Stages of the foundation

When marking the site, it is advisable to use geodetic equipment. After the work on the project of the future building is completed, you should proceed directly to the construction work. First of all, the design drawings are transferred to the area.

The construction site is divided using centerlines - thin wire or twine, stretched over pegs.

These pegs are installed in such a way that the center lines, crossing each other, form the perimeter of the future building. Then earthworks are carried out. Their nature and volume completely depend on the type of the designed foundation.

To evenly distribute the weight of the building on the supports, it is necessary to calculate as accurately as possible on the terrain the points of the foundations under the pillars.

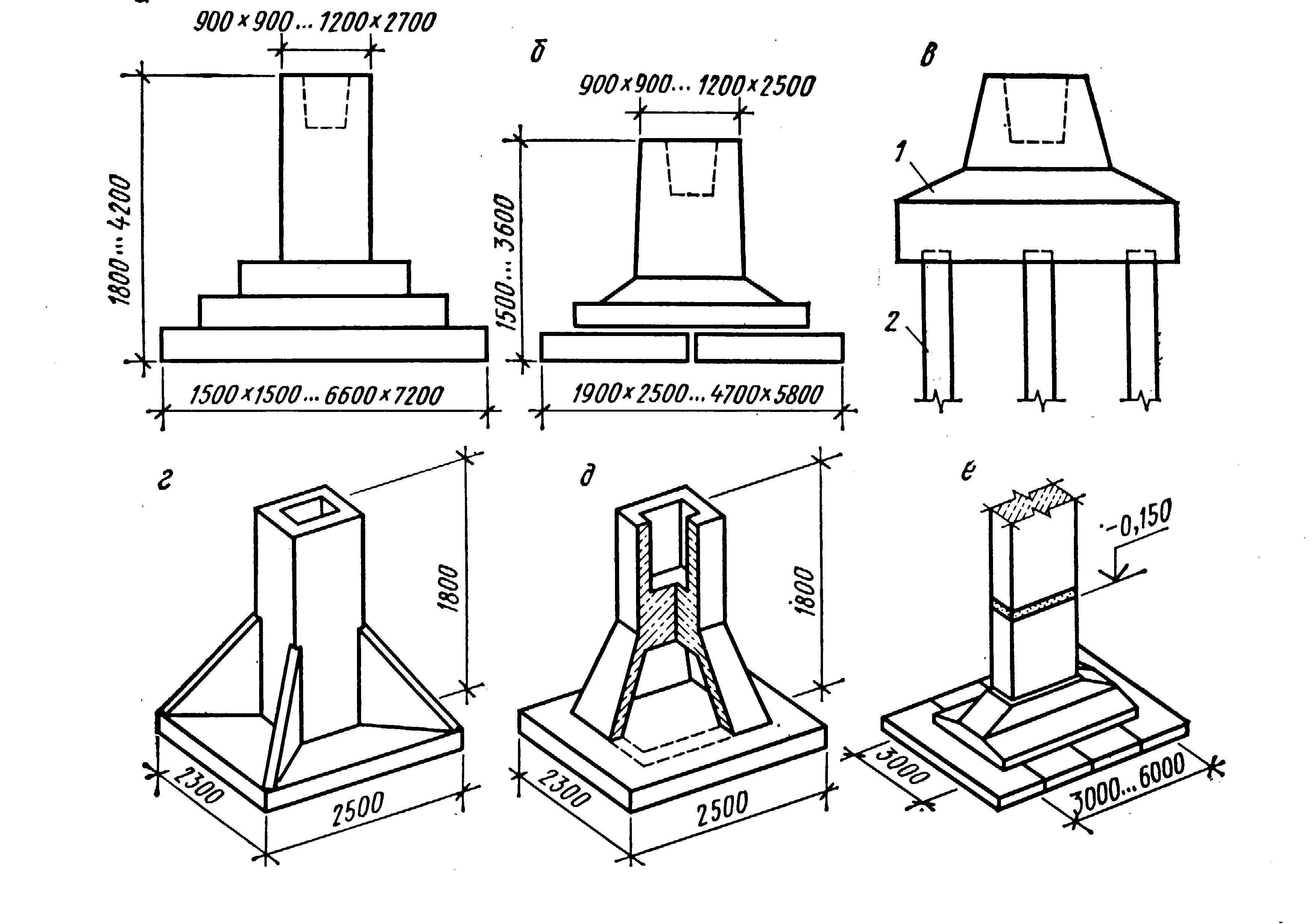

Below we will consider the features of the device of monolithic foundations for columns produced using various technologies.

