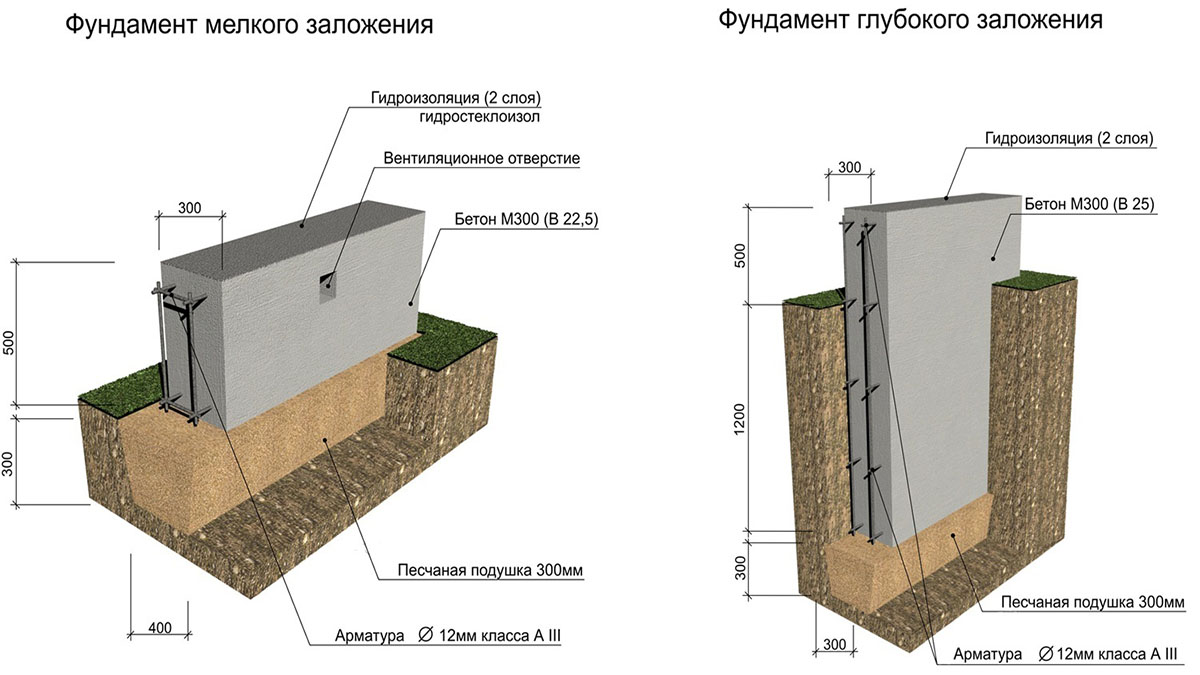

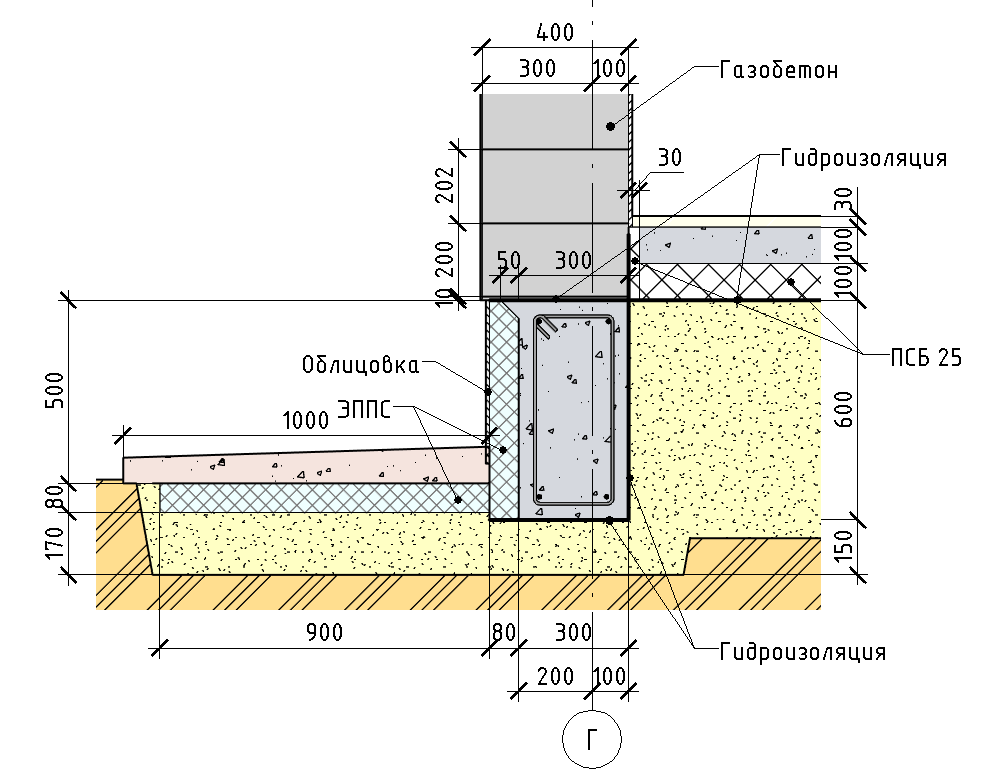

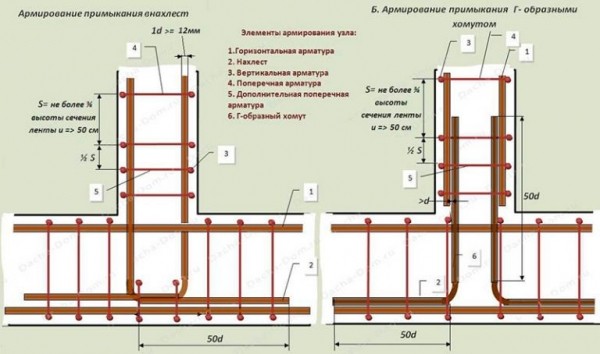

Reinforcement scheme for strip foundation

Reinforcement is very important for a quality foundation and a solid home. Thanks to metal rods, it is possible to strengthen the structure, increase the ability to withstand various loads, and avoid premature destruction.

