Classification of concrete mortar

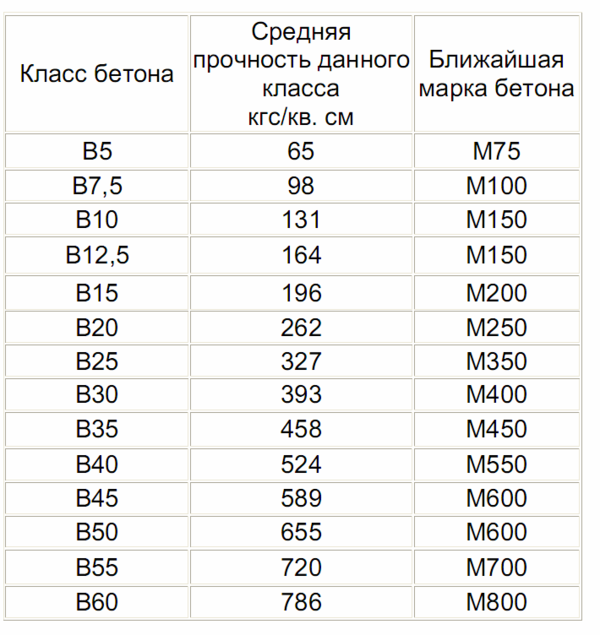

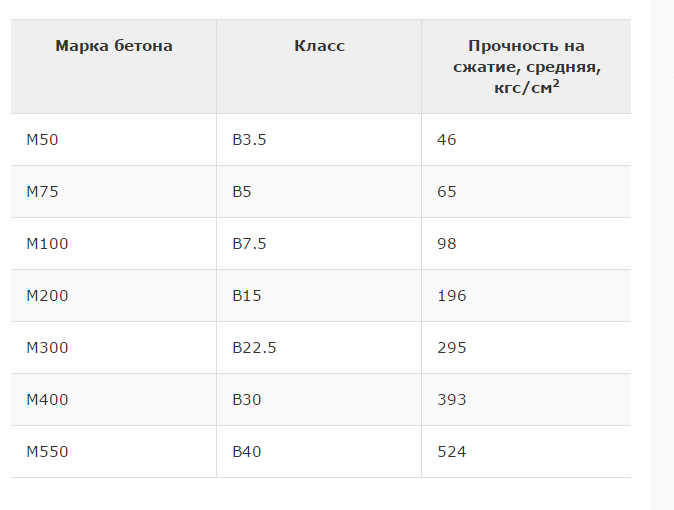

In accordance with GOST 36663-91, concrete, depending on the strength characteristics, is assigned a class (designated by the letter "B") and a brand (designated by the letter "M"). What is the difference between these values, and what indicator is more correct to focus on when buying a solution?

It should be noted that the concept of concrete class was introduced not so long ago. Previously, builders were guided by the only indicator of strength - the brand.

Concrete grade

So, the brand is the calculated average indicator of the strength of concrete. Literally, it means how much the maximum kilogram-force a concrete surface with an area of 1 cm2 will withstand until the moment of destruction. The brand is assigned in production after laboratory tests.

For this, a concrete cube is formed, which is exposed to various impact methods:

- Press;

- Ultrasound;

- Shock impulse.

Concrete cubes for laboratory tests

Concrete cubes for laboratory tests

Deviations in the stated parameters may in fact fluctuate by 5%. At the same time, such an error in the indicators is quite understandable and does not arise at all through the fault of the manufacturers or as a result of non-compliance with the recipe.

The calculated indicator is influenced by:

- the performance of the aggregates used;

- adherence to technology in the pouring process;

- external conditions in the process of gaining maximum strength.

Class

The fundamental difference between brand and class is that the latter describes the guaranteed strength. This indicator has already taken into account all possible errors.

The class of concrete, as an indicator of the strength characteristics, was introduced precisely in order to clarify the actually obtained qualities of the cement stone. This became necessary because, within the same brand, the run-up in characteristics turned out to be very significant.

At first glance, it may seem that the difference in the grade and class of concrete should be minimal. In fact, this is far from the case. The brand is always the average rounded value. At the same time, the gradation of the brand and class is different. Let us explain specifically with an example.

Concrete classes:

- from B1.5 to B5 are divided into 1.5 classes,

- from B5 to B30 for 2.5 classes,

- from B30 to 5 classes.

Grades over M100 are divided by values with a difference of 50 kgf / cm2, and after M600 the step is 100 kgf / cm2. In this regard, the difference in numerical values can be quite significant.

