Installation of floors with strip foundations

Floor design is dependent on owner preference and future operating conditions. There are several methods that can be applied to flooring in houses with shallow foundations.

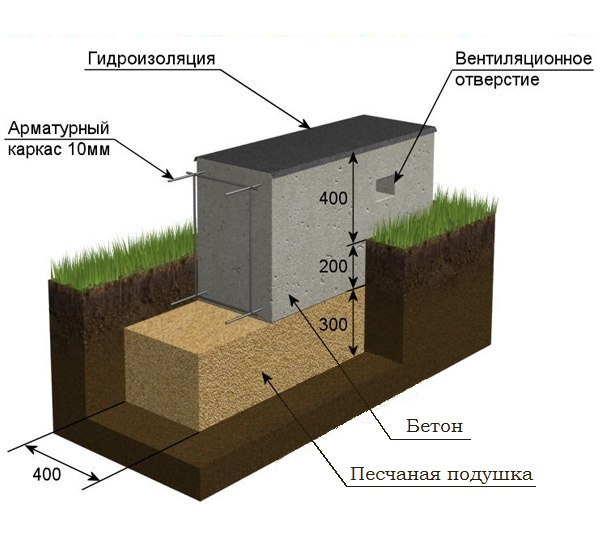

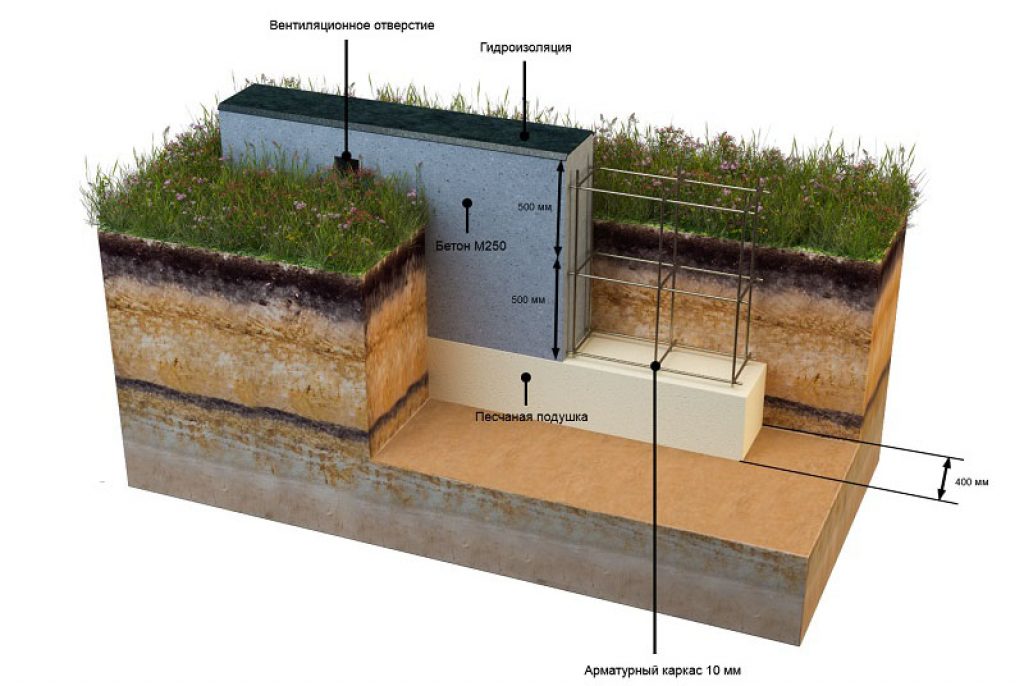

The easiest way is to cover the base with a slab, which will be the base of the floor. In this case, it is imperative to take care of creating ventilation, especially if the building is being erected in a too humid or swampy area. If this is not done, the concrete slab will eventually begin to deteriorate from moisture, especially if the building is located in swamps. The ventilation holes are made in the foundation, and since it is low, the holes can be covered with snow in winter, which is unacceptable.

Therefore, it is best to carry out the installation of floors on the ground. Beginners are usually interested in what is the right thing to do - build walls and a roof, and then deal with the floor, or vice versa - first the floor is laid on the base, and then the walls are erected? Both options are acceptable, so everyone chooses the one that suits him.

The flooring begins with leveling the soil:

The earth, taken out of the trench and placed in the inner perimeter, is leveled and compacted, watering it several times with water after 2-3 hours.

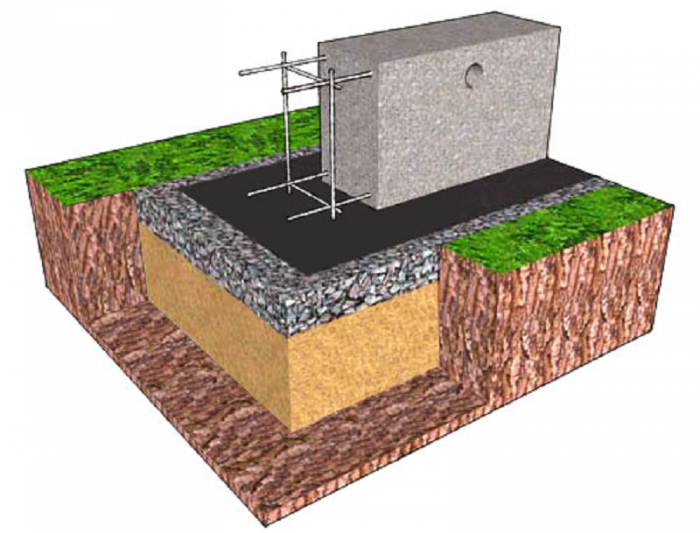

- Pour a layer (not less than 10 cm) of expanded clay or crushed stone.

- Pour a rough concrete screed. Its thickness is about 7-8 cm. For this, the crushed stone is covered with plastic wrap and the solution is poured. But you can fill the crushed stone with liquid sand-cement mortar and not use the film.

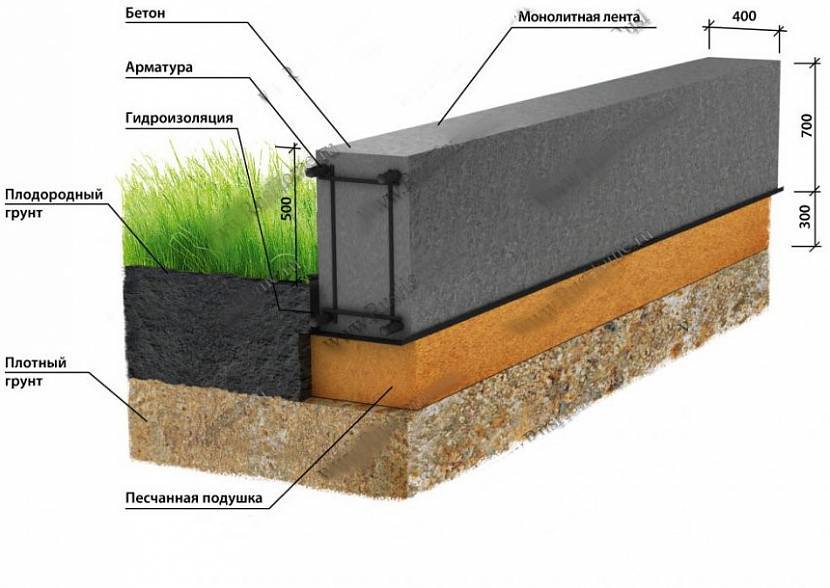

- Hydro-vapor barrier is carried out - bitumen is applied to the frozen solution, roofing material or PET film is put (in 2 layers).

- Equip a vapor barrier layer. To create it, you can use mineral wool, foam glass, expanded polystyrene or any other material.

- A fine cement screed with a thickness of 5 cm or more is poured. For its reinforcement, a welded metal mesh is used.

- Installation of the finishing floor covering is carried out. Tiles, linoleum, floorboards, laminate, parquet, etc. can be used as floor slabs.

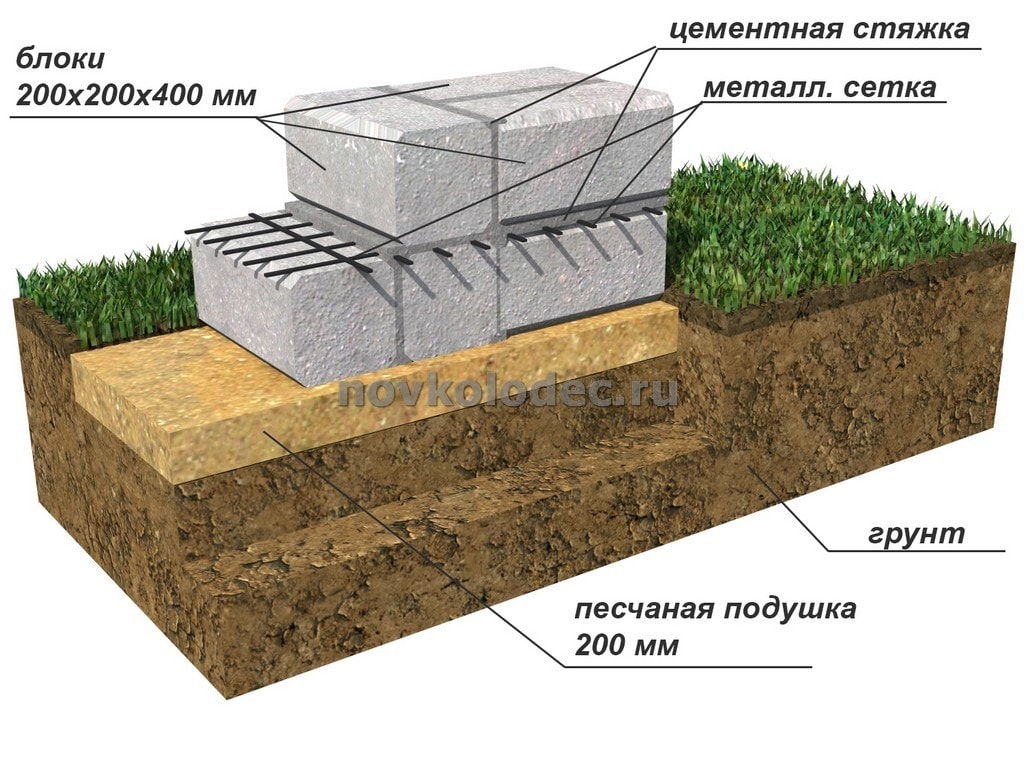

Making the pillow right

If the base is of poor quality, then a cut in the walls is possible, the basement collapses and other problems appear.