Columnar monolithic base

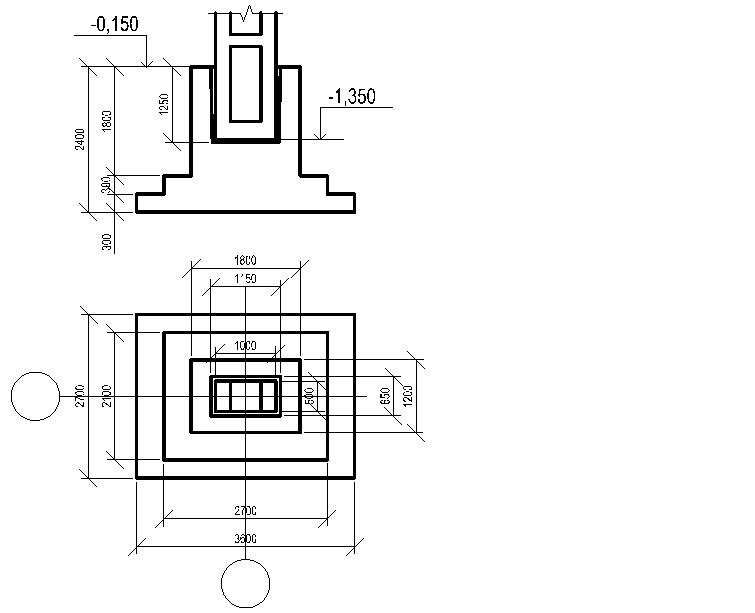

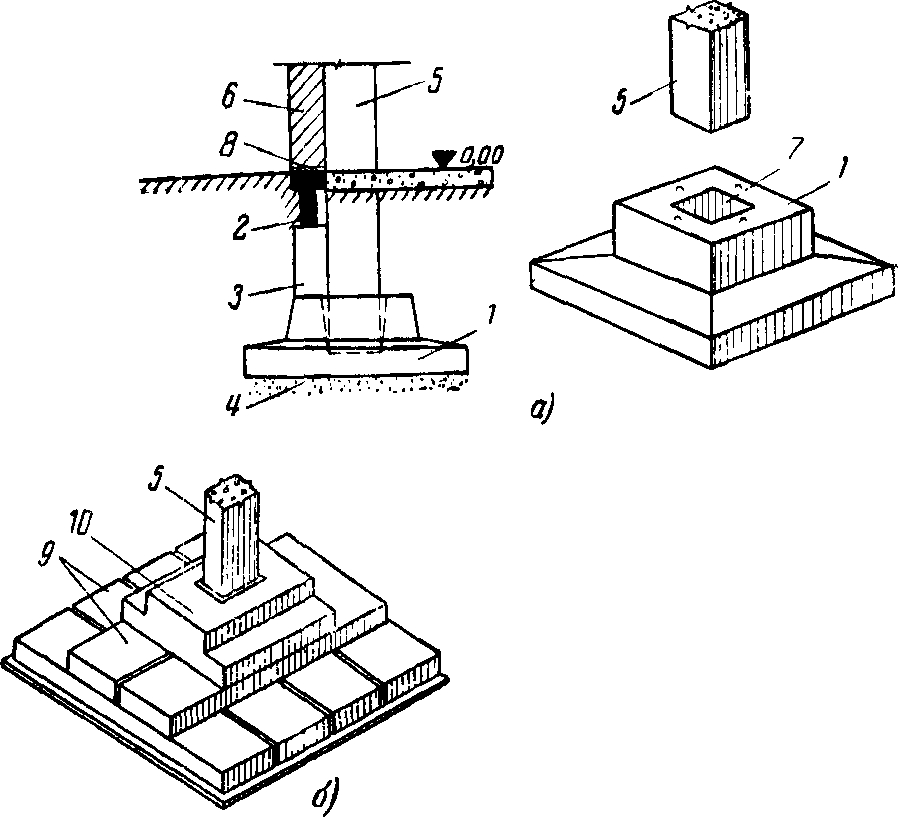

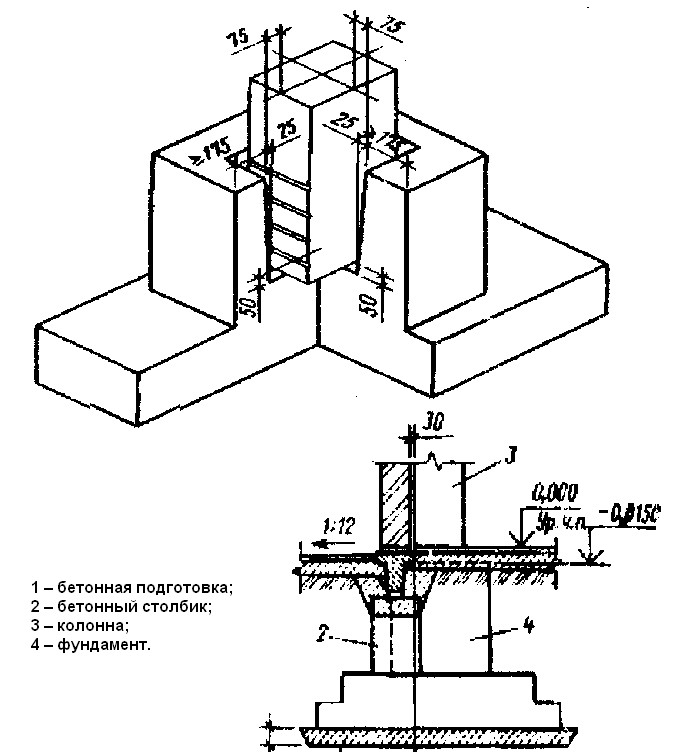

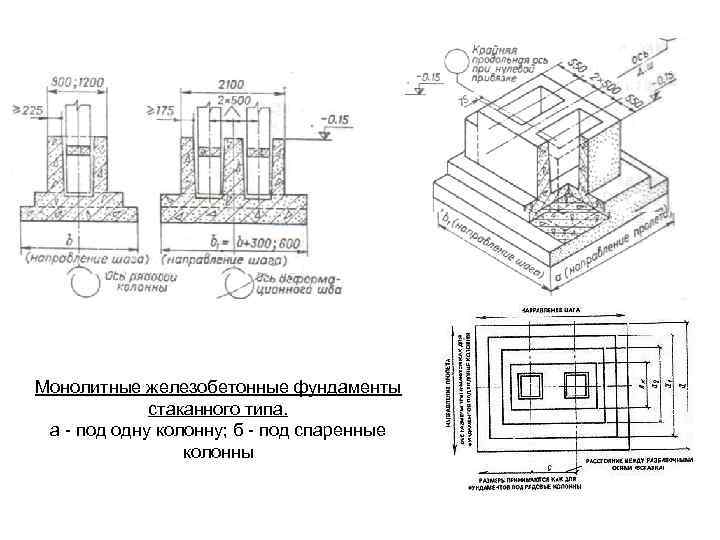

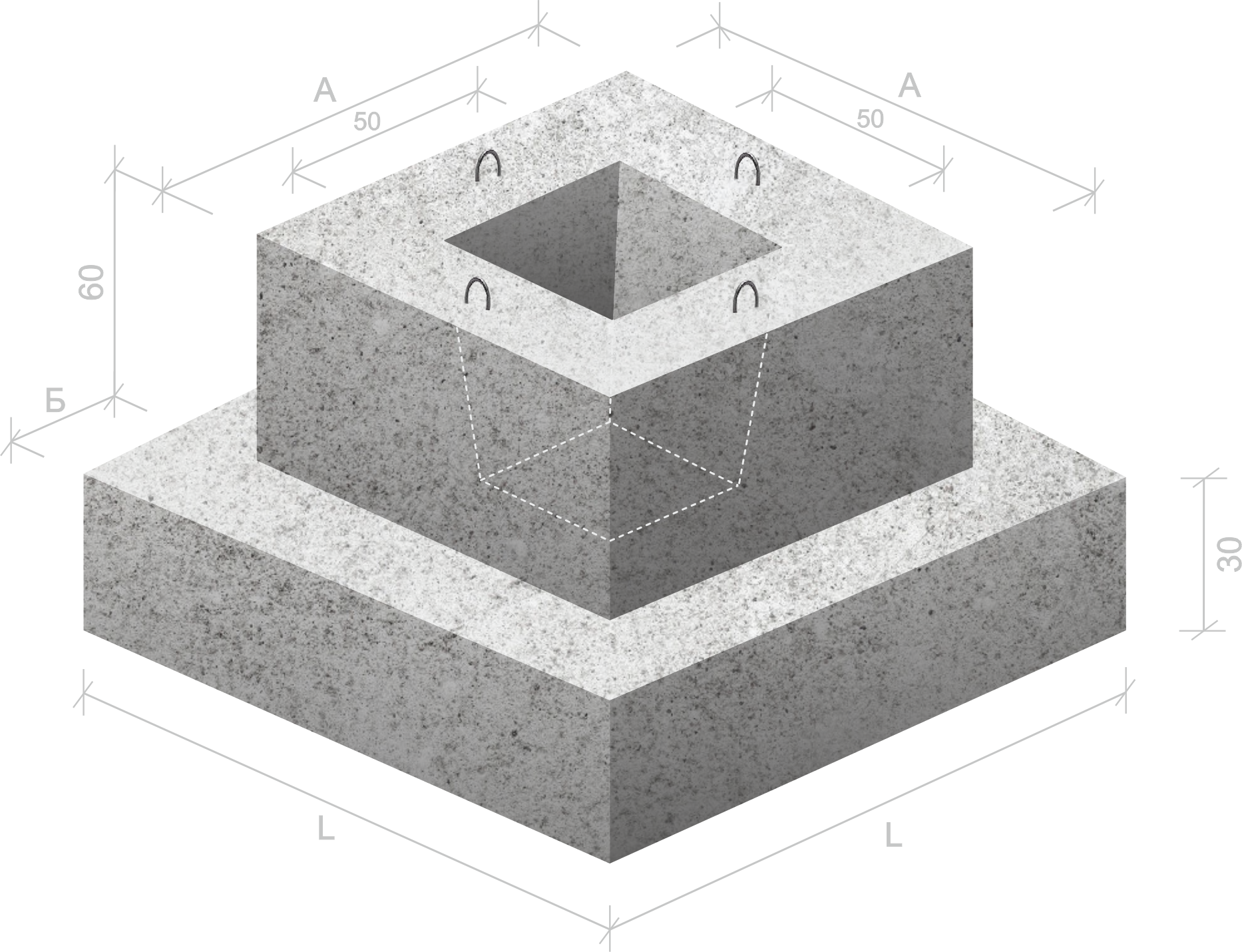

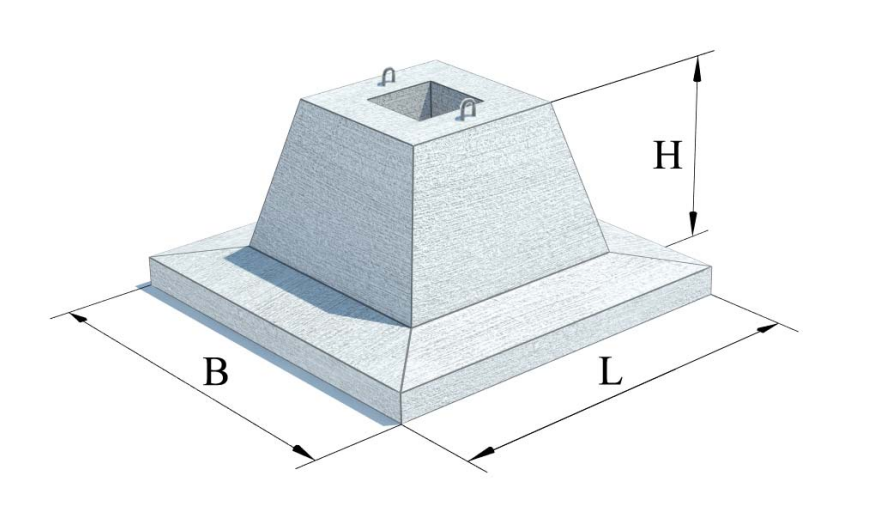

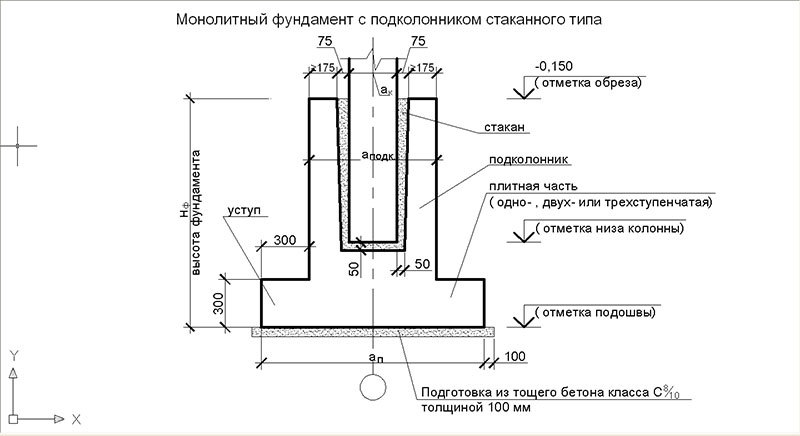

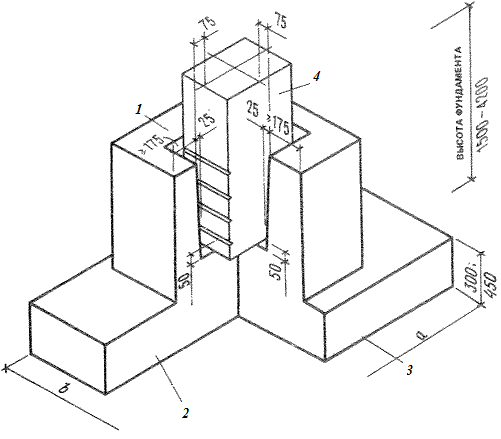

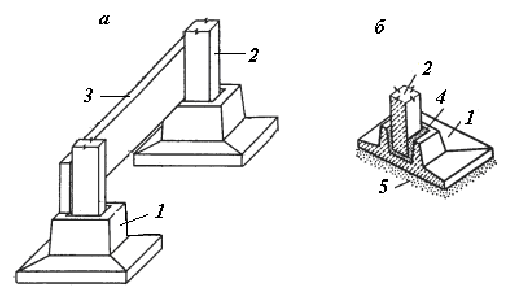

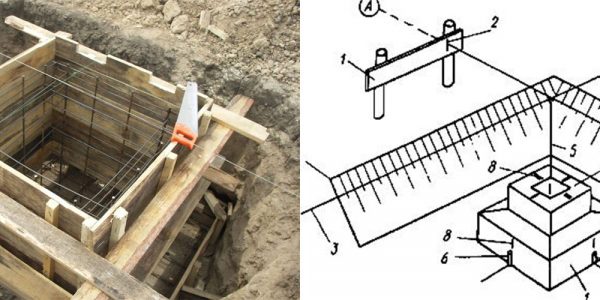

For the installation of a columnar monolithic foundation, it is enough to dig a hole of the required depth for pouring a monolithic glass, or to install a ready-made "glass". A sand and gravel cushion is also built at the bottom. Before pouring the monolithic columnar foundation, the point of installation of the column is measured and the formwork is constructed.

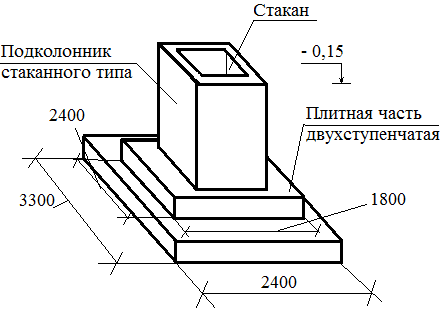

A frame is placed inside it with a mortgage or with pins protruding upwards for fastening the future support. Structurally, the columnar base can be made both in the form of a monolithic slab, and in the form of a stepped pyramid of two or three ledges. In the latter case, each step is poured separately, starting from the lowest.

Watch a video on how to install a column in a glass.

Monolithic tape base

In this case, a trench is dug around the entire perimeter of the building, as well as where the internal load-bearing walls will pass. At the points of installation of the columns, extensions or depressions are made in the ground, if the project provides for the installation or pouring of concrete "glasses" in these places.

Column strip construction

If the total mass of the building under construction is not so large, you can do without such a strengthening of the structure. It will be enough to only strengthen the frame at the points of mounting of the bearing supports with the help of thicker reinforcement, the release of vertical rods or the installation of metal plates - "embedded".

