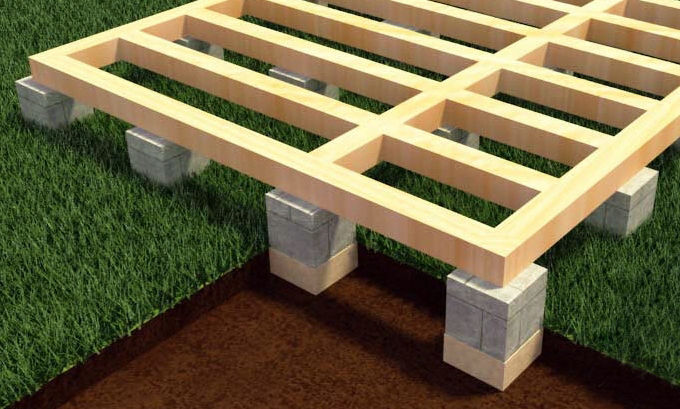

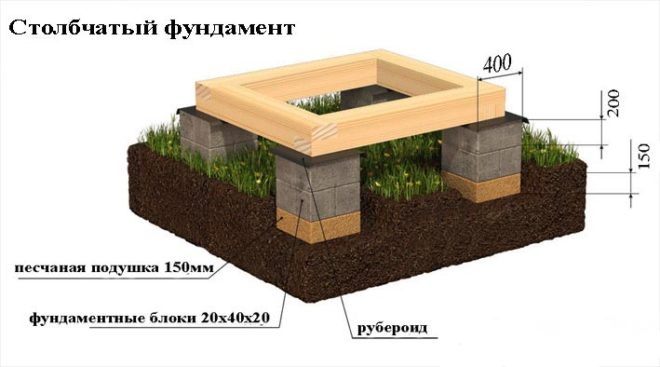

Erection of a columnar foundation

The base in the form of columnar supports is erected for buildings with low weight, it can be a wooden or forged gazebo. The work is carried out in the following order.

Site preparation and marking

The area set aside for the construction of the gazebo is cleared of large vegetation and large debris.

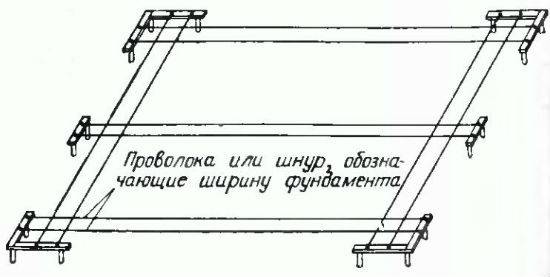

You will need wooden pegs and a rope to make the markings. For a rectangular structure, the angles are determined by the method of the "Egyptian" triangle. To do this, put a peg in one of the corners, measure the distance of 3 meters and put the second peg, then measure 4 meters in the other direction and put the peg again. If the distance between the marks is 5 meters, then the angle corresponds to 900. The rest of the corners are checked in the same way.

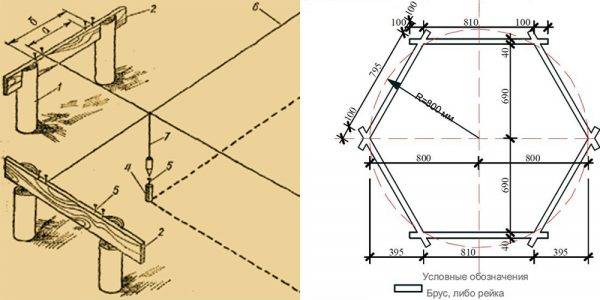

Layout and preparation for a columnar foundation

To mark for a hexagon-shaped gazebo, you need to take two pegs and connect them with a rope. One peg is stuck into the ground approximately in the center of the site, with the other a circle is drawn, slightly pulling the cord. Then a line is drawn through the center of the circle and in those places where the circle and the line intersect, additional marks are put.

Further, other angles are determined, for which a peg with a rope is placed in one of the marks and a semicircle is drawn, which should have intersection points with the main circle. They also put marks here. Similar actions are performed on the other side of the circle. As a result, you should get six pegs, they are connected with a rope.