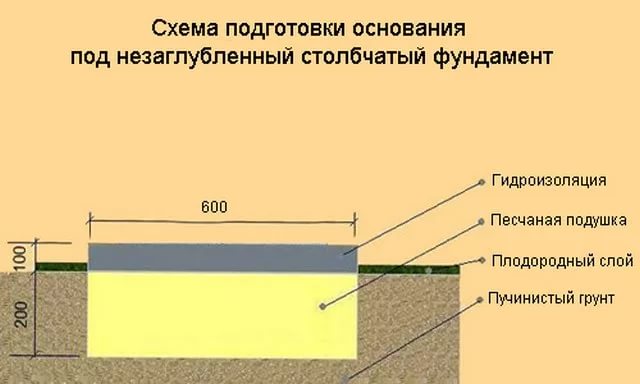

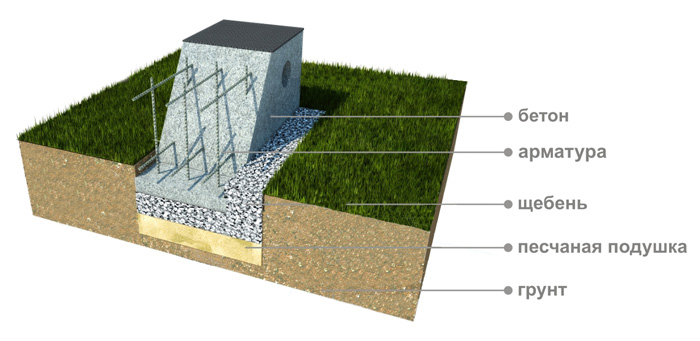

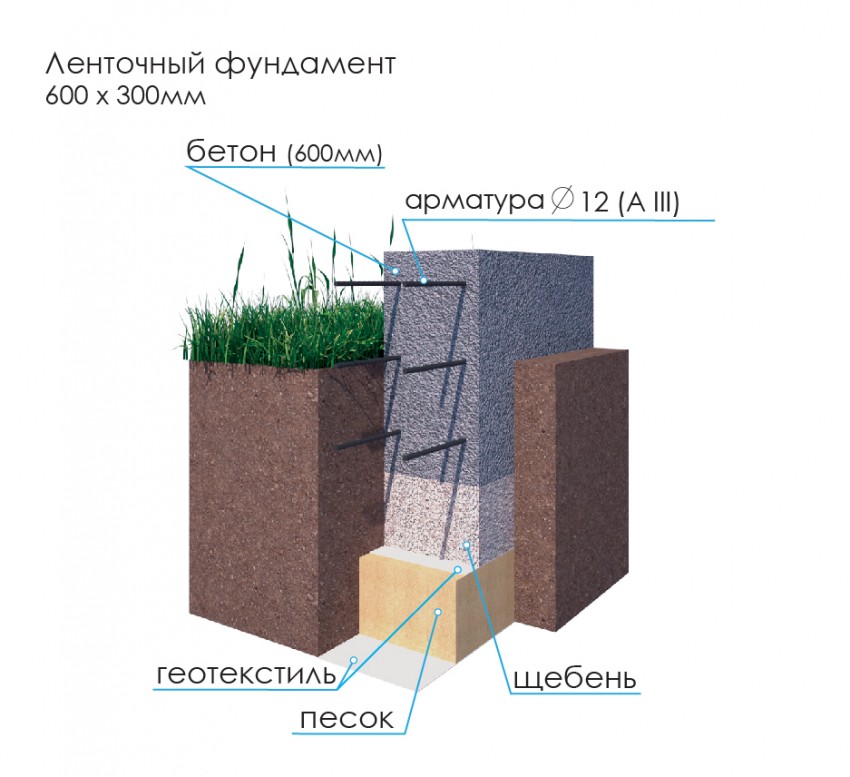

Geotextiles must be placed under the soles of the foundations. With this tool, the risk of moisture penetration into the base material is reduced. Next, you need to pour a layer of the selected material.

When all the material is filled up, the water-repellent material is closed. At the end, sand is added, but not more than half a centimeter, so that an unburied foundation on a sand cushion does not impair the properties of the protective coating.

Clay sand cushion is also used in home construction, but sometimes it's better to resort to more durable options. The decision is made depending on what kind of soil the building will be built on. If the groundwater is near the surface, it is best to create a solid sole to avoid future problems.

According to SNIP - building codes and regulations, what kind of sand is used and the height of its fill is determined from calculations and terrain conditions. If they are normal, then:

- For a strip foundation, a fifteen-centimeter embankment is sufficient. After tamping, it should be up to 30 cm high.

- A tiled base requires a bedding of 10-15 cm, and a brick one - 25 cm.

- If the foundation is on columns or piles, then a mixture of crushed stone and sand is required up to 30 cm, and sometimes up to 60 cm.

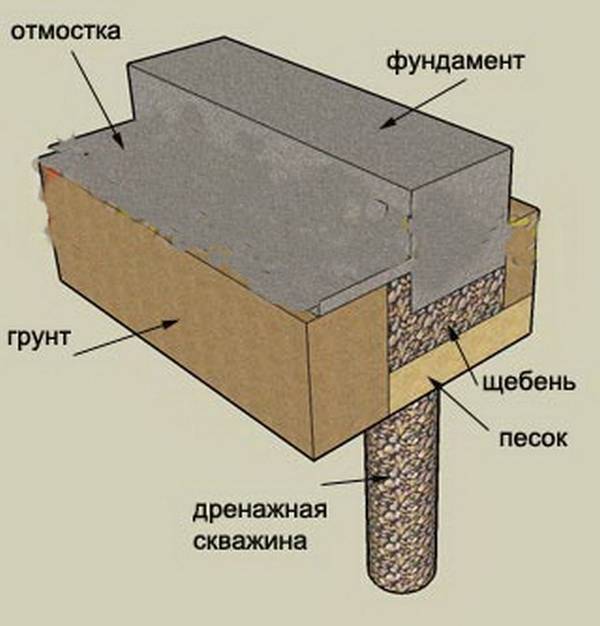

If the area is swampy or groundwater is too close to the surface, then the help of people who understand these issues is needed. They will determine why the sand cushion under the foundation in this case and what to make it from.It is undesirable to use the usual layer for such cases. To increase efficiency, you need to continue drainage, drainage.

For what purposes, an intermediate link between the soil and the foundation is arranged, it is to connect the building with the ground.

During filling, a number of recommendations must be followed:

- Form slopes with a steepness of 1: 1.15.

- Sow the grass, sod and strengthen the soil in other ways available.

- Make a slope of at least three degrees from the center to the outside.

- It is imperative to place geotextiles under the soles of the MTI foundations.

For ordinary sand, any means at hand is suitable, but if you add gravel, you will need heavier artillery in the form of:

- vibrolegs. For its operation, a motor is installed that runs on diesel fuel. The big heel compresses the material.

- vibrating plates. Suitable for the device of plate-type bases;

- vibratory roller. With its help, the sand layer is compacted on large construction sites.

This approach to creating a substrate has a lot of advantages:

- no need to spend a lot on materials;

- mail is not overloaded;

- there is no need to rent expensive construction equipment, since the embankment can be made denser by affordable means.

Therefore, such bases are very popular in construction. They ensure the stability of the foundation and protect the house from shrinkage, destruction of the basement and other damage that can entail significant financial costs.

Types of strip foundation and some of the nuances of its laying

In turn, the strip foundation itself is different. The type of foundation is chosen depending on the soil and the severity of the structure, i.e. it is imperative to take into account what kind of material the construction will be carried out. Some people ask what is an unburied strip foundation and how is it different from a submerged one?

In turn, the strip foundation itself is different. The type of foundation is chosen depending on the soil and the severity of the structure, i.e. it is imperative to take into account what kind of material the construction will be carried out. Some people ask what is an unburied strip foundation and how is it different from a submerged one?

