Materials and sizes of foundation blocks

Manufacturing materials:

- expanded clay concrete. The main components are Portland cement and expanded clay. Due to expanded clay, the material has a low density (up to 1.8 tons per cubic meter) and a relatively small weight - 260-1500 kilograms. Marked with the letter L (i.e. lungs). Pros: excellent thermal insulation properties, the most affordable price. When using threefold savings: cheaper material itself, easier installation (cheaper equipment rental), less consumption of heat-insulating materials. The best option, but only for light structures in a relatively dry area: the water resistance of materials from expanded clay is low and the bearing capacity of finished blocks is also;

- reinforced concrete (aggregate - gravel). Grades M100, 150, 200. For a one-story light construction, 100 is enough. The weight of the foundation block made of reinforced concrete is the largest, from 300 to 2000 kilograms, depending on the dimensions, the density is not less than 2 tons per cubic meter. Marked with the letter T. Unlike expanded clay concrete, reinforced concrete is suitable for heavy brick and stone buildings, incl. for multi-storey construction.

- silicate high-strength concrete. Medium-weight material (C mark). The astringent is lime. Average density 1.8 tons per cubic meter, weight 300-1630 kilograms. The strength of these blocks is greater than that of expanded clay concrete, but the water resistance is even lower, therefore, they are usually not used for foundations.

The choice of the type of concrete blocks for the foundation depends not only on the climate, but also on the chemical composition of the soil. For example, on deoxidized soils near Moscow, a material with crushed stone in the composition is preferable, it has a higher resistance to acids. The chemical composition of the soil is determined using a special test (can be purchased at an agricultural store).

To increase frost resistance, special additives are added to the original composition of all blocks.

Types of blocks according to GOST: FBS, FBP, FBV, FL and BF

For the construction of technical underground rooms, the construction of basement walls, devices, as well as the construction of walls of low (often unheated) buildings, other structures operated at temperatures ranging from +50 to -70 degrees, concrete blocks of three types are traditionally used (according to GOST 13579- 78): FBS, FBP and FBV. They are made from heavy or silicate, as well as expanded clay concrete. The density of such products should be 1800 kg / m3 and higher.