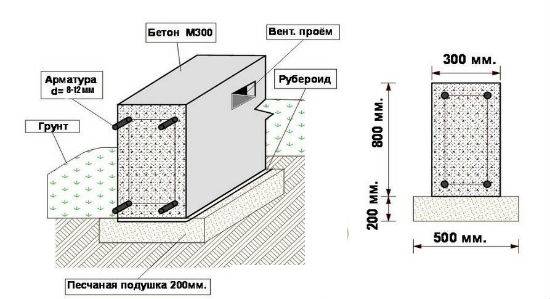

Excavation

At this stage, it is necessary to make pits for the pillars, which must necessarily be located at the corners of the gazebo and along the line of long walls. Most often, the distance between the posts is 1.2-1.5 meters. The pits can be about 0.7 meters deep. The bottom of the finished recesses is covered with sand, moistened and compacted well. The height of the sand cushion should be at least 20 cm. Its main purpose is to reduce the impact of heaving forces during seasonal soil movement.

Formwork construction

If loose soils prevail on the site, then it is necessary to assemble the formwork using boards or thick plywood for this. You can use strips of roofing material by rolling them into rolls of the required diameter. Quite often you can find asbestos-cement pipe formwork. If the soil is dense and the walls will not shatter, then you can simply fill the sand with a layer of lean concrete and proceed to reinforcement.

Reinforcement

Three or four rods are installed in each hole and tied together, forming a kind of frame. The bars of the reinforcing frame should protrude 0.2 meters above the ground.

Pouring concrete

The structure of the formwork and the reinforcing frame is poured with concrete mortar, which is prepared from cement grade M400 and sand in a ratio of 1: 3. The poured mixture must be compacted to remove air bubbles.

The operation of the columnar base and further construction work can begin only after a month.

Unusual versions

It turns out that the foundation can be made even from truck tires. For the first time this method was invented, and after a while and patented by a resident of St. Petersburg Mikhail Semykin. The craftsman suggested laying the tires of buses, trolley buses or tractors in two layers on a flat surface. With proper organization, a solid foundation can be obtained from large boulders and even from underground burrows.

From plastic pipes

The main advantage of such a foundation is the cost of work available to every third Russian citizen. The foundation can actually be prepared in 7 hours, and thanks to its design features, the autonomous building near the dacha rises about 15 cm above the ground.This is quite enough to protect the structure from flooding.

The presence of free squares contributes to the prompt installation of not only external, but also internal communications. Even if over time there is a desire to make major repairs, you will not have to dig a hole.

In this case, plastic pipes serve as permanent formwork, thanks to which the correct geometry of the structure is possible. The main thing is to adhere to a clear sequence of actions, and then even the smallest gazebo from a terrace board will last at least 30 years.

In order to avoid technical errors, it is better to use the instructions:

- Free the area from the roots of perennial plants and debris.

- Use stakes and cords to mark the pile field.

- Taking into account the characteristics of the soil and possible loads, choose the optimal number of supports.

- Make 2 meter holes for the pipes.

- Install floor slabs in places of additional load.

From tires

This refers to a non-standard type of foundation, acceptable only for light buildings made of lumber or plastic

It is important to remember that the more tires, the stronger the base. It is better to fill the gaps between the tires with a mixture of gravel and finely divided bricks. Dense linoleum will come off as a top layer

Dense linoleum will come off as the top layer.

To make the fill uniform, you need to lay sheets of roofing material on the finished base. Around the tires - build a formwork wrapped in wooden boards. At the end of the work - lay the reinforcement and concrete the covering.

The minimum service life of such a foundation often exceeds 15 years.

From barrels

200-liter drums with a wall thickness of at least 1.5 mm are on the list of the most popular and relatively inexpensive foundation materials. They can be used in the construction of terraces, open verandas and wooden arbors.

Before work, it is important to prepare the material: remove the removable covers, and if necessary, remove the bottom. In the future, such a product can be used as a formwork.

