The ultimate design goal

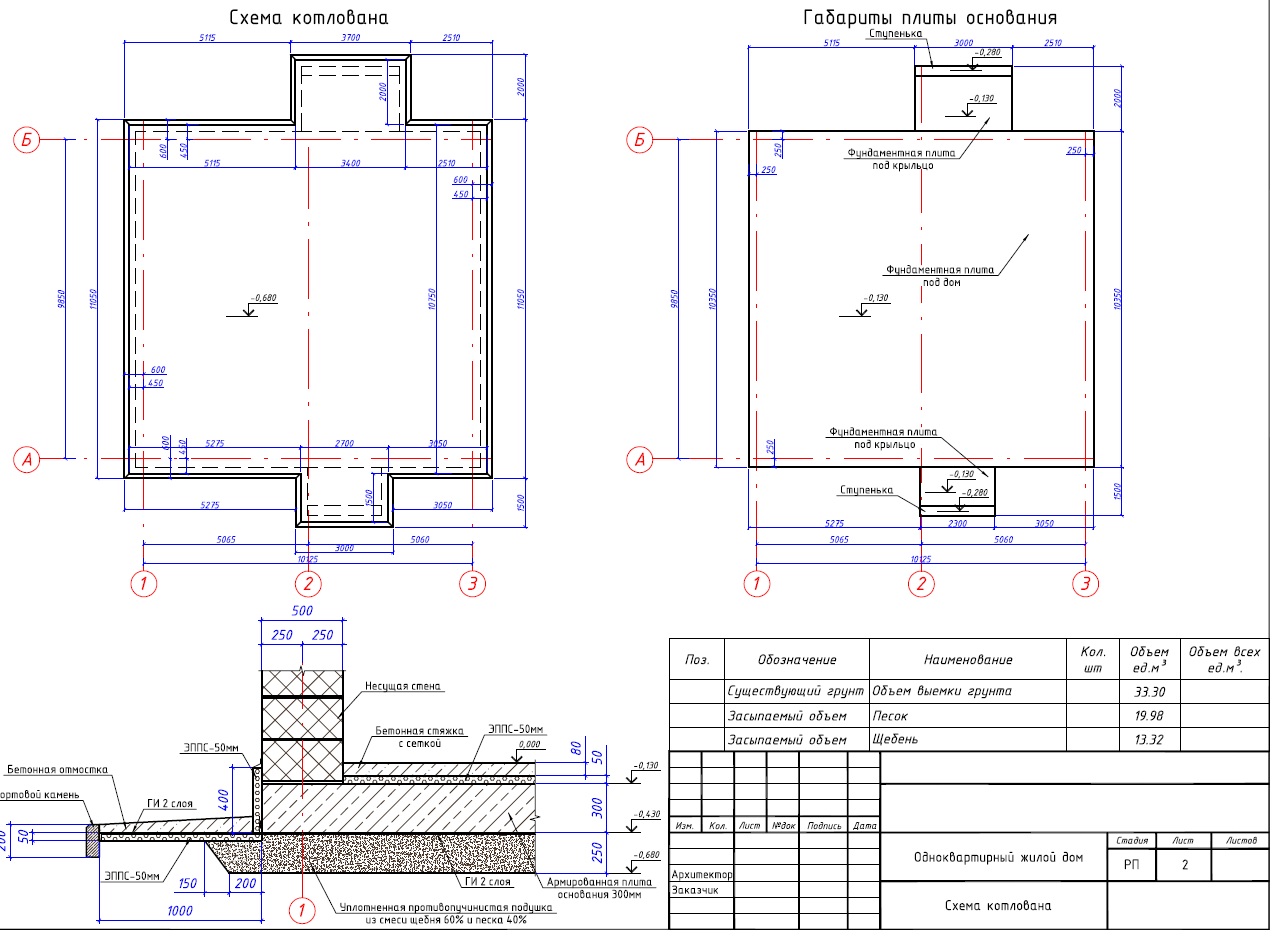

The design result should be:

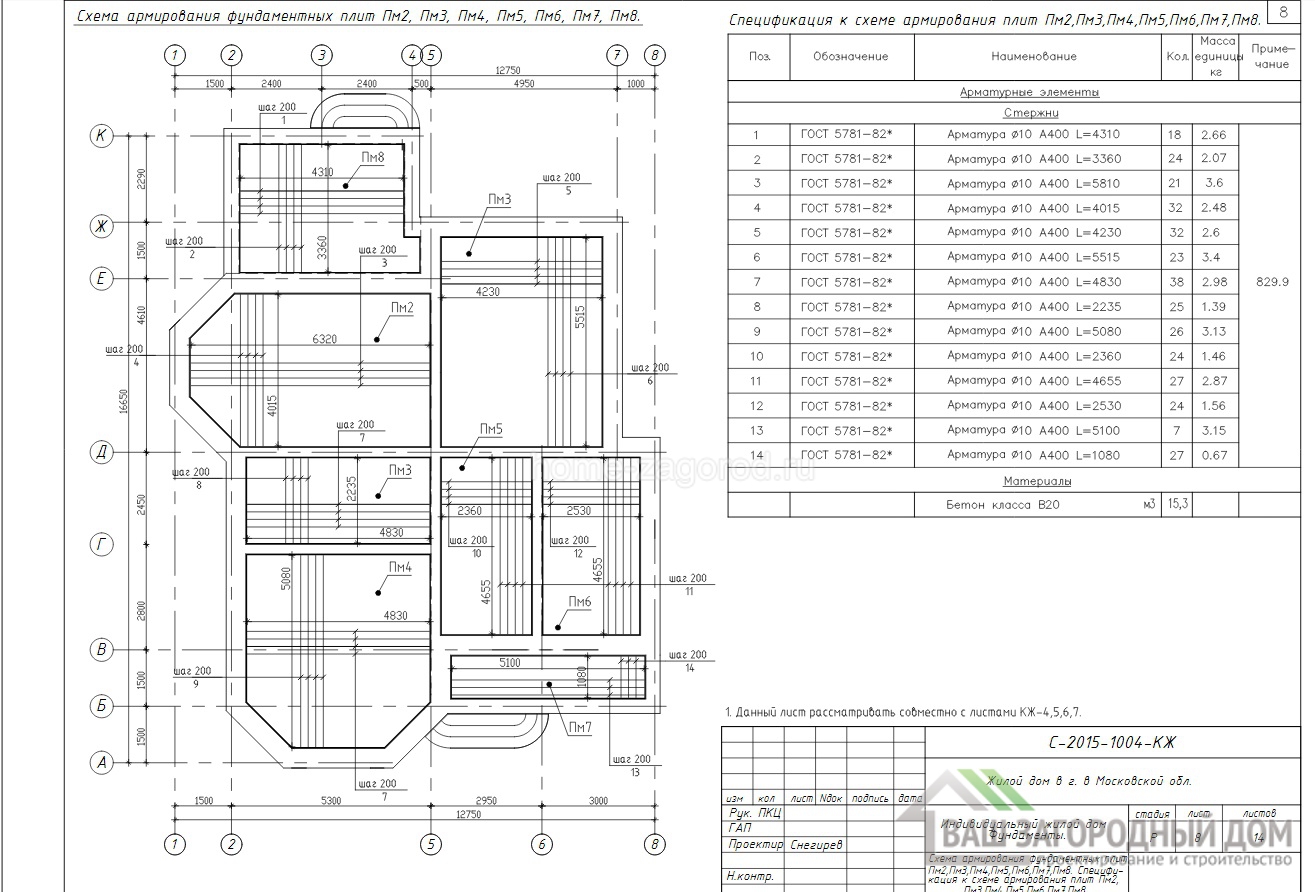

- assembly drawing of a monolithic foundation;

- text documents - calculations and justification of the project;

- foundation marking plan and linking it to the terrain;

- the plan of the excavation pit;

- formwork construction plan;

- plan for the placement of materials at the construction site;

- delivery plans and concrete pouring agreed in time.

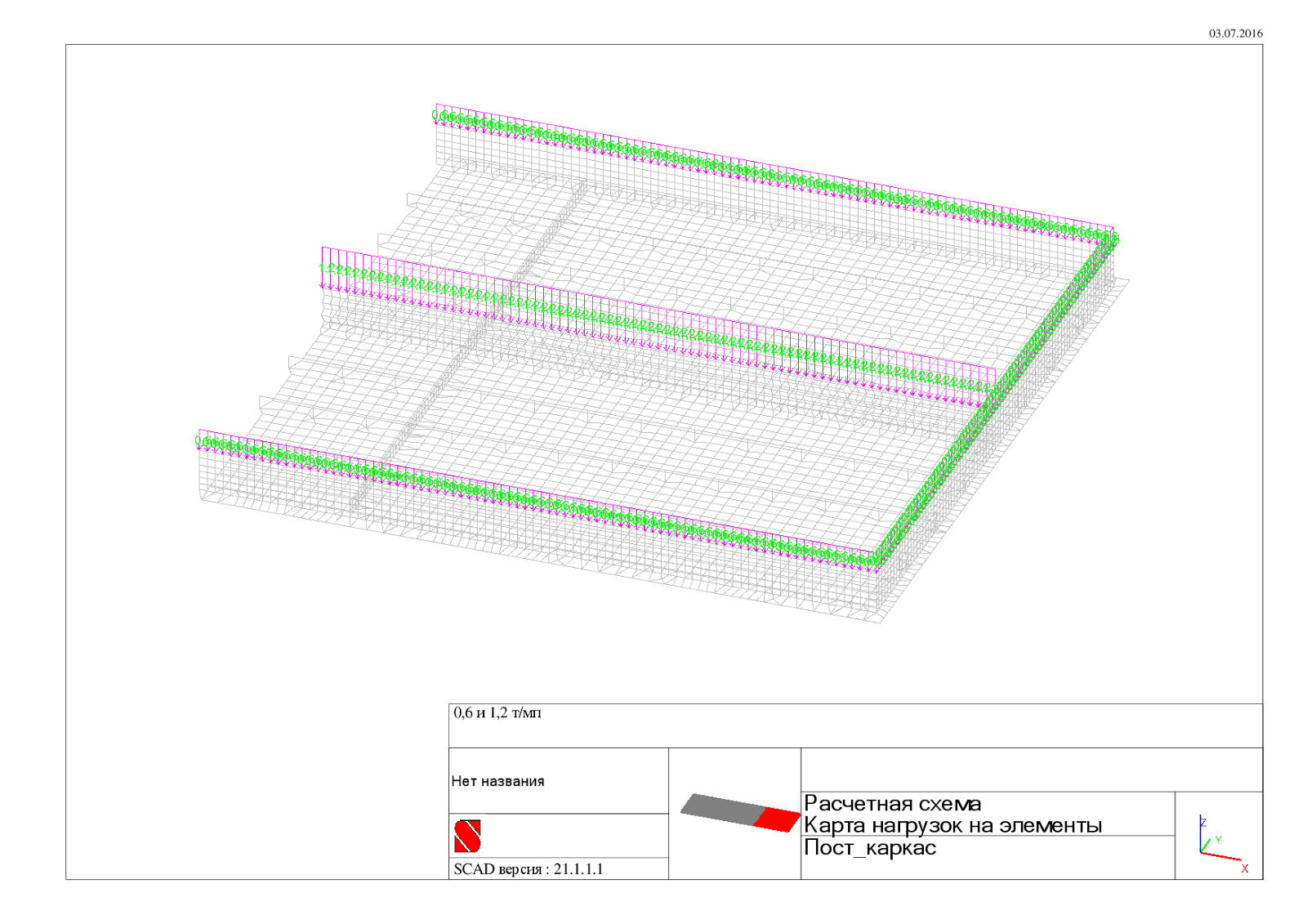

The calculation of the foundation slab can be carried out by the finite element method.

But the easiest way to calculate the foundation slab is using a calculation calculator. It contains all the necessary formulas and techniques.

Some calculators help to calculate the required amount of sand, cement, crushed stone, the total amount and cost of materials.

Based on the results of the calculations, an assembly drawing of a monolithic foundation and all detailed drawings are developed:

- embedded parts;

- assembly drawing and detailing of the reinforcing cage;

- calculated layout of finished wireframe meshes;

- an exemplary device for disposable formwork from boards or a device for metal reusable formwork and a diagram of its use, etc.

We calculate the slab foundation

The most important point in the calculation is to determine the thickness of the building base plate. The complete and most accurate calculation is performed by a professional builder with an appropriate level of knowledge and design experience. But this takes time, money and a professional. For a private non-professional developer with a slight excess of material consumption and less accuracy, a simpler calculation of the foundation slab may be sufficient.