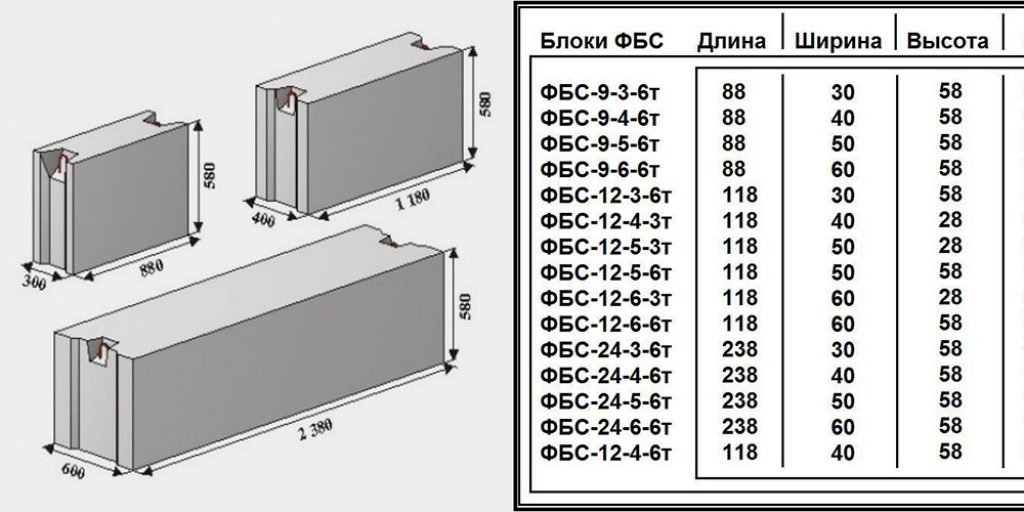

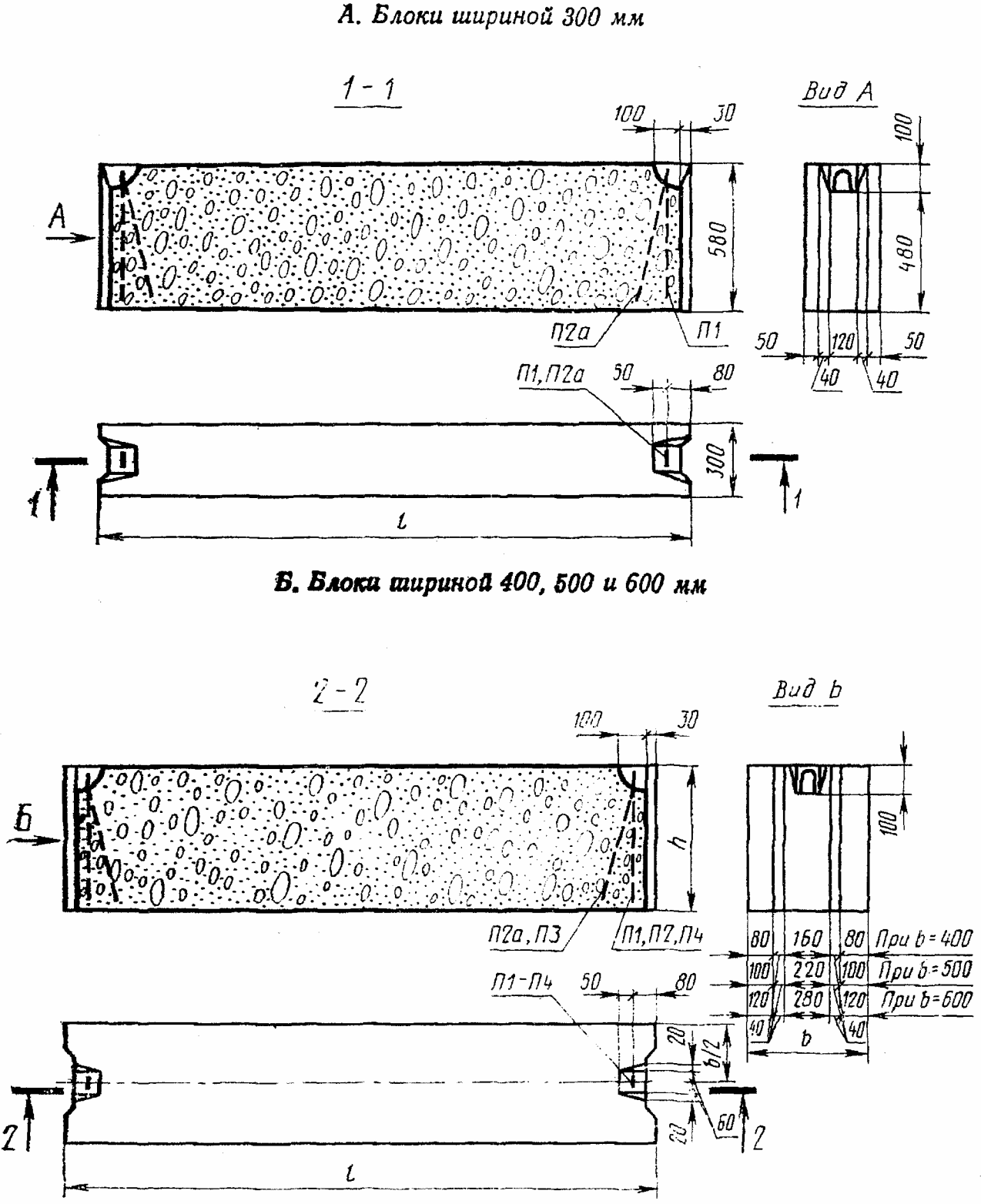

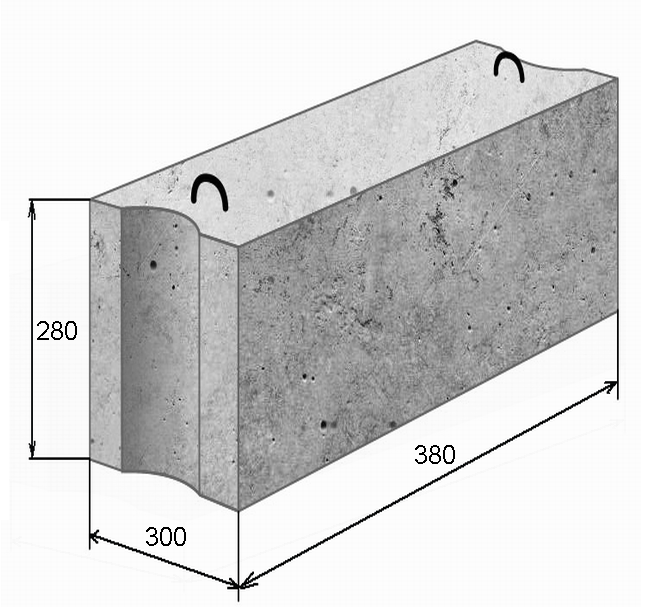

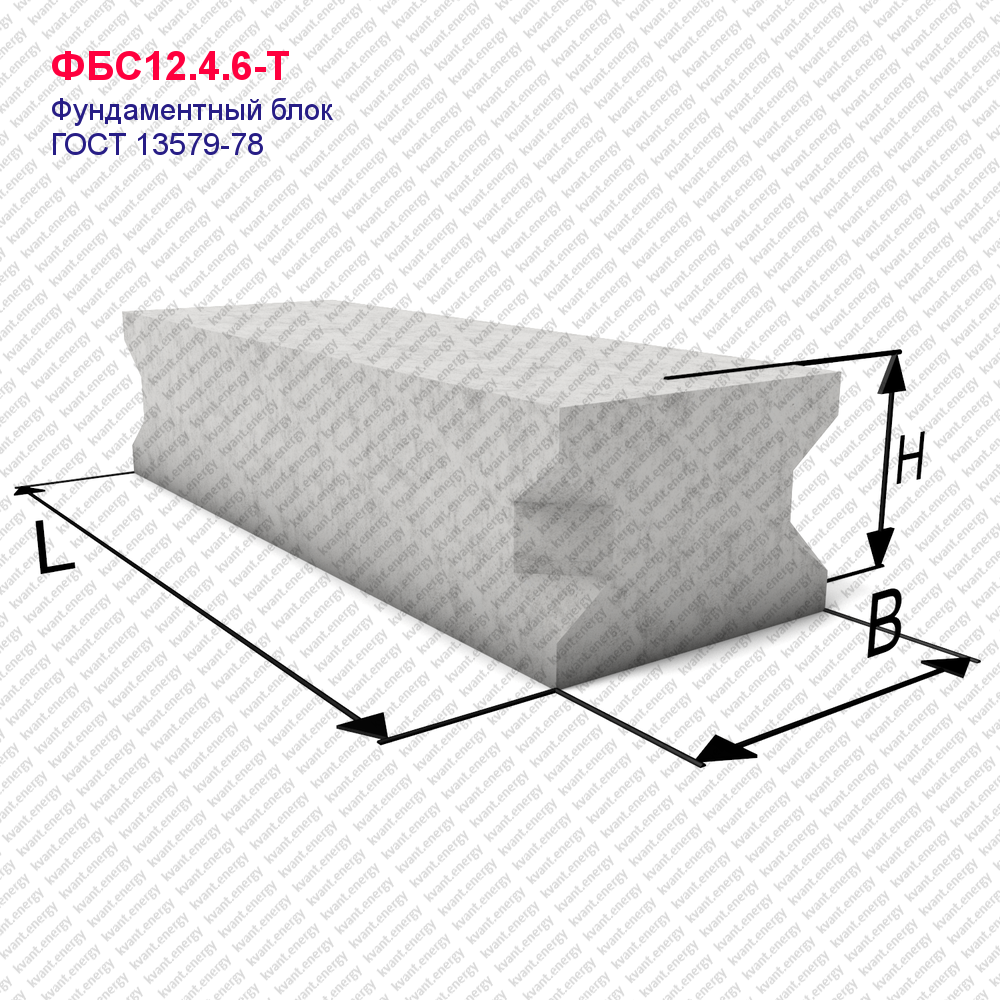

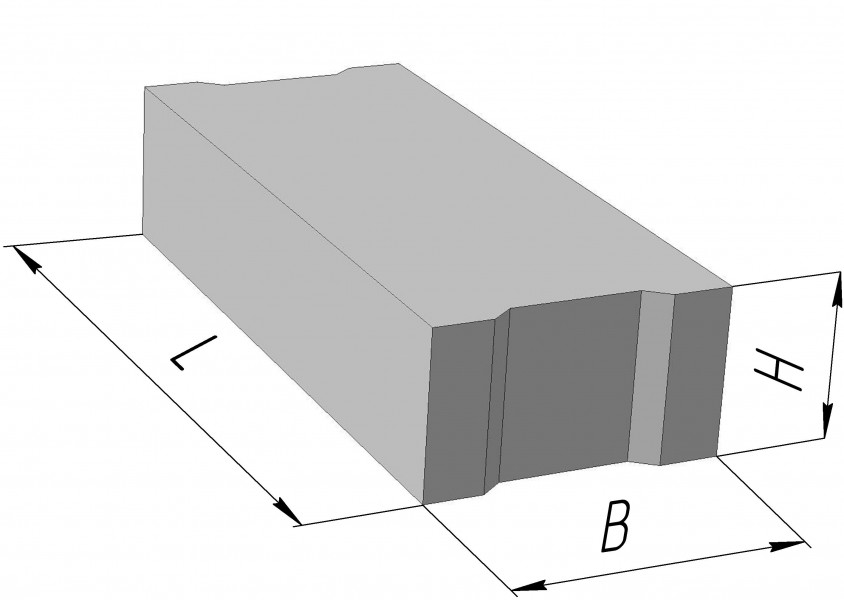

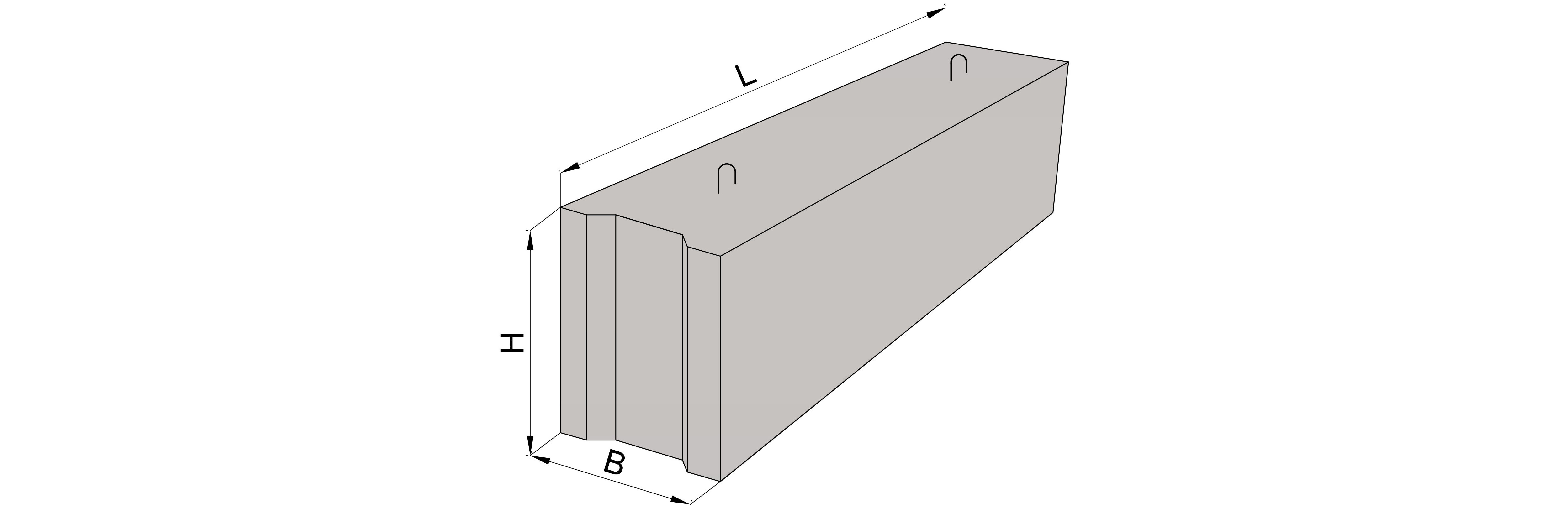

FBS is a solid foundation block with a maximum strength index. Small products are not reinforced, they are only equipped with mounting metal hinges. Dimensional blocks are reinforced with longitudinal steel rods, which significantly increases the weight and strength of building elements.

FBV blocks assume the presence of a longitudinal dimension in the cavity of the product itself. We need this section to carry out the installation of various utilities. Such products are manufactured using the same technology as FBS, but from. In construction, such blocks are rarely used, they are usually ordered at the factory. Sizes are standard: length 88 centimeters, height 58 and width 40/50/60 centimeters.

FBP are lightweight hollow blocks with square open holes located at the bottom of the element. They produce blocks of concrete grade not lower than M150, their standard length is 238 centimeters. The linear dimensions can be very different, which determines the cost of the product. FBP is used in the construction of foundations for industrial equipment, for arranging walls inside the basement.