The specification for the project describes the required concrete strength class

How to mix brand and class

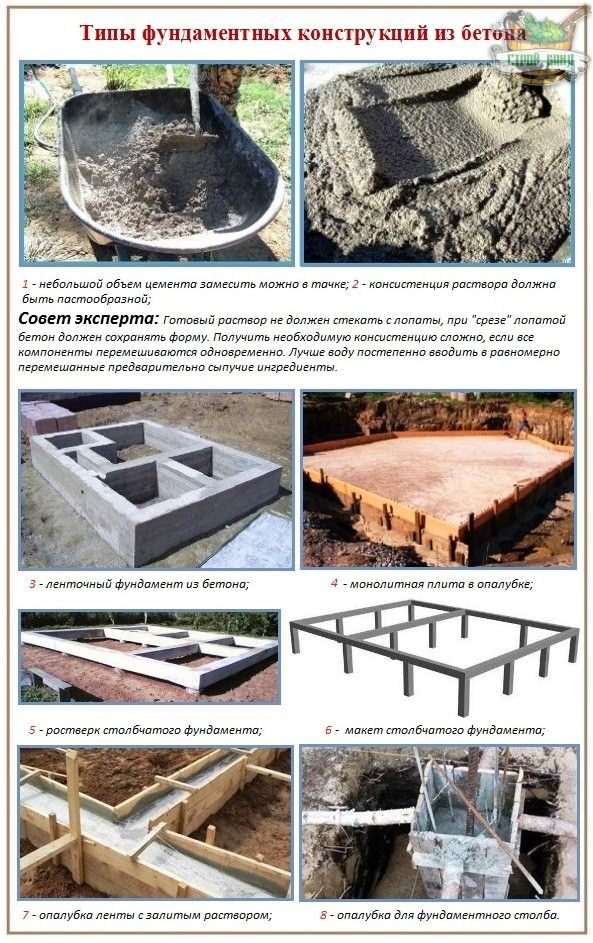

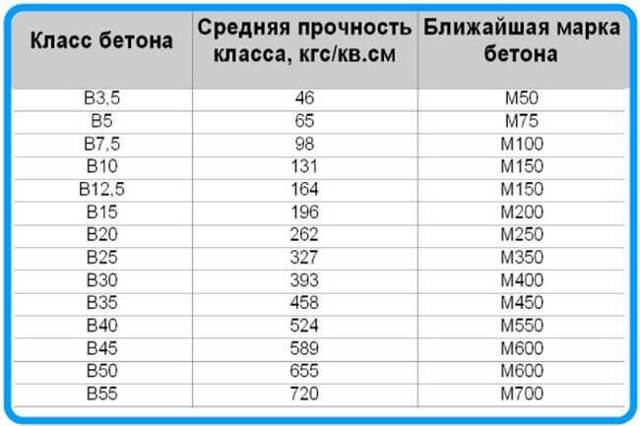

It is quite difficult for a non-professional builder to independently navigate these indicators. But what if you decide to fill the foundation with your own hands? To choose the right class of concrete for a strip foundation, and not get confused in the calculations, you can refer to the summary table.

| Concrete grade "M", numerical value after the letter | Class, "B", numeric value character field | Average strength, kgf / cm2 | Brand deviation from class,% |

| 50 | 3,5 | 45,8 | +9,2 |

| 75 | 5 | 65,5 | +14,5 |

| 100 | 7,5 | 98,2 | +1,8 |

| 150 | 10 | 131 | +14,5 |

| 12,5 | 163,7 | -8,4 | |

| 200 | 15 | 196,5 | +1,8 |

| 250 | 20 | 261,9 | -4,5 |

| 300 | 22,5 | 294,7 | +1,8 |

| 350 | 25 | 327,4 | +6,9 |

| 27,5 | 360,2 | -2,8 | |

| 400 | 30 | 392,9 | +1,8 |

| 450 | 35 | 458,4 | -1,8 |

| 500 | 40 | 523,9 | +5 |

| 600 | 45 | 589,4 | +1,8 |

| 700 | 50 | 654,8 | +6,9 |

| 55 | 720,3 | -2,8 | |

| 800 | 60 | 785,8 | +1,8 |

Other indicators

So, using the table, you can decide which brand to use concrete for the strip foundation.

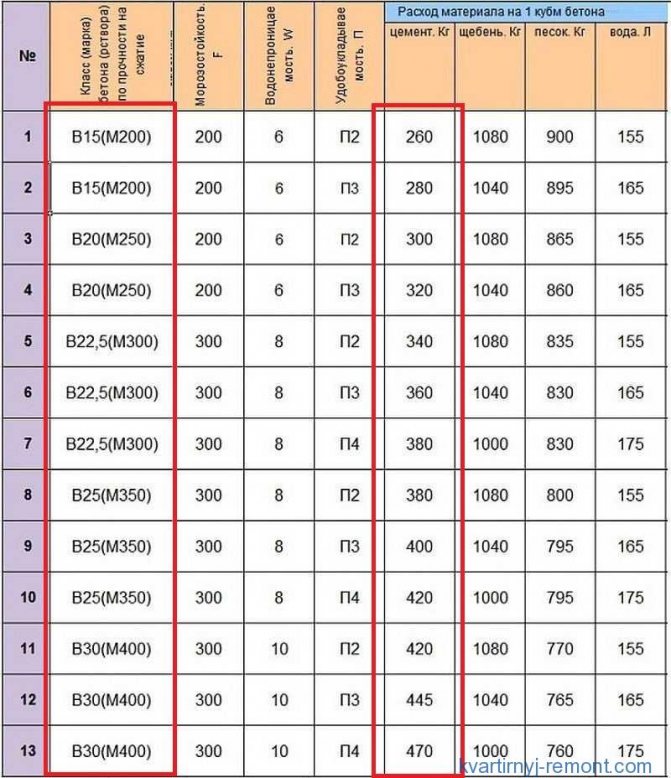

But in addition to class and brand indicators, when building, you should carefully consider other indicators of concrete characteristics:

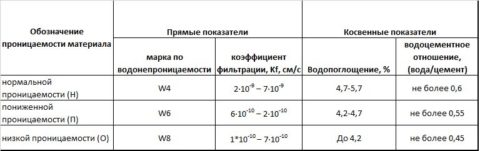

The letter "W" describes the resistance of the monolith to groundwater pressure. This indicator is especially important if the foundation is poured in conditions of their close occurrence. The numerical value of the indicator varies from 2 to 20. The larger the figure, the more stable the monolith.

The coefficient of water permeability of concrete, depending on the brand

The coefficient of water permeability of concrete, depending on the brand

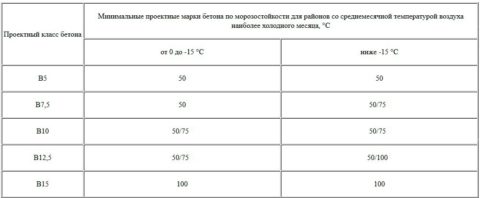

Letter "F" indicates the maximum possible number of freeze-thaw cycles and denotes the frost resistance of concrete.For each region, this indicator is different; in the conditions of central Russia, concrete with a frost resistance index F is suitable

Required values of frost resistance, in accordance with the strength class of concrete, depending on the natural operating conditions

Required values of frost resistance, in accordance with the strength class of concrete, depending on the natural operating conditions

Concrete composition for the foundation

Concrete is a material consisting of:

- Astringent. Most often it is cement (Portland cement). There is also non-cement concrete, but it is not used for foundations.

- Placeholders:

- sand;

- crushed stone or gravel.

- Water.

The grade of concrete is determined by the proportions of all these components, as well as by the conditions of its hardening (setting). Optimal conditions for concrete to gain strength are created at a temperature of + 20 ° C. Under such conditions, the process is very active in the first 7 days. During this time, concrete gains about 50% strength. With such parameters, it is already possible to continue construction further. The design strength, which is taken as 100% in design, under such conditions is recruited in 28-30 days. In reality, the process continues further, but at a very low speed. The strength gained after 30 days is not taken into account anywhere - it goes "in reserve".

At what strength can the construction be continued depending on the grade of concrete

With a decrease in temperature, the setting time increases significantly (at + 15 ° C it takes about 14 days to reach 50% strength). At a temperature of + 5 ° C, the process practically stops, and under such conditions, winter concrete is already needed - with appropriate additives and / or measures to increase the temperature (wrapped, heated in a mixer, heated through the formwork or heated directly by attaching heating cables to the formwork from the inside ).

Cement

For the manufacture of concrete, various types of Portland cement are used. The most common are:

- Portland cement - begins to set no earlier than 3/4 hours and no later than 3 hours after mixing. The end of the setting is in 4-10 hours.

- Slag Portland cement - after mixing, depending on the temperatures and parameters of the solution, it begins to set in 1-6 hours, finishes in 10-12 hours.

- Pozzolanic Portland cement - hardening begins in 1-4 hours, ends in 6-12 hours.

-

Alumina cement - begins to harden in 1 hour, finishes in 8 (but not later).

Any of these types of binder can be used to prepare concrete. Only you will need to take into account the setting time of the solution - you need to lay and vibrate it before hardening.

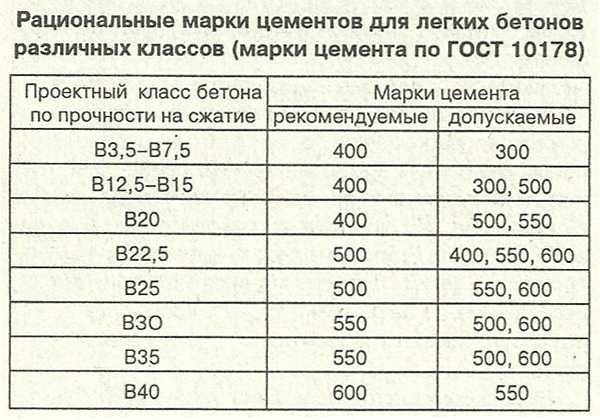

Recommended grades of cement for concrete

Placeholders

Aggregates also influence the quality of concrete. It is necessary to adhere not only to the recommended proportions, but also to quality indicators - moisture and graininess.

Sand

Depending on the size of the grains, the following types of sand are distinguished:

- large size of grains of sand 3.5-2.4 mm,

- medium - 2.5-1.9 mm,

- fine 2.0-1.5 mm;

- very small 1.6-1.1 mm);

-

thin (less than 1.2 mm).

For backfilling, mainly large and medium ones are used, less often small ones. The sand should be clean - not contain any foreign inclusions - roots, stones, plant residues, pieces of clay. Even the content of dust and silty substances is standardized - they should not be more than 5%. If you decide to "extract" the sand yourself, check the amount of pollutants.

