Geotextile for blind area

When arranging the blind area, you can also use geological textile canvases. In this design, the material prevents mixing of the layers of crushed stone and sand that are used for dumping. When the layers are separated, the geotextile allows water to pass through and filters it. Consequently, crushed stone does not fall into sand or clay, thereby preventing soil subsidence under the blind area.

When choosing geological textiles for arranging the blind area, the main attention should be paid to the density of the material and the method of its manufacture. Most often, needle-punched fabric is used for this purpose, which is characterized by increased strength characteristics and the ability to qualitatively filter water.

Also, we must not forget about the density of the material, due to which the strength of the canvas is ensured.

It should be noted that as the density of the geotextile increases, its cost increases. However, at the same time, the material is more resistant to loads during seasonal soil movements. The optimum density is 100-150 g / m2.

In a previous publication, we looked at how to calculate materials for a monolithic foundation.

Creating a blind area cushion using geological textiles is performed as follows:

- A waterproofing material is laid on the leveled bottom of the trench around the house, leading its edges onto the walls of the basement. In this case, you can use ordinary plastic wrap or roofing felt.

- Coarse sand is poured on top of the waterproofing with a layer of about 5 cm.

- The sand is covered with geological textiles. In this case, the fabric is also brought onto the wall, pressing it against the surface with a special rail. This will keep the material from moving away from the wall.

- Next, the geotextile is covered with crushed stone of the middle fraction with a layer of 10 cm, which is again covered with geotextile.

- Then you can re-fill rubble or pebbles, providing a tighter fit for the geological textiles.

- The final stage will be the decorative design of the blind area.

If you have any difficulties or have any questions, then read our article "How to make a blind area".

There are many advantages to using modern materials such as geological textiles. However, in any case, the structure receives protection, while the strength, reliability and durability of the structure as a whole are significantly increased. Subject to the rules of installation and the correct choice of material, you can independently perform all activities related to the use of geotextiles.

What methods are used in drainage geotextile

How to properly lay material in drainage systems? There are several ways:

Laying geotextiles

- For sandy and rocky ground. The work is carried out as follows - the trench is filled with drains, which are previously wrapped in a thermally bonded geotextile. Such a protective effect will prevent mixing of soil and gravel, and will also prevent the drainage system from clogging;

- For clay soils. In this case, crushed stone is used. Such drainage is used on almost all soils. Crushed stone will become a water-conducting layer, and geotextiles will protect it from siltation and soil from erosion. This drainage of water from the land is very efficient.

The process of performing drainage work is divided into stages:

- Trenches are being dug;

- The bottom of the ditches is lined with needle-punched material so that the walls are also covered with it for half a meter with a margin;

- The cloth, which was laid, is strewn with rubble, which occupies 2/3 of the trench;

- Overlapping rubble is wrapped with a geotextile cloth. The layer is located on the adjacent layer by 10 centimeters, provided that the ground is even.If the surface is uneven, then the indicator should be increased by another 20 centimeters. Connect the canvas by sewing or welding;

- Sand is laid in a small layer;

- The slope is observed in the direction where the water will flow.

The main function that the geotextile performs in the drainage is to combat the ingress of gravel into the water, settle the trench and ensure the structure is stable.

How to choose for a foundation

The industry produces geotextiles of several types, classified according to the characteristics:

- material - polypropylene, polyester, natural fiber (wool, cotton);

- thread size - monofilament dimensionless or short cuts (staple);

- method of fastening the canvas - needle-punched, hydro-punched method, thermal bonding.

Hydro-penetrated geotextiles made of polypropylene monofilament are more suitable for construction technologies. Less commonly, needle-punched polyester geotextiles are also used from an endless thread. Staple, woven modifications do not have sufficient strength and are not used in construction.

The second name of the material is "dornit", it comes from the name of the road institute DorNII, in which the geotextile was created by analogy with the French non-woven synthetic material. However, at present, the Dornit trademark, patented by Plasteks, is a polyester staple synthetic winterizer, unsuitable for construction, except for drainage pipes.

Attention! For the foundation, you should purchase geotextiles from Sibur (100% propylene monofilament), Belarusian manufacturer Pinem (completely similar to the previous material), MogilevKhimVolokno (polyester monofilament, so the canvas gets a little wet in the ground). The recommendations of experts, which core to choose is better for the excavation stage, in principle, boils down to determining the drainage properties and density of the canvas

European products Terram, Typar cost one and a half times more (customs, transportation, markups at points of sale), which unreasonably increases the construction estimate

The recommendations of experts, which core to choose is better for the excavation stage, in principle, boil down to determining the drainage properties and density of the canvas. European products Terram, Typar cost one and a half times more (customs, transportation, markups at points of sale), which unreasonably increases the construction budget.

