Instructions for making a foundation for a fence

Almost any base for a fence can be made with your own hands, if you carefully study the technology and follow all its instructions.

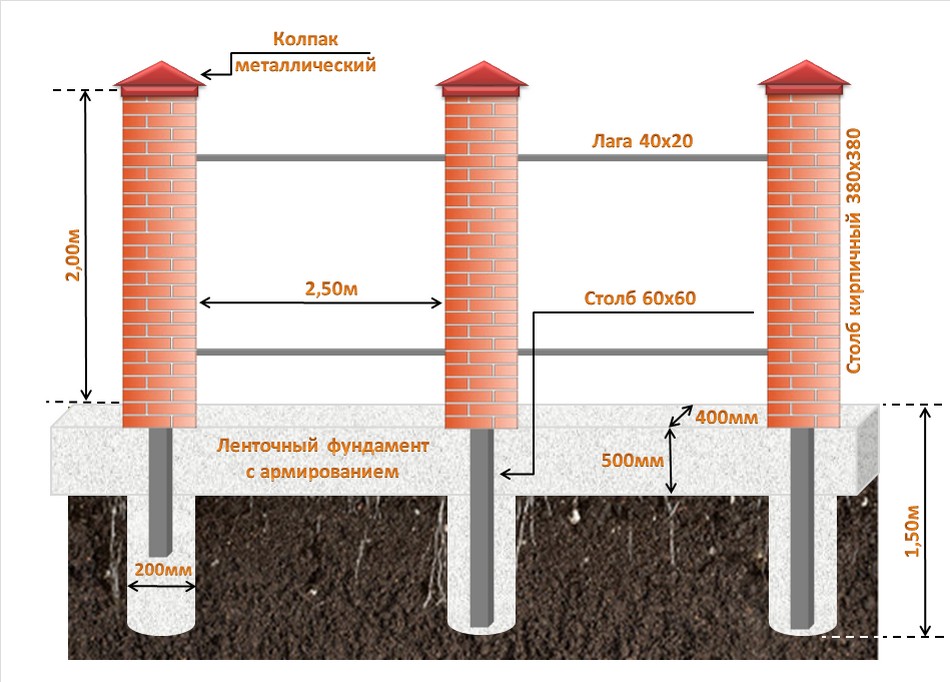

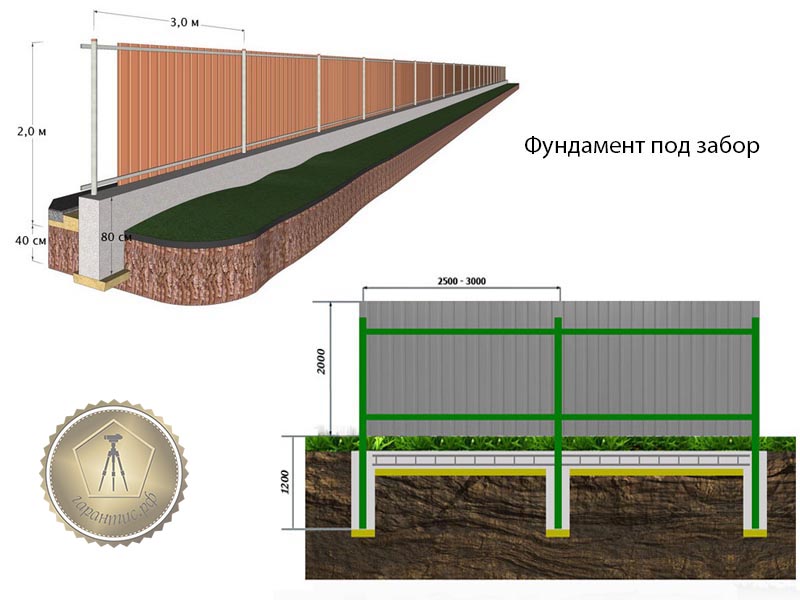

Strip foundation

The process of creating this type of fence base consists of certain sequential stages. With the consistent and careful execution of each of them, in the end you will get a solid foundation for your fence. So, you need:

- Carry out the marking of the territory. To do this, along the perimeter of the site, which will be surrounded by a fence, you need to drive in pegs, between which to pull the string. Separately, it is necessary to designate the location of the wicket and gates.

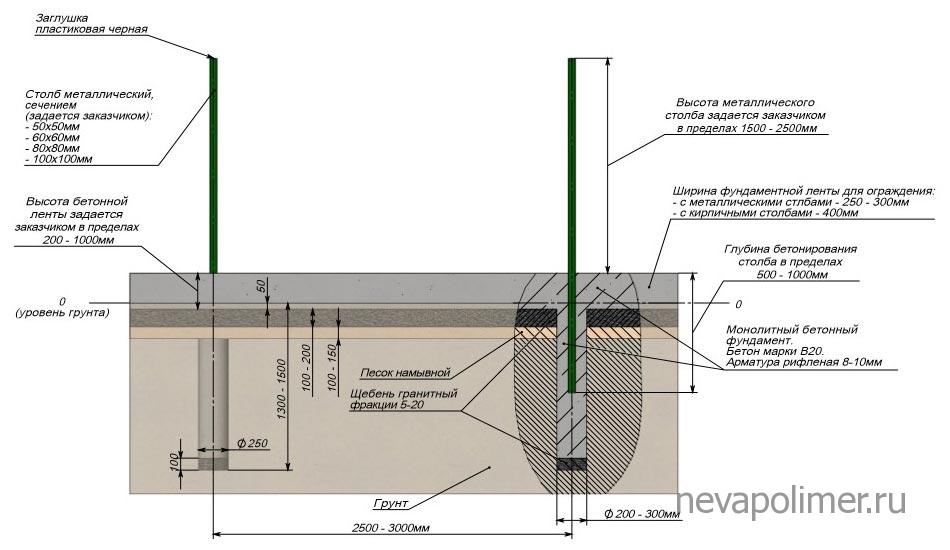

- Dig a trench. The depth of the ditch is not less than 35 cm, in the places where the supports are installed - 60–90 cm. The width is about 40 cm.

- Install the support posts. Any material can be used in their capacity. Usually these are pipes with a diameter of about 80 mm. Their height should be such that when digging into the ground, it will be enough for the entire height of the future fence. They need to be installed in prepared holes, covered with broken brick, gravel or stone.

