What to choose: concrete or brick plinth?

This issue should be considered in two aspects - the cost of work and the complexity of the work. In this case, it is necessary to immediately make a reservation - the term "brick" means a certain type of building material. As you know, bricks are: silicate, clinker, facing, refractory and ceramic ("red"). The latter is lightweight (with transverse through holes in the body) and full-bodied.

The basement of the building is allowed to be built exclusively from bricks of the following type - "Solid ceramic brick M 100 GOST 530-2012", both from new and from bricks that were in use. Moreover, the option of building from a used brick is the most preferable for the following objective reasons.

The basement of the building is under constant harmful destructive effects of atmospheric factors: wind, rain, snow and temperature changes. In addition, the material of construction is negatively affected by capillary moisture coming from the soil.

That is why the plinth cannot be built from bricks of other types, and often it cannot be built from new ceramic bricks. The fact is that many manufacturers of "red" brick seriously violate the technology of its production.

In particular, in pursuit of a beautiful appearance, productivity and the desire to save on expensive energy resources (natural gas), brick is not burnt out. If you build a basement from such a material, it will begin to rapidly collapse after the first winter. And no options!

The brick, which was in operation, was made during the times of the USSR. At that time, it would not have occurred to anyone to violate technology in the name of beauty, economy, or other factors. Therefore, a base made of such material will last for at least 100 years or more.

Given the above, you can no longer consider the question: Erect a basement of concrete or brick? Summing up: "Only concrete!" Nevertheless, for completeness of information, it is worth highlighting the issue of cost and the issue of labor intensity of construction from brick and concrete.

Without bothering the reader with detailed mathematical calculations, we will immediately give the average cost of erecting 1 running meter of a standard base of 400x500 millimeters:

- Brick base: 1500 rubles;

- Concrete base: 1600 rubles.

At the same time, the increase in the cost of a concrete basement is solely due to the purchase of boards and beams for formwork for pouring, which can then be used for other purposes. As you can see, the difference is very, very insignificant, in order to risk the entire building by buying a low-quality brick.

The laboriousness of the construction of a concrete structure, provided that the concrete is made on our own, is a priori significantly higher. In addition, you will have to spend time on manufacturing, fitting and installing the formwork.

Applications in base construction

Since such a base does not have high strength, it will not work for a brick house, due to its heavy weight. However, for less heavy buildings, such a foundation would be an excellent solution. The foundation for a brick gazebo is an excellent solution, due to the simplicity of its construction. However, it should be remembered that only red bricks are allowed.

A brick barbecue also needs a solid foundation. It needs to be made reliable, so a brick foundation for a grill is also needed. The same can be said for a brick barbecue. The construction of such a small structure is necessary for those who love to spend time roasting meat or fish in the company of friends. However, not many people know that a foundation for a barbecue is also necessary.

Another case where the construction of a reliable foundation is very important is the construction of a furnace. The foundation for a stone stove will last for many years

Brick foundation technology

Different types of foundation supports are erected from working bricks, including columnar ones. They support the building at the corners and at the junctions of the load-bearing walls. The step between them is at least two meters.

Bricks are also used to create tape supports. That is, erected under the walls of the building. When calculating the parameters of this foundation, it is necessary to take into account the total mass of the building, the condition of the soil on the land plot. The type of support for the building will be determined after the calculations.

The methods of constructing a strip structure from a working brick consists of several stages, they cannot be neglected.

For this type of construction, a pit must be dug. It can be shallow or full, that is below the depth of freezing.

