Technology of basement insulation with expanded polystyrene

This type of insulation for the foundation of a house is most often used in private construction, since expanded polystyrene has the following advantages:

- The material has high strength and durability.

- Has a high moisture resistance.

- The material is easy enough to mount and fix on the plinth, which allows you to do it yourself.

- Expanded polystyrene is inedible for rodents and is resistant to damage.

- It is not difficult to carry out external decorative finishing.

- The cost of the material is affordable for almost everyone.

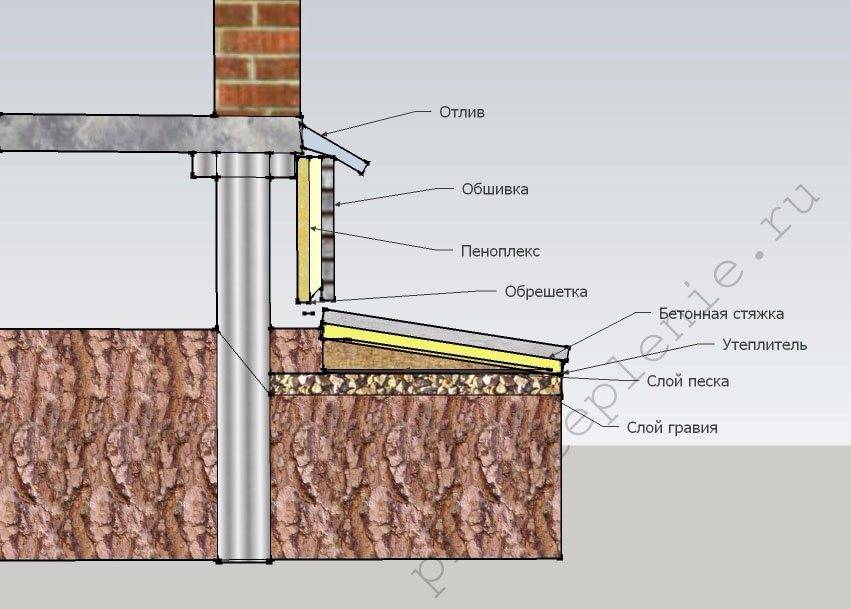

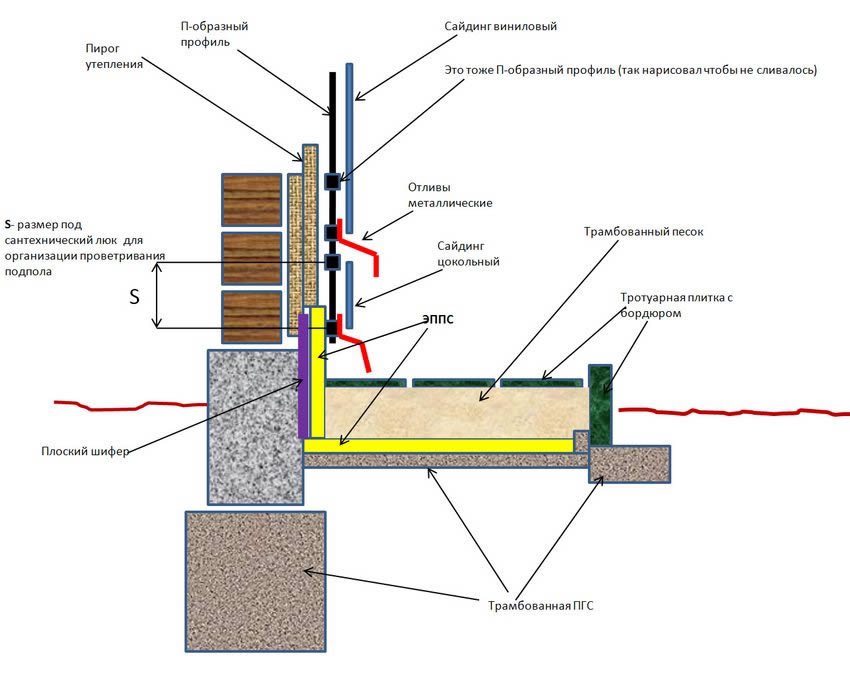

With regards to the technology of finishing the foundation from the outside, it is as follows:

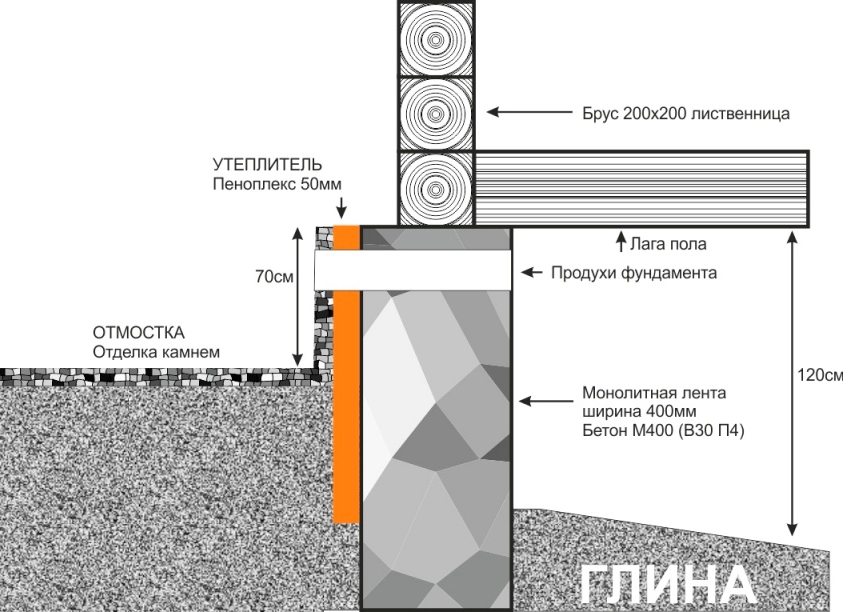

- It is necessary to insulate the foundation of the house from the outside immediately after it is erected and the rough floor of the first floor is completed. However, it is also possible to insulate the foundation of an already finished house, but for this you need to dig a trench around the foundation with a width of at least 1 m and a depth equal to the depth of the foundation.

- Before proceeding with insulation, the walls of the foundation must be cleaned of all contamination.

