Landing on self-tapping screws

The wood is attached to the uprights with self-tapping bolts. The place of contact is laid with roofing felt oiled with linseed oil. To the bottom of the structure, the elements are mounted using a through fastening or an anchor. The block must be securely attached and fixed with a hammer. As an additional way to strengthen the strength of the structure, metal corners and fastening spikes are used:

- it is advisable to use corners in corner joints of elements;

- the structural detail is selected according to the exact dimensions of the pile corner section;

- fasten the element with durable self-tapping screws.

About installation rules

Note that there are installation rules. For the installation of screw piles, it is not forbidden to choose the soil next to which underground utilities pass. It should be said that it is possible to make a pile foundation for adding extensions to the house. This method is also popular for the construction of suburban buildings.

Note that there are installation rules. For the installation of screw piles, it is not forbidden to choose the soil next to which underground utilities pass. It should be said that it is possible to make a pile foundation for adding extensions to the house. This method is also popular for the construction of suburban buildings.

Note that the base can also be installed by machine.

It is important that the elements to be installed are placed strictly vertically, securely fixed, with a distance of up to 3 m between them. These subtleties during construction will help to build a reliable house.

The mechanical method is also popular during installation.

The drill rig will help you install. It is better to choose a model with the following torque indicator - 2000-4000 Newtons.

To fix the channels, you will need to make heads. Choose a blade width 3 cm larger than the outer diameter of the pipe. The pile can be installed in soft clay, peat, water soil. It can also be installed in winter.

Strong steel is used for production.

Before starting the construction of the basement, you need to build a pile field. Thus, the house built will be very durable.

To build a house, corner piles are screwed in, they will serve as landmarks that simplify the layout. They should be deepened below the level of soil freezing. Using a level (plumb line), you can control the horizontal position. This is how a pile field is made or constructed.

It is important that the following order is observed: the part should be screwed in step by step to the end. When scrolling, it is necessary to deepen it. This will give the installation of screw piles a greater bearing capacity.

When installing screw piles with your own hands, it is important to screw the parts completely. This will make the foundation elements the most reliable.

When installing screw piles with your own hands, it is advisable to use a lever. You can use scrap, steel pipe. When installing, two pipes are put on the specified lever, they should be slightly larger.

When installing the pile-screw foundation, it is important to control the angle of inclination, the vertical arrangement of the elements. You can fix the magnetic level, it is important that the angle of inclination is no more than 2 °. It is important to take this into account in the device of screw piles, otherwise they can deform.

When making screw piles with your own hands, it is advisable to choose a channel, a tape, an I-beam, a bar.

When installing a pile-screw foundation with your own hands, it is worth considering the condition of the soil. If it contains a lot of hard rocks, then you will need helpers and knowledge of what the screw pile technology implies.

When installing the foundation on screw piles, it is advisable to use single piles for the construction of an extension. They will hold the individual elements.

When constructing a pile-screw foundation, it is advisable to use pile tapes, they are mounted under the walls of the building.

When building a pile screw foundation for key elements of the building, columns use a standard foundation.

Knowledge of screw pile installation technology makes it possible to install screw piles manually quickly and build a solid house. Subtleties

Knowledge of screw pile installation technology makes it possible to install screw piles manually quickly and build a solid house. Subtleties

technologies for installing screw piles are designed for knowledge of the soil, correct calculation.

There are no special restrictions for the installation of a pile-screw foundation in winter.

As you can see, the use of foundations is in demand, since it allows you to quickly build a house on a solid foundation at low financial costs.

Calculations

The theoretical part of the work includes an accurate calculation of the number of screw piles and their bearing capacity. Such calculations are carried out by the design departments of construction organizations. If you wish, you can make a simple calculation yourself. In this case, it is necessary to be guided by the normative document SP 24.13330.

In the course of calculations, the distance between the supports in a straight line is determined, at the points of joining of the walls, as well as in places intended for the construction of special structures with an increased load (fireplace, stove, boiler, stairs).

Determination of the level of penetration of piles

To find out the required screw-in depth of the supports, geological surveys should be carried out. If this is not possible, a trial deepening of the screw pile is carried out. In parallel, use a device that controls the twisting force.

As a result of the field test, it is possible to determine the depth of the dense layer, the composition of the soil, and the level of groundwater. It should be understood, however, that the results thus obtained are approximate. Therefore, to correct the data in the calculations, a correction factor equal to 1.6-1.7 is used.

