Strip foundations and soils: why is it so important

When choosing the type of foundation, it is important to know exactly two characteristics of the underlying soils: their bearing capacity and heaving. The bearing capacity is highest in rocky soils; they are followed by gristly - a mixture of sand and clay with small stones and rubble

Sandy soils are prone to subsidence, the properties of sandy-clayey (sandy loam and loam) depend on the ratio of clay and sand. The lowest bearing capacity is found in soils of organic origin: peat, sapropel, silt

The bearing capacity is highest in rocky soils; they are followed by gristly - a mixture of sand and clay with small stones and rubble. Sandy soils are prone to subsidence, the properties of sandy-clayey (sandy loam and loam) depend on the ratio of clay and sand. The lowest bearing capacity is found in soils of organic origin: peat, sapropel, silt.

Building codes prohibit supporting the foundation directly on organic soils with low bearing capacity.

Water-saturated soils with a variable layer structure are also considered complex. The problem of soft soils is typical, for example, in areas located in the place of drained swamps. Building a house on a shallow strip foundation on such soils is theoretically possible, but requires quite costly work. So, if the depth of the weak-bearing layer is not more than 1 m, and there is a more "hardy" one under it, then during construction the layer of weak soil is removed and a sand substrate or concrete preparation is arranged in the trench. Also, bad soil is sometimes compacted mechanically, replaced with a gravel pillow, or reinforced with special nets. Experts, however, recommend in such situations to abandon the strip foundation in favor of the pile foundation.

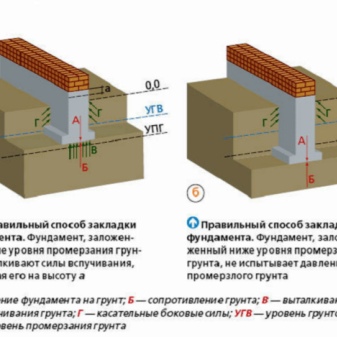

The heaving of the soil is directly related to its ability to retain water, and frost heaving is an increase in the volume of the soil due to the expansion of water when it freezes.

Non-porous soils: hard clays, slightly moistened gravelly, sandy soils with deep groundwater.

Slightly bulging: semi-hard clayey; slightly water-saturated silty and fine sands, coarse-clouded soils with a clay and sand content of 10-30%.

Medium-loamy soils: tough-plastic clayey, moist silty and fine sands, coarse-grained soils with a clay and sand content of more than 30%.

Heavily weathered and excessively weathered: soft-plastic clayey, silty and fine sands with strong water saturation.

On highly heaving soils, it is possible to build small (1-2 floors) wooden houses on a shallow strip foundation made of monolithic reinforced concrete. For heavier houses, a complex of works will be required to lower the level of groundwater, organize drainage and drainage.

The higher the groundwater is, the more heaving the soils will be, regardless of their composition. The critical groundwater level for the construction of the foundation differs for different soils and is calculated by the formula: the lower limit of soil freezing (in meters) plus the following number:

- sands - 0.8-1 m

- sandy loam 1 - 1.5 m

- loam 2 - 2.5 m

- clay 2.5 - 3.5 m.

When groundwater occurs below the indicated values, they do not affect the degree of heaving of soils.

In general, the construction of a strip foundation on highly heaving soils with a high level of groundwater is considered inexpedient: in such conditions, the pile-grillage foundation shows itself best of all.

When planning construction, it is best not to skimp on a professional survey of the soil on your site: this will help to avoid big problems in the future.The services of a specialist cost money, but this investment is worth it. It will be much more expensive to save a house, the foundation of which has been deformed due to errors in assessing the properties of the underlying soils.

What types of foundations can be used

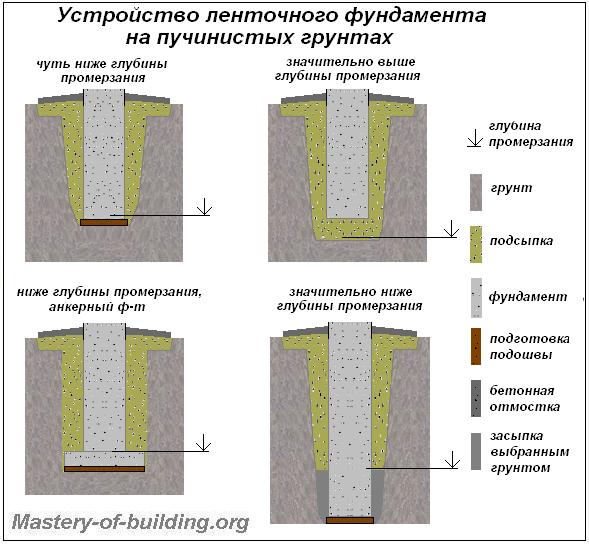

For heaving soils, the most important thing is the depth and water level. It is depending on them that the foundation is selected

There are several of the most common options for different cases.

Buried and shallow

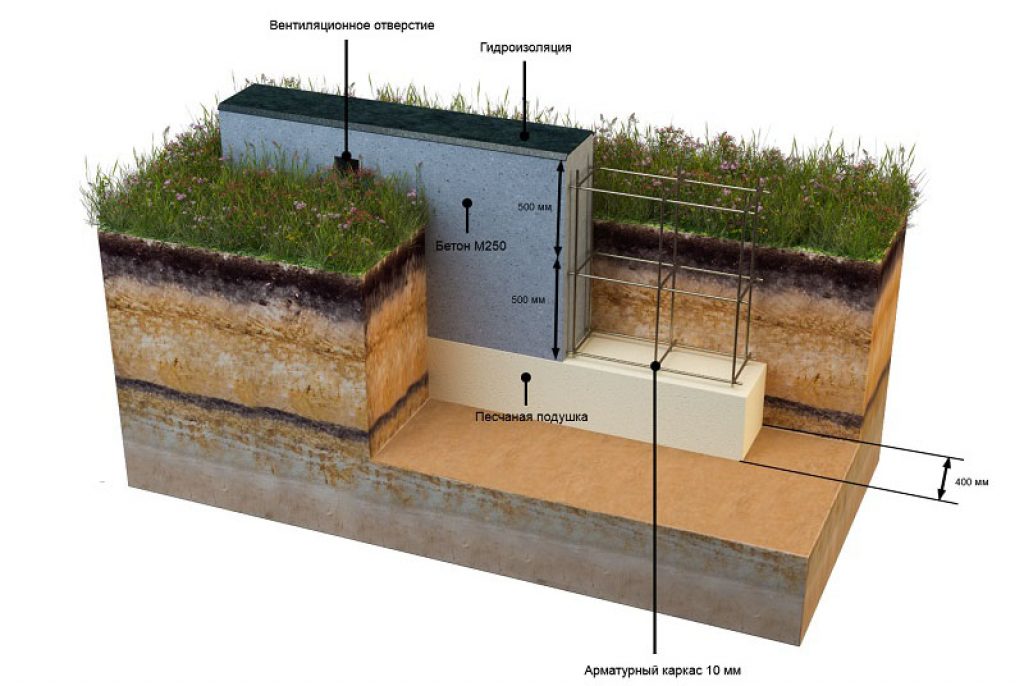

If the groundwater level is located deep enough (more than 1.5 m), strip and columnar foundations are used. At the same time, it is controlled that the sole mark is at a distance of at least 50 cm from the water in the clay soil. If we talk about water-saturated soils, then the depth of filling for clays, loams, sandy loams and fine sands is no less than freezing, and for coarse-grained soils - any (for buried, it depends on the height of the basement, for shallow ones from 0.5 m). You can also choose a shallow or deep slab foundation.

At the same time, to prevent the appearance of forces of frost heaving and flooding of structures, it is necessary to provide the following measures for the foundation:

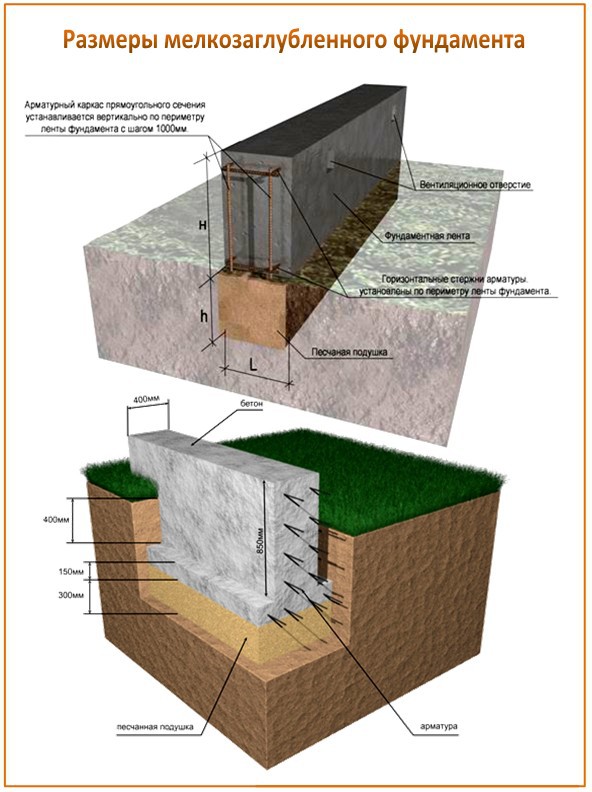

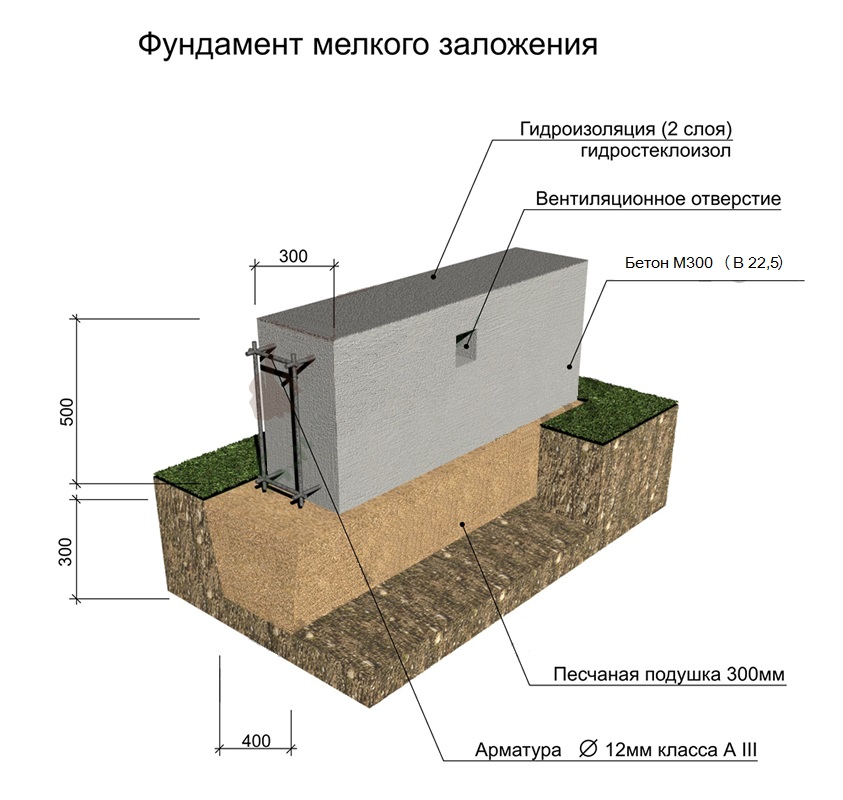

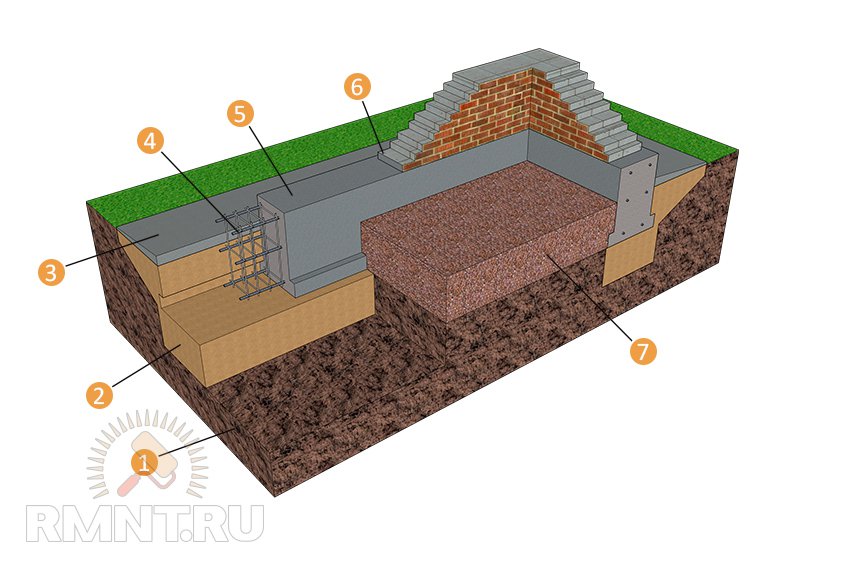

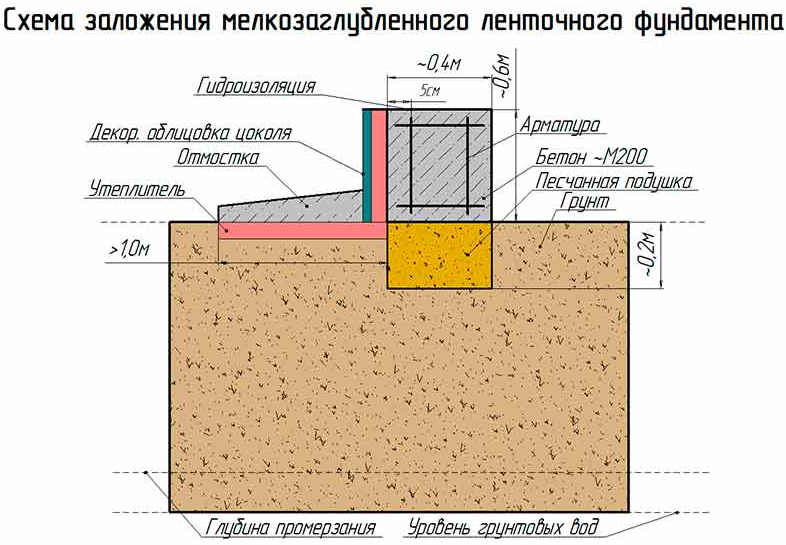

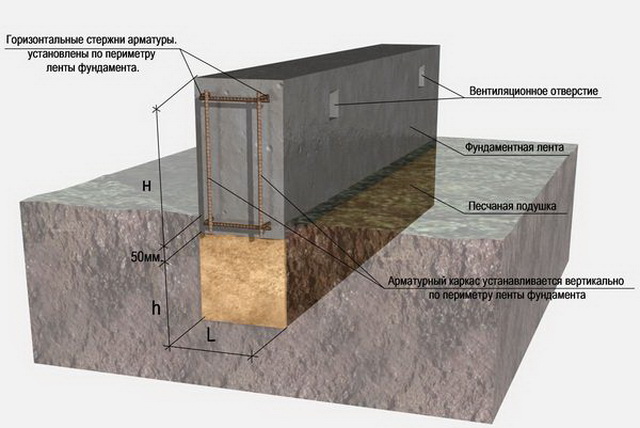

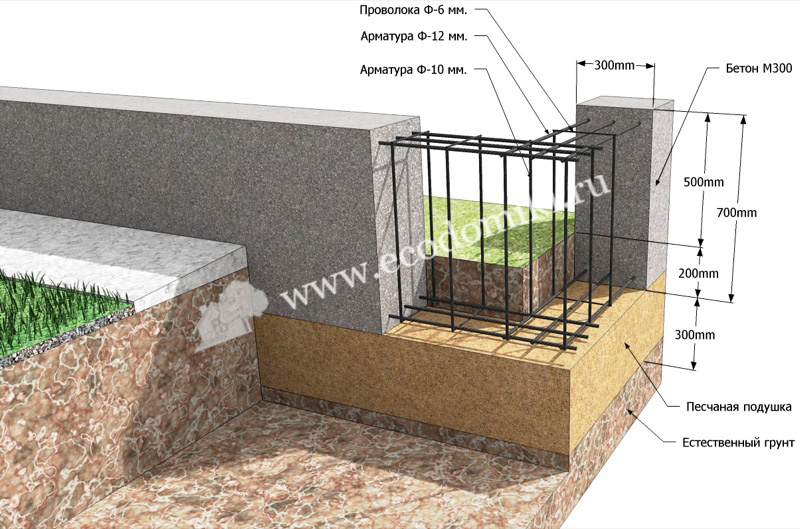

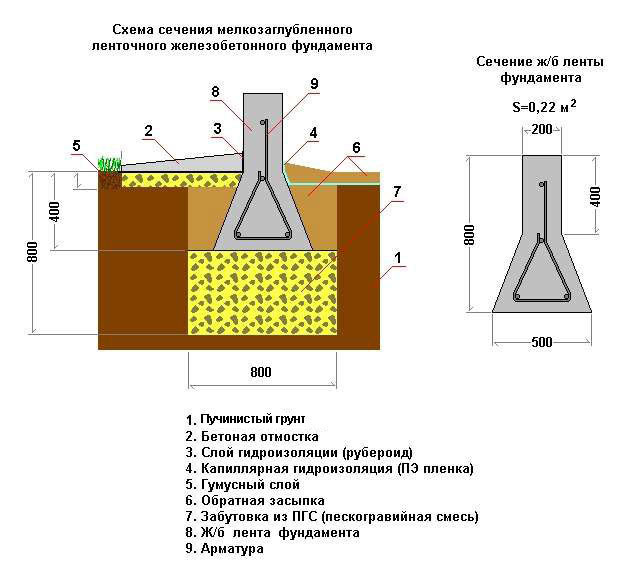

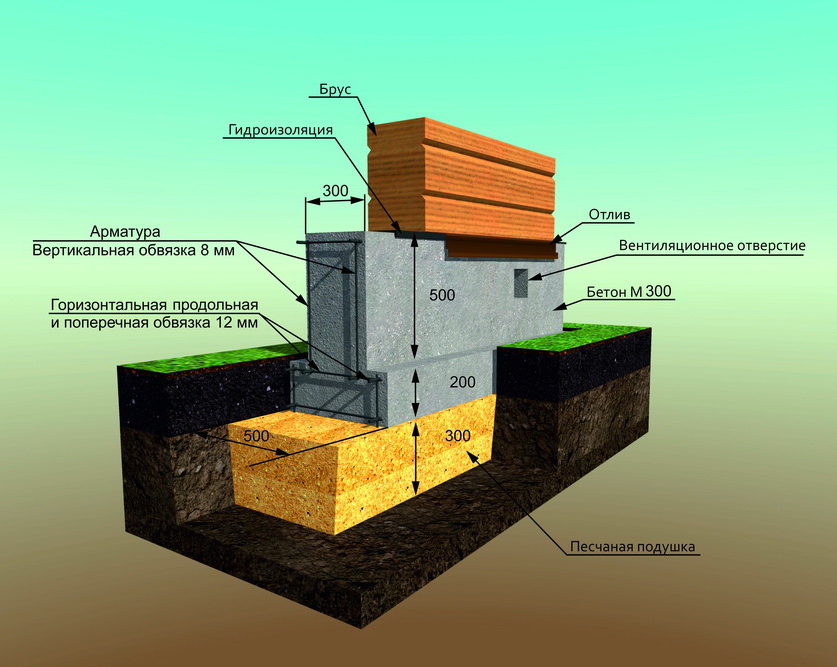

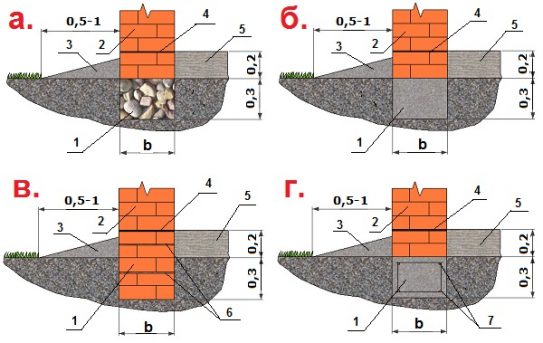

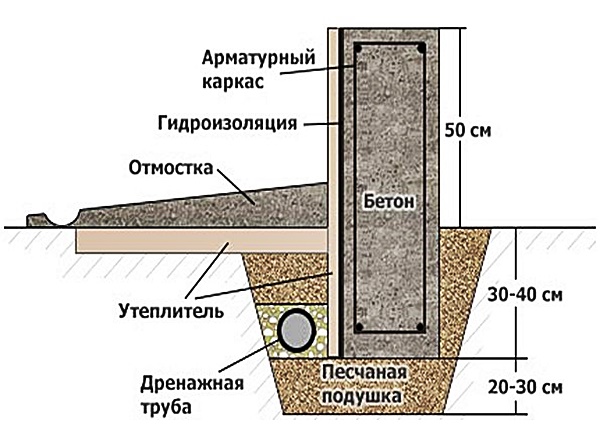

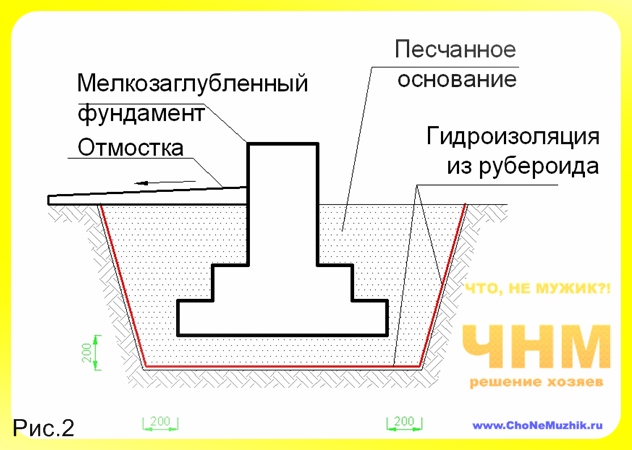

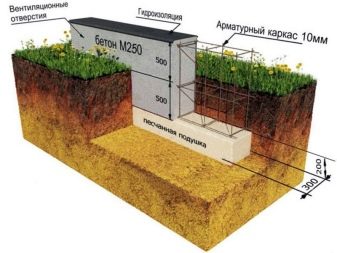

- Adding. A layer of bulk material is provided under the sole of the tape or individual posts. It will become a drainage and leveling element. Crushed stone, gravel, coarse or medium sand are used as material for creation. Sometimes builders, in order to save money, suggest using slag as a bedding. This