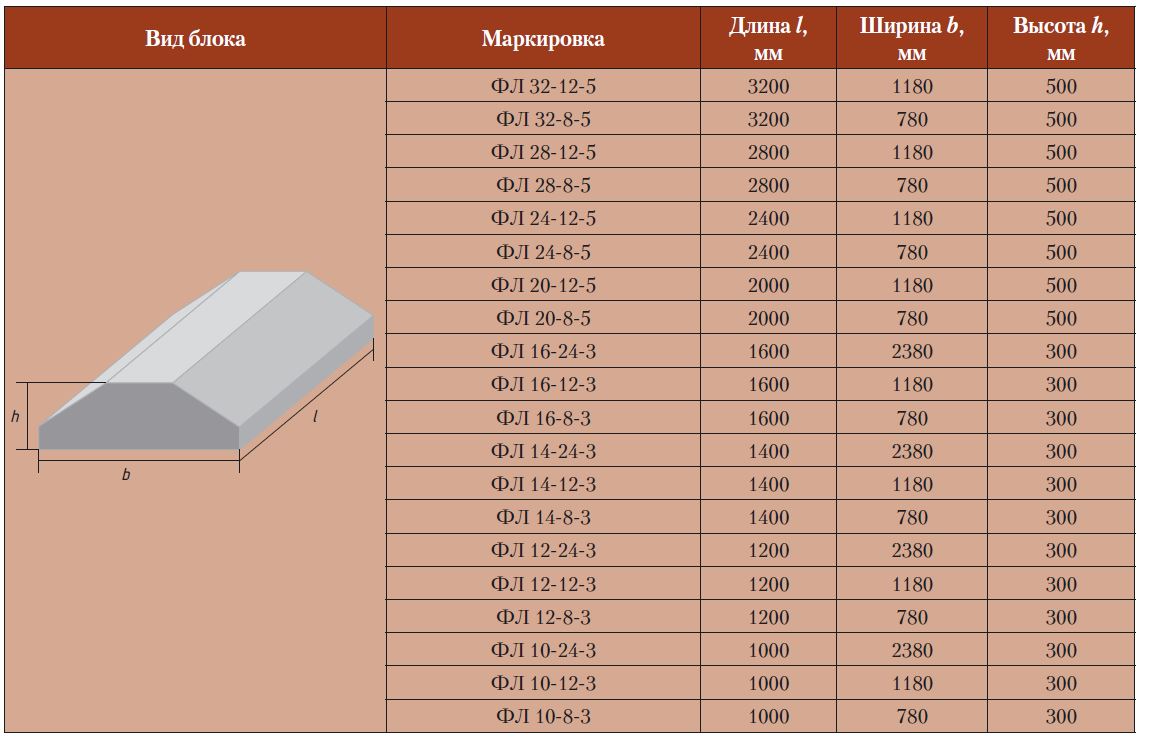

There are also blocks marked FL, which have a trapezoidal shape and are usually used as a base for a strip / column type foundation. The dimensions and parameters of these kind of "pillows" are regulated by GOST 13580-85.The height of the elements can be 30/50 centimeters, width - from 60 to 320 centimeters, length - 78-298 centimeters.

The smallest blocks have dimensions of 118 by 60 by 30 centimeters, the largest ones suggest a size of 298 by 200 by 50 centimeters.

BF blocks are used for the construction of external / internal walls of buildings of industrial and agricultural enterprises. Reinforced concrete belt blocks are made of heavy concrete, in accordance with the standards of GOST 28737-90. There are only 6 types of block cross-section sizes.

Manufacturing technology

FBS are made in the form of a parallelepiped. For manufacturing can be used:

- heavy concrete;

- expanded clay concrete;

- silicate concrete of medium density.

Concrete blocks are not reinforced. For the manufacture of concrete blocks for the foundation, various technologies are used, the most common are:

- natural drying (100% strength is achieved on day 28);

- steaming (forced drying to obtain 100% strength in a short time. The block, which is in the steaming chamber for a day, acquires strength from 70% and more).

The most important ingredient in a block is quality concrete. In the end part of the FBS, grooves are provided, which are filled with mortar during installation work.

Figure 2 - Form for filling

The block manufacturing process is as follows:

- Prepare a mixture of concrete using cement, aggregate and water (the mortar is mixed using the blades of a forced-type mortar mixer).

- Load the mortar into the block mold (manually or using a concrete pump-pneumatic blower).

- Compact the mortar (a deep vibrator is used to compact the mortar). The concrete compacting process takes a few minutes.

- Take out the finished blocks after a day (removal occurs earlier, in the case of using hardening accelerators).

To prevent the block from drying out, cover it with plastic wrap and water it occasionally. This is necessary for the block to gain strength.

Weight of products

In GOST, which regulates the characteristics of FBS blocks, not only the dimensions and strength of products are normalized. The special documentation provides for accounting for the mass of products. It is needed for quality control. This is due to the fact that under construction conditions it is not possible to estimate the density of the material.

The mass of the blocks is also needed for the optimal selection of loading equipment. In addition, the choice of vehicles transporting building materials depends on this indicator. FBS is usually transported using 10 or 20-tonnages.

The strength and durability of the foundation depends on many parameters, including the correct calculation of the number and dimensions of individual elements of prefabricated structures. One of the most popular foundation options is the creation of a foundation from concrete products.

For such structures, it is not necessary to construct formwork, and the high strength of the products is guaranteed by the technological features of their manufacture. Concrete in the process of creation is steamed and vibrated.

During the construction of foundations on soft soils, the foundation blocks are placed on special cushions. Such products are slabs in the form of a prism, which can significantly reduce the load on the soil.

In addition to the construction of foundations for houses, such products are used in the construction of overpasses, ramps and fences. GOST, which regulates the conditions for the manufacture of blocks, was adopted back in 1978.

How to lay FBS

In any row, styling starts from the corners. Then blocks are placed in places where the walls are taken off. They are called lighthouses, and then everyone else is equal to them. The verticality of their exposure is checked, corrections are made if necessary. More often than not, the unit needs to be lifted again, moved and put in place.

After the lighthouse elements are exposed, the moorings are pulled - the cords along which they are guided when installing the following blocks.They mark the boundaries of the wall, and so that the FBS are symmetrical about the middle of the FL block (pillow block). The maximum permissible deviation is 12 mm. All subsequent rows of blocks should also be placed exactly above the middle.

When stacking blocks, make sure that they are stacked one above the other without too much displacement.

It is more convenient to pull the cords 2-3 mm from the side surfaces of the lighthouse blocks. It will be easier to exhibit this way. Intermediate blocks are set starting with the largest: first they put everything 2.4 meters long, then 1.2 and then 0.9. The correctness of their installation is checked with respect to marking cords, verticality - with a plumb line.

Product characteristics

Foundation blocks are selected according to the purpose of the material

Foundation blocks are selected according to the purpose of the material

In addition to the fact that the foundation blocks are selected by density and mass, there are many properties that affect the determination of the purpose of the material:

- Standard size. Foundation blocks must be determined by their shape, purpose and marking:

- In the form of a cylinder with the letter "F" - products used for pile, columnar type foundations.

- Reinforced concrete products in the form of a trapezoid are used as a support for a tape, columnar base, are marked "FL", the parameters are regulated by GOST 13580-85.

- Elements in the shape of a rectangle, equipped with ears at the ends, are FBS blocks, they are shown in the photo, they are used for the construction of a strip foundation, the construction of basements, and the construction of walls. Dimensional gradations are specified in GOST 13579-78.

- Hollow products designed to create non-removable formwork are designated "FBP". Shown for the construction of high-rise buildings, in a small-format private house-building use of the material is unprofitable - a huge margin of safety will not be fully used. GOST 13579-78.

- Beams in the shape of a rectangle, trapeziums are marked "BF" and are standardized by GOST 28737-90.

Deciphering the notation is quite simple.

Deciphering the notation is quite simple.

The decoding of the designations is quite simple: the designations of the numbers are the dimensions of the elements (dm): the first is the size of the length, the second is the width, the third is the height. The dimensions and weight of the products provide for the use of a crane, a winch, but manufacturers offer small-format blocks for the foundation 20 * 20 * 40 cm, which, as a rule, are produced by the same plant as large-format products. The production includes vibrocompression processes, using a solution of Portland cement, clean sand and coarse aggregate, due to which the desired density of the solution is achieved.

There are small-format foundation blocks for solid and hollow:

- Solid elements are shown for arranging foundations for low-rise (1-3 floors) buildings on solid soils.

- Hollow core elements are ideal for building wall panels.

- Frost resistance. The standard is determined only for certificates that are issued for products and is calculated in the number of complete freezing / thawing cycles of products.

- Resistance to aggressive environments is another parameter required for accounting. In this case, it is better to choose the type of concrete using a preliminary soil test. Testers are sold in building materials stores and cost about $ 2. After testing, the developer will be able to pick up wall or foundation material with crushed aggregate - they are much stronger than expanded clay and more resistant to alkaline acidic soils.

Manufacturing technology

If we consider the technology for creating FBS, then today there are several options for their manufacture.

If we consider the technology for creating FBS, then today there are several options for their manufacture.

If we consider the technology for creating FBS, then today there are several options for their manufacture. The choice of approach depends on the concrete filler. So, on the market you can find the following methods:

- Expanded clay or silicate models. The density is 1800 kg per cubic meter. m, and determines the size of the weight of the blocks.

- Foundation blocks made of high quality concrete;

- Cement block M 100 is one of the cheapest categories.

According to Gost 78, the FBS outflow should take place in special forms or by the method of momentary stripping. The second method is characterized by a trapezoidal section. It is worth considering that in addition to cement, the blocks include plasticizers and additives.

Features of calculation and installation

As you said, calculating the number of blocks is pretty straightforward. To do this, you need to determine the volume of the future foundation and divide it by the volume of one block you have chosen. As a result, you will receive the required number of designs for ordering.

You don't have to worry about the number of storeys in the building. The strength of the factory block is quite sufficient to build a five-story building on it.

The condition of the soil is much more critical for such a structure. Here you need to take into account one feature of block bases - low solidity. Unlike a solid strip foundation, a block foundation has vertical and horizontal seams that weaken it. Therefore, before installing the FBS blocks, a monolithic reinforced concrete belt is poured along the bottom of the trench. It takes over a significant part of the heaving forces that arise in freezing wet soil.

If the foundation of the building is high (there is a basement), then experts recommend making an armored belt every two rows of blocks.

The ideal foundation for a block foundation is soils composed of coarse sand with a deep aquifer. Since such conditions are very rare, in all other cases the block grillage needs to be strengthened. In addition to using an armored belt, each row of blocks should not be laid dry, but on a concrete M 150 mortar with a thickness of at least 3 cm.

