Insulation of the pile base

Installation of insulation implies the erection of a frame (frame), directly to which the insulation will subsequently be fastened. The erection of this element, as a rule, is implemented in the following ways.

Watch the video instruction for insulating the basement:

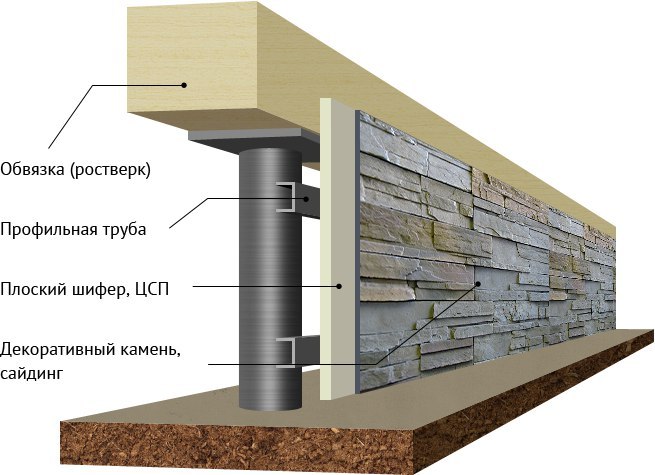

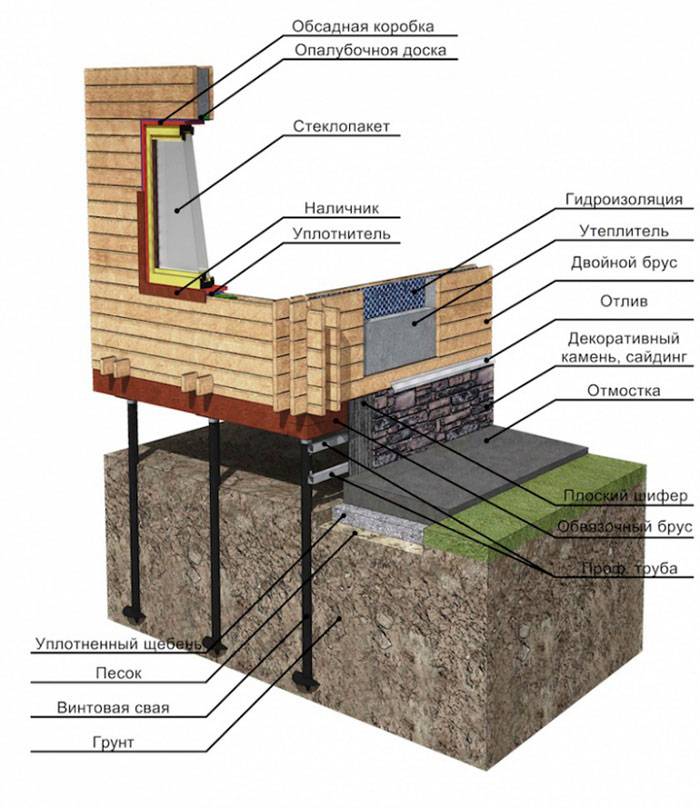

Insulation with siding or sandwich panels

Brickwork. By connecting each of the piles with a transverse beam, a certain frame is formed, along the perimeter of the base of which a trench with a depth of 20 to 50 cm is pulled out and poured with concrete. Subsequently, the resulting foundation is laid with bricks with a layer thickness of 1.5 - 2 blocks. Then, using a welding machine, a metal frame is constructed with a crate for the type of facing material: siding, sandwich panels, and their installation is performed.

Penoplex insulation

Insulation of the basement from the outside with polystyrene foam and expanded polystyrene

Insulation of the basement from the outside with polystyrene foam and expanded polystyrene

Penoplex (expanded polystyrene). By its nature, the presented material has high heat-insulating and sound-absorbing properties. Due to the moderate thickness of the slabs of 30-40 mm, the installation of penoplex significantly saves the interior space of the equipped basement of the house. The insulation process is as follows:

- along the perimeter of the finishing space, all cracks are filled;

- the leveled surface for the best adhesion to the sheets is treated with a primer composition;

- the boards are glued from the inside of the basement by using a special adhesive or foam (in the case of using foam, the foam sheets are pre-fixed with umbrellas to prevent their deformation at the time of foam swelling);

- docking slots are foamed;

- for the best insulation, polystyrene foam plates are mounted in several layers with overlapping joints;

- to ensure protection from the establishment of rodents, a special metal mesh with a small fraction is installed on the plates;

- from the inside, the insulated surface is sprinkled with soil or expanded clay.