Reinforcement rules for strip foundations:

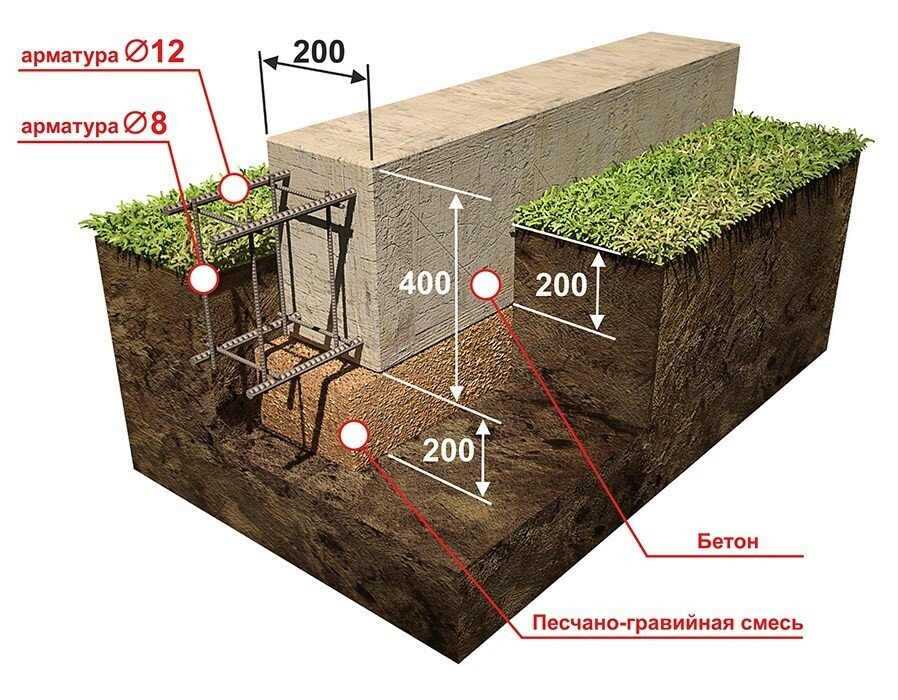

Minimum diameter of all working rods of reinforcement at the base should be equal to 0.1% of the cross-sectional area of the foundation.

The working reinforcement of the longitudinal arrangement in areas of more than three meters should be 12 millimeters in diameter.

The maximum pitch between the working rods of the longitudinal reinforcement is 40 centimeters.

The distance between the clamps should be a maximum of 40 centimeters.

The overlap of the reinforcement should be 50 centimeters.

The foundation tape with a height of more than 70 centimeters presupposes the installation of constructive longitudinal reinforcement.

The distance between rows of structural reinforcement of longitudinal arrangement should be less than 40 centimeters.

The cross-section of the transverse reinforcement must be at least 25% of the cross-section of the working longitudinal reinforcement (but not less than 6 millimeters).

For example: the height of the base tape is 1 meter = 1000 millimeters, the width is 400 millimeters.

Calculation of the minimum cross-section of longitudinal reinforcement:

The cross-sectional area of the foundation is 1000 x 400 = 400,000 millimeters.

The total section of longitudinal reinforcement is 400,000 x 0.1 = 400 millimeters.

Search in the table for the number / diameter of working rods.

A structural series of reinforcement is added to the frame.

Home weight calculator

Allows you to determine the amount of pressure on the base from the side of the building and choose the right type of foundation.

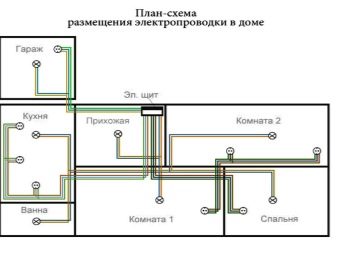

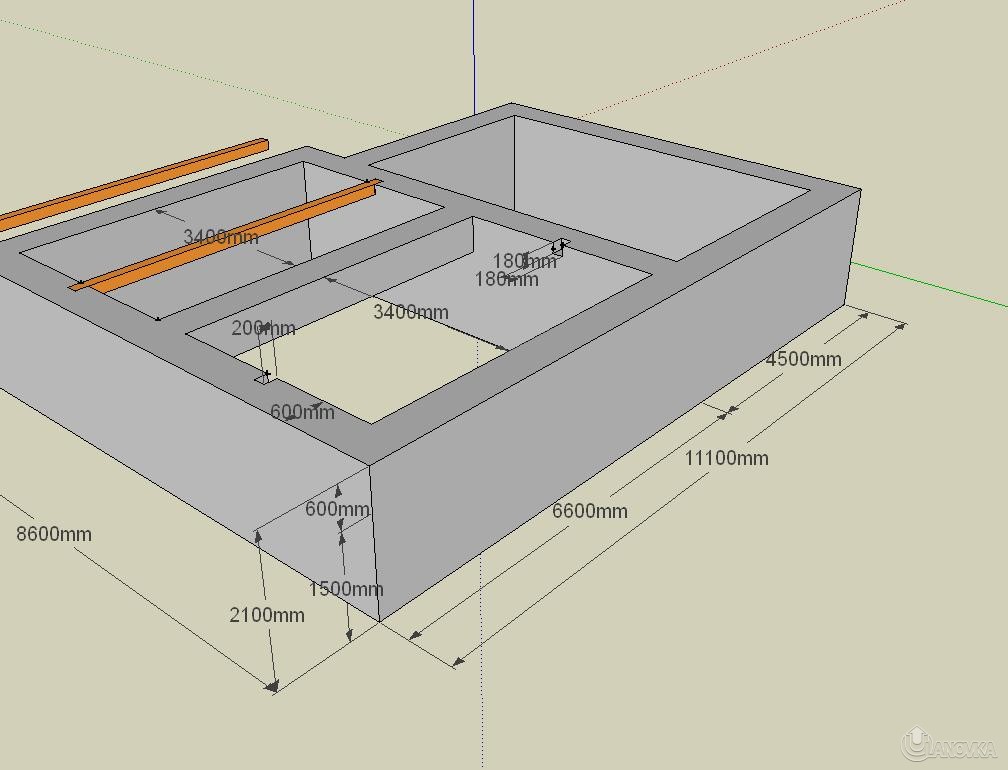

The calculations are performed in two stages. At the first, the total length of the walls is calculated; this requires a drawing of a plan for a future construction.

At the second stage, an assessment of all loads on the base of the structure is carried out.

The calculations take into account a number of factors:

- materials of structural elements of the building from expanded clay concrete blocks;

- roof features;

- regional weather conditions;

- scheme and dimensions of the attic space;

- plinth height.

The pressure on the foundation is made up of a mass of external walls and internal partitions. The presence of a screed and a type of finish matters.

The best option is to evenly distribute the loads on all fragments of the foam concrete structure. When calculating, it is recommended to provide for a reserve.

Peculiarities

Aerated concrete is autoclaved aerated concrete. Throughout the history of its existence, it has found application in almost all areas of construction of structural elements of buildings and structures of any type. The characteristic features of this material make it very competitive in the building materials market.