For gazebos ranging from 8 to 12 m², 4 anchor points are required. When building more spacious buildings - from 10 or more. To isolate the foundation from the outer surfaces, a layer of waterproofing must be placed on the top of the concrete-poured barrels. If desired, the shells can be inserted into the frozen soil, and when installing them directly on the ground, it is advisable to prepare a 12 cm sand compensation support.

To correctly bookmark such a foundation, you must:

- Stretch the cords, along which it will be possible to determine the location of the drums in the future.

- Dig a 60 cm hole under each item.

- Make a sand pillow, on top of which you need to lay several layers of roofing material.

- Fill the gaps between the barrels with a loose mixture.

- Fill the wooden container with concrete.

From roofing material

It is on the quality of the waterproofing of the structure that its resistance to adverse conditions depends. Therefore, up to 40% of specialists prefer a base made of roll materials. Before construction, they are cut into layers and glued to the base using bitumen mastic.

As soon as the material adheres to the base, the foundation can be covered with soil. In this case, the concrete prepared for pouring the pillars is already protected from groundwater. As a result, the shelf life of the future structure increases long before its commissioning.

Sometimes the cost of the foundation exceeds the cost of overhauling the suburban area. But since we are talking about a supporting structure that can withstand heavy loads, there is no place for savings.

The foundation for the gazebo

Even the simplest gazebos for summer cottages require support - a foundation. This is due to the presence of groundwater, which, depending on its volume, can destroy the structure above the ground surface.

The construction of the pile-screw foundation is carried out in several stages:

- Marking the area for the foundation;

- Leveling the ground;

- Deepening of piles, depending on the type of soil (the flow of water at a low level gives a reason not to deepen the pillars much, but with a high flow, the piles must be screwed in deeper - by one and a half meters);

- Wrapping support piles with polyethylene;

- Filling the finished holes with rubble - the gaps between the piles and the walls of the soil.

- Pouring holes with concrete.

Further, pillars are built into the piles. The bottom must be supplemented with load-bearing elements for the flooring. Thick bars act as the first, and the process itself is called the lower strapping. Later, horizontal logs are attached to the bars, which can be sheathed with boards.

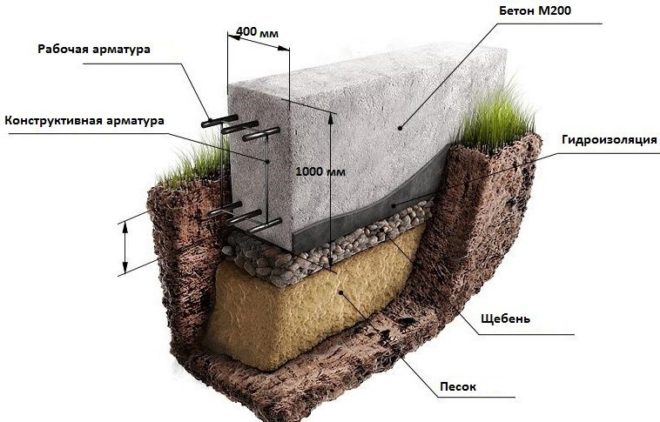

Construction of a strip foundation for a gazebo

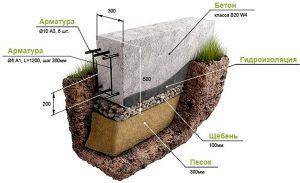

In most cases, the strip base is a reinforced concrete strip, erected under the load-bearing walls of the building. To make such a foundation with your own hands, it is enough to follow certain instructions.

Site preparation

Like all foundations, the concrete tape is erected on a flat, pre-cleaned area. To do this, it is necessary to remove excess vegetation, large debris and level the site well.

Next, the site is marked according to a previously drawn up drawing. Pegs are placed in the corners of the future foundation and a construction cord or ordinary rope is pulled between them.

Excavation

A trench 30-35 cm wide is dug along the stretched cord. The depth of the trench is determined by the occurrence of sandy soil, and in its absence by the level of freezing.

A sand cushion is arranged along the bottom of the trench, which will act as a shock absorber during vertical movement of the ground. To equip the pillow, it is necessary to pour a layer of sand 10-15 cm thick, pour it over with water and tamp it thoroughly.