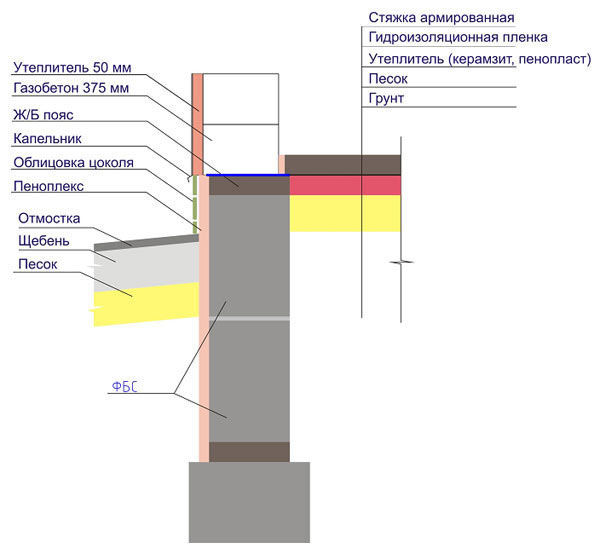

One of the very first operations in the construction of this support will be marking. The first step is to remove the fertile soil layer. When performing this operation, the corners of the house are marked. A trench of the required depth is being dug along the perimeter of the future house. For bases that are located in heaving soils, the depth of the foundation should lie at the level of freezing. There is also a variant of shallow foundations, the depth of which is 500 - 700 mm. The width of the trench is determined by the moisture content of the soil. The larger it is, the wider the trench should be for laying the foundation. For the arrangement of the foundation in those places where the groundwater reaches very high to the ground level, its width must be sufficient for the construction of drainage. At the bottom of the trench, a pillow is built, consisting of sand and gravel. After the pillow is rammed, you can proceed to the construction of the formwork. For its manufacture, boards are used, even non-planed ones. Roofing material is laid in the formwork. It acts as a hydraulic isolation. This material should be installed as long as it is enough to insulate the entire foundation. This waterproofing will provide resistance to capillary moisture.

At the end of the construction of the formwork and its waterproofing, concrete can be poured. After pouring, it is advisable to close the brick foundation and leave it for several days, at least 5 - 7. This time is necessary for them to gain strength.

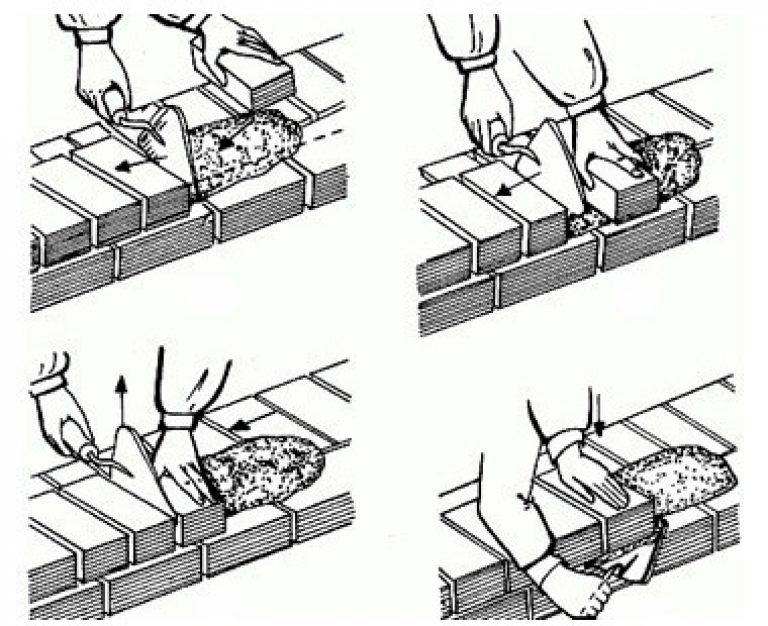

The construction of a brick foundation with your own hands is performed in the following sequence. A brick is laid on the resulting base. In this case, you can use a typical dressing. Reinforcement is laid between the first and second layer of bricks. This can be a bar or masonry mesh. The reinforcement is also laid before laying the last row.

The solution sets in one to two days. But he will gain ultimate strength in a week. Only after this time is it possible to start the hydraulic isolation of the entire foundation. As a rule, to perform these works, materials made on a bitumen basis are used.