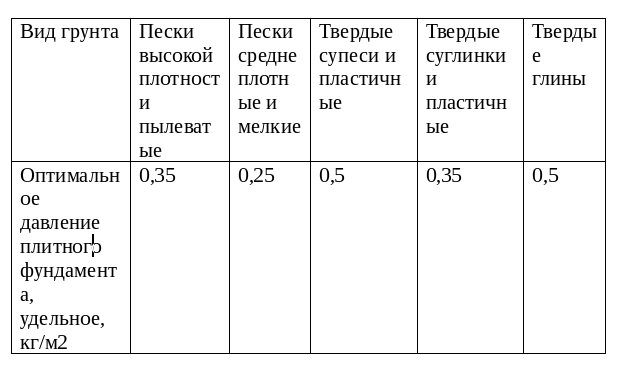

1. The calculation begins with determining the type of soil under the future building.

For example, you have fine sands with medium density. They withstand a specific foundation pressure of 0.35 kg / cm2.

Soil type definition table

Soil type definition table

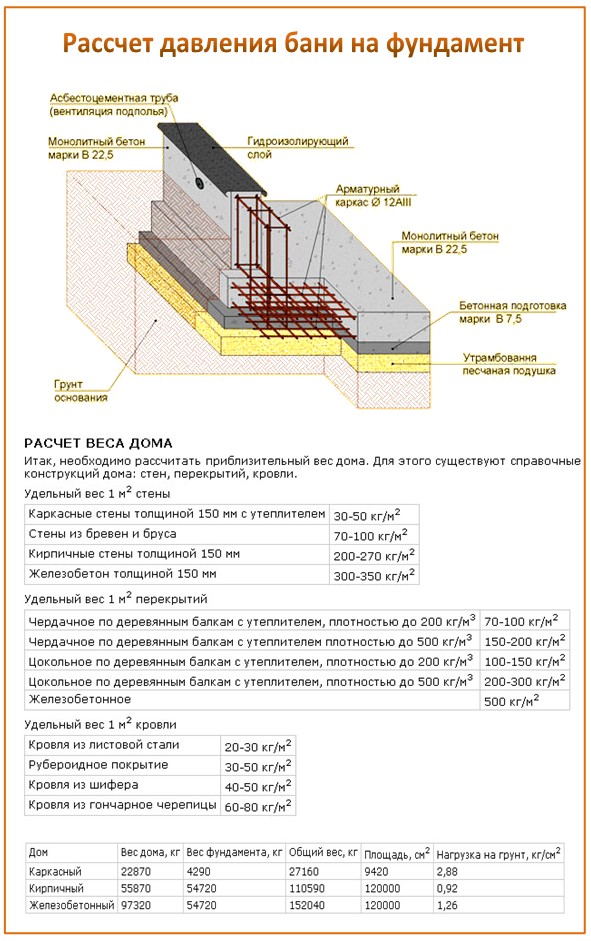

2. We calculate the total mass of the future home

- Knowing the dimensions of the house, the location of windows, doors, openings, the material of the walls, floors, their configuration and the thickness of the structures and, taking into account the specific gravity of the materials, we determine the weight of individual parts of the building.

- Summing up the found values, we get the total mass of the building.

- Having the area of the building, we calculate its snow load associated with the angle of inclination of the roof and the region of construction.

Calculation of slab foundation

Calculation of slab foundation

3. We calculate the specific pressure of the building on the ground

The calculated total mass of the building is divided by the area of the monolithic foundation slab. We get the specific pressure of the building on the ground (without the weight of the foundation). Determine the required weight of the slab.

4. We calculate the optimal volume and thickness of the foundation

We divide the mass of the slab by the density of reinforced concrete, which is approximately 2500 kg / cubic meter. m. Divide the volume by the area of the slab, we get its thickness.

5. Round off the resulting thickness

We round the resulting thickness to larger and smaller values, multiples of the size of the building step of 50 mm. We choose a suitable value and, taking it into account, we recalculate the mass of the foundation slab. Adding the resulting mass with the mass of the house, we calculate the specific pressure on the ground.

Then we compare the obtained figures with the tabular characteristics of the site soil. Spread should be less than ± 25%.

Monolithic foundations

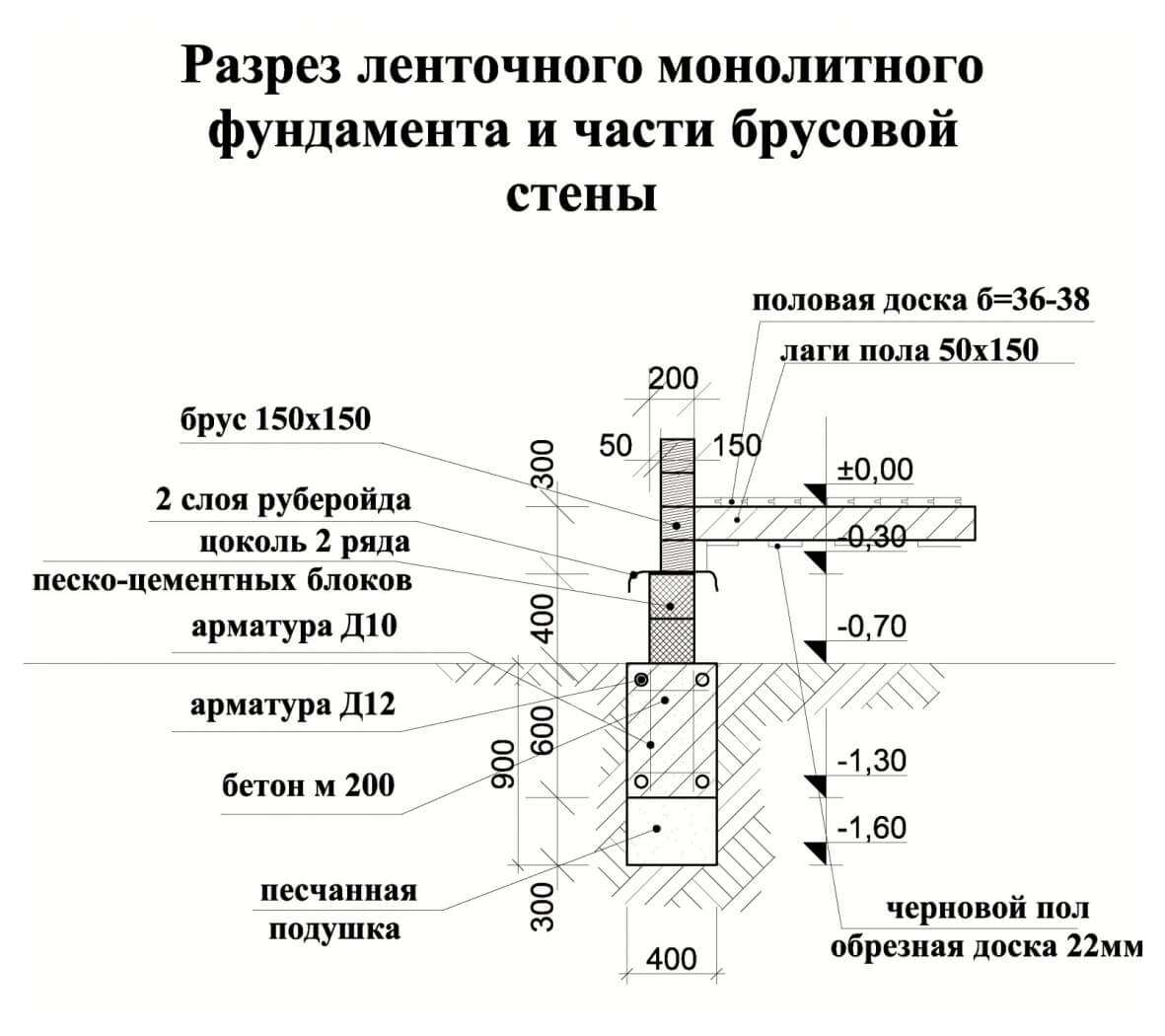

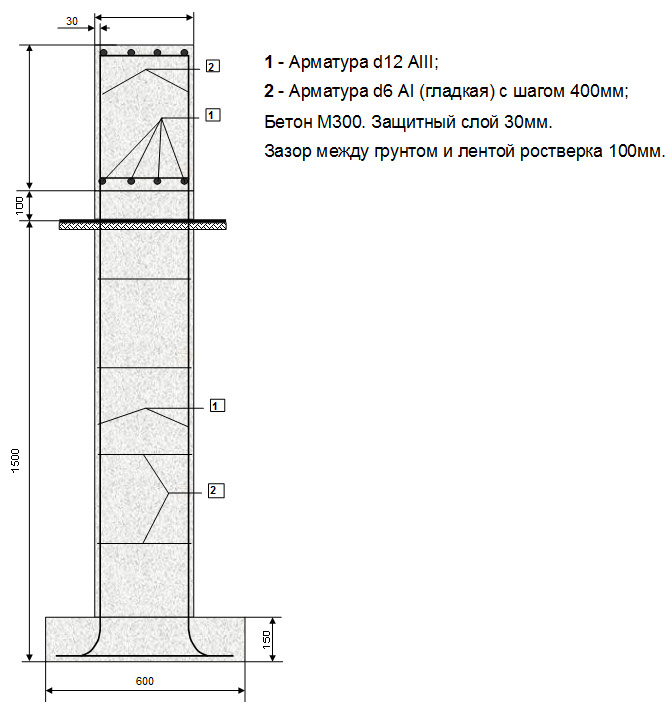

Monolithic tape base

Monolithic tape base

The main characteristic advantage of monolithic reinforced concrete is the spatial integrity of structures. In order to comply with the technology of installing a monolithic foundation, you need to try to concreting the grips without interruption.

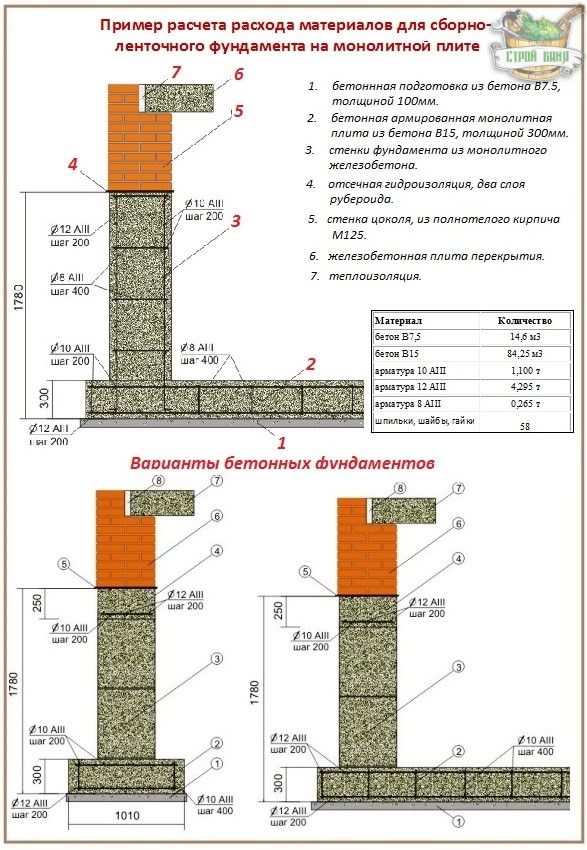

To do this, you need to organize a timely supply of the mixture - prepare it on the site, or order it at the nearest BRU or reinforced concrete plant. In addition to the consumption of the solution, it is necessary to calculate how much reinforcement is required.

