How to build?

Making each type with your own hands is quite possible, stock up on the necessary literature and patience.

The first step in a tile installation is to prepare a groove in the soil for future installation. The dimensions and depth in this case are not fixed by anyone (although there are recommended dimensions - up to 500 mm), the developer must independently select the optimal characteristics.

The next stage is filling the pit with rubble (up to 10-15 cm) and tamping. You can fill in the finished solution after waterproofing the structure with roofing material. The composition of the filling in this case is 1/3/5 (cement, sand, crushed stone). Often this type is installed on the basement floors of small buildings.

A pile foundation or a foundation on screw piles is an equally reliable and easy-to-install type. For it, you will need to dig holes in the corners of the proposed slab (while the diameter must remain at a level of at least 20 cm). The pits are pre-filled with moistened sand and gravel (from 10 to 15 cm) - it is necessary to do it for ease of tamping.

The preparation of the formwork for the further pouring of concrete requires the installation of a roofing felt sheet and an armored belt. After ramming, pouring and coating the piles, the latter are mounted with each other and serve as bases for reinforced concrete or concrete slabs. As already mentioned, there is a type of pile foundation without excavation.

An in-depth view is more difficult in design and installation. There is a sequential installation plan here.

- Make sure that the pit you dug is 10-15 centimeters larger than the dimensions of the stove itself. This figure must be observed on each side of the pit. Depth characteristics in this case are not fixed, everyone follows different rules, but most often it does not exceed one and a half meters.

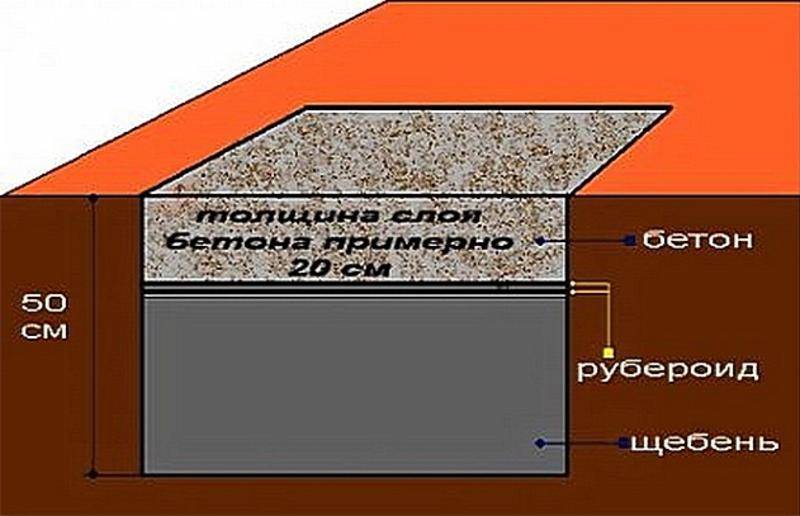

- The next step is to compact and tamp the bottom of the excavated pit. For this, rubble can be used (pre-moistened or not - it's up to you). After compacting the bottom of the pit, the thickness of the crushed stone should not fall below 15 cm.

- For a tighter compaction, the developer can use a sandy loam layer up to 30 cm thick, the latter moistened with a small amount of water for greater compaction. When the sand layer is dry, you need to add another layer of rubble on top of it. This time - already up to 20 cm.

- The next important step is to make wooden formwork. The inner surface can be pre-lubricated with bitumen, so you will provide waterproofing to your structure.

- Further installation of the buried view is similar to the installation of a pile foundation, however, the formed space from the walls of the soil to the foundation in this case is covered with sand.

The shallow type is represented by three separate types: columnar, monolithic slab, lattice. Each of these types has its own installation features.

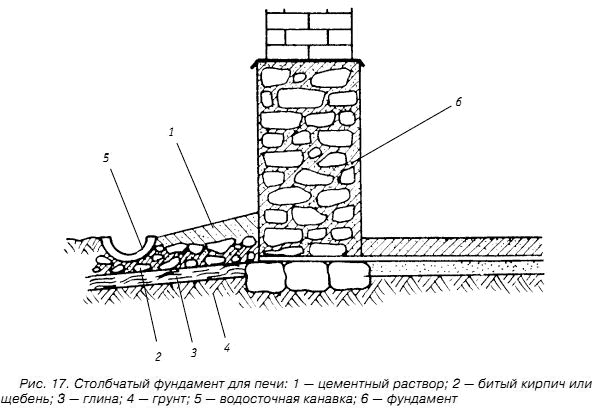

- Columnar is a cheaper option and is presented in the form of several vertical supports, immersed in the prepared soil by no more than 30%. The approximate distance between the supports should be 2 meters.

- A monolithic slab is more suitable for installing a foundation on soils without soil subsidence. But this type is applicable to lighter buildings, as it is subject to the influence of external factors - mechanical damage and others. Hydro- and heat-insulating elements can be brought under the finished monolithic slab - in order to avoid freezing in the winter season.

- The lattice type is perhaps one of the simplest types of non-buried foundation. Making it involves mounting a large number of slabs with fittings. This will save your resources when pouring. In addition, the lattice type is more resistant to breakage.In case of breakage or formation of cracks in certain parts of the foundation, the risk of transmission of damage to another part of it is reduced.

The foundation for a metal stove in a bath

The finished metal furnace weighs no more than 150 kg, so for many, the question of how to make a base for such a structure becomes relevant.