On top of the sand, crushed stone of a fine or medium fraction is poured, the thickness of this layer is also equal to 10-15 cm. The crushed stone is leveled, tamped and poured with lean concrete.

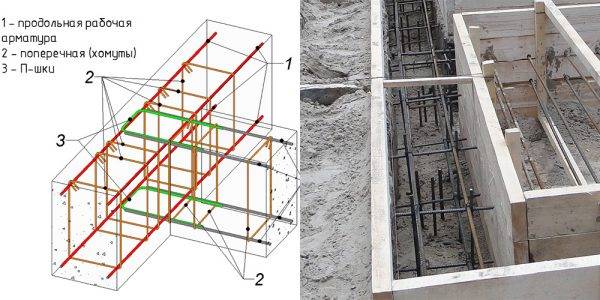

Reinforcement

We reinforce the formwork

Any foundation must have a reinforcing frame, the base for the gazebo in this case is no exception. To create a frame, you can take building reinforcement with a diameter of 8-10 mm and a soft knitting wire. The reinforcement rods are laid horizontally at the bottom of the trench and tied together. Next, vertical rods are exposed, the height of which should slightly exceed the height of the trench. These elements are also tied to horizontal bars. You can use welding equipment to connect the reinforcing rods.

However, it should be remembered that the welded connection may not be able to withstand the stress. This will cause deformation not only of the foundation, but also of the gazebo.

Formwork

The formwork structure is erected if the foundation has an elevation above the ground. For construction, you will need planed boards, plywood sheets or other flat materials. For fixing the formwork, wooden bars are used, which are used to make supports. Between the walls of the formwork, bars are also installed, cut into segments along the width of the foundation.

Pouring concrete

The entire structure is poured with concrete, preferably in one go. The poured mixture is pierced with a bayonet or metal bar to remove air from the concrete.

How to fill the foundation under the gazebo with your own hands

So, we have already figured out how to choose the right foundation, depending on the type of construction and the geodetic features of the site. The base for the gazebo with barbecue: tape, on poles, or on piles.

Foundation construction rules:

- Pillars and piles should be located at a distance of no more than 2-2.5 m from each other.

- The width of the strip base cannot be greater than its height. The optimal belt width is 300-400 mm.

- Non-buried strip foundation is suitable for regions with a mild climate, for the device only a soft fertile soil layer is removed, a depth of 300-500 mm.

- To fill the shallow strip foundation under the gazebo, a trench 700 mm deep is required.

- If the gazebo provides supporting elements - pillars, then it is better to fill in a columnar or pile foundation below the level of soil freezing, with an unburied monolithic-concrete grillage strip.

- Piles are always arranged below the level of soil freezing by 200-300 mm. Indicators vary by region.

Basic rules to help you choose the foundation for the gazebo correctly

The beginning of time

Before laying the foundation for the gazebo with your own hands, you should clear the site for construction, make markings, hammer stakes in the corners and pull a rope between them.

Layout of the site for the gazebo

Next, you need to check the geometry of the perimeter: with a square or measure the diagonals, which should be equal. For a more accurate check, use the Pythagorean theorem: the square of the hypotenuse is equal to the sum of the squares of the legs. Then remove the fertile soil layer on the site.

For the device of a strip, slab or columnar foundation, pits, a foundation pit or a trench of the appropriate depth are dug under the gazebo, the bottom is carefully leveled and rammed, it is better to cover it with geotextiles to avoid silting.

Next, a pillow is arranged: 100-200 mm of crushed stone of the middle fraction, 100-200 mm of sandstone, the pillow is compacted, after which the foundation can be poured.

Important: For the construction of a stove, barbecue, barbecue in the gazebo, you should provide your own, independent foundation, not tied to the main one. Usually it is a monolithic concrete slab. If the strip foundation for the gazebo is poured with your own hands and immediately the base for the furnace, then in some cases the foundation platform for the furnace is tied to the tape and poured at once, but it is recommended to make a double horizontal reinforcing belt in the slab.

If the strip foundation for the gazebo is poured with your own hands and immediately the base for the furnace, then in some cases the foundation platform for the furnace is tied to the tape and poured at once, but it is recommended to make a double horizontal reinforcing belt in the slab.