Views

Before starting the process, the strapping technology is carefully selected. Piles can be fixed using:

- threads;

- welding;

- clamps.

It is possible to make a strapping with a landing on self-tapping screws if wooden posts were used in the structure. They should be fairly tight and thick. With this technology, correctly calculate the thread. The fastening of screw piles with a bar is applicable in the construction of wooden, frame, block and brick houses.

Welding installation of base elements is used if the piles are metal. Welding the foundation will be the best option and will allow you to firmly hold all parts of the structure.

The use of clamps is a variant of the strapping technology for solid wood piles. Clamps can be used with small post thicknesses. The installation method is chosen depending on the characteristics and parameters of the piles.

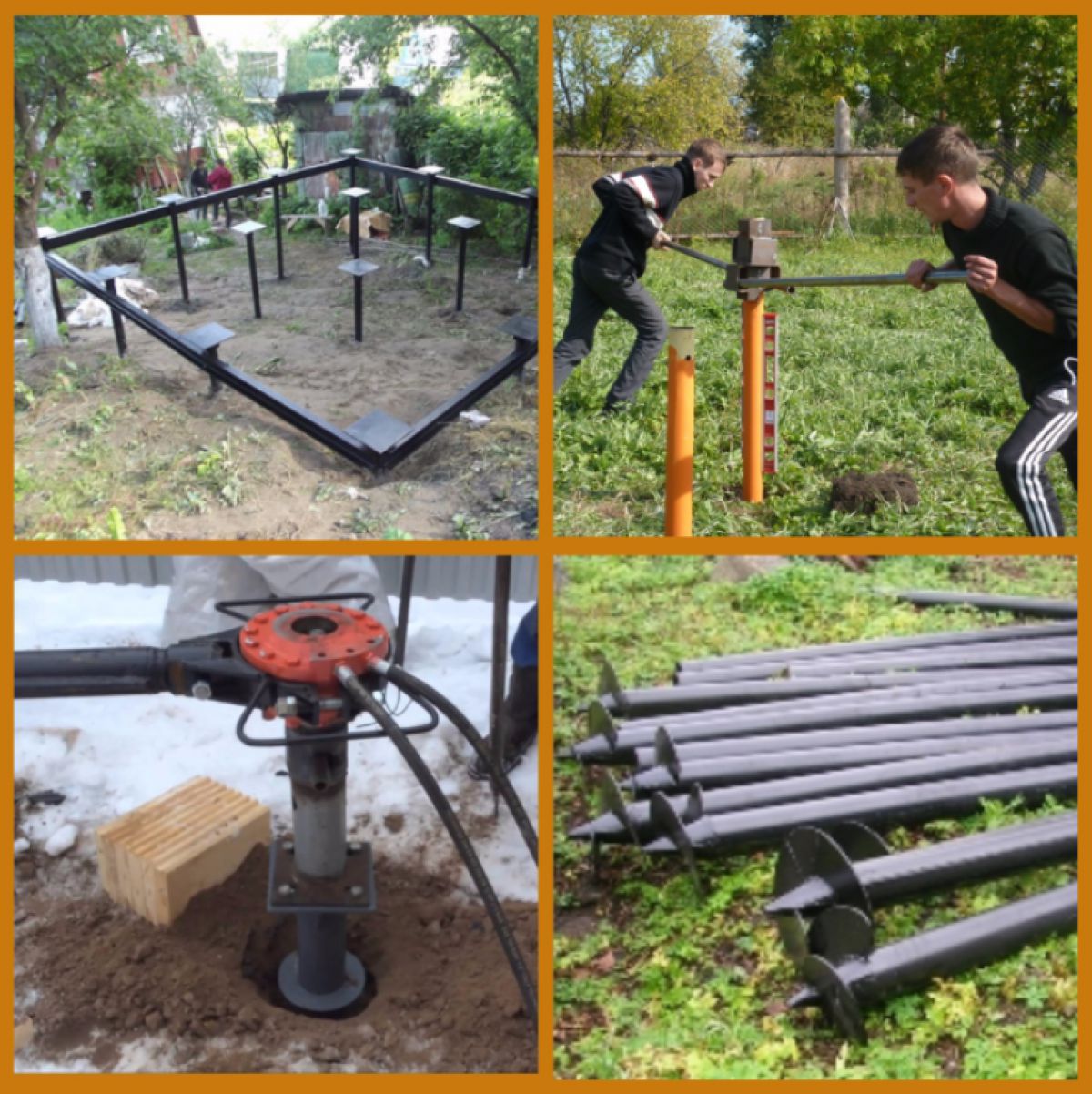

Step-by-step installation instructions

The technology for installing screw piles provides for preparatory work, during which soil analysis is carried out on the ground. Based on the results, the size of the cone supports is selected and their number is calculated. They also mark the site with markers of the places where the dive is planned. The screw rods themselves must be treated with an anti-corrosion agent or primer and the level of their immersion noted.