Stages of insulation with expanded polystyrene

Insulation stages

Insulation stages

- The base is cleaned from dirt with a metal brush.

- A thoroughly cleaned surface is repaired, eliminating irregularities, chips and cracks.

- Several layers of waterproofing are applied.

- Polystyrene glue is alternately applied to each board, drops of glue are placed along the edges and in several places along the surface of the board. Allow the glue to dry a little, and stick it on the foundation, achieving a snug fit.

- When gluing each subsequent board, it is necessary to align the mounting grooves.

- Leave the glued material to dry completely (up to two days).

- Backfilling of the underground part of the base is carried out.

- Before gluing the base, first lay a non-combustible insulation 15 - 20 cm wide (on the upper part), separating the wood from the polystyrene.

- The insulation is fastened and glued, and then the plates are fixed using special fasteners: holes are drilled into which the dowels are driven all the way.

The third method is the most traditional and least expensive. With the help of expanded clay, you can insulate the base and space from the inside of the floor. A covered pillow made of this material absorbs well and removes moisture from the base. Expanded clay creates an air gap at the surface of the foundation, which provides good insulation and prevents heat loss and freezing of the base of the house. In addition, it additionally performs the function of waterproofing.

Construction of a basement frame mesh

Option number 1

This mesh can be made of wood or metal. Both structures also require waterproofing.The work is not difficult, just take into account that the crate cells should be smaller than the plates of the selected material for insulation, then its installation to the frame will not cause problems.

The basement frame is erected along the entire perimeter of the structure, if metal is used, it is welded and slightly buried in the ground. To give additional inviolability, the base of the structure is recommended to be poured with concrete.

Option number 2

The basement is also built of brick. Such work is quite laborious and requires a shallow foundation. The method is not very popular, as it requires spending on cement, facing bricks, sand and crushed stone. Another problem will arise - the inability to hide the piles, and it is not always possible to take out the masonry.

First, a trench is dug about 20 cm deep. Rubble is poured into it, which is rammed, then the operation is repeated with sand. The latter must be well moistened, but wait until it dries completely. Now brick is being laid according to the standard technology in construction.

Range of potential heaters

The following materials may be suitable for insulating the basement:

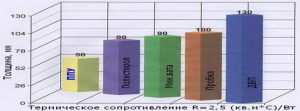

- Styrofoam. It has the most attractive price, which also has the other side of the coin - if you compare it with other heaters, then its thermal conductivity is quite high. Its strength also leaves much to be desired. The region in which the house is located also plays a role. For northern latitudes, the thickness of the slabs should be at least 150 mm, for middle latitudes - 100, and for southern latitudes - up to 50 mm.

- Mineral wool is a popular option, but it will require a waterproofing layer, it can be roofing material.

- Penoplex, unlike the first on this list, just boasts low thermal conductivity and sufficient strength, which has already brought many fans to its camp. In addition, rodents do not like Penoplex, and its moisture resistance is at a height. These advantages made it an "expensive thing", but it will serve for a long time.

- Polyurethane foam is the fourth in this list, but in fact it is the winner, since its seamlessness speeds up work at times. Not without its drawbacks: polyurethane foam strongly requires expensive equipment.

To determine the required thickness of the material, a heat engineering calculation is needed, which helps to determine the intensity of the cold entering the living quarters.