Underlying layer

Experts consider the foundation as a single structure with the base (soil), on which it rests, transfers loads. Therefore, the calculation of the bearing capacity of a slab, tape or pillars is carried out according to the design resistance of the soil in the building spot. On peat bogs, embankments or silty sands, the cottage structure may sink.

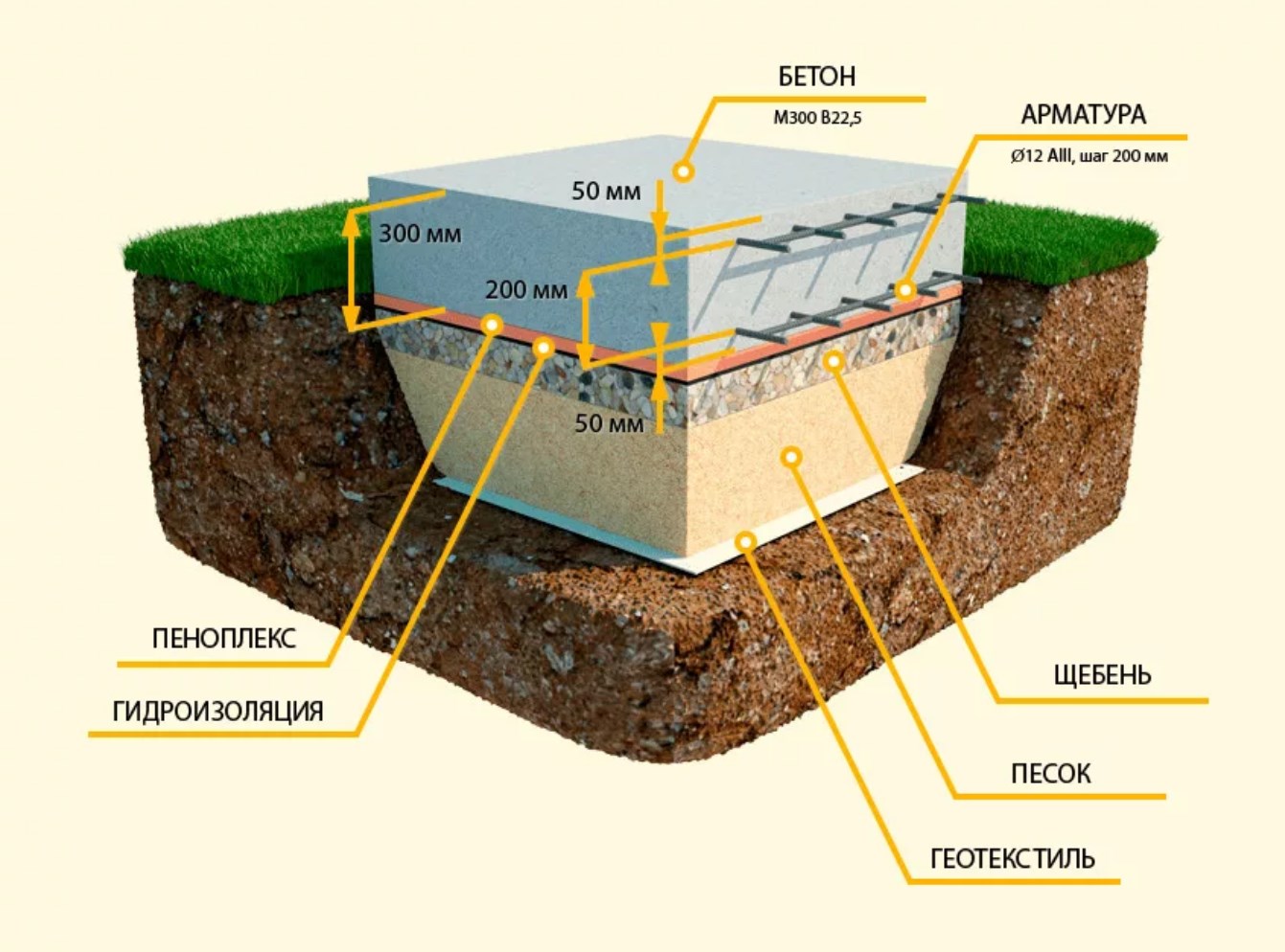

Geotextiles laid under the slab foundation cushion.