After the hydraulic insulation is completed, the foundation for the brick house is insulated from the outside. For insulation, foam or mineral wool is used. After that, sand and crushed stone are poured into the trench. This allows water to be drained away from the base and prevents heaving of the adjacent soil. In areas where there is a large amount of moisture, it is advisable to carry out drainage. To do this, at a distance of about one meter, geotextiles are laid from the outer side of the base, rubble is laid on top of it and pipes with pre-perforated pipes are placed next to it. They are taken out into specially dug wells or canals.

A brick foundation, in comparison with a concrete one, provides good thermal insulation and, with high-quality hydraulic insulation, can last about fifty years.

By the way, repairs are made, simply, the damaged areas are replaced.

Stages of construction of a strip foundation

The device of the strip foundation.

The tape type of base, due to its performance, is most often used in the construction of country houses. To more accurately understand what type of foundation is needed, before starting construction, it is necessary to determine the depth of soil freezing and the level of groundwater. Further marking of the site is done for the future building. Given the measurements taken, you can purchase the right amount of building materials.

- Preparatory work. They consist in digging a trench under the foundation and arranging a sand and crushed stone pillow 10 cm thick. Next, it is necessary to fill the bottom of the trench with concrete to prepare the basis for future masonry.

- Bricklaying. You need to start from the corners. After the first laid row, a cord is pulled from one corner to another. Along the way, a reinforcing mesh is laid between the horizontal rows. Its end must be folded and inserted into the vertical seam. The cord helps to make the row evenly. After the foundation begins to rise from the ground, you can put a metal profile pipe along a plumb line in each corner, or better - a corner. It is needed, like a lighthouse, to maintain the vertical of the masonry. The standard joint thickness is 1 cm. Do not forget about waterproofing.

After the basement is built, it is necessary to start lining it. The safety of the foundation, and hence the service life of the entire building, depends on the quality of this event and the materials used. The ideal option is insulation of the basement, construction of a ventilated facade.

The second equally important element is the blind area. Its construction is also necessary. The blind area prevents the penetration of external moisture to the walls of the foundation, thereby protecting it from destruction. If the groundwater is close enough, it is best to drain it to remove moisture from the base of the building. The measures to protect the base of the building, taken in the complex, will help to ensure a long lasting, and therefore the entire house.

The choice of material for the base

The base is considered the most important element of a residential building. For this reason, the base must be structurally reliable and durable.

A structure in which a brick is used as a basis, according to experts, is considered reliable and durable. Before installing the base, you should very carefully select the block:

The main part of the base of the building is considered to be foundation bricks, which in turn must be of high quality. It should be remembered that only ceramic bricks can be used for such a construction. The silicate white type of material cannot be used, since it does not have protection against moisture, and under its prolonged exposure it collapses. The required volume of foundation bricks will directly depend on the size of the structure, as well as its level of burial. This level often develops differently in each region. In order to determine the required amount of immersion of the foundation brick in the soil structure, you can use a special table in which all the data are clearly described. Multiply the size of the base by the number of elements in 1 m3 - this will be the number of bricks per foundation

In order to simplify the calculations of the number of foundation bricks, it is necessary to multiply the total volume of the base by the number of elements in one cubic meter. As a result, taking into account the size of each joining, approximately 400 blocks are obtained.

At the same time, it is important to use solid brick, because it is considered more reliable in long-term operation. Hollow red brick has increased moisture resistance, but withstands small loads in comparison with solid ceramic bricks.

This material is best used for the construction of the walls of a residential building.

The standard dimensions for red brick foundations are 250-125-88 mm.Most often, at the time of construction work, we use the brand of cement m250, 300, 200. At the time of purchasing the material, it must be remembered that only 360 pieces can be placed on one pallet.

Comparison of the main types of bricks for building a basement at home

When erecting masonry, the following types of bricks are the best choice:

Clinker brick

This type of brick is the most durable of all existing modern counterparts. It is distinguished by high compressive strength, durability, no need for finishing, and absolute waterproofness.

The only drawback is the high cost. Because of this, it is rarely used in basement masonry. It is mainly used to lay out furnace fireboxes.

Varieties of ordinary clay bricks

Differs in high strength (grades 150-250), good indicators of frost resistance from 50 to 100 seasons, low cost. Of the minuses, we note a poor appearance, so additional decoration of the foundation masonry will be required.