In this case, you can fill the foundation for the furnace according to the following scheme:

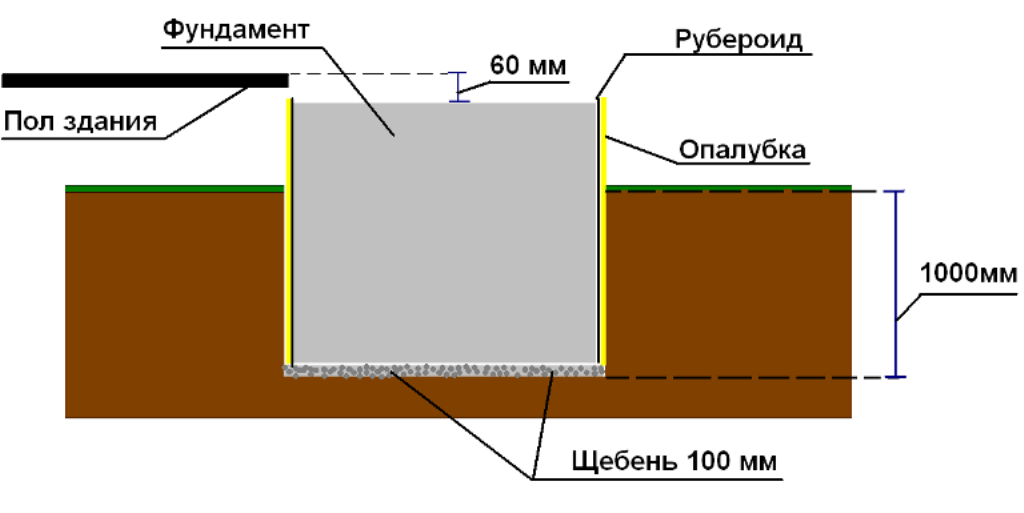

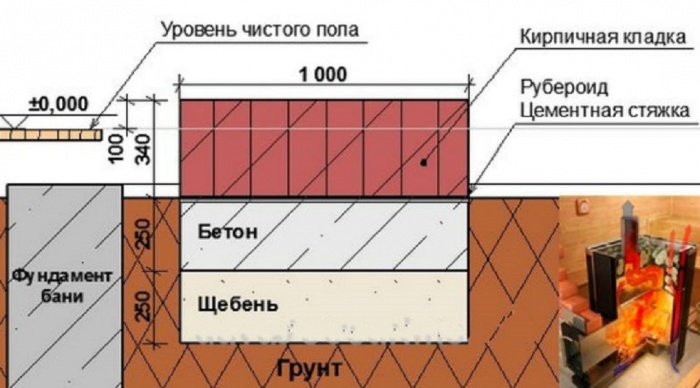

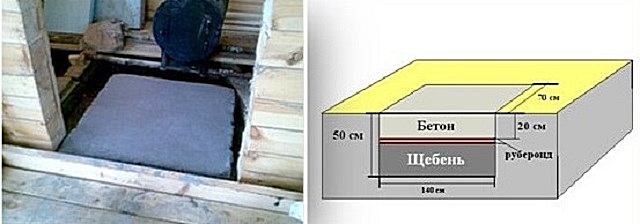

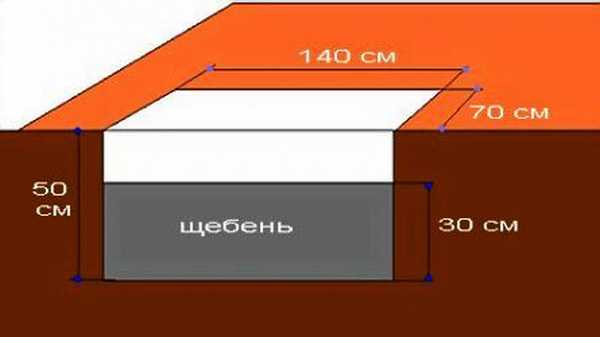

- They dig a pit 50 cm deep in accordance with the dimensions of the purchased sheet steel furnace. The bottom of the pit is leveled and tamped.

- Crushed stone is poured into the pit with a layer of 30 cm and is also well compacted.

- The crushed stone layer is poured with a solution of sand and cement, taking the components in a ratio of 1: 4. The finished mixture should have the consistency of thick sour cream.

- The process is suspended until the cement has completely solidified, 20-24 hours are enough for this.

- Roofing material is laid on the frozen cement, creating a waterproofing layer for the foundation.

- Then the entire pit is filled with concrete, the surface is leveled at a horizontal level.

- The remaining distance to the floor level is laid out with red fired brick.

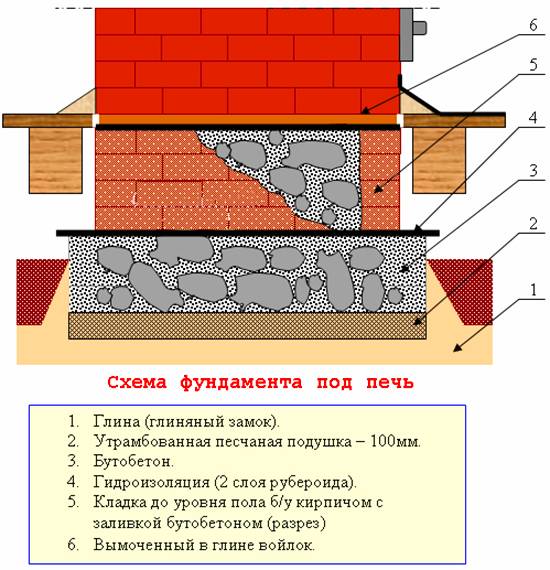

To quickly and easily make the foundation for the furnace, it is enough to concreted the dug foundation pit. A reinforcing cage is additionally laid under a massive brick oven. In some cases, the process of formwork installation can be excluded. Several rows of bricks are laid out on the poured base of the foundation, bringing the structure to floor level. The last row is leveled horizontally with cement mortar. The finished structure is covered with roofing material for waterproofing and covered with dry boards, also treated with a waterproofing compound. The work is completed by laying a brick box in accordance with the dimensions of the base of the furnace. Slag or broken bricks are poured inside the box.