The optimum thickness of the slab for the oven is not less than 400 mm

Formwork and reinforcement

When the sand-crushed stone pillow is prepared, a layer of roofing material is lined on it, it will serve as the lower horizontal waterproofing. Further, a crate is installed in the trench, usually it is knocked out of a board with a thickness of 50 mm or from plywood with special impregnation. The lathing is reinforced with struts, and pulled together with bars from above to maintain the geometry of the foundation when poured with concrete.

Diagram of how to make a crate for a foundation

A reinforcing cage is mounted in the crate. For a shallow strip foundation, it consists of 2 horizontal layers, in one layer there are 2-3 corrugated rods with a section of 8-12 mm, vertical, supporting, racks can be of smooth reinforcement. It is better to fasten the frame with knitting wire or plastic clamps, the structure weakens from welding.

How to make a frame from reinforcement for a strip foundation

Before installing the frame, stones or supports should be placed on the bottom of the trench so that a gap of 50 mm is formed below. The fact is that the reinforcement should be deepened into concrete from all sides, not less than 50 mm. The solution can be poured into the prepared base.

In the photo, the formwork with the reinforced frame installed

Fresh concrete is bayonetted or processed with a submersible vibrator so that no bubbles remain inside, voids can subsequently lead to the destruction of the foundation.

Scheme of how to equip a strip foundation in a gazebo

On the 7th day, you can remove the formwork, the sides of the tape should be pasted over with roofing material or treated with a coating-type waterproofing. If necessary, the foundation can be insulated. A month later, when the concrete has completely risen, backfilling with soil is done, and the base can be loaded with the walls of the gazebo.

Design selection and sizing

All types of strip base are built for lightweight frame buildings. The differences between them are in the method of installation, materials and depth of installation.

Foundations also differ in depth, which depends on the type of soil. Shallow ones are built on slightly weeping and dry soils. If the swelling is strong, they are satisfied with the deepened ones. A minimum of equipment will make it possible to make a tape-type foundation of any kind. Each of them requires drainage, insulation, waterproofing, sand cushion installation. These measures increase the lifetime of the foundation.

On slopes, the structure is subjected to high shear forces; therefore, it is not recommended to arrange belts there. On fine sandy soils, embankments, the sole is expanded with a concrete slab.

Belt depth

depends on the region where the structure is being erected, as well as the total weight of the structure.

The weight of frame buildings is small, therefore, the foundation for them is laid to a depth of 0.4 to 0.7 m.If construction is carried out in the northern region, where the soil is severely frozen, a different approach is required. The formula is applied: the depth of the foundation sole is 30 cm more than the seasonal freezing of the soil.

Shallow foundations are built for lightweight structures. Recessed bases are more durable, less deformed from heaving of the soil. They are mainly used if they plan to arrange a basement under the house. Then the concrete base serves as its walls.

It is not recommended to lay a foundation deeper than 2.5 m. If the bearing layers are lower, instead of building a strip base, another version of the foundation is used - the installation of supports from pillars.

Width, height of the structure

Frame buildings are fixed on a strapping laid on top of the foundation. It is made of either a wooden bar of a standard width of 15 cm.For the strength of the structure, the width of the concrete base itself should be 30-40 cm.If the frame is to be lined with bricks, increase to 50 cm.

The height of the tape should exceed the width by 2-4 times, which under standard conditions is 0.6-1.2 m.

Criteria for choosing a foundation for a gazebo

The foundation is the fundamental part of any, even the smallest, structure. Any foundation is bad and does not fulfill its functions if it is built incorrectly.

Basically, there are very few types of foundations. They all have a certain depth; lie on a cushion of draining rubble, pebbles, sand. There is always waterproofing between the foundation itself and the structure erected on it. As exceptions, pile foundations can be noted, which do without a pillow (although sometimes there is a buried grillage of the pile foundation on the pillow), and not buried, simply lying on the pillow, foundations used for the lightest structures.

Types of foundations

By the depth of location, all foundation foundations are subdivided into buried, shallow and not buried.