Preparation of the base

For the base under the blocks, it is enough to make a sand bed. It plays the role of a leveling layer and its thickness usually does not exceed 15 cm. If the construction is carried out on dry sandstones, then the blocks can be placed directly on the ground.

For buildings erected on problem soils, reinforced concrete foundation cushions (FL) are placed under the blocks to increase the support area.

Installation of a foundation made of concrete blocks

The norms prohibit the installation of a foundation from FBS blocks if the bottom of the trench is covered with snow or flooded with water. The movement of these structures is performed by a crane.

First, blocks are installed at the corners of the foundation and at the junction points of the inner walls. They act as assembly beacons. Having checked the coincidence of the upper planes of all the lighthouse blocks with a leveling level, a cord is pulled between them and intermediate structures are set along it. At the points determined by the project, gaps are left between the blocks for the passage of engineering networks.

Before installation, the blocks are cleaned of dirt and moistened with water. Installation is carried out on a concrete solution with bandaging of vertical seams (due to displacement of rows and the use of additional blocks). Vertical seams are also filled with mortar, sealing it with a bayonet shovel.

Helpful advice: when buying foundation blocks, be sure to check with the seller for a certificate of conformity and ask for a copy for yourself. This document guarantees that the quality of the products meets the requirements of the current GOST. It may be needed to substantiate the claims that have arisen and to recover damages.

Related videos:

Manufacturers and prices

Concrete products such as FBS and other blocks are produced by many concrete plants, so it will not be difficult to find them in Moscow and the regions. The volume of production can be different, but all serious manufacturers guarantee high quality and technology compliance in strict accordance with the current GOSTs.

One of the largest manufacturers of FBS in Russia is the Factory of Industrial Building Parts. All products are manufactured in accordance with GOSTs, are durable and quality, the average price of foundation blocks starts at 1200 rubles per piece.

Vira, a Russian company, specializes in the creation of various concrete elements.The range of products includes more than four hundred items, among them there are different types of foundation blocks. The cost is different, depending on the size and type, on average it starts from 1650 rubles.

The products of the "Master" company are distinguished by their high quality. The plant creates various types of concrete blocks, the cost of which depends on the position, but is at a level slightly lower in comparison with other manufacturers.

The Alexandria expanded clay plant produces various types of concrete products. Small concrete blocks used in the creation of load-bearing walls, columns, fences, as well as used as supporting elements of semi-basement, basement, basement floors, are in rather high demand. All blocks are produced in special shapes, which guarantees dimensional accuracy. The cost is different, depending on the type and size of the element.

Good products are supplied to the construction market by the Zlatoust plant - the range includes FBS, FVP, FBP, panels, stairs, road slabs and lintels. All are sold at an affordable price, the cost of the foundation block starts at 950 rubles apiece.

How is acceptance and quality checked?

After manufacturing, the foundation blocks are accepted by the employees of the technical control service in batches of up to 200 pieces. During acceptance tests, the dimensions, strength characteristics, and welded joints are controlled.

All blocks of this class are made of heavy grades of concrete, they must meet the requirements of GOST for bases and foundations

Both laboratory and visual control methods are used. The surface category, crack opening width and accuracy are selectively checked. Visually control the correctness of the designation, the presence of embedded elements, safety lugs.

For product control, laboratory equipment, ultrasonic testing and other methods are used to check:

- Moisture absorption coefficient.

- Resistance to negative temperatures.

- Strength characteristics.

- Dimensional tolerances.

- Strength of welded joints.

- Waterproof.

- Marketable condition.

- The presence of a protective layer.

- The state of the reinforcement cage and embedded parts.

Characteristics and features of FBS foundation blocks

FBS is produced from 1800 to 2400 kg / m3. The specification assumes the following three variants of the mixture: with a strength above B7.5 (grade M100), at least B12.5 (grade M15), heavy concrete with strength from B3.5 (grade M50) to B15 (grade M200).

The low temperature resistance shown by FBS must be at least F50 (which means that the foundation block can withstand a minimum of 50 freeze / thaw cycles). The optimal level of moisture resistance is W2, the thermal conductivity of the block is quite high, but for the foundation it is not scary.

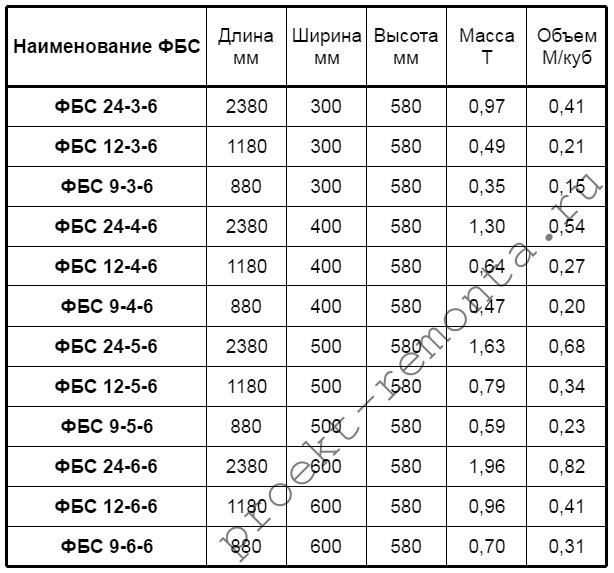

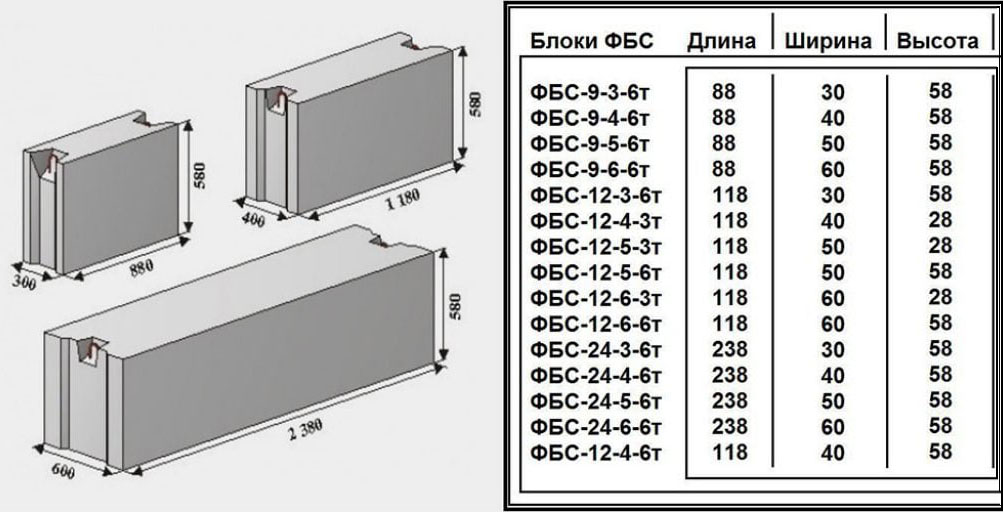

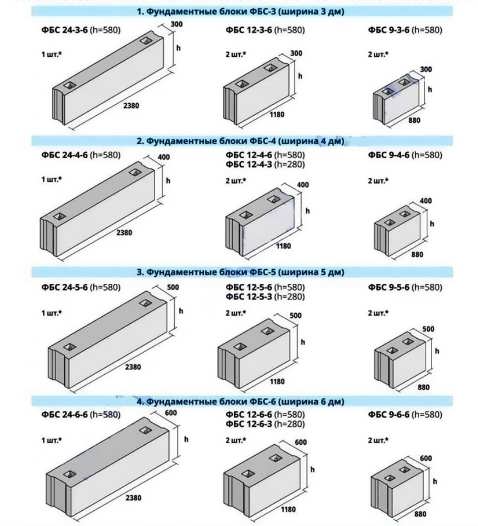

Designating the size of the FBS, indicate its value in decimeters, rounded up. In addition to the dimensions, they also indicate the type of concrete from which the FBS is made: heavy (T), silicate (C), expanded clay (P, with a porous base).

An example of decoding the marking of the FBS-24-4-6 T block: the size of the foundation block is 240 centimeters in length, 40 and 60 centimeters on the side, it is made of heavy concrete. Marking can be done in different ways (with dots, hyphens, spaces), but always presupposes the indication of the basic values.

The weight of the FBS starts at 260 kilograms, so the construction of the foundation is carried out exclusively with the involvement of special equipment, it will not be possible to do the work with your own hands.

In the construction of residential buildings, foundation blocks of small length are usually used, multi-storey and industrial buildings are the largest. In the production of blocks, a certain size error is allowed.

Size tolerances in the standard:

- In height / width - deviation up to 8 millimeters.

- Length - no more than 13 millimeters.

- Along the cutout - up to 5 millimeters.

When buying and choosing blocks, it is important to pay attention to the correspondence of the size and mass of the FBS. So, if the weight is below the specified value, and the dimensions are normal, this indicates the presence of void areas in the blocks, poor compaction of the material, which negatively affects its strength. It is better not to use such blocks in the construction of the foundation.

It is better not to use such blocks in the construction of the foundation.

To facilitate the installation process, the blocks are made with special metal lugs, which are placed on top. They are made from periodic metal profiles or steel. If necessary, you can order small blocks without hinges. According to GOST, there should be no cracks or deformations on the blocks. In addition to the main types, blocks FBP, FBV and others are also produced for the construction of residential and public buildings.