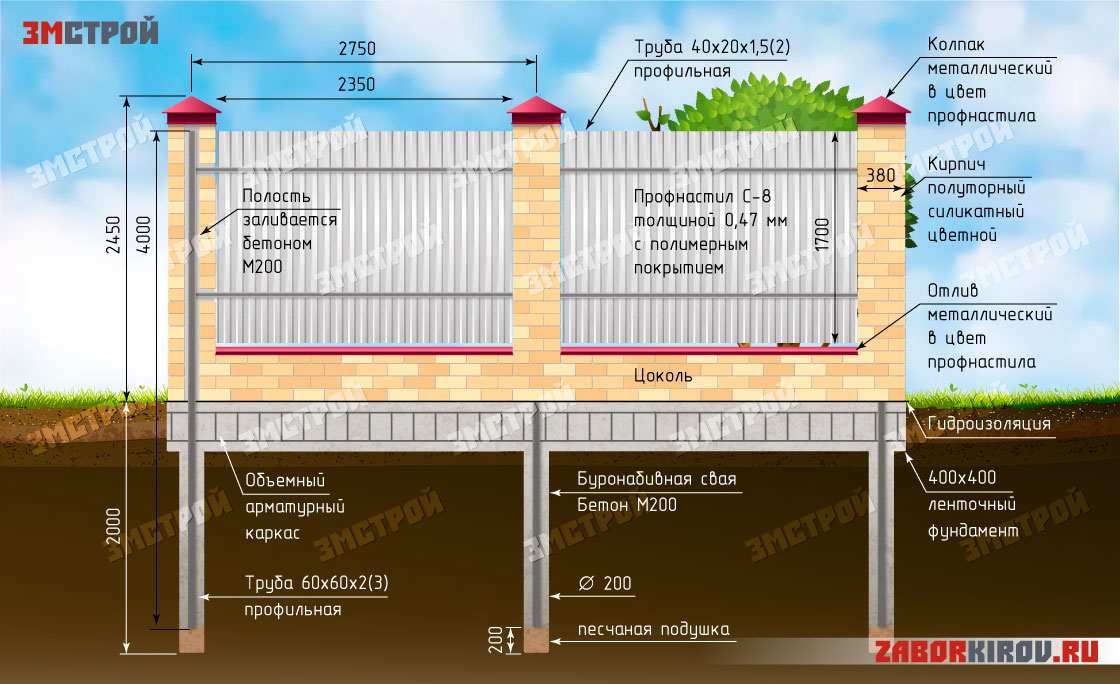

The strip foundation can be considered the optimal solution for the fence

Formwork is usually made from planks

The tape should protrude slightly above ground level

Video: strip foundation for a fence with your own hands

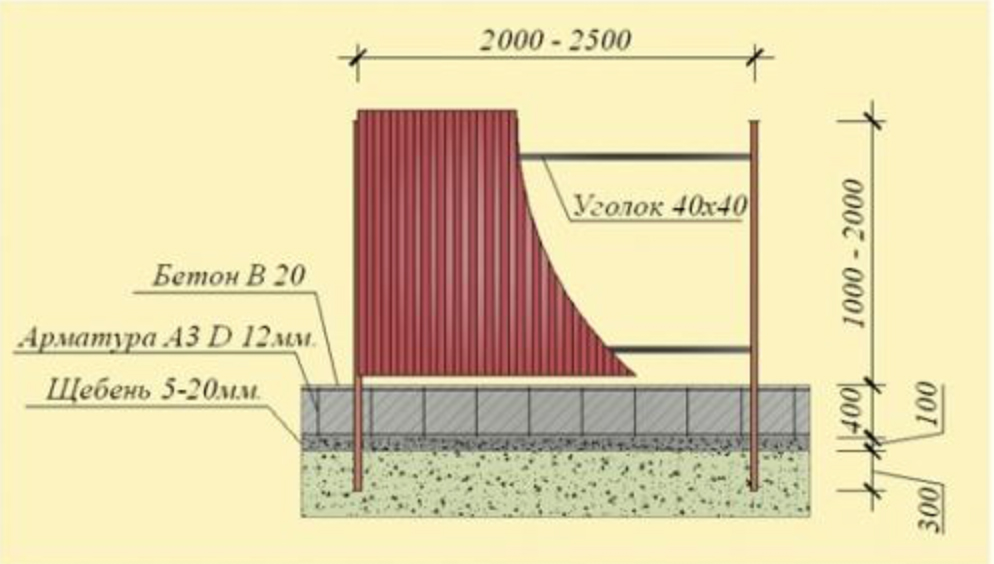

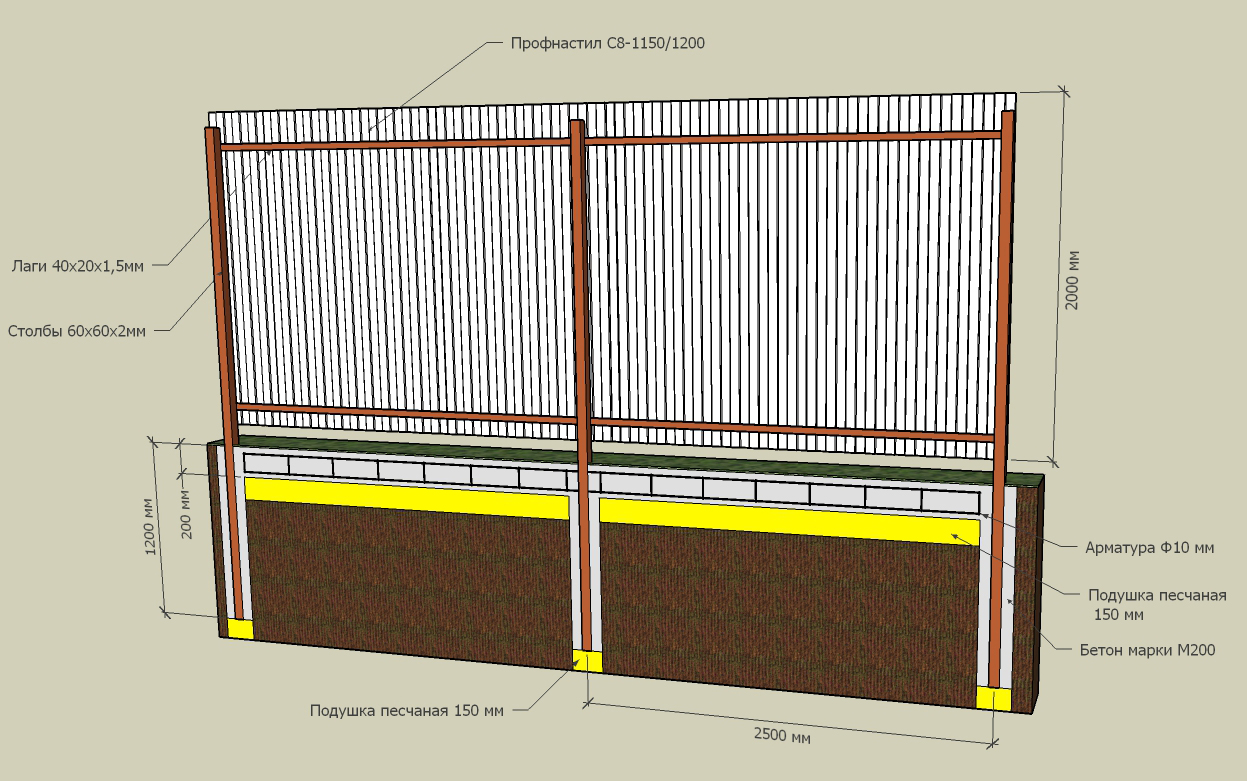

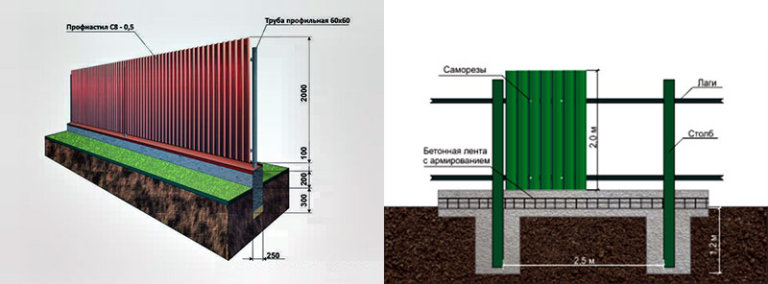

Base for a light fence made of corrugated board

For a fence made of profiled sheet, the foundation may not be so solid. Such a fence can be installed on a columnar foundation:

- First, the marking is carried out, while it is necessary to indicate the location of the pillars. The distance between them should be about 2 m.

The posts must be treated with an anti-corrosion solution.

It won't take a lot of time to build a fence from corrugated board

To increase the strength of the foundation, you can additionally dig a shallow trench, the bottom of which is covered with geotextile, covered with rubble and covered with a film. Next, install the formwork, reinforce the bottom, then fill it with a cement mixture.

