Calculation by calculator

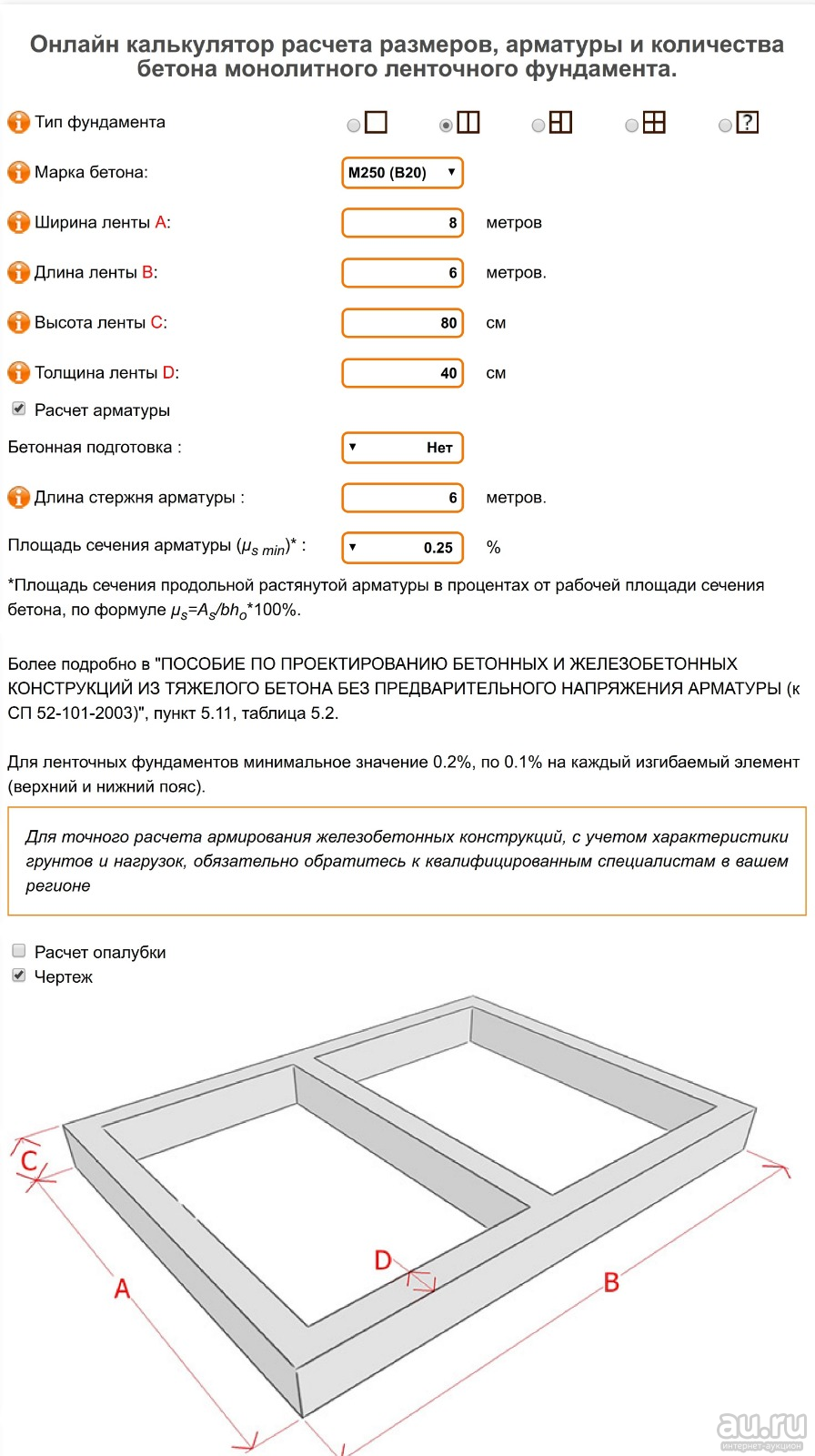

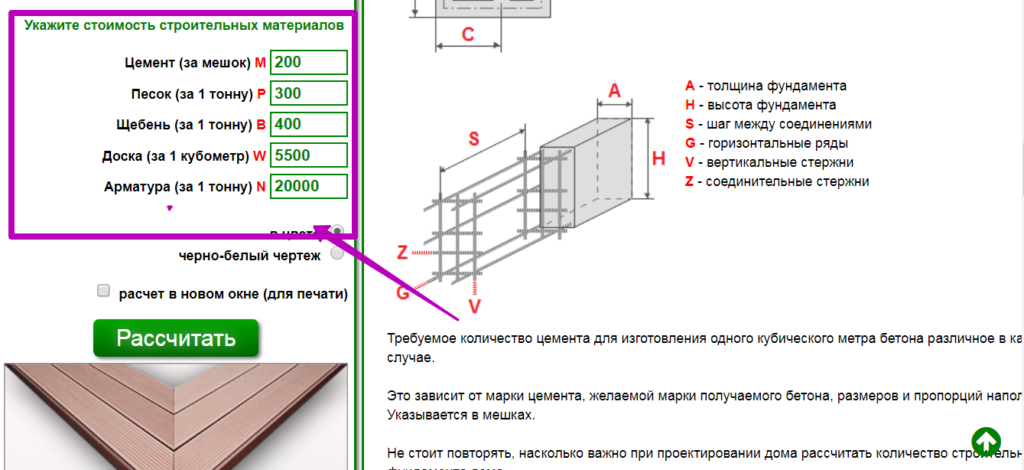

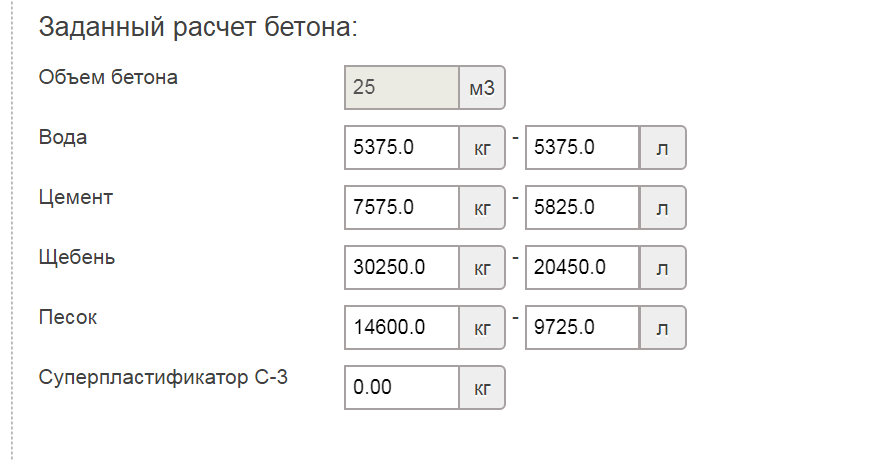

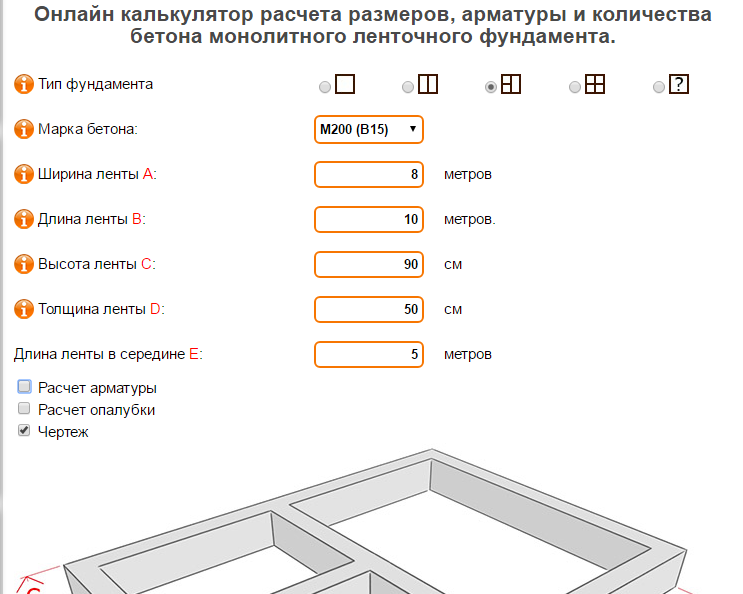

There is a special program: online concrete volume calculator. You just need to fill in the data in the table, there are explanations for each action. You can calculate how many materials you need for concrete, sand or crushed stone, for example.

A convenient way to calculate the volume of concrete and its binders. It is also possible to calculate for a single batch or even a bucket. Of course, this calculation will be approximate, unambiguously, you need to try to knead and look at the result.

This is for manual kneading of all ingredients. During production mixing, all indicators are, of course, more accurate. Using the calculator, you can also save your time, you do not need