material is characterized by a low cost, but can lead to negative consequences: shrinkage, danger to human health. The thickness of the backfill depends on the characteristics of the soil, on average it is 30-50 cm.

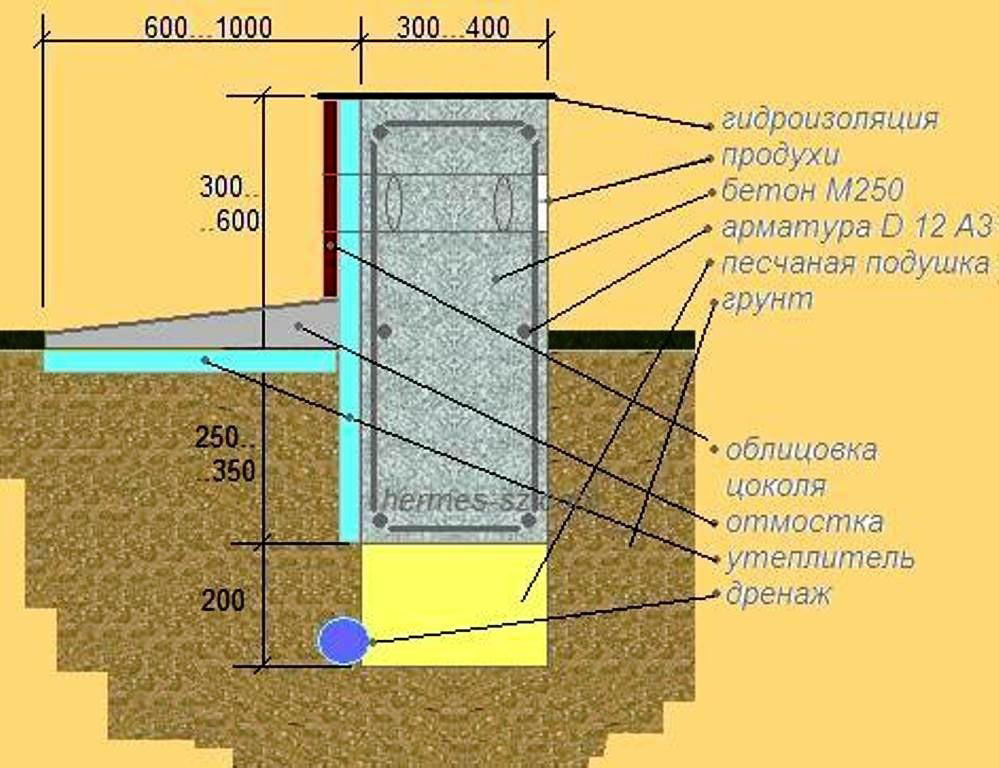

- Foundation waterproofing. For tape, it is imperative that vertical coating with bitumen or processing with other materials is required, laying roll insulation along the edge of the foundation (for example, roofing material) and a blind area, which will prevent the ingress of rain and melt water.

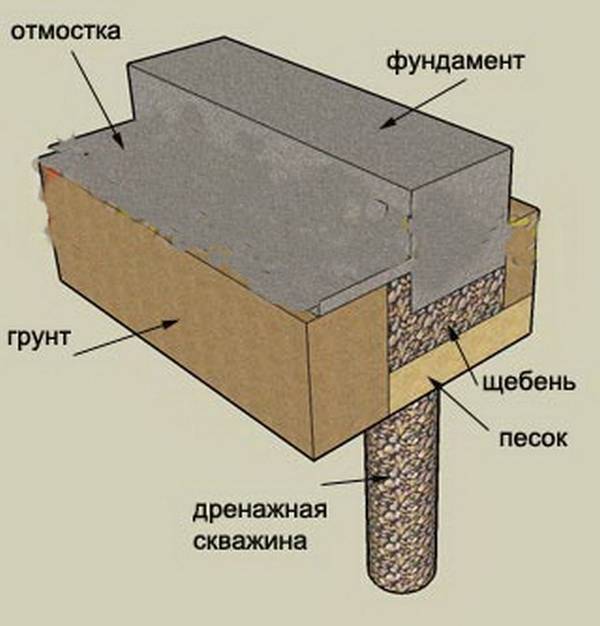

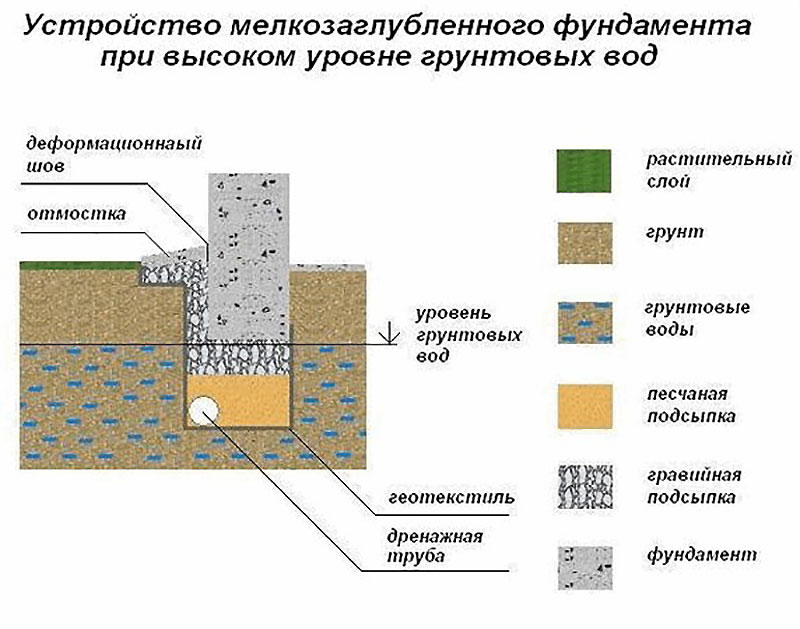

- Drainage. It is arranged around the perimeter of the building 30-50 cm below the foot of the foundation. The pipe is laid no further than 1 meter from the structure.