Remember that the construction of the foundation, namely the rolling of the piles, is customary to begin with an angular milestone located at the highest point of the relief. Next, proceed to the installation of the corner rods, and then place the remaining supports according to the given step.

Manual installation

At the place of the mark, holes of the required diameter are drilled with a special drill (drill). This process does not need to be done with a drill, and the holes can be done with an ordinary shovel. Piles are placed in the holes, the verticality of their installation is measured and twisting to the required level is carried out.

Preparing a pit for support

Preparing a pit for support

To twist the pile, you will need to use a metal rod or scrap, which is inserted into the technological holes of the supporting element, and reinforced pipes of the appropriate diameter are already put on them - this structure will be rotated. Manual twisting is carried out clockwise until the required depth of the pile. Usually, the rotation is carried out by two people, and another person controls the verticality of the rod using the level.

Support deepening

Support deepening

When all the elements are installed, they must be aligned in height, cutting them at the level of the mark determined by the optical rangefinder or a tensioned wire. The base of the house must be reliable, therefore, the piles are reinforced by pouring concrete mortar, after which solidification, it is necessary to weld the headrests. The seams left by the welding machine are treated with an anti-corrosion compound.

Reinforcement with concrete mortar

Reinforcement with concrete mortar

Do-it-yourself installation of screw piles does not take so much time, and the installation of each individual element will take less than half an hour

Please note that the supports are deepened at least one and a half meters - this is the average mark of soil freezing. If you do not adhere to this rule, the piles will be mobile during freezing and thawing of the soil.

Mechanical installation

For this type of installation, a machine with hydraulic rotators for large-bore piles, located on an excavator or truck, is required. It is better to install supports of medium and small diameter with a twist - this is a special compact device.

The immersion of the screw support is carried out by hydraulic motors operating in different power modes. Both types of devices quickly put the piles in place, while the depth is verified very carefully, and special centering devices or on-board computers monitor the angle of inclination and ensure perpendicular entry of the pile.

Mechanical installation of screw supports

Mechanical installation of screw supports

The pile is placed on special seats on the equipment and their fixation is ensured. The mechanical device sets the support at the intended point and deepens it to the required level. Further, the holders are removed from the screw cone and its final processing is carried out:

- poured with concrete;

- headrests are welded;

- process the seams.

It depends on each stage what the finished base of the house will be, therefore it is strongly not recommended to neglect the instructions during the construction of the foundation.

Binding of the pile field and the necessary tools for installation

The installation of the pile field is the first and most important stage in the construction of the foundation for the structure under construction. The work of the foundation during operation and the service life depend on the correctly selected supporting soil layer, the size of the products and the diameter of the blades according to the calculations, high-quality installation, compliance with the technology.

Required tools when installing piles

To carry out work on linking the location of the pile field on the site, installing products on our own, the following tools will be required:

- Laser or water level, level.

- Welding machine.

- A portable generator if there is no electrical connection point.

- Angle grinder for trimming the pile head to the design level.

- Two magnetic levels. It is allowed to use one.

- The drill is manual or driven by a hammer drill with dimensions = the diameter of the pile blades for the construction of pits.

- Round metal finger> 400 mm long, finger thick, 2.5-3 meters long for hand tightening.

- Two tape measures> diagonally long along the axes of the foundation of the house.

- Level marker and twine.

- Rebar pegs or round wooden pegs.

- Hammer for driving pegs, bayonet shovel.

Binding the pile field on the site

Binding to a section of the pile field according to the rules given below guarantees the correct design location and geometry of the foundation for the house.GOST allows the following deviations during the installation of products:

Deviation from the vertical no more than 0.1% of the length.

Axial deviation in one row The easiest way to screw the pile

Those who control the levels should try to keep the body of the product in an upright position or correct it by tilting. After 2-3 turns, it is necessary to stop, check the verticality with levels.