To eliminate the swelling of the soil under shallow foundations of 40 - 80 cm, the soil layer is replaced with non-metallic materials. The simplest way to increase the bearing capacity of these soils, to prevent their mutual mixing with rubble and sand is to lay geotextiles under non-metallic material:

- the canvas reinforces the soil;

- excludes mixing of products with high drainage characteristics;

- is relatively cheap for a strip foundation.

Geotextiles laid under the strip foundation.

Attention! Geotextiles are laid under similar underlying layers in communication trenches (water supply, external sewerage) for similar tasks. Even with heavy traffic in the places where the pipeline is laid, there are no ground movements, the resource of life support systems increases

The density of the dornite in the sub-base must be higher than 300 g / m³, therefore it is necessary to use cloth made of propylene monofilament.

Drainage system

It is quite easy to understand why a nonwoven material is needed in a drainage system.When collecting underground drains, crevices, drain holes gradually silted up. If you use dornit as a filter, the drainage properties remain the same, the pipes get an increase in the service life.

Drains are laid in a natural filter casing (usually crushed stone) to increase the flow of fluid from denser soils. Therefore, between the stones, silt and impurities also accumulate. Crushed stone is laid on geotextiles, rammed, the mounted drains are covered with the same material, covered with the remaining canvas from above.

Attention: For drainage, it is better to choose a needle-punched synthetic fiber (polyester, propylene) with a density of 200 g / m³. Strength is less important here, but the material costs much less.

Protective layer

To protect the foundation from getting wet and freezing, concrete surfaces are waterproofed, pasted over with expanded polystyrene. After that, these materials themselves need protection from mechanical damage when backfilling the sinuses of trenches. The choice of medium density geotextiles (100 - 150 g / m³) for covering surfaces is a budget option for increasing the resource of structures.

How to lay geotextiles under the foundation?

The primary responsibility of the developer before designing the future building is to determine the properties of the soil under the object. It is well known that only rocky soils can be a reliable foundation. In this case, it is not necessary to use geotextiles. Another thing is when the soil contains a large percentage of organic matter or consists of sedimentary rocks.

Each of these types of soil has its own disadvantages for the construction of buildings. Clay soil is not able to withstand heavy loads, sandy soil needs additional protection from groundwater, and peat soil cannot be used at all in construction as a reliable base. It is in such a situation that the positive qualities of geotextiles will be useful.

The structure and main advantages of geotextiles

All properties of this material are determined by its composition and structure. Geotextile fabric is divided into 2 types - woven and non-woven. It consists of polypropylene (sometimes polyester) monofilaments.

It is produced in the following ways:

- Needle-punched.

- Thermally bonded.

- Hydrobonded.

Among the main advantages of geotextiles are:

- Long service life (from 25 years).

- Suitable for use at extreme temperatures.

- High environmental friendliness.

- Excellent resistance to aggressive environments.

- Excellent culverts.

- Excellent elasticity and strength.

- Prevent flooding.

- Separation of layers of various building materials.

Geotextile for foundation arrangement

Due to all of its above properties, geotextile fabric has found wide application in construction. It is used in the construction of roads and railways, sidewalks and airstrips. Of course, this material is also used in the construction of residential buildings and industrial facilities.

Until recently, for this process, it was advised to choose high-quality needle-punched geotextiles made with polypropylene yarns, but now it is increasingly being replaced by hydro-bonded material. It is produced in the same way as needle-punched, but instead of needles, the thinnest jets of water are used, which are supplied under high pressure.

This canvas is suitable for the construction of a block, pile, strip foundation. It will become a reliable filter that will prevent flooding and strengthen the soil. Geotextiles will allow for a redistribution of the load in favor of increasing the bearing capacity of the base plate. It is also needed in order to avoid mixing layers of crushed stone and sand with each other and the formation of holes in the soil.

It will be correct to lay geotextiles on the bottom of the excavation dug under the base.

If it is necessary to mechanically strengthen the foundation, the geotextile fabric should be laid in such a way that its area exceeds the area of the future object. Geotextiles should extend from the walls of the building, not less than a meter.

It is important to remember that non-compliance with this norm will lead to the impossibility of strengthening the soil with geotextiles.

Recommended brands of geotextiles

- To protect the foundation from groundwater it is best to use heat-set geotexil-200.