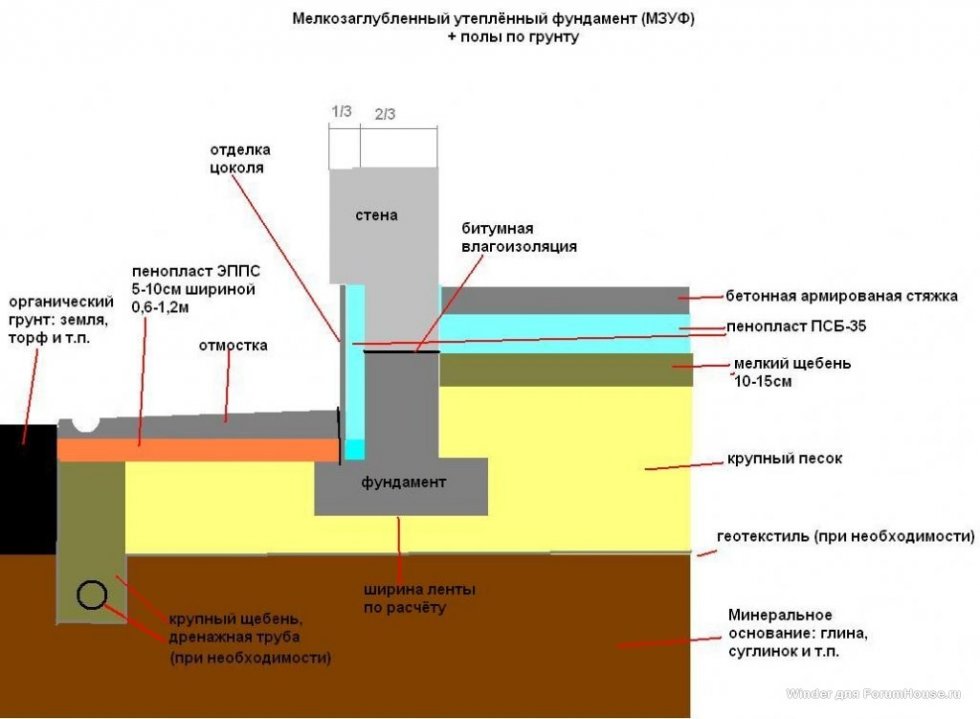

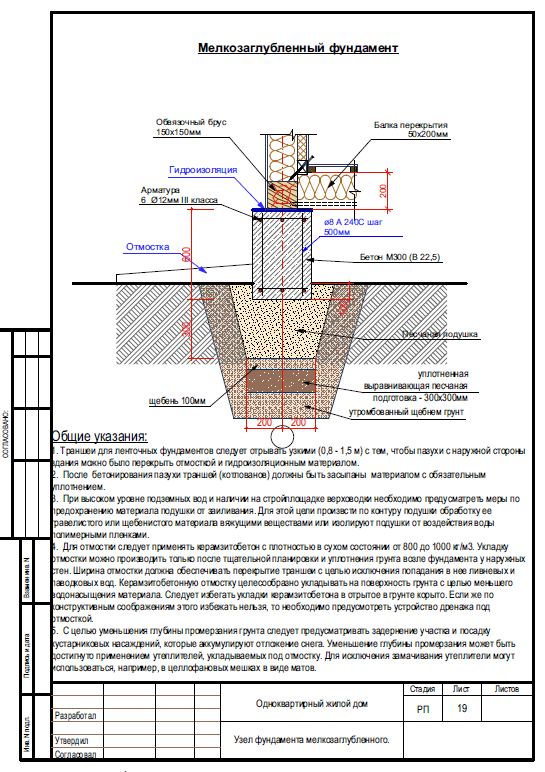

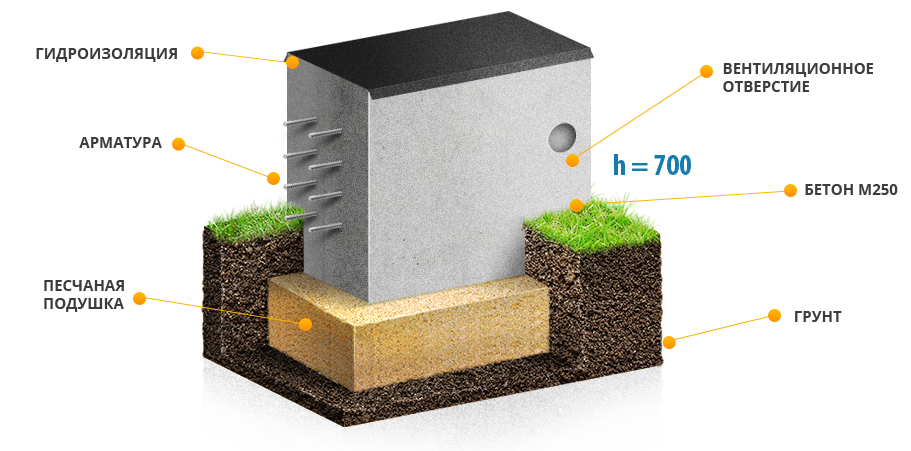

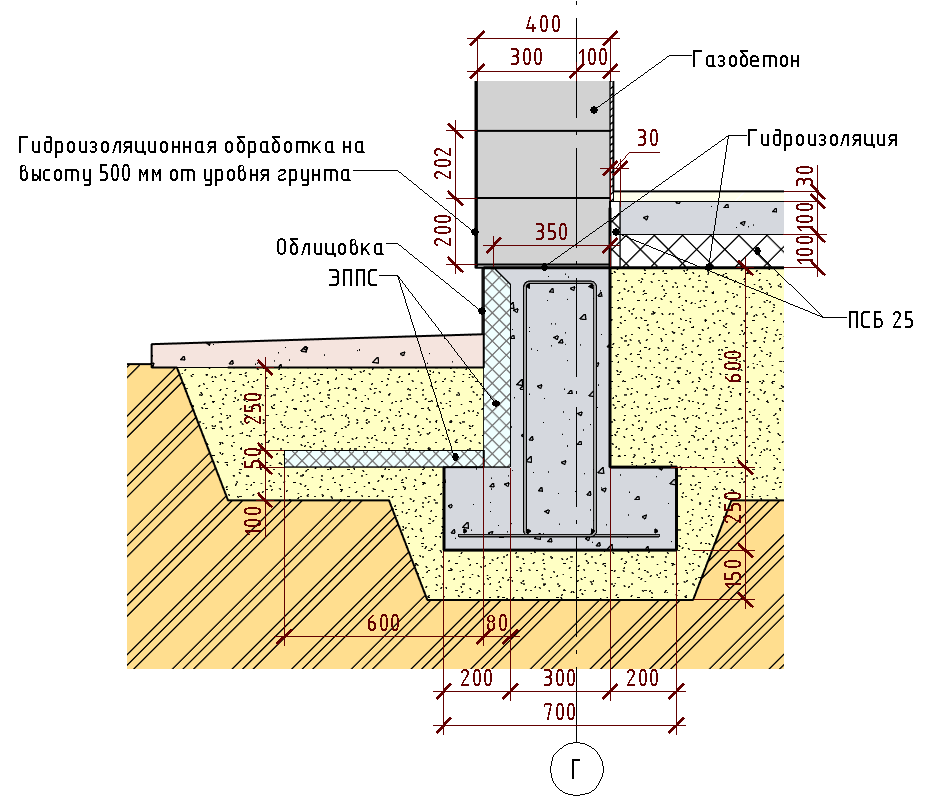

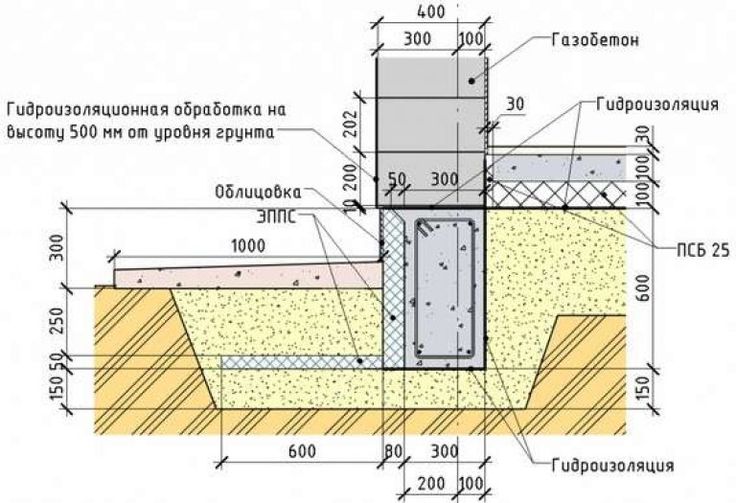

When laying below the freezing depth, the supports will not need insulation, for shallow ones it is necessary. Extruded polystyrene foam can be called the most optimal material for performing work.

Shallow (plate and tape)

If the groundwater level is close to the surface, but the depth of location is more than 50 cm, slab foundations and non-buried strip foundations are used

It is important to remember that a tape not buried in the ground can only be arranged for small buildings and must be used with extreme caution. Shallow columnar supports cannot be used due to their low bearing capacity

At the same time, it is important to take care of the insulation of the foundation, since it is not protected from frost by a layer of soil. For pouring the strip foundation, you can use expanded polystyrene formwork

This element is not removed after pouring and serves as thermal insulation. For insulation of foundation slabs, extruded polystyrene foam is used, which differs from the usual in higher strength.

To ensure reliability, you can replace part of the soil on the site with soil with sufficient strength characteristics. If the soil available on the site is unstable, you can make a backfill. At the same time, it is difficult to calculate how much material is required, it is added until the base becomes stable, excess moisture is not squeezed out, and the bulk material does not stop going into the soil.

Pile

If the groundwater level is located closer than 50 cm from the earth's surface, it is worth abandoning unburied foundations in favor of pile elements. There are two possible options, the first of which is the most time consuming. The method consists in the fact that a temporary dewatering is performed on the site and bored piles are buried below the freezing depth.The second option is screw piles. This is an easier way. Screw piles are also used for swampy terrain where other types of foundations cannot be used.

Elements using TISE technology can become one of the options for bored piles. These are piles with a widened bottom (resembling a nail with a head down). The widening will prevent pulling out under the influence of frost heaving forces and increase the bearing capacity.

Whichever type of foundations is chosen, all the necessary actions for clayey soils and a high level of groundwater must be done simultaneously and in full. Only a set of these measures will prevent damage to the foundation laid above the freezing depth in heaving soil.

Good publicity

Features of clay soils

The main problem when designing a building on clay soil is frosty uneven swelling. However, in clause 5.9 of the set of rules of SP 22.13330 of 2016, measures are indicated to reduce the effect of deformations in soils on reinforced concrete structures intended for operation inside the soil.

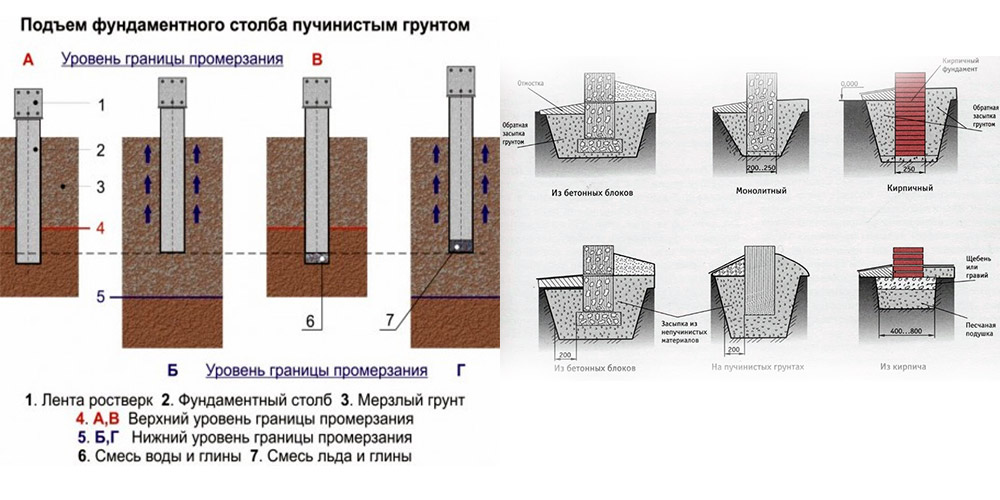

The principle of frost heaving is as follows:

- soils contain particles of clay, which is saturated with moisture (rain, ground, melt, waste water);

- freezes in winter to a certain depth (not the same in different regions);

- water in the lenses of clay scales increases in volume by 9%;

- soils tend to push out the reinforced concrete structures in them;

- or overturn them when applying forces to the lateral faces of pillars, belts or piles.