Video: post base for the fence

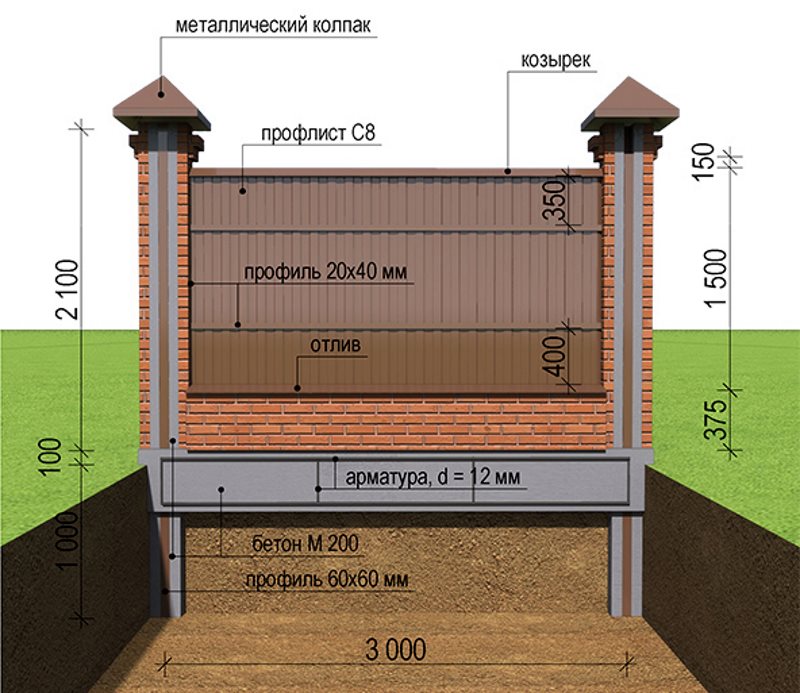

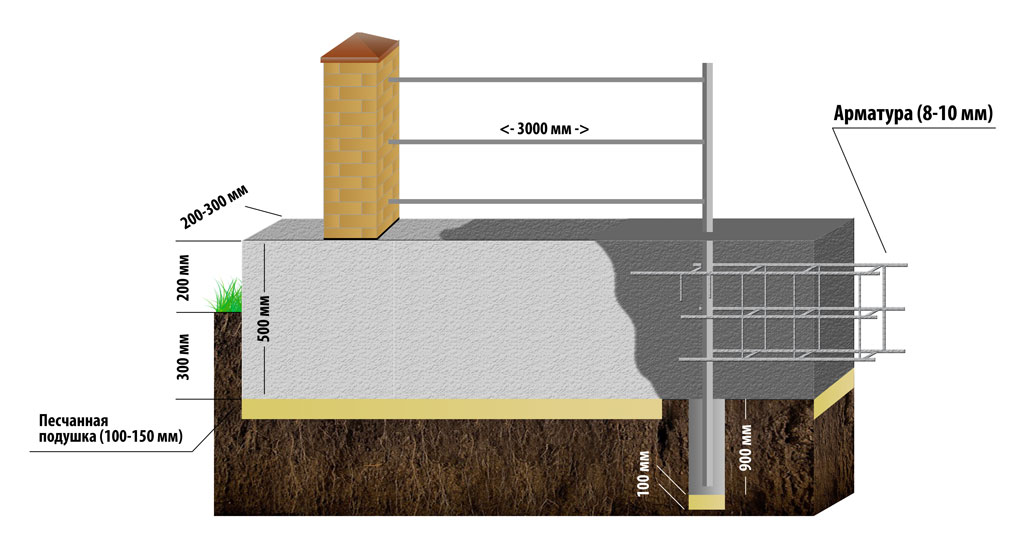

Brick fence foundation

A brick fence needs a solid and solid foundation, because the mass of such a structure is impressive. The consequences of not following the technology or choosing the wrong type of base can manifest itself in the form of cracks on the fence itself. There are two options for arranging the foundation for a brick fence, which are equally suitable for both a three-meter structure and a small fence:

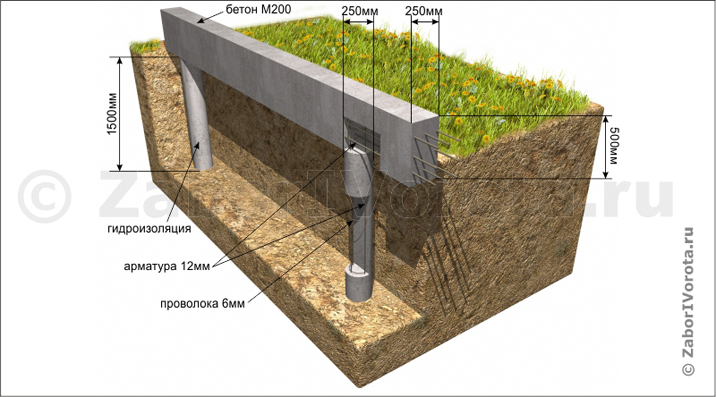

- strip foundation (depth 40-50 cm, width 40 cm), part of which is located above the ground (it must be reinforced with reinforcement 12-14, two at the top and bottom);

- the grillage is set up in the locations of the pillars to the depth of freezing, that is, 120–1250 cm deep into the soil, and between them is the usual reinforced tape.

The second option for arranging the foundation is more reliable in the case of building a brick fence.

Brick fence requires a solid foundation

There are secrets, knowing which you can significantly increase the life of the foundation:

- under the tape, you can equip a sand cushion, which is additionally moistened with water, which will significantly reduce the risk of displacement of the base;

- use cement not lower than M-200 grade;

- pour concrete in one go;

- if you do not make the solution yourself, but ordered from a specialized company, then you need to order 10% more, since part of the water will necessarily be absorbed into the soil;

- there must be a waterproofing layer between the foundation and the brickwork.