When submerged, the blades compact the soil above them, it becomes more difficult to correct the direction of approach

Therefore, it is important to twist vertically immediately.

The pile is rolled up to the design level. If there is not enough strength to twist, it is allowed to increase the length of the levers with pipes or crowbars.

Do not twist your head around the mounting hole.

Mount the second corner screw pile in the same way along this axis. Here, in addition to verticality, it is necessary to additionally take into account the calculated distance between the centers with the first pile. At the slightest deviation from the dimensions, tilt the pile in the direction opposite to the displacement, make 1-1.5 turns, align, check the size in the centers. If there is still a deviation from the dimensions, repeat the process with a tilt. It is important that all elements are mounted correctly and strictly in size.

When installing the next two corner pieces, the observance of the diagonal dimensions in the centers is added. Therefore, the process becomes more complicated, it is necessary to align at the same time in 2 planes

It is important not to rush, take measurements more often, correct deviations as described in paragraph 11.

After installing the corner pieces tightly, without sagging, pull the string over them. Use tape to mark the position of the remaining piles along the outer axes

Consider the geometric dimensions between the centers.

Mount the piles. The maximum permissible deviation from the axis of the heads should not exceed 1/3 of the body diameter, but try to avoid this.

- The last are marked out, the elements of the internal axes are installed.

See a detailed description of the process in the video: Instructions on how to tighten screw piles. Installation of the pile-screw foundation

Choosing a dive method

Specialized equipment will tighten the piles much faster

Specialized equipment will tighten the piles much faster

Manual pile installation requires physical strength, the pace of work is low, and the help of several people is needed.

This method can be recommended only when it is not possible to use mechanisms. The financial gain is in doubt, the savings arise from the free work of relatives and friends.

A somewhat more advanced solution is to use special gearboxes that convert the high-speed rotary motion of a hand drill into a slow but powerful turn. This equipment requires moderate rental costs, but will significantly reduce labor intensity.

Two men can handle a svayakroot

Two men can handle a svayakroot

The specialized equipment includes portable ply twists created for this type of work. Their price is higher, for qualified use an operator is required. The mechanisms are electrically or hydraulically driven.

The working body is attached to the pile head, after which it is installed vertically. The tool is fixed with a counterblock, blocking its rotation around the stand, and starts.

Two people are enough for the installation of piles, although usually the team consists of four or five, which allows you to effectively control the process and distribute efforts.

The best results are achieved with the use of specialized equipment that allows mechanizing the movement, positioning and installation of elements.

The best results are achieved with the use of specialized equipment that allows mechanizing the movement, positioning and installation of elements.

The working body that creates the rotational moment is powered by the hydraulic system of the platform, which can be used even by small tractors and manipulators.

Why this particular type of foundation?

Everything is quite simple and logical. It is not always possible to carry out the correct support of the building on the ground.Due to weather or climatic conditions, the physical properties of the soil are not at all suitable for building anything. Low bearing capacity, unstable bedding, permafrost zones and much more prompted new technical solutions over time.

As a result, the installation of a pile foundation favorably ensures the stability of the building in theory and in practice. How it works? In a nutshell, the transfer of loads from a building (house, summer cottage or cottage) is provided by more stable and dense soil layers located below.

Performing calculations

To do this, you need to invite a surveyor who will analyze the soil and draw a written conclusion about its bearing capacity. It will be quite expensive, but if you plan to build a house for permanent residence, you will have to spend money.

If we are talking about a small private house, then an approximate calculation of piles can be done without the help of specialists. You will have to take into account a lot of factors, such as:

- the weight of the roof and building structures;

- weight of thermal and waterproofing, roofing;

- the weight of the attic floor, etc.

Calculating the number of screw piles for such a house is quite simple. You need to go to the manufacturer's website (provided that it is the factory piles that are used) and see the bearing load for which specific products are designed. For a medium-sized pile with a blade diameter of 30 cm, this load is approximately 3500 kg. It turns out that for a house with a weight of 5 tons, 14 pieces are required. If the number of piles is inconvenient from a constructive point of view, then it can be increased, but only upwards.

Now a few words about the height of the piles. Their underground part is screwed in below the level of freezing of the soil, while the height of the aboveground one is selected based on the relief features (on average, it is 0.5 m).

What soils are they suitable for?