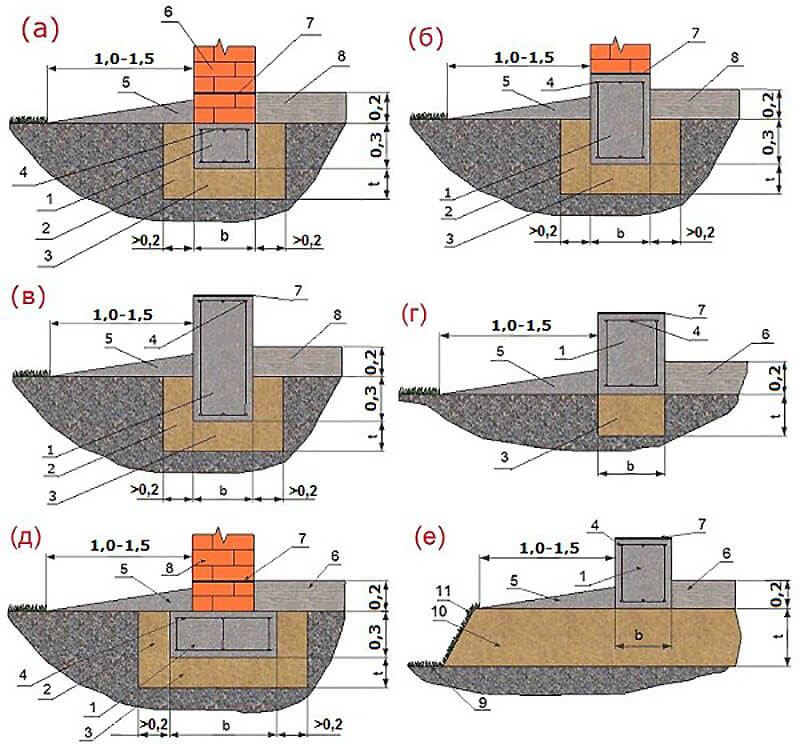

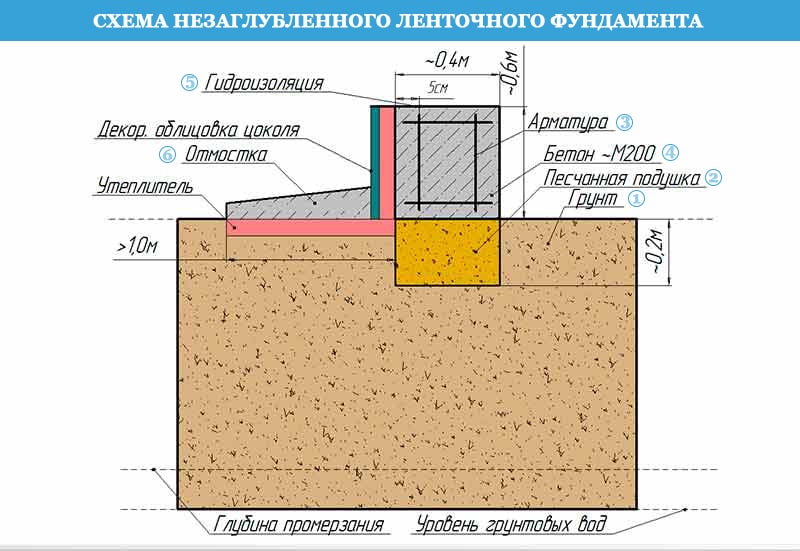

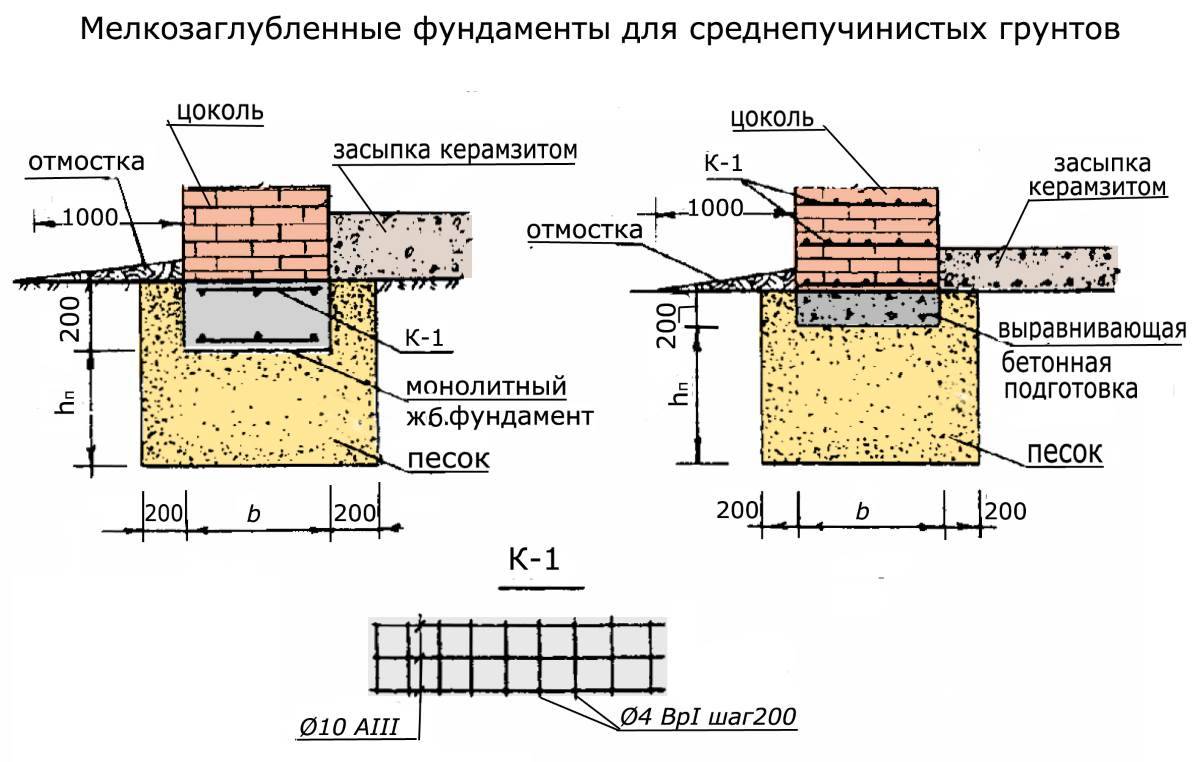

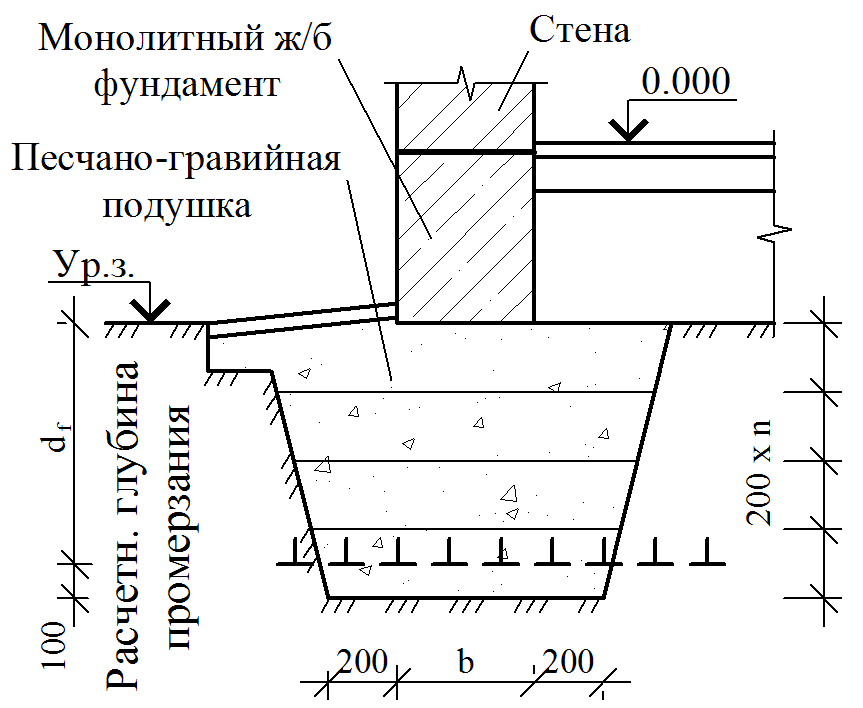

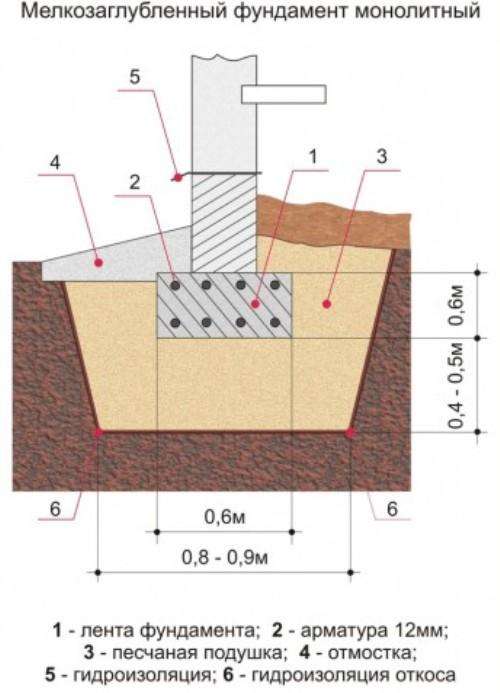

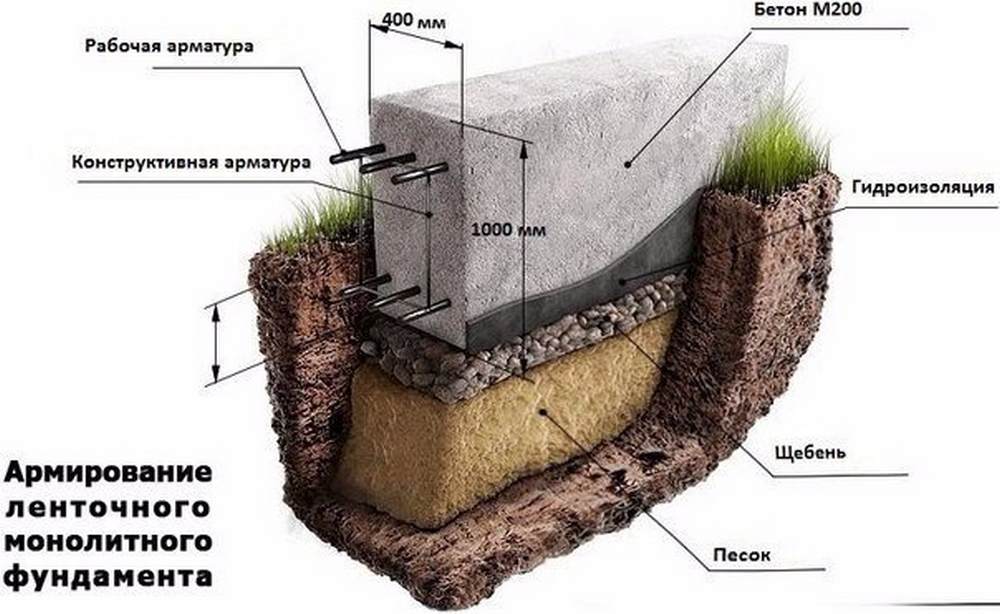

Shallow, or it is also called a shallow foundation, and got its name because it goes deep into the ground to a very shallow depth. That is why tape-type foundations are divided into:

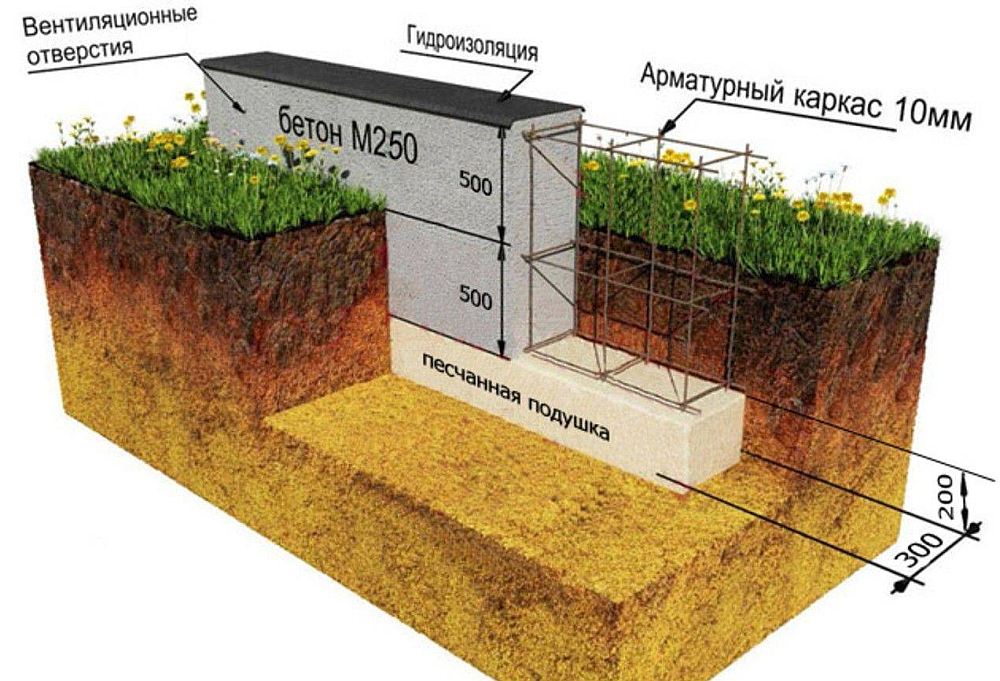

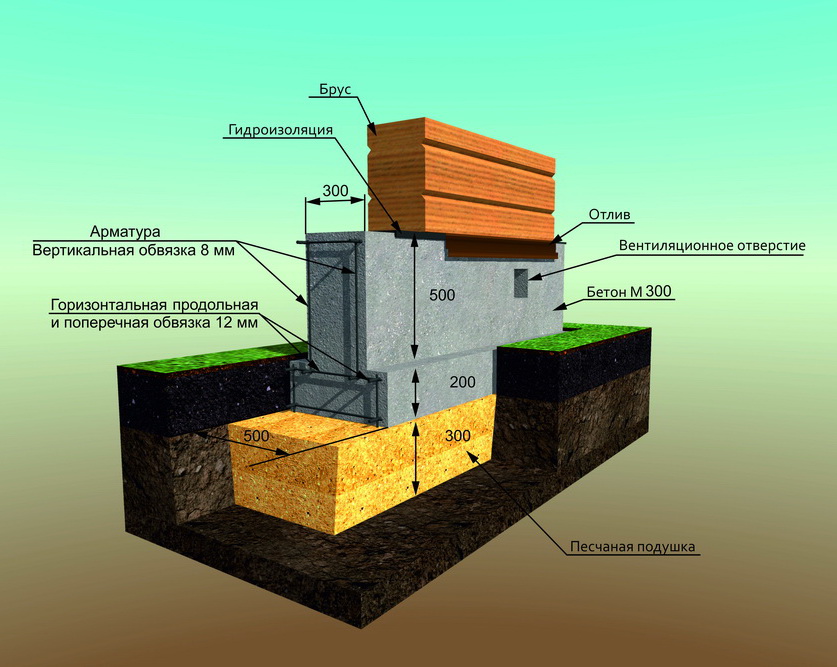

- Recessed - these are massive foundations made of concrete, which is made with a depth of up to 1.5 meters or more, depending on the soil, the severity of the building, etc.

- Shallow, or they have another name, shallow, which are mainly applicable for outbuildings, capital garages, houses that do not have more than 2 floors planned. They go deep into the ground for a small distance, which depends on the ground.

This type of foundations is very well suited for sandy loam, sandy soils, it has proven itself very well on clay soils. A shallow foundation pays off in the area where the soils are saturated with water. Although, in the latter case, this applies to frame houses or some kind of timber buildings. Strip foundations are also recommended for construction in hilly terrain where other types of foundations are not suitable. Strip foundations are also good for the construction of basements, basements.

Shallow foundation

There are many types of foundations today, but the most popular is the non-buried strip foundation.

There are many types of foundations today, but the most popular is the non-buried strip foundation.

If the condition of the soil on the site allocated for construction, its antinode, looseness and other quality characteristics allow you to build a house on such a basis, then you should further outline the markings for the future foundation pit and bring in the necessary building materials.

The type of foundation is a concrete structure of a tape format, which radically differs from a monolithic pouring and allows you to save a decent amount of concrete used. It is laid by lining up tapes under the external and internal load-bearing walls.This method is significantly less expensive than buried, but no less reliable.

In the construction of a building, the foundation performs the following tasks:

- Transfer most of the loads to the load-bearing walls;

- Protects the building from mechanical damage in the form of cracks, deformation due to the impact of underground groundwater, freezing and looseness of the soil;

- Serves as an obstacle to the penetration of water into the premises, especially through the basement or basements.

These functions are perfectly handled by this type of laying of the base of the building. It is preferable to build houses in this way on heaving soils. But on other lands it is possible to do this, observing the rules of waterproofing and insulation.

Spring floods, released frozen over the winter and thawed groundwater always cause the appearance of small shifts and cracks in erected houses and can lead to a loss of stability of the building, and sometimes to its destruction. The design of the strip non-buried foundation is devoid of such disadvantages. Everything here is thought out and calculated. Therefore, we recommend that you opt for it. Reviews of the owners of such structures are only positive. For all the time, not a single house installed on a base of this type has been deformed.