If the foundation for the furnace is arranged in soil with high humidity, then iron ore brick is used. In this case, concrete or rubble concrete is used to fill the lower part, and the upper part is laid out of bricks. When building on dry ground, a clay mortar is prepared with the addition of cement.

Carrying out work on the construction of the foundation for the furnace, one should not save on materials, especially on their quality. The sturdy construction of the base will ensure a long service life for both the stove and the bath itself.

Basis for installation

Any modern heating device weighs relatively little, but add here a lot of stones in a mesh casing, water in a tank, loaded logs, brick lining. As a result, the load constantly experienced by the floor is quite serious. If the firebox stands on four point legs, over time, they can push through the wooden covering.

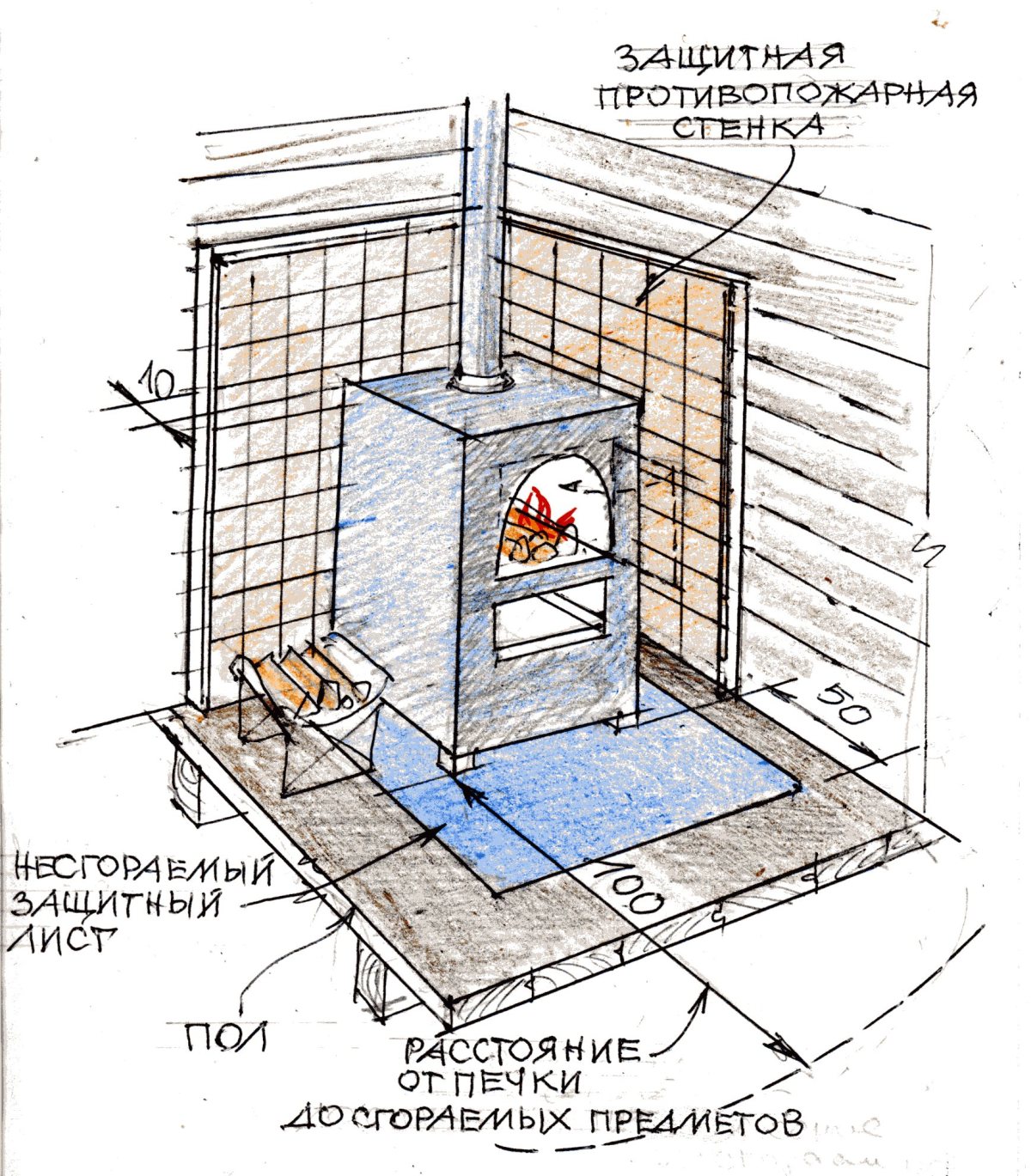

If the floors are non-combustible, they do not need additional screening. A screed poured over the ground will already be a sufficient solution. Although it is still better in any case to lay a separate fire-resistant base. The main thing is that the total weight of equipment and fuel does not exceed 700 kg.