The main advantages of building foundations from this material:

- independence from temperature extremes;

- a light weight;

- fast installation and ease of installation;

- environmental friendliness;

- moderate cost;

- excellent heat and sound insulation;

- high resistance to frost, and due to porosity, water does not penetrate quickly into the material;

- versatility: aerated concrete can be sawn, drilled, thanks to which aerated concrete blocks can be given different shapes;

- at the factories where gas blocks are made, there is a laboratory that controls the quality of the material;

- aerated concrete refers to stone materials, but is considered a fairly light material. Almost any type of foundation is suitable for it, which meets the requirements for rigidity and deformation.

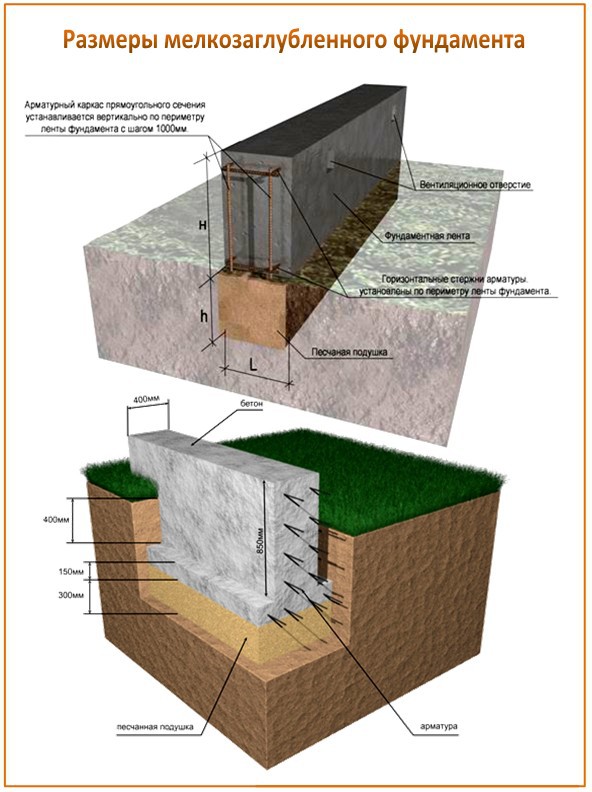

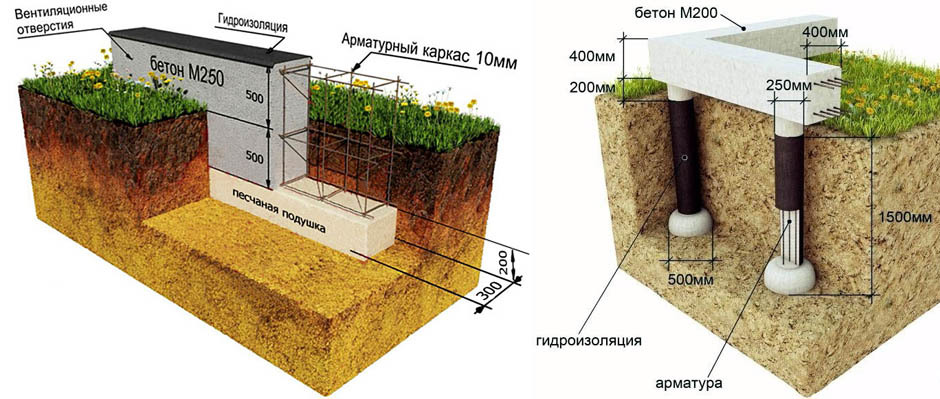

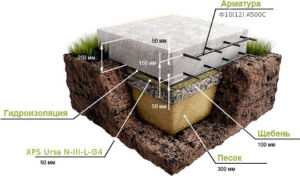

Calculation of sand and crushed stone pillow

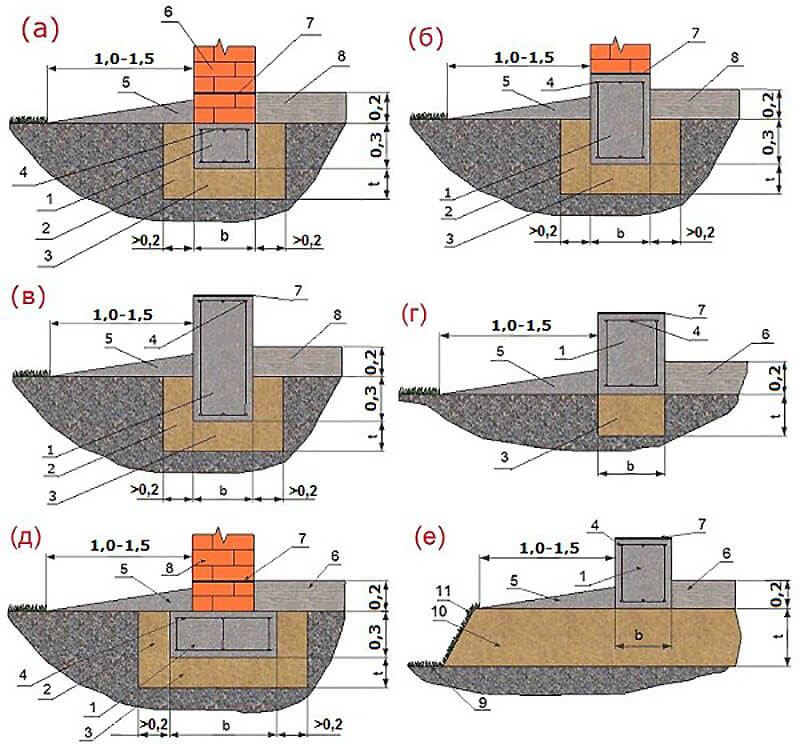

Schematic representation of a slab foundation with an indication of the thickness of the sand-crushed stone cushion

Schematic representation of a slab foundation with an indication of the thickness of the sand-crushed stone cushion

The thickness of the pillow often changes depending on the condition of the soil and the type of building and what the house is made of. The thickness depends on many indicators, because for wooden buildings a pillow 15 cm thick is enough, but for massive houses made of aerated concrete - no less than half a meter. But, as a rule, the thickness of the pillow is calculated for each house individually, the following factors are taken into account here:

- condition and structure of the soil;

- the degree of soil freezing;

- heaving of soils and seasonal movements;

- soil moisture and the height of the soil horizons;

- house material and total mass of the building;

- dimensions of the slab.

Crushed stone in the pillow is needed to compensate for the heaving of the soil, therefore, crushed stone compensates for the low density of the soil with rockiness. It is also an excellent drainage material, especially on clayey soils with a high moisture content. The sand ensures an even distribution of the building's mass over the entire sole area.