The basement part of the fence is integral with the foundation

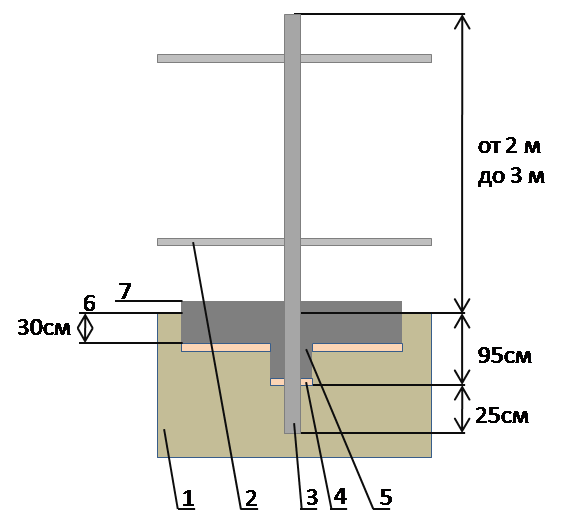

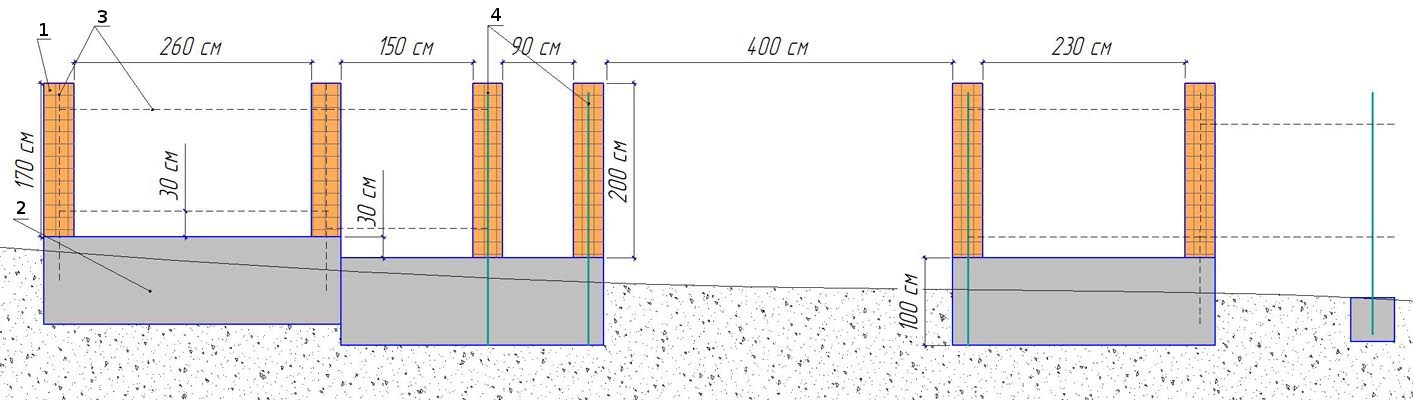

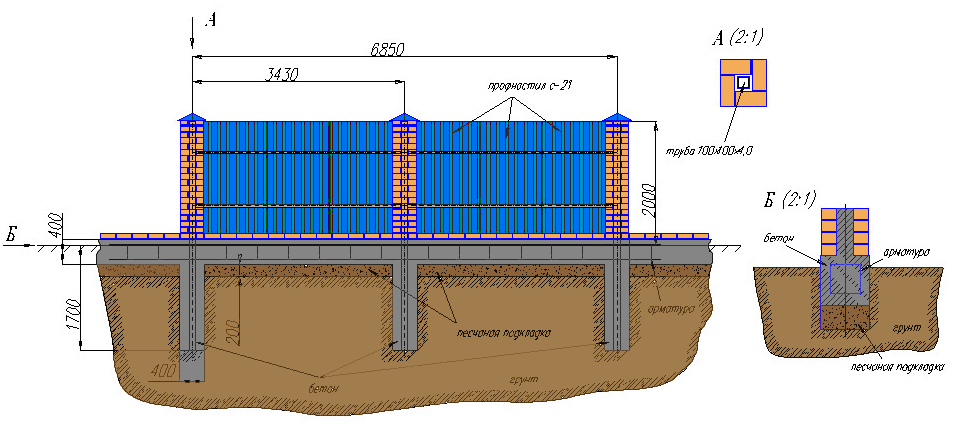

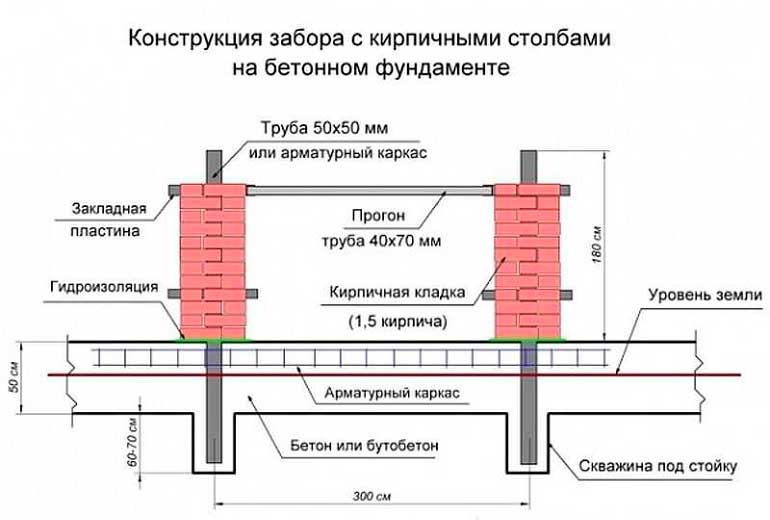

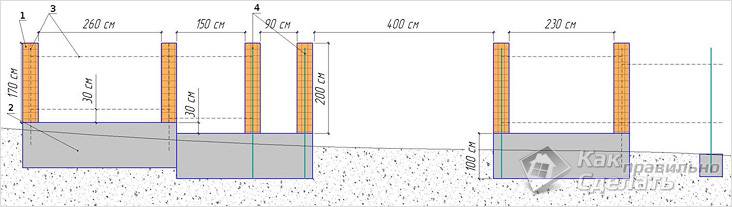

Fence foundation with brick pillars

Brick pillars perform rather a decorative function than a practical one.However, such a fence can be installed in those areas when it is necessary to slightly level the difference. heights on the site.

A pile foundation can be used under brick pillars.

The process of creating the foundation takes place according to the following plan:

- Dig a ditch around the perimeter of the future fence up to 70 cm deep and at least 80 cm wide.

- Place a drainage pad on the bottom. You need to use sand and coarse gravel for this.

- Lay roofing material.

- Pour a 20 cm layer of cement mortar. In this layer, lay the reinforcement mesh. Use a rebar with a diameter of 6 mm.

- After the concrete has completely hardened, cover it with roofing felt.

- Now you can equip the tape with two bricks. It will have to be raised to ground level.

- Now you need to reinforce the locations of the pillars. A wire with a diameter of 3 mm will suffice.

- Lay out a brick base, and both the base and the pillars are laid out as a whole. Further, the pillars are laid out with monolithic masonry.

The strip foundation looks original under the fence with brick pillars

Concrete foundation under the fence - a feature of the technology

The technology that makes it possible to build a strip foundation of a fence made of monolithic concrete provides for the creation of a shallow solid slab, taking into account the following requirements:

tape with a width of more than 30 cm and a height of 20 cm performed along the contour of the future fencing;

The most difficult problem can be called heaving soils. In winter, such soil freezes through, expanding and rising, and begins to push out the base, which leads to its cracking

- excavation works to prepare the pit provide for digging a trench up to 0.8 m deep;

- at the bottom of the pit, a crushed stone-sand cushion is prepared to compensate for the reaction of the soil;

- the base is reinforced with steel rods with a diameter of 0.8–1 cm, with the help of which a reinforcing cage is formed;

- a sealed formwork is installed into which concrete mortar is poured.

The technology allows you to create a reliable concrete foundation for the fence. The features of the base are:

- Increased strength to support the mass of the enclosing structure.

- Ease of arrangement, thanks to which the construction of the base can be carried out independently.

- Reduced terms of work execution, taking no more than one week.

At the preparatory stage, it is important to responsibly treat the following points:

- assessment of the condition of the soil, the movements of which affect the stability of the structure;

- correct execution of calculations, which should be entrusted to professionals;

- determination of the dimensions of the base corresponding to the mass of the fence;

- the choice of the dimensions of the reinforcement, which increases the resistance of the monolith to the effects of deformations.

Other options for foundations for a fence made of corrugated board

If, for some reason, you are not satisfied with the technology described above for erecting a base for a fencing from a profiled sheet, there are other options. They will cost a little more, but in fact they turn out to be much more interesting than a simple concrete foundation. Each of them has certain characteristics. And the construction methodology for each of them will be different.