to display all the calculations by the formulas yourself. In addition, the margin of error is minimal when calculating online. No one wants to overpay if the error is in the big direction, and then look for a place where this concrete can be identified. And when counting down, of course, you don't want to call the concrete mixer several times and pay extra for the delivery of concrete. Many calculators have hints.

How many cubes of concrete do you need for a foundation?

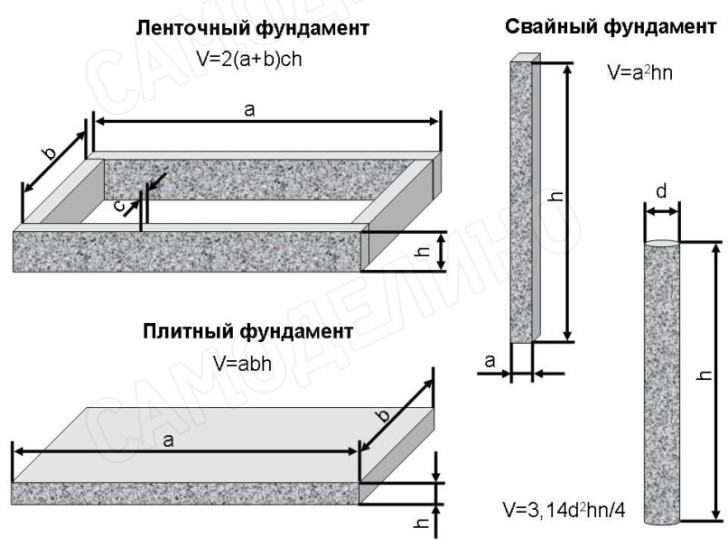

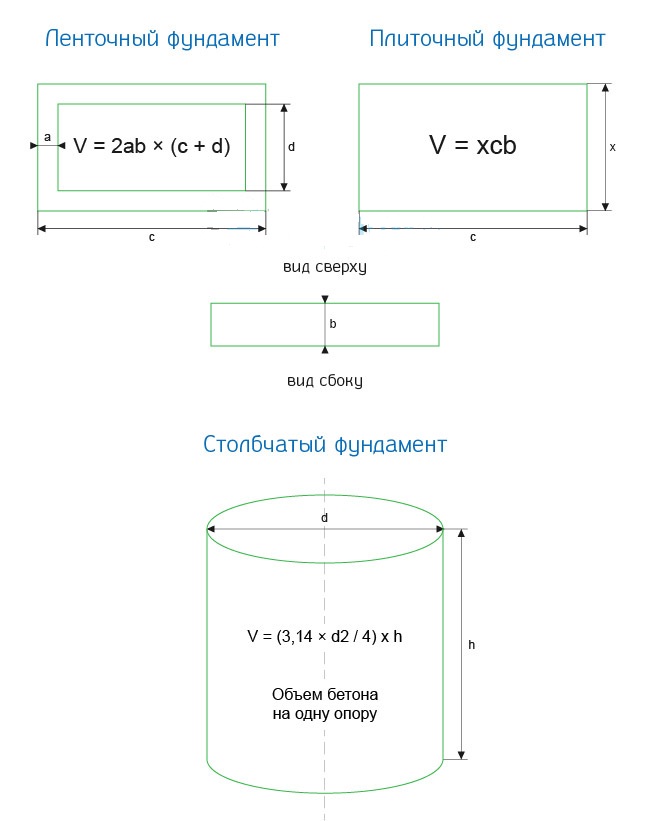

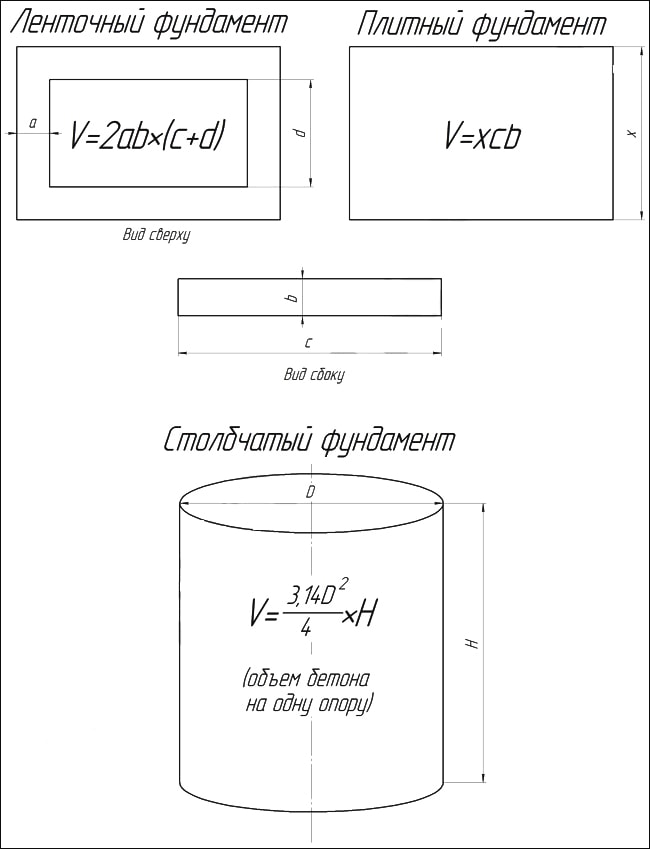

For calculating the number of cubes concrete, many use an online calculator. But you can also do it yourself, using the formula for the volume of concrete to calculate. First you need to consider what foundations are, and, based on their composition, choose a specific formula.