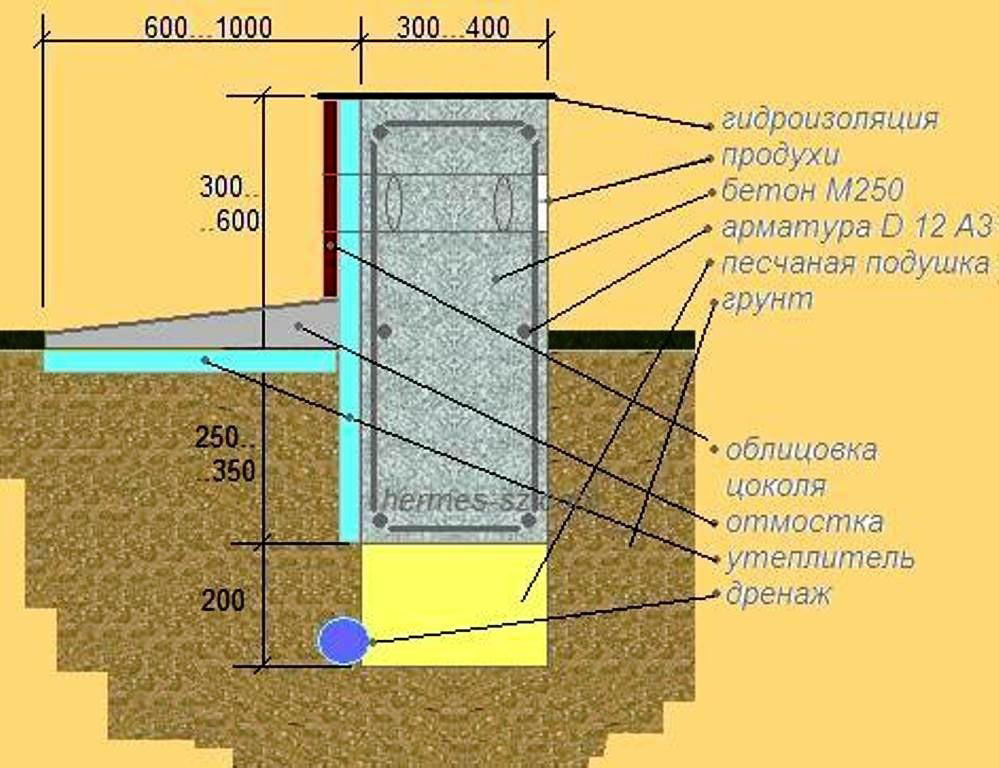

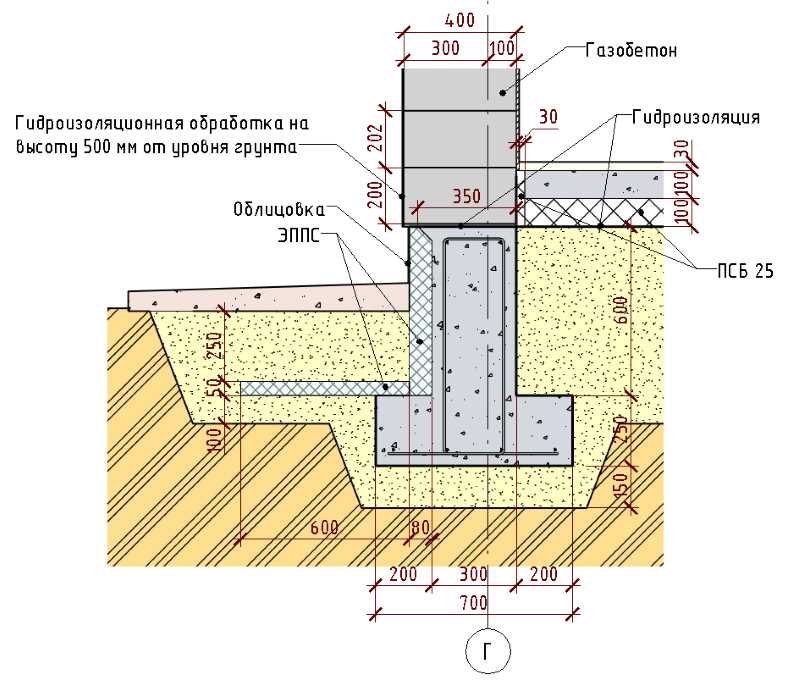

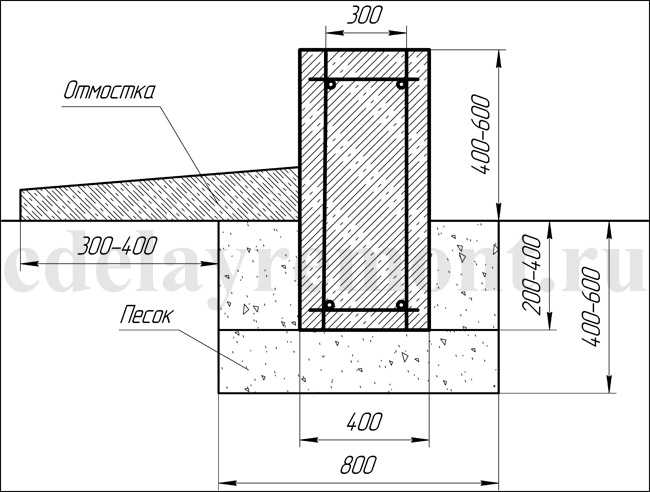

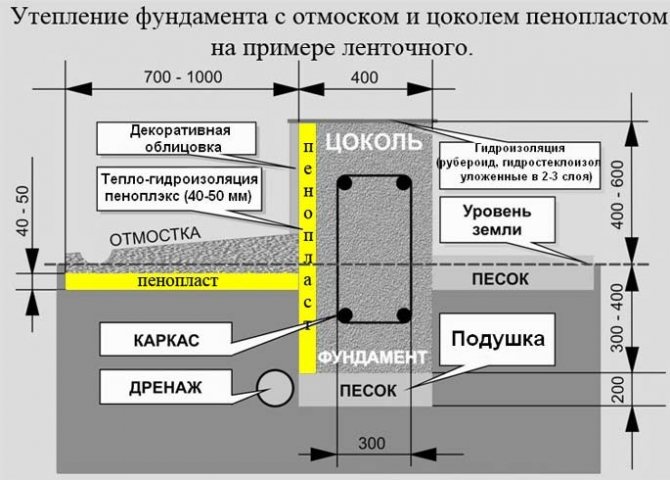

Insulation of the basement and blind area

It is imperative to insulate the basement and the blind area, since this technique makes it possible to slow down the frost front, significantly reduce the depth of soil freezing. Throughout the entire time of exposure to negative temperatures on the base, frost should not pass under the structure and create vertical frost heaving forces that can even lift the base.