To test 200 cc. centimeters of sand are poured into a half-liter container (can, bottle), filled with water. After a minute and a half, the water is drained, poured again and the sand is shaken. The procedure is repeated until the water is clear. If there is 185-190 cubic meters of sand left cm, it can be used - its dust content does not exceed 5%.

You also need to pay attention to the moisture content of the sand. All proportions are based on dry components. Even dry and loose sand has a moisture content of at least 1%, ordinary - 5%, wet - 10%

This must be taken into account when dosing water.

Crushed stone and gravel

Crushed stone is obtained by crushing rocks.Depending on the size of the fragments, the following fractions are distinguished:

- extra small 3-10 mm;

- small 10-12 mm;

- average 20-40 mm;

-

large 40-70 mm.

For the preparation of concrete, several fractions are used - so the distribution of crushed stone over the volume is more uniform, and the strength increases. The size of the largest fragments is normalized: it should not be more than 1/3 of the smallest size of the structure. With regard to foundations, the distance between the reinforcement rods is taken into account. SNiP also determines the amount of fine crushed stone: it must be at least 1/3 of the total volume.

Gravel has approximately the same fractions and sizes, but when it is used, the water-cement ratio (water / cement or w / c) increases by 0.05 (5% more water must be poured).

Water

For the preparation and watering of concrete, potable water is used. Including the one that can be drunk after boiling. Sea water can be used with Portland and alumina cement. Any other industrial water is not suitable.