Ceramics

Medium bending and compressive strength, medium price range (it all depends on the brick brand and manufacturer), high decorative properties. In addition to solid samples, hollow modifications of ceramics are produced, which can significantly reduce the weight of the foundation structure.

Porous brick

Due to the presence of pores, a minimum load on the entire foundation masonry is produced. In addition, like ceramics, it does not completely need further cladding and has modifications in the form of large-format blocks.

However, its cost is even higher than ceramics, therefore it is extremely rarely used for a base.

Semi-dry and dry pressed bricks

In terms of external characteristics, it very much resembles ceramics, but the difference lies in the fact that the samples do not go through the firing stage. As a result, an inexpensive sample is obtained, but with low frost resistance and a good aesthetic appearance. It is used without external cladding only in areas where there is no sharp temperature drop.

Characteristics of the soil

Brick is used to create the above-ground part of the foundation and its basement parts. Laying it below ground level is strictly prohibited. Brick quickly absorbs moisture and can collapse even with a slight decrease in temperature. In addition, a brick can simply decompose in a couple of decades.

Brick bases are rightly called the optimal solution for rocky soils.

Soils, which include gravel and stone debris, are called gristly. This type of soil is distinguished by its strength parameters and is considered a good basis for the construction of brick supports.

Check calculation

The margin of safety of the foundation allows you to save materials and money for its construction. For a verification calculation, the width of the tape is reduced by 15 cm.

So:

- The reference area of the base will be: (9 + 6) x2x0.25 + 9x0.25 = 9.75 m2 = 97,500 cm2

- Foundation volume: 9.75x1.8 = 17.55 m3

- Estimated weight of the foundation: 17.55x2500 = 43875 kg

- Total weight of the building: 90045 + 6966 +43875 = 140886 kg

- Ground load: 140886 kg / 97,500 cm2 = 1.45 kg / cm2

Recommended video:

With a safety margin of 20%, the design load will be 1.74 kg / cm2. This value is less than the control value. The calculation can be taken as a basis. Video: A more precise calculation of the load of a building structure on the base soil allowed saving 10.53 m3 of concrete and reducing the cost of reinforcement.

Types of plinths

This is determined by the location of the front wall of the basement in relation to the front:

- speaker. The option is used when it is necessary to increase the bearing capacity of the basement. In this case, the element is moved two to three centimeters beyond the wall plane. There is a drawback - you will have to take measures to remove rain moisture flowing through the building;

- sinking. The façade wall hangs over the basement.It is best to use this option when durable building materials that do not need additional finishing were used for the manufacture of the base;

- in one plane. The basement and the wall are in the same plane. This method is rarely used and mainly on outbuildings of secondary importance. The finishing layer is made with one material.

There are no specific requirements for the height of the basement part - everything is determined by the presence of the basement and the foundation itself.

Construction of a columnar foundation

The columnar foundation is shallow (to a depth of 40 to 70 cm) and well ruined, which drops below the freezing level by 30-50 cm. When building one-story buildings, square pillars are chosen with an edge size of 38 cm, rectangular pillars are used with 38 * ribs 51 cm. For two-story buildings, the minimum rib size is 51 cm, and often concrete cores in the posts are used to increase strength.

After applying the markings on the ground, holes are dug 20 cm deep more than the height of the underground part of the pillar. The width of the pit should be convenient for masonry work. Before the laying begins, sand is first poured into the bottom and tamped, and then crushed stone, waterproofing is placed on top, and only after that they start laying. The bricks should be staggered, and each row should not deviate vertically and horizontally by more than 2%. The finished pillars must rise at least 20 cm above the ground level.

Brick foundations in residential and industrial construction

As a base, a brick foundation is technically suitable for any building. The compressive strength of a typical brick reaches 150-200 kg / cm2.