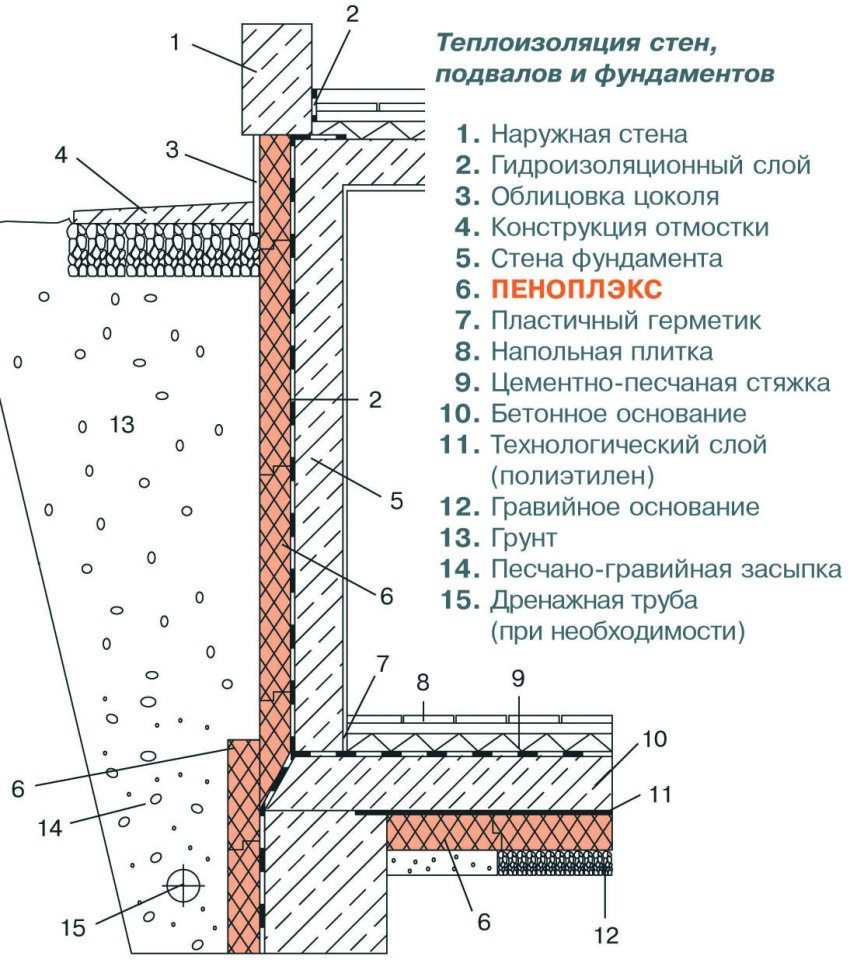

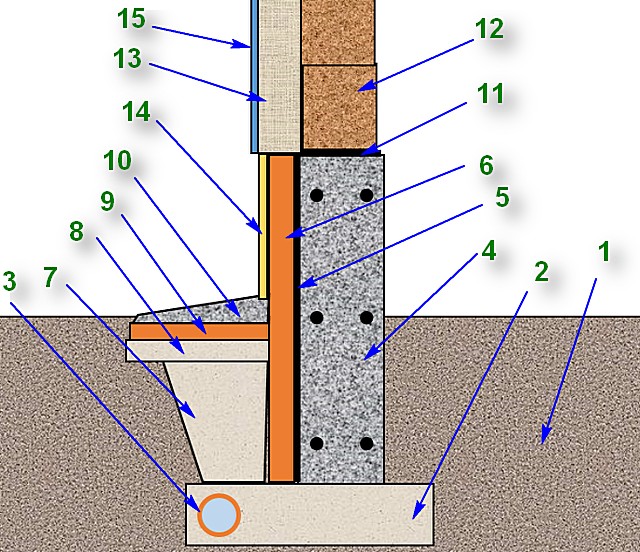

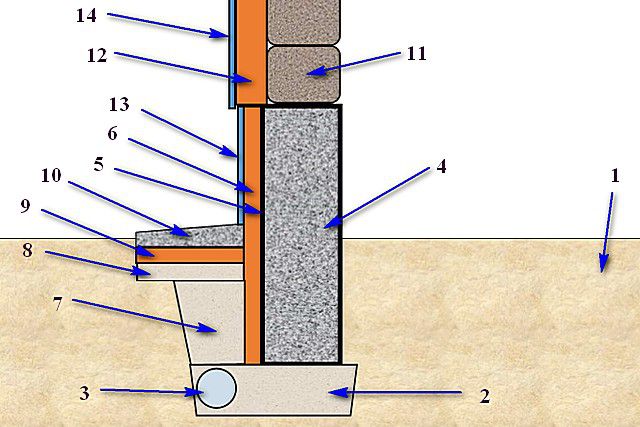

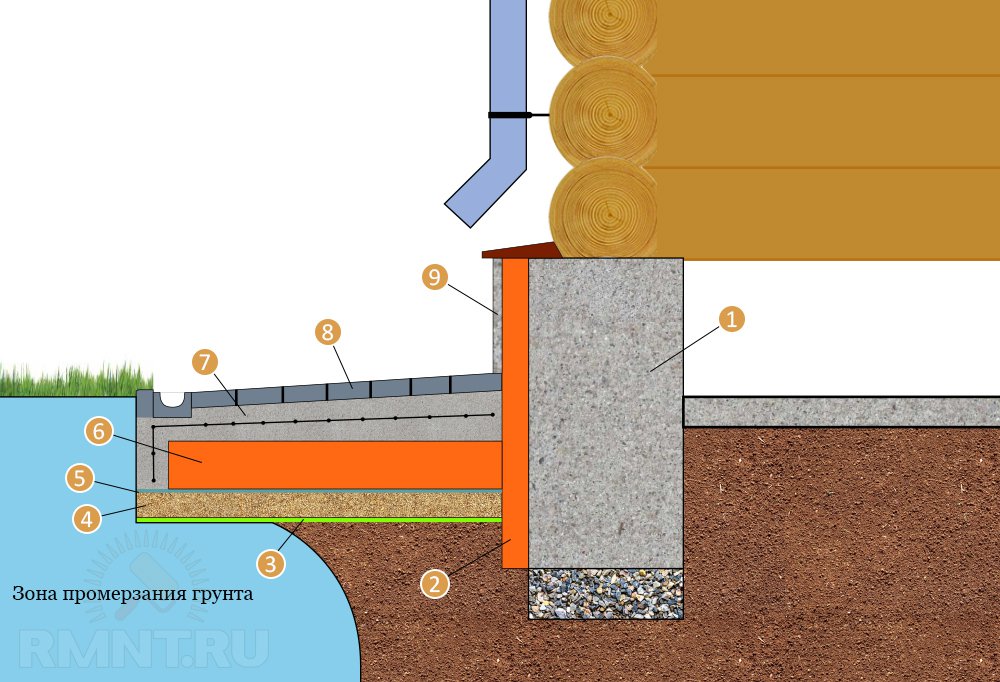

- If the level of groundwater is raised at the construction site, then a drainage system must be completed. To do this, a layer of sand is poured onto the bottom of the trench, a layer of geotextile is laid, then perforated pipes, about 10 cm in diameter, into which gravel is poured. The pipes are also wrapped with geotextiles and covered with sand. They need to be taken to a special collector well.

- The next step is to coat the walls of the foundation with a latex-based primer. Such a primer will completely fill all gaps and small cracks in the foundation, as well as provide good adhesion to the waterproofing material.

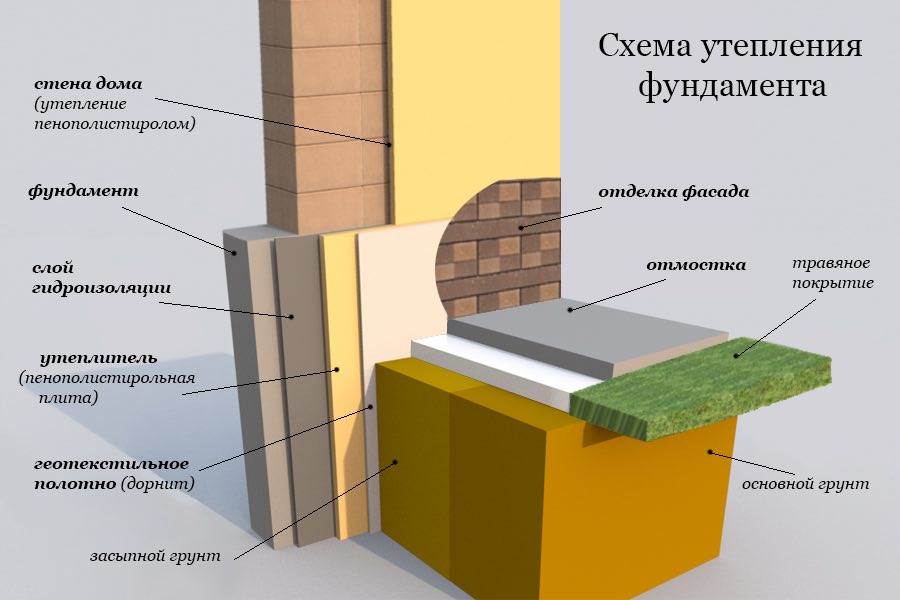

- Then waterproofing (usually self-adhesive) is done, which is ironed with a roller, and the joints are glued with a special sealant.

- Now you can start laying the insulation. It is fixed on the walls using special glue, which is applied to expanded polystyrene in a small strip at a distance of 1-2 cm from the edge of the sheet, as well as in small dots around the entire perimeter.

- Thus, continue along the entire perimeter of the foundation. If the foundation is high, and one row of expanded polystyrene is not enough, then the insulation is laid in a checkerboard pattern, like a brick, in several rows.

- When all walls are insulated, large gaps are sealed with foam or sealed with sealant.

- Where the foundation will subsequently be covered with sand, there is no need to additionally strengthen the expanded polystyrene, but on the protruding part it is fixed using special dowels.

- Further, the insulation must be plastered, while it is necessary to use a reinforcing mesh to give strength (it must be drowned in a layer of plaster).

Thus, having done everything correctly, you can achieve high-quality insulation without leaving cold bridges. In addition, this finish gives the house a full-fledged finished look.

High strength sealed board with PU foam

Polyurethane foam or polyurethane foam is a modern building material with many advantages. It is characterized by low thermal conductivity, strength, durability and environmental friendliness. It is easy to work with polyurethane foam - no additional fasteners are required for installation, its application to the surface is quick. PPU has high waterproofing properties that prevent moisture from entering, thereby protecting the building.

