We install a pile foundation made of asbestos pipes

This design is chosen for reasons of economy for the construction of auxiliary buildings for utility purposes, such as:

- barn;

- utility block;

- summer cuisine;

- workshop;

- a garage without a viewing hole and other structures of a similar purpose.

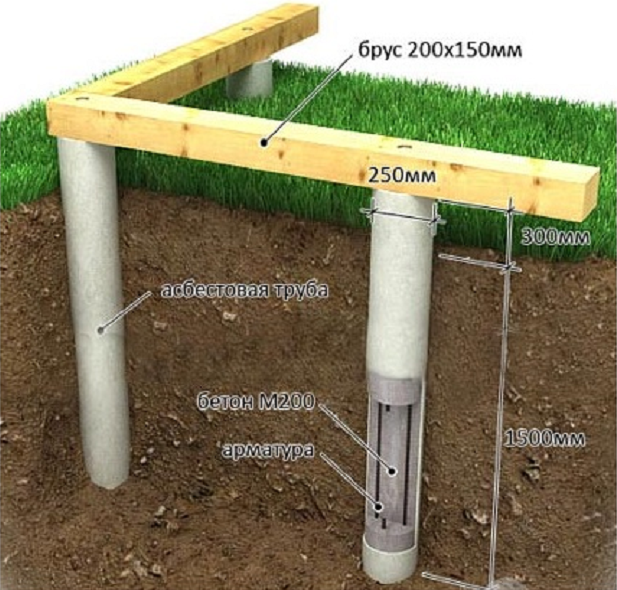

The basis of the foundation for such buildings are piles from asbestos pipes. Based on the results of exploration drilling, their number and depth of immersion are determined. One of the strongest arguments in favor of using such a foundation design is construction on a site with a slope.

Such a support base arrangement allows the use of inconvenient land for construction.

Drilling pits for piles

The above purpose of foundations of this type does not imply the use of powerful heavy pile materials. Therefore, drilling for them is often done independently using the simplest tools, in particular, a garden drill.

Photo gallery: simple drilling tools and accessories

Filling piles with concrete

It is preferable to use 300 grade concrete for the piles, which implies the use of 400 grade cement in an appropriate ratio with sand, medium gravel and water. When doing work with your own hands, it is preferable to use a small concrete mixer. The advantage of a pile-slab foundation is the ability to interrupt work. Several piles can be poured without leaving unfinished piles the next day. The work must be performed in the following order:

-

Install pipes and reinforce them. If concreting is carried out in a pit, it is reinforced directly. But in this case, you need to install a formwork on each trunk. Moreover, each of them must be set horizontally along a stretched cord, since the pile heads will be the supporting surface of the slabs. When using pipes, reinforcement is done inside them, and the top edges are also aligned with the cord.

- Pouring with concrete. In the process of pouring, the concrete must be carefully tamped in order to prevent the formation of air bubbles in it. For this, it is best to use a vibrator, but an ordinary wooden pole of the required length is sufficient.

- Concrete gains its strength to complete crystallization within 28 days.

Foundation installation

This operation consists in installing floor slabs on a pile foundation. For this, ribbed slabs are usually used, which, with a lower weight, are close to solid ones in terms of bearing capacity. Plates are installed using lifting equipment. For small buildings, hollow core slabs up to 15 centimeters thick can be used.

It should be noted that a combined foundation with a grillage is more applicable for such structures. It is more expensive, but more reliable.

Technology of making a pile foundation from asbestos-cement pipes

- Preparation must begin with marking. Remove debris and foreign objects from the construction site, level it if possible and remove the sod. The contours of the future building, corners, intersections of walls are marked with the help of pegs and a rope. The pile installation sites are marked with pegs. To check the perpendicularity of the corners and the correctness of the markings, check the equality of the diagonals.

- They begin to drill wells under the support pillars. This can be done with the help of a drill, and in the absence of it, you can dig holes with a diameter greater than the diameter of the pipes. The depth of the well is 20 cm more than the estimated size of the underground part of the piles, which is necessary for the construction of a sand cushion.