Scope of application of different grades of concrete

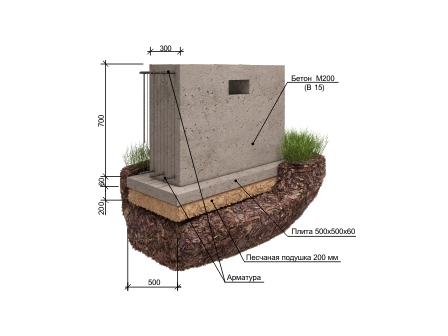

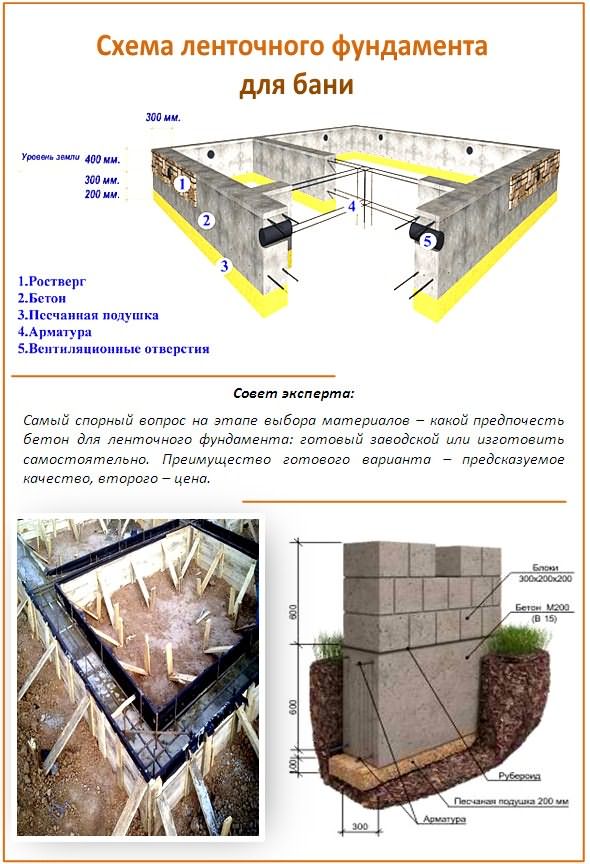

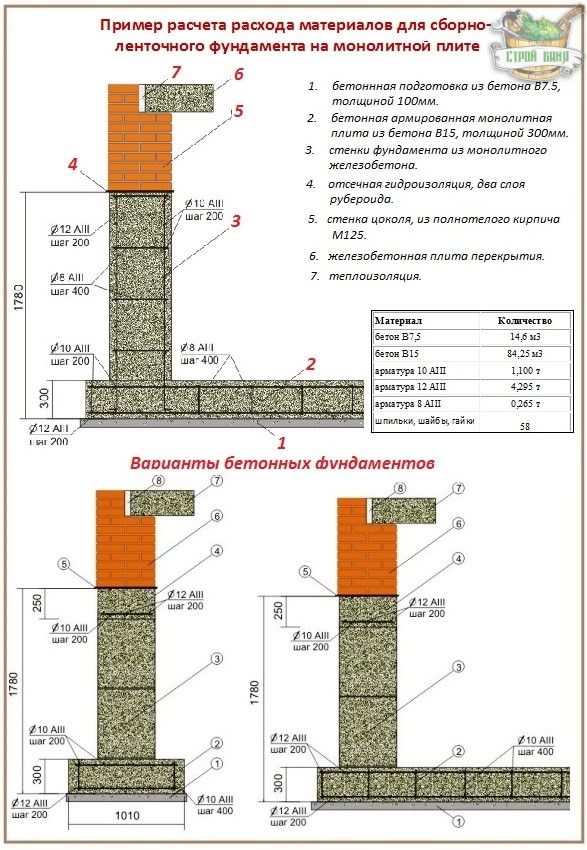

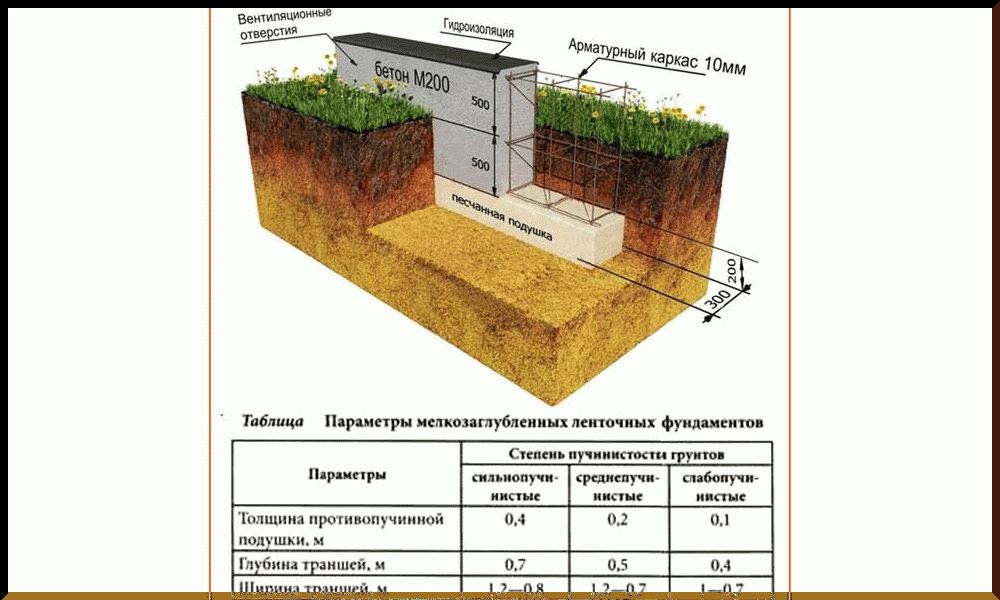

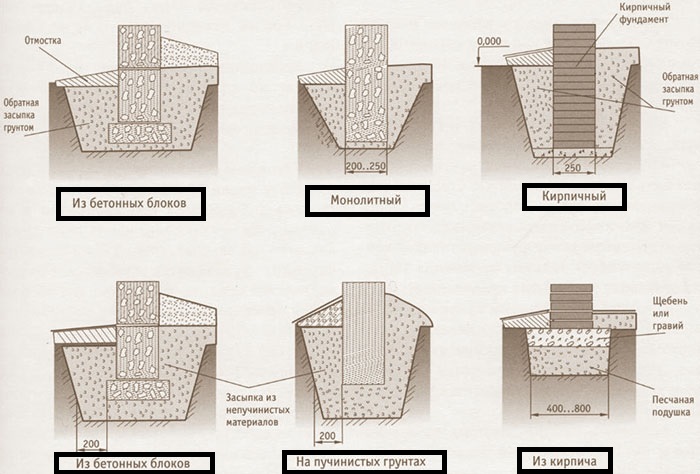

The device of concrete strip foundations is used for any construction technology. Panel, half-timbered, panel, frame, log cottages are based on MZLF tapes. Concrete, brick bungalows, chalets, townhouses stand on deep belts.

SNiP standards regulate the use of concrete grades for tape bases, depending on the technology of building a dwelling box:

- М150 - concreting of terraces, verandas, reinforced concrete cushions for the main foundation;

- М200 - terrace walls, foundations in low-rise construction, internal and external stairs, blind area of buildings;

- M300 - foundations of two-story, attic cottages, floors, monolithic partitions, walls, stairs;

- М350 - tape bases for difficult operating conditions (terrain with slopes, high ground level, soft ground);

- М400 - foundations in earthquake-prone regions, coastal strip, swampy areas.

Practice shows the sufficient strength of concrete grade M150 for light walls of one-story cottages without an attic made of aerated concrete, self-supporting insulated wire panels or erected using the half-timbered technology, frame construction. 90% of cottages use concrete M200, either hand-made or ordered from manufacturers.

Practice shows the sufficient strength of concrete grade M150 for light walls of one-story cottages without an attic made of aerated concrete, self-supporting insulated wire panels or erected using the half-timbered technology, frame construction. 90% of cottages use concrete M200, either hand-made or ordered from manufacturers.

The quality of the tape reinforcement is no less important than the choice of the concrete grade. In longitudinal chords, it is recommended to use corrugated reinforcement of 12 mm, horizontal lintels, vertical posts can be made from bars of a smaller section or from smooth reinforcement

When building up rods, the recommended overlap is 15 diameters; it is forbidden to build up armored belts at the corners (closer than 0.5 m).

M400 - M250 concrete can be poured into a strip formwork in several steps only using special technologies:

- vertical cutoffs;

- expansion joints at an angle of 45 °;

- other methods.