Around the entire perimeter of the trench, a pillow of coarse sand, gravel or crushed stone is poured onto the bottom, and then a volumetric frame is laid. It is assembled and mounted in such a way as to rise above the trench level to a certain height (at least 30-40 cm), which is necessary to protect the walls of the building from melt and rainwater flows. The protruding part of the frame is taken into the formwork.

Solid monolithic base

To pour a solid reinforced concrete slab, it is necessary to remove the topsoil over the entire area of the future building. Then the site is leveled horizontally and covered with crushed stone, sand or gravel. A volumetric frame is laid on top of the sand and gravel cushion, the frame is also reinforced at the mounting points of the supports, rods (anchor bolts) are produced or a metal embedded plate is mounted.

We recommend watching a video on how the column is installed on the finished base.

Pile monolithic foundations

By the type of device, such bases can be of several types, but perhaps only bored technology can be attributed to monolithic foundations for columns. In the places of installation of future columns, a hole is made with the help of a drill, where the formwork is installed.

It is better to install embeds, anchors or outlets of reinforcement for the future column before pouring the monolith. In this case, it is possible to fasten these parts to the frame, which makes the connection of the column to the base more durable. In addition, it will take much less effort and time.

Since the reliability of the building and the durability of its operation depend on the correct choice of the foundation, it is necessary to approach the calculations very responsibly. The best option would be to contact specialists who can draw up a project taking into account all the smallest nuances.

How is the calculation of the column foundation done

Monolithic columnar foundation for a metal column

As a rule, the calculation of the foundation for a metal column implies whether the soil is able to withstand the design load of the foundation with which it will act on a square centimeter of the area, and the collection of all data on future construction. In fact, you need to get complete information about the building, soils and groundwater, collect and systematize the data obtained and, on their basis, transfer the finished project to the builders. For this you need:

- receive from the architect the project of the future building, the specification of building materials and communications;

- calculate the total support area;

- collect all the parameters, systematize them and get the actual design pressure of the building as a whole.

How do you know the load that the building itself will create? To do this, you need to obtain detailed data about the building itself, to collect the mass and characteristics of all materials that can be used in its construction, as well as projected communications, future furniture, the amount of snow on the roof. This calculation consists of several parts:

- Calculation of building floors and steel columns. First you need to find out the mass of the metal column itself, because it also, albeit slightly, creates pressure on the ground. This requires calculating the volume of the structure. This is done according to the geometric formula for calculating the volume of a cylinder. This gives the volume, which is then multiplied by the density of the metal to obtain the mass of the steel column.

- Then you need to find out the mass of the floors. As a rule, these are manufactured products and each manufacturer already indicates their weight. Therefore, it is enough to contact the suppliers.

- There are times when a grillage structure is installed on metal columns. Its mass is also not a problem to calculate, because for this it is enough to know how much concrete or ready-made concrete structures will go to the construction of the grillage.

- Calculation of the mass of the walls. Much depends on the material, because a brick weighs less than concrete, but more than foam blocks. Accordingly, it is worth collecting data on all building materials used in the construction of the building.

- Roof calculation. This includes the specification of the materials from which the attic is made, as well as the specification of all roof materials, right down to the outer covering. When designing a structure, the architect provides a detailed specification, so it will not be difficult to calculate the total mass of the structures.

- After summing up all the data received, a figure will be calculated that characterizes the maximum permissible load on the foundation supports.

To find out what force is pressing on a unit of support area, you need to know its overall dimensions. If the steel post has a square section of 50 x 50 cm, then the support area will be 2500 cm². Then the pressure that will act on a unit of soil area is calculated by dividing the mass of the building by the area of one support.

But there is always a rule: more supports will not be superfluous, therefore, designers often install supports with an interval of approximately 1.5 - 3 m.This is done in order to provide the necessary strength reserve for structures associated with unauthorized completion, arrangement of premises or installation of heavy industrial equipment. As a rule, in the calculations, a mandatory 50% safety margin for each support is provided.

Features of the foundation for metal columns

There are buildings with increased strength requirements. These are buildings related to industrial and energy facilities.

As a rule, a columnar foundation is used here for a frame-type metal column, when the load from the building falls on metal pillars installed inside a bowl made of concrete. The peculiarity of the foundations for steel columns is that a pillow is preliminarily prepared, inside which a recess is made. This is where the column will be attached by anchoring.

Construction stages

The use of metal pillars does not imply the presence of prefabricated structures. Otherwise, an additional calculation of the bearing characteristics of the structure would have to be done.

The best option is to use a monolithic concrete foundation. The specified type of base is stronger, quickly poured. The construction process is divided into the following stages:

Pre-calculate the maximum permissible loads exerted on the base cushion;

The marking of the points where the columns will be installed is carried out. Then earthworks are carried out;

A well is being dug. The length and size of the pit depends on the section of the metal column and the estimated depth;

Now you need to make the outer formwork. For this, boards are taken, it is recommended to use plywood with a moisture-resistant coating. As a rule, such formwork is not removable;

A pillow is made of sand and gravel. Previously, the surface of the soil is leveled, then sand is poured. The layer is not more than 15 cm, it is carefully rammed. Crushed stone is poured on top. The layer is no more than 20-25 cm. It is also carefully rammed and leveled horizontally;

The next step is to create a reinforcing belt, which will be the main one. Metal rods are installed around the perimeter of the pillow. The armature is positioned both vertically and horizontally;

Now the prepared foundation pit is filled with concrete mortar.

It is important to use concrete grade 200M. Before starting the solution, it is necessary to establish geodetic levels, as well as elevation marks

These will be the pointers where the metal columns will be placed. Also, these pointers will help when carrying out repair work on the foundation, due to subsidence.

Anchor connections are installed inside the recesses, with the help of which the steel elements are fastened. But here, too, there are some peculiarities.

The reliability and strength of the fastening is checked as follows: after the anchors are welded to the reinforcing layer, the concrete base is broken and the condition of the bolts is examined. If the latter remained in place, it means that the installation was carried out correctly and the construction can continue. In the case when the structure deviated from the center even by 2 millimeters, it becomes necessary to replace the anchor bolts. Compliance is checked after each installation. Otherwise, the erected structure will be unstable and can lead to the destruction of the building.