Insulation methods

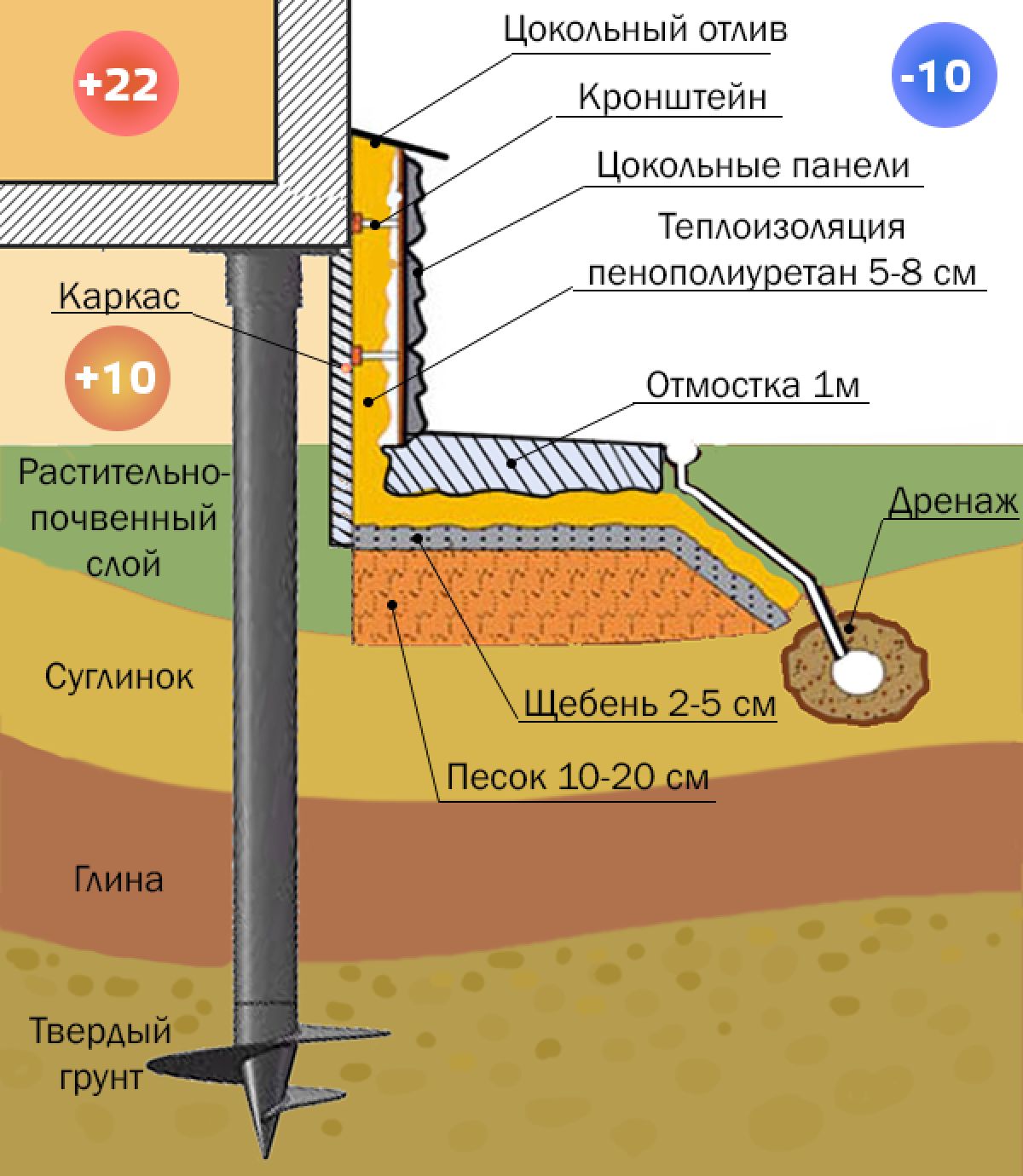

There are two options:

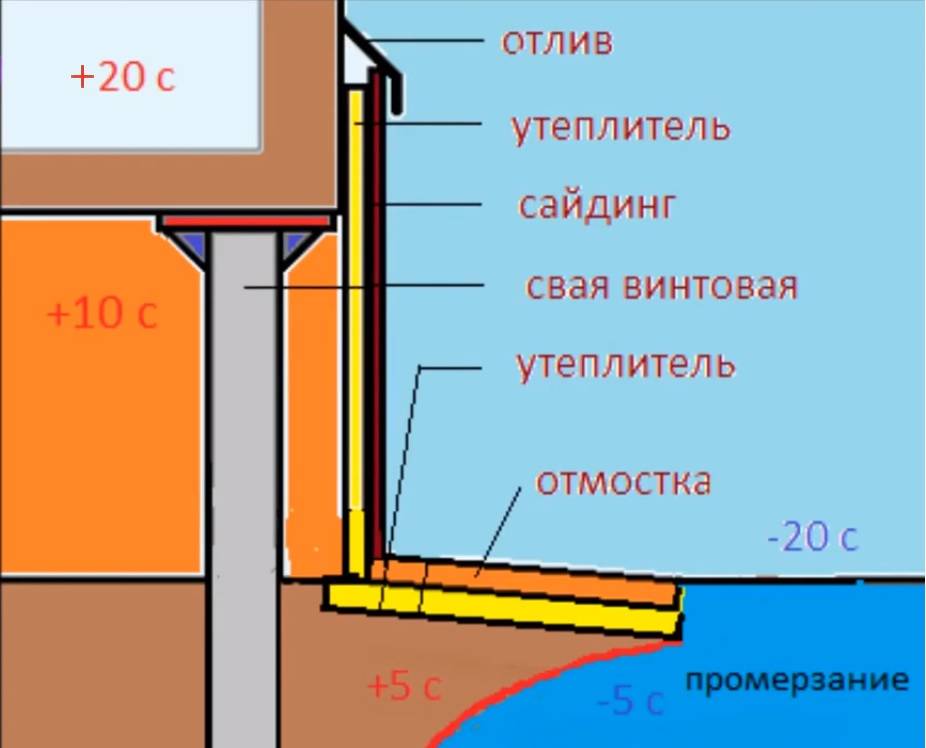

- The basement itself is qualitatively insulated, the internal atmosphere and the space of the subfloor of the house are communicated, as a result of which a sufficiently high temperature is kept in the latter. This method is suitable for owners of houses on metal (screw) piles and in the presence of a technical underground with the introduction of communications. There is a possibility of periodic maintenance of the metal parts of the foundation, fittings for entering communications, the danger of freezing of pipelines disappears.

- Continuous backfilling of the subfloor space with a heat insulator is made. Expanded clay is usually used, which does not rot and does not lend itself to external influences. The only problem with the material is that when it gets wet, it dries for a very long time, so it is necessary to ensure reliable waterproofing of the basement. This option is good for reinforced concrete (driven or bored) foundations that do not require regular maintenance. Continuous backfill allows you to get great savings on heating and excludes wetting of the floor of the first floor.

Overlapping (floor)

Floor insulation is performed in cases where there is no need to increase the temperature of the subfloor. There are no open pipelines with water, heating mains and other nodes that are demanding on the operating temperature.

Alternatively, a layer of insulation is laid, after which a screed with a floor heating system is poured. As a result, effective heat saving of the floor is ensured and the complete absence of condensation in the subfloor.

If necessary, it remains possible to periodically penetrate into it and service metal parts (apply an anti-corrosion coating).

All common materials can be used as heat insulators, but, taking into account the specifics, one should abandon the use of moisture-permeable types (mineral wool, ecowool, etc.).

The most successful choice would be:

- Styrofoam. The correct name of the material is polystyrene granular foam. It is the leader among thermal insulators due to the lowest price. It is a lightweight material that comes in the form of slabs of various thicknesses. Practically does not interact with water, does not rot, retains heat well, is easy to cut and process. The foam pellets contain carbon dioxide, so it does not support combustion.

- Penoplex. This material is called extruded polystyrene foam. It is the closest relative of foam, but it is made using a different technology and is a solid mass of solidified foam, and not glued individual granules. In all respects, it is somewhat superior to polystyrene, but has a higher price, so the demand for it is slightly lower.