The immersion of screw piles is carried out to a sufficient depth to exclude the effect of vertical loads of frost heaving. Only lateral impacts remain, which, due to the small contact area, are not capable of exerting a decisive effect on the supports.

Therefore, when determining the suitability of the soil, it is customary to consider only the mechanical properties.

The most suitable types are the following types of soil (in descending order of suitability):

- Sandy.

- Sandy loam.

- Loams.

- Clay.

Rocky and rocky-clastic species are absolutely unsuitable soils. In addition, biogenic types are contraindicated - peat bogs, or loose subsidence soils.

Care must be taken when dealing with heavily watered areas subject to strong seasonal fluctuations in groundwater levels. During construction in such areas, it is necessary to carry out test drilling and increase the immersion depth to the maximum.

During construction in such areas, it is necessary to carry out test drilling and increase the immersion depth to the maximum.

Advantages and disadvantages of the pile screw foundation

Screw piles are now widely used in the construction of private houses, but before choosing a house on a screw pile foundation, it is necessary to study their positive and negative sides. The pluses include:

- strength due to the use of steel as raw material;

- durability, the service life of such a base can reach 150 years, subject to the manufacturing and installation technology;

- low cost of the product itself and its installation;

- simplicity and high speed of installation;

- the ability to use on terrain with difficult terrain, for example, on slopes;

- ensuring reliable operation on poor soils, such as sedimentary rocks, swampy areas;

- the ability to reuse if necessary.

Simplicity and speed of installation is possible due to the fact that:

- lack of preliminary soil development (digging trenches or pits);

- there is no need for complex special equipment;

- simplicity of technology does not require special skills and knowledge;

- unlike concrete foundations, you do not need to wait 4 weeks until the structure is fully ready.

All these positive characteristics made it possible to obtain mass distribution of screw piles, but do not forget about the negative aspects. Especially if you can prevent their consequences in time.

Pile screw foundation video

Pile screw foundation cons:

- corrosion of metal;

- limited bearing capacity;

- impossibility of installation close to the walls of an existing structure;

- the impossibility of arranging a basement in the house.

Corrosion can be avoided by treating the material with special compounds. With individual construction, there are no large loads on the foundation, so the second point does not become essential. With an impressive list of advantages, not a small number of disadvantages, which are rather operational features and are completely preventable, screw piles become an excellent support option for a private house.

General information

The foundation is the foundation, the basis of any building structure. The foundation makes the structure reliable and durable. For example, on buildings where the foundation was made by hand in an inappropriate way, serious problems begin with the integrity of the walls. The house simply collapses, and there is only one way out in such cases - the complete dismantling of the pile equipment.

The quality of the soil also seriously affects the reliability of the pile foundation. So, do-it-yourself strip foundations, operating on weak or uneven soils, can give a serious crack, which is completely unacceptable.

The same applies to columnar foundations, although they are screwed in and are not designed to withstand uneven loads. However, this does not apply to industrial columnar foundations that are mounted in special glasses.

At the same time, after improperly laying the foundation with your own hands, problems do not appear immediately, but begin only in winter, when the walls begin to crack due to frost. The house will automatically be declared emergency and will need immediate and very costly repairs.

Types of foundations

The installation of screw piles, although it is the most effective for a house, which must stand securely in winter and not sink into the ground, despite the frost, is far from the only one. There are several methods for creating a foundation:

- tape;

- columnar;

- slab;

- pile.

Foundation piles in the ground

Each of the listed types of foundation is correctly used, focusing on the specifics of the house being created, therefore, as mentioned above, for the foundation of the house with your own hands, which must be properly protected from cracks on the walls and subsidence into the ground in winter, use the pile method, performing it, in including screwing it mechanically.

Do-it-yourself piles are conveniently installed, they are able to withstand multidirectional loads and transfer them into the ground, no matter what structure it has.

The binding of screw piles with a grillage, after screwing them in, makes it possible to make all these elements a rather rigid structure, which has good plasticity.

How to screw in the latter - we will consider below.

Externally, the helical pile looks like a thick-walled metal correctly hollow pipe, having a pointed tip on one side and a tip similar to a helical blade on the other. Correctly screw the piles into the ground, deepening the screw tip directly into the ground. You can do this both with your own hands and with the help of technology.

To join the screw type of the foundation and the future house, a head is welded to the other end of this peculiar pipe, on which, in fact, the future building will be correctly fixed. The head is then connected to the grillage. It is necessary to make a kind of tying belt of the pile foundation.