The curing times must be strictly observed for foundations. It is forbidden to pour into the formwork without heating (with the exception of non-removable expanded polystyrene blocks) at negative temperatures. In hot weather, it is necessary to protect the top layer from excessive evaporation (film, burlap or sawdust), a prerequisite is periodic moistening of the surface.

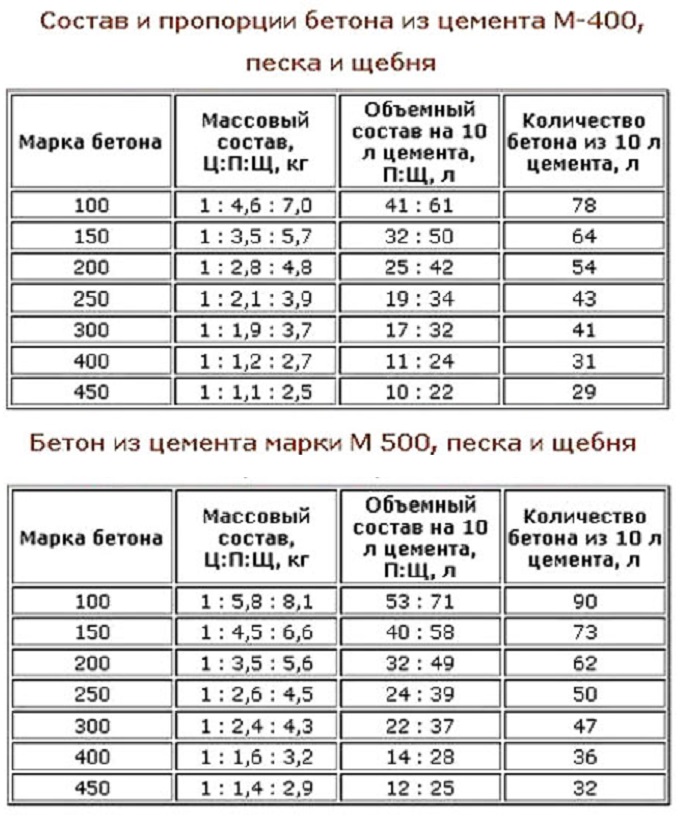

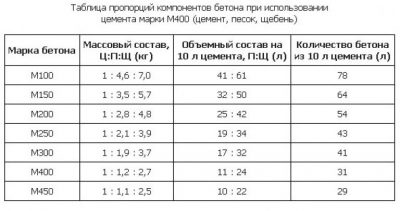

Self-calculation of the concrete grade

The strength of ready-made ready-mixed concrete depends on characteristics such as:

- cement grade;

- filler / binder proportions (crushed stone, sand / Portland cement, respectively).

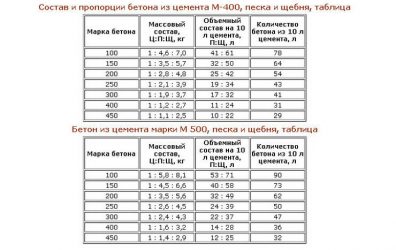

For example, a high-quality strip foundation of concrete grade M200 is obtained at a ratio of 4.8 / 2.8 / 1 (crushed stone / sand, cement, respectively). For other brands, SNiP standards recommend the proportions of crushed stone / sand:

- M500 - 2.5 / 1.1;

- M400 - 2.7 / 1.2;

- M300 - 3.7 / 1.9;

- M250 - 3.9 / 2.1;

- M150 - 5.7 / 3.5.

In each case, the ratio of cement for these mixtures is equal to one, all of them are given for the most affordable Portland cement M400 in the retail network. From the given data, the dependence of the increase in the construction budget with the increase in the grade of concrete is visible.

The nuances of choosing concrete for strip foundations in terms of strength

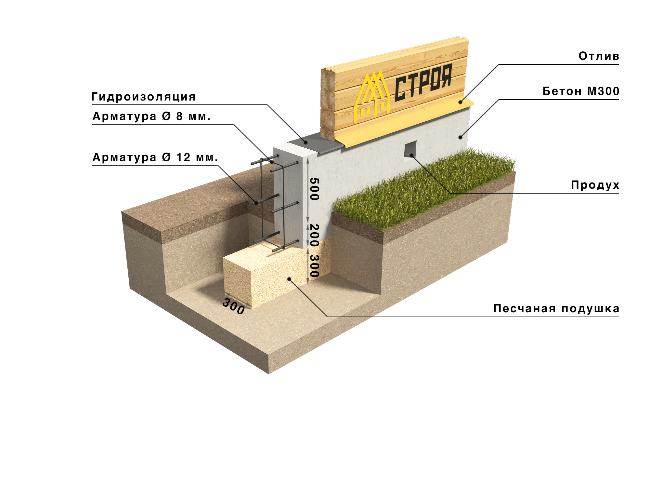

The concrete grade for strip foundations is selected taking into account the specified operating conditions. However, in difficult cases, additional protection of the bases from heaving forces, aggressive media is necessary.The main technologies for ensuring measures to increase the resource of the foundation are:

- Insulation of external walls - the tape is pasted over with expanded polystyrene from ground level to the bottom, the same material is used to line the bottom of the trench (0.7 - 0.5 m around the perimeter), the heat insulator allows you to preserve the geothermal heat of the bowels, preventing freezing, reducing the heaving forces.