- Liquid polyurethane foam. A material that allows you to insulate complex, curved and highly fragmented surfaces. It is applied by spraying, which requires special equipment. As a result, a sealed layer of insulation appears, absolutely resistant to the effects of water or biological manifestations, which reacts little to temperature changes. The only limiting factor is the relatively high price and the need for the use of special equipment.

Cladding

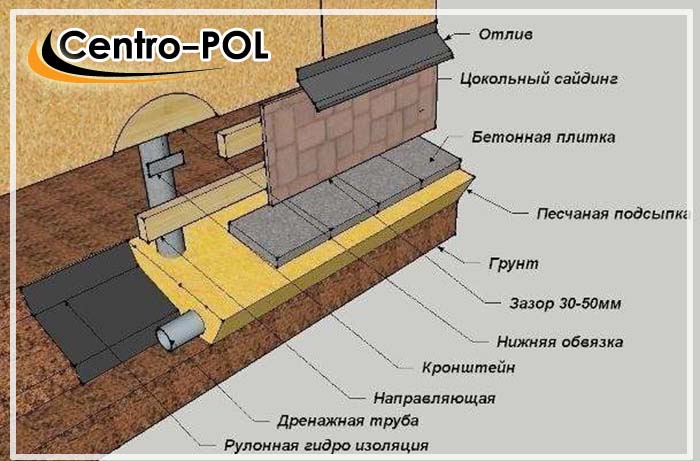

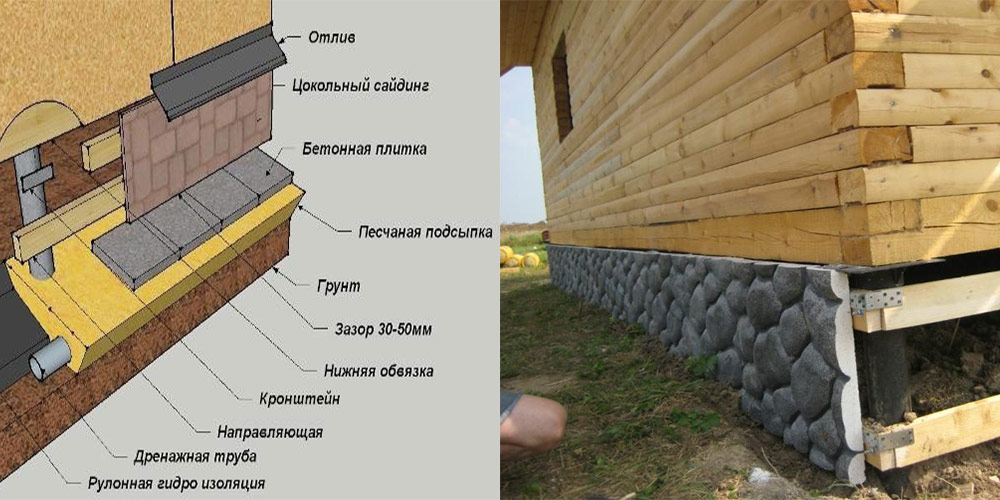

At the final stage, it will be necessary to carry out the lining of the basement. This is usually done with siding. Installation instructions are as follows. Along the perimeter of the house, it is necessary to fix the starting profile to the crate. It is located vertically, therefore it must be installed using a building level.

The panels are inserted with the lower part into the starting profile, and with the upper part they are attached to the crate. It is necessary to use self-tapping screws. At the final stage, additional elements are installed, namely corners and ebbs. When facing the lathing, it is necessary to provide for air vents that will be needed for ventilation of the underfloor space.

Internal floor insulation on a pile foundation

Insulation of the floor on the described base is carried out in several stages. The vapor barrier for the floor is laid from the outside over the entire area. Above is installed insulation of the type of expanded polystyrene, which is sheathed with boards. This floor can be used as a ready-made basement ceiling.

For hydro and wind protection, you can use modern moisture and wind insulation membranes. They are easy and quick to fit, but the cost of multifunctional items can put you off.