By engineering design, they are divided into four main types: slab, tape, pile and columnar.

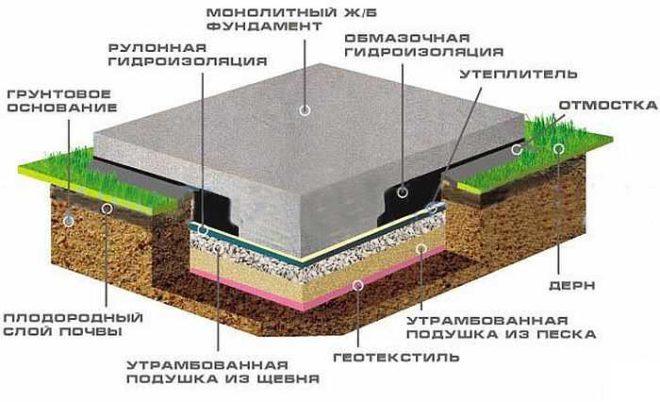

Platen

It is used in cases of quicksand, close occurrence of waters, subsiding soil. Advantages: solidity, reliability; in our case, a thin monolithic foundation can be much more convenient than a strip foundation, since a platform is immediately created - the floor of the gazebo. Disadvantages: requires more labor and more materials than other types, respectively, it is more expensive.

The heavy slab foundation shown in the diagram is, of course, redundant for the gazebo

Tape

Usually, strip foundations are the most popular option, but not for gazebos. Advantages: solidity, reliability. Disadvantages: completely redundant for a gazebo. Although if it is very heavy, then a strip foundation is preferable to a monolithic one - it is cheaper and better copes with soil deformations.

A strip monolithic foundation is not the best solution for a gazebo

Pile

These are supports of a small cross-section, deeply embedded in the soil and well-fixed in it - asbestos-cement or metal pipes. Rarely, but still sometimes such a foundation is made of a wooden beam, but its special preparation is necessary. In some cases, factory-made metal screw piles are used, which increases the reliability of the structure and adhesion to the soil. Advantages: ideal for unstable soil, when building on a slope; a pile foundation made of asbestos-cement pipes does not require large financial investments. Disadvantages: requires labor and great care when strengthening the piles and is often unnecessary in the case of building a gazebo.

Pile foundation with screw piles and concrete grillage used on slopes

Columnar

The lightest in execution and most often used for gazebos is the foundation. Sometimes it is buried, shallow and not buried. For gazebos, the last two types are used. The blocks are placed on a crushed stone or gravel bed either directly on the cleared area or in the pits. Advantages: extreme ease of execution, very cheap, suitable for any soil. There are no downsides.

Column foundation made of blocks with a wooden grillage - the best solution for a gazebo

Video: construction of a slab foundation for a gazebo

Since your main house has already been built, you already have on hand the expert opinion on your grounds, made before designing it. Moreover, you already know how your buildings behave: what are subsidence, soil shifts, flooding. The choice of a type of foundation for a gazebo or veranda will be based on the opinion of professionals and your own personal experience. Of course, you have to consider the indicators of the site survey. But in the case of a gazebo, everything is much simpler: the requirements are not so stringent; deepening is either insignificant or absent; the grillage is the simplest.

Construction of a frame gazebo with a pitched roof

To avoid serious mistakes and minimize construction costs, you need to start with the simplest. For example, a rectangular gazebo with a pitched roof and on a slab foundation is taken.

Construction of a frame gazebo with a pitched roof

Necessary materials:

- large stone or rubble;

- sand;

- concrete solution;

- formwork boards;

- timber 100x100 mm and 50x50 mm;

- boards with a section of 30x150 mm;

- primer for wood;

- dye;

- slate or corrugated board for the roof;

- screws and bolts;

- reinforcing bars.

You will also need tools:

- shovel;

- building level;

- rule;

- hacksaw;

- jigsaw or circular;

- screwdriver;

- hammer;

- paint brushes;

-

Bulgarian.