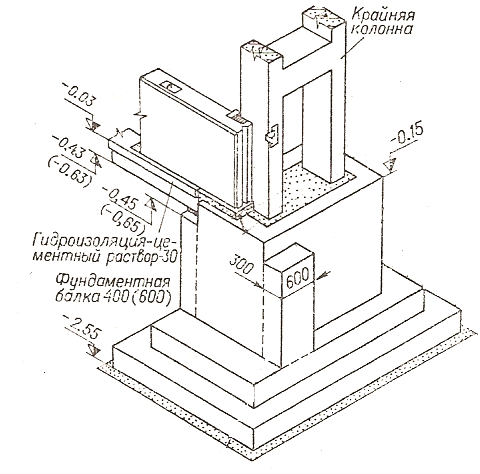

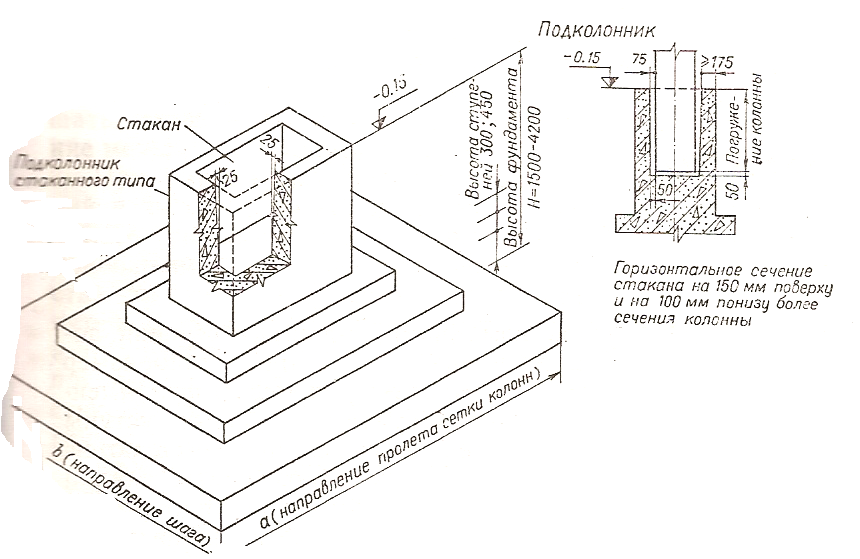

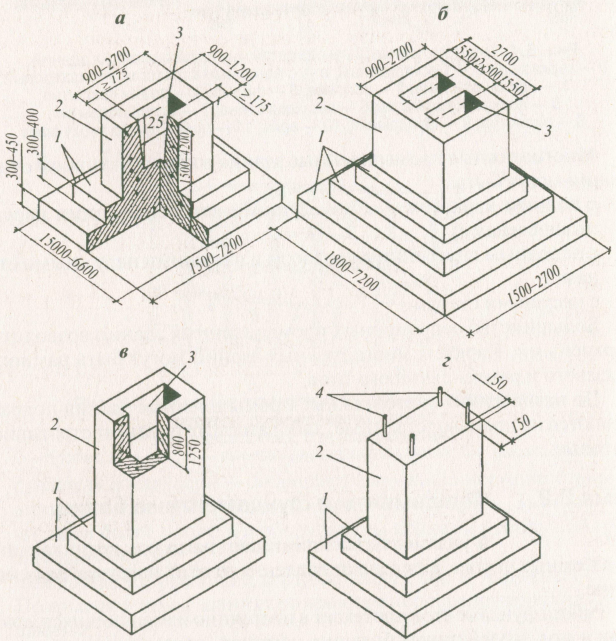

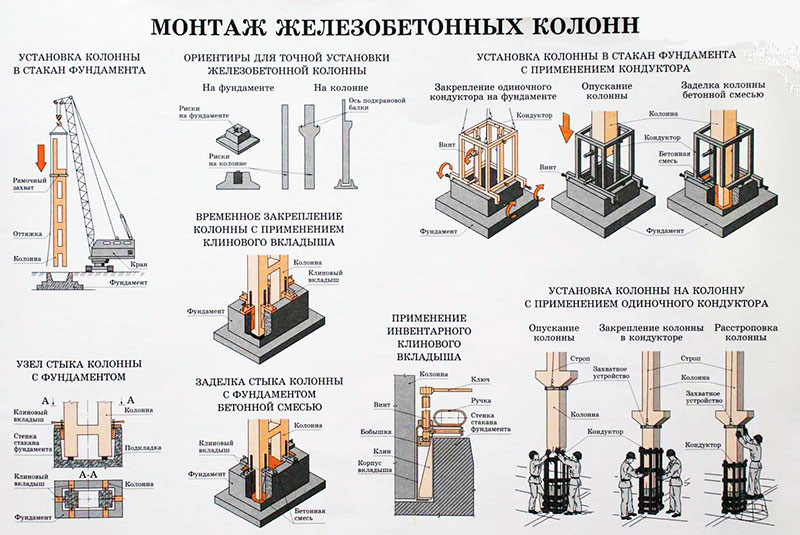

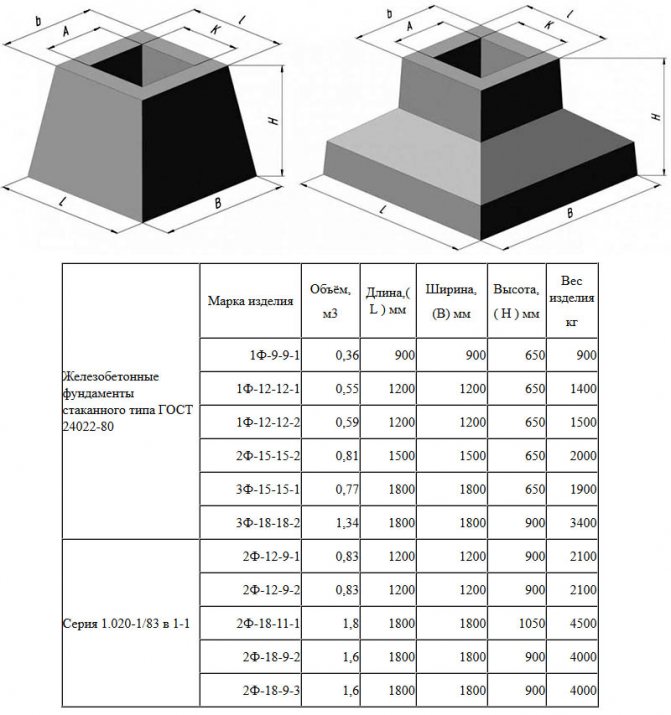

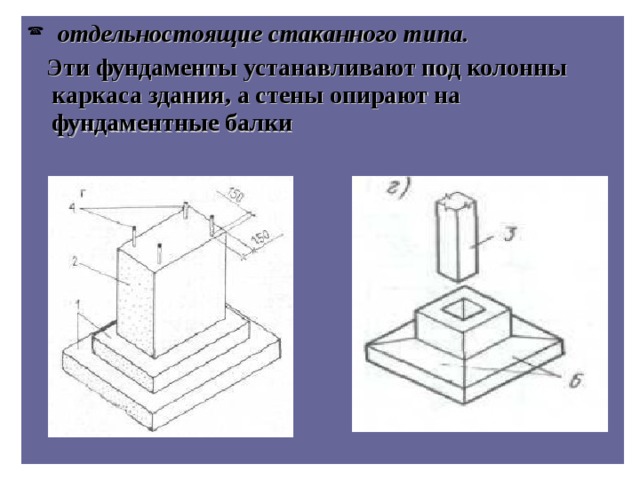

Glass-type foundation construction technology

Glass foundations are built in strict accordance with applicable standards. The process is carried out with heavy construction equipment and under the guidance of experienced craftsmen. In general, the construction technology consists of several stages.

Stage 1. Site preparation and earthworks

The construction site must be thoroughly cleaned. This removes not only construction waste, but also the top vegetative layer of the soil.

Preparing the site

In addition, it is necessary to prepare a pit for the blocks. It can be made separately for each support or in the form of a continuous trench passing along the perimeter of the future structure. In some cases, the blocks are installed at the bottom of a large excavation pit, which is being developed using an excavator.

After excavation, the bottom of the pit is cleaned, leveled and carefully tamped.