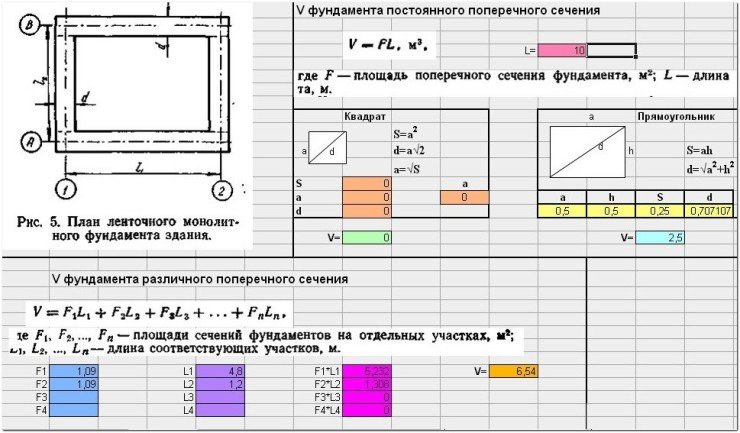

Calculating the volume of concrete

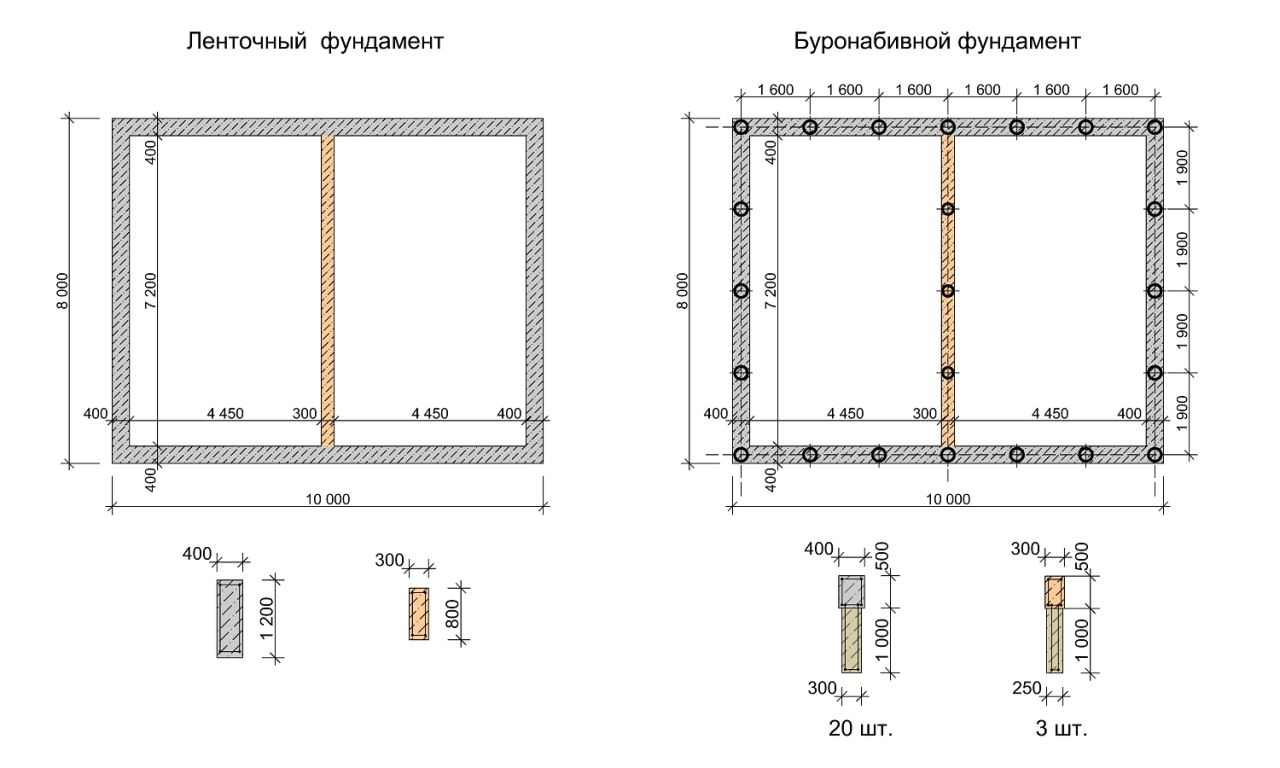

To calculate the volume, you should divide the body of the future foundation into grips, which are the simplest geometric shapes and use mathematical formulas to calculate their volume. The volume of the strip foundation is calculated as the sum of the volumes of the parallelepipeds enclosed in the perimeter of the house.

Competent calculation of concrete is the key to fast construction

Competent calculation of concrete is the key to fast construction

The height of the foundation slab should be taken into account together with the part protruding above the ground. The pile volume is calculated as the volume of a symmetrical cylinder. The main parameter affecting the volume of the mixture is the shrinkage of the solution. For high-strength concretes starting from the M12 grade, which are recommended for use when constructing foundations, this indicator is Ky = 1.05.

This factor takes into account the concrete stock taking into account the instantaneous shrinkage of the mixture. You can clarify the shrinkage coefficient in the assortment of concrete mixtures or directly from the manufacturer. When making a concrete mix by hand on the site, you need to purchase the estimated amount of the components of the solution with a significant margin.

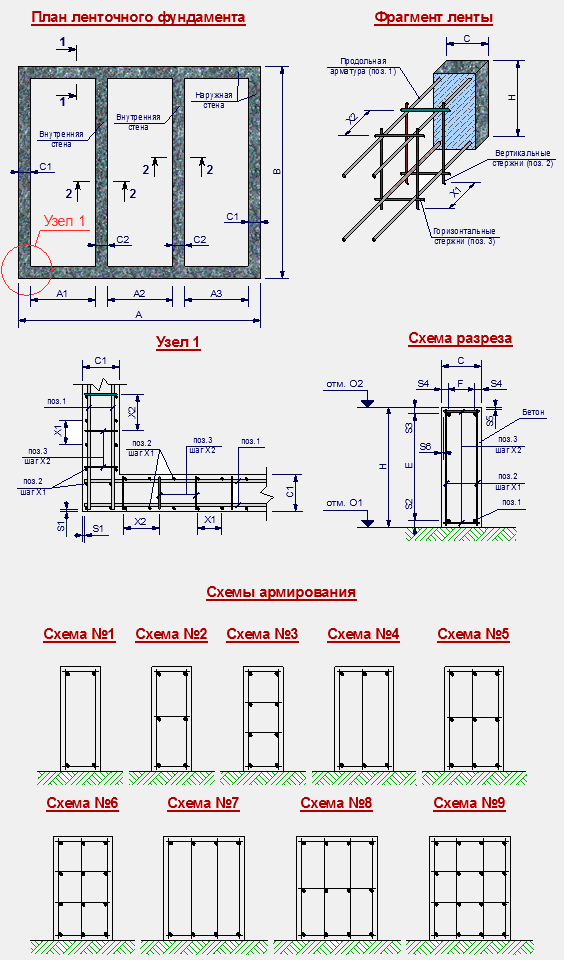

Calculation of the number of reinforcement

The number of reinforcement is calculated taking into account the reinforcement cage diagram. Typically, suppliers sell rolled material by volume or weight, making it difficult to determine the exact amount. Determine the amount of longitudinal reinforcement to be laid on a meter section of the frame, and then multiply this value by the total length of the building perimeter. Consider the fact that the inner perimeter of the foundation trench is smaller than the outer, so calculate the length according to the total length of the center line.

The number of reinforcement is calculated taking into account the reinforcement cage diagram. Typically, suppliers sell rolled material by volume or weight, making it difficult to determine the exact amount. Determine the amount of longitudinal reinforcement to be laid on a meter section of the frame, and then multiply this value by the total length of the building perimeter. Consider the fact that the inner perimeter of the foundation trench is smaller than the outer, so calculate the length according to the total length of the center line.

The amount of transverse reinforcement to be laid will depend on the spacing of the rods and the height of the foundation slab. To calculate you need:

- Divide the length of the perimeter of the house by the step of the reinforcement - for example, the perimeter is P = 20 m, and the step is 0.5 m, we get a value equal to 20;

- Calculate the length of one transverse reinforcing ring - for this add the height of the foundation with the width and multiply the sum by two;

- Multiply the values obtained in the first and second paragraphs - this number will be the desired value.

Watch the video on how to correctly determine the amount of reinforcement for strip bases.

The sum of the lengths of the longitudinal and transverse reinforcement is multiplied by the mass or volume of one meter of the reinforcing bar with the required parameters (thickness, steel grade). You can find the mass in the assortment of rolled steel products. The recommended stock of reinforcement should be at least 5% of the total - it takes into account the costs of cutting reinforcement. To calculate how much composite reinforcement you need, you should follow a similar scheme.

Calculation of materials for the foundation (calculator) - determine the need for cement

When preparing a concrete solution, cement of various brands is used as a binder. The strength, reliability and service life of building structures depend on the characteristics and amount of Portland cement introduced into the concrete mixture. When calculating the material for the foundation, the calculator, which is a special program, processes a set of initial data and provides information on the need for cement for the foundation foundation.

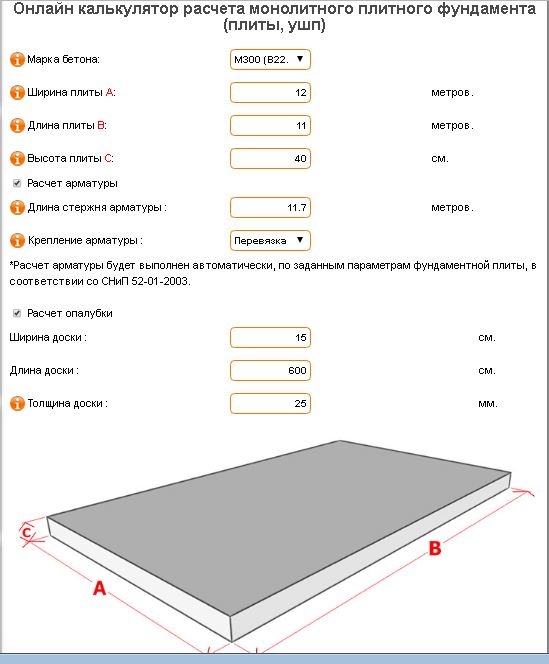

Monolithic Foundation Slab Material Calculator

Monolithic Foundation Slab Material Calculator

Based on this ratio, the number of different brands of cement is determined per one cube of concrete:

- M100 is used in the amount of 160-200 kg;

- M150 requires 200-220 kg;

- M200 is added at 240-280 kg;

- M250 is introduced at 300-330 kg.

With an increase in the grade of Portland cement, its amount in a cubic meter of concrete composition increases and is:

- M300 - 320-380 kg;

- M400 - 400-420 kg;

- М500 - 510-530 kg.

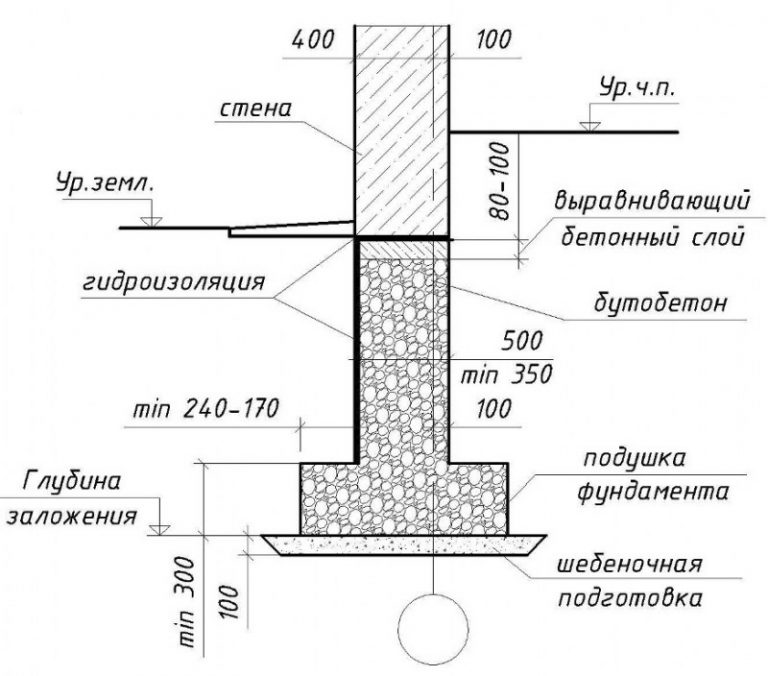

Calculation for strip foundation

Calculation of the depth of the foundation.

First, you need to find out several parameters: the width of the walls, the height of the fill, the perimeter of the room of the future structure; these data are needed to determine the volume of the casting.The height of the base should correspond to the following formula: F≥Z + 10 cm, with Z ≥ L, where F is, Z is the depth of the column embedment into the glass, and L is the anchorage length of the prestressing reinforcement.

The volume of the casting is recognized as follows:

- Casting volume = the width of the walls is multiplied by the perimeter of the room and by the height of the casting.

- Internal volume = width and length of the foundation multiplied by the height of the casting. The volume of the casting is subtracted from the result obtained (we get the volume for the filler).

- ... First, the area of the side surfaces is found: the perimeter is multiplied by two and by the height of the casting. Next, the area of one board is calculated: the width of the board is multiplied by its length. The number of boards = the area of the side surfaces divided by the area of one element.

Foundation trench.