Moreover, from bricks, you can build both a tape and a columnar base. The main thing is to prepare a reliable foundation for brickwork. The foundation, equipped on a reliable basis, will withstand any load. Moreover, unlike pile or large-block construction, which is impossible without the use of heavy equipment and a whole staff of professional builders, a foundation with your own hands - made of bricks - is within the power of even a small team of two or three bricklayers.

The foundation, equipped on a reliable basis, will withstand any load. Moreover, unlike pile or large-block construction, which is impossible without the use of heavy equipment and a whole staff of professional builders, a foundation with your own hands - made of bricks - is within the power of even a small team of two or three bricklayers.

Thus, as a building material used for the construction of foundations, brick has practically no technical contraindications. In addition, a similar situation is observed in terms of the aesthetics of the facade. Brickwork is compatible with most building materials. Moreover, it is possible to build the base of the structure and the load-bearing walls of the house from bricks.

Insulation of the basement

If not insulated, a large amount of heat will leave the house during frosts. This will be unpleasant for both residents and the house itself.

It is best to use extruded polystyrene foam for insulation from the cold. It is glued to the walls with cement mortar glue. This is followed by additional fixation.

To save money, many use a cheaper material for insulation - polystyrene. He's too soft. It will be gnawed by mice.

Extruded polystyrene foam is dense and rigid. It is very even, so after erecting the basement, they can level the masonry.

Carry out preparatory work before thermal insulation:

- Clean the wall from the protrusions.

- Remove irregularities with an iron brush.

- Cover the wall with a primer.

- You can start installing insulation.

After the insulation, reinforcing mesh and plaster are attached to the wall.

Rules for self-erection of a brick foundation

- The basic rule: strict selection of bricks for foundation masonry. You should choose only a solid red clay brick, necessarily burnt, since the main reason for the destruction of a brick is high humidity, and a burnt ceramic brick is characterized by low moisture permeability.

- The laying of the brick foundation is carried out on a cement-sand mortar of increased strength (1: 3) with waterproofing additives.

- An obligatory device for thorough waterproofing when erecting brick foundations in areas where groundwater lies close to the earth's surface.

- The execution of the base sole with concrete casting and its special filling are necessary to improve the operating conditions and strengthen the brick foundation.

- The calculation of the depth of the brick foundation is carried out according to general rules, but a prerequisite is its erection on a layer of stable, solid soil. *

* Columnar brick foundation is not recommended for use:

- on weak horizontally moving soils (the possibility of overturning the foundation);

- in areas with elevation differences on the ground from 2 meters or more.

How to choose the right bricks

Diagram of a brick foundation for a greenhouse.

The foundation is a structure that bears the main load of the entire structure; therefore it has its own peculiarities. Plus, a material is used that is different from that used for the construction of walls and other structures. What material is better to choose for the construction of the foundation of the future building?

The main element of the foundation is brick. Therefore, its selection must be approached with special care. Only a red, ceramic stone will do. Silicate does not withstand prolonged contact with moisture and is destroyed. The required amount of ceramic bricks depends on the depth, dimensions,. The first parameter is directly related to the freezing point, which is different in each region.

To determine the required number of bricks, you need the volume of the foundation, expressed in cube. m, multiply by the number of bricks in one cube of masonry (approximately 400 pieces of single material, taking into account the seams). For a good foundation masonry, only solid brick is needed. The one with voids inside has a higher moisture permeability and less strength, so it cannot be used to build a foundation.

It is necessary to make masonry using bricks of a certain brand. A stone with a strength of M300, M250 or M200 is best suited

You also need to pay attention to the frost resistance index F. It should be within 35-50 cycles.

Water absorption should not exceed 15% (for bricks in direct contact with the ground). A single stone has dimensions of 250x120x65 mm, a one-and-a-half stone - 250x125x88 mm. When buying, keep in mind that 1 pallet fits from 300 to 350 pieces.

Advice

Before starting construction work, be sure to make sure that the foundation is horizontal.

Moreover, it does not matter at all what kind of foundation was built on the site - tape, columnar or any other. In its correct execution, you will need to make sure in any case.