Pink 20Ñ20Ñ40

Til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, til, t, t, t, t, and t Roughness. Saucer line 190Ñ190Ñ390 saucer line. Bark, bark, bark, bump, 30 b, 30 b, b, b, b. Burgundy birch bark Lol 35 Lt 75 L ±. L · Ð ° кÑ. Saucer 20Ñ20Ñ40 saucer 62 sartorial , Heart, heart, heart, heart, heart, heart

Foundation block marking

Marking starts with a few letters. Depending on the application by design, the elements of the zero cycle are divided into:

- F - reinforced concrete and concrete from heavy concrete for columns (the so-called glass type);

- FL - reinforced concrete made of heavy concrete for the construction of strip foundations;

- FBS - concrete solid unreinforced for the construction of basement walls, technical underground floors and foundations;

- BF - reinforced concrete tape made of heavy concrete for the construction of external and internal walls of buildings of industrial and agricultural enterprises;

- FR - reinforced concrete from heavy concrete under three-hinged frames;

- FBP - foundation concrete hollow.

Subsequent numbers mean the dimensions of the foundation block in decimetres, rounded up to an integer: length, width and height in decimeters or width and length (for FL). The first number is the length, the second is the width, and the third is the height of the foundation block.

Table 1. Dimensions of FL foundation blocks

| Brand | Dimensions, mm | Weight, t | Concrete consumption, m3 | ||

| L | B | H | |||

| FL6-24 ... | 2400 | 600 | 300 | 0,93 | 0,37 |

| FL6-12 ... | 1200 | 600 | 300 | 0,45 | 0,18 |

| FL8-24 ... | 2380 | 800 | 300 | 1,15 | 0,46 |

| FL8-12 ... | 1180 | 800 | 300 | 0,55 | 0,22 |

| FL10-30- ... | 2980 | 1000 | 300 | 1,75 | 0,69 |

| FL10-24- ... | 2380 | 1000 | 300 | 1,38 | 0,55 |

| FL10-12- ... | 1180 | 1000 | 300 | 0,65 | 0,26 |

| FL10-8- ... | 780 | 1000 | 300 | 0,42 | 0,17 |

| FL12-30- ... | 2980 | 1200 | 300 | 2,05 | 0,82 |

| FL12-24- ... | 2380 | 1200 | 300 | 1,63 | 0,65 |

| FL12-12- ... | 1180 | 1200 | 300 | 0,78 | 0,31 |

| FL12-8- ... | 780 | 1200 | 300 | 0,50 | 0,20 |

| FL14-30- ... | 2980 | 1400 | 300 | 2,40 | 0,96 |

| FL14-24- ... | 2380 | 1400 | 300 | 1,90 | 0,76 |

| FL14-12- ... | 1180 | 1400 | 300 | 0,0,91 | 0,36 |

| FL14-8- ... | 780 | 1400 | 300 | 0,58 | 0,23 |

| FL16-30- ... | 2980 | 1600 | 300 | 2,71 | 1,09 |

| FL16-24- ... | 2380 | 1600 | 300 | 2,15 | 0,86 |

| FL16-12- ... | 1180 | 1600 | 300 | 1,03 | 0,41 |

| FL16-8- ... | 780 | 1600 | 300 | 0,65 | 0,26 |

| FL20-30- ... | 2980 | 2000 | 500 | 5,1 | 2,04 |

| FL20-24- ... | 2380 | 2000 | 500 | 4,05 | 1,62 |

| FL20-12- ... | 1180 | 2000 | 500 | 1,95 | 0,78 |

| FL20-8- ... | 800 | 2000 | 500 | 1,25 | 0,50 |

| FL24-30- ... | 2380 | 2400 | 500 | 5,98 | 2,39 |

| FL24.24- ... | 2380 | 2400 | 500 | 4,75 | 1,90 |

| FL24.12- ... | 1180 | 2400 | 500 | 2,30 | 0,91 |

| FL24.8- ... | 780 | 2400 | 500 | 1,45 | 0,58 |

| FL28.24- ... | 2380 | 2800 | 500 | 5,90 | 2,36 |

| FL28.12- ... | 1180 | 2800 | 500 | 2,82 | 1,13 |

| FL828-8 ... | 780 | 2800 | 500 | 1,80 | 0,72 |

| FL32.12- ... | 1180 | 3200 | 500 | 3,23 | 1,29 |

| FL32.8- ... | 780 | 3200 | 500 | 2,05 | 0,82 |

The brand of the slab is assigned by the project according to the value of the design pressure on the base under the base of the foundation, which is determined by dividing the calculated vertical uniform linear load (with a load safety factor equal to 1.0) by the width of the slab. The reinforcement and concrete grade of the slab are also assigned by the project.