Stage 2. Creation of a compacting bed

Compaction under a glass foundation is necessary if construction is carried out on soft soils, which tend to shrink under the influence of the weight of the building and foundation. For the arrangement of the compacting bed, sand and fine crushed stone are used.

The size of the compacting bed must exceed the size of the base plate by about 0.3 meters. Neglecting this rule can cause the reinforced concrete structure to skew.

Soil compaction

The compaction height depends on the mass of the glass block, while the thickness of the layer of sand and crushed stone should be the same. Crushed stone is laid in the first layer, it is evenly distributed along the bottom of the pit, leveled and tamped. To do this, you can use a manual rammer or special jib crane equipment. Then I fill up the sand, moisten it with water from a hose and also compact it well using similar equipment.

Step 3. Marking the axes

At the bottom of the prepared pit, the marking of the locations of the glass foundation blocks is performed. To do this, the breakdown axes are fixed on the stripping boards. At the intersection of the axes, a plumb line is installed, which determines the central point of the location of the supporting monolithic slab.

Next, they make a template for a glass foundation block and transfer its contours to the ground. At the same time, the corresponding marks are made with pegs and a cord or thread.

We mark the axes of the foundation

Having noted the location of the block at the bottom of the pit, additionally check the horizontalness of the sealing bed. If necessary, it is leveled to the ideal level.

Stage 4. Installation of blocks

For faster installation on glass-type foundation blocks, there are mounting loops. Their condition must be checked before starting installation work. If the hinges are deformed during transportation, then they should be straightened with a hammer.

The hooks of the cables of the jib crane are hooked onto the mounting loops, and the hook can be carried out with two or four hooks in accordance with the dimensions of the monolithic block. Each hook should be checked for strength. With the help of a crane, the block is slightly raised above the ground and the adhering earth is removed. After that, the crane moves the block to the desired location.

Before final installation, you should manually correct the position of the block, if necessary, unfold it and move it in the desired direction. After that, the unit can be installed in its place.

The installation of other elements of the foundation of the glass type is carried out in a similar way.

At the final stage, backfilling of soil is performed, which is used to fill the space around the blocks. The backfilled soil must be carefully tamped. Excess soil is evenly distributed over the site or taken to specially designated places.

To strengthen the glass-type structure, reinforcement of glasses, columns and slabs is performed. In this case, the reinforcement rods are connected to each other by welding. The reinforcement is laid in each element of the glass-type foundation at one of the stages of production.

Where is it used?

- Bridge structures (over water bodies, rivers, as pedestrian crossings);

- Underground garages, parking lots, other social facilities;

- Machine rooms - for example, a heating plant, a power plant, a boiler room;

- Warehouses in the agricultural sector, industrial plants with lightweight products.

- One-level sports, shopping malls with a lightweight construction.

Frequent customers of columnar bases are government services, the municipality, social organizations. Demanding to fulfill the requirements regarding the type of structure, functional component, material.

For construction, reinforced concrete, pure concrete are used (less often, due to reduced strength). The constructive component at the drawing stage is certified by specialists.

A step-by-step guide to erecting glasses

Preparation for laying the foundation

The installation of columnar foundations takes place with the obligatory use of construction equipment - excavators, cranes, winches.

- A preparatory process aimed at thoroughly cleaning the surface for the foundation. It should be flat. A pit of a given size is being dug. The level of laying a monolithic slab should not be less than one meter, as well as when sealing the sole of the strip base.

- Trench ramming with crushed stone and sand. Thanks to this, you can get a fairly even and uniform surface.

- The column foundation should be erected using construction measuring tools, constantly monitoring the horizontal and vertical alignment of the prefabricated structures. You need to use a level and a level.

- Mandatory breakdown and marking with the help of pegs of the prepared bed of the axes on which each separate glass will be located.

- Glasses that have already been delivered to the construction site should be cleaned of possible debris. With the help of a crane, the elements are gripped by the mounting loops and delivered to the monolithic support. Center the position of the glass and slowly set it to the prepared place. The coincidence of the lines is checked.

- Guiding a kind of mesh with a thread between the really located elements.

- Precast concrete foundations require constant checking with a geodetic instrument. After each installation of the glass, measurements must be taken.

- The soil that has been dug is poured back into the pit to the top of the block. After that, the support beams are installed on glasses or on special posts. The size of the pit depends entirely on the type of structure and its area. Sometimes it is necessary to dig out a large amount of land if large-scale construction is planned.

Installation of glass-type foundations is focused on the constant leveling of the surfaces of prefabricated elements. The slightest displacement must not be allowed, since the entire structure is a heavy concrete frame. During work, all design calculations should be observed. Those products that do not comply with standards and GOST cannot be used. It might not be safe.

All work related to the design, making the necessary measurements, soil analysis using special geodetic equipment should be carried out in strict compliance with the norms and requirements that apply to the columnar foundation. Most often, reinforced concrete prefabricated parts are used for the foundation. The calculation of their strength and composition is carried out at the manufacturing plant. The work is carried out by technical specialists, so the products are simply obliged to comply with the stated design requirements.

Foundation for walls

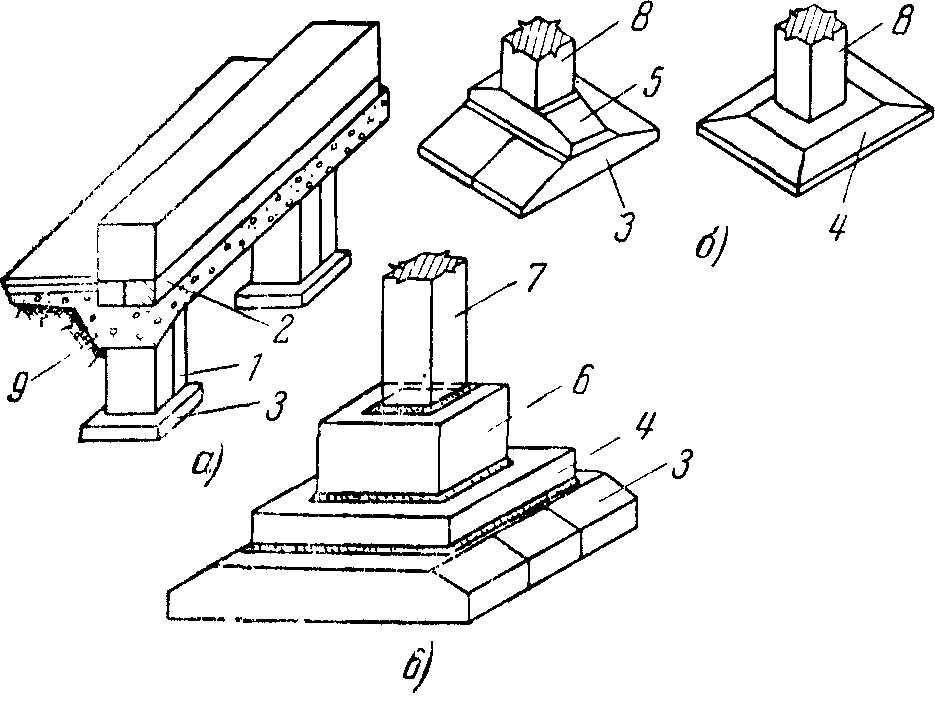

The basic rule for pouring this category of foundations is that they must be monolithic. In this case, the pressure on a separate section of soil is distributed over the entire length.