The main advantage of using polyurethane foam as insulation is the impossibility of spoiling the result - the final coating is always obtained without cracks, irregularities and joints.

How to work with polyurethane foam?

Warming of the foundation with polyurethane foam occurs by spraying insulation on the surface using special installations. The resulting foam is firmly connected to the base of the structure, filling all cavities. The result is a high-strength slab, very hard and tight. Since the material has a closed structure and there is no air gap, condensation cannot appear in such a product.

Thermal insulation of the foundation with polyurethane foam is the most effective method. It is suitable both for new buildings and for thermal protection of an old house. But the cost of such insulation is high and it is impossible to carry out the work on your own, since special equipment is required.

There are many options for waterproofing and insulation of the foundation, it remains only to choose which one is most suitable.

Types of internal thermal insulation

As well as with external insulation, the following methods can be distinguished:

- Insulation with glass wool. One of the most common insulation methods is glass wool. Waste glass is used in the production process. The finished material is in the form of plates or rolls packed in cellophane film. It has a number of indisputable advantages: elasticity, good water resistance, non-toxicity, good sound insulation.

- Backfill with expanded clay. This method is not considered convincing enough and is suitable for summer cottages. Its obvious advantages are low material cost and ease of use. In addition, it is good at preventing the cooling of the floors of the house.

- Insulation of basement walls with expanded polystyrene, polystyrene or expanded polystyrene foam. This is an irreplaceable method that, together with interior decoration and external thermal insulation of the recessed parts of the house and the foundation, shows excellent results.

- Thermal insulation with polyurethane. Polyurethane creates a seamless heat-shielding layer that effectively insulates the foundation. It can be an independent or additional thermal insulating agent. Its only, but very significant drawback is the inability to independently perform its installation. You need a special installation and professionals who know how to use it.

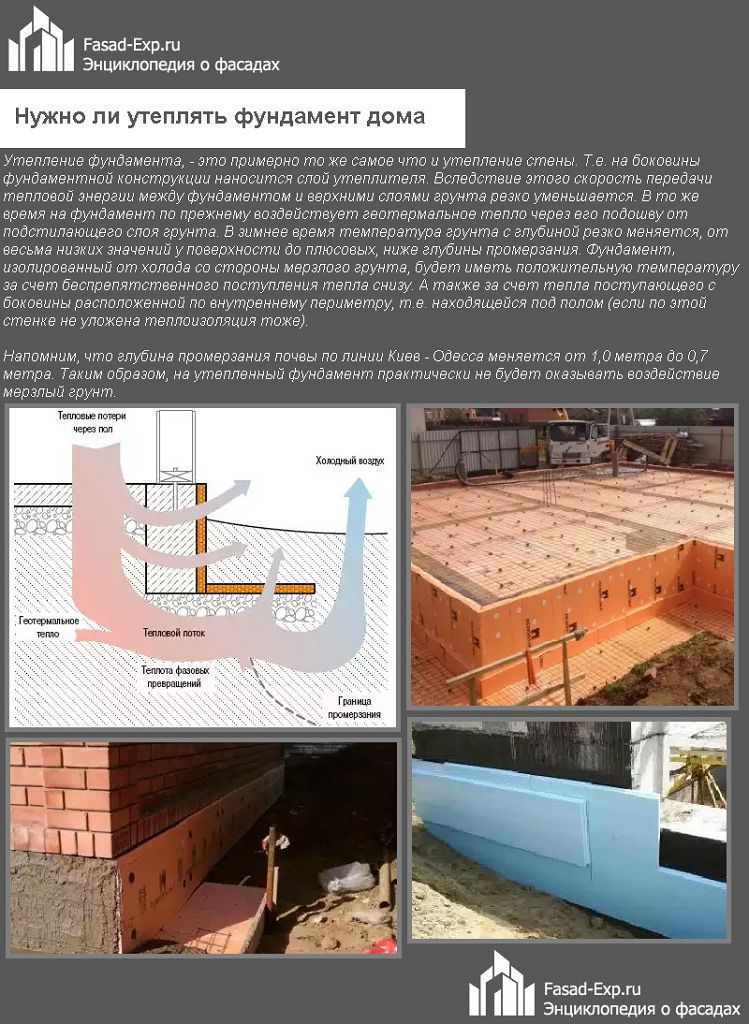

What and how to insulate in the foundation

Oddly enough it sounds, but any attempt to insulate the walls of the foundation or basement from the inside significantly worsens the conditions for the concrete surface outside the foundation. If you do not insulate the basement, leave it extremely cold, without thermal insulation from the inside of the room, all the heat and energy that gets inside through the air and the ceiling of the basement heats up the concrete base of the foundation structure and the soil around the blocks. This compensates for the temperature drop due to the penetration of frost from the surface into reinforced concrete.