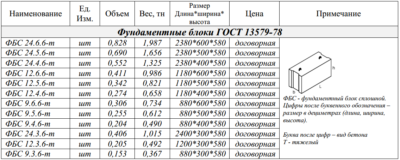

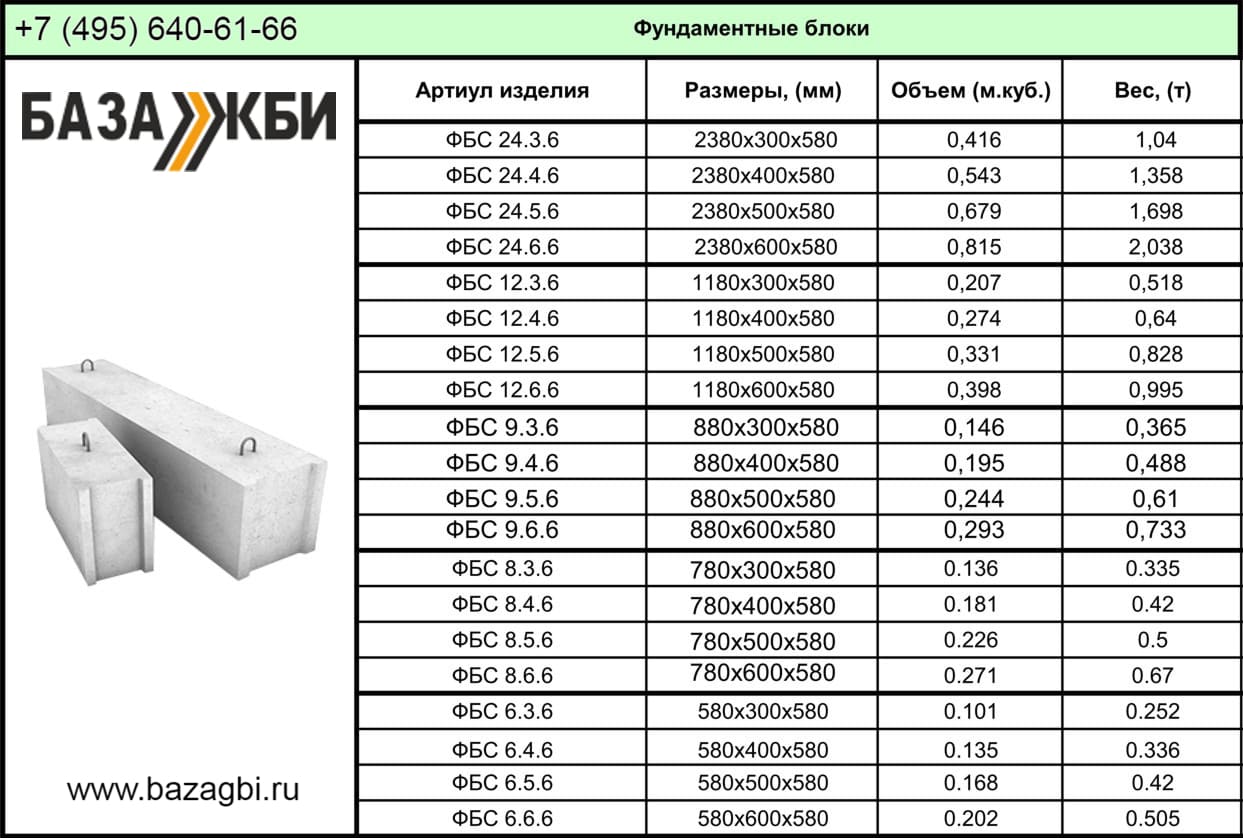

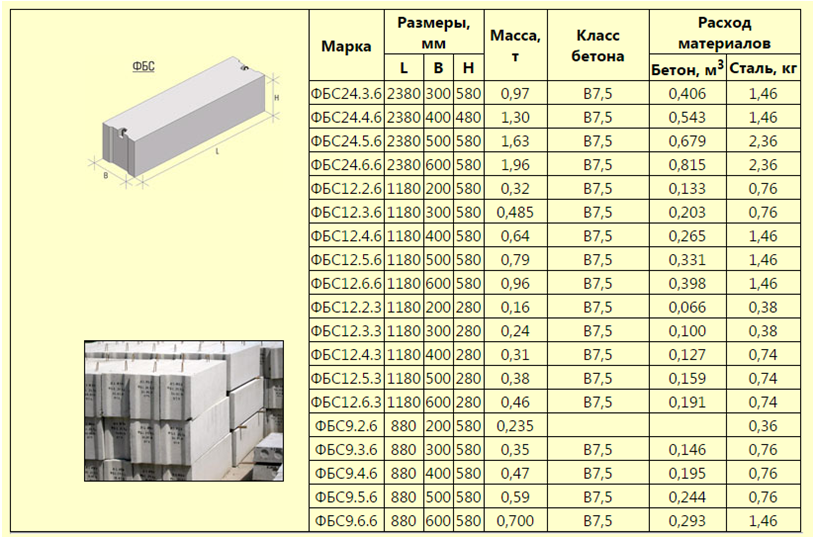

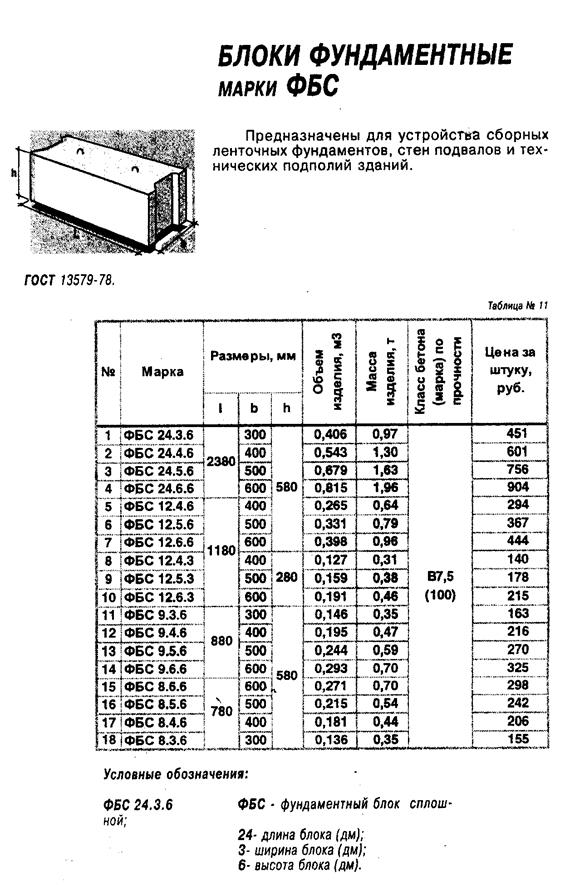

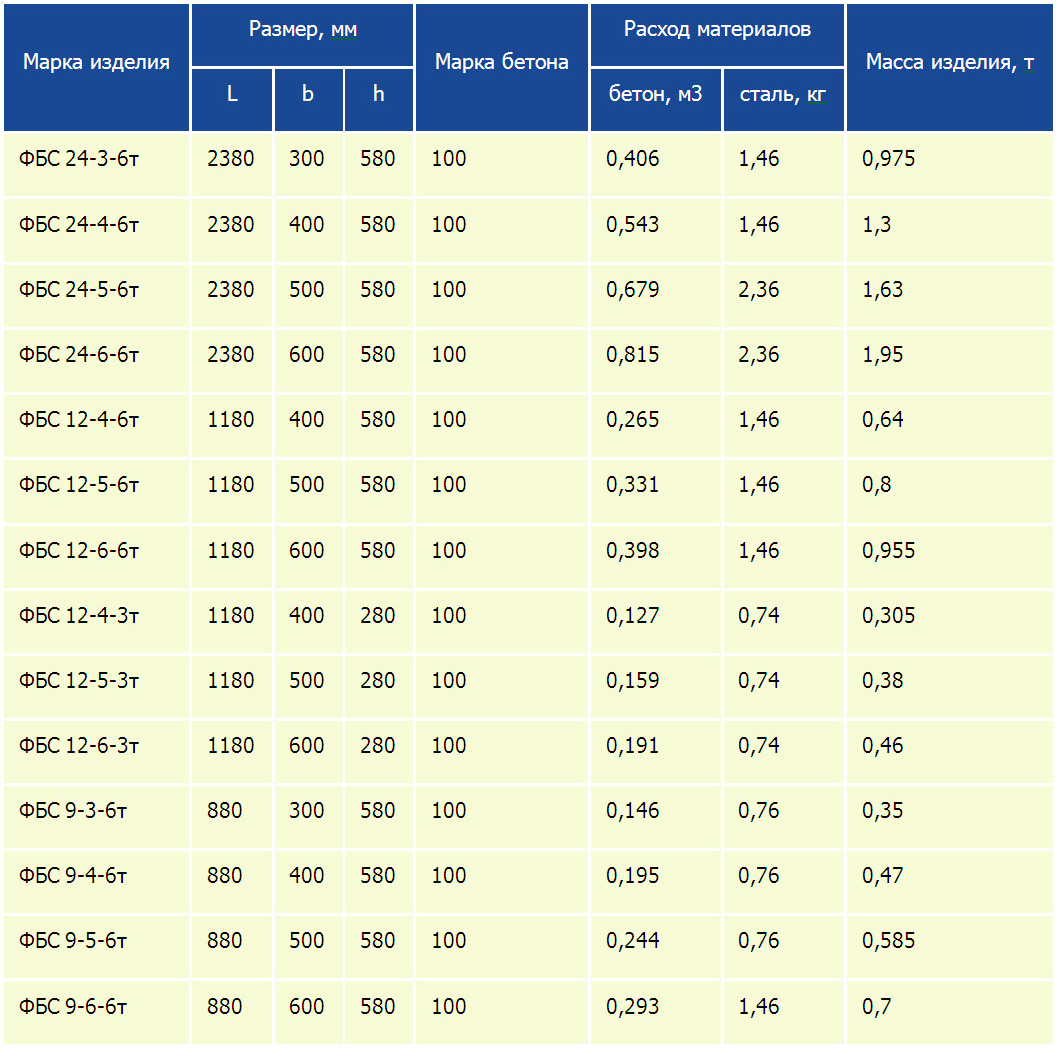

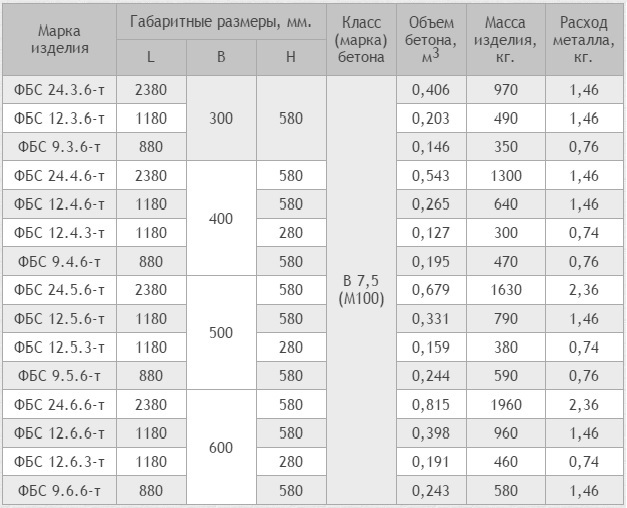

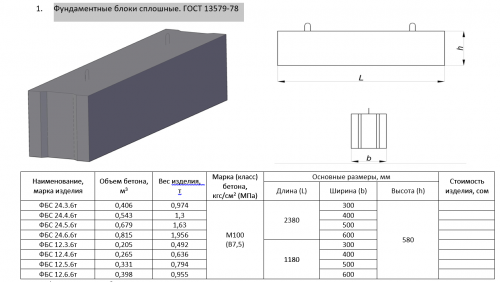

Table 2. Dimensions of FBS foundation blocks

| Brand | Dimensions, mm | Weight, t | Concrete class | Consumption of materials | |||

| L | B | H | Concrete, m3 | Steel, kg | |||

| FBS24.3.6 | 2380 | 300 | 580 | 0,97 | B7.5 | 0,406 | 1,46 |

| FBS24.4.6 | 2380 | 400 | 480 | 1,30 | B7.5 | 0,543 | 1,46 |

| FBS24.5.6 | 2380 | 500 | 580 | 1,63 | B7.5 | 0,679 | 2,36 |

| FBS24.6.6 | 2380 | 600 | 580 | 1,96 | B7.5 | 0,815 | 2,36 |

| FBS12.2.6 | 1180 | 200 | 580 | 0,32 | B7.5 | 0,133 | 0,76 |

| FBS12.3.6 | 1180 | 300 | 580 | 0,485 | B7.5 | 0,203 | 0,76 |

| FBS12.4.6 | 1180 | 400 | 580 | 0,64 | B7.5 | 0,265 | 1,46 |

| FBS12.5.6 | 1180 | 500 | 580 | 0,79 | B7.5 | 0,331 | 1,46 |

| FBS12.6.6 | 1180 | 600 | 580 | 0,96 | B7.5 | 0,398 | 1,46 |

| FBS12.2.3 | 1180 | 200 | 280 | 0,16 | B7.5 | 0,066 | 0,38 |

| FBS12.3.3 | 1180 | 300 | 280 | 0,24 | B7.5 | 0,100 | 0,38 |

| FBS12.4.3 | 1180 | 400 | 280 | 0,31 | B7.5 | 0,127 | 0,74 |

| FBS12.5.3 | 1180 | 500 | 280 | 0,38 | B7.5 | 0,159 | 0,74 |

| FBS12.6.3 | 1180 | 600 | 280 | 0,46 | B7.5 | 0,191 | 0,74 |

| FBS9.2.6 | 880 | 200 | 580 | 0,235 | 0,36 | ||

| FBS9.3.6 | 880 | 300 | 580 | 0,35 | B7.5 | 0,146 | 0,76 |

| FBS9.4.6 | 880 | 400 | 580 | 0,47 | B7.5 | 0,195 | 0,76 |

| FBS9.5.6 | 880 | 500 | 580 | 0,59 | B7.5 | 0,244 | 0,76 |

| FBS9.6.6 | 880 | 600 | 580 | 0,700 | B7.5 | 0,293 | 1,46 |

What to choose

Let's consider which foundation is cheaper, strip or block, if we compare their arrangement in the same conditions from the point of view of the geology and hydrology of the site, the characteristics of the planned construction.