The foundation can be: tape, pile and slab, there are also many other types of foundation, but it is in these three that concrete is used for pouring.

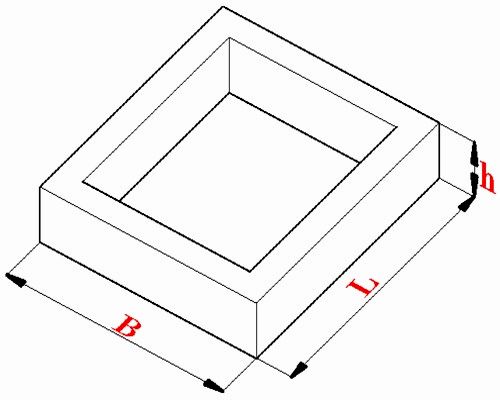

Formula for strip foundations. Before making a calculation, you need to know the width and height of the foundation tape. After that, we multiply the width by the height and get the volume of concrete needed for pouring. It looks like this: V = S * L, where V is the volume of concrete, S is the cross-sectional area, L is the length of the foundation tape. To get the S value, you need to multiply the width of the tape by the height.

For example, given the values: 50 cm - width of the tape, height - 180 cm, length - 49 m. Solution: V = 49 * 0.5 * 1.8 = 44.1 cubic meters of concrete.

Formula for a pile foundation. S = 3.14 * r, S is the surface area of one pillar, r is the radius of the pile.

V = H * n, where H is the height of each foundation pillar, and n is the number of pillars. For example, the diameter of the post is 20 cm, the length is 2 meters. You will need 0.0628 cubic meters of concrete.

Formula for slab foundation. V = S * H. S is the total area of the entire slab and H is the thickness of the slab. For example, for a slab 5 m long, 5 m wide and 0.15 m thick, you will need: V = 5 * 5 * 0.15 = 3.75 cubic meters of concrete.

Concrete rings

What is precast concrete? These are reinforced concrete products. Concrete rings are made of reinforced steel and concrete. The purpose of these rings is to build wells, this is its frame. You can also calculate the volume of concrete in rings of reinforced concrete products by accessing Internet resources, using various online calculators for counting. You only need to know the height, diameter and thickness of the ring.

But there is also a formula for self-counting. It looks like this: V = H * S, where H is the height of the ring, S is its area. To determine the area, you need to calculate the parameters of the outer circle, for this one second of the number "pi" is multiplied by the diameter and 2. It looks like this: S = 1 / 2π * D * 2. Then, using the same formula, you need to calculate the inner circle, and then the area of the inner circle is subtracted from the area of the outer circle, and we get the parameters of the ring.

What to look for when building a foundation

In some cases, the cost of installing a foundation foundation reaches a third of the cost of the entire construction, so the desire of some developers to save money turns into sad consequences. There are also mistakes due to inexperience and negligence of the performers. We will briefly list what should not be allowed when constructing a foundation:

1. Inconsistency of the base structure with the type of soil on the building site.Strip foundations, in particular, are set up on stable, dry soils. On watered soils, pile or slab structures are preferable. If there is no design solution, specialists should recommend the type of foundation.

Wall cracks from foundation settlement

2. Incorrect arrangement of the sole under the strip foundation. Often, the sole is arranged casually, because unscrupulous builders do not consider it necessary to carefully carry out work, the result of which is difficult to control. As a result, the distribution of the load on the sole turns out to be uneven, the foundation “creeps” in it, and then cracks appear in the constructed building.

3. Incorrect installation of the formwork and, as a consequence, an insufficient outer layer of concrete in order to guarantee the covering of the reinforcement cage, corrosion of the reinforcement. Insecure formwork fastening.

4. Lack of calculation of the cube of concrete. Such a calculation must be done when pouring it yourself. Since the constituents of concrete have different properties, the cube of concrete should be calculated in order to accurately determine the volume of materials for the foundation device.

5. Inaccurate observance of the geometry of the structure. Uneven corners in rooms are not the biggest nuisance that can be the result of irregularities. The consequence of such an error may be, for example, a shortage of the length of the slabs for the floor device.

6. Lack of reinforcement or "economy" on diameters and quantity threatens that the foundation will not withstand the load.

7. Incorrect dressing (or lack thereof) of foundation blocks when constructing prefabricated types of foundations.

As a measure - a bag

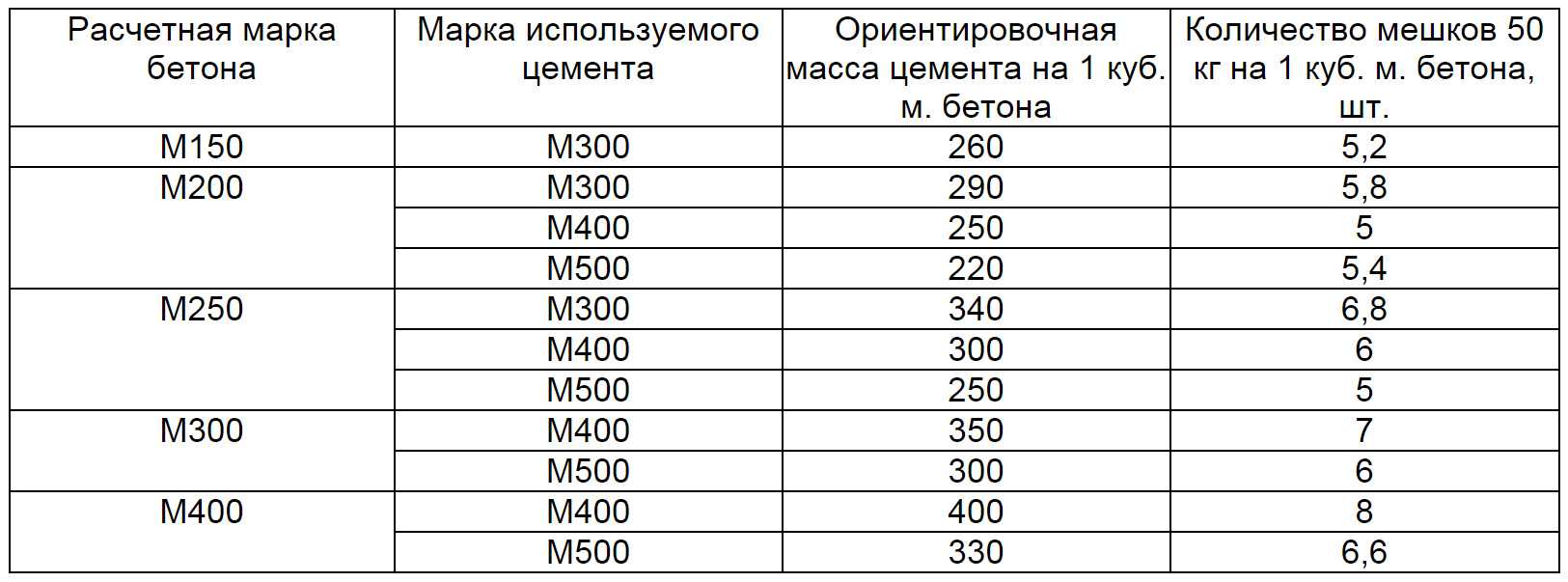

In order to simplify the calculations, buy building material in 50 kg bags.