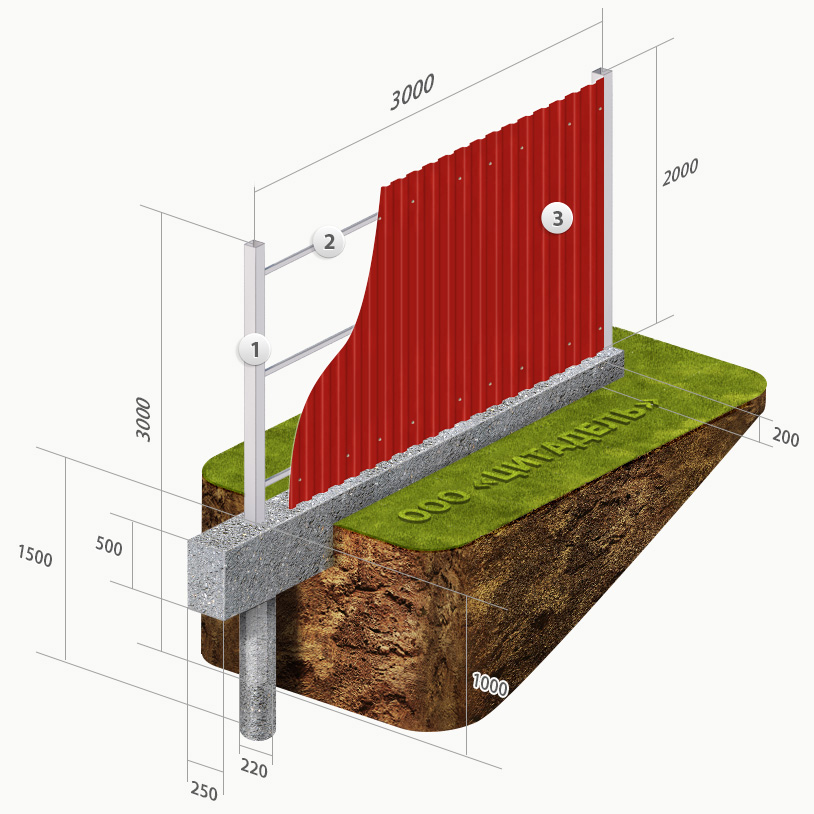

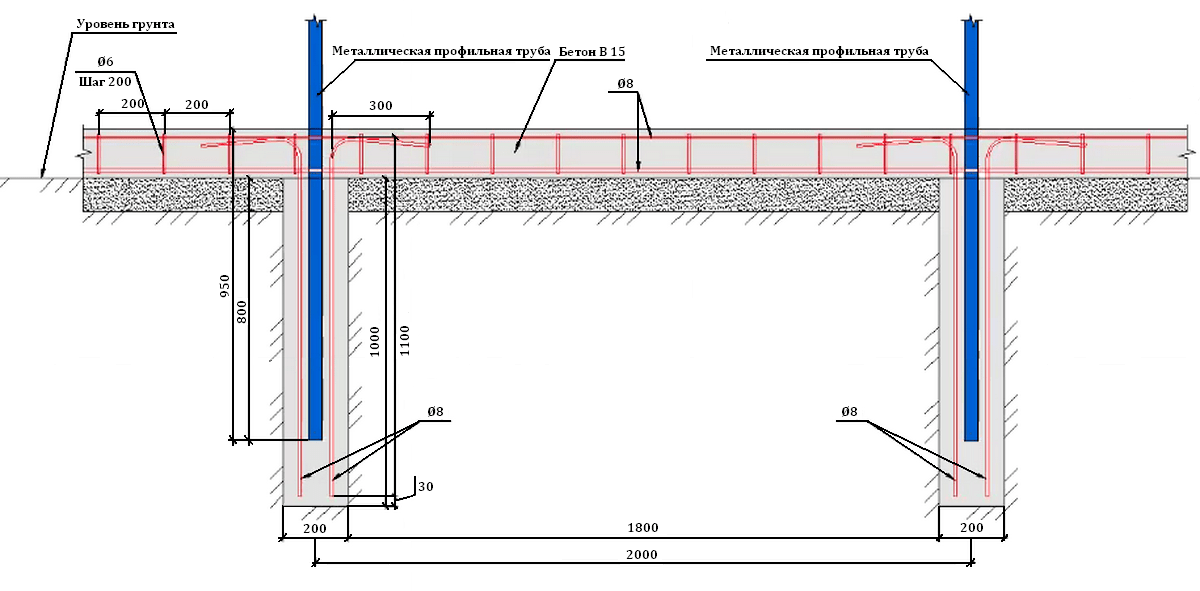

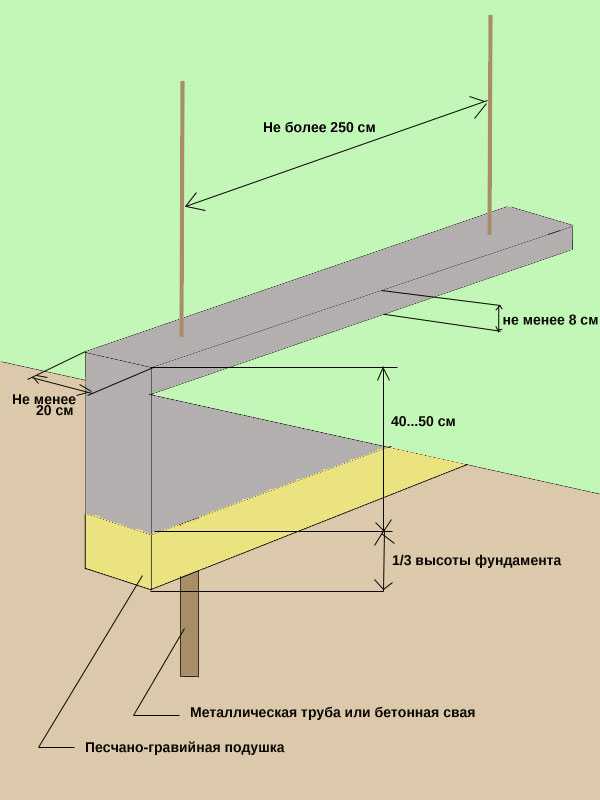

Installation of a fence on a columnar foundation

One of these technologies involves the use of metal poles. If you want the fence to serve you for at least half a century, then this is just the option you need. This solution is quite costly, but the performance characteristics of the fence will be high. The process of erecting a foundation with metal pillars is quite time consuming and includes the following stages.

- Earthworks - marking the territory and digging a trench 20-40 cm deep. Places where metal supports will be located are marked with milestones. The distance between them should be 2-2.5 m. The first, second and third milestones should indicate the corner connection of the fence, the place where the gate or wicket will be placed, respectively.

- Formation of supports. Most often, a square metal pipe is used, from which 2.5-meter posts are cut. A meter section of each of them should then be coated with an anti-corrosive primer.

- Preparation of wells for pillars. Here you should use a hand drill with a diameter of 10 cm or more. Wells should be done in those places that were marked by milestones.

- Preparation of mortar for concreting support pillars. The solution is made from cement (1 part), fine gravel (5 parts) and sand (4 parts).

- Installation and concreting of supports. The pillars should be placed in the ground with a part lubricated with an anti-corrosion agent, a mixture of cement and sand is poured into the free space. Use a hydraulic level to level the feet.

- Installation, reinforcement and casting of the formwork. A layer of geotextile is laid at the bottom of the trench, then a ten-centimeter layer of rubble and a polyethylene film, on top of which a wooden formwork is mounted. Its upper edge is pulled together with transverse bars. Then it is necessary to introduce two rods into the formwork and connect them with transverse dressings every 30-40 cm. After that, you can fill with a solution of cement and sand.

At the bottom of the trench, it is necessary to place a drainage cushion, consisting of a layer of sand 15 cm thick and a ten-centimeter layer of fine gravel. On top of it, you need to roll out a roll of roofing material, pour concrete on top (the layer thickness should be 20 cm). In the body of the fill, it is necessary to place a reinforcing mesh made of rods with a diameter of 6 mm, after hardening - to cover one more layer roofing material. A tape is laid along the upper layer, which is arranged according to the rules of laying in two bricks.

The brickwork must be raised to ground level. Then you need to designate the foundations of future pillars. These places should be reinforced with wire with a diameter of 3 mm. Up to a certain height (in fact, up to the height of the basement), both the pillars and the basement must be laid out as a whole, and then brick pillars can be erected with simple monolithic masonry.

As mentioned above, brick is an expensive material, and pouring a concrete base takes a lot of time. To speed up the process of building the foundation, ready-made reinforced concrete slabs and foundation blocks can be used, and bricks can only be used for cladding, purely for decorative purposes.