Working with soil

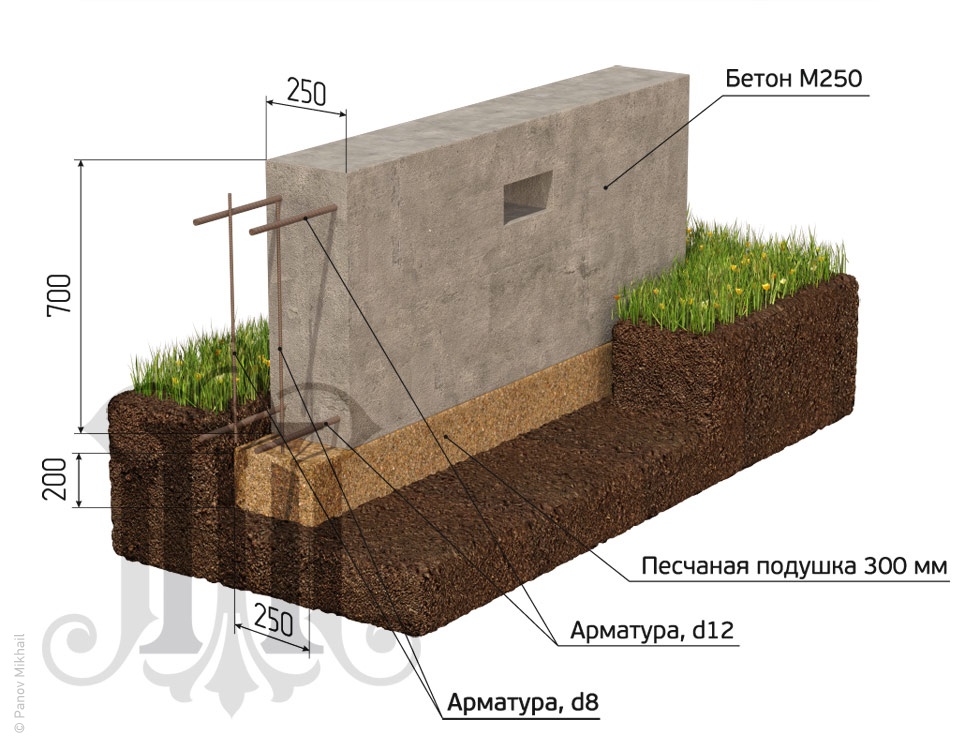

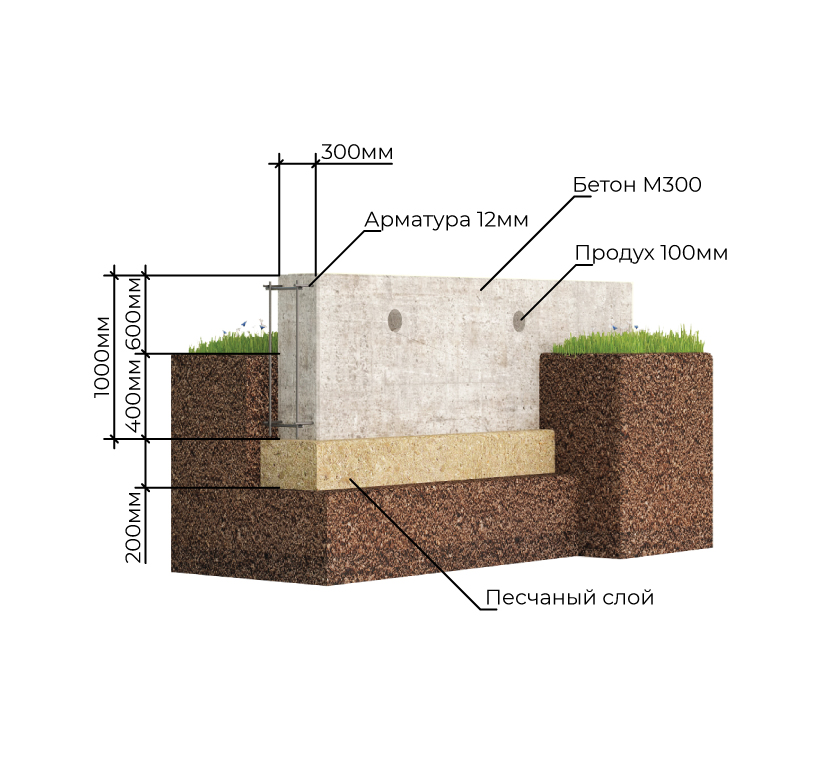

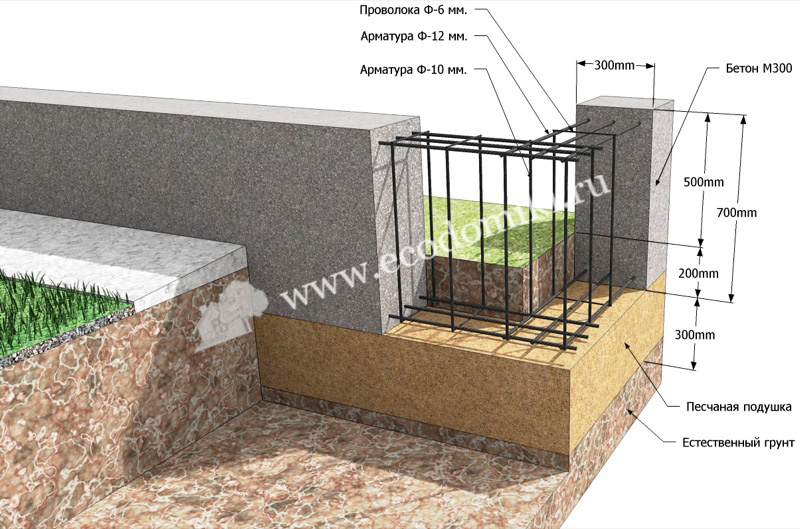

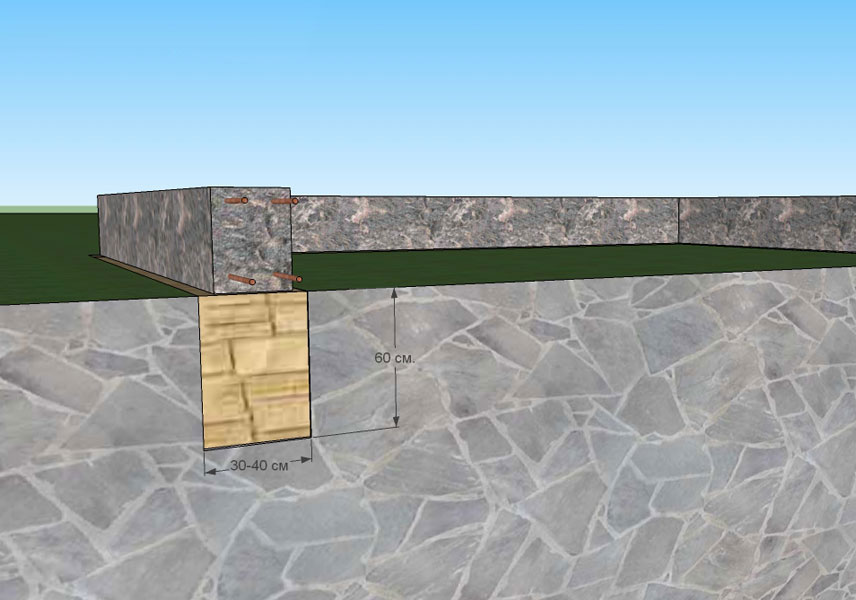

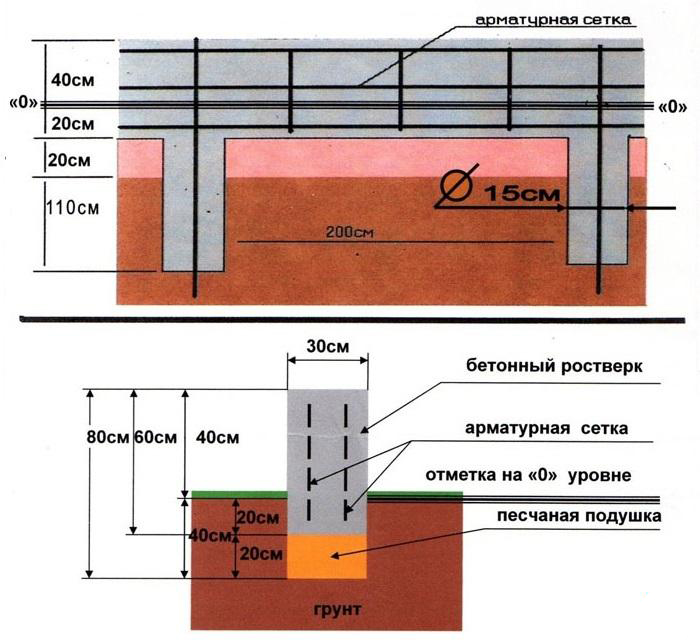

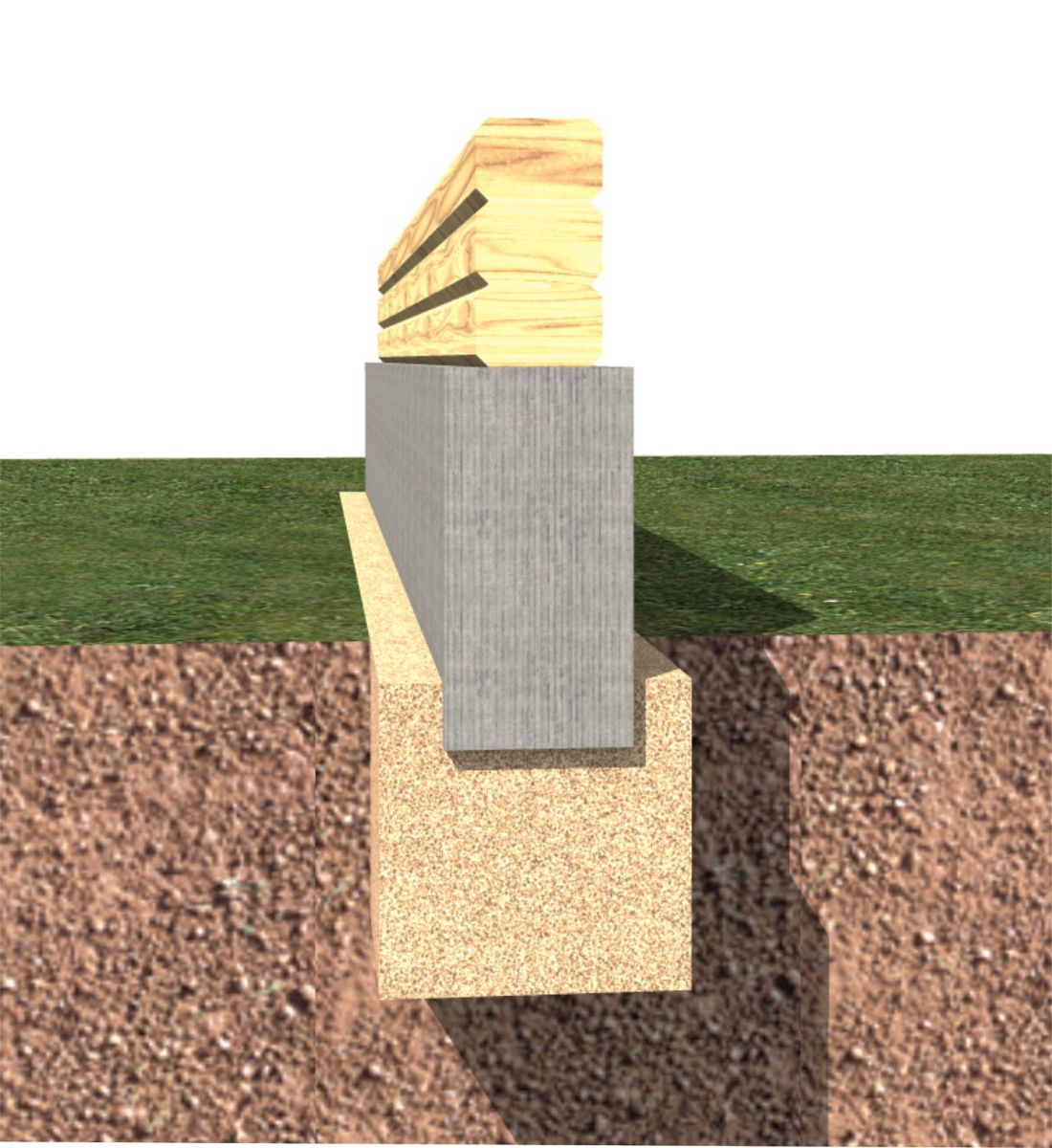

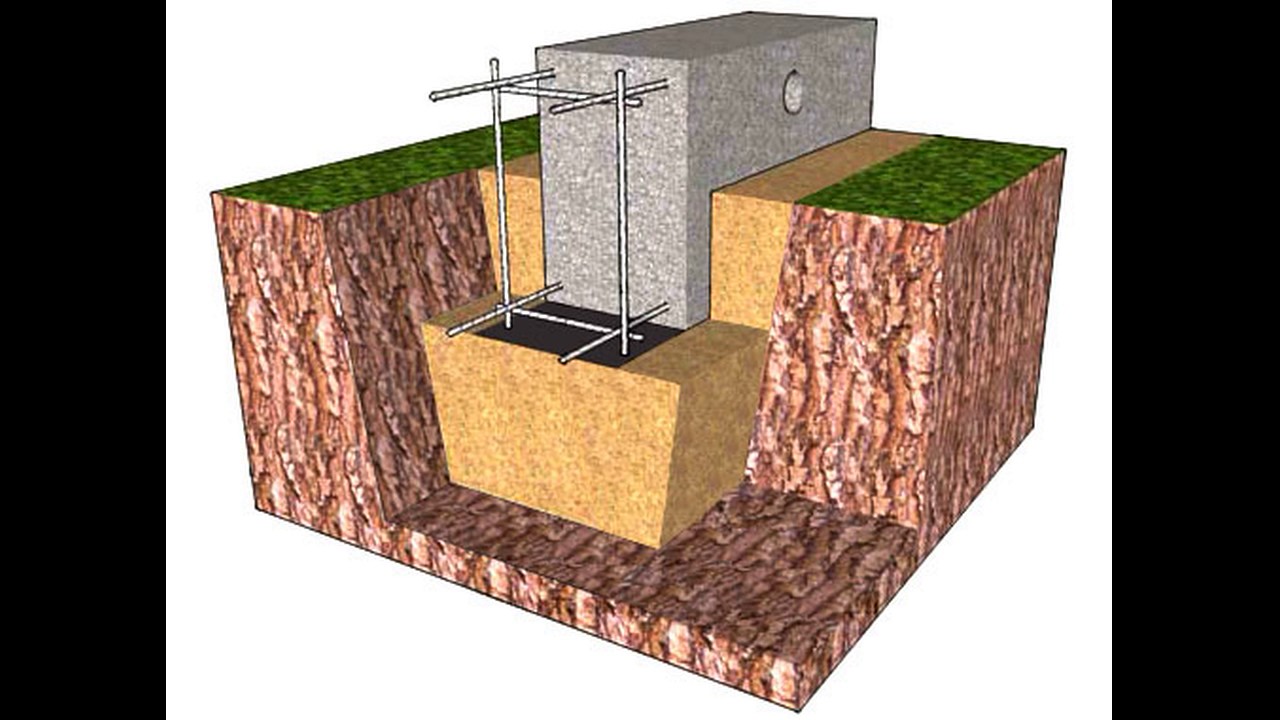

Soil excavation is the preparation of a trench. The depth of the trench for the strip foundation depends on the material that will be used to build the structure, while the height of the part recessed into the ground ranges from 50 to 70 cm.

You can dig a trench with an excavator. Especially if you have to work on heavy soil, consisting of wet clay - it is very difficult to work by hand with it. When performing fine work, it is better to dig by hand, but if there is a possibility, it is advisable to dig the entire pit by hand: thanks to this, the soil will retain its structure intact and the likelihood of collapse will decrease. In addition, the manually dug trench for the strip foundation comes out much more accurately, which greatly facilitates the implementation of further work.

If you have to build a foundation on swampy soil, it is best to work in the fall or early summer, when the ground contains a minimum of moisture.

To what depth to dig if a new structure is being erected on the site of an old one? The base of such a structure under construction must necessarily be 5-7% deeper from the base of the old building. If you have to level the surface of the earth in a problem area with unpredictable heterogeneous soil, a protective cushion is made. For this, the prepared trench is covered with sand. The height of the sand cushion after compaction should be at least 30-40 cm - this will protect the structure from deformation.

The foundation on sandy soil is not very susceptible to heaving, since it practically does not retain moisture. Therefore, there is no need to equip a sand cushion, but in order to ensure the strength of the building foundation, it is necessary to make a crushed stone cushion at the bottom of the prepared pits.