Selection of the type and size of the foundation for the furnace

It is advisable to lay it down at the design stage. After all, if you act already with an equipped steam room, you will have to remove the floor, replace the damaged structure, then fix new logs or reinforce the old ones.

What are the foundation options? If we are guided by the current SNiP, these are:

- A monolithic reinforced base, not combined with a bath, laid below the soil freezing line.

- The pile-slab base is also separate - it will come in handy when building on heaving soil.

- Shallow foundation (up to 0.6-0.7 m down), going in conjunction with the sole of the steam room and adjacent rooms. Just reinforce it with anchoring to prevent vertical movement of the slabs in frost.

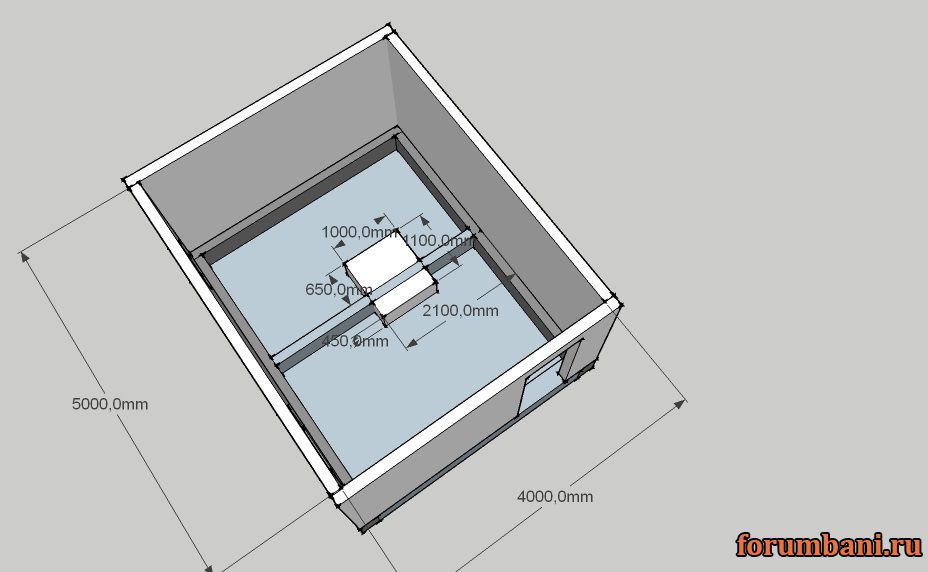

The dimensions of any of the options depend on the dimensions of the rooms, so this is always an individual indicator.The main thing is that from the edge of the perimeter to the beginning of the walls there is a distance of 7-10 centimeters.

Advice

Wooden walls can be reliably and economically protected with minerite.

For energy efficiency, supply a heat exchanger and hot water tank.

During operation, pay attention to the condition of not only the furnace, but also the chimney, as well as stones in the mesh casing.

Now you know how and where to correctly install the stove in the bath - the steps are described in sufficient detail. But we recommend that you show the finished result to specialists so that they confirm that you did everything correctly.

Informative videos

Step by step instructions

- Before making a columnar foundation with a grillage, it is necessary to prepare a site at the site of its construction, for which all vegetation is removed from the designated area and sod is removed (25-30 cm and 45-50 cm for clay soil). Then all the depressions and irregularities are covered with sand and gravel.

- After laying the sand and gravel cushion, mark the dimensions according to which the supporting columnar foundation will be poured with their own hands. At this stage, you will need pegs and a cord. With their help, it is necessary, strictly according to the scheme, to mark the distance between the future pillars (no more than 2 m). The main rule of this step is accuracy, and it must be observed strictly.

- In order for the columnar foundation of blocks to securely anchor in the ground, it is necessary to dig holes for the piles. Depending on the type of soil and base material, the depth can vary from 30 cm or more in relation to the limits of the base (gap for a cushion of sand and gravel). Deep wells (from 1 m) are recommended to be strengthened with special wooden supports.

Further step-by-step instructions for installing a shallow pillar foundation, will differ depending on what design features need to be implemented, as well as on the material of the support pillars.

A grillage is called a structure that is arranged on the surface of the pillars and connects their upper parts to each other. It also serves as the basis for the load-bearing walls of the building.

Monolithic columnar foundation

Reinforced concrete columnar foundation with grillage is the most popular among developers, because it is reliable and strong. Here, the pits for the supports should exceed the width of the similar parameters of the columns (the difference between them will be at least 15 cm). It is necessary to install a wooden formwork in these recesses, which must be reinforced with reinforcement and concreted. After the solution has solidified, the pillars are connected by a grillage - reinforced concrete, metal or wood. This method has its drawbacks, since the technology of its manufacture is rather laborious.

Prefabricated columnar foundation

A shallow columnar foundation made of blocks (20x20x40 cm) has its advantages, but it also has its disadvantages. The advantages of such structures include the availability and ease of installation, and the disadvantages are lower strength in comparison with the previous version, which is why it is categorically not recommended to tinker on moving soils. Their installation technology looks like this:

- the width of the recesses is 40 cm;

- gravel and sand are poured into the pits in layers;

- 4 blocks are installed (one on top of the other), fastened together with a cement mass.

The grillage columnar foundation of blocks can be installed on a reinforced concrete slab, which serves as an additional support. The advantage of this solution is that it prevents soil subsidence.