It is better to buy building material in bags, packaged in 50 kg. This will make your calculations easier. For example, to make M100 out of cement, you will need 166 kg, or 3 bags plus 16 kg. And for the M150 brand, 205 kg or 4 bags and another 5 kg are required.

It is cost-effective and very convenient to use the bag as a kind of measuring device. For example, some builders make a mortar like this: 1 bag of cement hardener, 5 bags of rubble, and 3 bags of sand. The result is a high quality solution.

From the lessons of mathematics it is known that in 1 cube there is 1,000,000 cm³. Consequently, in one part 111 111 cm³, while in 1 cm³ 3 g of cement, thus, the consumption per cube of concrete is 333 333 g or 333 kg.

- grade M-450 - 469 kg;

- M-400 brand - 417 kg;

- brand M-300 - 319 kg;

- brand M-250 - 300 kg;

- brand M-200 - 241 kg;

- brand M-150 - 205 kg;

- brand M-100 - 166 kg.

The rate of cement input per cube of concrete.

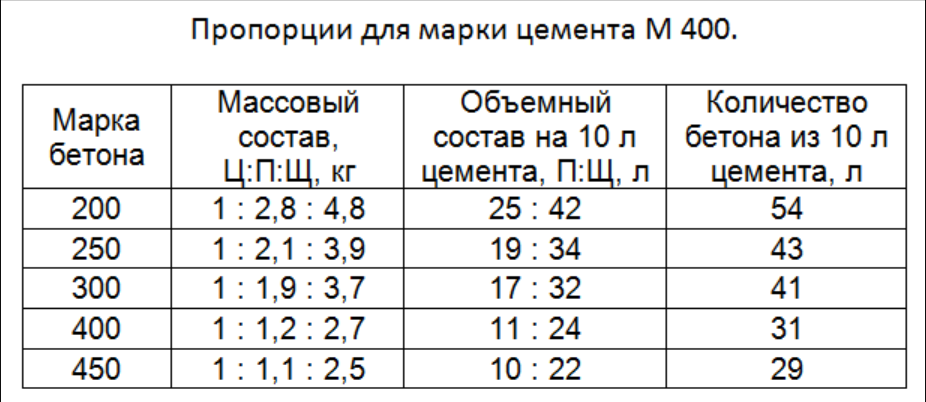

In the manufacture of concrete mortar, cement of grade 400 is mainly used as a binder. When using a lower grade, its amount is increased. So, for example, when using the M-300 brand, the amount of cement should be increased by 30%.

To make a concrete mixture, the water must be absolutely clean, without any admixture of oil and other foreign elements. It is rather difficult to determine the required amount of water in advance, because the moisture content of sand and gravel, as well as the moisture demand of cement, is important here. The required volume of water is determined already in the process of mixing the concrete mixture. To obtain medium-plastic concrete with 20 mm crushed stone particles, 205 liters of water are required.

For the production of high-quality concrete, it is necessary that the components (sand and crushed stone) are clean and the cement fresh. It is advisable to wash the crushed stone from particles of earth and clay, and carefully sift the sand using an inclined mesh with cells of no more than 1x1 cm, it is better to rinse if possible.

It is better to use sand for concrete clean, coarse, without unnecessary inclusions of clay, silt and organic particles. To exclude the ingress of foreign particles into the solution, it is advisable to sift the sand in advance. The strength of the concrete solution depends on how clean the sand is. The ingress of dirty sand entails an increase in cement consumption (from the standard rate by about 10-20%).

It is better to take small aggregate (crushed stone) (with a fraction of 5-20 mm). Good results are obtained by using crushed stone from natural rocks, crushed or small river gravel.

Now we know how much cement is needed to prepare 1 cube of concrete. When calculating the amount of building materials, the main thing to remember is that the higher the planned load, the higher the cement grade is required.

Ivan, in this case, you need to push off from a bucket with a volume of 10 liters. Fill a full bucket with sand and add 1/3 of the cement; everything will be mixed with 10 liters. or.

October 16, 2015

How is the calculation of ready-made concrete for 1 square meter of a 5 cm thick screed? How much sand and cement is required for this? So as not to buy too much. Want.

12 october 2015

For different brands of concrete, if measured by volume, then only the ratio of sand and crushed stone to cement changes, and exactly half of the volume of cement is always taken water.

20 October 2015

Ivan, in this case, you need to push off from a bucket with a volume of 10 liters. Fill a full bucket with sand and add 1/3 of the cement; everything will be mixed with 10 liters. or.

October 16, 2015

How is the calculation of ready-made concrete for 1 square meter of a 5 cm thick screed? How much sand and cement is required for this? So as not to buy too much. Want.

12 october 2015

For different grades of concrete, if measured by volume, then only the ratio of sand and crushed stone to cement changes, and exactly half of the volume of cement is always taken water.

A few additions: 1. If you need to perform high-quality waterproofing with liquid rubber, it is advisable to apply geotextiles over the entire surface. Consumption.

23 september 2015

How and how to make the upper border of the foundation cladding (natural stone, slab)?

Copyright 2014–2017,.

- foundation work

- Reinforcement

- Protection

- Instruments

- Mounting

- Finishing

- Solution

- Payment

- Repair

- Device

- Foundation types

- Tape

- Pile

- Columnar

- Platen

- Other

- About the site

- Questions to an expert

- Editorial staff

- Contacts

How many bags of cement do you need per cube of concrete?

It is at this stage that it is usually required to determine how much cement is in a cube of concrete.