For example, a strip foundation (rectangular shape) has a length of 10 m, a width of 3.5 m, a casting height of 20 cm, a belt width of 18 cm.To determine the volume, as mentioned above, you need to multiply the width of the walls by the perimeter premises and to the height of the casting (27x0.18x0.2 = 0.972). Next, it's up to determining the volume of the inner part. Multiply width and length strip monolithic foundation to the height of the casting: (3.5x10x0.2 = 7). Subtract the volume of the casting from the result obtained (7-0, 97 = 6.03). 0.93 is in our case the volume of the casting; 6.03 m³ is the volume for the aggregate.

Now let's calculate the amount of reinforcement that is needed for reinforcement. Suppose we will lay two rods (12 mm) horizontally and one vertically every half a meter, with a perimeter of 27 m we will get 54 m of reinforcement horizontally. Vertical: 54/2 + 2 = 110 pcs.; plus the elements for the corners, which means that there are a total of 114 rods. With their height of 70 cm, we get 0.7x114 = 79.8.

The last stage is the calculation of the formwork. It is built from boards, here are the standard values: thickness - 2.5 cm, length - 6 m, width - 20 cm. The area of the side surfaces: multiply the perimeter by 2 and by the height of the casting (2x27x0.2 = 10.8 m²). Next, calculate the area of one board: multiply the width of the board by its length (0.2x6 = 1.2). We obtain the number of boards by dividing the area of the side surfaces by the area of one element (10.8 / 1.2 = 9 boards).

Another formula for! The area of the centrally loaded base = the standard load from the base to the rack divided by (design pressure minus the average load from the unit of the foundation and the soil on the foundation ledges) multiplied by the depth of the foundation).

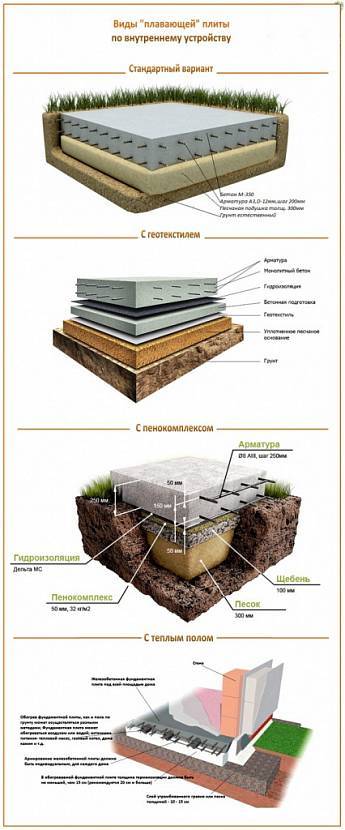

What is a slab foundation?

People at all times tried to build their house on a solid stone foundation. It was this approach that gave reliability and durability to the constructed buildings. And it was he who led to the design and construction on slab foundations.

People at all times tried to build their house on a solid stone foundation. It was this approach that gave reliability and durability to the constructed buildings. And it was he who led to the design and construction on slab foundations.

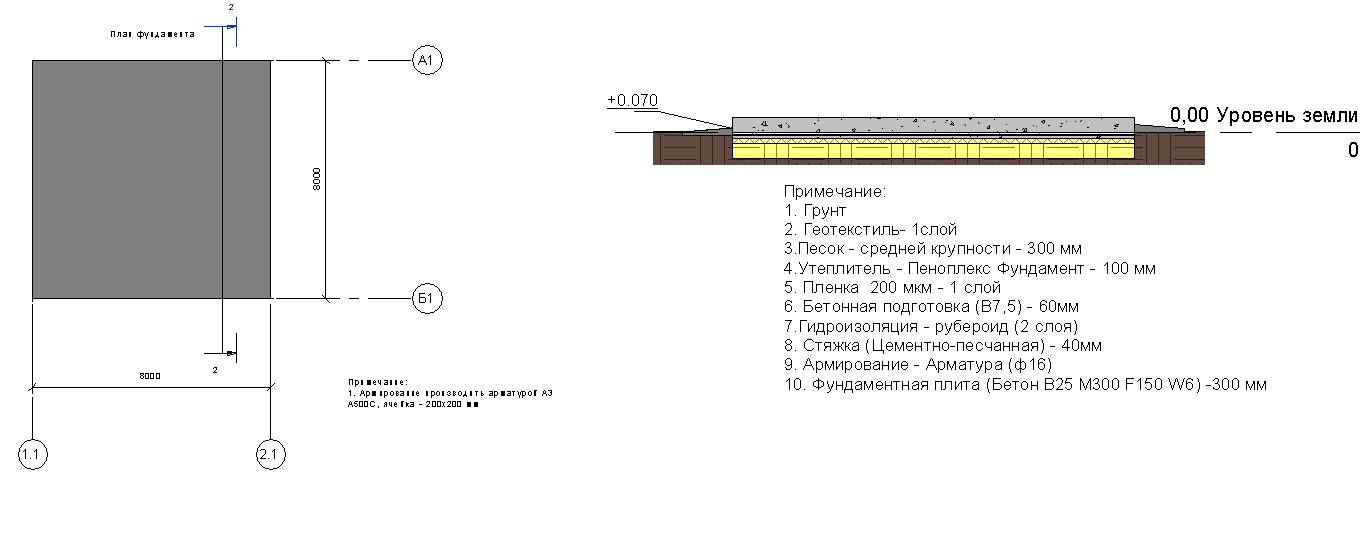

It is customary to call a slab foundation a foundation structure for a building, which has the form of a reinforced concrete monolithic slab located within the boundaries of the building perimeter, and more often slightly extending beyond them.

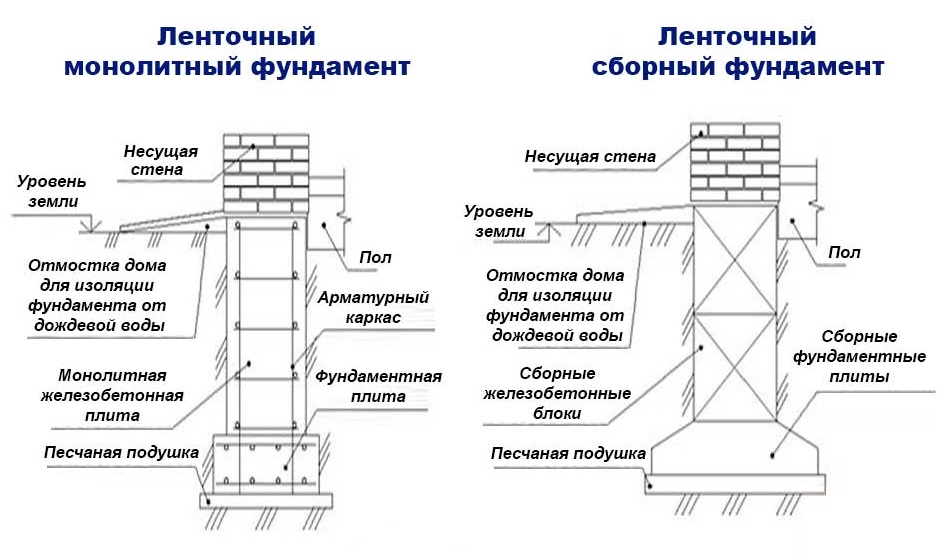

There are two types of such foundations:

- prefabricated, assembled into a single plate from ready-made factory blocks or plates;

- monolithic, made directly at the construction site and representing a one-piece rigid structure made of reinforced concrete.

the slab is constructed from ready-made reinforced concrete slabs produced at ZZHBI - a plant of reinforced concrete products. For manufacturing, plates of the type can be used:

- PD - road slab;

- PDP - road surface;

- PDG - road with corrugated surface;

- PDN - road with stressed reinforcement;

- PAG - airfield and many others. dr.

The prefabricated slab foundation holds the load well on dry, solid and non-porous soils. And they work best on soils with a fine or coarse stone structure. For this type of base, a shallow depth of soil freezing is desirable. Therefore, prefabricated slabs are more often used for construction in the southern regions of the country, where the soil does not freeze or the depth of freezing is insignificant.

But once the sandy loam, clay, and especially the loess soil gets a little wet, for example, from melting snow or prolonged autumn rains, the subsidence of individual slabs immediately begins and after that the walls and ceilings of the house crackle.

