to insulate the foundation made in the form of a slab.

Heat-saving technologies allow to achieve a significant reduction in heat loss during the operation of the house. The invested funds pay off over time, and living in a warm house becomes more comfortable.

Insulation of the slab base is carried out after the leveling of the bottom and walls of the trench has been done.

Step-by-step instruction:

- Spread strips of roofing material with an overlap of 150-200 mm.

- Sheets of polyurethane foam are laid on top.

- The surface is poured with a cement screed.

- Reinforcement cage is mounted.

- The slab base is poured with concrete.

Foundation diagram

Thermal insulation of a columnar foundation

Before insulating the columnar base, a basement is mounted, it will prevent heat loss due to the gap between the floor of the house and the ground.

A trench is dug along the perimeter of the house, with a depth of 200 to 400 mm. Sand and crushed stone are poured into it so that the height of the layers does not reach the ground level by 50 mm.

Bars are attached to the posts, the harness is mounted. After that, the surface is waterproofed and insulated.

No. 2. Is it necessary to insulate the basement of the house?

The peculiarity of the domestic mentality is such that you want to save on everything. Hence the popular question: is it always necessary to insulate the basement of a private house? Thermal insulation may not really be needed in such cases:

- if the house is intended only for summer residence;

- if the house does not have a basement, and the basement is small (0.5 m) and is arranged in order to avoid flooding;

- if the house is located in an area where there is no harsh winter.

In all these cases, you can do with an insulated floor. If the climate in the region is harsh, the house is used for permanent residence, and it is supposed to store food in the basement, equip a garage, boiler room or other utility rooms, then one cannot do without insulation.