The following technologies are classic methods of protection against frost heaving:

- drainage - the device of a contour of perforated corrugated pipes along the perimeter of the foundation allows you to collect moisture, drain it by gravity into an underground reservoir;

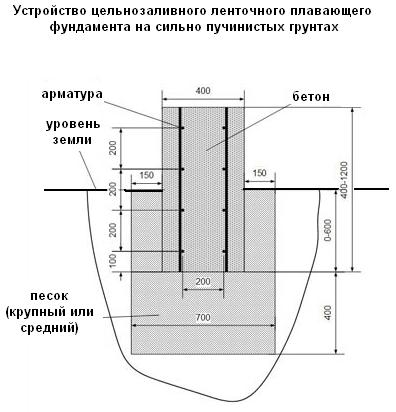

- replacement of clay soils with non-metallic material - natural soil is removed under the sole of the tape, slab or pillar, an underlying layer of crushed stone, sand 40 - 80 cm thick is created (it will not work without drainage with water saturation);

- insulation of the blind area and basement - it is used only for slab and strip foundations, allows you to exclude freezing due to the preservation of geothermal heat of the subsoil;

- backfilling - with the same inert materials that were used for the underlying layer (sand, crushed stone), eliminates pulling forces from tangential loads on the lateral surfaces of posts and belts.

Clays and loams by default have a high design resistance to prefabricated building loads. Therefore, the problem of shrinkage is completely absent. The question of choosing a foundation is decided from the standpoint of the available budget and the need for a basement floor.

How to identify clay soil

After choosing the type of foundation (deep tape for the basement floor, MZLF for a brick cottage, pillars for a log house, piles for a dwelling on a slope), you need to order geological surveys of the site or do it yourself.

It is possible to determine the clay content in a building spot without laboratory analysis:

- clay rolls into a thin rope, the ball from it practically does not crack when squeezed with fingers;

- loam can be rolled into a thick rope (from 1 cm), when the ball is compressed, small cracks form on it.

None of these activities can be done with sandy loam, especially with sand.

After that, it is necessary to plan a set of works to prevent swelling, depending on the chosen foundation:

- pillars - only below the freezing mark, drainage around the perimeter at the level of the sole, a pit for each pillar, the thickness of the backfill layer is from 40 cm on all sides, the blind area is insulated only for a low grillage;

- tape - a full range of similar works;

- plate - insulation of the blind area over the drainage.

Calculation of the index of flexibility of building structures

1. Index of flexibility

building structures l is determined by the formula

,(1)

whereEJ - reduced stiffness on

bending of the cross-section of building structures in the foundation-plinth-belt system

reinforcement - wall, tf.m2, determined by the formula (4);

WITH - stiffness coefficient

foundations with heaving of the soil for the bases of strip foundations;

L —

length of the wall of the building (compartment), m;

,(2)

for reasons

columnar foundations

,(3)

Here pr, hfi, b1 - the same designations as in paragraphs. -;

Af - the area of the foot of the columnar foundation, m2;

ni - the number of columnar foundations within the length of the building wall (compartment).

2. Reduced stiffness at

bending of the cross-section of building structures in the foundation-plinth-belt system

reinforcement-wall, tf / m2, is determined by the formula

[EJ] = [EJ]f + [EJ] z + [EJ] p + [EJ]s,(4)

where EJf,

EJz, EJp,

EJs - accordingly, rigidity

on the bending of the foundation, basement, reinforcement belt, building walls.

3. Flexural stiffness, tf / m2,

foundation, base and reinforcement belt is determined by the formulas

f= gfEf(Jf+ Ayc2);(5)

z = gzEz(Jz+ Azyz2);(6)

p = gpEp(Jp + Apyp2);(7)

where Ef, Ez, Ep - respectively, deformation moduli tf / m2,

foundation material, base and belt;

Jf, Jz, Jp- respectively moments

inertia, m4, cross-section of the foundation, base and reinforcement belt

relative to its own main central axis;

A, Az, Ap- the area of the transverse

section, m2, foundation, base and reinforcement belt;

y, yz, yp - respectively, the distance, m, from the main

the central axis of the cross-section of the foundation, plinth and reinforcement belt up to

conditional central axis of the section of the entire system;

gf, gz, gp

- respectively, the coefficients of the operating conditions of the foundation, basement and belt

gain, taken equal to 0.25.

Bending stiffness

a foundation consisting of blocks that are not interconnected is taken equal to

zero. If the basement is a continuation of the foundation or their joint is provided

work, plinth and foundation should be considered as a single constructive

element. With no reinforcement belts EJp

= 0. In the presence of several belts of reinforcement, the bending stiffness of each of them

is determined by formula (7).

4. Flexural stiffness, tf / m2,

walls made of bricks, blocks, monolithic concrete (reinforced concrete) is determined by

formula

s = gsEs(Js

+ Asys2),(8)

where Es - deformation modulus

wall material, tf / m2;

gs

- coefficient of working conditions of the wall, taken equal to: 0.15 - for walls made of

bricks, 0.2 - for block walls, 0.25 - for monolithic concrete walls;

Js- the moment of inertia of the transverse

section of the wall, m4, is determined by the formula (9);

As

- cross-sectional area of the wall, m2;

ats—

distance, m, from the main central axis of the cross-section of the wall to the conditional

the neutral axis of the section of the entire system.

Moment of inertia of the cross-section of the wall

is determined by the formula

,(9)

where J1 and J2 - respectively, the moment of inertia of the wall section

along openings and walls, m4.

Cross-sectional area

walls are determined by the formula

,(10)

where bs - wall thickness, m.

Distance from center of gravity

the reduced cross-section of the wall to its lower edge is determined by

formula

,(11)

5. State from main

the central axis of the cross-section of the foundation to the conditional neutral axis

systems foundation-plinth-reinforcement belt - the wall is determined by the formula

,(12)

where Ei, Ai- deformation modulus and area, respectively

cross section i-th structural element

(base, wall, belt);

ji - coefficient of working conditions ith constructive

element;

yi - distance from the main central axis of the cross section ith

structural element to the main central axis of the cross-section

foundation.

6. Flexural rigidity, ts.m2,

walls made of panels is determined by the formula

,(13)

where Ej, Aj- respectively, the modulus of deformation, tf / m2, and the area of the transverse

section, m2, j-to communication;

m —

the number of links between panels;

di- distance from j-that connection to the main

the central axis of the cross-section of the foundation, m;

y - distance from the main

the central axis of the cross-section of the foundation to the conditional neutral axis

foundation-wall systems of the building, determined by the formula

,(14)

wherein n —

the number of structural elements in the foundation-wall system.

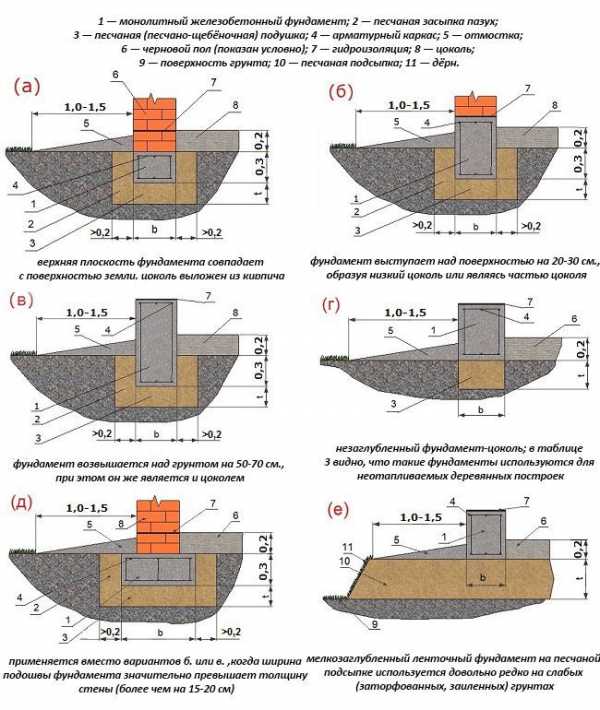

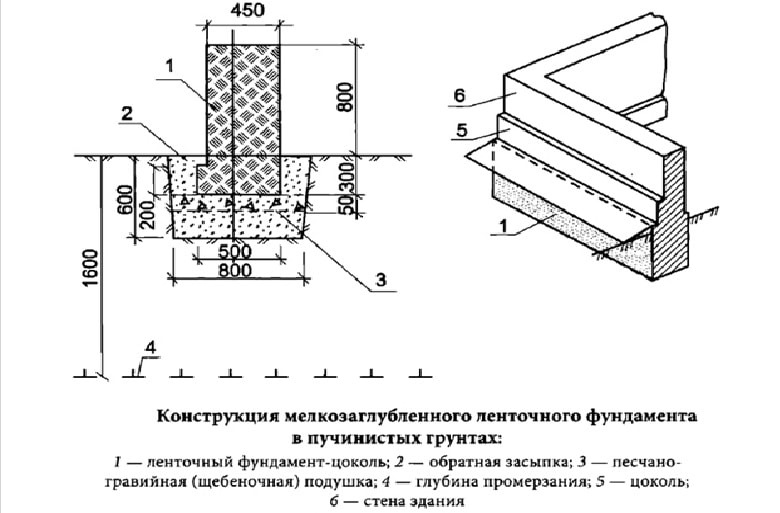

Tape deep foundation on heaving soils with a freezing depth

Recessed foundation

Recessed foundation

Such a foundation is often practiced when erecting small buildings, because it has a number of key disadvantages at once:

- Too large a side surface increases the load on the walls of the structure;

- The installation cost is too high, because it is necessary to dig deep trenches and protect the walls from collapse;

- Expensive building materials;

- It is necessary to carry out complex calculations of balancing the heaving forces and the mass of the building itself.

These are material-intensive and labor-intensive bases that are not able to provide optimal protection of the building from the effects of the soil. But at the same time, they are practiced in relatively cold regions, where the freezing line is high, and under it there is a solid ball of rock. If the technology is used correctly, the sole of the trapezoidal concrete base is installed directly inside the solid rock, which is no longer subject to heaving.

Protection against lateral movements is eliminated by the method of corner reinforcement using intermediate concrete beams. Also, strip buried foundations are often used when you need to build a building with basements.

Payment

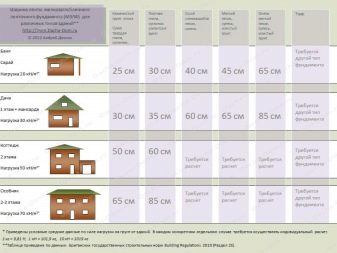

Before you start laying the foundation, you must complete the design and make accurate calculations. The complexity of calculations for a shallow strip base is to determine the hydrogeological characteristics of the soil on the site. Such studies are mandatory, since not only the depth of the foundation will depend on them, but also the height and width of the slabs will be determined.