If you have chosen a silicate brick for the construction of the basement, then you should remember that, although it is very durable, it quickly absorbs liquid, after which it swells and loses its strength qualities. It is recommended to use this building material only if you live in a region with a fairly dry climate. In this case, you will need to take care of good waterproofing of the basement structure.

If you still could not find the perfect brick for organizing the basement, then it can be built from concrete.

Before proceeding directly to the installation work, you should calculate how much you need to buy building material. To do this, it is permissible to use online calculators and services on construction portals, or try to do all the calculations yourself. Of course, in most cases, people turn to the first method, because it is much more difficult to make a mistake.

Experts strongly recommend purchasing a brick for a basement with a small margin, given the possibility of collision with defective parts or damage during transportation.

Basement bricks are often supplemented with various kinds of facing materials. Beautiful stonework is especially popular today. It looks harmoniously with most existing facades in different shades. Thanks to this addition, the home will look much more interesting.

Masonry mortar can be bought not only ready-made, but also prepared independently. For this, cement and sand are taken in a ratio of 1 to 3.

When equipping a basement structure made of bricks, the mortar should be laid in a thickness of no more than 1 cm

Observing this rule is especially important if the foundation of the building is made of reinforced concrete blocks.

Many users are interested in whether it is permissible to use a brick that was not fired during the manufacturing process to organize the basement. Yes, the use of such building materials is permitted, but experts advise giving preference to blocks that have nevertheless transferred this procedure. It is recommended to apply to the use of unfired bricks only if it is not possible to purchase other materials.

Do not forget about the basement insulation if you are building a residential building. It should also be borne in mind that there are three types of basement structures - incoming, butt to outer walls and recessed. The latter is always constructed for residential buildings at a depth of 6 cm below the outer wall foundations.

For information on how to choose and lay out a basement brick, see the next video.

The advantages of ceramic bricks

Red solid brick is chosen because it meets many of the requirements for building the foundation of a private house.

Its main advantages are that it:

- Cheaper than its counterparts, resistant to deformation: bending and tearing.

- It tolerates temperature extremes better than concrete and sand-lime bricks.

- Allows to carry out the foundation of any width and configuration.

- Easy to install.

- With a properly prepared mortar and good laying technique, it has high strength.

All the advantages are complemented by a number of disadvantages:

- Absorb water, due to which dampness and fungus appear in the basement, therefore such a foundation needs waterproofing to extend its service life.

- According to GOST 530–2012, solid brick, depending on the density, is a “conditionally effective” and “ineffective” heat insulating agent. In a hollow species, thermal conductivity starts from 0.47, in a corpulent species - from 0.43 and above.

- To preserve heat in the house and basement, it is required to insulate the foundation with special materials from the outside.

Which brick is better to use for the foundation

Recommendations, which is better to use a brick in the manufacture prefabricated strip or columnar foundation from small-format materials are given in SP 15.13330 of 2012. Masonry is allowed from ordinary red, facing solid ceramic bricks with a width of 51 cm or more concrete blocks measuring 20 x 20 x 40 cm.With an unlimited budget, you can choose a clinker stone with the highest possible moisture resistance. For the basement part of the foundation, the requirements are much lower than for underground structures.

For plinth

With normal horizontal waterproofing of the foundation with 2 - 3 layers of roll material, the supporting part of the basement can be laid out of porous bricks. Any materials are allowed in the facing layer, for example: silicate, hyper-pressed bricks, crevice, hollow ceramics.

When deciding which brick is better to use, it is necessary to take into account:

- the basement is an independent supporting structure;

- distributes uneven loads from solid walls.

Therefore, it is still better to use solid concrete wall blocks or solid ceramic stone. Usually, standard sizes of NF or one-and-a-half, double bricks are used to increase the performance of the masonry.

It is much easier to protect concrete blocks, brickwork from getting wet in the basement part. It is enough to coat the surface with bituminous mastic, decorate the basement with siding.

We recommend: How to make a brick plinth for a strip foundation.