Strip foundation

This is the most common type of foundation for industrial buildings. It has the following device. A cushion block is used as a sole. A wall block is installed on it (marking - SP). This element has standard dimensions: 600 mm high, 300-600 mm thick and 2.4 meters long. It should not have voids. For ligation of blocks, SPD models with a length of 80 centimeters are used. This option of foundations is poured under load-bearing walls made of bricks or blocks.

In the case of concrete panels, a monolithic structure is used. At the same time, an armored belt is mounted in the trench twice as wide as the foundation itself. Then the main part of the structure is poured. To reduce the cost of concrete work, the pad can be made in the form of separate thick plates. For this, an additional recess is made in the trench, into which a metal frame is installed. The distance between these elements is 20 to 90 centimeters. If the soil has a high shrinkage factor, then the pad should be solid. The strip foundation provides maximum dimensional stability.

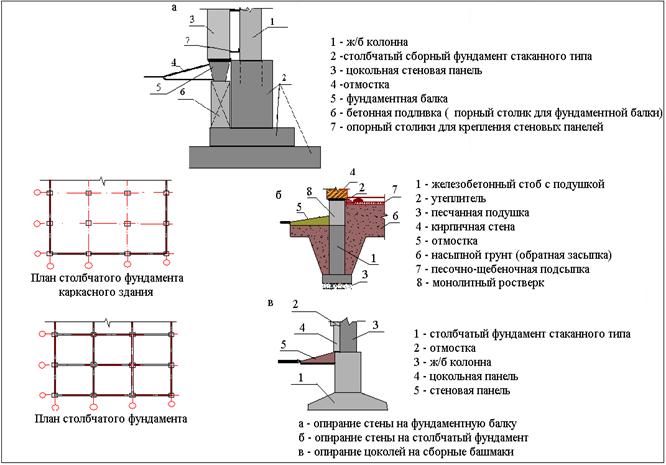

Column foundation

The main reason for using a columnar foundation for industrial buildings is in the case of dense soil that does not significantly shrink. The device of such a base consists of a monolithic shoe and a concrete pillar, which is installed in a special groove, so that it does not move when vibrations occur. It is used if the load on the walls is insignificant.

Vibrating paw for compaction of soil

Vibrating paw for compaction of soil

The maximum distance between these elements should not exceed six meters. They must necessarily communicate with the main parts of the structure using concrete lintels.

Before pouring the base for the post, the soil area under it must be compacted with a vibrating paw. Sand bedding at the bottom of the trench with a depth of 30 to 60 centimeters will ensure minimal compaction during the operation of the building. Columnar foundations of industrial buildings are complementary rather than basic elements. Most often they are used as bases for partitions indoors. They save money on filling the base for internal lintels. However, if a dimensional lift or other device is installed on the wall, which will take on additional load, then a more stable structure should be poured.

Pile foundation

The main use is in the case of soft soil with high shrinkage. The device of such a foundation consists of a pile driven into the ground, on which the monolithic base of the building is located. The piles used in this case can be round and square (in section). To avoid deformation of the element, a yoke is put on top of it, and a shoe is put on the bottom. These are steel tips. They allow the concrete structure to withstand strong hammer blows from the pile driver.

Driving in piles with a pile driver

Driving in piles with a pile driver

Less commonly, wooden piles are used. In this case, they should be made of coniferous wood (to prevent premature decay of the base). In exceptional cases, a metal analogue is used. In both cases, it should be taken into account that such a foundation has a shorter working life than a concrete pile. The installation depth of the pile depends on the characteristics of the soil, as well as the size of the building. These calculations can be made by the local design and construction organization.

The advantage of this base option is the minimum shrinkage of the overall building in areas with soft soil (sandy or swampy terrain), as well as lower costs for earthworks.

Our services

accepts applications for the following types of work: pile driving, pilot drilling for piles, sheet piling. See more details about our services in the site menu. To leave a request for work, fill out the form:

"]" Data-sheets-userformat = ",, NULL, NULL, NULL, NULL, NULL, NULL, NULL, 0, NULL ,, NULL, 11]" style = "font-size: 110%; font-family: arial, sans, sans-serif; ">

The foundation for a bath: their types and comparison

carries out the immersion of piles during the construction of foundations for various structures: residential, industrial, economic, therefore, according to ...

More details

The foundation for a country house

The construction of a foundation even for a small country house has a large number of features. They take into account the types of soil, the level of occurrence of groundwater, climatic conditions in the region ...

More details

Foundation for an extension to the house

Construction specializes in the construction of foundations of varying complexity and type in Moscow and the region. If you decide to expand your residential ...

More details

TISE foundation

In this article we will talk about TISE pile-strip foundations. You will learn in what cases it is rational to use such bases, what advantages and disadvantages they have.

Reinforced concrete foundation

On this page, we will consider the main types of reinforced concrete foundations, the technology for their construction and determine whether it is rational to independently engage in their construction.

Briefly about the main features

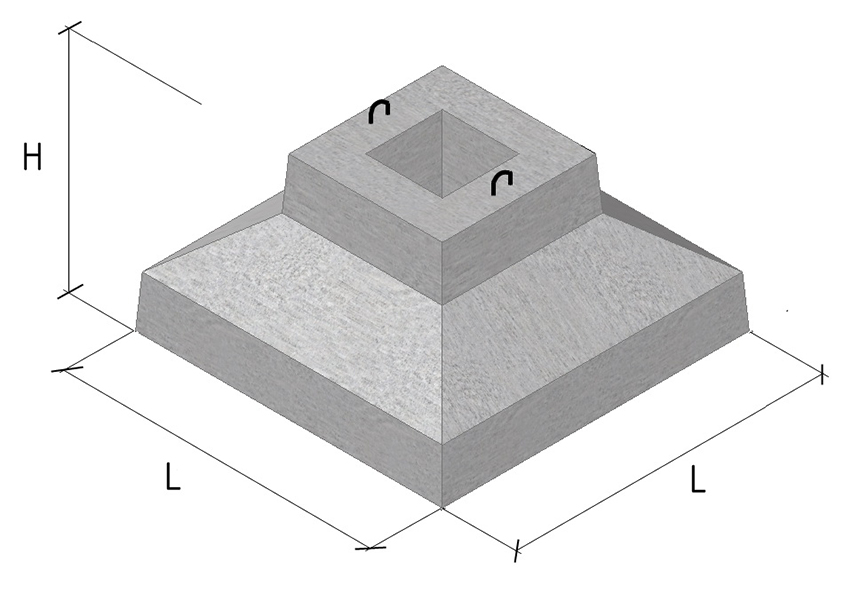

Glass-type foundations are one of the varieties of columnar foundations

Glass-type foundations are one of the varieties of columnar foundations

Glass-type foundations are one of the varieties of columnar foundations. The product is used in the installation of industrial buildings and structures, as well as in the construction of wide sectional spans near structures for various purposes.

