Reinforced concrete columns of industrial buildings.

In buildings without overhead cranes, columns without consoles are arranged, and in buildings with overhead cranes - columns with consoles on which the crane beams are supported. The columns of the extreme and middle rows are distinguished by their location in the plan: the first are also installed in rows adjacent to the longitudinal expansion joints.

Reinforced concrete columns can have rectangular and I-sections, as well as be two-branch. Compared with columns of rectangular cross-section, two-branch columns have increased rigidity, but they are more laborious to manufacture. They are used in a building with a height of more than 10.8 m.

In buildings equipped with more than two bridge cranes in the span, according to the safety conditions of the service personnel, through passage galleries are provided along the crane tracks. In these cases, two-branch columns with manholes are used, located at the level of the top of the crane beams.

The branches of the cross-section columns are connected with spacers every 1.5-3.0 m in height.

In reinforced concrete columns, steel embedded elements are provided, with the help of which roof structures, crane beams, wall panels (in the columns of the outer rows) and vertical ties are fastened. Steel sheets are laid in U1stakh supporting the rafter structures and crane beams: they are fastened with anchor bolts. At

non-anchor fastening of truss structures to the columns, steel plates are sealed in their heads.

To increase the stability of buildings in the longitudinal direction, a system of vertical ties between the columns and in the coatings is provided. In buildings without bridge cranes and with overhead transport, intercolumnar connections are installed only at a room height of more than 9.6 m. In order to reduce the efforts in the frame elements from temperature and other influences, vertical ties are placed in the middle of the temperature blocks in each row of columns.

Ordinary columns are connected to the tie columns with spacers placed on the top of the columns, and in buildings with bridge cranes - by crane beams. Ties are made of corners or channels and are attached to the columns using gussets by welding.

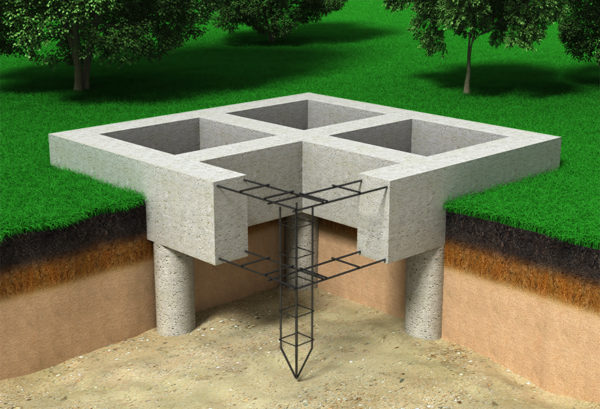

Column foundation

The peculiarity of this category of the base is that it is installed under individual elements of the structure (directly under the column).

The device of such a base consists of a single or multi-stage shoe, as well as a glass in which the column is placed. For reinforcement, welded steel mesh must be used.

Monolithic base

This type of column base has a monolithic structure. To fill it, a hole of the required size is dug in the ground, and the formwork is mounted. The height of each step should not be less than 300 millimeters. The monolithic version is simpler and more reliable in installation and operation

It is important that all the edges of the individual steps are symmetrical. The total depth of such a foundation (up to a glass for a column) can be from 1.2 to three meters

Prefabricated base

The device of such a base is easier to manufacture. For this, formwork is made, and a concrete slab of the required dimensions is poured. The thickness of the product should not be less than 30 centimeters. The elements do not need additional fixation. The weight of the individual column, as well as of the structural elements of the building fixed to it, will not allow them to move. Watch the video on how to install the column to the base.

The column can be attached in several ways. The first is in a special groove, cast during the creation of the slab (with subsequent grouting after installing the support). The second is fastening to mortgages (metal beams, corners, or channels), poured with concrete.

If metal columns are used in an industrial enterprise, then they are attached in a special way. During the pouring of the base, threaded studs are attached to the reinforcing layer. After solidification, a metal support is connected to the structure. It is fixed either by welding or by a screw method to the welded plate at the bottom of the post.

When creating the foundation for vertical building elements, it is important to maintain a perfectly right angle (90 degrees). In this case, all elements of the building will be securely fixed in place.