Heaters can be used different, but most often they use extruded polystyrene foam. For the center of Russia and even warmer regions, insulation up to 50 millimeters thick is enough, colder regions require the choice of insulation up to 100 millimeters thick. The process of performing the work is quite simple: the sheets of insulation are glued to the base with foam, additionally fastened with disc dowels.

The blind area is usually made up to 100 centimeters wide. Under it, all fertile soil is removed with a layer of 30 centimeters deep, replaced with sand, well moistened with water and well tamped. The thickness of the concrete blind area is 8-10 centimeters; they must make a slope towards the house for effective drainage of water.

The blind area is reinforced with a mesh with cells measuring 10 x 10 centimeters. In addition, it is desirable to strengthen the reinforcement additionally by installing longitudinal reinforcement bars. To fill the blind area, concrete of the M150 / M200 brand is used.

To eliminate the likelihood of cracks, the blind area is divided into parts of 2-3 meters each, the seams are carefully covered with a silicone-based sealant. The blind area should not be rigidly attached to the foundation; it is performed floating, since it will feel the frosty swelling of the soil.

Basic rules of execution:

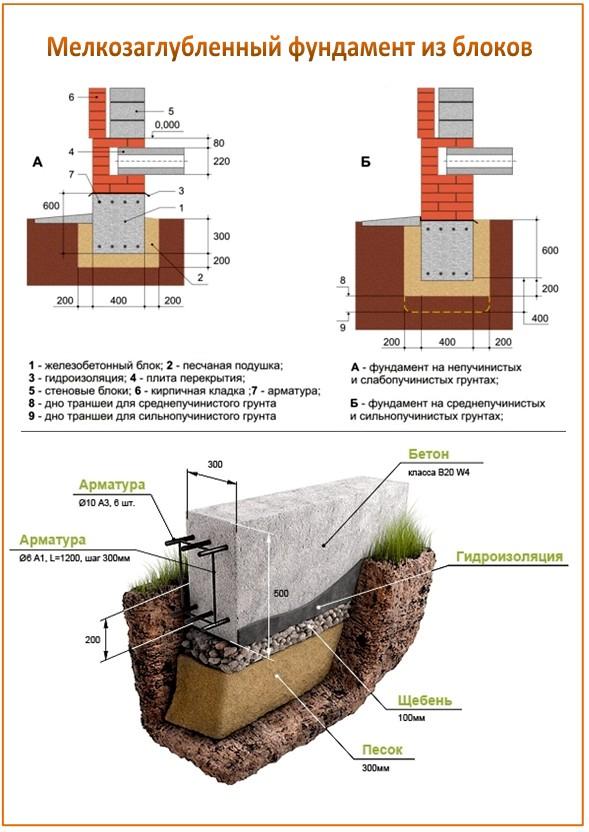

- Correct calculations of the reinforcing cage should be the basis for creating the most rigid tape. The walls of the base should be as smooth as possible.

- If you want to build a brick basement, it is tied from above with a reinforced concrete belt, which significantly increases the rigidity of the structure.

- Regardless of the level of strength and rigidity of the foundation, it must be performed without fail.

- To increase the level of strength of the monolithic tape, you can expand it at the base, which will increase the area of support on the soil.

- It is undesirable to use foundation blocks to create the main support of a house from aerated concrete, since they will not give the required rigidity, as a result of which the walls can become covered with cracks.

Shallow tape is an excellent choice, which, subject to technology and careful adherence to the rules, will create a solid and rigid foundation for the building.

Foundation construction stages

So, having figured out what kind of foundation is needed for a house made of aerated concrete, you can proceed directly to construction, which consists of several stages:

- Site marking and trenching;

- Preparation of cushion and reinforcement;

- Pouring trenches with concrete.

Now let's take a closer look at all these stages.

Trenches

Preparation

Construction of the foundation for a house made of aerated concrete begins with preparatory work. First of all, you need to mark the site in accordance with the design data and clear it of debris, grass, etc.

After that, the work is done in this order:

- Trenches are marked and dug with their own hands. Their depth depends on the design calculation. As a rule, it is 0.5-0.6 meters. The width depends on the thickness of the walls.

- Further, the walls of the trenches and the bottom are leveled.