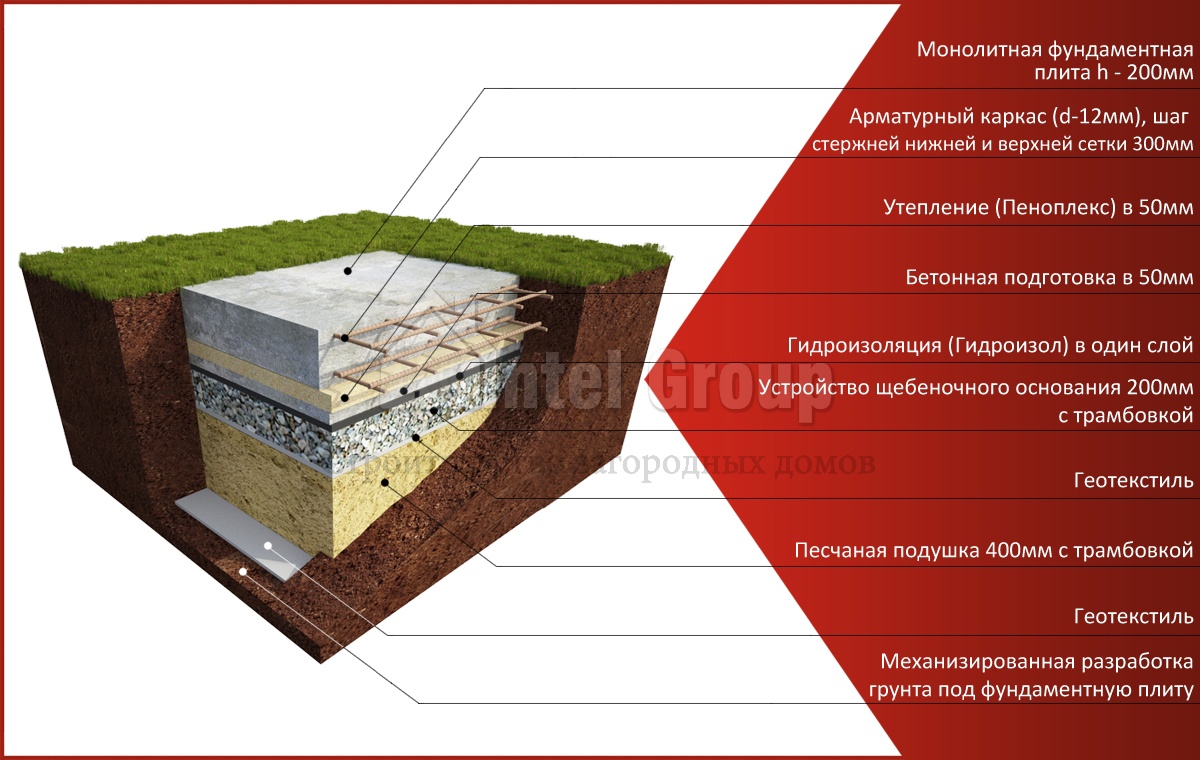

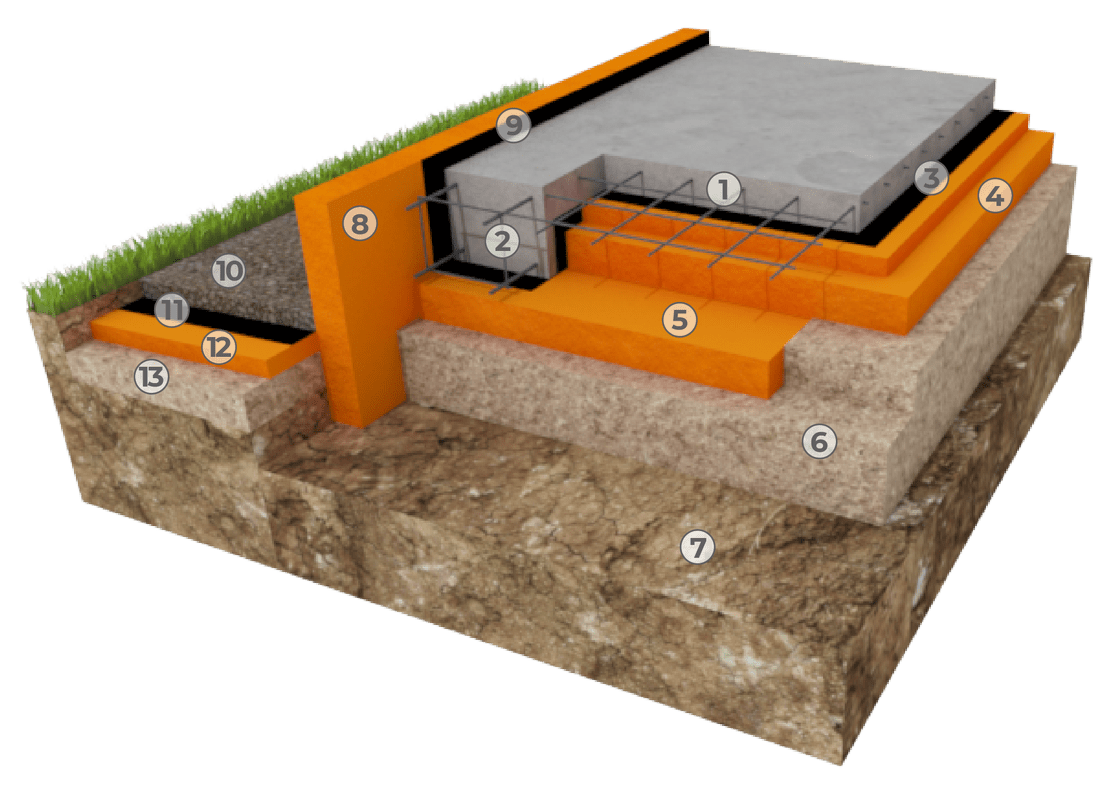

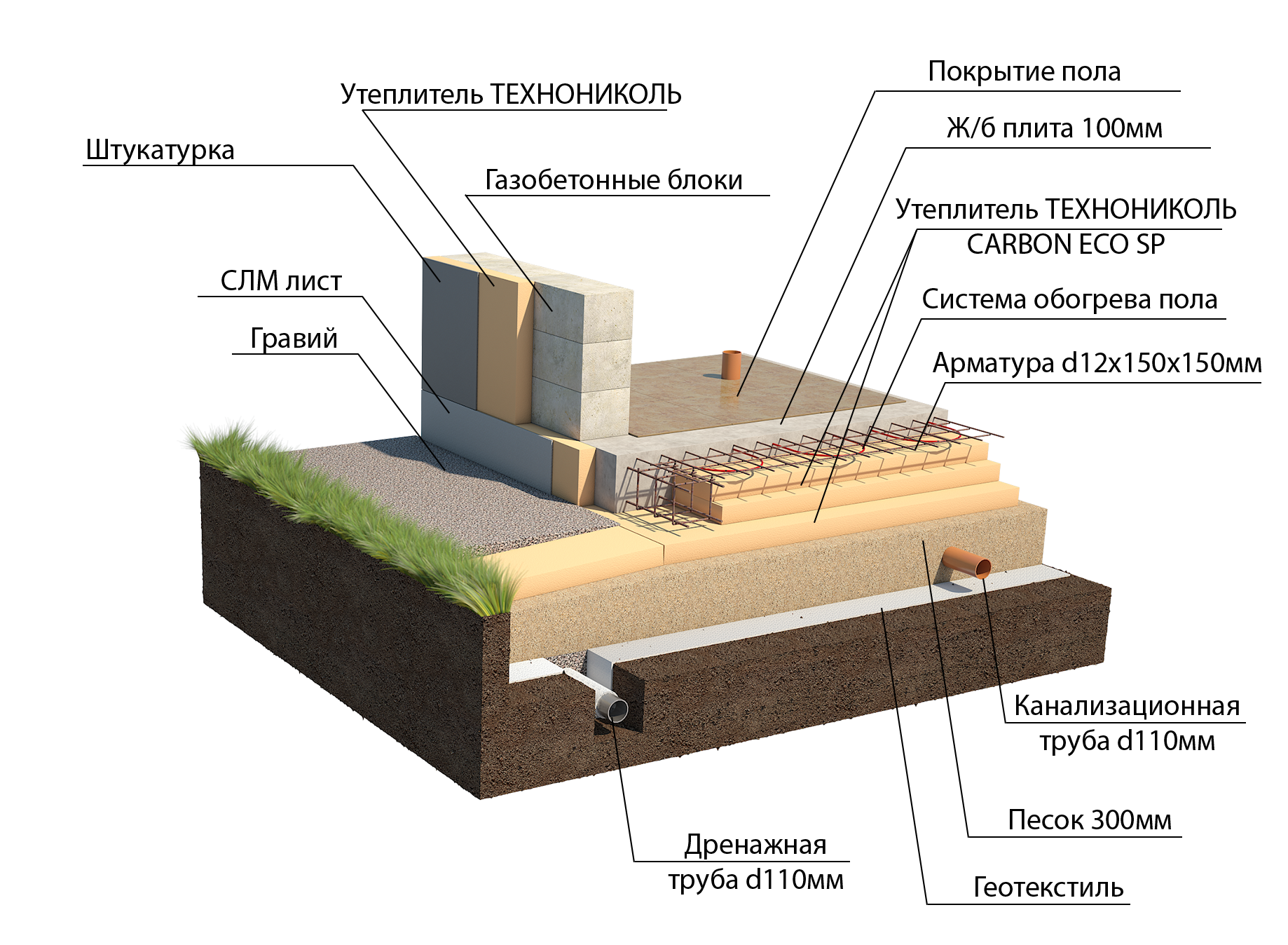

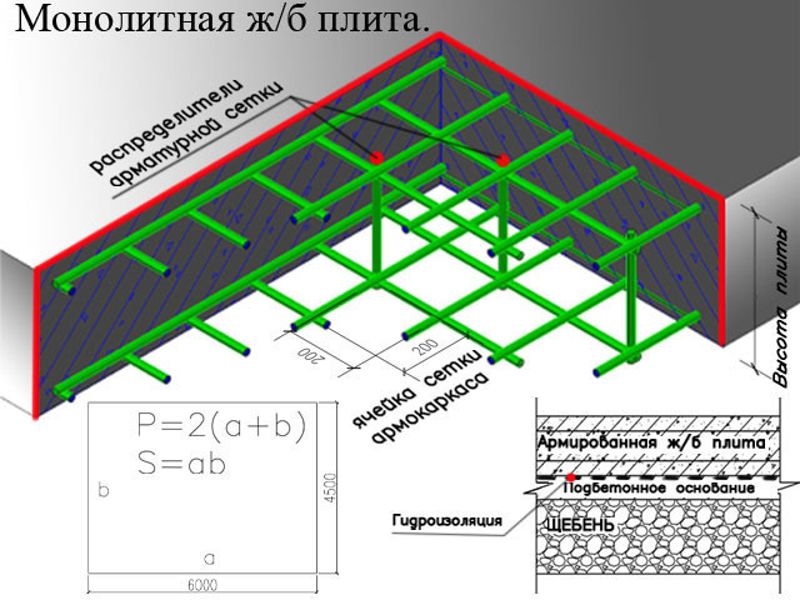

- Slab is a huge artificial flat stone of high strength. The compressive strength of the monolithic foundation is ensured by using the appropriate grade of concrete, and the bending strength is ensured by its reinforcing cage.

- The structure of the frame is made of reinforcing bars of the required diameter and steel grade, using the data of GOST 5781. The frame can be made of composite materials - glass or carbon fiber. Part of the composite reinforcement is made on the basis of basalt fiber.

- On site, the steel frame is electrically welded or tied with soft steel wire. A composite frame is only knitted with wire, in the same way as a steel one.

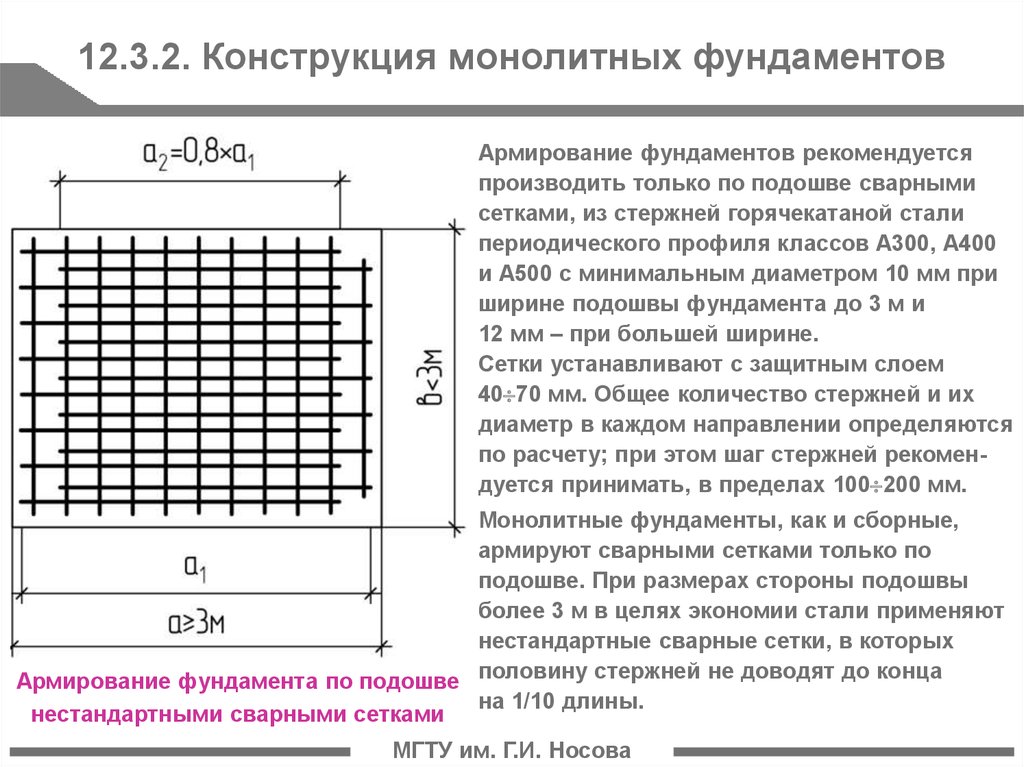

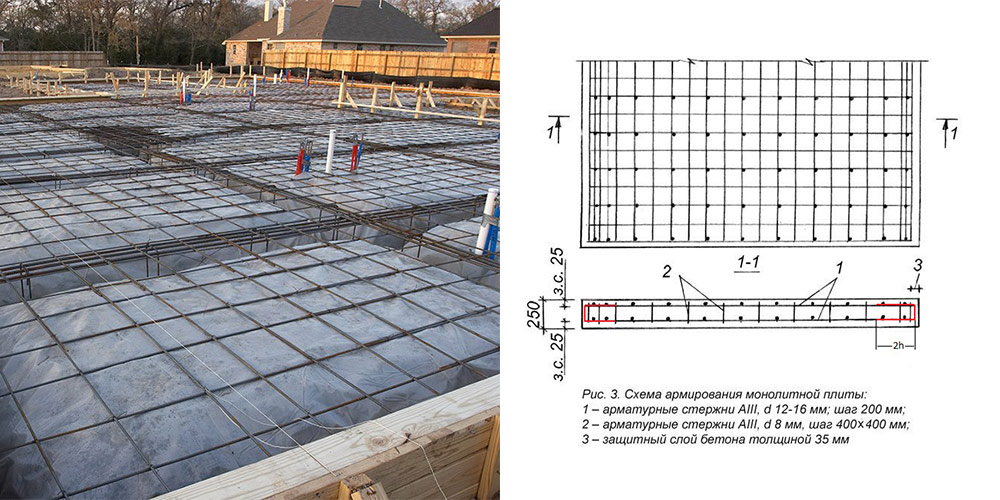

- The reinforcement cage has the form of a spatial structure in which the reinforcement is located in mutually perpendicular directions and forms two planes in the form of horizontal meshes. Its scheme is determined during design.

- The cell size of these grids is calculated during the design and is in the range of 200 x 200 - 300 x 300 mm. The fittings are used with a diameter of 12 - 16 mm.

Types of slab foundations

Types of slab foundations

The frame is installed on plastic "chairs" - supports. Their height provides an exact distance from the bottom and top planes of the foundation, and is 50 mm. The frames are mounted so that the distance from their edges to the formwork is also 50 mm. When pouring and compacting concrete, this gap forms a special layer that protects the reinforcement cage from corrosion. After the concrete has hardened and the strength set by the calculation in the design is set, the monolithic foundation is ready for the construction of the building.

Prefabricated foundations

Precast foundations are fast and easy to install. For columnar, shallow and shallow foundations from small-piece products, interruptions in work are uncritical and you can always buy the missing amount of material. Large-block foundations require heavy equipment to be hired, and most contractors work on an hourly basis. Lack of material means additional costs to compensate for downtime or additional calls for the crane, slinger and installer.

We recommend that you watch the video that shows how to use the online calculator to determine the number of blocks for a base.