Types of foundations

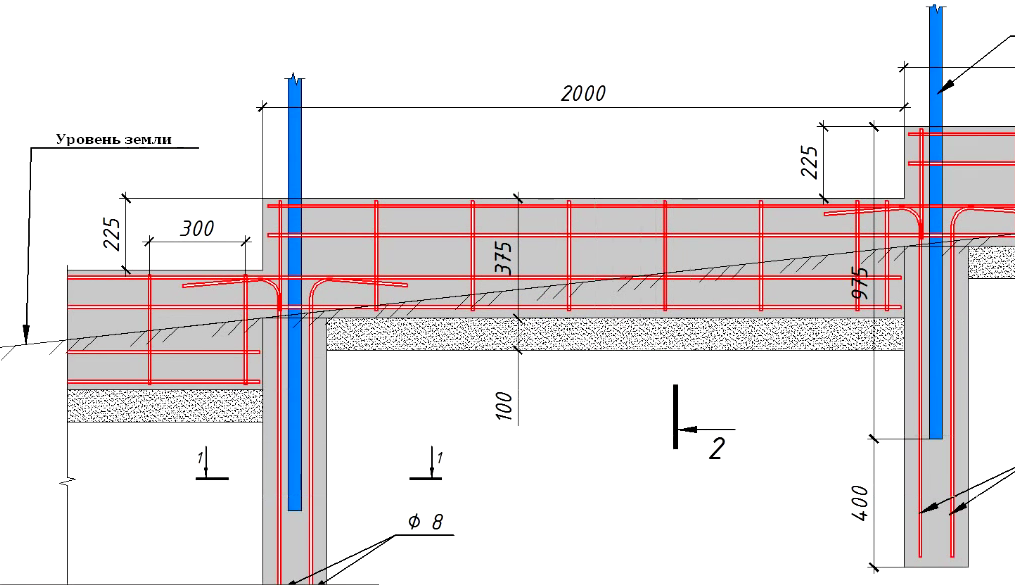

Diagram of a strip foundation for a fence

Diagram of a strip foundation for a fence

Taking into account the fact that a reliable and sufficiently strong foundation is required for the future fence, when choosing it, the main design parameters of the fence must be taken into account  Foundation pouring process (in particular, its own weight and height). At the same time, it is quite natural that with an increase in the dimensions of the enclosing structure, the load on its foundation base will also increase.

Foundation pouring process (in particular, its own weight and height). At the same time, it is quite natural that with an increase in the dimensions of the enclosing structure, the load on its foundation base will also increase.

Finding a suitable foundation for your fence and type of foundation comes down to choosing one of the following options:

- strip-type foundation;

- conventional columnar supports;

- combined (strip-and-pillar foundation);

- rubble support bases.

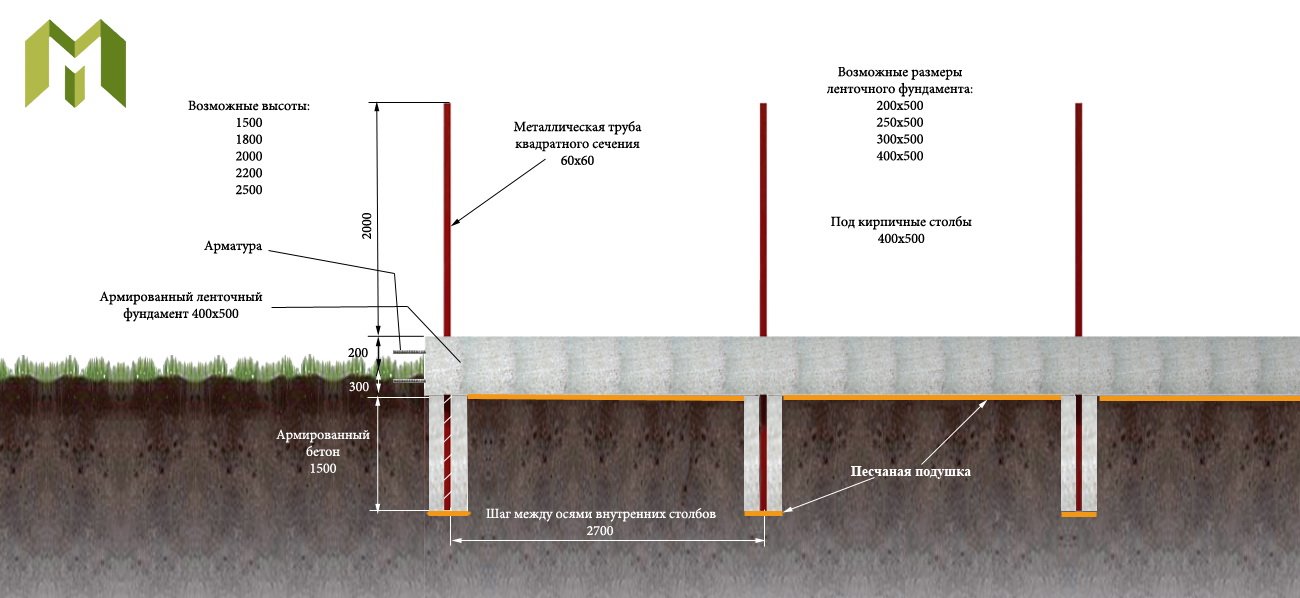

In the case of arranging a massive fence, it is most reasonable to use a shallow strip foundation.

Construction diagram

Construction diagram

With an insignificant weight of the fence, it is not at all necessary to pour concrete tape around the entire perimeter. In such a situation, it will be enough to prepare several support pillars, poured into pre-prepared pits (the so-called columnar foundation).