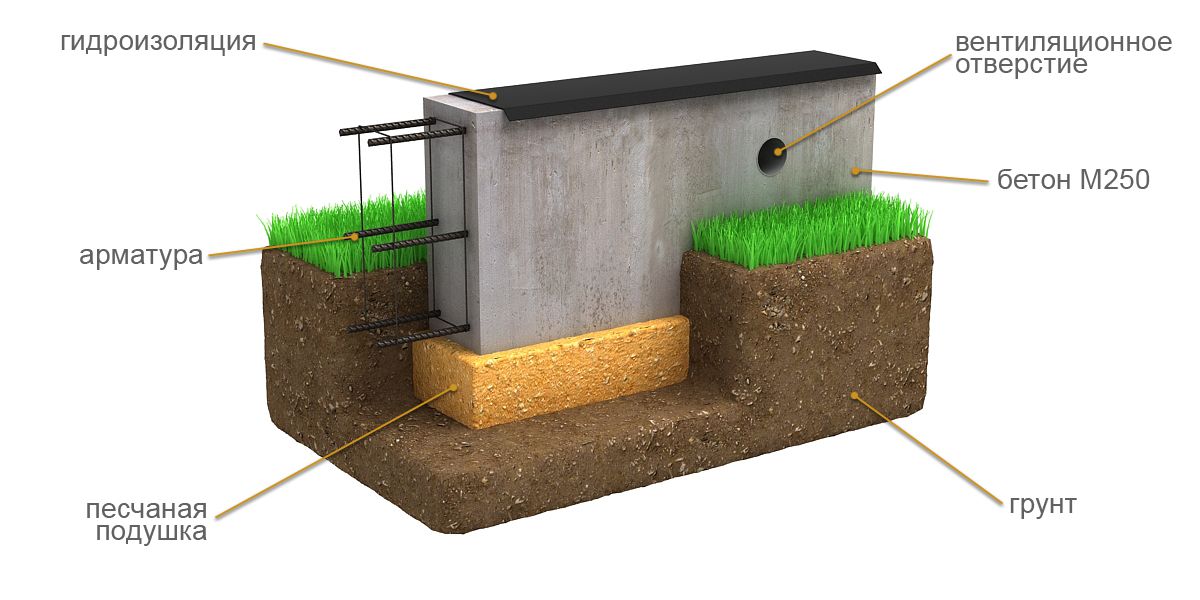

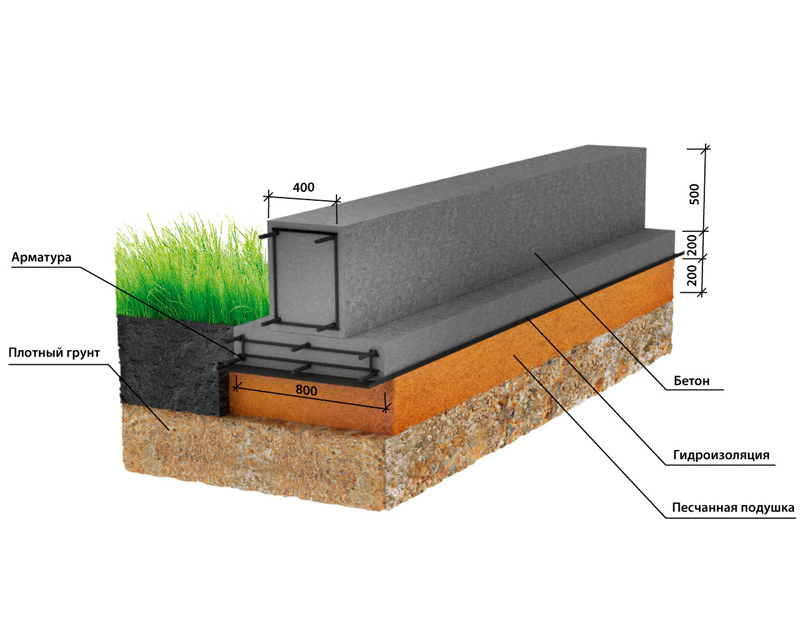

Waterproofing works

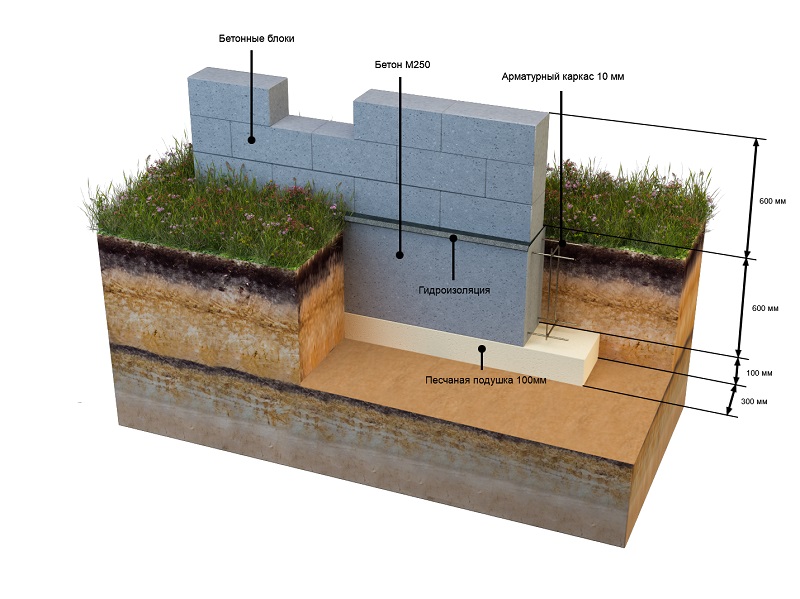

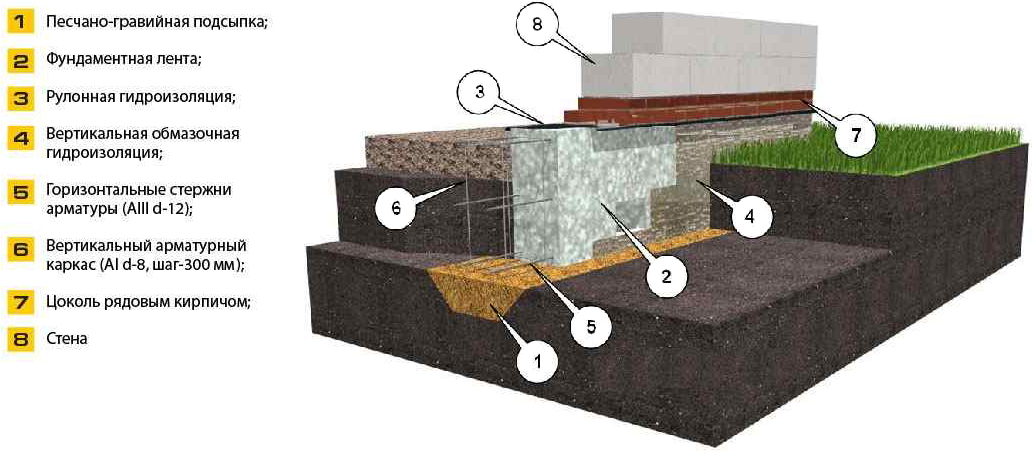

This stage is the most responsible and difficult: waterproofing should maximally protect the strip unburied foundation from moisture penetration. The choice of material depends on the type of waterproofing:

- Horizontal. For its manufacture, roll materials are used (for example - roofing material, plastic wrap).

- Vertical. There are two types - free-flow and anti-pressure. Free-flow is a trench clogged with clay and then rammed, which is dug around the perimeter. So that moisture does not linger in the clay, it is poured with cement mortar and a storm gutter is mounted. For the manufacture of anti-pressure waterproofing, plaster, paint, various lubricants and other materials are used - they are applied to the insulated surface.

Calculation of the heaving intensity in the area

To calculate the degree of soil heaving on a construction site with your own hands, you must use the formula: E = (H— h) / h, in which:

- E - corresponds to the degree of heaving of the soil;

- h is the height of the soil mass before freezing;

- H - the height of the soil mass after freezing.

To calculate the degree, it is necessary to make the appropriate measurements in summer and winter. The soil can be considered a heap, whose height has changed by 1 cm at freezing by 1 m. In this case, "E" will be equal to the coefficient 0.01.

Soils with a high moisture content are more susceptible to heaving processes. When frozen, it expands to the state of ice and thereby raises the ground level. Loamy soils are considered: clay soils, loam and sandy loam. Clay, due to the presence of a large number of pores, retains water well.

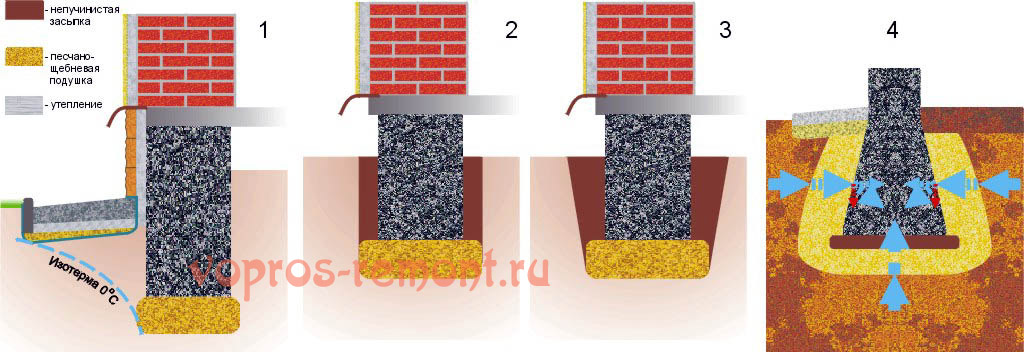

How to remove the effect of heaving on the ground?

There are simple ways to remove the swell around the foundation with your own hands:

- Replacing the soil layer under and around the base with a non-porous layer.

- Laying the foundation on the soil mass below the freezing layer.

- Thermal insulation of the structure to prevent soil freezing.

- Drainage system.

The first method is the most time consuming. To do this, it is necessary to dig a pit under the foundation, at a depth below the freezing level of the earth, take out the heaving soil, and fill in heavily compacted sand in its place.

It exhibits high load-carrying capacity and does not retain moisture. The large amount of land work makes it the least popular, although it is an effective way to fight heaps. This technique is effective for the establishment of low-rise buildings, shallow burial, such as a barn.

A feature of the second method is the removal of the effect of heaving on the base of the foundation, but its preservation when exposed to the walls of the base. The average lateral pressure on the walls is 5 t / 1 m2. It can be used to build brick houses.

The third method allows you to make an unburied foundation for a private house with your own hands in heaving conditions. The essence of the method is to lay the insulation around the perimeter of the foundation to its entire depth. The calculation of the material is done as follows: if its height is 1 m, then the width of the insulation should also be 1 m.

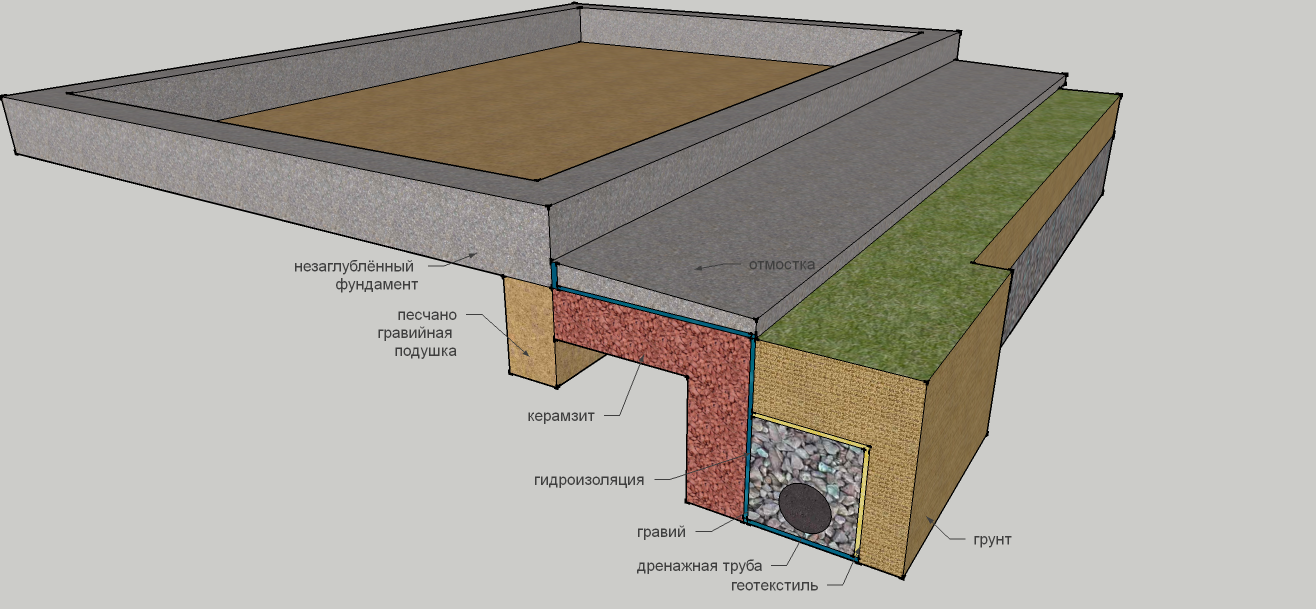

To drain water around a house or shed, you need to build drainage. It is a ditch at a distance of 50 cm from the building, the depth of which is the same as the level of the structure. A perforated pipe is laid in a drainage trench at a technical slope and wrapped in geotextiles, and then filled with coarse gravel and sand.

Below - we will consider the types of bases that can be used on soil prone to heaving.

Scope of use of tape-type foundation bases

The tape base has found its wide application in the process of erecting buildings of a wide variety of varieties. So, for example, if there is a need to build a house from heavy materials, the use of a massive strip foundation will become relevant. Thus, a similar base can be used in the process of erecting buildings from bricks and concrete blocks. Also, if there are walls with brick lining, then a similar type of foundation is very relevant here. The laying of such a foundation is carried out deeper than the level of soil freezing of at least twenty centimeters.

It is also worth noting that the foundation under consideration is applicable in cases where it is inappropriate to use a columnar foundation, or its use is completely prohibited. So, for example, in the process of erecting a building in conditions of terrain relief, as well as on a slope

In these cases, it is imperative to take into account the lateral soil pressure factor.The best method that most effectively neutralizes the uneven effects of lateral pressure is the use of a belt-type base.

This is explained by the fact that all its components are rigidly connected with each other, and this is done in both directions - both longitudinal and transverse.