All elements of a wooden house on piles are treated with a compound with antiseptic properties

It is important not to forget about the vapor barrier for the floor. It can be a polyethylene film, which is laid on a layer of heat-insulating material

When installing steam and heat insulation, do not leave gaps between individual elements. This can lead to the formation of cold bridges. In this case, the insulation under the floor can quickly deteriorate during operation. For additional protection of the interior from the cold, chipboards, floorboards or plywood sheets, which do not conduct heat well, can be used.

Do-it-yourself insulation work

Usually a fake base (or, as it is commonly called, a pick-up) is a strip of sheet materials installed on a crate of bars.

For high-quality insulation, this option is not suitable, since it is necessary to provide not only a supporting structure for the heat insulator, but also to form a strong and reliable cut-off for water.

Therefore, it is necessary first of all to build a brick base and a high-quality blind area, equipped with a thermal break strip.

This approach will completely eliminate soil wetting in the area of the pile field and will create conditions for the full functioning of the heat insulator.

Decorative panels are sheets of basement siding glued to sheets of heat insulator (most often, penoplex). Installation of such panels allows you to combine decorative finishing and insulation in one procedure, which significantly saves time.

At the same time, the cost of purchasing panels significantly exceeds the cost of purchasing conventional heat insulators, and the quality of insulation is not the best. The option can be used in regions with relatively mild winters.

Installation is carried out as tightly as possible, without cracks or gaps. All detected gaps are immediately filled with polyurethane foam. The effectiveness of the insulation depends on the thickness of the foam.

In practice, the most successful slab size is considered to be 50 mm, but thicker sheets can be used in regions with frosty winters.

Penoplex installation is practically no different from the foam installation technique. The same materials and methods are used, the thickness of the foam is chosen, guided by the same considerations.

The efficiency of the material is slightly higher, but the main advantage is its strength.

The application of this material from the outside is carried out using special equipment. At the same time, it is possible to create a completely sealed layer of any thickness.

In this case, there are no cracks or gaps, the formed layer is absolutely sealed.

The material is convenient for warming uneven surfaces with a lot of protruding elements. Due to its high price, it has not yet become widespread, but users who have used this type of insulator highly appreciate its performance.

Can the foundation do without insulation?

Many people may have a fairly reasonable question: if we insulate the floor in the house, is it possible to do without the "fundamental" approach? In fact, thermal insulation can help with other important tasks. For example:

the house will look much prettier if you build a frame for the basement;

the very presence of a false base will save the building from an abundance of snow or water, which will undoubtedly choose a place under the house;

communications passing there will be protected from freezing, but here you will have to pay attention to them, insulating them additionally.

If the arguments are convincing, then it is worth going in search of suitable methods.

What are the insulation options?

Insulation of a house on piles consists of a whole range of measures that, together, successfully solve this problem. But before starting the struggle for precious warmth, you will have to evaluate your home from all sides.

Consider both its placement and the material and height of your pile foundation.

After analyzing all the initial data, you can apply the following methods:

- Engage in the construction of the basement, after the construction of the structure, insulate and decorate it in accordance with the tastes of the owners.

- If the first method is not feasible for some reason, then you will have to deal with external floor insulation.

- Carry out "total" insulation: both inside the building and outside.

Stages of warming with expanded clay

Insulation with expanded clay from the inside

Insulation with expanded clay from the inside

- Most often, wooden structures (and not only) are insulated with this material from the outside. The walls of the foundation are dug up and cleaned of the earth with an iron brush.

- Perform the necessary repair of damage with cement mortar, leveling the surface.

- Arrange a layer of waterproofing on the outside of the base in one of the available ways.

- The dug trench along the perimeter of the foundation is covered with expanded clay and a concrete blind area is arranged. This layer will prevent possible water ingress and siltation.

- Outside, the basement is plastered or insulated with plates.

- Backfilling the semi-basement space with expanded clay from the inside is a good and inexpensive way to insulate a house when replacing a subfloor or in front of a flooring.

The following order must be followed:

- prepare a sand pillow;

- cover it with a waterproofing layer to prevent the suction of moisture from the ground;

- pour expanded clay from above to the level of the subfloor.

Filling can only be carried out 40 cm from the inside of the perimeter of the base. In this case, first a well-fixed fixed formwork is installed from scraps of boards or slate, and then expanded clay is backfilled between it and the base.