In addition, in order to make the correct calculations, you need to know the main indicators.

- The material from which the construction of the building is planned. The strip foundation is suitable both for a house made of aerated concrete and for buildings made of foam blocks or timber, but it will differ in its structure. This is due to the different weight of the structure and its load on the base.

- Size and area of the sole. The future base must fully comply with the dimensions of the waterproofing material.

- External and lateral surface area.

- Dimensions of the diameter of the longitudinal reinforcement.

- Grade and volume of concrete solution. The mass of concrete will depend on the average density of the mortar.

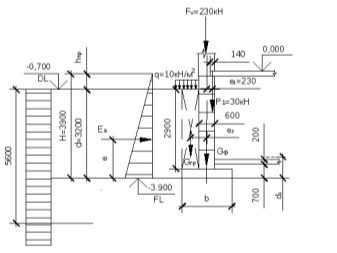

In order to calculate the depth of the laying, it is necessary first of all to determine the bearing capacity of the soil at the construction site and the parameters of the sole of the tape, which can be monolithic or consist of blocks. Then the total load on the foundation should be calculated, taking into account the weight of the ceiling slabs, door structures and finishing material.

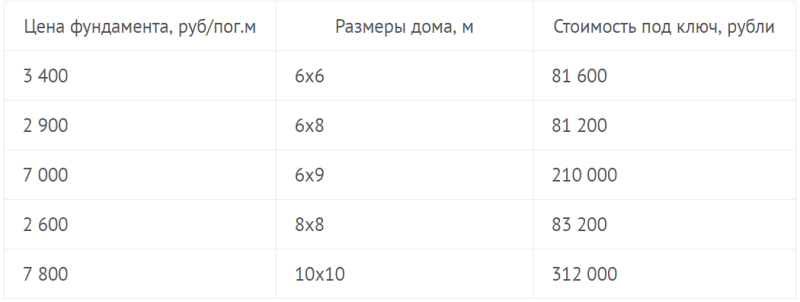

What is the price of a monolithic MZLF for a home?

Developers who prefer to trust specialists pay special attention to the prices for carrying out foundation work

It is important to bear in mind here that a self-respecting construction company will not announce the cost of its services by phone only on the basis of the size of the house you declared. The specialist will make an estimate of the order after studying the site and the project

Typically, the cost of laying a foundation includes several items:

The specialist will make an estimate of the order after studying the site and the project. Typically, the cost of laying a foundation includes several items:

- Cost of materials.

- Site preparation and planning.

- Excavation work to dig a ditch.

- Formwork installation and fabrication of a reinforcing frame.

- Pouring concrete solution.

The average cost of a shallow strip base is from 2,600 to 3,000 rubles per running meter. It is somewhat more expensive than a pile foundation, but despite this, most people choose the tape. To quickly determine prices depending on the perimeter of the building without taking into account the walls, it is enough to use the table.

These figures are rather approximate, because the width and height of the tape are taken into account in the final calculations.Most construction companies include in the estimate all costs for the delivery of materials to the site.

Features on heaving soils

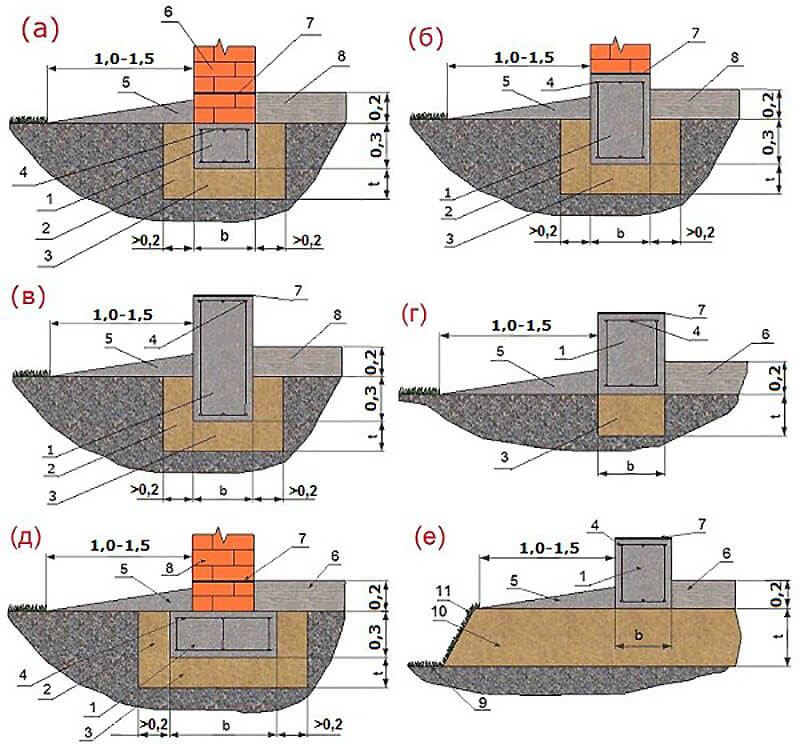

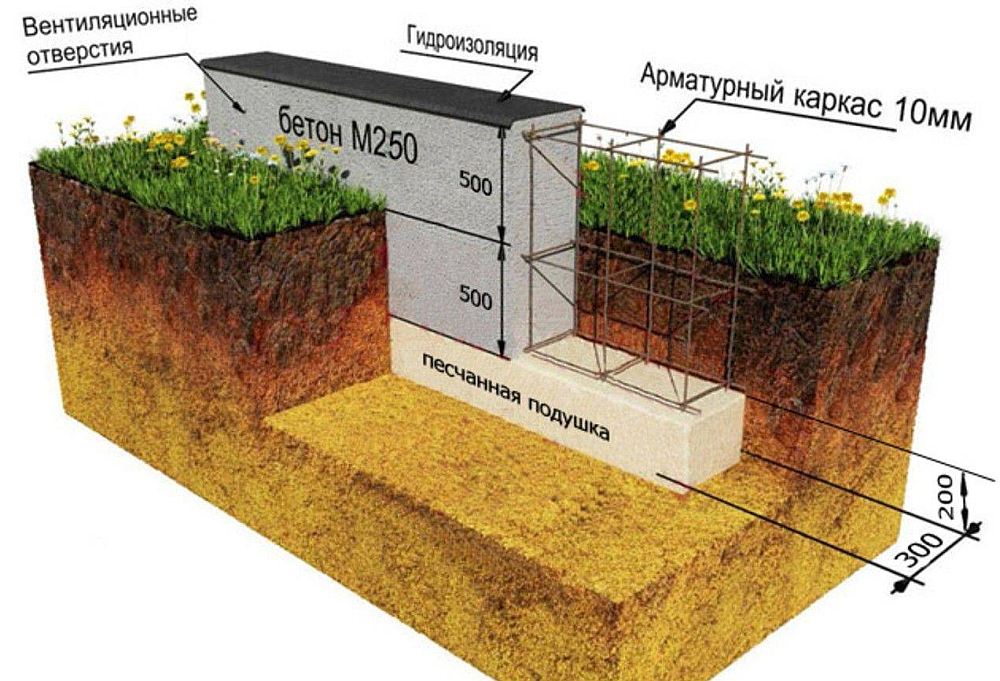

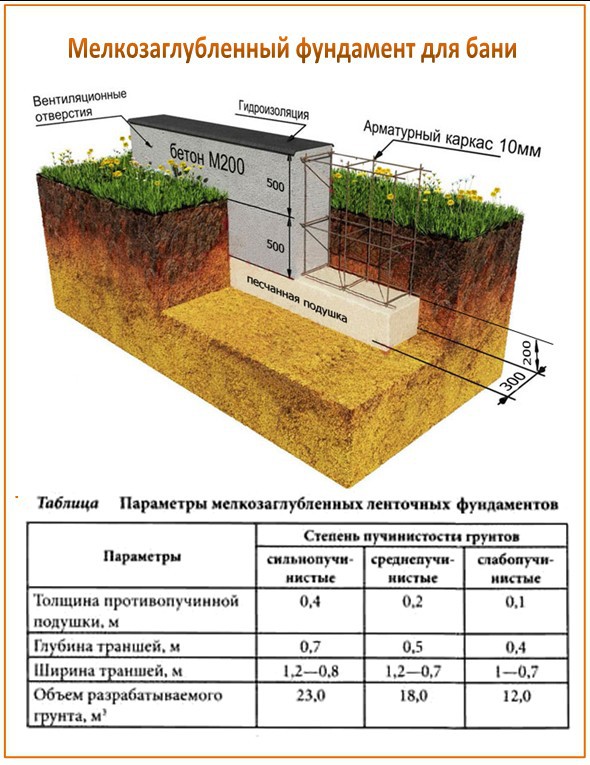

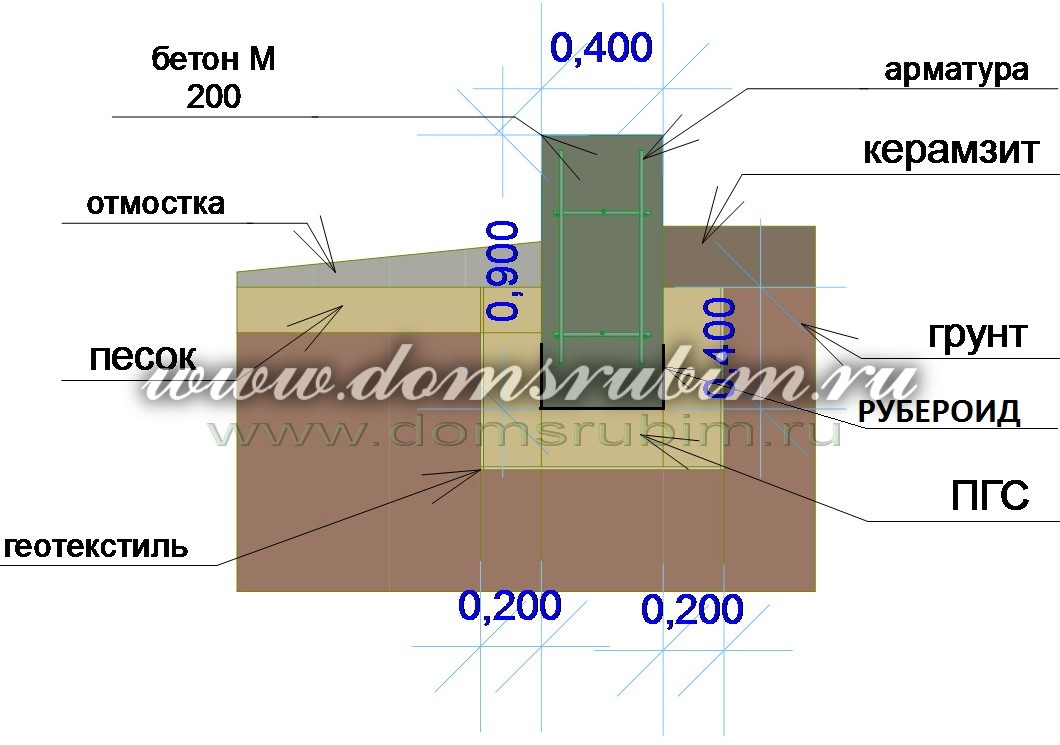

The departmental building codes for low-rise buildings VSN 29-85 provide recommendations for dwellings on heaving soils. The main requirements are:

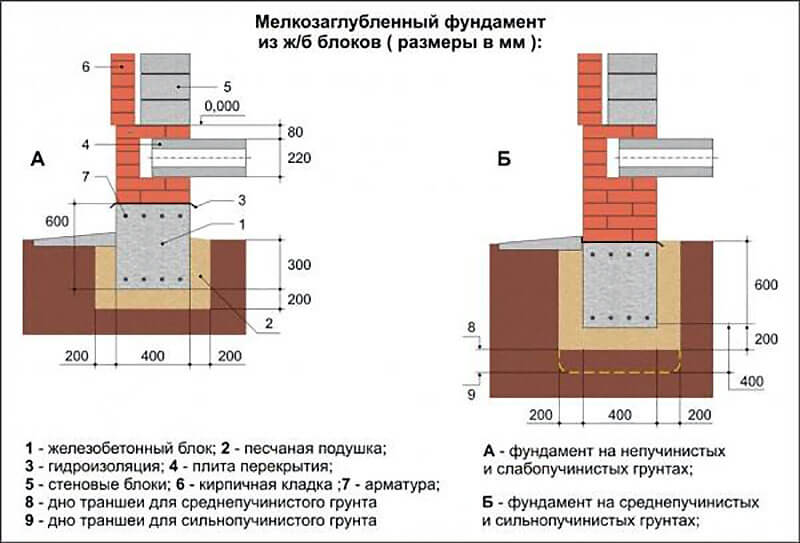

- when the swelling intensity is more than 0.05 units, a monolithic foundation or a prefabricated tape with rigid pinching of the beams inside the structure is required

- the calculations take into account the stiffness of the building walls, due to which the deformations of the tape are reduced

- the pillow is created from crushed stone, coarse sand or ASG with a crushed stone content of 60%

- when building a prefabricated tape on medium heaving soils, the blocks are laid on 10 - 20 cm reinforced concrete, fixed from above with a standard armored belt 20 - 40 cm in height

In VSN 29-85 there are instructions for the construction of unburied foundations, depending on the wall material, construction technology of the dwelling box. For example, a log house, self-supporting insulated panels, panel board, half-timbered, frame house can be supported on excessively heaving soils on:

- monolith;

- rigid connection of reinforced blocks.

If the soils are medium heaving, two-row laying of blocks with a length of within 2 m with a section of 25 x 20 cm with reinforcement inside is allowed. For foam, aerated concrete blocks, brickwork, the requirements are stricter:

- strongly heaving soil - armopoyas at the level of the Mauerlat, interfloor floors, above door, window openings + monolithic tape;

- medium heaving soil - the blocks are laid between the armored belt, a foundation for rigid fixation.

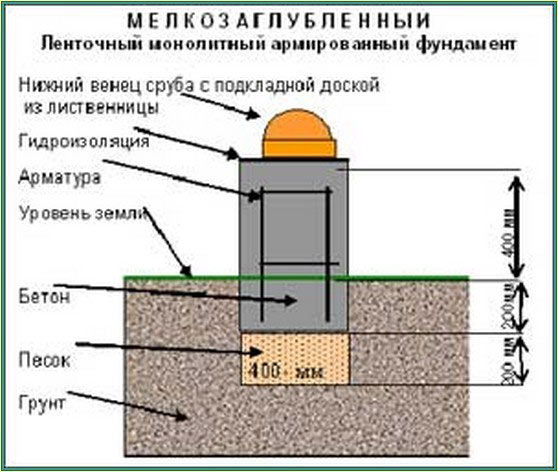

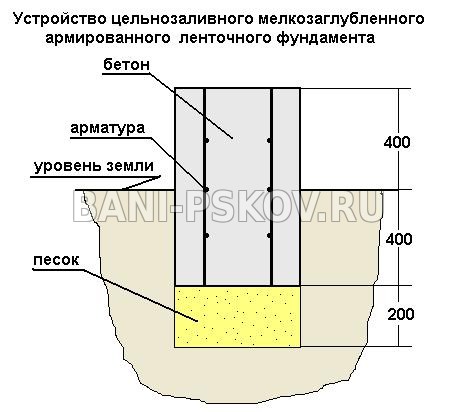

The technology for the construction of a non-buried tape on heaving soils is as follows:

- trenches to a depth of 40 - 60 cm;

- backfilling in layers of 20 cm of crushed stone, ASM, sand on geotextiles, laid on the bottom of the trench with the edges running on the walls, is compacted with an areal vibrator;

- installation of formwork, placement of the reinforcement cage;

- concreting, moistening of the material gaining strength in the first three days.

Stripping for waterproofing is possible at 50% of the strength of the tape, which in hot weather is usually equal to two days. The maximum demolding period of 27 days will be at a temperature of + 5 degrees.

Thus, an unburied foundation is suitable for almost any soil, wall materials. It allows to reduce labor costs by 40%, construction budget by 60% in comparison with buried belt. The developer will not be able to get the underground floor, the cellar under the room may be present in the project with a low GWL.

Good publicity

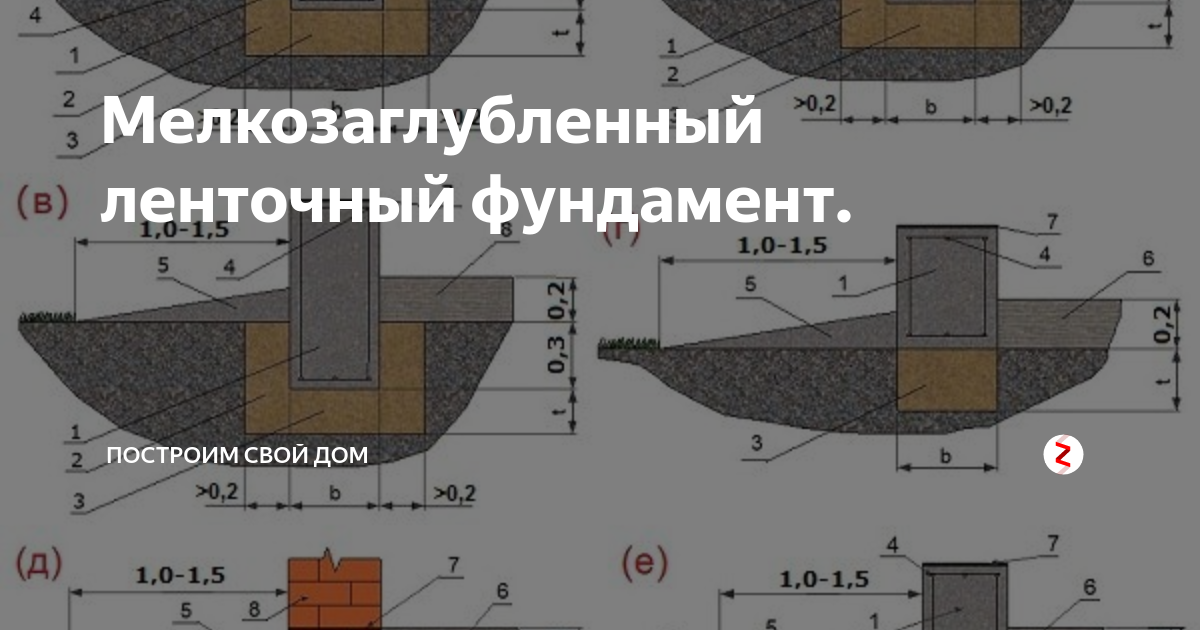

NZLF execution options

There are several ways to build an NZLF for outbuildings or a residential building in the country.

Precast strip foundation

Such a foundation is most often performed on low-loamy sandy soils. FBS blocks are used as material.

It is not recommended to equip a prefabricated foundation on heaving soils, because pushing out and subsidence of concrete blocks during frost heaving will be carried out unevenly.

FBS blocks are conveniently mounted due to mounting gaps and hinges, which significantly speeds up the assembly of the strip base.

Basic requirements for arranging a prefabricated foundation structure:

- a bedding is made under the base;

- FBS are installed in one plane;

- to connect individual plates, steel embedded parts are used (welded together) or a mortar based on cement grade M200 / 300;

- it is advisable to additionally strengthen such a foundation with a metal frame.

Advantages of precast foundation structures:

- ease of installation;

- minimal time spent on construction work;

- there is no need for the arrangement of formwork, preparation and pouring of concrete;

- low cost of construction.

Disadvantage: Heavy concrete blocks cannot be manually installed, therefore a construction crane must be hired.