The main advantage of such structures is their high bearing capacity and strength. Installation is carried out in strict accordance with GOST. The main disadvantage is the high cost of the structure, but it is compensated by high technical characteristics and durability.

The load from the main structures of a building or other structure is transferred to reinforced concrete support elements, and from them to the base of the foundation, which contributes to the uniform distribution and transfer of the load to the ground. These supports are rigidly attached to the inside of the glass. In the upper part, all the supports are connected by means of a grillage into a single structure, which makes the structure rigid. Such a grillage can be installed even at a certain distance from the ground surface.

Technology for the construction of glass foundations

It is necessary to erect such foundations only strictly according to the recommendations of the existing GOST and under the supervision of specialists. It is not difficult to assemble a glass base if you adhere to the existing technology.

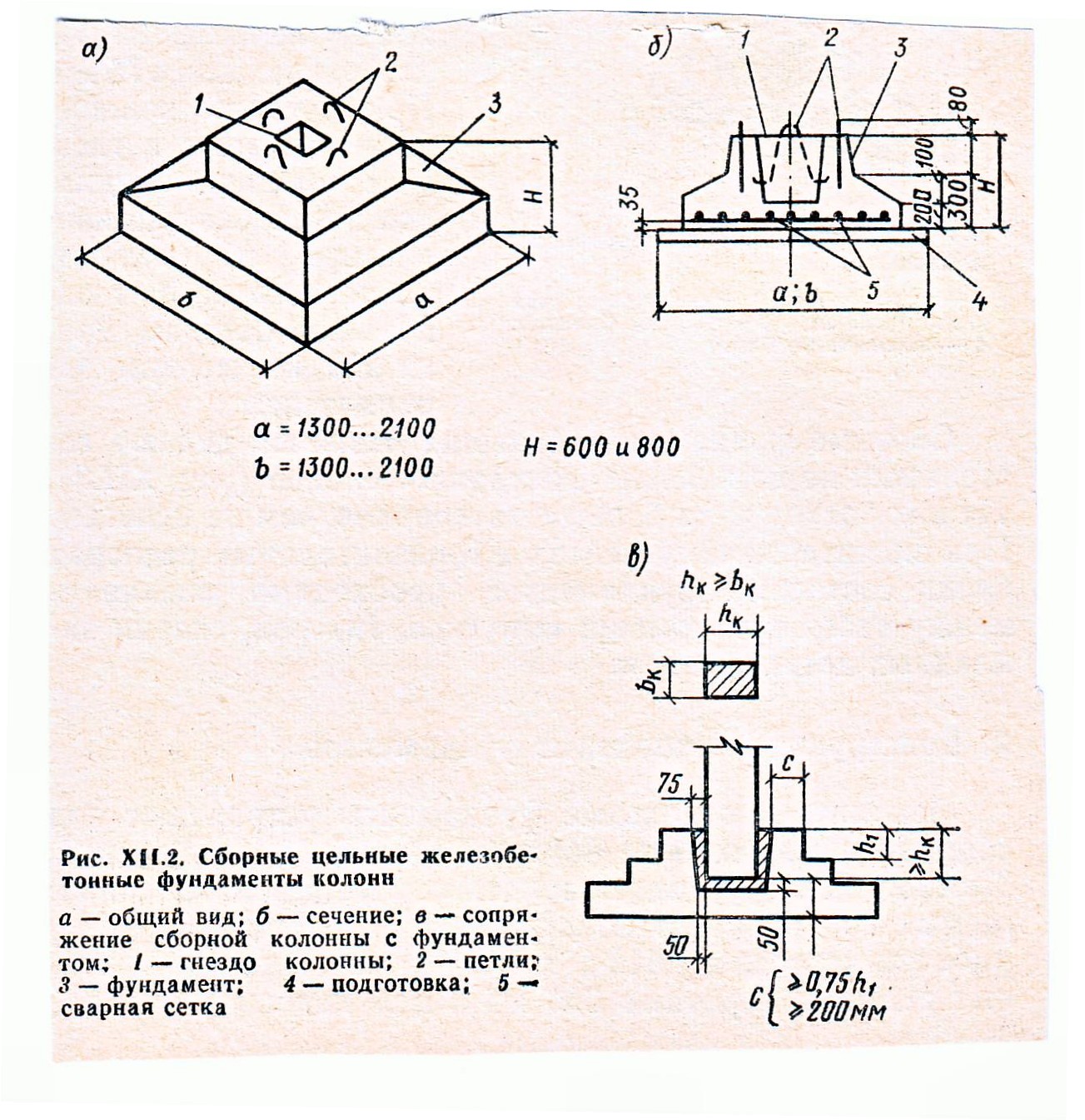

Calculation of individual monolithic or prefabricated slabs for the future foundation

If you pay attention to the section of such a slab, then you can pay attention to the complex system of reinforcing rods encircling the slab and the glass. Each element of the reinforcement mesh is calculated separately, as well as the width of the glass.

And the slabs already have standard dimensions of length, width and thickness.

Surface preparation. First you need to clear the territory of the construction site, mark and align. Alignment is done for the reason that reinforced concrete slabs cannot be displaced. Therefore, the surface should be perfectly flat, a displacement of no more than 1-1.5 degrees according to GOST is allowed. If the surface is too uneven, then sanding is allowed, its level should be at least 30 cm above the level of the sole of the base.

The axes of the future foundation are being marked. To do this, mount a rigid wire or steel cable on the castoff and make a broach in the direction of the letter and perpendicular axes. All connection points and markings are clearly indicated in the design of such a foundation, as well as the lengths of the intermediate connecting beams are clearly indicated.

Then the contours of the future foundation are applied and trenches are dug to a given depth. At the bottom of the pits, a sand and gravel cushion is made, moistened and rammed.

When all the preparatory work is completed, the installation of reinforced concrete blocks begins. It is made strictly in accordance with GOST, horizontal and vertical accuracy is observed. After the installation of the blocks, complex reinforcement of the structure is carried out, and in the open plane of the glass there must be a horizontal and vertical intersection of the rods of the supporting structure.

After installing the blocks, you need to wait until the concrete gains its brand strength and then start installing the pillars for the supporting structures.

Varieties of columns

At the edges of the house (where the load is less), the columns can be made of a steel square pipe with a cross section of 150 mm. The pipe is anchored to the base and ceiling. Steel columns are installed locally with a crane.

1 of 1

On the picture:

Pay attention to the wooden walls that are being built around the columns. They will not be carriers

The role of columns can also be played by small in area, but functionally important brick walls. The walls, made in the form of light wooden box structures, are independent and do not experience vertical loads.

On the verandas and on the porch, the columns can be made of wooden beams and rounded logs. Their fixation on a concrete base is carried out by installing them in steel glasses fixed with anchors.

1 of 1

On the picture:

Fixation of a wooden column in a metal "glass".

Finally, the most important columns are in the center of the house. Usually, columns of the design section are made here on a metal frame - they are cast from concrete in inventory formwork.

When to remove the formwork from the column?

The structure is decomposed only after the concrete has gained residual strength. This is one of the reasons why the use of steel columns is economically feasible. After all, inventory formwork is not cheap, and it is expected at other facilities. So the combination of concrete and steel columns can reduce the cost of civil works.