Insulation of the basement

Insulation of the basement of the pile foundation allows you to make the interior space of the premises more comfortable. First, you need to build a base, and then proceed with insulation in any of the existing ways. The device of the base is allowed in certain ways. You can lay a wall that will cover the row of screw piles. The height of the wall should be equal to the length of the line from the blind area to the lower belt of the harness of the house.

You can arrange a pick-up, which is a fake base. It will be arranged on a frame base and will have an outer cladding. If you chose the first method, then the laying must be done in half a brick. The items will be red ceramic, as they are the most resistant to high humidity.

To begin with, you must prepare the foundation, for which a trench is dug around the perimeter of the building. The depth and width will be 0.3 and 0.25 m, respectively. The bottom is well leveled and filled with coarse sand. The layer thickness should be 10 cm. After that, the sand mixture is tamped and moistened.

A reinforcing cage of longitudinal and transverse rods is laid on such a base, after which the concrete mixture is poured. After the concrete solution has hardened and the strength has been gained, you can begin to build a brick wall.

Floor insulation

Floor insulation in a wooden house

Floor insulation in a wooden house

An important feature when improving the thermal insulation properties of a building is floor insulation. To accomplish this task, you must perform the following steps:

- from the inside of the building, the floor slabs are covered with a vapor barrier;

- the selected type of insulation is fixed;

- the installation of the finishing layer from the wooden lathing and the installation of the floorboard are carried out.

Such an insulated floor can subsequently be used both as an equipped basement floor ceiling, and as the only possible option for insulating a house.

The video below shows well how to insulate floors using the example of a frame house.

In conclusion, I would like to note that the correct insulation of the pile foundation will allow in the future to forget about the problem of cold floors forever and will significantly save the budget when heating the house. And strict adherence to the proposed instructions and high-quality installation of heat-insulating sheets will largely ensure the reliability and durability of the building.

Why carry out insulation

Indeed, the question arises: is it necessary to insulate the pile foundation? After all, he digs deep into the ground and he is not afraid of swelling. But vulnerabilities remain that require a special solution:

- If a reinforced concrete grillage is being poured, this structure itself is a conductor of cold at low temperatures. It will absorb significant amounts of heat, which will have to be replenished by increasing the cost of heating the house;

- If the house is built on a metal or wooden grillage, everything would be fine, but there is a lot of space in the underground space that is not protected from blowing winds and frosts. You can use multi-layer insulation, but it is better to completely cover the base with an insulated structure;

- If engineering communications are provided in the house, they will pass precisely through the underground space under the house. Therefore, thermal insulation of the pile foundation is required to prevent freezing of the pipeline;

- Outwardly, the house will look much more spectacular. The closed basement can be beautifully finished on the outside to create a single finished home design.

Final work

Completion of work on insulation of the foundation

Completion of work on insulation of the foundation

The basement of a building is a very important component of any structure.

It needs to be given special attention due to the regular impact of the environment on its structure. The cladding material should have the following quality indicators:

- low thermal conductivity;

- reliability;

- solid adhesion;

- sufficient wear resistance and strength at the same time;

- low hygroscopicity.

Materials that work best:

- ceramic granite or clinker slabs;

- artificial or natural stone;

- profiled sheets;

- brick;

- decorative or mosaic plaster;

- siding or PVC panels.

To protect the plastered layer, it is additionally coated with acrylic, water-based, silicone, alkyd or oil paint. To make the finishing of the plinth inexpensive, you should opt for plaster. But it must be borne in mind that such a finish is short-lived and it can easily be damaged by any object.

Experts do not recommend using enamel for painting. It is not environmentally friendly, and besides, it does not let the air in.

Warming methods

Comparative characteristics of heaters

Comparative characteristics of heaters

- Insulation with polyurethane foam

- Warming with polystyrene, polystyrene and polystyrene foam

- Warming with expanded clay

The first method is the most expensive and most modern. The new technology makes it possible to achieve good thermal insulation properties, but the work will require the participation of specialists. However, the rather high cost fully justifies itself. Insulation with this material can be performed outside and inside the foundation of the house. The work is carried out quickly and does not require special preliminary preparation. You just need to clean the base and repair cracks and chips.