What to look for when buying

When choosing a brick for the foundation, you must pay attention to the accompanying documentation. The grade of the stone must be higher than M150, frost resistance from F25, geometrical dimensions correspond to GOST

During transportation, unloading and storage, edges often break off, which is not a significant defect. In most cases, plaster waterproofing is used for brick foundations. Irregularities will only increase the adhesion of the protective layer.

When a brick is tapped on a ceramic metal object, there should be a distinct sonorous sound, and not a stifled dull sound. The ringing indicates the quality of the raw materials used, the correctness of the firing technology, the absence of microcracks and voids.

Styling nuances

To increase the reliability of a brick foundation, several conditions must be met:

- whole brick - the masonry must be carefully tied up by displacing the vertical seams in adjacent rows, therefore, it is necessary to select a whole brick, transport it carefully, store it in a building spot, move it at the facility;

- reinforcement - in each 4th row, the dressing of spoons / poke is required, the use of a masonry wire mesh with a cell of 2 x 2 - 5 x 5 cm;

- wetting - it is recommended to lower the brick into a bucket of water at the time of laying it on the bed from the solution;

- additives to the solution - the penetrating mixture will ensure the moisture resistance of the seams;

- foundation - unlike monolithic structures, brickwork is sensitive to unevenness of the base, the underlying layer of non-metallic materials, it is recommended to pour 5 cm of the screed, twice the size of the strip or column foundation.

Experts recommend using the upper armored belt for all prefabricated foundations. It is poured into the formwork, having previously laid the reinforcement cage. The structure receives additional spatial rigidity.

Advice! The brick breaks easily in any direction, so you don't need to buy ¾, halves, ¼, which are more expensive. It is wiser to use an ordinary, and not a face stone, which is not visible underground.

Thus, a brick foundation cannot compete with monolithic reinforced concrete structures in terms of service life and spatial rigidity. However, this option will save budget and construction time. He does not need to gain strength for 28 days, the walls can be erected in a week.

Decoration options

In addition to the operational properties of facing bricks, important characteristics are the color and texture of its surface.

Tools and fixtures

Compact concrete mixer will simplify the process of working with concrete

To cover the base / plinth home or fence was not only interesting in design, but also durable, you need to follow the technology of its implementation.

To finish the surface of the supporting structure from the outside, the following is necessary:

- container for solution;

- concrete mixer;

- trowel (trowels);

- level, plumb line, tape measure and cord;

- hammer;

- device for joining seams.

In addition, fine clay sand, water, cement and pigment are required to tint the solution to the color of the building's foundation cladding. The number of bricks is calculated in accordance with the overall dimensions of the basement and the perimeter of the house.

Cladding colors

Hyper-pressed bricks can be of different colors

Hyper-pressed bricks are colored by adding pigment to the molding mass. Due to the absence of firing, all bricks have the same color throughout the volume, and different batches of material have the same tone. However, the addition of cement mutes the brightness of the colors, so this finish of the basement of the house has a grayish "concrete" shade. Her palette is presented in a variety of colors, including: black, white, terracotta, straw and chocolate. The facing of the foundation of a peach, pistachio, bright green or sky blue shade looks interesting.

The colors of clinker and ceramic bricks are presented in all sorts of variations of red, brown, beige and other tones. The intensity of the color can be changed using various impurities and additives. Affects the color of bricks and exposure to high temperatures during firing, so different batches of material do not match in brightness. Such products are used for a foundation or a mixed fence, which allows you to create the effect of a smooth transition of shades on the surface.

A specific color of sand-lime bricks can be obtained by adding pigment to the molding mixture or by coloring the face layer on both sides. The latter finish is less durable and quickly loses its attractiveness and brightness.

We recommend watching a video on how to choose a brick for cladding.

Surface texture

You can also diversify the decorative design of bricks for facing a house with the help of reliefs, which are created by a combination of depressions, depressions and roughness. The resulting pattern can be chaotic or orderly. Other ways to form an interesting brick texture for finishing the basement of a house are:

- gunning or application of mineral chips to the surface, which is performed before clinker firing;

- ceramic coating (engobing), obtained by spraying a liquid mass and subsequent firing;

- glazing with a special composition.