Prefabricated strip foundations, as well as serial piles are purchased in accordance with the project for the construction of the supporting structure. The number of piles depends on the calculation of the bearing capacity, but the number of prefabricated tape blocks is more difficult to calculate. Depending on the design of the blocks, the stacking scheme will change, as well as the standard sizes of piece elements - in accordance with them (and also taking into account the mortar joint b = 5-10 mm), the number of blocks is considered. Usually, the project includes drawings with the layout of the foundation blocks, since this is an important design element.

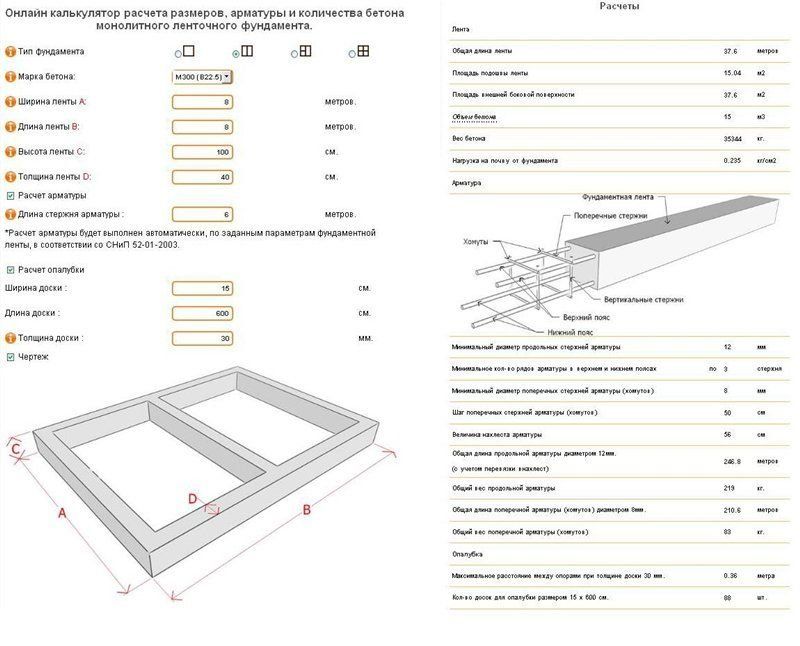

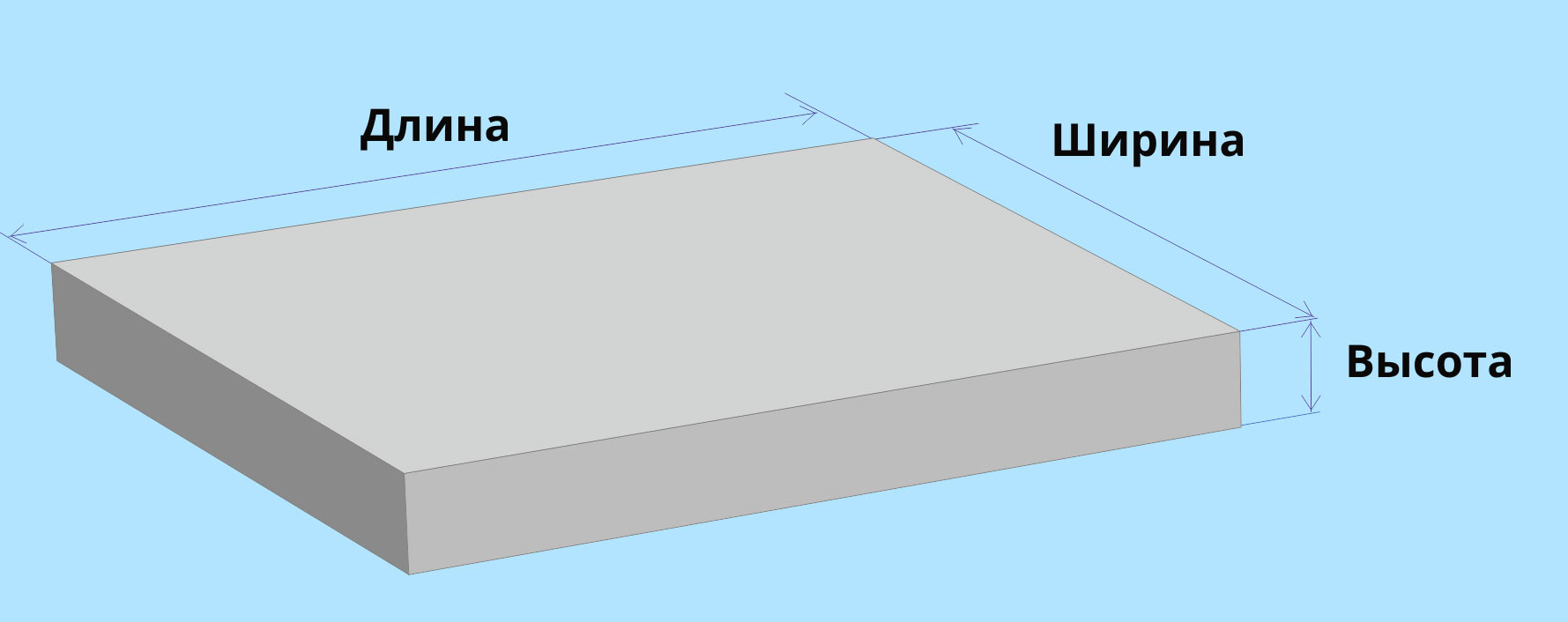

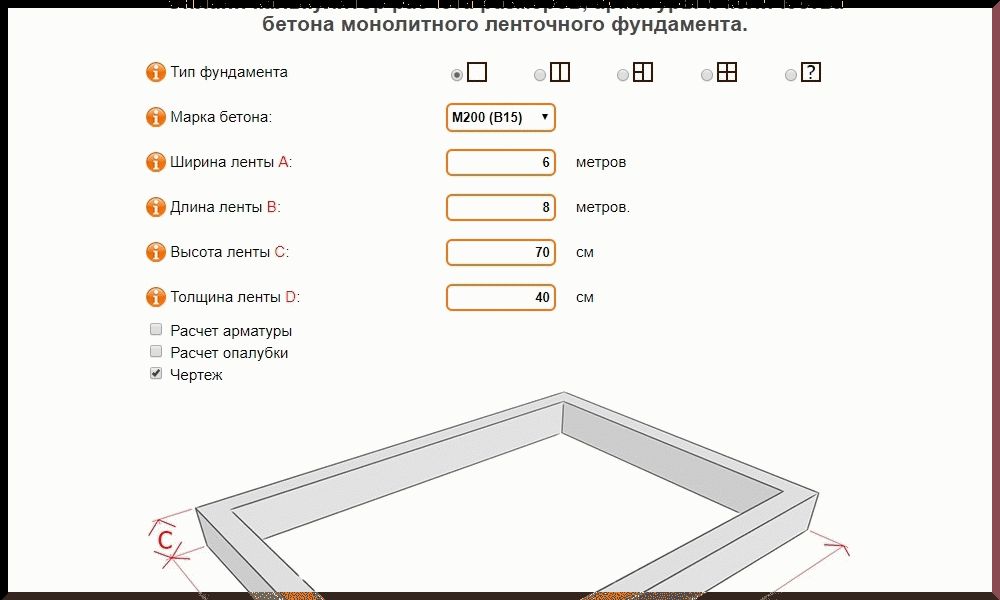

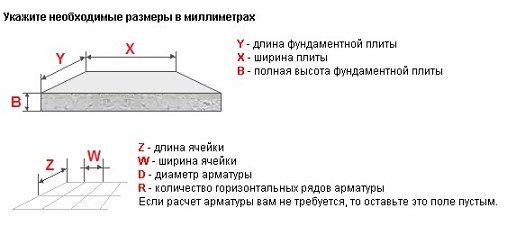

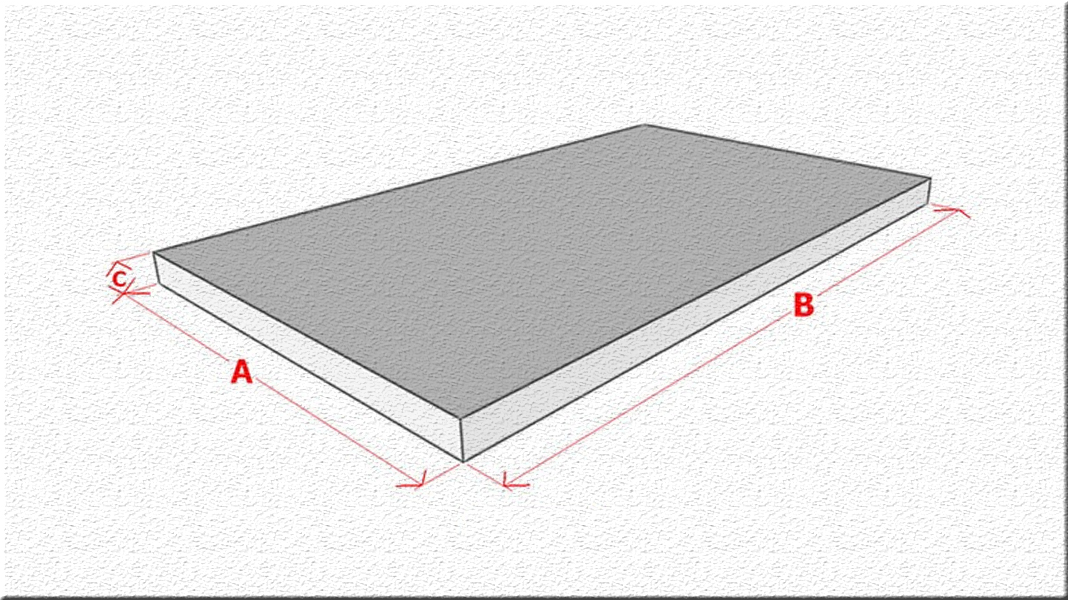

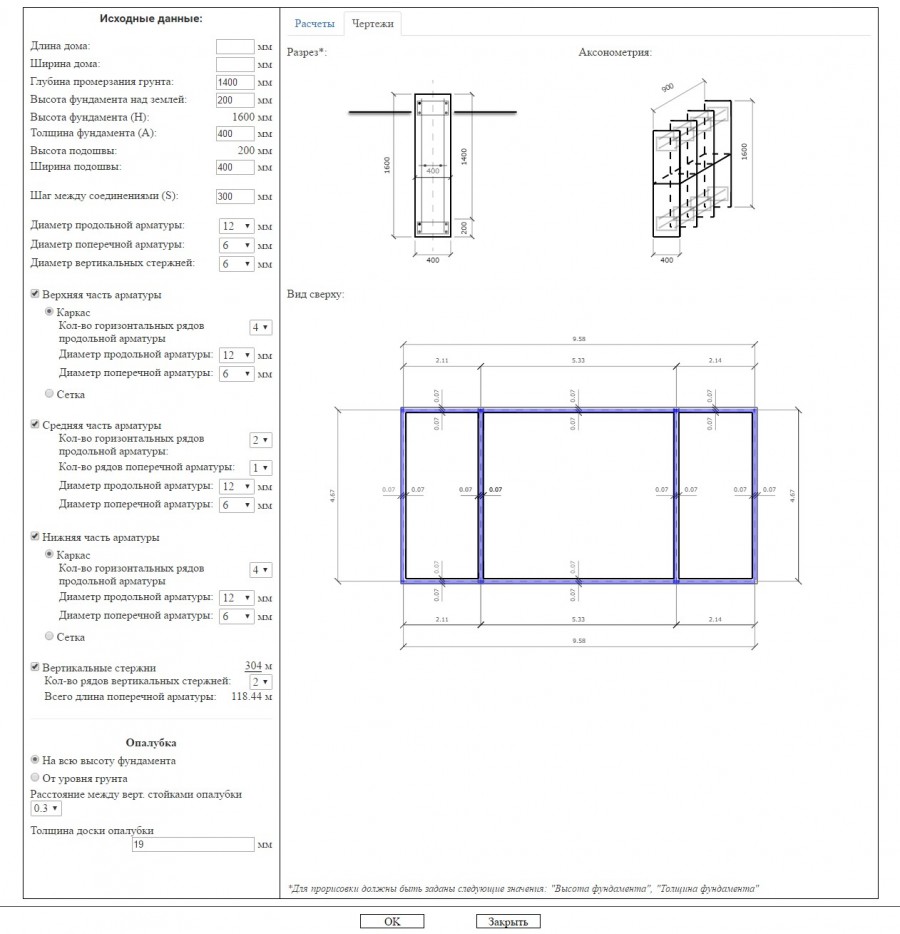

Instructions for the calculator for calculating the slab foundation

Specify the required scale of the drawings.