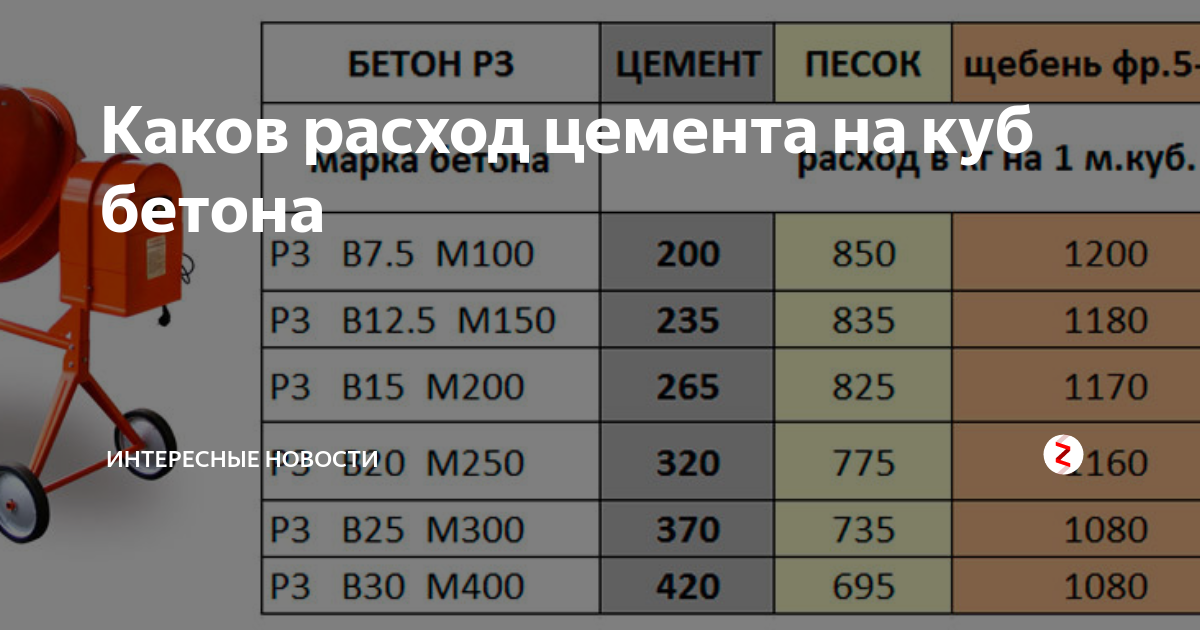

Today, there are a large number of concrete grades that differ in their composition, or rather, in the volume or mass ratio of its constituent components. For example, to create 1 cubic meter of 100 grade concrete, 200 kg of cement is required, to create 1 cube of 400 grade concrete, 360 kg of cement is required.

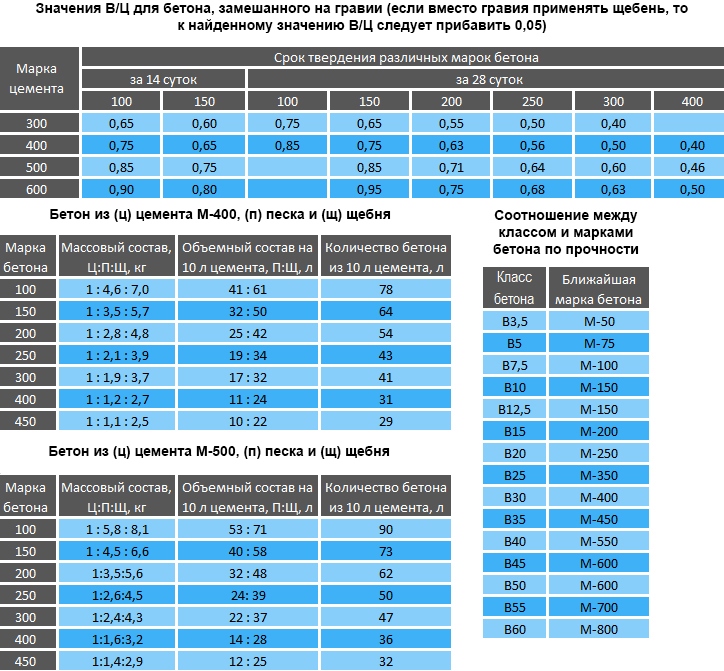

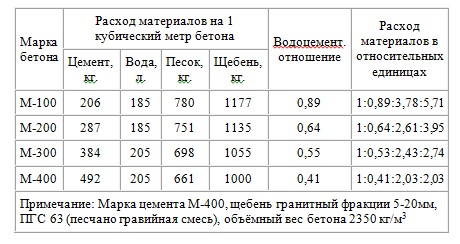

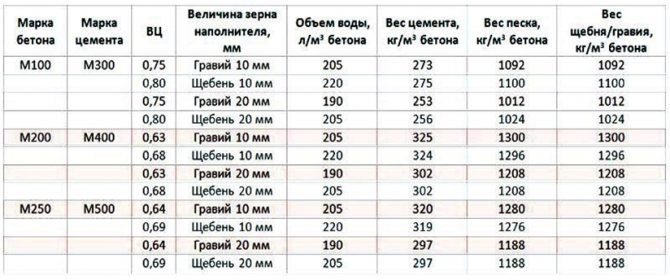

There are special tables from which you can understand not only how much cement per cube of concrete is required, but also the percentage of other concrete components in the finished composition.

So, for example, for the most running grade 300 concrete, it is necessary to mix 382 kg of M400 cement, 705 kg of sand, 1080 kg of crushed stone and 220 liters of water. For concrete of 100 brands, you will need 214 kg of cement (M400), 870 kg of sand, 1080 kg of crushed stone and 210 liters of water.

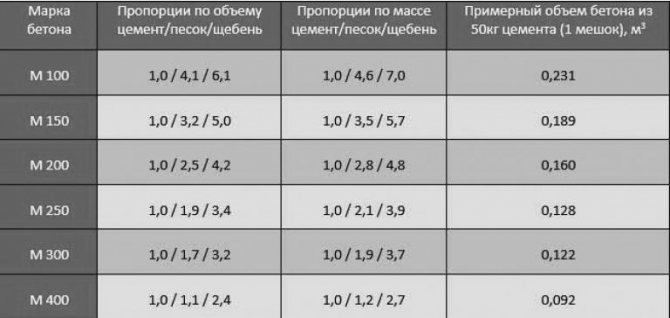

In general terms, you can determine how much sand is in a cube of concrete, according to the following scheme:

1 volume fraction of cement in grade 100 concrete accounts for 4.1 shares of sand and 6.1 shares of crushed stone; for concrete grade 150, the ratio of cement (M400), sand and crushed stone is 1 to 3.2 and to 5.0; for concrete M200 - 1 to 2.5 and to 4.2; for М250 - 1 to 1.9 and to 3.4 (cement: sand: crushed stone); for 300 1 to 1.7 and to 3, "; for 340 1 to 1.1 and to 2.4.

Table 1.