Design features

A conventional columnar foundation is a structure in the form of individual pillars, often rectangular in shape, which are installed under such structural elements of a building as columns or pillars. The traditional strip foundation is arranged in the form of an extended strip on which the load-bearing walls rest. If you combine these two types of foundations, you get a structure similar to a pile foundation with a grillage that unites the piles. However, the columnar-strip foundation has fundamental differences from the pile foundation, which are as follows:

- Pile foundations are used mainly in soil conditions with weak soils with low bearing capacity. The function of the pile is to pass through a layer of soft soil and find support in a layer of high bearing capacity. To find this layer, geological research is done. Therefore, the length of the piles can be up to 10 meters or more. Columnar-strip foundations are used in soil conditions with a normal bearing capacity of the base, while the depth of the pillars in the ground should be a value that is only 200-250 mm higher than the depth of seasonal soil freezing, that is, within 1.5-2.0 meters ...

- Piles transfer the load from the building through the bottom and side surfaces. Unlike piles, pillars in a columnar-strip foundation transfer the load only through the sole.

- The cross-section of the piles is in most cases much smaller than the cross-section of the foot of the pillars.

- Pile foundations can be used for almost any buildings and structures, strip-and-column foundations are used mainly for light structures - one and two-story residential buildings - frame and frame-panel, wooden from a bar or log, from SIP panels, for houses made of aerated concrete, aerated concrete and foam concrete blocks, baths, garages, fences, etc.

The only thing these two types of foundations have in common is the grillage or tape that connects the individual supporting elements of the structure. At the same time, in the strip-column foundation, the tape performs the same functions as the grillage in the pile - it plays the role of a multi-span beam on the supports, transferring the load from the walls of the building to the pillars, which in turn transfer the load to the ground. This is where one common misconception lies: a tape in a strip-and-column foundation is considered an element that transfers part of the load to the ground along with the pillars.

The fact that the tape in the columnar-strip foundation plays the role of a hanging grillage is also related to the nature of its reinforcement. The tape is reinforced with a space frame, in which both the upper and lower reinforcing bars are working.

Installation of a monolithic grillage

To pour concrete mortar, it is necessary to mount high-quality formwork

To pour concrete mortar, it is necessary to mount high-quality formwork. Start with the lower retaining shields. To do this, it is necessary to cut boards equal to the step between the foundation columns. For their fastening, it is recommended to drive the retaining stakes into the ground. The formwork boards are laid on the stakes flush with the upper edge of the pillars.

The side formwork panels are fixed at the edges and securely fixed. The side formwork strips can be covered with roofing material.

The next step is to reinforce the entire structure.Here, an armored belt made of horizontal rods with a cross section of 12-16 mm and longitudinal elements with a cross section of 6-8 mm is used as standard.

It is important in the places of the pillars to tie the reinforcement with the rods protruding from the columns

Filling the grillage solution must be carried out in one stage. Therefore, it is better to order a construction mixer or concrete mixer of the required volume. When pouring concrete, it is necessary to ram the mortar every 30 cm.The total thickness (height) of the grillage, as a rule, does not exceed 60 cm.

After 7-10 days, subject to good dry weather, the concrete is considered completely solidified. Now you can remove the formwork and let the foundation settle. All surfaces of the grillage are also covered with waterproofing materials.

After the structure has completely dried, it is necessary to backfill the pit with compaction of soil around the columns. The pit is filled up flush with the mark of the above-ground part of the foundation columns. To decorate the pillars and reduce heat loss, you can use decorative siding of the pillars or lay natural stone.

Features of the foundation for reinforced concrete columns

The bases for reinforced concrete pillars are selected based on the positive and negative characteristics of each type separately. In this case, the most optimal would be to use a glass base, which has the following positive characteristics:

- They are reliable;

- They have increased strength.

In construction, two types of foundations are used:

- Monolithic;

- Made.

Construction stages

Compliance with the rules during construction foundation for reinforced concrete columns, helps to increase the service life of the structure, quality.

- The pillars are set into the ground to a depth of at least 70 centimeters;

- At the construction site, the soil should not be mobile or subject to temperature heaving;

- Groundwater should be at least 1.5 meters deep;

- It is recommended to level the platform so that it does not have sharp slopes and turns;

- To ensure the strength of the foundation, the grillage must be assembled from reinforced concrete. Of course, the grillage device will require financial costs, but this will make the frame more durable;

- For walls, it is recommended to use building materials related to light: foam blocks, beams, panels, logs.