- Waterproofing - by spraying polyurethane foam, pasting with roll materials, coating or impregnation with special compounds, avoids cracking during operation.

- Drainage - perforated corrugated pipes are laid around the perimeter of the building, collecting excess moisture from the soil, they have a common slope to the underground reservoir, from which the drains are periodically pumped out or used for the needs of the site owner.

- Blind area - prevents the penetration of melt, flood, rainwater into the base material.

- Drainage - necessary for collecting rainwater from the roof, drainage into specially provided stormwater reservoirs.

What determines the choice of concrete

When choosing a building mixture, the main criterion is the grade of concrete used for the device of the strip foundation. It shows the mechanical load that a material can withstand in compression. For example, the M200 marking means that for every 1 cm² of the base area, a load of 200 kg can fall. The binding material is cement, and sand and crushed stone are most often used as fillers.

Other factors are also considered when choosing a tape mix. These are climatic conditions, the more severe they are, the stronger and more frost-resistant the composition should be

Pay special attention to the soil - its density, moisture saturation

Foundation load

The foundation must serve as a reliable foundation for the entire service life of the structure. It is almost impossible to repair it, therefore, miscalculations made during construction will lead to irreversible consequences. And here the question of what grade of concrete is used for the strip foundation is key.

It is possible to select a grade of mixture for a base of this type only after calculating the load. It depends on the weight of the walls and floors, for which it will serve as a support. Less pressure is exerted by panel-board or small wooden structures, such as gazebos, baths or country houses. Brick or monolithic walls require grades with a strength index of M250.

Soil characteristics

Before starting work, it is necessary to carry out a geo-prospecting of the land plot, which will help to calculate the depth of laying, strength, and take into account other features of the foundation. Exploration will make it possible to find out the composition of soils, characteristics, depth of groundwater. When choosing what brand of concrete is needed for a strip foundation, it is necessary to take into account the type of foundation on which it will be laid - clay, rock or sand.

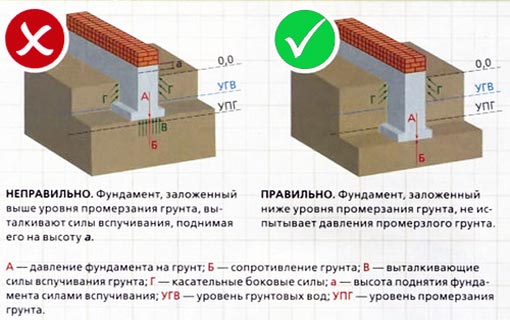

Studying the properties of soils, pay attention to the depth of their freezing in the selected region. The base of the foundation must be below the level of freezing of the soil, otherwise it will collapse

Depending on the moisture content of the soil, the degree of reinforcement with metal elements is calculated. On unstable soils, at the corners of the belt, where the load is maximum, reinforced concrete pillars are buried.

The most "convenient" soils are rocky and sandy with high density. They can use cheaper mixes with less cement. Clays and loams swell when freezing, so trenches are dug deeper, a more durable material is taken. On unstable swampy wet soils, concrete with increased water resistance is used, special piles or pillars are used.

Other factors

The characteristics of the solution also depend on other factors. One of them is the quality of the aggregates used to make the mortar. The used sand is free of foreign inclusions such as clay or organic elements.The water should be clean, without impurities and salts dissolved in it.

The strength is influenced by the fraction of crushed stone, it is advisable to choose as large as possible

It is also important what this filler is made of - the best option is granite crushed stone, but gravel with similar strength indicators can be used in the tape

Concrete composition

Concrete is a mixture of cement (plays the role of a binder), filler (sand, fine gravel particles or other components), additives (additives that increase frost resistance and other parameters of the finished structure) and water. The composition of such a mixture is periodically improved, more "recipes" for the preparation of better quality mixtures appear.

For example, for strip foundations, some people prefer to make rubble concrete. In this case, large rubble stones are used as a filler, of which at least 15% at the base. This saves on cement and creates a stylish base that does not actually need finishing. Such a foundation is not only more durable, but also much more resistant to low temperatures and the influence of groundwater. Thanks to these characteristics, such a foundation will last up to 150 years.

But, such a composition is more expensive, therefore, usually in private construction, more classic mixtures are preferred.

Standard composition

Before building a country house, fence, shed and any outbuildings, you should pay attention to the features of the components:

- Sand. Not everyone is suitable for durable concrete. It is necessary to choose exclusively cleaned sand (can be river or quarry). If there are impurities in it, then such a foundation will not last long.

- Crushed stone. This component gives strength to the mixture. As a rule, gravel is used with a fraction of 5-20 mm.

- Plasticizers. You can do without them. But, today there are many additives on the market that increase the life of the base, simplify the mixing process.

Healthy! It is recommended to use additives that increase the plasticity of the mixture if you are using a reinforcing frame.