Marking the base of the gazebo

Marking the future gazebo

Choose a flat, open area of the garden and mark it up. To do this, determine the location of one of the corners of the gazebo and mark it with a peg. They measure the distance to the remaining corners, put beacons, pull a string between them. The diagonals are measured in the resulting rectangle: if they are of the same length, the marking is made correctly.

Pit preparation

Sand filling and ramming

The soil is selected with a shovel to a depth of about 25-30 cm, the bottom is leveled, it is carefully tamped. The pit walls must be strictly vertical. Then coarse sand is poured with a layer of 10 cm, it is well leveled and abundantly moistened for compaction. Formwork from boards up to 10 cm high is placed along the perimeter, reinforced with a bar.

Pouring the foundation

The pit is laid out with large flat stones or covered almost to the top with large rubble. At the corners of the perimeter between the stones, pieces of reinforcing rods are driven in; the rods should rise above the finished foundation by at least 10 cm. A concrete solution is prepared and the foundation pit is poured. The surface is leveled with a rule or smoothed with a trowel.

Foundation

Installing the frame

For the frame, 4 beams of 100x100 mm are taken and cut to the height of the arbor. The front beams are left 15-20 cm longer than the rear ones to make the roof slope. After that, the supports are well treated with a primer and dried. In the lower end of each support, a small hole is drilled along the diameter of the reinforcing rods, which protrude from the concrete at the corners of the base. They put the bars on the rods, set them vertically using a level and additionally strengthen them with metal plates and anchor bolts.

Frame made of timber

After installation, the side supports are interconnected with boards of 50x150 mm, and then the braces for the rafters are mounted. At a height of 10 cm and 0.5 m from the floor, the racks are connected with horizontal jumpers from a bar of 50x50 mm. Vertical bars are fixed between the lintels with a pitch of 40 cm. The doorway is left free. All fastenings are carried out using bolts and steel corners, which are screwed to the tree with self-tapping screws.

All fastenings are carried out using bolts and steel corners, which are screwed to the tree with self-tapping screws.

Prices for various types of timber

Beams

Roof installation

Roof layout

On the boards connecting the support beams, logs are stuffed with a step of 30 cm. From above, the logs are sheathed with an edged board of 30x150 mm. Gaps with a width of 5 to 15 cm are left between the boards. Of course, all roof elements must be treated with an antiseptic primer and well dried. You can cover the top of the board with glassine and fix it with staple staples. Thin strips are stuffed over the film so that there is a ventilation gap between the roofing and the film. Slate is laid on the slats and fixed with 120 mm nails with galvanized heads.

Arrangement of the gazebo

Painting the gazebo

After installing the frame and roof, all wooden surfaces must be painted. When the paint dries, a wooden table and benches along the walls are placed inside the gazebo. Electricity is connected from the house to the gazebo, they hang a light bulb or lamp. To add coziness to the room, you can hang the walls with a dense light-colored fabric. The interior decoration completely depends on the taste and capabilities of the home owners.

This version of the gazebo is basic. If you wish, you can improve the design: install wooden gratings between the supporting beams, sheathe the walls with clapboard or waterproof plywood, lay logs on the concrete base and make a wooden floor. Instead of beams for the frame, you can take metal pipes, and replace the slate with polycarbonate or soft tiles.

Platen

If the land on the site is prone to subsidence, and the groundwater is too close to the surface, the foundation must be made slab. The advantages are obvious: it is very reliable and solid. Compared to tape, it is much more convenient. During installation, a platform is formed - the floor for the gazebo is ready. The disadvantages are huge labor costs. And since a slab foundation needs a lot of building materials, it is more expensive.

Reinforcement of slab foundation

Arrangement of not deep, but shallow foundation will help to partially reduce costs. It is better to take assistants to carry out the work. Their participation in the working process is especially indispensable at the stage of pouring the concrete mixture into the formwork. The monolithic slab reduces the load on the soil, the support area is always large.

Pouring the slab foundation

To increase the resistance and durability, additional reinforcement is carried out. The recommended thickness of the reinforced slab base is 30 cm. It is buried 15-20 cm into the soil. It is advisable to make a slab foundation in an elevated area. If you build a drainage area from rubble around the entire perimeter, water will not wash away the structure.