- If it is necessary to create a distribution load it is advisable to use a woven or heat-set geotextile fabric with a density of 350 to 600 g / m2 (it is impossible to give a more specific brand, it all depends on the materials used in construction and the properties of the soil).

Geotextile for laying paving stones

Today, paving slabs or paving stones have become the main materials for decorating sidewalks, squares, streets, roads, adjoining territories and other surfaces. The variety of paving stones offered by manufacturers is huge. She

Geotextile laying technology

Earlier, when there was no abundance of materials in the construction market, people living in private houses depended on major repairs, which could be repeated more and more often. With the replenishment of the market with various goods that make it possible

Fertilizers

What kind of soil is needed for violets, you already know. It remains to apply fertilizer - and she will be ready for planting a plant. If you plan to plant the plant in purchased soil, then additional complementary foods can be applied only 4 months after planting and rooting of the outlet. Often, store mixes are already saturated with fertilizers, an excess of them will be harmful.

If you prepare the soil yourself, then charcoal or ash can be used to saturate it with mineral components. One glass of crushed coal is enough for a bucket of soil.

Ground egg shells will also be an excellent organic fertilizer. It will enrich the soil with potassium, calcium and reduce acidity.

When preparing the soil with their own hands, flower growers often think about whether to put fertilizers in it. Some buy bags of white mineral powder, while others prepare their own feed using natural and non-hazardous ingredients.

Mullein is one of the sources of essential elements for the growth of Saintpaulias. If you plant a flower in the ground with the addition of a mullein, it will bloom magnificently and effectively. The main thing is not to fertilize the ground with large pieces of top dressing. They are crushed. Without adding mullein when planting, don't get upset. After soaking it, they subsequently use the water obtained rich in microelements for irrigation.

Fertilize the ground with eggshells. It contains potassium and calcium. These components reduce acidity. Store-bought soil is not fertilized if it already contains nutrients, as indicated on the label. Otherwise, due to an excess of fertilizers, the plant will die.

In the next video, you will find the secrets of the perfect soil for violets.

Selection of geotextiles for drainage

It is difficult to make the final choice of material on your own without proper experience, therefore it is often recommended to involve specialists for consultation. It is possible to make mistakes even when purchasing a very expensive geotextile.

You cannot take geotextile from mixed raw materials for immersion into the soil - cotton fibers are gradually completely washed out and the coating loses its filtration qualities. When using such geotextile, frequent system repairs are required.

A person saves on the procurement stage, but spends a lot on restoring the integrity of the structure. It is better to immediately buy a fabric that is more expensive, but more suitable.

The manufacturers indicate the filtration coefficient on all panels. The parameter 125 - 140 m / day is suitable for most types of soil. If there is a lot of water on the site, it flows high, then a fabric with a higher indicator is taken.

The density of the raw material is selected based on the expected load. The longitudinal pressure should be maintained at 1.9-3 kN / m, with a transverse load - 1.5-2.4 kN / m, with a total density of the purchased material from 400-500 N.

Protective sheet for the foundation

To protect the foundation from excess water, drainage is often placed inside the blind area, tightly adjacent to the base of the house.

To protect concrete from water, it is necessary to establish the exact level of ground moisture, the composition of the soil at the site. Then, crushed stone of a suitable fraction is selected, pipes.

Only after preparations can you choose geotextiles.

A trench is dug around the building, deepening one level with the foundation, creating an outward slope. The walls of the dug trench will slope outward, creating an expanded space at the top and narrow at the bottom.

Base protection with geotextiles

Base protection with geotextiles

The slope usually corresponds to the direction of water flow, and the width corresponds to the section of the pipes to be laid. All walls are leveled, the bottom is rammed, creating the most even edges.

The next step is to fill up a pillow of sand, ram it, creating a total thickness of the layer of 5 cm. Geofabric is laid on top of the embankment, and immediately the bottom is covered with gravel. Then, pipes are laid, they are connected, and sprinkled with rubble on top.

Layers of gravel on the sides and on top should be at least 10 cm.

Then, the prepared drainage is covered with parts of the canvas brought out to the sides, enveloping the entire structure with a cloth. Binding with a wire is carried out every 30 cm of fabric. It remains to backfill.

Non-woven core

The non-woven version of the product, which is the result of working with a polymer substance, has become widespread.

Unlike analogs, dornit is created not by gluing, but by punching the fibers with a sharp needle, sometimes with heating.

Dornite variations

Dornite variations

Such a canvas can withstand increased load without damage.