1. Scope of land works. The costs of digging out the pits are almost the same - a little more soil will have to be removed for a monolithic foundation, since a place is required for fixing the formwork.

2. Cost of materials.The cost of FBS and ready-mixed concrete, based on the price per cubic meter, is approximately the same. But in addition to ready-mixed concrete, formwork and reinforcement will be required.

3. Installation work. The foundation blocks are laid on the cement mortar using a truck crane. The arrangement of a monolithic tape requires:

- installation of formwork panels;

- installation of the reinforcement cage (using wire or welding);

- delivery of concrete mix by automatic mixer;

- placing concrete in the formwork with compaction using a vibrator;

- proper maintenance of the structure (concrete must be covered with a film and regularly moistened during the period of strength gain to 70%, this will take 3-7 days, depending on the weather).

4. Access roads. Equipped in both cases, since the involvement of special equipment and freight transport is required.

5. Waterproofing. The costs are the same, since the reinforced concrete structure needs protection from groundwater, regardless of the technology of its installation.

6. Substrate under the foundation. Under both types of foundations, a gravel-sand cushion is laid at the bottom of the pit, on which a reinforced concrete tape with a waterproofing layer is mounted. A widened tape is required for a monolithic foundation, but this does not significantly affect the overall financial costs.

So, the main differences in financial investments relate to the cost of installation work. A truck crane with a long boom, capable of feeding blocks to any part of the excavation from one parking lot, plus a team of three people, which will carry out the whole range of works on assembling the prefabricated structure in 3-4 days. At the same time, renting a crane and wages for workers will cost at least two times cheaper than paying for the entire range of work associated with arranging a monolithic foundation.

To further reduce the cost of the block foundation, it is assembled from used FBS - if the block does not have serious damage, it is not inferior in strength to the new one, while its cost is noticeably lower. In addition, it is allowed to carry out installation work in the cold season, when construction organizations offer discounts on the rental of special equipment.

It is possible to reduce the cost of a monolithic foundation only by doing the work independently, abandoning the vibrator in favor of manual processing of concrete using a reinforcing bar, using a mini-concrete mixer, etc. But this reduces the final quality of the foundation and prolongs the time for its installation.

In general, the FBS construction is a good alternative to the strip base. But the laying of an underground foundation from blocks is used primarily in the arrangement of buried structures, since they are less exposed to loads from the soil.

How to choose the right size of FBS blocks for construction

It is from the design load of the object on the foundation that the size of the blocks needs to be selected depends

The strength of the structure, the technological process of assembling the elements, the lead time of the "zero cycle" and the cost of the products depend on the size of the product. The dimensions of building blocks are determined based on the type of soil and its bearing capacity. It is also necessary to take into account the thickness of the walls and floors, the weight of the structure, the area and strength of the foundation.

The lower the stability of the soil, the larger the foundation blocks should be. For example, for clay surfaces, you should choose the largest elements, and on coarse soils, you can arrange bases from small-sized products. To create the tightest styling, it is recommended to use products of different sizes.

FBS foundation blocks have their own marking, which is a certain set of letters and numbers