Brick columnar foundation

The brick support-column foundation, as the name implies, is assembled from bricks and reinforced with a metal mesh. Such structures are necessarily supplied with roofing felt or bituminous waterproofing. The base of asbestos pipes implies a permanent formwork. By the same principle, a shallow foundation is assembled from steel pipes or screw piles.

Columnar bases are assembled according to the following scheme:

- Wells are drilled in the ground, 5 cm larger in diameter than the piles themselves. If you plan to build a lightweight house, you can limit yourself to supports with a diameter of 20 cm. Before the vertical installation of the pillars, the bottom of the wells must be tamped tightly, and the pillars themselves are compacted with sand and earth.

- Concrete is poured a third of the depth of the piles, then they are raised so that the mortar evenly covers the bottom and gives the support additional strength.

- A reinforced frame is placed inside all pipes with the condition that the rods peep out of the hole by 20 cm. The rest of the mortar is laid in layers to the zero mark, while it will correctly subject the base to periodic vibration pressing.

It is not recommended to leave the grillage foundation made of pipes unloaded for a long time, otherwise the soil can push out the piles and their deepening will be uneven. Between the installation of the supports and further construction, no more than 3 days should elapse from the moment the solution hardens.

Wooden shallow columnar foundation is assembled from beams pre-treated with antiseptic agents. The diameter of the supports must be at least 20 cm, otherwise the house will tilt and quickly collapse. Choosing wood is between oak and conifers. In this case, the deepening depth will be at least half a meter.

Wooden columnar foundation

Soil types

A strong and high-quality base for the stove is the key to its long service, since any movement of the ground can cause serious damage to any structure. This is especially true for stoves made of brick or other stone. The question often arises, do you need a foundation for a furnace that is relatively light, weighing up to 750 kilograms? This type of stove is really an exception to the rule and only needs a solid floor structure.

A strong and high-quality base for the stove is the key to its long service, since any movement of the ground can cause serious damage to any structure. This is especially true for stoves made of brick or other stone. The question often arises, do you need a foundation for a furnace that is relatively light, weighing up to 750 kilograms? This type of stove is really an exception to the rule and only needs a solid floor structure.

In the conditions of the Russian climate, winters are accompanied by frosts, the result of which is the freezing of the soil to a considerable depth. Therefore, when building foundations in our strip, it is recommended to lay the foundation at least to the depth to which the soil freezes in a specific area.

It is important to take into account the type of soil itself.

All soils found in Russia can be divided into four types:

- Sedimentary and alluvial soils

They form in places where in the past there were seas, lakes and rivers. The density of such soil is sufficient to erect any foundation on it for a bath stove. As an exception, porous clay and loess soils. Porous clay, absorbing moisture, is able to significantly swell and expand even more when frozen. Loess soils, when saturated with moisture, completely lose their strength, turning into slurry. When equipping the foundation in conditions of porous clay, it is necessary to pull out a pit below the depth of soil freezing. As a basis for it, stone rubble is tamped and a sand cushion of 50-100 centimeters is arranged. The masonry itself is best done from rubble stone or using it. - Continental soils Continental soils are gravel-sandy soil formed as a result of the destruction of rocks for natural reasons. They are rightfully considered one of the most successful types of soil for the construction of a foundation, since they are least susceptible to the influence of weather conditions.

- Fill-in soils Fill-in soils are formed at the places of construction sites, as well as on sites where a building previously stood. Sands mixed with gravel or crushed stone, and caked for at least three years, can, without special preparation, serve as an excellent foundation for a foundation. If the bulk layer is less than three years old, and it is not possible to get rid of it, you can tamp it together with the rubble layer.

- Permafrost A significant part of the territory of Russia is covered by permafrost.The foundation for a stove in a bathhouse on such soil should not only serve as a reliable support and protect against frost heaving, but also act as thermal insulation between the surface of the earth and the stove itself.