The material is actively used when laying roads, strengthening the soil, preventing the washing out of raw materials with ground liquid.

Drainage in the garden

When working with plantations, optimization of conditions is required - regulation of the amount of water. Some plants need a lot of moisture, others will be killed by excess moisture, and drainage maintains the moisture level at an optimal level.

Geotextile in the garden, vegetable garden

Geotextile in the garden, vegetable garden

To create conditions, separate trenches are dug around the perimeter of the landing site, and they are buried inside the pipe - separate independent elements. The branch pipes are connected with tees, everything is wrapped in geotextile.

Crushed stone is poured on top of the textiles, a textile layer is spread, a stone layer is poured again, and only then the soil is returned.

Prices for the area of geotextile

The price of a running meter of canvas is not too high, which makes the product available for different sizes of the construction budget.

For a drainage structure, the cost of a canvas starts at 10 rubles. for 1 m. If you need to save money, it is better to consider the products of domestic production - the finished geotextile is not inferior to foreign production in terms of technical parameters. At the same time, the difference in price will be significant.

The cost of the coating should not be high or low, the main thing is that the material meets the requirements.

The cost of the material is formed from several factors: the strength of the coating, the density of the woven fabric, the method of production, the cost of raw materials, the manufacturer's opinion. Sometimes you can find geotextile from a large manufacturer cheaper than from a small brand.

If you build drainage yourself, you can save a lot, but there is no guarantee that everything is done correctly. Hiring specialists can cost differently, the minimum price for such work starts from 30 rubles. for 1 sq. m construction.

Laying geotextiles during the construction of foundations

The level of effectiveness of the use of protective geological sheets for the foundations of buildings largely depends on the exact adherence to the technology of laying the material. For each type of foundation, it has certain characteristics. But before laying geotextiles under the foundation, you should study the basic principles:

- the surface of the soil or bulk material must be well compacted and horizontally leveled as much as possible;

- the overlap of adjacent canvases during laying is a strip - not less than 200 mm, if there is a slope - twice as much;

- if possible, it is recommended to use the thermal method of joining the canvases, otherwise plastic or metal staples should be used.

A gas torch or blowtorch is used to weld the blades. After sufficient heating, the adjacent edges are superimposed on each other and pressed tightly. Concrete is not poured onto geotextiles. Before concreting, the canvas is covered with a layer of compacted sand 50-100 mm thick.

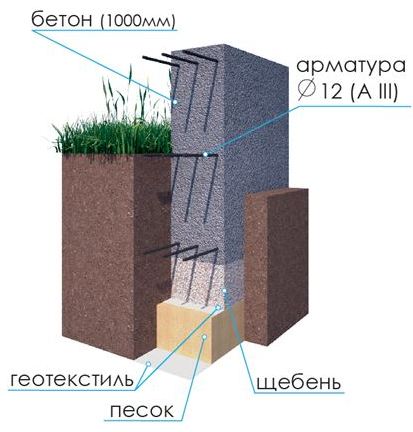

Monolithic strip-type foundation

A geological bed with a density of 300 g / m2 or more is laid on the bottom of the trench before backfilling the underlying cushion. If a layer of gravel and sand is filled up separately, and not in the form of a mixture, then they should also be separated with geotextiles under a strip foundation with a density of 200-300 g / m2. This will eliminate the gradual washing out of sand into the gravel layer.

The lower layer of textile should be connected to the vertical sheet from the outside of the tape and only then proceed with the assembly of the formwork structure. With a fixed formwork made of expanded polystyrene, a vertical strip of roll insulation is not needed, since the foam will already provide sufficient protection by itself.

At the end of the pouring of the concrete mixture and its setting, the upper plane of the monolithic tape should also be covered with a canvas with a density of 150-250 g / m2. A higher density is not required in this case.

Precast concrete strip foundation

The difference between protection from a monolithic structure is that the side wall of the tape is protected with geotextiles, gluing it to the concrete surface using bitumen mastic. In this case, the edges of the side sheet should go beyond the edges of the wall and connect with other layers.

Slab bases

The strips of canvases are spread along the entire bottom of the pit in such a way that they extend beyond the perimeter of the foundation by 150-200 mm. Then the formwork is installed, the reinforcement cage is assembled and the concrete is poured.

After removing the formwork panels, the film is wrapped on the side ends and glued with bitumen mastic. The top plane of the monolithic slab is not insulated, since it will be closed from external influences.