Proportions of cement, sand and crushed stone by concrete grade

| Concrete grade | proportions cement: sand: crushed stone | |

| cement grade 400 | cement grade 500 | |

| 100 | 1,0 : 4,1 : 6,1 | 1,0 : 5,3 : 7,1 |

| 150 | 1,0 : 3,2 : 5,0 | 1,0 : 4,0 : 5,8 |

| 200 | 1,0 : 2,5 : 4,2 | 1,0 : 3,2 : 4,9 |

| 250 | 1,0 : 1,9 : 3,4 | 1,0 : 2,4 : 3,9 |

| 300 | 1,0 : 1,7 : 3,2 | 1,0 : 2,2 : 3,7 |

| 400 | 1,0 : 1,1 : 2,4 | 1,0 : 1,4 : 2,8 |

| 450 | 1,0 : 1,0 : 2,2 | 1,0 : 1,2 : 2,5 |

Knowing these proportions, you can not only easily find out, for example, how much rubble is in a cube of concrete, but also knead absolutely any amount of high-quality concrete without much difficulty.

Table 2. Relationships between the class and concrete grades in terms of strength.

|

Brand |

Class |

Strength, kg / cm2 |

|---|---|---|

|

M-100 |

B7.5 |

98,2 |

|

M-150 |

AT 10 |

131,0 |

|

M-150 |

B12.5 |

163,7 |

|

M-200 |

B15 |

196,5 |

|

M-250 |

B20 |

261,9 |

|

M-350 |

B25 |

327,4 |

|

M-400 |

B30 |

392,9 |

|

M-450 |

B35 |

458,4 |

|

M-500 |

B40 |

532,9 |

It is important to note that the physical and mechanical properties of the concrete will depend on the grade of cement used to make concrete. So, if instead of cement M400 add cement M500, the grade of concrete will increase (say, instead of 200, it will become 350)

In order to get good concrete, you should choose crushed stone, the grade of which will exceed the grade of concrete that we want to get by 2 times.

Simple concrete mixing scheme

If for construction you do not need factory accuracy, and there is no need to strictly maintain the grade of concrete, you can use a simplified scheme: take 0.5 parts of water, 2 parts of sand and 4 parts of crushed stone for 1 part of cement. For the manufacture of 1 cubic meter of concrete, the weight fractions of the components at this ratio will be as follows: cement - 330 kg (0.25 cubic meters), water 180 l (0.18 cubic meters), sand 600 kg (0.43 cubic meters), crushed stone 1, 25 tons (0.9 cubic meters).

How much cement, sand, gravel (crushed stone) and water is needed to get a cube of concrete:

M50 concrete

- Portland cement M400 - 380 kg.(1)

- Gravel - 608 kg. (1.59)

- Sand - 645 kg. (1.69)

- Water - 210 l. (0.55)

M75 concrete

- Portland cement M300 - 175 kg. (1)

- Crushed stone - 1053 kg. (6.02)

- Sand - 945 kg. (5.4)

- Water - 210 l. (1,2)

M100 concrete

- Portland cement M300 - 214 kg. (1)

- Crushed stone - 1080 kg. (5.05)

- Sand - 870 kg.

(4,07)

- Water - 210 l. (0.98)

M150 concrete

- Portland cement M400 - 235 kg. (1)

- Crushed stone - 1080 kg. (4.6)

- Sand - 855 kg. (3.64)

- Water - 210 l. (0.89)

M200 concrete

- Portland cement M400 - 286 kg. (1)

- Crushed stone - 1080 kg. (3.78)

- Sand - 795 kg. (2.78)

- Water - 210 l. (0.74)

M250 concrete

- Portland cement M400 - 332 kg. (1)

- Crushed stone - 1080 kg. (3.25)

- Sand - 750 kg. (2.26)

- Water - 215 l. (0.65)

M300 concrete

- Portland cement M400 - 382 kg. (1)

- Crushed stone - 1080 kg. (2.83)

- Sand - 705 kg. (1.85)

- Water - 220 l. (0.58)

M350 concrete

- Portland cement M400 - 428 kg. (1)

- Crushed stone - 1080 kg. (2.5)

- Sand - 660 kg. (1.54)

- Water - 220 l. (0.51)

p.s. The sequence of laying materials in a concrete mixer affects the quality of concrete.

Related materials:

The need for accurate calculations

In the photo - large-scale concreting in industrial construction

Why is it so important to know the volume of the required solution correctly, because if there is not enough material, more can be done? In fact, the maximum strength and durability of monolithic structures is ensured only if the mortar is fed into the formwork for concrete products without prolonged downtime. You can avoid downtime, which can lead to the stratification of concrete, by knowing the exact amount of the mixture that will be required to carry out certain construction work.

To avoid downtime, which can lead to the stratification of concrete, you can know the exact amount of the mixture that will be required to carry out certain construction work.

Actual calculation formulas

In the photo - an installation for the preparation of mortars in limited quantities

At the moment, there are many ways to carry out calculations, for example, you can use a concrete volume calculator. But an online calculator may not be available at the most crucial moment, and therefore we will consider those formulas that can be implemented in practice at any time and under any circumstances.

It is no secret that there are several types of foundations, laid to one or another depth before the start of the main construction work. Depending on the configuration of these structures, their size and, as a result, the volume of solution that will be required differ.

Formula for columnar bases

In the photo - formwork for a columnar (pile) foundation

So how do you calculate the volume of concrete? To do this, you need to measure the height of the structure, find out the area and multiply these indicators. But the approach to calculations in accordance with the formula V = S * H is relevant only to simple structures, while calculating the volume in relation to complex structures will require a different approach.

The calculation method for columnar bases with round piles is as follows:

- We calculate the area of the base of each pillar, we do it according to the formula S = 3.14 * r², where r is the radius of each individual pile;

- Then we multiply the parameters of the area by the estimated height of the pile and get the volume;

- Then we multiply the resulting volume by the number of piles that will be applied according to the project.

Calculations for slab-type bases

In the photo - slab base formwork

Now let's look at how to calculate the volume in m3 of concrete for a slab foundation.

The instruction in this case is simple, since such a base is a one-piece structure.

- To begin with, we divide the planned perimeter of the foundation into rectangles. This must be done if the shape of the base is complex. If the configuration is simple and is a rectangle or square, we find out the area by multiplying the length by the width.

- Next, we determine the depth of the bookmark and multiply this number by the resulting area.

Calculation of the volume of material for a strip foundation

In the photo - the formwork of the strip base

A strip concrete foundation is by far the most popular type of foundation, as it is characterized by sufficient strength and durability.In addition, choosing this type of base, you can save the solution, since it will not be poured along the entire perimeter of the object, but only under load-bearing walls and partitions.

The calculation of the volume of concrete in this case is not difficult and is performed as follows:

- We measure the estimated width and total length of the tape. We multiply the obtained parameters and get the area of the base.

- Then we determine how deep the foundation will be, and multiply this number by the area and we get the nominal volume of the solution, which is necessary for pouring into the formwork.

Determine how much cement, sand, gravel and water is in a cube of concrete.

4 June, 2013 - 12:35 Concrete is one of the most demanded materials in construction. Such popularity of concrete is explained by its excellent properties: compressive strength, ease of forming and laying, waterproofing, water resistance, low price.

For the manufacture of concrete, cement, water and so-called aggregates are used, which can be coarse (crushed stone) or fine (sand). Builders often face the question of how to mix concrete correctly. It is at this stage that it is usually required to determine how much cement is in a cube of concrete.