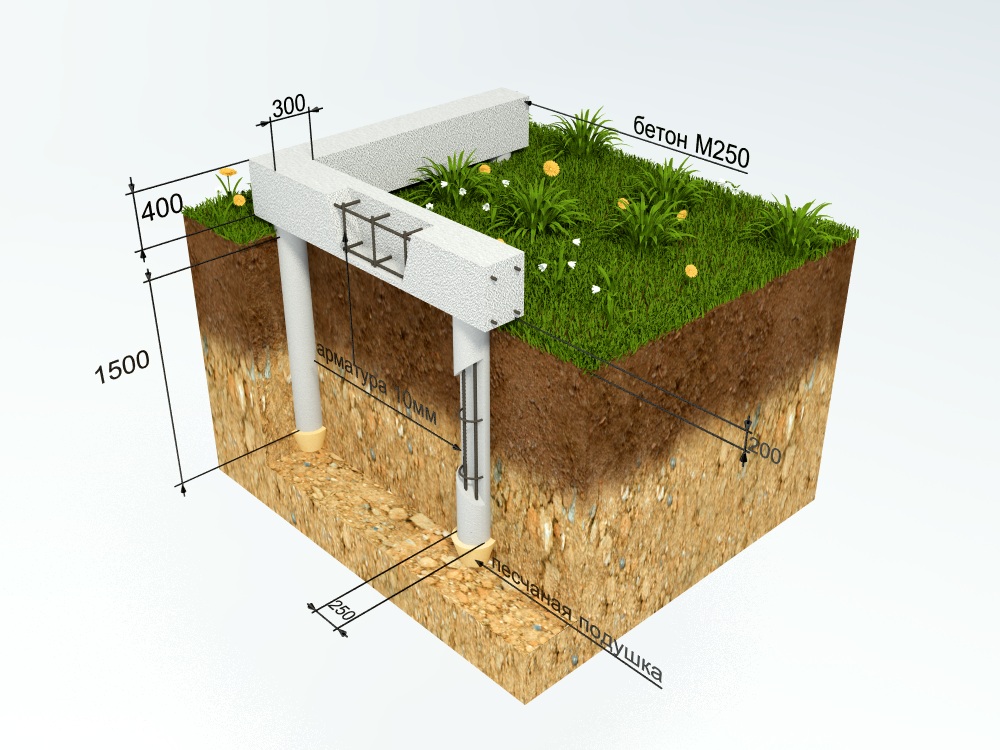

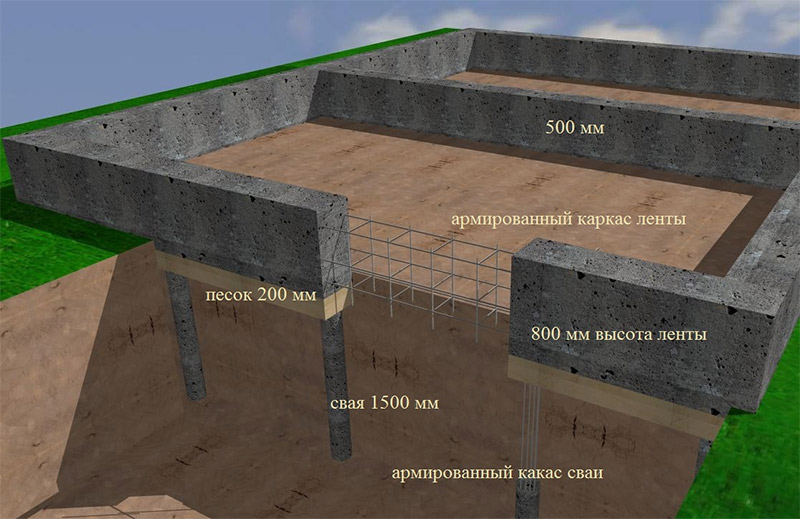

- After that, coarse sand is poured to the bottom. I must say that the sand cushion plays a very important role, as it allows you to level the soil, thereby giving additional strength to the structure. The thickness of the pillow should be approximately 20 cm.

- Then the sand must be watered and tamped well. The result should be a flat and solid surface.

- The final stage in the preparation of trenches is laying polyethylene on the bottom. This prevents fluid leakage when pouring the grout.