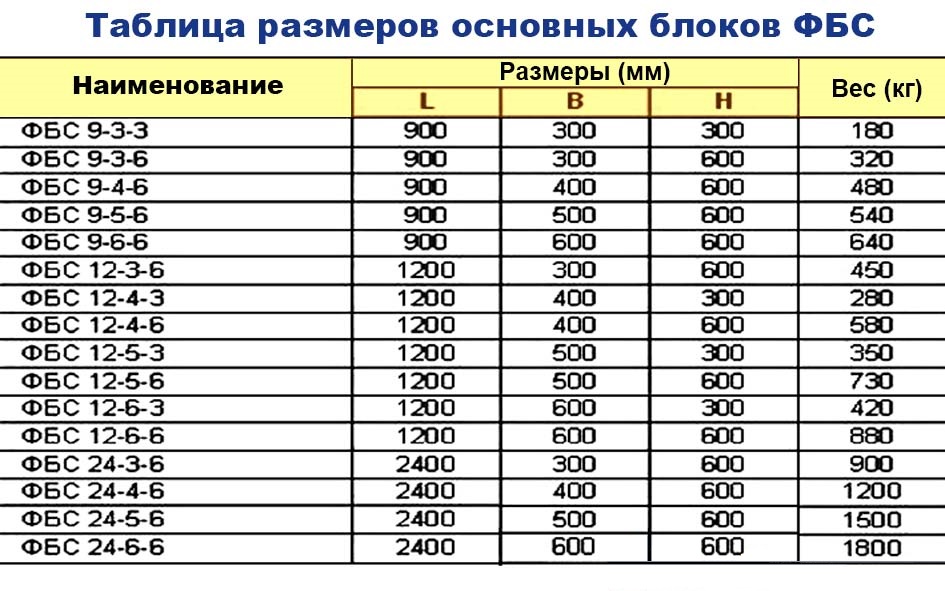

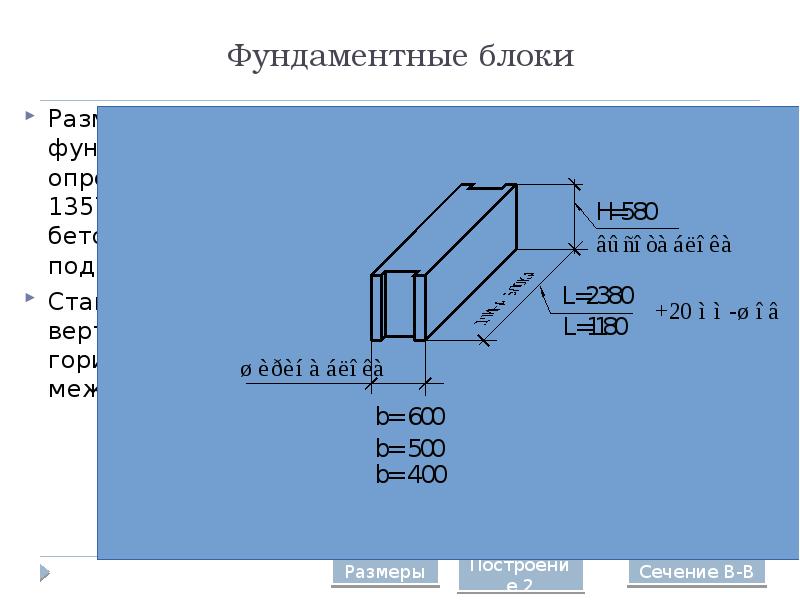

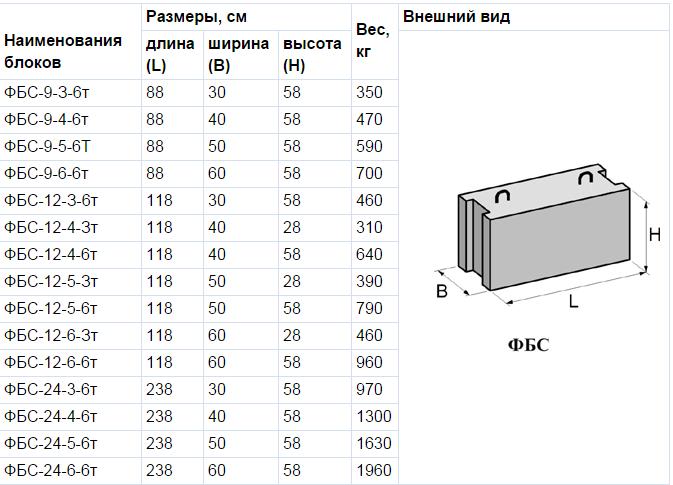

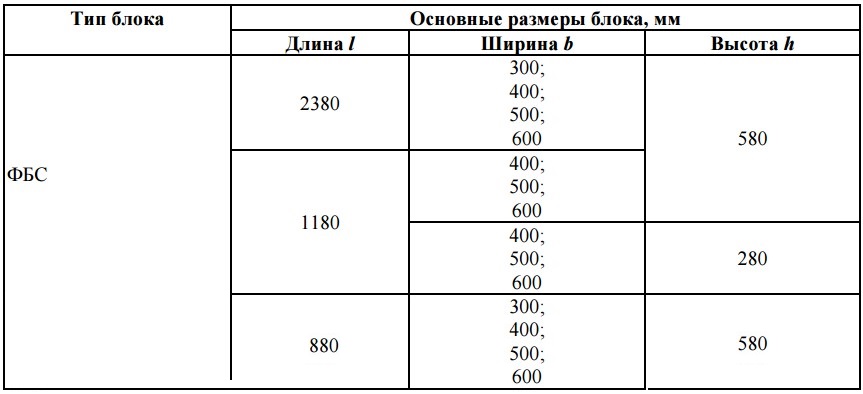

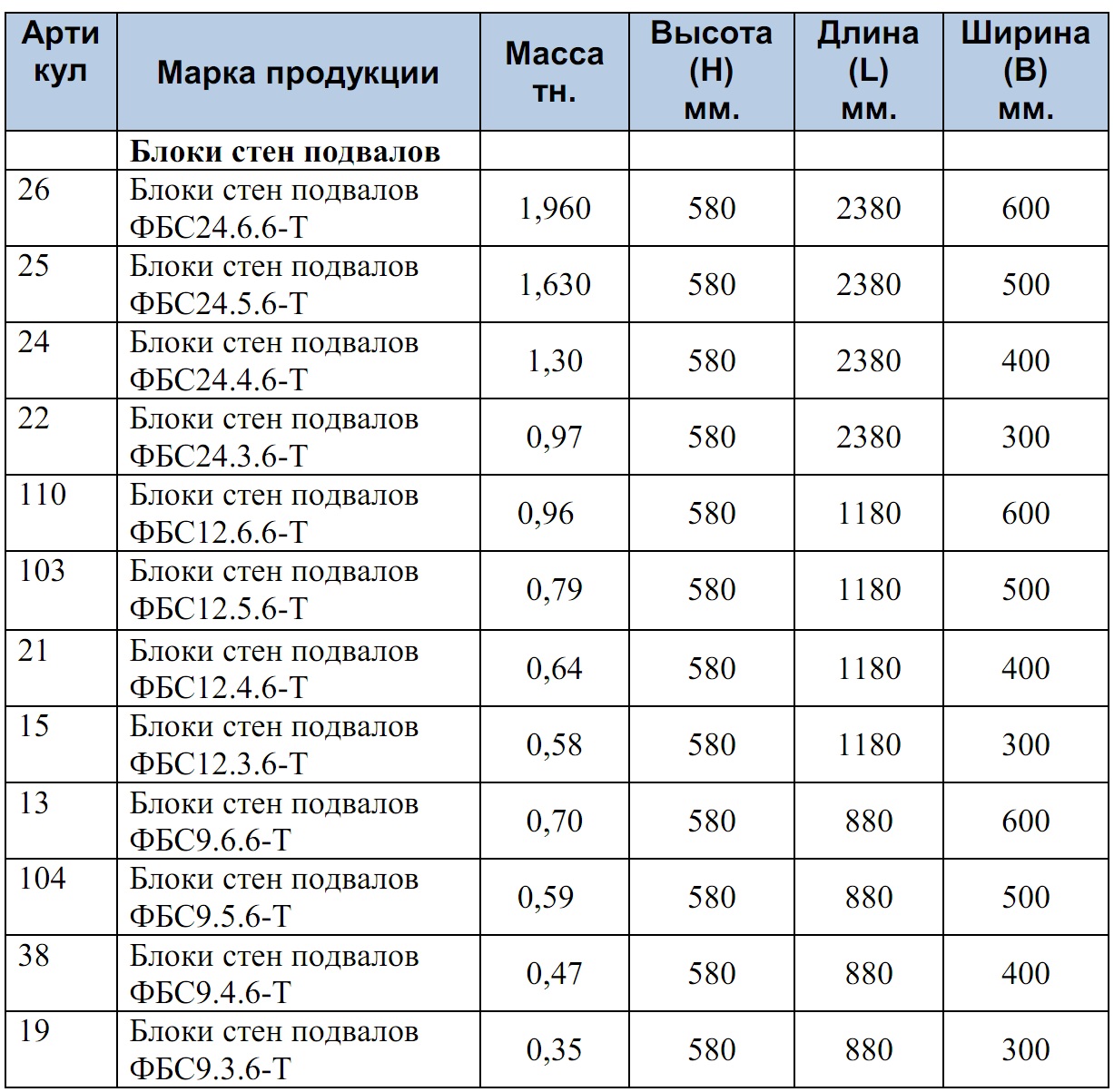

According to GOST, the FBS block is presented in 15 standard sizes, where an important dimensional characteristic is the width of the products, which is 300-600 mm. Along the length of the FBS, the assortment is divided into three standard sizes with values of 880, 1180 and 2380 mm

The height of the products is 580 mm. Only a block with a length of 1180 mm has a product height of 280 mm.The smallest element has dimensions of 880x300x580, and the largest foundation block FBS 24.6.6 is 2380x600x580 mm.

| Designation | Width, mm | Height, mm | Length, mm | Item weight, kg |

| FBS.24.6.6 | 600 | 580 | 2380 | 1960 |

| FBS.24.5.6 | 500 | 580 | 2380 | 1630 |

| FBS.24.4.6 | 400 | 580 | 2380 | 1300 |

| FBS.24.3.6 | 300 | 580 | 2380 | 970 |

| FBS.12.6.6 | 600 | 580 | 1180 | 960 |

| FBS.12.5.6 | 500 | 580 | 1180 | 790 |

| FBS.12.4.6 | 400 | 580 | 1180 | 640 |

| FBS.12.3.6 | 300 | 580 | 1180 | 460 |

| FBS.12.6.3 | 600 | 280 | 1180 | 460 |

| FBS.12.5.3 | 500 | 280 | 1180 | 390 |

| FBS.12.4.3 | 400 | 280 | 1180 | 310 |

| FBS.9.6.6 | 600 | 580 | 880 | 700 |

| FBS.9.5.6 | 500 | 580 | 880 | 590 |

| FBS.9.4.6 | 400 | 580 | 880 | 470 |

| FBS.9.3.6 | 300 | 580 | 880 | 350 |

Sizes of FBS blocks according to the assortment

When erecting foundations, different sizes of foundation blocks can be used, and the price per item of the product will depend on its dimensions. To accurately determine the size of the blocks and their number, you should unroll the base. On a special drawing, all products are conditionally laid out along the length and height of the basement wall of the building. Here you should take into account the dressing between the blocks, which is at least 25 cm.

The width of the product is selected based on the thickness of the walls of the building. In this case, minor overhangs of overhead structures are allowed. If the walls are to be built of bricks, then the size of the ledge should be no more than 40 mm on each side. Here you can use FBS 600 mm wide for 640 mm walls and 500 mm for 510 mm structures.

The length of the foundation block must be determined by the sweep, where elements of different sizes are located so that they lie flat, without forming significant protrusions.

FBS foundation has a much higher construction speed with a significant reduction in labor costs

The weight of FBS blocks is an important value, knowing which, you can decide on the special equipment necessary for stacking products, as well as on the transport that will be involved in the delivery of blocks to the construction site.

the strength of the building that is being built on such a foundation;

- construction assembly technology;

- time of work execution;

- the cost of the blocks.

The choice of the sizes of individual elements is carried out depending on several indicators:

- strength characteristics, degree of stability and type of soil;

- the thickness of the walls of the building;

- total base area;

- the mass of the building;

- selected type of masonry;

- structural strength of the base.

When constructing walls, it is important to know the standard characteristics. It is better if about 4-5 elements go to one wall.

For example, for a structure with a length of 10 m, it is better to use 4 structures of 24 dm each than 8 structures of 12 dm.

When choosing the dimensions of the blocks used, the type of soil on which the building is arranged should be taken into account. The greater the instability of the soil, the larger the FBS should be. For loam and clay soils, products with a length of 24 dm are usually chosen. For sandy soils, smaller products are used.

To create a high-quality base, you will need to add sand. This layer will act as a leveling underlay. It is usually 15 cm thick. For houses that are built on problem soils, reinforced concrete cushions are installed under the blocks to increase the support area.

Varieties of foundation blocks

The most common type is a solid concrete foundation block, denoted by the letters FBS. It is used for installation under external and internal load-bearing walls.

All types of foundation blocks are divided into three main types:

- monolithic (FBS) - these are solid concrete blocks with steel reinforcement, they are the most durable of all types;

- monolithic with a groove (FBV) - they are also made of reinforced concrete, but have special cutouts designed for laying various types of communications;

- hollow (FBP) - have cavities inside. They are the least durable and are almost never used for the construction of the foundation. Can only be used in the construction of a light frame or wooden house.

- blocks-pillows (FL) - have the form of a trapezoid. They are laid on a prepared base and serve to increase the bearing capacity of the foundation.

Assembling the foundation from FBS blocks

Installation of the prefabricated foundation begins with marking and digging a foundation pit.Moreover, such designs imply the arrangement of a classic pit (rectangular cut), and not a trench.

The marking of the future construction site is carried out with the help of milestones and wire, which outline the upper boundary of the pit. Its dimensions will be larger than the corresponding dimensions of the foundation to the depth of immersion of the sole of the base. Since the walls of the pit for the prefabricated base are equipped with a slope of 45 degrees.

The excavation stage is completed by adding a sand cushion to the bottom of the trench dug along the perimeter of the pit. The width of this recess must match the width of the foundation sole.

Further assembly of the base is performed as follows:

- A tape of roofing material is laid on a sandy pillow - it will protect the base from unwanted contact with soil moisture.

- A special, FL type block is mounted on the waterproofing layer. It is these products, the cross-section of which resembles a trapezoid, that form the cushion of the future foundation.

- The first row of FBS products is mounted on the FL blocks. Stacking solid blocks from corner to center. The vertical seams between the blocks and the horizontal seam between the sole and the first row of the foundation wall are filled with a bonding mortar.

- The next row of blocks is laid according to the rules of brick dressing - the upper product should be based on the two lower ones, overlapping the vertical seam with its center.

- Upon completion of the wall installation, a monolithic grillage (reinforcing belt) is poured on the upper edges of the extreme row of blocks.

Such a construction scheme can be simplified by eliminating the FL type blocks. In some cases, prefabricated structures are replaced with a monolithic sole cast over the waterproofing layer. This technique reduces the construction budget, but increases the duration of the entire process of building the base.

About the site

zalman