Furnace foundation device

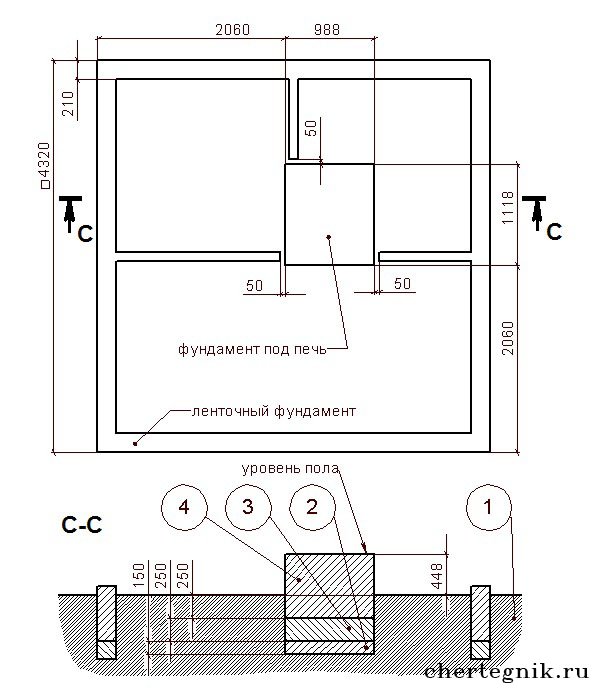

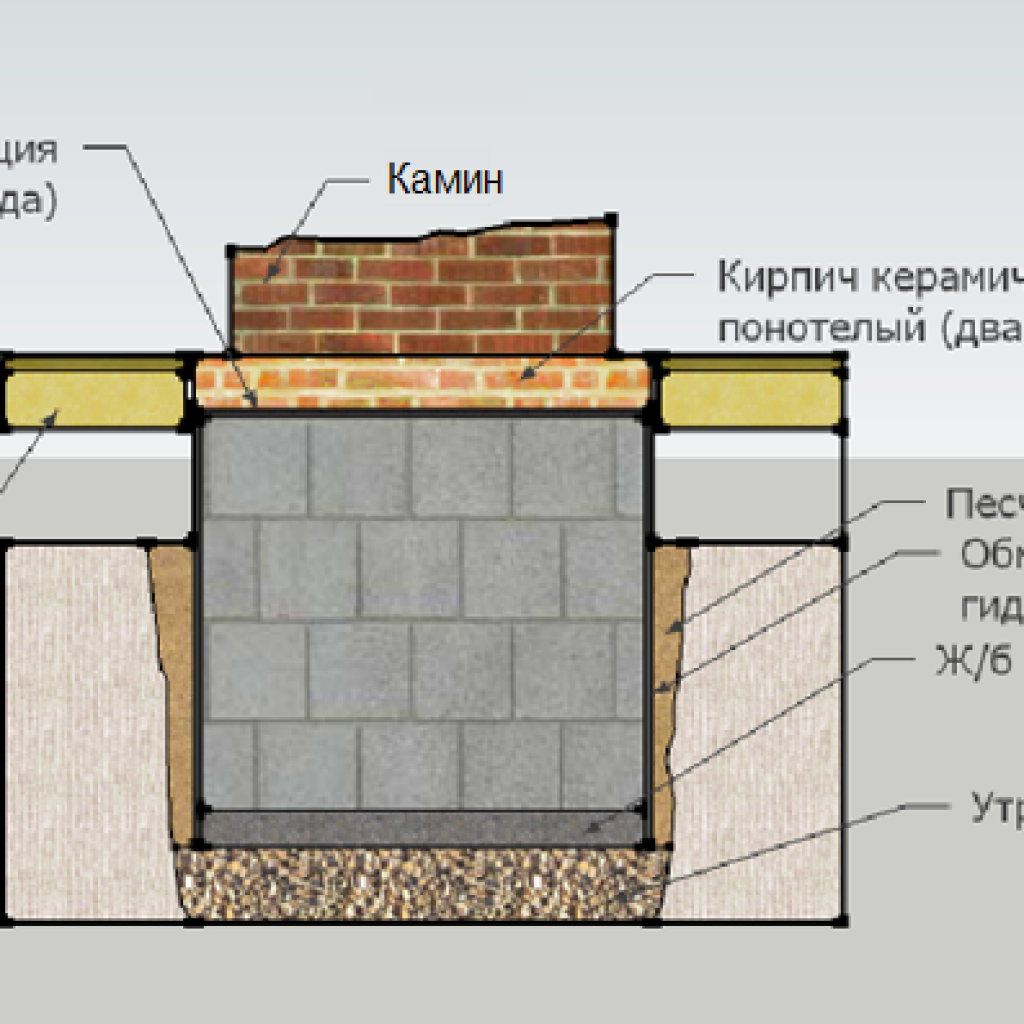

If a decision is made to build a classic massive brick stove in the bathhouse, then the foundation must be designed so that a space of 40-50 centimeters remains between the planned stove and the walls of the building. Its dimensions need to be made 5-6 centimeters larger than the oven installed on it.

Since the weight of the kiln is critical in choosing the type of foundation, it makes sense to calculate the total weight of the bricks going into the building. The calculation is easy to carry out, taking the figure of 3.5-3.6 kg for the standard weight of a red brick. Stoves-heaters are rarely lighter than 1200 kilograms, therefore they require such a massive base, with which only a foundation for a Russian stove can be compared.

On clayey soils with groundwater close to the surface, the foundation for such a furnace is best arranged on piles (a metal frame or a slab of reinforced concrete is installed on top of the pillars dug to the depth of freezing of the soil). The foundation for the furnace must be arranged separately from the foundation of the walls, leaving a gap of at least 3-5 centimeters between them, thereby ensuring a free settlement of each structure. It is best to fill the gap between them with dry sand, insulated on both sides with roofing material.

On clayey soils with groundwater close to the surface, the foundation for such a furnace is best arranged on piles (a metal frame or a slab of reinforced concrete is installed on top of the pillars dug to the depth of freezing of the soil). The foundation for the furnace must be arranged separately from the foundation of the walls, leaving a gap of at least 3-5 centimeters between them, thereby ensuring a free settlement of each structure. It is best to fill the gap between them with dry sand, insulated on both sides with roofing material.