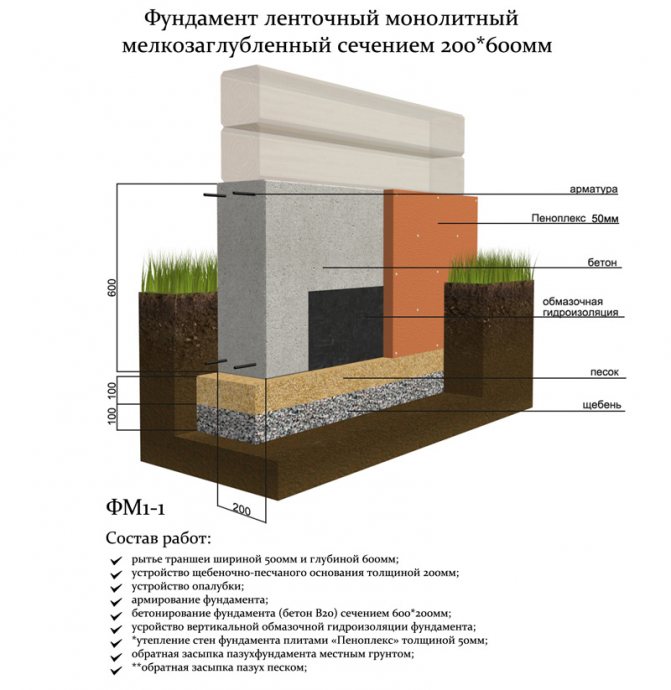

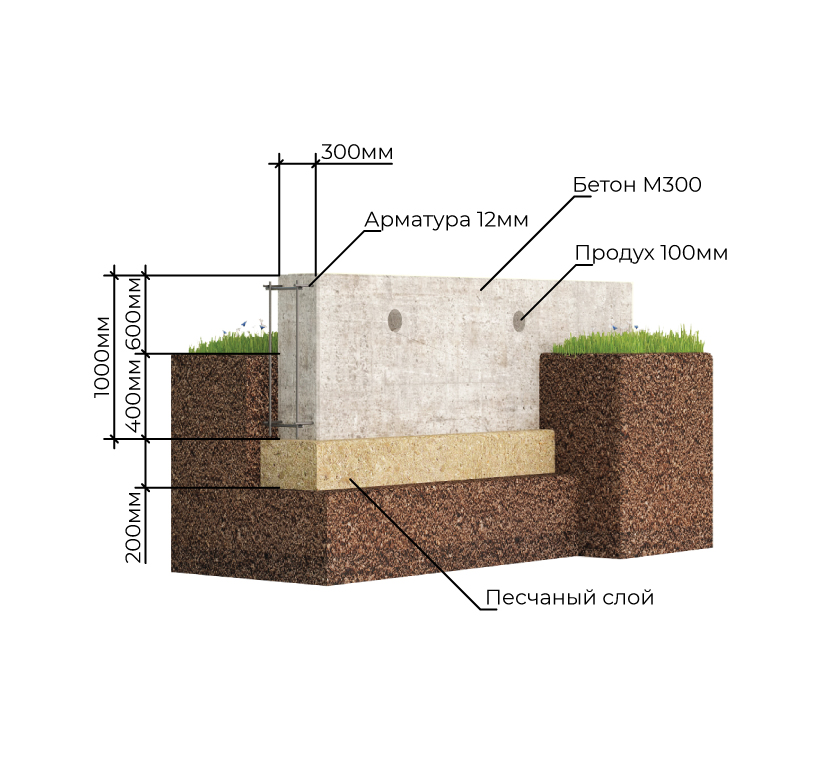

Monolithic

Formwork is pre-assembled under a monolithic concrete base.Such a foundation can be used for the construction of private residential buildings on heaving soils, but with the obligatory filling under the foundation and the arrangement of an effective drainage system.

Differs in durability and stability on moving ground.

Advantages of monolithic NZLF:

- the possibility of erecting the foundation of any parameters;

- all construction work can be performed on their own without special construction equipment, the involvement of experienced workers;

- low cost.

Disadvantages: high labor costs, the hardening time of the concrete mass - up to 30 days.

Combined

An unsubmerged strip foundation can be made combined:

- columnar base - the foundation tape is mounted on pillars dug into the ground;

- precast-monolithic base - part of the foundation is erected using FBS slabs, the other part is poured with concrete mortar using a formwork structure.

It is impractical to use combined base structures for small buildings.

Calculation for a shallow foundation

An example of the calculation of shallow foundations on heaving soils should be given. For example, a one-story house is being built with the following dimensions:

- height - 4 meters;

- width - 5 meters;

- length - 10 meters.

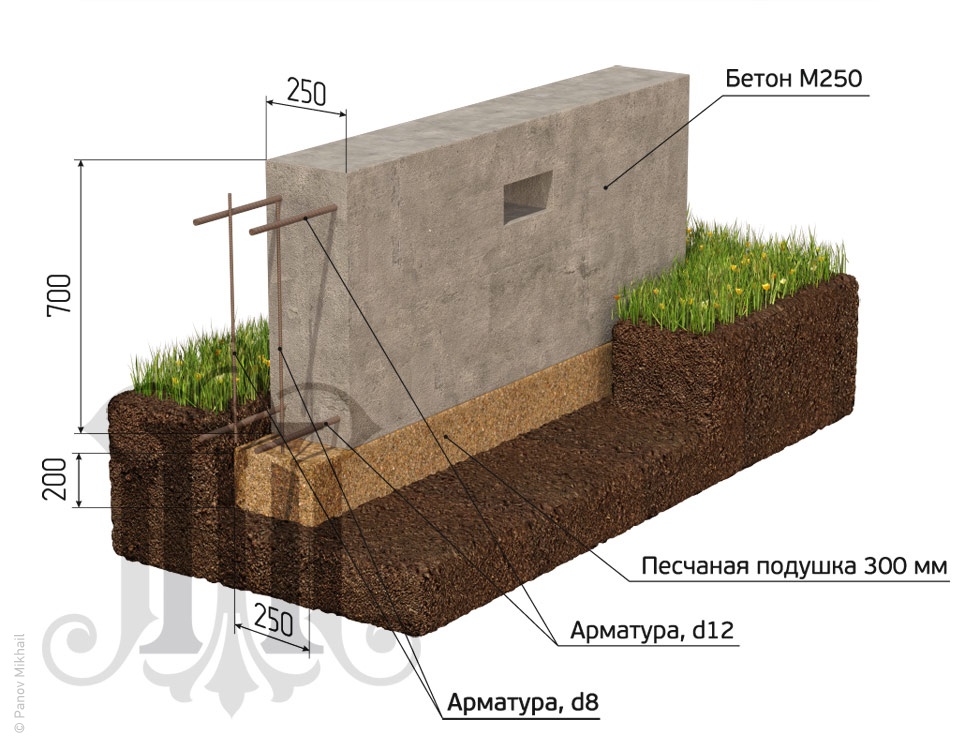

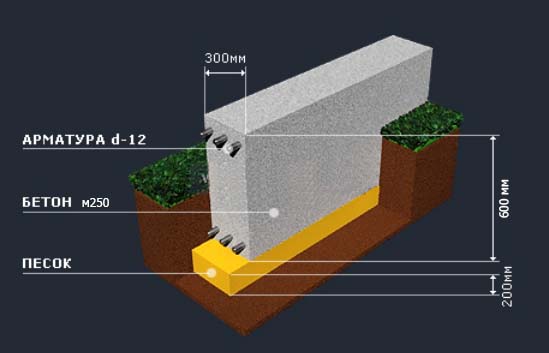

The structure includes two load-bearing internal walls, each 4 m high and 3 m long. The floor does not rest on the foundation, it is poured with concrete. The base will be in the form of a tape with a base width of 40 cm and a depth of 70 cm. The foundation is made of reinforced concrete, for which reinforcement with a diameter of 12 mm is used. The frame will have two belts, each of which consists of five rods, jumpers with a length of 25 cm.Such jumpers are placed in 50 cm increments.

To find out the mass that the strip foundation will have, it is necessary to determine the following values:

Scheme of a shallow foundation with waterproofing on a baked pillow.

- geometric dimensions of the structure;

- the density of the building material used.

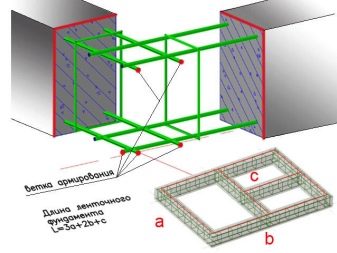

It is quite easy to find out the geometric dimensions. So, the length of the foundation is equal to the perimeter of the future building, that is, you just need to calculate the sum of its sides:

10 + 10 + 5 + 5 + 3 + 3 = 36 meters.

The strip foundation will be poured not only under the external facade walls, but also under the internal load-bearing ones, therefore, they are also taken into account.

Now you can find the volume based on the fact that the height of the tape is 70 cm and the width is 40:

V = 36 × 0.4-0.7 = 10.08 cubic meters.

But this is the total volume from which the reinforcement must be subtracted in order to find out the amount of concrete. Knowing that the strip foundation has two belts of five rods with a dressing, they calculate the length for each:

10-0.5-0.5 = 9 meters.

The length of all belts will be equal to:

2 × (9 × 2 + 4 × 2 + 2.5 × 2) = 62 m.

Each belt has five rods, which means that their total length is: 62 × 5 = 310 m.

Now determine the length of the required lintels for the reinforcement:

Reinforcement scheme for a shallow foundation.

9 / 0.5 + 1 = 19 pcs.,

4 / 0.5 + 1 = 9 pcs.,

2.5 / 0.5 + 1 = 6 pcs.

For one upper belt, the number of jumpers is:

19 × 2 + 9 × 2 + 6 × 2 = 68 pieces,

Since the length of one jumper is 0.25 meters, the total length is:

68 × 0.25 = 17 meters.

For all horizontal frame lintels, the length is:

17 × 2 = 34 meters.

For vertical jumpers, it is taken into account that there are 68 of them on the one side and the same number on the other. That is, it turns out 136 pieces with a length of one of 40 cm.Their total length is:

136 × 0.4 = 54.4 m.

Now calculate the total length of the reinforcement required by the shallow foundation:

310 + 34 + 54.4 = 388.4 m.

To find out the cross-sectional area for reinforcement, use the formula for the area of a circle:

Scheme for the preparation of concrete solution for the foundation.

3.14 × 0.000036 = 0.00011 sq. meters.

To obtain the volume, use the formula:

0.00011 × 388.4 = 0.04 cbm meters.

Now the volume is obtained for reinforcement only:

10.08-0.04-0.04 = 10 cubic meters meters.

A value of 0.04 is taken on the basis that a shallow foundation will be reinforced at the corners as well.

With the help of such a not too complicated calculation, it is determined what requires:

- 10 cubic meters meters of cement (with a density of 2500 kg per cubic meter);

- 0.08 cc meters of metal reinforcement (with a density of 7800 kg per cubic meter).

That is, the total mass of the entire foundation, which is being erected on heaving soils in the form of a strip foundation, will be:

10 × 2500 = 25000 kg,

0.08 × 7800 = 624 kg,

25000 + 624 = 25624 kg.

That is, the strip foundation has a mass of 25624 kg.

Building a house on heaving soils is not the best option. But if there is no other way out, then it is necessary to carefully calculate the future foundation so that after its construction the structure is not pushed out of the soil during the winter heaving. This is not so difficult to do, but care must be taken so that during operation there are no deformations of the foundation, and therefore the house itself.