Shallow LF on heaving ground

The use of this type of foundation also includes heavy brick and stone buildings. This also includes buildings made of reinforced concrete monolith. Let's apply an unburied strip foundation on heaving soils. The considered type of strip base is relevant when arranging the basement floor and, as already mentioned above, the basement. If it is necessary to erect a shallow foundation, preference is most often given to the LF base.

As for the varieties of strip foundation bases, they are of two types:

- Shallow. It is often also referred to as shallow by specialists. Equip such a foundation when building houses, the number of storeys of which does not exceed 2 floors. Such structures should not be overly heavy.

- Recessed. This variety is distinguished by a depth of up to one and a half meters. A strip foundation of this type is suitable for more massive buildings that are larger and heavier in weight.

In most cases, the strip base is erected on sandy and clay soil; sandy loam soil can also be attributed here. If necessary, in arranging the foundation on water-saturated soil, a strip base can also be used, only of a shallow type. But in this case, only small and light buildings of timber or frame type can be erected.

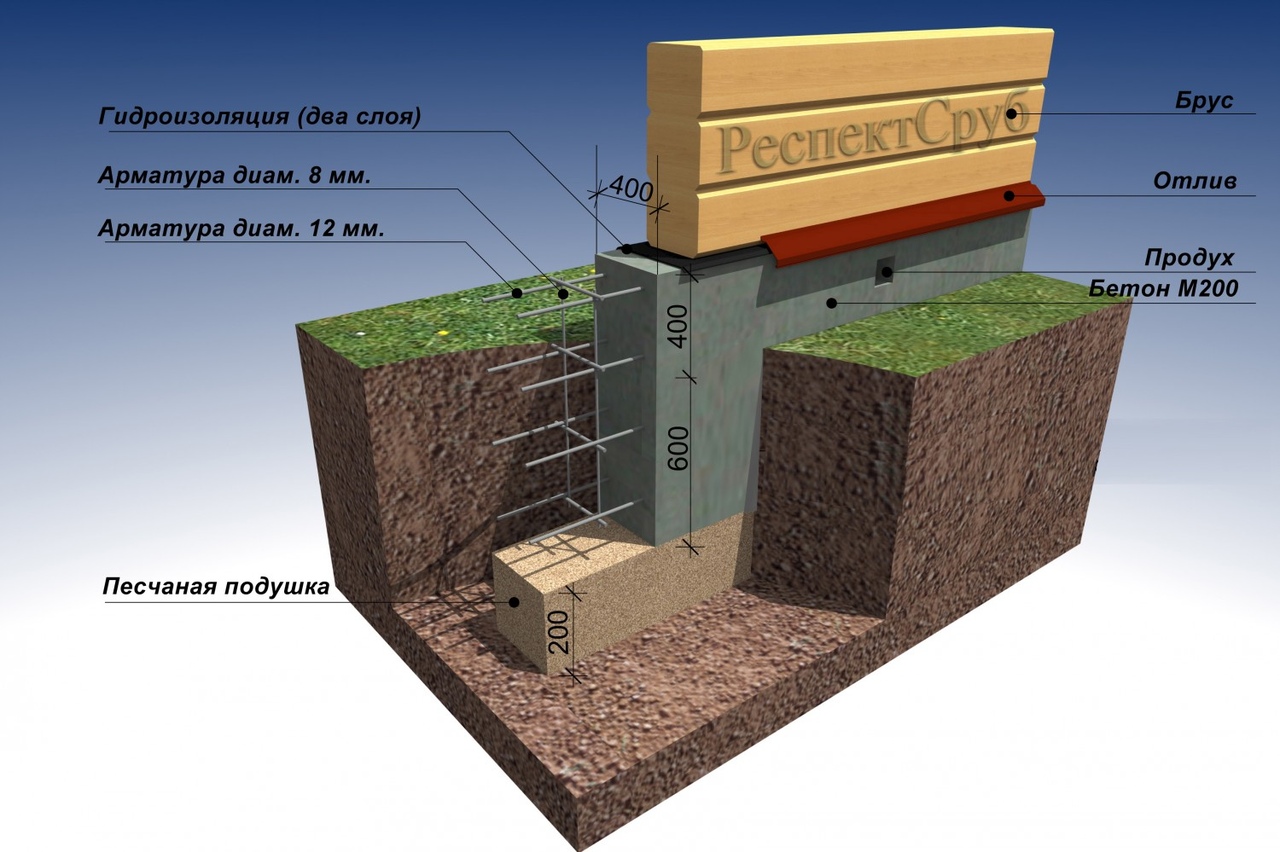

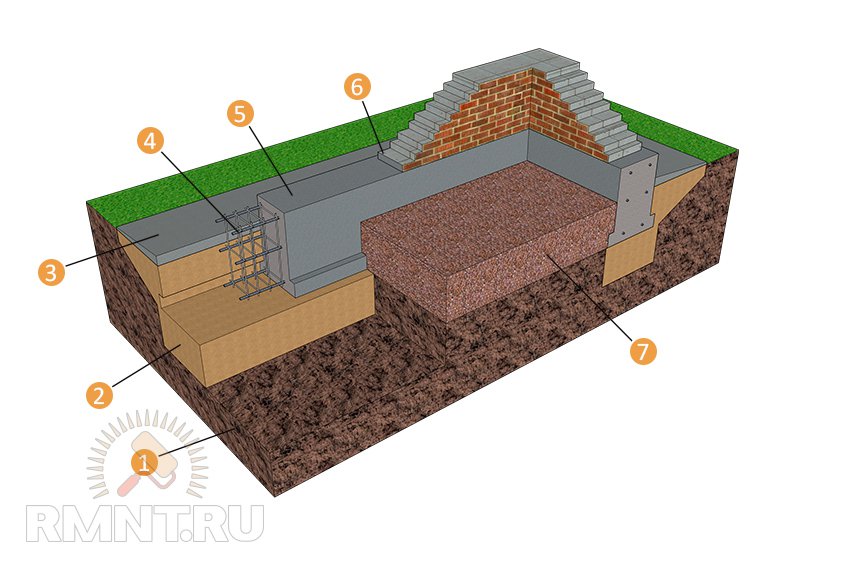

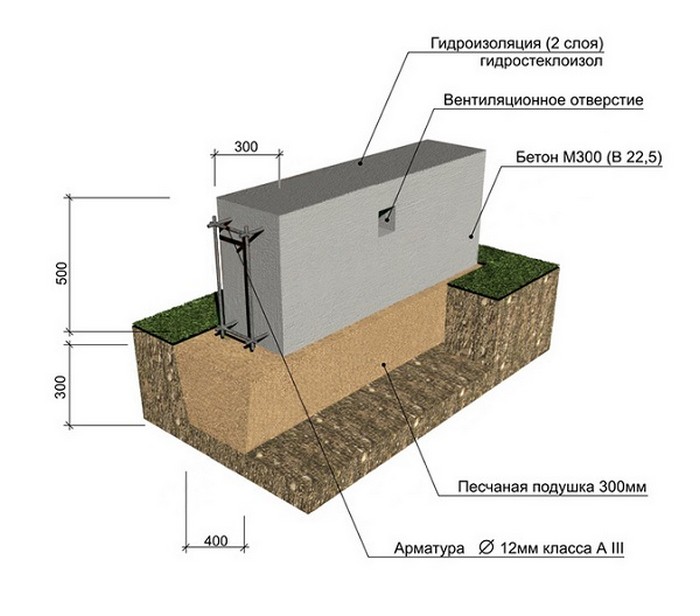

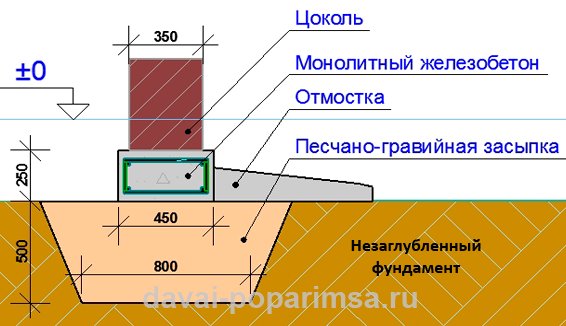

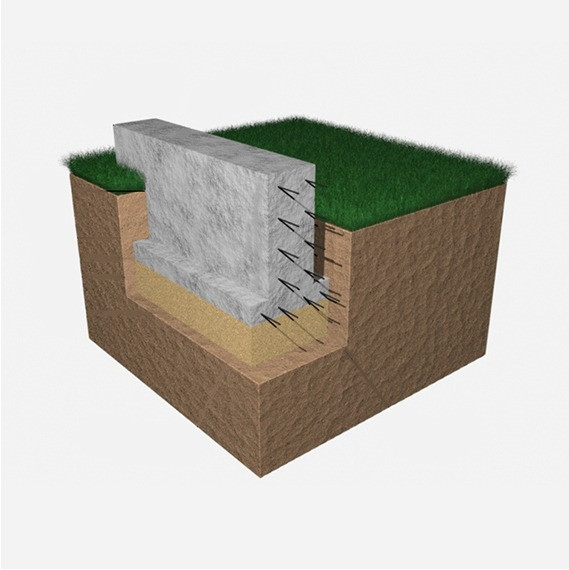

Considering the question of what an unburied strip foundation is, you can disassemble its structure in more detail. The base of the LF consists of a preparation (pre-erected platform), an external wall, a base, a blind area, as well as a waterproofing component. During the construction of this foundation, the following work is carried out: the formation of a pit, pouring with concrete, as well as the implementation of reinforcement. As for such parameters as the width and depth of the tape-type base, it directly depends on the type of soil, the depth of the freezing point of the soil and the weight of the planned building.

It is interesting: Do-it-yourself construction of a strip monolithic foundation: we study carefully