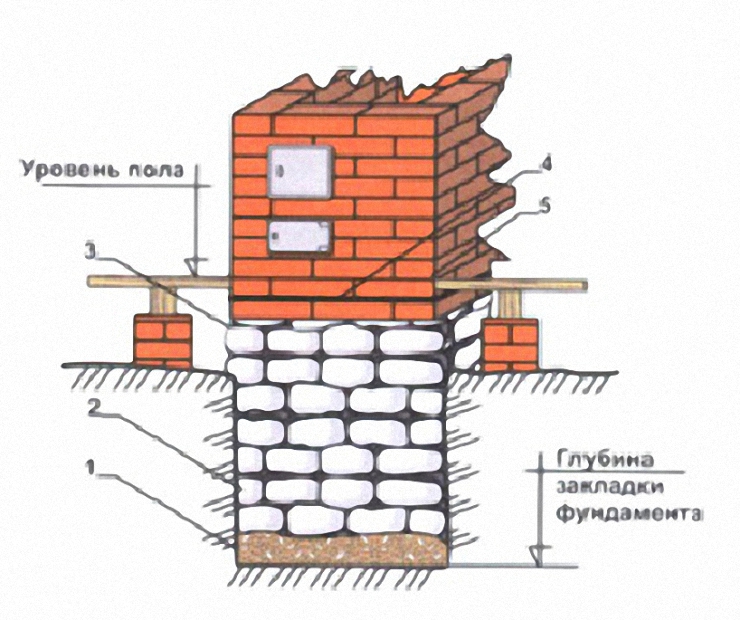

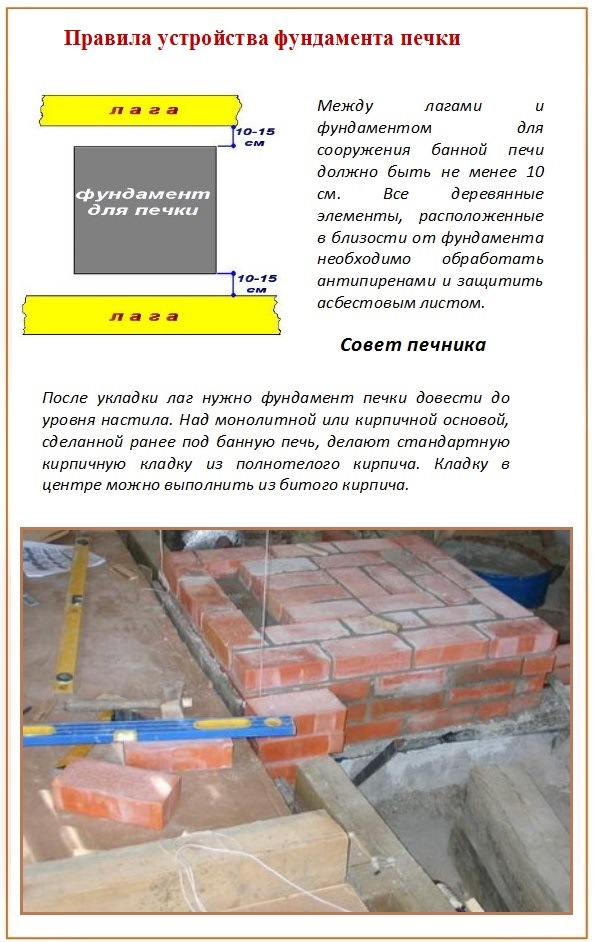

It is necessary to leave 15-20 centimeters between the proposed floor of the bath and the site of the stove foundation, that is, the distance for 2-3 rows of brickwork. After laying the foundation, its surface should be covered with a cement screed (a layer of cement mortar) a couple of centimeters thick and leveled to ensure a completely horizontal surface. The first row of the brick base of the stove should be laid out on top of the waterproofing, which reliably protects the brick from dampness. Moisture has a destructive effect on this material. In addition, a damp bottom row of bricks can create dampness in the bathhouse and, as a result, mold and mildew.

Do I need a foundation for a stove in a bath

Basically, the presence of a foundation is determined by the size and weight of the stove, which, in turn, depend on the overall size of the bath. That is, the large volume of the room requires a large furnace, which has significant weight and must be supported on a sufficiently strong foundation. Experts have determined the maximum weight of the furnace - 700 kg (some sources indicate 750 kg), which can be installed without arranging a separate foundation. For furnaces, the weight of which exceeds this value, the presence of a full-fledged foundation is required.

For your information! This applies to buildings that have a strip, columnar or pile-screw foundation. If the bath is built on a solid concrete cushion (slab type), a separate area for the stove is not required.

For the final solution of the issue, it is necessary to consider all aspects - the weight of the furnace, the type of the main foundation, the type of soil, the volume of the boiler (which can increase the total weight of the furnace several times), the material of the furnace, etc. It should be taken into account that a separate foundation is needed for the furnace, which is not connected with the general foundation of the building.

This rule is due to the need to reduce the load and exclude deformation of the furnace in case of any shifts or subsidence of the common base of the bath. The pressure on the ground created by the walls and the furnace is different, which is why the amount of subsidence and movement is significantly different.

In addition, the response of structural elements to precipitation is not the same. Small changes that do not cause major problems for walls and floors can be disastrous for a stove, especially a brick one. The formation of even a small crack is fraught with the appearance of carbon monoxide gases, smoke, the penetration of sparks into the room.Therefore, the need for a reliable, separate base for a large oven of large size and weight is undeniable.

When you can do without a foundation

If the weight of the stove does not exceed 700 kg, or the general foundation of the bath is a solid monolithic slab of concrete, a separate foundation for the stove in the bath does not need to be erected. Relatively light stoves, most often metal, they have a higher strength than brick ones. Such structures can even be installed on a wooden floor, while observing all fire safety requirements. See the article on installing a metal oven.

Brick stoves are heavy, but with a common monolithic foundation, they are built without any separate foundations. In this case, there is a danger of destruction of the furnace due to deformation of the base plate, therefore, its arrangement must be taken with full responsibility.