Today, there are a large number of concrete grades that differ in their composition, or rather, in the volume or mass ratio of its constituent components. For example, to create 1 cubic meter of 100 grade concrete, 200 kg of cement is required, to create 1 cube of 400 grade concrete, 360 kg of cement is required.

There are special tables from which you can understand not only how much cement per cube of concrete is required, but also the percentage of other concrete components in the finished composition.

So, for example, for the most running grade 300 concrete, it is necessary to mix 382 kg of M400 cement, 705 kg of sand, 1080 kg of crushed stone and 220 liters of water. For concrete of 100 brands, you will need 214 kg of cement (M400), 870 kg of sand, 1080 kg of crushed stone and 210 liters of water.

In general terms, you can determine how much sand is in a cube of concrete, according to the following scheme:

1 volume fraction of cement in grade 100 concrete accounts for 4.1 shares of sand and 6.1 shares of crushed stone; for concrete grade 150, the ratio of cement (M400), sand and crushed stone is 1 to 3.2 and to 5.0; for concrete M200 - 1 to 2.5 and to 4.2; for М250 - 1 to 1.9 and to 3.4 (cement: sand: crushed stone); for 300 1 to 1.7 and to 3, "; for 340 1 to 1.1 and to 2.4.

Table 1. Proportions of cement, sand and crushed stone by concrete grades

| Concrete grade | proportions cement: sand: crushed stone | |

| cement grade 400 | cement grade 500 | |

| 100 | 1,0 : 4,1 : 6,1 | 1,0 : 5,3 : 7,1 |

| 150 | 1,0 : 3,2 : 5,0 | 1,0 : 4,0 : 5,8 |

| 200 | 1,0 : 2,5 : 4,2 | 1,0 : 3,2 : 4,9 |

| 250 | 1,0 : 1,9 : 3,4 | 1,0 : 2,4 : 3,9 |

| 300 | 1,0 : 1,7 : 3,2 | 1,0 : 2,2 : 3,7 |

| 400 | 1,0 : 1,1 : 2,4 | 1,0 : 1,4 : 2,8 |

| 450 | 1,0 : 1,0 : 2,2 | 1,0 : 1,2 : 2,5 |

Knowing these proportions, you can not only easily find out, for example, how much rubble is in a cube of concrete, but also knead absolutely any amount of high-quality concrete without much difficulty.

Table 2. Relationships between the class and concrete grades in terms of strength.

| Brand | Class | Strength, kg / cm2 |

| M-100 | B7.5 | 98,2 |

| M-150 | AT 10 | 131,0 |

| M-150 | B12.5 | 163,7 |

| M-200 | B15 | 196,5 |

| M-250 | B20 | 261,9 |

| M-350 | B25 | 327,4 |

| M-400 | B30 | 392,9 |

| M-450 | B35 | 458,4 |

| M-500 | B40 | 532,9 |

It is important to note that the physical and mechanical properties of the concrete will depend on the grade of cement used to make concrete. So, if instead of cement M400 add cement M500, the grade of concrete will increase (say, instead of 200, it will become 350)

In order to get good concrete, you should choose crushed stone, the grade of which will exceed the grade of concrete that we want to get by 2 times.

Simple concrete mixing scheme

If for construction you do not need factory accuracy, and there is no need to strictly maintain the grade of concrete, you can use a simplified scheme: take 0.5 parts of water, 2 parts of sand and 4 parts of crushed stone for 1 part of cement. For the manufacture of 1 cubic meter of concrete, the weight fractions of the components at this ratio will be as follows: cement - 330 kg (0.25 cubic meters), water 180 l (0.18 cubic meters), sand 600 kg (0.43 cubic meters), crushed stone 1, 25 tons (0.9 cubic meters).

How much cement, sand, gravel (crushed stone) and water is needed to get a cube of concrete:

M50 concrete

- Portland cement M400 - 380 kg. (1)

- Gravel - 608 kg. (1.59)

- Sand - 645 kg. (1.69)

- Water - 210 l. (0.55)

M75 concrete

- Portland cement M300 - 175 kg. (1)

- Crushed stone - 1053 kg. (6.02)

- Sand - 945 kg. (5.4)

- Water - 210 l. (1,2)

M100 concrete

- Portland cement M300 - 214 kg. (1)

- Crushed stone - 1080 kg. (5.05)

- Sand - 870 kg. (4.07)

- Water - 210 l. (0.98)

M150 concrete

- Portland cement M400 - 235 kg. (1)

- Crushed stone - 1080 kg. (4.6)

- Sand - 855 kg. (3.64)

- Water - 210 l. (0.89)

M200 concrete

- Portland cement M400 - 286 kg. (1)

- Crushed stone - 1080 kg. (3.78)

- Sand - 795 kg. (2.78)

- Water - 210 l. (0.74)

M250 concrete

- Portland cement M400 - 332 kg. (1)

- Crushed stone - 1080 kg. (3.25)

- Sand - 750 kg. (2.26)

- Water - 215 l. (0.65)

M300 concrete

- Portland cement M400 - 382 kg. (1)

- Crushed stone - 1080 kg. (2.83)

- Sand - 705 kg. (1.85)

- Water - 220 l. (0.58)

M350 concrete

- Portland cement M400 - 428 kg. (1)

- Crushed stone - 1080 kg. (2.5)

- Sand - 660 kg. (1.54)

- Water - 220 l. (0.51)

p.s. The sequence of laying materials in a concrete mixer affects the quality of concrete.

Varieties of concrete mixtures

Concrete is distinguished by the strength and density of the composition, which directly depend on the types of crushed stone used and its ratio with other components. There are such types of mixtures:

Lightweight concrete has a density of 400 to 1600 kg / m³. The main filler here is sand, and ordinary crushed stone is practically not used. Instead, the solution is filled with shell rock, expanded clay and other lightweight fillers. In most cases, the same amount of filler is taken as sand; in rare cases, a 1: 2 ratio is allowed.

Heavy concrete with an index from 1600 to 2600 kg / m³. It is the most popular building material used everywhere. They use conventional types of aggregates of various fractions. Their number depends on the brand of the solution and is entered in special tables.

Superheavy or particularly durable types have a density of about 3000 kg / m³ and higher. They use high-strength barite, hematite or magnetite rock.

Such compositions are expensive, so it is important to clearly know their ratio, which is calculated individually for each design.

The mixtures are characterized by strength grades. Most often, marking is used from M100 to M400. At the same time, there is a general rule that the strength of crushed stone should be twice the expected strength of the monolith. For example, you need to add the M400 placeholder to.

Calculation of the composition of the concrete mixture

In the article on concrete for the foundation, we described in sufficient detail the characteristics of the concrete mixture and how they affect the reliability and strength of the monolith erected from them. But the data presented there is clearly not enough to make the required amount of concrete with your own hands. When calculating the percentage of concrete mix, there are no trifles: you need to take into account both the water-cement ratio (W / C), and the characteristics of the aggregates (sand and crushed stone), and the brand of cement used. Where do you start?