Fill in the dimensions in millimeters:

X - The width of the foundation is determined by the width of your house, taking into account the bearing capacity of the soil.

Y - The length of the foundation, like the previous parameter, depends on the dimensions of the house.

H - The height of the cross-section (i.e. the thickness of the slab) is selected taking into account the nature of the soil, the depth of the laying and the loads acting on the base during operation. The H value is taken in the range of 150-400 mm (recommended - 250 mm).

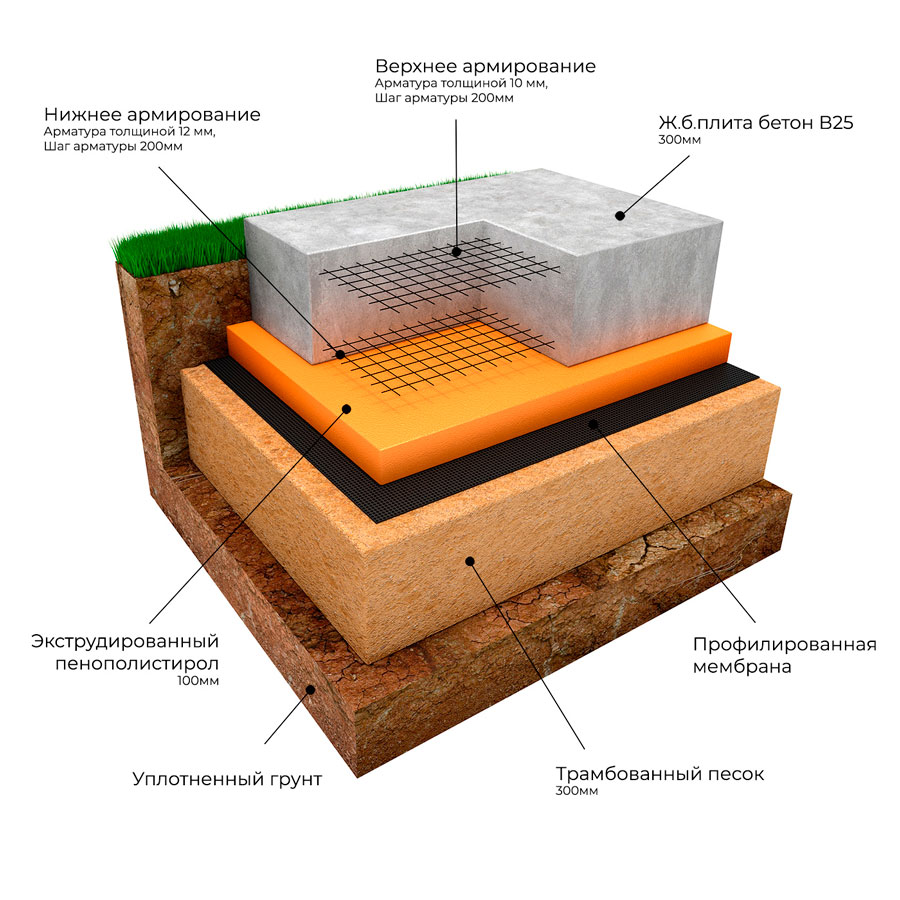

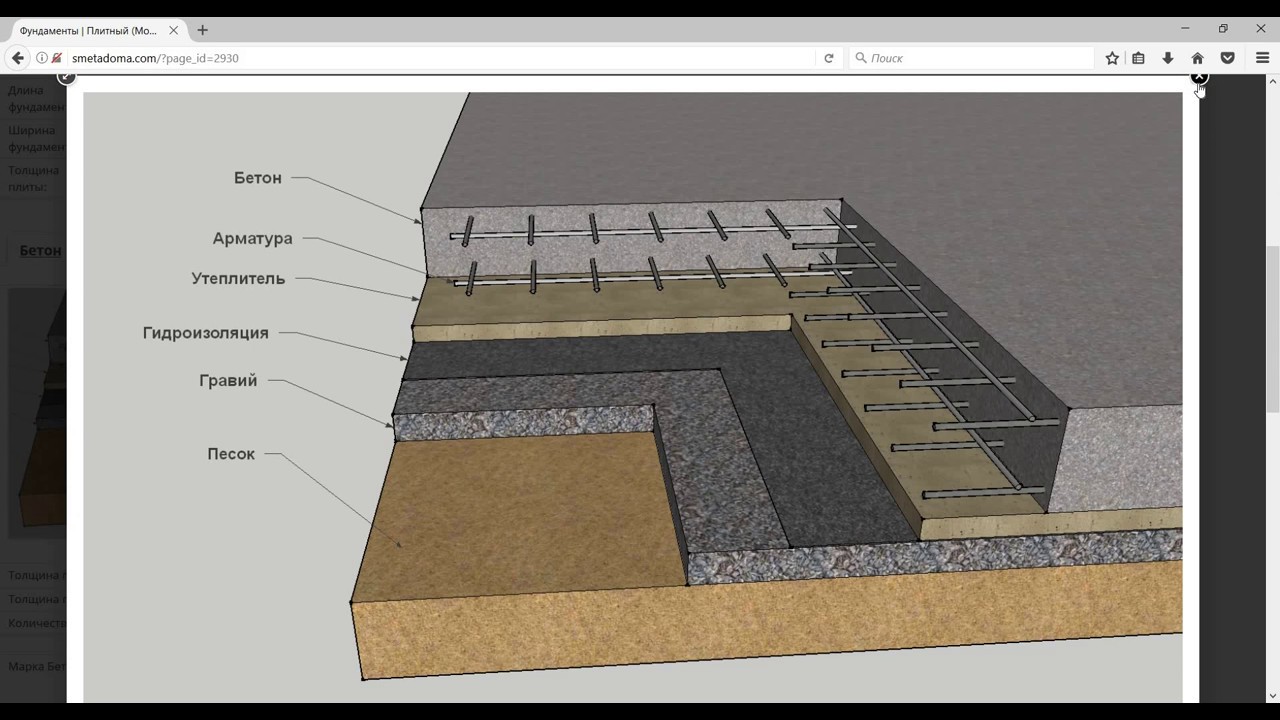

The slab foundation involves the preparation of the base - digging a foundation pit up to a depth of about 500 mm (for brick structures, less for lighter buildings), followed by adding sand - a layer of about 300 mm and crushed stone ≈200 mm. Materials for arranging a gravel-sand cushion must be considered additionally. You can estimate the scope of work on digging a trench or foundation pit using our calculator. On top of the sand bed, it is imperative to arrange waterproofing, since without it, the water from the concrete solution will go into the sand, which will significantly reduce the strength of the slab.

Rebar parameters:

Z - Cell length, i.e. distance between longitudinal rows of reinforcement.In reinforced concrete and slabs in accordance with SP 63.13330.2012 "Concrete and reinforced concrete structures" (Updated edition of SNiP 52-01-2003), the value of Z is chosen about 200 mm - with a cross-sectional height H H> 150 mm - Z ≈ 400 mm.

W - The width of the cell between the transverse rows is taken from 75 to 400 mm.

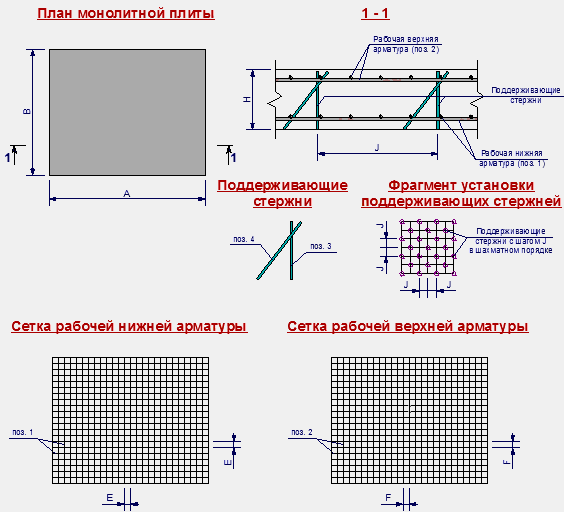

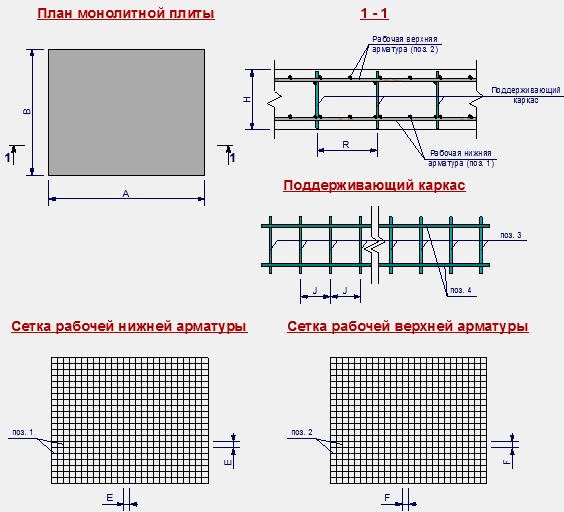

R - Number of rows of reinforcement. The classical reinforcement scheme involves the installation of two rows of reinforcement, with the lower row of reinforcement working in tension, the upper one in compression. Useful recommendations regarding the calculation of reinforcement can be found in SP 63.13330.2012.

The weight of 1 m of reinforcement depends on its diameter. The approximate weight of one meter of popular diameters of iron reinforcement is given in the table.

| Diameter

reinforcement, mm |

Weight of 1 running meter of reinforcement, kg |

| 6 | 0,222 |

| 8 | 0,395 |

| 10 | 0,617 |

| 12 | 0,888 |

| 14 | 1,21 |

| 16 | 1,58 |

| 18 | 2 |

| 20 | 2,47 |

| 22 | 2,98 |

| 25 | 3,85 |

| 28 | 4,83 |

| 32 | 6,31 |

Formwork parameters:

Board in thickness for formwork assembly accepted from 25 mm to 50 mm.

The board is long. This parameter is usually chosen in the order of 4000-6000 mm, depending on the profitability of the price of the board for formwork.

The board is wide. For the manufacture of formwork, an edged board with a width of 100-200 mm is used.

It is important to cover the assembled formwork from the inside with plastic wrap, this will prevent concrete leakage and make it possible to reuse the boards for construction purposes. Concrete composition parameters:

Concrete composition parameters:

Bag weight, kg - here enter how much 1 bag of cement weighs in kilograms.

The proportions of concrete by weight. The approximate ratio of components for a concrete mixture is 2-3 parts of sand for 1 part of cement, 4-5 parts of crushed stone, 1/2 part of water (the mixture must be plastic and not too liquid). However, depending on the required grade of concrete, the grade of cement used, the characteristics of sand, crushed stone, the use of plasticizers or additives, the proportions may vary. Typical cement consumption rates for the preparation of prefabricated and monolithic concrete, reinforced concrete products and structures are regulated by SNiP 5.01.23-83.

Enter the prices for building materials: cement (per bag), sand (per 1 ton), plank (per 1 cubic meter) and reinforcement (per 1 ton).

Click Calculate.

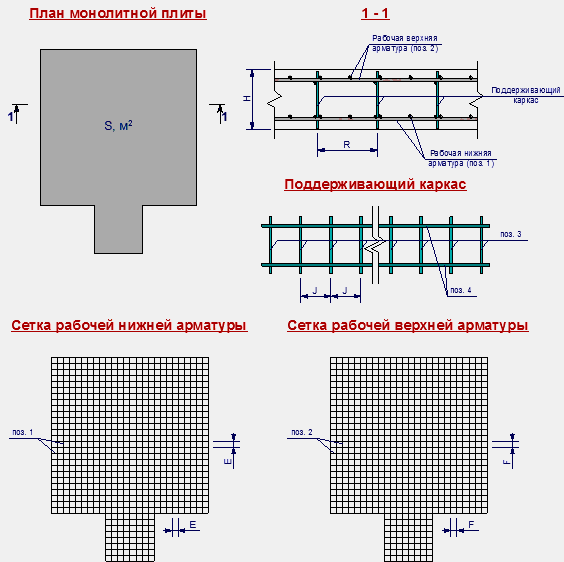

This online construction calculator will calculate the following parameters:

- the area of the monolithic foundation slab;

- the required volume of concrete for pouring this type of base;

- the area of the formwork (i.e. the area of the side surfaces);

- the required amount of timber for formwork and their price;

- how many bags of cement, tons of sand and crushed stone are needed for the construction of a slab foundation and the cost of these components of concrete for pouring;

- the calculation of the required number of horizontal and vertical rows of reinforcement, its length, weight and cost of reinforcement for the foundation slabs will also be made.