Columnar and pile foundations

The pillars and piles themselves do not need geotextile waterproofing of the foundation. But, if there is a basement floor, before installing the grillage, it is recommended to cover the leveled soil with a canvas and pour sand, gravel on top or pour concrete on the surface. After that, you can proceed to the installation of the grillage and basement walls.

As a protective material, you can choose a non-woven film material with a density of 150-200 g / m2.

Self-cooking

Experienced flower growers prepare their own soil for indoor plants at home. For saintpaulias, you will need several required components.

- Leafy humus. It is used to improve soil structure. It is a good mulch and acidifier component. Leaf humus is made from different plants, but for saintpaulias, fallen leaves are collected from birches and placed in special bags for decay.

- The turf has a high water-lifting capacity and low moisture permeability and water holding capacity. It is harvested in a place where deciduous trees and shrubs grow, carefully cutting off the outer layer of soil with interlacing of plant roots.

- Vermiculite and / or perlite.Gardening stores sell small or large chunks of minerals. For saintpaulias, small substances are bought and added to the soil as a baking powder. They retain moisture to give Saintpaulia roots until the next watering.

- Sphagnum. Moss can be used to fluff the soil. Sphagnum is added instead of vermiculite, collected in the forest, near water bodies or in swampy areas. It is stored raw, dried or frozen. In the latter case, the frozen moss is thawed before use.

- Coarse river sand. With its help, the soil becomes airy, and its other components receive reliable protection from drying out.

- Coconut substrate. This nutritional supplement is sold at a flower shop or sourced from supermarket-bought coconuts.

Types of geotextiles

The use of different materials and manufacturing methods has resulted in a variety of product variations. Geotextiles for paving slabs and other options, depending on the manufacturing technology, are of the following types:

- woven - the interlacing of several polymer threads is used;

- non-woven - heat treatment of polymer fibers;

- needle-punched - is made by penetration with needles;

- thermally bonded geotextile - melting of polymer filaments;

- hydrobonded - non-woven fabric, pores are created by streams of water;

- knitted nonwoven - a canvas of several layers.

Woven geotextile

This material is produced in the same way as a regular fabric using a specific weaving pattern. Woven fabric is made from polyester and glass fibers. Based on the material of the threads and the method of their weaving, the features of the obtained canvases differ. They are impregnated with strengthening compounds and passed through special calenders for partial melting and as a result of compaction. The average service life is 50 years. A similar view is used for:

- separation of ground layers when creating tracks;

- strengthening the structure;

- sharing the load on the base;

- landscape design.

Non-woven geotextile

The material is made from polyester or polypropylene fibers that are bonded in different ways. Nonwoven geosynthetics are subdivided into the following types:

- Needle-punched geotextile... It is made by weaving polypropylene yarns with a woven base. Possesses increased filtering characteristics. Can be improved with reinforcing mesh.

- Thermally bonded... It is obtained by bonding threads under the influence of high temperatures. For manufacturing, only polypropylene is used. The canvas allows a small amount of water to pass through.

Used in the following situations for:

- strengthening the foundations;

- reinforcement of slopes;

- landscape design;

- strengthening the road surface.

# 1. Geotextile production technology and its properties

Geotextiles, one of the types of geosynthetics, are made from synthetic raw materials, often polyester and polypropylene threads, other polymers and fiberglass are used. The method of production of geotextiles and, therefore, the main qualities of the finished material and the scope of its application depend on the raw material.

The most durable geotextiles are made from polyester and polypropylene yarns. Also on sale you can find material from blended yarns, in the production of which wastes from the textile industry are used. If cotton or wool threads were mixed, then such material is not particularly suitable for drainage work, as it wears out quickly, but for garden and landscape work it is quite suitable. If the manufacturer used glass inclusions, then the strength of such geotextiles will be at a height.

According to the method of production, geotextiles are divided into the following types:

- needle-punched. This material is called the most suitable for the organization of drainage. It passes water well due to elastic pores and can be used on almost any type of soil;

- thermally bonded (thermoset). The material is characterized by high strength, durability, mold resistance, but it passes water mainly in the transverse direction. It can be used for the organization of drainage on stony soils and on soils with a high content of coarse sand. It is also used for strengthening slopes, laying paving stones and for weed control;

- The knitting and stitching method is used for the production of geotextiles, a subspecies of geotextiles. It is produced by weaving synthetic fibers, resulting in a durable material that is used primarily for strengthening and reinforcement, but not for drainage.