Metal foundation pile

A grillage on piles can be made either in the form of connected monolithic beams or a solid slab. It all depends on the type of house, pile material, types of fasteners and several other factors. In some cases, the grillage can be made not reinforced concrete, but metal or even wooden.

Before screwing in the foundation, various design methods are used. A "step" is used, which is a special construction manual marking.

Using the screw method of laying the foundation with their own hands, builders are guided by the parameters of the future house

First of all, paying attention to the weight and type of structure of the house, as well as analyzing the depth of laying the foundation

Without such a detailed analysis of the upcoming construction work, the price of which is quite high, it will not work to lay the foundation for the house correctly, which should protect the building from frost in winter.

How hand twisting is done

When planning the manual tightening of screw piles, it is important to evaluate your own strength. Massive foundations for a large country cottage will require the involvement of technology

Small household buildings, a summer house or a veranda can be done by hand, the video will show the stages of such an activity.

Tools required for the work

Having decided to twist them yourself, you will need to prepare:

- Leg-split.

- Roulette.

- Metal fittings (rods).

- Scrap.

- Two pipes acting as levers.

Having decided to perform the work by twisting the screw piles yourself, first of all you will need to carefully consider their choice. Experts recommend giving preference to finished products made from reliable metal alloys by long-established manufacturers on the market.

Secure screwing in, performed only if the length of the metal reinforcement is calculated. They should reach a depth below the level of soil freezing.

Marking the pile field

When learning how to tighten screw piles with your own hands, it is important to determine the place of work and determine the area of future construction. Depending on the area of the base of the building being erected, the number of piles is determined

Pile field marking

Pile field marking

When marking finished piles, their bearing capacity must be indicated on the marking. Due to this, for the installation of the future structure, it will only be necessary to calculate their number based on these data. The calculations use data on the future specific weight of the structure being created and its dimensions.

The project, on the basis of which it will be possible to tighten the screw piles with your own hands, must take into account the following mandatory requirements:

- The distance between the supports should not exceed three meters, this will avoid the sagging of the strapping.

- They must be screwed in at the corners of the future structure and around its perimeter.

These conditions must be taken into account for the installation of supports and the future screwing in of screw piles with your own hands. Further, the installation of supports is carried out, which are connected with twine. Marking elements are checked using a building level.

How to carry out self-installation of screw piles further?

The work is still carried out with the help of at least one or two assistants. And also the work will be simplified by the simplest lever structure, also created with your own hands. To create it:

- The scrap is inserted into the hole that exists on the product.

- The length of the lever is increased by the pipes put on the scrap.

These screw supports will be used by two workers who manually tighten the screw piles. It is desirable for the owner of the future structure or one of his assistants to exercise control using a magnetic level. This check is performed several times during installation.The first level check is performed before the start of screwing and then it is advisable to carry it out after each 360 ° rotation. This will ensure vertical placement of the pile.

These screw supports will be used by two workers who manually tighten the screw piles. It is desirable for the owner of the future structure or one of his assistants to exercise control using a magnetic level. This check is performed several times during installation.The first level check is performed before the start of screwing and then it is advisable to carry it out after each 360 ° rotation. This will ensure vertical placement of the pile.

The procedure for screwing in piles using improvised equipment

The use of improvised equipment will help to facilitate the process and screw your own reliably. To do this, it is enough to find out how to screw a screw pile with your own hands using a drill and a minimal additional set of tools.

In this case, tightening will require:

- Drill.

- Gear wrench.

- Bolts and durable fasteners.

To increase rigidity, a channel gasket can be used to increase rigidity and prevent deformation. In this version of the work, it is also problematic to tighten the screw piles alone. It is advisable to perform work with the help of 2-3 assistants. In such a situation, a specialized machine is not required and it can be screwed in reliably and quickly.

The use of a drill and a gearbox accelerates the screwing of screw piles into the ground

When screwing in screw piles using the technique, it is important to control the vertical screwing of screw piles using a magnetic building level

What depth is it important to immerse the supports

When creating this foundation, an important role is given to the immersion depth of the screw supports. Introduced into the soil by screwing, they are twisted until the moment when the soil begins to provide maximum resistance when the piles are inserted. Work continues until the equipment allows you to continue screwing in the pile. If the work is stopped earlier, the lack of load on the dense soil layer will cause a possible subsidence of the foundation under the weight of the structure.