Base device

Before laying a brick on the unit, you need to well prepare and strengthen the base under it. Since metal structures are lightweight, they do not need a separate foundation for the furnace, but brick cladding will have an additional load equal to tens of kilograms.

Not every floor covering can support this mass. For this reason, before laying a brick on the boiler, it is imperative to disassemble the floor and equip a separate foundation - columnar or monolithic.

Most often, a monolithic base is made. To do this, they dismantle the floor under the stove. The parameters of the foundations should be such that a gap of 10 to 15 centimeters remains between the future brick cladding and the metal body of the unit.

First, a hole is dug about 30 centimeters deep, crushed stone and sand are poured onto the bottom, tamped, reinforcement installed and poured with concrete. The foundation will harden for about 2 weeks.

For arranging a columnar foundation, pillars are installed at the corners of the facing box and in places of the highest load. The advantage of this base is that no drainage or waterproofing is required.

The sequence of actions during the construction of a columnar foundation is as follows:

- Markings are made at the corners of the oven for mounting pillars.

- Dig holes located strictly vertically, having a depth of about 50 centimeters.

- A 10-centimeter layer of sand is poured onto the bottom of all the pits and tamped down.

- A mortar is prepared from cement and sand in a ratio of 1: 2, it should have the consistency of thick sour cream.

- The solution is poured over the sand layer in a 10 cm layer. Crushed stone or brick chips are added to it.

- After hardening, brick pillars are laid out so that they rise 7-10 centimeters above the floor.

- Install a bar of the lower strapping. The most reliable way will be to lay the channel around the perimeter and weld the edge.

The use of concrete posts is allowed. You can make sure they are vertical with the help of a building level.

The way the foundation is arranged depends on whether it already exists and what it is. And also on whether you are covering an already connected and working oven or performing its installation and cladding at the same time.

If you already have a solid concrete foundation with a thickness of 20 cm or more, it will surely withstand the expected load. In this case, it is possible to impose a brick on the iron stove immediately, without preparatory work.

In the absence of a foundation for the furnace, it is recommended to fill in a solid reinforced concrete base. Its area should be larger than the area of the cladding. When calculating it, keep in mind that the distance from the metal case to the brick walls is taken to be 8-10 cm.

The foundation is being prepared in stages:

First, you need to dig a hole 30 cm deep in the ground, fill it with sand, rubble, broken brick and tamp this pillow;

Arrangement of crushed stone cushion under the base

- Then, along the perimeter of the pit, formwork is built up to the level of the floor in the furnace room;

- A concrete mixture is poured into it, which is reinforced with a metal mesh or rods;

Cast base for oven and cladding

- The concrete base must be allowed to dry for 2-3 weeks;

- After that, it is covered with roofing material and a brick platform with a height of one or two rows is laid on top of it.

A brick base is laid on a layer of waterproofing A common picture - it is required to brick an already operating furnace

This is possible if the wood flooring is able to withstand the additional load from the brickwork. To make sure of this, the floor must be disassembled and the logs inspected. For this, the stove will still have to be temporarily dismantled by disconnecting it from the chimney.

Having opened the floors, inspect the logs.

They must be dry, without traces of damage and rot, and the distance between them should not exceed 60-80 cm. If it is more, another support with a cross section of at least 10-15 cm must be laid at the place of installation of the stove.

The distance between the lags and their cross section must be such as to withstand the load from the furnace

The floorboards themselves should be dry and strong, and their thickness should not be less than 30-40 mm.

After the revision and reconstruction of the wooden base, first a metal sheet, and then a refractory material such as asbestos board, is laid on the floor according to the markings and fastened with self-tapping screws. And a brick base is already being laid on it.

Part of the furnace and brick walls will rest on a wooden floor - we cover it with refractory material

Classification

The bases used for installing heating units in the bath differ in the following points:

- the level of penetration into the soil;

- design features;

- material used for manufacturing.

By the degree of deepening, the supporting structures are classified into the following types:

- Buried in the soil no less than the depth of freezing. Allows you to install a furnace weighing more than 2 tons. They represent a monolithic concrete mass with a height of about 1 meter, formed on a compacted cushion of rubble.

- The depth of laying is no more than 0.7 m, which makes it possible to ensure the stability of structures weighing up to 1.5 tons. The base is formed in a pit filled with compacted sand, stones, gravel, concrete, the level of which exceeds the zero mark by 15 cm.

The foundation for the stove in the bath differs in design features, it can be made in the form of:

tape repeating the configuration of the heating device. It is used for small-sized and massive heating devices. Construction of a tape base is a laborious and costly process;

Any foundation can be built on sedimentary soil

- reinforced monolithic slab, the construction of which does not require significant financial investments, labor costs. The slab is susceptible to soil movements, it is used on non-porous soils to install stoves with a large weight;

- concrete base installed on support elements. The columnar base allows for reliable installation on sandy and heaving soil with a high concentration of clay;

- support surface mounted on screw piles. The design allows you to save on earthwork, concrete work. It has a high bearing capacity, resistance to compressive loads, and is characterized by minimal shrinkage.

The material is used:

- Concrete, which is the best material option for a massive kiln.

- Brick used for lightweight ovens with small dimensions.

- Rubble stone, which is a budget material in order to make a foundation for a stove in a bath.

Let us consider in detail how to independently build various types of foundations for installing a heating device in a bath.

It is more convenient to lay the base for the stove at the same time as the bath foundation device