If the walls are insulated from the inside, the amount of heat entering the foundation from the air will be reduced by 80-90%, respectively, an increase in the air temperature inside the basement by 10 ° C will be equivalent to an increase in the cooling effect of frost on the outer surface by the same amount. For dry and low-loamy soils, the state of the foundation blocks will not change, possibly, the groundwater level will decrease. If you insulate the foundation system of a house on highly weathered soil, it is possible that the crushing effect of frozen soil will only increase. In this case, it will be necessary to insulate the outer layer with the same equivalent that was laid from the inside of the basement or foundation.

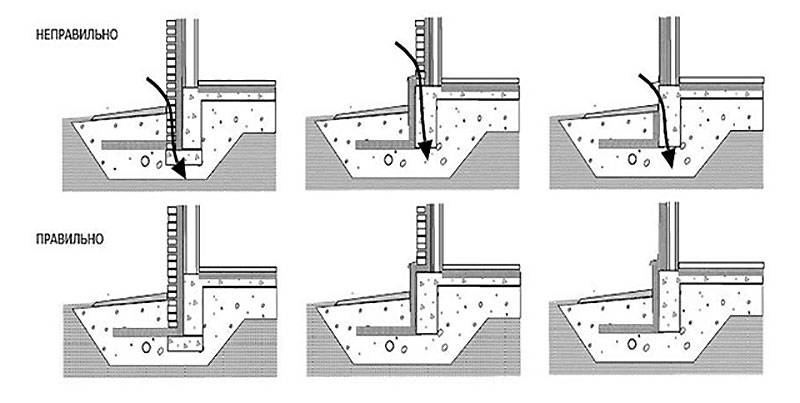

If you properly insulate the inner walls of the foundation structure of the house, the situation will be as follows:

The ventilation conditions of the basement will significantly improve during the cold season, the higher the temperature difference outside and inside the room, the higher the draft in the ventilation pipe;

Air humidity will decrease, it will be possible to remove condensation on the walls due to good ventilation and improved water evaporation;

Heat loss in the house will decrease.

It is interesting: Profile for drywall: we study in order

Internal insulation methods

How to insulate the foundation from the inside of the house? Building technology recommends 3 ways to insulate a basement from the inside. But any of them requires waterproofing with a diffusion film or roofing material of all surfaces of the floor and walls of the basement, up to the level of the finished floor. Vapor permeability is allowed only from the side of the house

It is important to provide for both the biostability of the insulator and its fire resistance.

1st method: basement insulation is carried out using sheets or plates of heat insulator. Universal insulation for these works is extruded polystyrene foam. It is durable, non-toxic, has the lowest water absorption rate. With a guaranteed service life (20-50 years), it is able to withstand mold and rodents.

Insulation plates are laid from the floor to the basement ceiling and fixed with bitumen mastic. Seams are filled with polyurethane foam. For reliable installation of the insulation, you will need frame sheathing. It should be foreseen that this type of thermal insulation will significantly reduce the volume of the room.

2nd method: to create a heat-insulating layer, polyurethane foam is used. It is sprayed with special equipment on concrete and metal structures. Foamed polyurethane foam reliably fills all cracks, irregularities and voids, negating the appearance of "cold bridges". This method has the highest speed of work on insulation, but should be performed only by specialists with protective equipment, since it is very toxic in production.

There is another way to insulate the basement internally, which came from the distant past - earth insulation, when the walls are covered from the inside with earth to the level of the insulated floor. But its labor intensity and the mass of the soil necessary for these purposes (the volume of KamAZ) make its cheapness unattractive.

Reconstruction of the foundation of a wooden house. You can read about it here.

And this article tells about a shallow strip foundation.