Please note that if the height of the slab is not a multiple of the height of the board, then the number of boards is calculated taking into account the overlap of the entire height of the slab. The final price of erecting a slab foundation will give an idea of the level of material investment in the foundation of your house and will allow you to make an informed decision about the advisability of this type of foundation.

Also, you can choose the best solution for you by calculating the parameters of other types of foundations using our calculators.

Monolithic strip foundation device

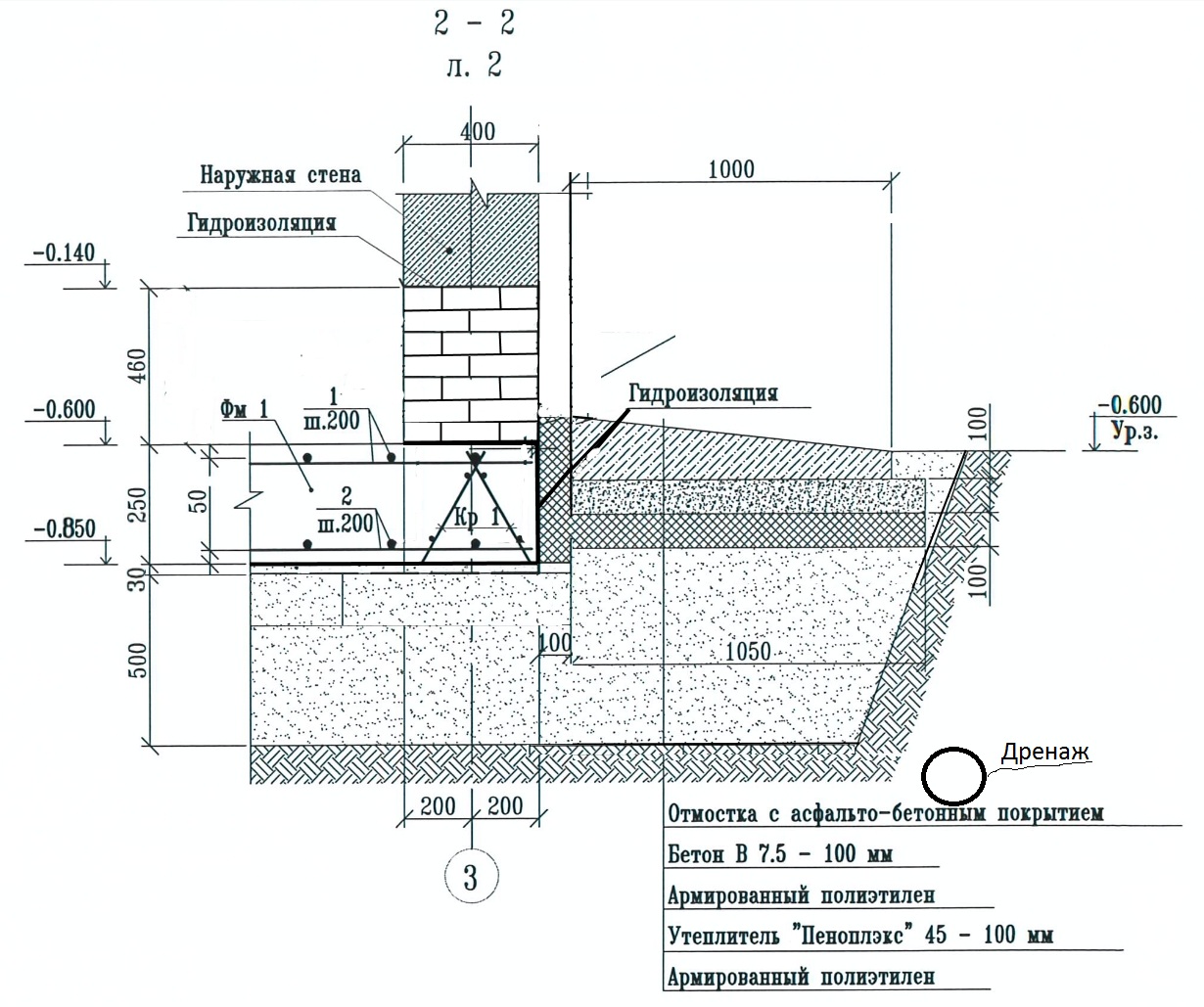

Strip foundation waterproofing scheme.

Construction is a simple process, you can completely do without a team of builders. The advantages of a monolithic base are reliability, the ability to arrange a basement and protect it from dampness, groundwater, and mold. If the soil on which a small object is being erected is stable, then the foundation does not require deep trenches, a shallow version is also suitable, this will save not only money, but also time. Start all work after drawing up the project, which should be done by a professional designer. For you will need:

- sand;

- fittings;

- cement;

- knitting wire;

- wire tying tools;

- waterproofing material;

- shovel.

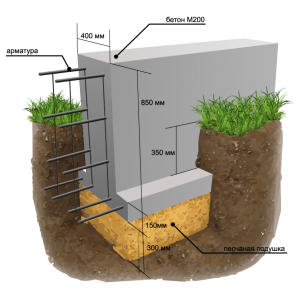

Digging trenches and sand bed

Diagram of the varieties of the strip foundation.

First, on the site, make a markup that would correspond to the location of the load-bearing walls and the facade. For the stability of the building, the width of the base is measured out by about 10 cm more than the design width (and it cannot be less than 40 cm) of the walls. By marking with a shovel, bump stop or excavator, make trenches - 40-60 cm, for buried - 60-80 cm.

Fill the sand with layers 15 cm thick, water each new layer from a hose with water, so it will be compacted, but it is important not to overdo it with moisture. Then fix the waterproofing on the sides of the trenches.

Arrange the formwork from boards (thickness - 5 cm), arrange them vertically, they should exceed the ground level by about 30 cm (see the exact number in your project, it means the height of the basement floor); Fill the finished structure with reinforcement and concrete.

Reinforcement and concrete pouring

Strip foundation pouring scheme.

Reinforcement is an important stage of construction, which affects both the quality of the foundation and the stability of the future building. The calculation of the cross-section of the reinforcement depends on the mass of the object, the diameter of the rods, by the way, should not be more than 1.6 cm and less than 1 cm.:

- diameter 1 cm - 1620 m;

- diameter 1.2 cm - 1126 m;

- diameter 1.4 m - 826 m;

- diameter 1.6 cm - 633 m.

Reinforcement is carried out in four rods with two belts. Place the longitudinal elements at a distance of 5 cm from the bottom and top from the edge of the base; keep a distance of 25 cm between the transverse ones; fix the intersection points, this can be done in two ways: with knitting wire or welding. The latter option has many disadvantages: it requires a lot of labor, and any awkward movement violates the integrity of the entire system.

Wire tying is a reliable method. To perform work, you can use one of the following tools:

- pliers;

- special hooks;

- wire tying gun.

The first two work is done manually, the process is long and physically costly; the automatic wire tying gun significantly speeds up and simplifies the work, and at the same time improves the tying quality. The unit is running on battery power.

Marking for the base of the strip foundation.

The mortar is made from a mixture of sand and cement (3: 1). Cement of the M-500 brand is the most optimal option for filling tape-type bases. A concrete vibrator will help to do the job efficiently, it will evenly distribute the solution, preventing the formation of voids; if you do not have this unit, then lay the mortar with wooden rammers by hand and tap the walls of the formwork.

Try to fill the trenches with concrete in one sitting: this will exclude the stratification of the solution and the formation of voids. The consistency of the concrete must not be liquid. Fill with a flexible hose, do not lift it too high, through it the solution will fall into the trenches thanks to the pump. It is undesirable to carry out work in the summer in the heat.

According to the technology, the strip foundation must include waterproofing. It is carried out after the concrete has hardened, by which time the formwork can also be removed. Apply bituminous mastic to the horizontal and vertical surfaces of the hardened base, attach an insulating material to it: one of the most reliable options is roofing material.

It is worth saying that it is necessary to strictly observe the parameters of the materials used, for example, it is unacceptable to use reinforced rods of a smaller diameter than it is prescribed in the plan, or to save on cement. It is also impossible to exceed the norm of sand or add more water to it than necessary. The thickness of the sand cushion and the depth of the trenches are two more points that require strict adherence to the rules: changing the parameters will lead to a distortion of the monolith, to the formation of cracks on the facade of the building.

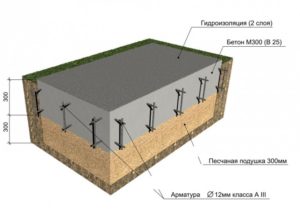

An example of calculating the thickness of a monolithic slab

Monolithic base plate

Monolithic base plate

The rules for calculating a monolithic slab are fully described in the building rules (norms) for the design and construction of monolithic foundations and foundations for buildings and structures. The stage of calculating the thickness of the slab consists of two operations:

- Collect the loads on the foundation;

- Calculate the bearing capacity values for the foundation.

When collecting the load, it is necessary to carry out work related to calculating the total mass of the building, taking into account the estimated weight of the snow load in the specified region. In addition, when calculating the weight load, the weight of furniture, roofing, installed equipment and the variable weight of people in the house are taken into account. These indicators are taken from the table depending on the material that will be used in the construction of load-bearing walls, partitions and floors. Also, when calculating, it is necessary to take into account the reliability factor - an average of 1.3. The snow load readings are taken from building codes for building climatology and are determined depending on the snow area where the structure will be erected.

As a result, the total mass of the building is formed as the sum of all ground loads multiplied by the total area of the future building. In this case, be sure to take into account that each of the loads indicated in the calculation must be multiplied by the normalized safety factor. Thus, the designers provide a margin of safety for the bearing capacity of the cast-in-place concrete structure.

Basic formulas and coefficients for calculating the thickness of the sole

Various loads have certain safety factors, which are standardized by SNiP. As a rule, values are indicated in the range from 1.05 to 1.4, depending on the type of load. For a monolithic concrete base, builders take a coefficient equal to 1.3.

The location of the foundation cushion

The location of the foundation cushion

The formula for calculating the sole and the loads on it is written in the following form:

The values of the specific load on the soil without taking into account the weight of the foundation are calculated as P / S,

where P is the sum of all loads on the building, and S is the design area of the future monolithic concrete slab.

Thus, having learned the specific load from the table from the building codes, you will select the appropriate sole width.

Justification of calculations

In construction, any action must be strictly justified. It would seem an obvious fact - before starting work, you should calculate how much material you need to purchase. But many developers neglect this stage and prefer to estimate the amount of work "by eye", instead of performing the simplest mathematical calculations. Sometimes an approximate calculation is not suitable - by the way, it is recommended to carry out concrete work in-line, without interruption, otherwise the formation of "cold seams" in critical areas will surely occur.

A responsible approach to the procurement of materials will help save

A responsible approach to the procurement of materials will help save

To buy material with a surplus means to waste the budget, and a shortage of material will lead to a suspension of construction. It is not always possible to urgently purchase additional material, and additional hiring of a delivery service will be expensive, and not every company will agree to deliver an incomplete number of assembly units. Surplus materials are rarely used with benefit, for example, the remains of concrete are always disposed of by pouring into technical trenches. To avoid senseless expenses, you need to determine the amount of work and make a small estimate.

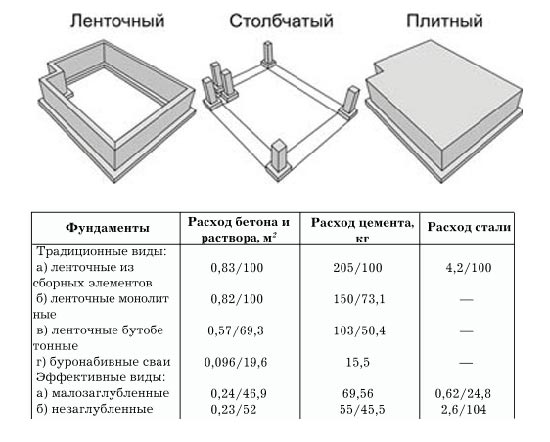

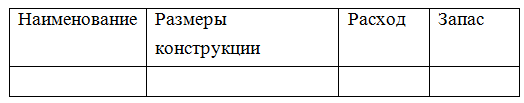

Table for self-calculation of materials

Table for self-calculation of materials

The simplest table will help you visually assess the required amount of components, make it simple, and convenient to use. In it, depending on the type of foundation being built, the volume of all necessary components is indicated, taking into account the geometric dimensions of the structure. To calculate the consumption of materials for a strip, columnar or pile foundation, taking into account the stock, you need to follow simple instructions.