Foundation

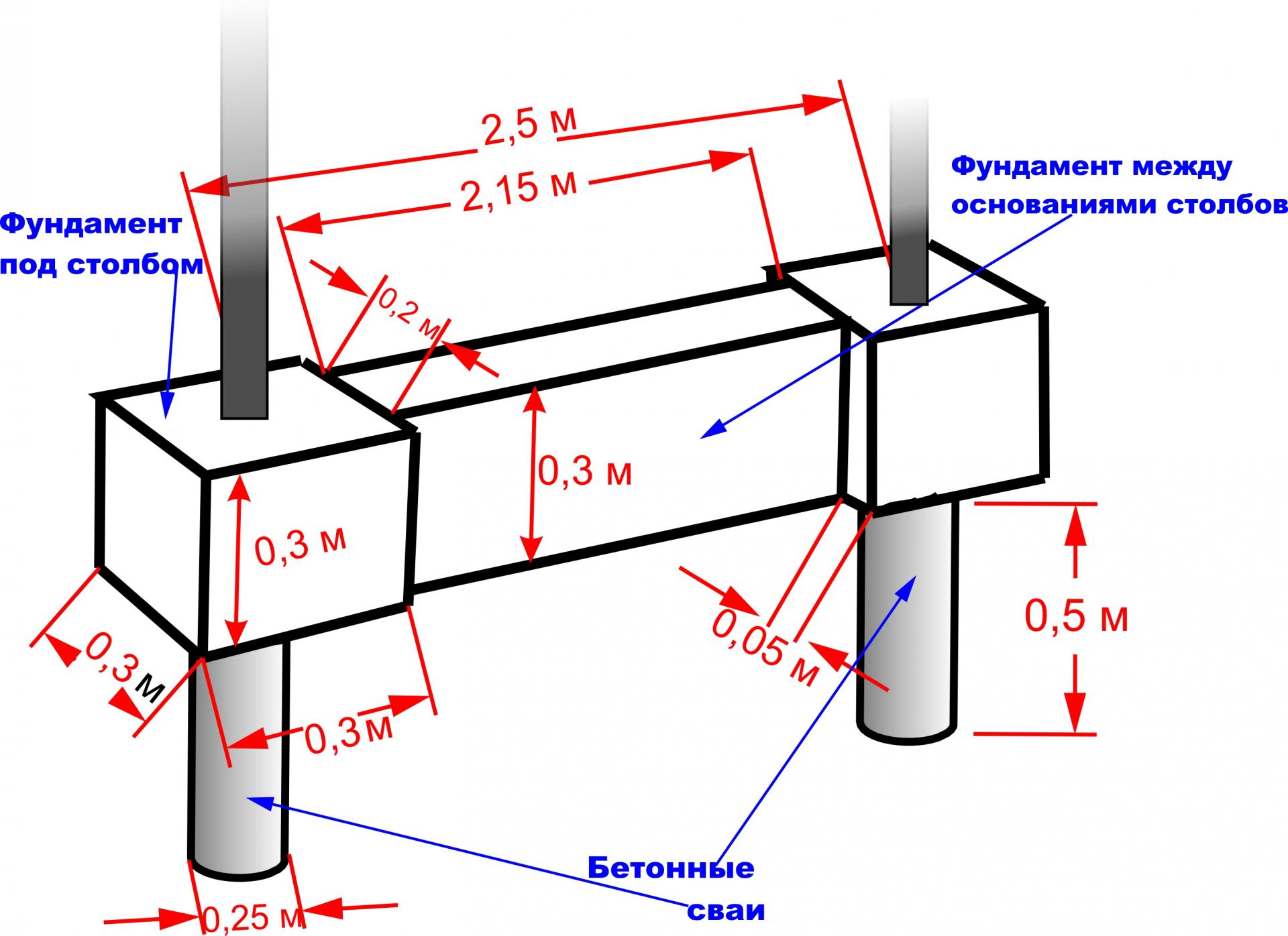

At the design stage, you need to think over the structure of the foundation for the fence made of brick pillars. It must be present, in the minimum version - columnar. That is, brick columns should at least rest on separate buried concrete supports and be connected to them. This, firstly, will make it impossible for them to overturn, and secondly, it will provide support on a stable ground.It is clear that the top layer, which is constantly wet and freezing, is not such.

When building on ordinary soil, the foundation under the brick fence posts should be buried 15–20 cm below the soil freezing depth characteristic of the region (see SNiP on building climatology). If the soil, due to the absence of clay inclusions, has good drainage properties (sandy or stony), a depth of 80 cm will be sufficient.

To make the support more stable, it can be made expanding downward. In this case, the linear size of the sole is doubled in comparison with the size of the upper platform, which is the base of the brick fence posts. This technique will be especially appropriate in the case of columns designed to attach a wicket or gate leaf.

If significant wind loads are expected or the fence sections will have a relatively large weight, it is advisable to lay a shallow strip foundation 20-30 cm deep under them.

Well, under a heavy stone or brick fence, you need to erect a strip foundation with full depth (below the freezing depth). Fence posts made of brick or stone are erected according to the same rules as for lighter canvases.

Having decided on the structure of the foundation, it will be easy to calculate the volume of concrete required for its manufacture.

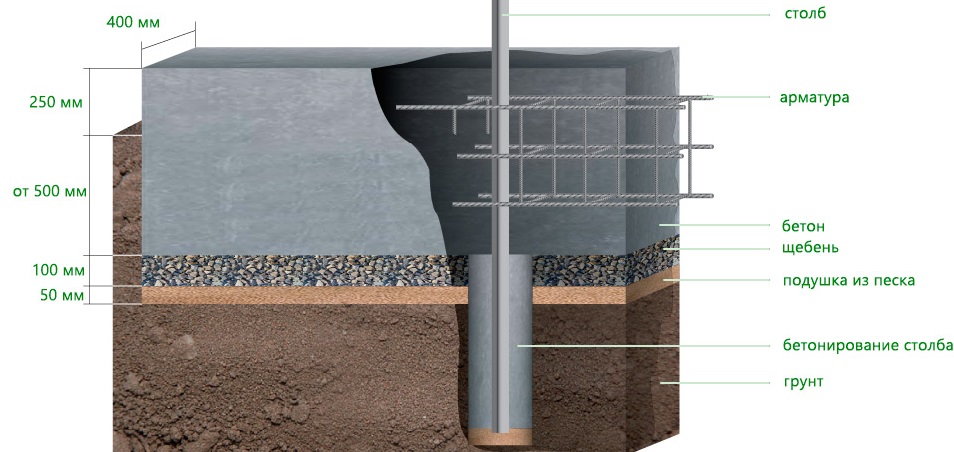

Pay attention to the following:

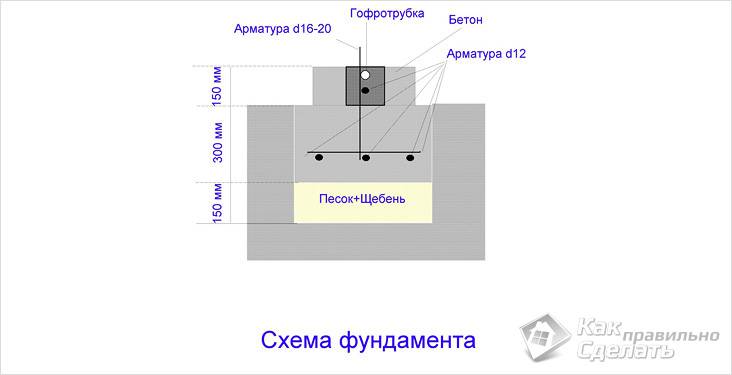

- All elements of the foundation should be located on gravel or crushed stone cushions 10-15 cm thick.

- The strip foundation must necessarily have a reinforcing cage inside.

- The concrete in the ground must be protected from moisture by two layers of roofing material.

The connection between the fence post and the concrete support is provided by a steel core that runs through both elements. For this role, you need to prepare a pipe or an 80th channel, sections of which will be welded in pairs into a box. The core must penetrate almost completely through the foundation - here it also performs the function of reinforcement.

As for the brick pillars, in those of them on which the wicket and gates will be mounted, the core must reach the very top; in all other cases, it may be 40-50 cm lower than the brickwork of the pillars.

Formwork construction and foundation pouring

The foundation is carried out according to the following scheme:

- A hole or trench is dug (for a strip foundation) of sufficient depth.

- Gravel or crushed stone is poured onto the bottom, which is carefully compacted (the layer thickness is 10-15 cm).

- A plank formwork is installed, which from the inside must be sheathed with two layers of roofing material.

- In the formwork for the strip foundation, a knitted reinforcing cage is installed, and for the foundation under the brick posts - a steel pipe or other core, set to a vertical position along a plumb line. For a more reliable fixation in concrete, the core can be equipped with a cross-corner thrust bearing or plate.

- Concrete is poured into the formwork and into the core. If you decide to cook it yourself, try to rent a small concrete mixer - it will be much easier to work. Concrete can also be ordered at the ZhBK plant - it will be delivered by an automatic mixer. It is better to fill the foundation entirely in one go.

Freshly poured concrete is pierced over the entire area with a shovel or reinforcement in order to remove air bubbles. After that, the structure is left to mature for 20–28 days, holding it under polyethylene and periodically pouring water over it. The formwork can be dismantled after 10 days.

In this case, you do not have to fiddle with the formwork: this function will be performed by roofing material rolled into a box and inserted into a recess.

Strip base under the fence - types of foundations and selection criteria

With an increase in the mass of the protective structure, a foundation base of greater strength should be used. For massive fence supports and structures with heavy brick or stone pillars, a reinforced concrete foundation is required for the fence. It is worth stopping the choice on a strip foundation, erected on all types of soil. The tape foundation for the fence is reliable and has an increased margin of safety.

A reliable fence is needed around a private house

For the construction of fences, the following types of belt-type foundations are used:

- composite. It is distinguished by its simplicity of design. The precast foundation is constructed from various types of concrete blocks or natural stone. On a prefabricated cushion, the stone fence is not subject to deformation and remains stable during operation. The technology for erecting a prefabricated base provides for the preparation of a trench, the formation of a cushion, followed by laying blocks or stone on a cement mortar;

- whole. The monolithic foundation structure is more popular than the prefabricated option. For the construction of the foundation tape, the soil is extracted along the contour of the future fence, the sand and gravel mixture is poured onto the bottom of the acceptance and the formwork is constructed. The height of the formwork is determined by the level of elevation of the foundation above the soil surface. Then the reinforcing grid is installed and concreting is performed.