Water. The main requirement is that it must be clean. If it is collected from a reservoir, then it is imperative to pass the liquid through a filter.

Of course, cement is also required for any foundation.

Required cement grade

The brand of cement and of the future concrete itself are designated by the symbol "M". The numbers after it define the mass load threshold. That is, if we mix cement M 200, then after the mass has solidified, such a base will be able to withstand up to 200 kg per 1 cm2 of surface. However, when it comes to concrete, Portland cement (PC) is usually used for it. It is a binder consisting of cement clinker, additives, and gypsum. There are many of its brands (from M 50 to M 600).

If you plan to build a foundation, then PC 200 or 400 is usually used for such bases. Portland cement 600 is much more expensive and is usually used in the construction of industrial or other specialized facilities. Therefore, PC 200-400 is sufficient to obtain concrete of the desired grade.

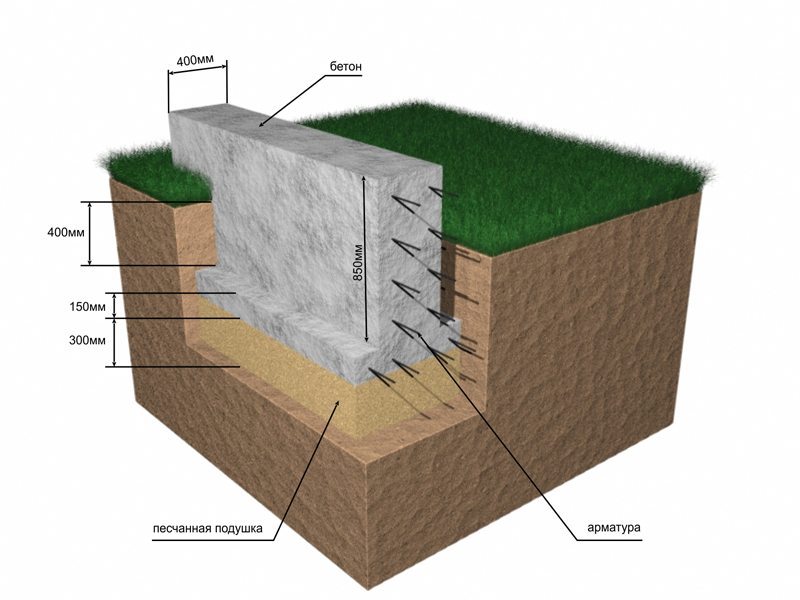

Foundation calculation

This procedure, as a rule, does not cause serious complications if approached with the proper level of responsibility. It involves the collection of load data and the study of the bearing layers of the soil. The thickness of the foundation for a two-story house will be determined depending on the ratio of these two components.

The video describes in detail how to calculate the base yourself.

The first step is to conduct a thorough study of the work area. The depth of the foundation for a two-story house made of foam blocks should be 35–55 cm higher than the average freezing depth.

Formwork and reinforcement

Such data are acceptable only if the living space is heated in the winter season.Otherwise, it is necessary to adhere to the set freezing temperature for a particular region.

The relative value of the width of the tape will be 25 cm. This value is approximate and will change during the calculation.

The next step is to calculate the pressure on the strip foundation for a two-story house. It is advisable to use the table below to determine the corresponding value.

| Construction type | Density (kg / m2) |

|---|---|

| Walls | |

| Brickwork (half brick) | 210–240 |

| Foam concrete houses | 170–180 |

| Log houses (d = 240 mm) | 130–145 |

| Houses from a bar (150 mm) | 11–125 |

| Overlap elements | |

| Attic (wooden beams) | 10–120 |

| Hollow concrete slabs | 30–380 |

| Reinforced concrete floors | 450–520 |

| Roof | |

| Metal tile, profiled sheet | 25–35 |

| Two-layer roofing material | 35–45 |

| Slate (comb height - 4 cm) | 50 |

| Snow load for the central regions of Russia | 100–120 |

The next step is to calculate the total weight of the strip slab. To do this, you must first calculate its volume, which is calculated using the product of length - L, width - A and height - B.

The resulting value is multiplied by the specific gravity of reinforced concrete, which is 2500 kg / m3. The end result is total weight. To calculate the total load - M - on the supporting soil layer, it is enough to add this value with the weight of the building.

Now it becomes necessary to set the optimal value of the base sole width - O. It is derived by the following formula: O = 1.3 * M / (L * R). A value of 1.3 serves as an indicator of the bearing capacity, and R is the density of the soil layer, which is indicated in the table below.

| Soil type | R |

|---|---|

| Clay with pebbles | 4,2–4,5 |

| Pise | 4 |

| Coarse sand | 6 |

| Medium-grained sand | 5 |

| Fine-grained sand | 4 |

| Sandy loam | 3,2–3,5 |

| Loam | 3,2–3,5 |

| Clay | 6 |

If the width of the tape is less than the approximate value, the final width will be the declared 20 cm. If, according to the results of calculations, this value has exceeded the original figure by more than 4–6 cm, it is necessary to re-calculate the base mass with a new value of the width of the tape.