Preliminary design allows you to make the base strong, but standards must be respected:

- The section of the columns is 20x20 cm. Practice shows the use of pillars with a section of 25x25 cm;

- It is recommended to make a shoe for each column. This means expanding the lower part of the well under the pile. The result is the distribution and reduction of the load from the building;

- Place the columns at a distance of 1 to 2 meters. In this case, the pillars should be located at the corners of the building, at the junction of the walls, under the protrusions: a fireplace, a stove.

To increase the strength, the pillars are reinforced with rods with a cross section of 12 to 16 mm. Depending on the material for the grillage, the height of the reinforcement is regulated:

- For a wooden bundle, the rods should not reach the upper part of 1-2 cm;

- When a reinforced concrete grillage is planned, then the reinforcement should protrude 40 cm.

Work with reinforcement should be done only after the concrete has gained the required strength.

Shoe mounting

As already mentioned, in wells it is recommended to enlarge the lower part to create a shoe. A plywood formwork is installed on a crushed sand cushion. Height 20-30 cm. The diameter of the prepared formwork should be 1.5 times larger than the diameter of the future pillars. Now the solution is poured into the prepared container. Within 10 days, the concrete hardens, provided that the weather is warm, dry.

Column installation

The next step is the installation of the formwork directly under the pillars. Wooden boards of the required length are fastened with clamps. It is recommended to cover the inner walls with roofing material.As a result of the measures taken, the walls of the columns are smooth, and most importantly, there is no damage when removing the formwork.

Now install the reinforcement and you can pour concrete mortar of grade 200M. If the construction takes place in the winter, it is better to add plasticizing additives that improve the solidification of the solution. Experts recommend carrying out such work when the air temperature is above 15 degrees Celsius. A metal rod is used to remove air from the liquid concrete. At an outside air temperature of 20 degrees and dry weather, the solution hardens within 7 days.

It is necessary to wait until it is completely dry and only then remove the formwork. Now waterproofing is applied along the entire height of the columns and shoe.

Grillage

The most reliable is a monolithic construction. But there are other options for connecting the foundation and the building:

- Fastening with a channel or I-beam. In this case, the element is laid with the shelf down and fixed with bolts. Such a bundle is not afraid of heavy loads;

- Reinforced concrete or monolithic grillage. For its construction, formwork and the installation of a reinforcing structure will be required. As a rule, a monolithic grillage is used for a panel house, frame construction, a wooden frame; 0

- Wooden grillage. The use of a bar is considered the cheapest option for a bundle of a columnar foundation.

Jig template for anchoring connections

When pouring a concrete base for metal columns, a special jig is used, with which the depth and height of the anchor bolts are controlled. In fact, this is a kind of template for installing anchors. Most often, the manufacture of the conductor is carried out from metal, on the upper surface of which there are risks for alignment with the axes and subsequent verification of the correct installation using a theodolite. Bolt holes are made according to the diameter of the anchors.

Before pouring with concrete, the bolts are welded to the reinforcement cage of the base, and after pouring with concrete, until it reaches its technical hardness, the correct position of the bolts is checked. The next step is to control the rigidity of the formwork and anchors. At the end of this control operation, the altitude-plan indicator of the location is checked.

Jig template for anchoring connections

For heavy steel structures, heavy or reinforced versions of anchor bolts are used. The dimensions of both the bolt diameter and its length and thread pitch differ significantly from lightweight anchor connections. Installation of reinforced heavy bolts is carried out using templates, in the desired position before the foundation is poured with concrete. For greater fixation of such templates, additional fixation with frame racks is used, giving the structure a more rigid appearance.

After pouring with concrete, the anchor bolt templates are removed, while, as a rule, the frame remains in place

When carrying out this stage of work, special attention is paid to the correct location of the bolts, literally all parameters are necessarily controlled - height, depth, and verticality of the installation. This is one of the most time-consuming processes, but it depends on how correctly the foundation was installed.

To facilitate the work at this stage, several reference jig templates are used. Welded from a metal channel or other metal profile of large thickness with the applied coordinates of the axes, it must have a large mass and rigidity. In the designated places, holes are drilled for the diameter of the anchor bolts. For light bolts, as a rule, a regular wooden beam is used.

Before installing the bolts, the correct installation of the jig is checked. It is aligned along the coordinate axes, and is set in height according to the marks on the frame racks.