According to the level of penetration into the ground, the tape-type foundation base is divided into the following varieties:

For the construction of the fence, it is important to choose the right type of foundation correctly.

- shallow foundation used for the installation of lightweight protective structures made of chain-link mesh, profiled metal or wood. A shallow version of the foundation is used for the construction of fences on stable and slightly loose soils. The depth of the foundation is 0.5-0.7 m;

- deeply buried foundation foundations used for heavy stone, block or brick fences. The base of the bottom of the buried foundation is located 0.3 m below the level of freezing of the soil. For the construction of the buried foundation, an increased volume of building materials is required, which affects the total cost.

It is important to choose the right type of foundation for the construction of a fence around the site. There are a number of factors to consider:

- design features of the fence;

- the mass of the constituent elements of the future fence;

- the value of the load acting on the support pillars;

- soil characteristics;

- the level of soil freezing;

- relief features;

- proximity to the location of aquifers;

- total cost.

The service life of the entire enclosing structure depends on how correctly the type of foundation is chosen The following points also affect the stability of the foundation:

- the likelihood of soil shrinkage with seasonal changes in humidity and temperature fluctuations;

- the impact of atmospheric factors and the possible erosion of the foundation by melt water;

- the total area of the protective structure, the windage of which causes deformation.

It is important to choose the right size of the foundation tape and determine the size of the reinforcing lattice. When choosing a type of strip foundation for a future fence, take into account the requirements for the foundation

Main selection criteria:

- ensuring the stability of heavy fences;

- even distribution of the fence mass on the soil;

- prevention of deformation of the fence and local shrinkage;

- preventing the fence from collapsing under wind load;

- maintaining the stability of the structure during soil movements.

To correctly determine the type of strip foundation, strength calculations should be performed based on the design features of the fence and the results of geodetic surveys.

The fence can be askew if the foundation is weak

Do-it-yourself solid strip foundation for a fence

An ordinary tape is arranged under the stone fence. How to do it right:

Dig a trench to the calculated depth below the freezing level

It is also important to observe the correct width of the recess: it should be 15-20 cm larger than the future wall on each side for the convenience of work.

A sand-gravel mixture of 15-20 cm is poured to the bottom, after which it is carefully tamped. To be sure, the layer can be well spilled with water - it additionally compresses the pillow to a working condition.

Preparing the formwork

Its design depends on the size and type of base chosen. Boards are hammered together by vertical bridges into a single wall. Install it at the bottom of the trench and fix it with additionally installed wooden stands for rigidity. For high formwork, additional reinforcement is made at the top: the sides are connected in pairs with boards. The step of vertical supports should not exceed 1-1.5 meters.

Prepare the frame. The longitudinal rods are positioned in such a way that a 3-4 cm margin remains to the edges of the structure to protect the reinforcement. For the base under the fence, 2 rods are enough on one plane... The height of the frame can be arbitrary, it is optimal to make a step between the longitudinal reinforcement of 200-300 mm. The dressing is carried out with clamps 6 mm in diameter, the pitch between them can be 200-250 mm. The finished frame is laid at the bottom of the trench on small bars 4-5 cm high - they are necessary to protect the reinforcement with concrete from the side of the pillow.

If necessary, in vertical supports made of pipes, they are installed after reinforcement, driven to a depth of 0.5-1.0 meters (a kind of pile is obtained) and leveled in height.

The next stage is pouring the strip foundation under the fence. It is advisable to carry out the process at a time so that the concrete does not seize successfully in separate sections. Laying the mortar begins from any angle, gradually filling the entire volume, compacting the mixture with vibrators or a shovel. If it happened that there was not enough concrete for the entire volume, before the next pouring, the seized layer must be chiselled to create a relief surface, thoroughly moisten it and only then continue laying. But it is better not to allow such a situation - unevenly solidified concrete will not work as a whole.

Installation of a fence made of corrugated board

The installation of the enclosing structure begins with the purchase of the necessary building materials. Would need:

- Support pillars;

- Beams, or lags. Profile pipe 40 × 20 × 2 mm (the best option). The length of the lag should be equal to the distance between the support posts;

- Professional sheets;

- Caps for support posts;

- Holders. Elements that will save on welding;

- Roofing screws and bolts.

To give the fence a complete look, you can install the end U-shaped strip along the upper edge of the profiled sheet. But this is not necessary with a modest budget. The bar does not have an essential functional feature. It is also worth taking care of the purchase of sand, gravel and cement in advance. These building materials will be useful even if the foundation will not be organized.

Fence foundation

If it is difficult to decide on the need to fill the base under the fence, carefully read the photo in the article. Fencing structures with and without a foundation look different.

It is easier, faster and cheaper to fill the strip foundation. It is versatile and suitable for all types of soils. At the initial stage, the territory is marked - they mark the border of the site, mark the location of the support pillars and functional elements of the fence, for example, a wicket or a gate. It will not be possible to make a high-quality fence from corrugated board with your own hands without earthwork. Therefore, after marking the territory, they begin to dig a trench along the line of installing the fence. The depth of the ditch is 45-50 cm. In the places where the support pillars are to be installed, they are deepened to a depth of 90 cm. The following instructions follow:

- Installation of formwork inside the trench.It can be made from scrap materials. The formwork is installed so that the foundation protrudes 40 cm above the ground level;

- Rebar laying;

- Posting of pillars;

- Pouring with concrete.

After completing the pouring, the foundation is left for 17-21 days. The formwork is not removed until the concrete has reached 55% strength. But it is better to withstand the entire 24-day period.

Installation of pillars and lags

Column fill will help you complete your work faster. Would need:

- Dig holes up to 1.5 m deep at a distance of 1.5-3 m from each other. The diameter of the ditch is 3 times the diameter of the pipe;

- At the bottom of the pits, make pillows of rubble and sand;

- Block pipes;

- Fill the pits with the pipes placed in them with cement mortar with gravel;

- Wait for the concrete to harden.

When marking the territory, do not forget about the sand pillow. If you do not want to carry out additional excavation work or there is no time, you need to raise the profiled sheets of the fence above ground level by 10-15 cm. With an uneven relief, this parameter must be increased so that the flooring installation line is even.

The lags are attached after the concrete has completely hardened. Their number depends on the height of the fence. For fences up to 1.5 m, a single crossbar is sufficient. Up to 1.7 m, two crossbars are required. And the reliability of the fence with a height of 1.8-2.1 m will be provided by three logs. They are installed along the upper and lower edges of the profiled sheet, stepping back 4-7 cm from the edges, as well as in the center.

We fix a fence from a profiled sheet

To correctly make a fence from a profiled sheet with your own hands, you need to seriously approach the choice of fasteners. The easiest way is to fix the flooring with self-tapping screws. You will need 35mm flat head metal fasteners. The wall material will hold securely if the screws are placed at a distance of 50 cm from each other on each crossbar. Installation of sheets at the joints is overlapped.

The final stage of work is the fastening of the U-shaped bar. When installing profiled sheets, there is a high probability of damage to the galvanized surface. If this happens, the defect must be eliminated immediately by painting the fence. Self-installation of the enclosing structure will take about 1.5-4 weeks. The timing depends on the size of the fence and the skill of the builder.

Gravel Fence Concrete Foundation

The main features of the foundation on gravel bed:

- increased load capacity;

- acceptable level of costs;

- simple construction.

The sequence of technological operations resembles the execution of work on the formation of other types of foundations:

- Prepare a trench around the perimeter of the fence.

- Fill the bottom with a layer of gravel mixed with sand.

- Consolidate the pillow to a layer thickness of 10-15 cm.

- Tie the reinforcement cage and place it in the trench.

- Install embedded elements, if necessary.

- Fill the pit with concrete mixture, level it.

If it is necessary to install support columns, they can be placed in the trench before the concrete is poured.