The second way is insulation ... The material is a modification of polystyrene with good strength and moisture resistance. Polystyrene is supplied in boards of various densities and thicknesses. This is quite convenient, since it makes it possible to choose the optimal thermal conductivity of the insulation.

... The material is a modification of polystyrene with good strength and moisture resistance. Polystyrene is supplied in boards of various densities and thicknesses. This is quite convenient, since it makes it possible to choose the optimal thermal conductivity of the insulation.

Pasting the foundation with expanded polystyrene sheets from the outside is one of the most common ways to insulate the foundation of a house. The foam structure of the material retains heat well and practically does not allow moisture to pass through.

The lack of material is its flammability, which is not relevant when it comes to insulating the buried part of the base. In the case of selecting plates for insulating the basement from the outside, it is necessary to select a material for insulation with flame retardant additives.

In Russia, plates with a thickness of 5 cm are most often glued. The exception is basements, in which a certain temperature must be maintained. In this case, a material of 10 cm is selected. To insulate the corners, thicker plates are laid (3 or more centimeters). This is due to the fact that the freezing of the foundation begins with them.

Warming options

Insulation of the foundation made of screw piles with brickwork

Insulation of the foundation made of screw piles with brickwork

Before carrying out work on the insulation of the foundation of the pile-screw type, a number of essential points should be assessed: the features of the building, its location, the height and material of the piles. Based on these factors, the base can be insulated using the following methods:

- External cladding. The whole point lies in the construction of the frame of the basement floor from the surface of the earth to the beginning of the floor slabs. Upon completion, depending on the climatic characteristics and the financial well-being of the owner, the insulation is installed along the perimeter of the frame and decorative finishing is performed. The relevance of the presented method especially increases with a small distance of the floor from the ground.

- Outdoor floor insulation work at home. There are often times when, due to the peculiarities of the structure, the characteristics of the soil, the excessive difference between the levels of the floor and the ground, it is not possible to insulate the base in the first way. In this case, it is more advisable to carry out floor insulation from the outside.

- Complete finishing. It includes both internal and external work to insulate the foundation and floor slabs.

The presented method in the course of its implementation is divided into the following stages:

The presented method in the course of its implementation is divided into the following stages:

- waterproofing measures;

- construction of a frame for the basement;

- installation of heat-insulating material;

- internal insulation of the basement;

- floor insulation.

Conclusion

The pile-screw foundation is easier to build, but requires insulation work. As a heater, you can choose both dense and liquid materials, each of which has its own advantages. If you carry out thermal insulation in accordance with the rules, you can get a warm and comfortable home with less construction costs.

Often, it is more correct to limit the insulation by cutting off the overlap of the first floor (zero level) in order to reduce heat loss inside the house and at the same time provide ventilation and free access to the supporting structure.

In other cases, other measures are needed to maximize the effect. But in any situation, first of all, you should find out whether there is an urgent need to install a heat insulator, whether this action will have positive results.

Otherwise, instead of a beneficial effect, only a waste of time and materials will be produced.

How to achieve the maximum energy saving and reliability of the building, insulate the pile foundation, and even achieve the maximum possible resource of the house? To do this, you should, first of all, carry out a complete design of the house and foundation before construction, and not "solve problems as they arise."

Before proceeding with the insulation of the foundation of a house built on a pile foundation, you need to decide on a way to implement the idea. There are only three most suitable methods. It is possible to achieve the maximum efficiency of thermal insulation by combining at least two of them.

Conclusion

House with insulated foundation

House with insulated foundation

In the process of erecting a wooden house, it is imperative to insulate the foundation. If this is not done, then the internal insulation of the building will not give special positive results due to the presence of cold bridges at the base. This is especially true for pile and columnar foundations. If you invest relatively small funds in such manipulations aimed at improving the performance of the base of a house made of wood, then in the future this will make it possible to save on utilities and enjoy comfort and coziness.