Reinforcement

Reinforcement

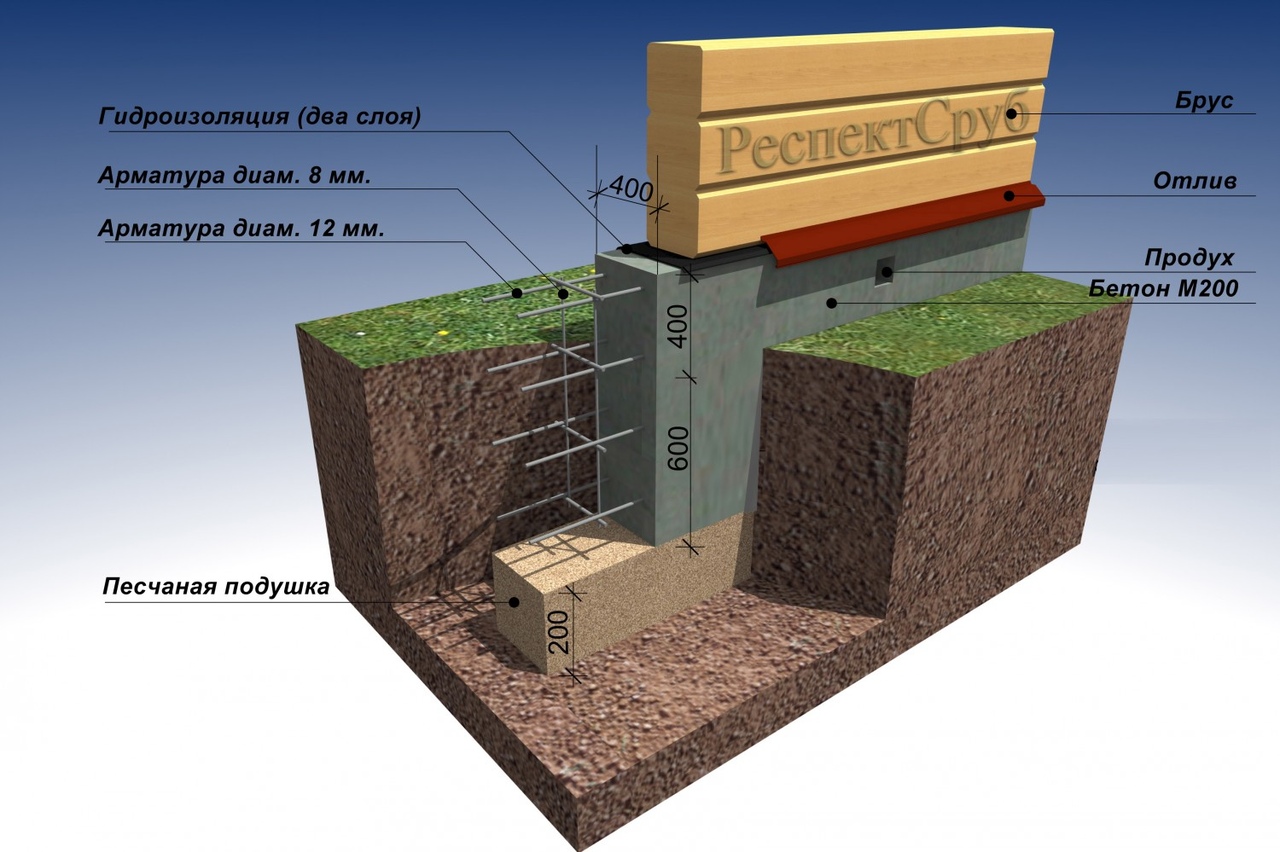

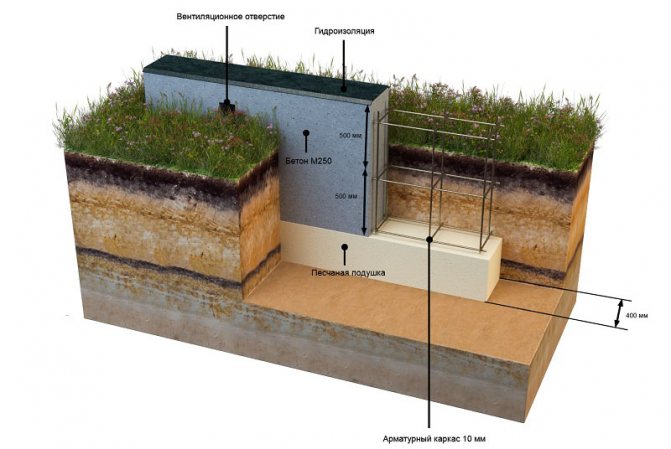

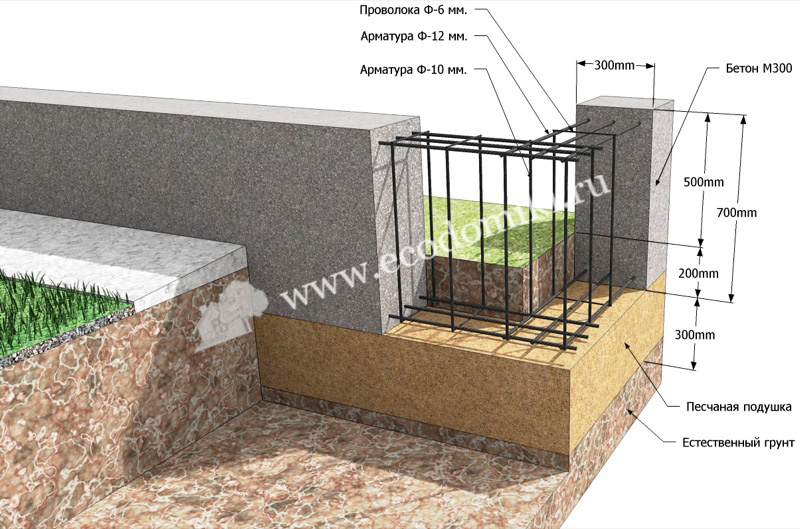

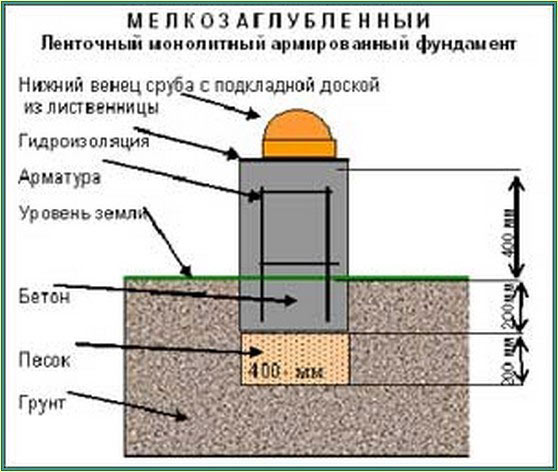

In order for the foundation for an aerated concrete house to turn out to be strong and reliable, it is imperative to perform reinforcement. In fact, this is a structure frame, which is made of metal rods with a diameter of about one centimeter.

Reinforcement should be both vertical and horizontal. The fittings can be welded together or tied with wire.

Fill

Before pouring, the basement formwork of the foundation must be installed. I must say that it is not rarely installed not from the surface of the earth, but from the bottom of the trench. This allows for better control over the shape of the walls.

Chipboards, boards or other material are usually used as formwork. The most important thing is that the structure must be strong, so the shields must be reinforced with spacers.

Fill

Further instructions for pouring are as follows:

First of all, it is necessary to knead the concrete solution. This procedure must be approached very responsibly, since the quality of the entire foundation will also depend on the quality of the concrete.

A solution is prepared in the following proportions:

- One part of M400 cement;

- Three pieces of sand;

- Five pieces of rubble.

First of all, dry components are mixed, after which water is gradually added.

- Further, the filling is carried out directly. The procedure must be performed in one pass, or at least the next layer is poured before the previous one hardens. During the entire pouring process, the mixture should be tamped.

- After the concrete is poured, all work must be stopped. After the mortar has set, it should be covered with plastic wrap. During the first few days, the surface should be moistened with water twice a day so that the mixture dries evenly.

- After the concrete mortar has set, the upper part must be trimmed if it has irregularities in order to end up with a horizontal plane. If there are significant irregularities on the surface, the reinforced concrete is cut with diamond wheels.

In the photo - the device of ventilation holes

This completes the process of building the foundation.

Features of aerated concrete as a building material

Aerated concrete is a building block made by mixing cement, quartz sand, water and chemical blowing agents.

Aerated concrete is a building block made by mixing cement, quartz sand, water and chemical blowing agents.

Aerated concrete is a building block made by mixing cement, quartz sand, water and chemical blowing agents. As a result of this chemical "neighborhood", the constituents foaming occurs, after which the blocks solidify. They are cut into the required lengths and tempered in an autoclave. Thus, the aerated material is gaining strength and wear-resistant characteristics.

It is a mistake to believe that a gas block house can not withstand ground shifts.If you choose the right foundation, then the block building is not afraid of any relief changes. The fact is that gas (foam) blocks have the lowest modulus of elasticity among all types of concrete available in the construction industry. That is why the strength of the blocks is not in doubt either among professionals or beginners.

And to ensure high-quality operation of a reliable block structure, a correctly selected foundation will allow. It should be chosen based on the following parameters:

- The composition of the soil on the site (sand, clay, loam, etc.);

- Groundwater level at the construction site;

- Embossed features of the building plot;

- The depth of soil freezing;

- Total number of storeys and weight of the finished building;

- Desire to have a basement;

- Design features of the finished house;

- Temporary load on the house (meaning the mass of all furnishings in the house, including plumbing equipment);

- And, of course, the budget allocated for building a block house.

Why you need to know the weight of an aerated concrete house

The total weight of the house (made of aerated concrete or any other material) is considered to be able to determine the required width of the tape or the soles of the base. The support area is selected in accordance with the calculated soil resistance.

So, if you plan to build a two-story aerated concrete house with walls up to 40 centimeters thick, lined with brick, on loam soil with a design resistance of 1 kg / cm2, you need to choose the optimal width of the base so that the pressure on the soil is 20% less than the design resistance ...