Let's say we need to get concrete grade M300 from Portland cement M400. We look at the values presented in table 1. It can be seen from it that the water-cement ratio is 0.53. These tables are relevant for a concrete mixture prepared on the basis of crushed stone and sand, the size modulus of which does not exceed 2.5 - components with an average grain size. If we need to prepare a concrete solution without crushed stone aggregate, then 0.1 must be subtracted from the W / C value. In our case, it turns out that the water-cement ratio will be equal to 0.43. What does it mean? In the first case (W / C = 0.53), when using 50 kg of cement, it is necessary to add 50 × 0.53 = 26.5 liters of water to the mixture, in the second (W / C = 0.43) - 21.5 liters. But we just explained the term "water-cement ratio". Let's move on to a specific example.

You need to get: 10 cubes of concrete M300 with mobility P2 (cone draft up to 50 mm)

Available:

- crushed stone (maximum grain size - 25 mm), density - 2700 kg / m3

- medium fraction sand, density - 2500 kg / m3

- Portland cement M400, the density of which in the composition of the water-cement mass is 3000 kg / m3

According to table 1, we find the value of V / C to obtain the design grade of concrete M300. It is equal to 0.53. We look at the data in Table 2. It indicates that when using crushed stone with a maximum grain size of 25 mm, 195 liters of water (or 0.195 m3) are required to prepare one cube of concrete.It turns out that for 1 cube of concrete you will need:

195 / 0.53 = 368 kg of cement

Next, you need to calculate how much by volume per cubic meter the aggregates (sand and crushed stone) occupy:

1 - ((368/3000) +0.195) = 0.682 m3 or 682 liters

Now, using the data in Table 2, we find the volumetric content of sand in the filler mixture. In our case, it is equal to 46% or just 0.46. Knowing it, it is easy to calculate the volume of sand:

682 × 0.46 = 313.7 liters or 0.314 m3

We subtract the volume of sand from the total volume of fillers and get the volume of crushed stone:

682-313.7 = 368.3 liters or 0.368 m3

Knowing the volumes of fillers and density, it is easy to calculate their mass. So, for sand it will be:

0.314 × 2500 = 785 kg, for crushed stone - 0.368 × 2700 = 993.6 kg.

In total, to prepare one cubic meter of M300 project grade concrete mix from M400 Portland cement, you will need:

368 kg of cement, 195 l of water, 785 kg of sand, 993.6 kg of crushed stone

To prepare ten cubes, the obtained values must be multiplied by 10. These data are used to correct the calculation of the foundation. You can also express the mass ratio of cement, sand and crushed stone:

368/785/993,6 = 1:2,1:2,7

According to table 3, we made sure that the calculated mass of cement is not less than the table values indicated for the preparation of concrete mixture M300 with a cone draft of up to 50 mm (P2) from M400 cement.

Consumption rates for different solutions

Depending on what the concrete is for, 1 m3 of mortar may contain a different volume of cement. In modern construction, concrete solution is used to implement four tasks: pouring the foundation, laying building blocks, pouring the screed and making plaster. For each of these types of work, it is assumed that a certain type of solution is prepared with a specified volume of cement.

The largest consumption of cement per cube of mortar is obtained in the preparation of a mixture for masonry or plaster. For pouring a foundation or screed, it is important to use large fillers (gravel, crushed stone, slag), which reduces the consumption of cement. The brand indicates the purpose of the solution (the properties of concrete and the main characteristics depend on it).

Calculation of cement per cube of concrete according to GOST:

- М100 - 170 kilograms of cement

- M150 - 200 kilograms

- M200 - 240 kilograms

- M250 - 300 kilograms

- M300 - 350 kilograms

- M400 - 400 kilograms

- M500 - 450 kilograms

On plaster

A standard plaster mortar is prepared from 3 parts sand and 1 part cement. If the layer is made with a thickness of no more than 12 millimeters, then 1.6 kilograms of M400 cement and 1.4 kilograms of M500 cement are weighed per 1 square meter of plaster. The volume of solution per cubic meter of masonry can be calculated as follows: 1m2 x 0.012 m = 0.012 m2 = 12 liters.

On masonry

For a square meter of brickwork one brick thick, you will need at least 75 liters of M100 mortar. The proportion of cement grade M400 and sand is 1: 4. Thus, the consumption of cement for laying bricks is 250 kilograms per cubic meter of sand. How many cubes of solution will be needed in general is considered by the size of the building.

Water is taken in the volume of half the weight of the cement. So, if you knead the solution using buckets, it turns out like this: 1 bucket of M500 brand cement, 4 buckets of sand, 7 liters of water.

For the foundation

To prepare a solution for pouring a foundation, everything must be calculated correctly. Usually, a solution of the M100-M300 brand is used. The strength of M100 is sufficient for low-rise buildings, M150 and M200 are suitable for a building with several floors. The higher the grade, the stronger the structure will be. For mixing, take cement M300 / M400 (1 part binder and 3 parts sand) or M500 (1 part binder and 5 sand).

Cement consumption per cubic meter of solution:

- M50 (based on M400 cement) - 380 kilograms

- M100 (based on M300 cement) - 214 kilograms

- M200 (based on M400 cement) - 286 kilograms

- M300 (based on M500 cement) - 382 kilograms

Such calculations are relevant if the mixture is prepared according to the proportion: 1 part of cement, 2-4 parts of sand, 3 parts of crushed stone / gravel.

For screed

The proportion for mixing is as follows: 1 part of cement and 3 parts of sand. Here is an example of correct calculations.So, you need to fill the surface of 3 by 4 square meters (12 turns out) with a layer thickness of 30 millimeters.

Calculation stages:

- Determination of the required volume of concrete solution: 12 m2 x 0.03 m = 0.36 m3.

- Choosing a concrete grade - we take M200, we prepare it from M500 cement, which needs 410 kilograms.

- Counting the number of bags of cement: 410 kg x 0.36 m3 = 148 kg / 50 = 3 bags (almost).

- How much sand is needed: 1600 kg / m3 (weight of a cubic meter of the mixture) x 0.36 m3 (the required amount of the mixture) = 576 x 0.75 (proportion of sand in concrete) = 432 kilograms. A cube of sand solution will take about 1200 kilograms.

Concrete types

The following types of solution are distinguished:

- By appointment. These include conventional and special solutions. The former are used for the construction of industrial and civil buildings, special ones are used for the construction of hydraulic, road and other structures.

- By the astringent. These include cement, gypsum, silicate mortars, etc.

- By placeholders. Distinguish between concrete on dense, porous and special additives.

- According to the conditions of hardening. They are divided into hardening in a natural environment, under conditions of wet and warm processing at normal atmospheric pressure, and when processing with heat and moisture at atmospheric pressure above normal (autoclave hardening).