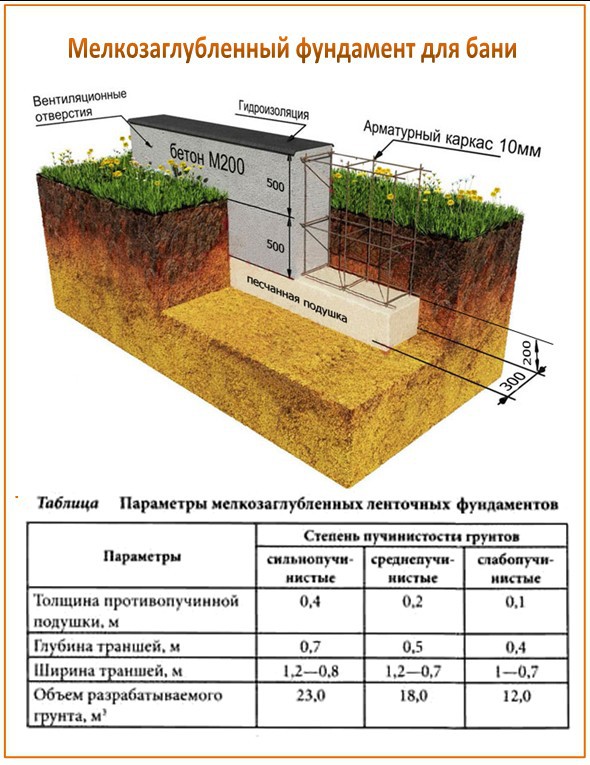

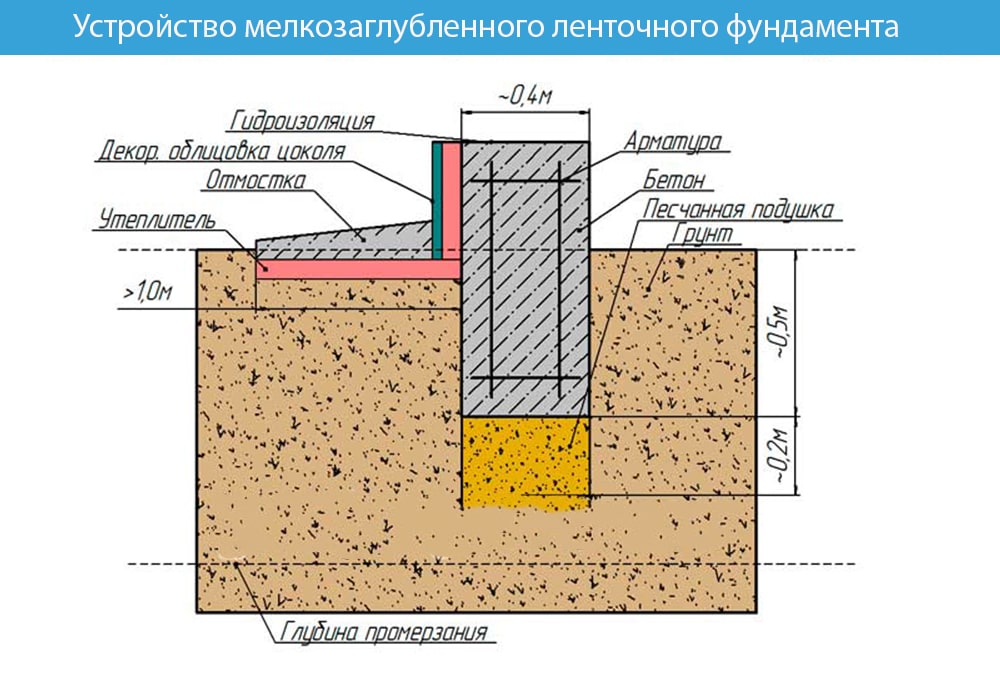

The main stages of the construction of the MZLF:

Planning - creation of a project, calculations, soil research, preparation of a drawing of a future building, drawing of a foundation diagram with load-bearing walls, corners, internal partitions.

Preliminary preparation of the land plot - cleaning the area from vegetation, debris (including the removal of trees and shrubs with roots).

Digging a trench - about 15 centimeters deep (if you plan to fill up a sand cushion, the same amount is allocated to it), 15 centimeters wider than the load-bearing walls, leveling the bottom of the trench (from notches and bumps).

The backfill of the sand cushion is made of coarse sand, with a layer 10-15 centimeters thick. Then they spill it with water, tamp it. If the soil is very heaving, the sand is reinforced with crushed stone fractions up to 5 centimeters.

Installation of formwork - from wooden boards or boards, beams, with installation in a trench or on the ground.

Reinforcement of the base - to strengthen the tape, a frame is created from metal rods tied with a knitting wire.

Drainage - to drain water so that moisture and underground flows do not destroy the foundation structure. The system is calculated before the solution is poured; it is a drainage system from pipes coated with an anti-corrosion agent. The pipes are immersed in the ground, they are needed to drain the accumulating water.

The main tape - concrete is prepared and poured in layers, the bottom layer in depth should not be more than 15 centimeters. When the first layer dries, the second is poured, and so on. After the final casting, the structure is covered with foil and allowed to harden.

Creation of waterproofing and insulation - sheets of roofing material are laid out on the base of the tape itself covered with mastic, the protection is allowed to adhere, then a suitable type of insulation is laid.

The foundation for an aerated concrete structure: nuances

Be sure to take into account the relatively light weight of the autoclaved aerated concrete

It is believed that aerated concrete, with all its advantages, is a rather brittle material, which means that the slightest deformations of the base will lead to the appearance of through cracks. But based on SNiP 2.03.01-84, it should be noted: the modulus of elasticity of autoclaved aerated concrete (at a density of D700) is the smallest value in the line of heavy, fine-grained, cellular concretes (class of concrete for compressive strength B 3.5), that is, it turns out that it is one of the most durable concrete materials. The higher the modulus of elasticity, the more fragile the building material is, for example, heavy unreinforced concrete is much inferior to autoclaved concrete mixtures.

Be sure to take into account the relatively light weight of the autoclaved aerated concrete.This advantage allows you to equip the foundation for a house of less weight, which means that it reduces the cost of building a building.

How to choose?

When choosing which foundation to lay for an aerated concrete house, consider not only the economic benefit, since the final durability of the base, as well as the entire building, depends on many factors.

Assess the soil in your area.

For example, a reinforced concrete slab is the best option, since it minimizes shrinkage deformations. When the soil moves, the slab moves with it, ensuring the safety of the house. Slab foundations are able to withstand even the most aggressive climatic conditions.

The tape shallow version is suitable for houses standing on slightly or medium-grained soils. And the base deepened to the depth of freezing can be placed on heaving soils.

The columnar type of foundation is built only on stable soils with a flat surface.

In turn, the pile foundation is suitable for any type of soil, even for clay.

Also, experts advise taking into account the number of storeys of the building, since depending on the number of floors, the total mass of the structure increases and, accordingly, the load on the base. If you have chosen a one-story house, then feel free to choose any option for the foundation from the above. But it is recommended to build a two-story one only on a slab monolithic or tape basis. In this case, the depth and width of the tape in the latter version should be greater than when erecting a one-story building.

Before calculating, you need to know:

- density and thickness of gas blocks;

- approximate weight of building materials and roof;

- number of storeys of the building;

- type of soil;

- approximate snow load.

The design process includes not only drawing up drawings, but also the development of basic communication details, design of a basement or garage in the basement, drawing up a wiring diagram, etc. After all, all these factors directly affect the choice of the type of foundation for future construction.