The process of drilling a well under a pile

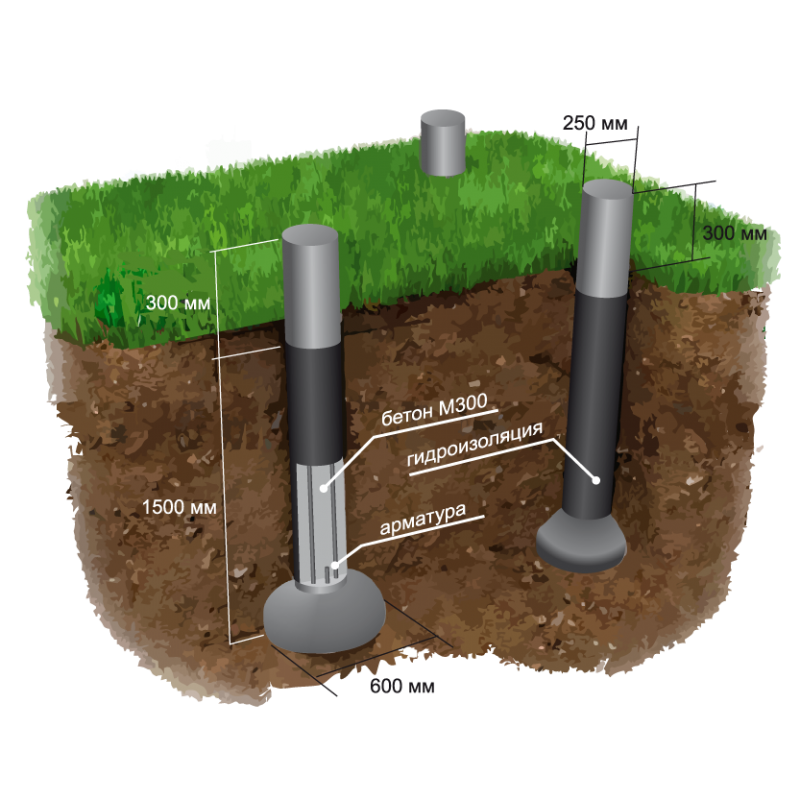

Arrange a sand cushion 20 cm thick at the bottom of each well, tamp it and spill it with water. After absorbing water, the bottom is lined with roofing material.After that, prepared pipes are installed in the well. If pipes have to be cut to the required size, it is necessary to leave a margin of about 10 cm in height in order to level the height of the supports after completing the foundation.

Installation process of asbestos-cement support pipes

The pipes are leveled, fixed with temporary supports made of wooden blocks. Check the equality of the diagonals again. In areas with a close occurrence of groundwater, pipes are waterproofed mastic based bitumen to ground level. Dry the mastic.

Alignment Process for Asbestos Cement Pipes Using Wood Formwork

- Concrete is prepared: 1 part of cement is mixed with 2 parts of sand, diluted with water to the consistency of a batter, after which 2 parts of fine gravel are poured into the resulting solution. Knead well and pour the base of the pipe 40-50 cm.

- The pipe is raised by 15-20 cm and left until the concrete has completely solidified. This technique will help create a solid support base that is resistant to pushing forces when the soil heaves.

- After the concrete hardens, the well on the outside of the pipe is additionally waterproofed with roofing material and covered with river sand, spilled and rammed, checking the installation by level. Pull a string between them or set a bar and align them horizontally.

The foundation of asbestos-cement pipes is ready

- Fittings are installed inside the pipe: several rods interconnected by transverse wire bridges. The concrete is mixed and the rest of the pipe is poured. To remove air from the solution, pierce it several times with a metal bar.

- After complete drying of the concrete, in two to three weeks, the foundation is ready for further construction. In order to extend its service life, it is recommended to waterproof it with bitumen or polymer materials.

The device of a pile foundation made of asbestos-cement pipes can reduce the cost of construction of a solid foundation for a building several times. However, under too much load, such a foundation may not be strong enough. In this case, it is better to choose another type of foundation, tape or monolithic.

In conclusion, be sure to read about the bored foundation with your own hands.

Plinth decoration and the need for a blind area

A base with piles raised above ground level requires additional finishing of the basement. This finish performs the following functions:

- Prevents blowing and "walking" of the wind under the floor of the first floor.

- Protects the overhead part of the supports from wind and moisture.

- Plays a decorative role, making the structure on elevated supports more attractive and familiar.

For finishing the basement, two options are most often used:

- The use of frame structures for siding or plinth panels. The advantage of this method is the low weight of the cladding and the high installation speed.

- Erection of a false plinth made of ceramic or facing bricks, which have high water resistance. This finish is suitable for houses built of bricks or other piece materials.

The final stage of the construction of the pile foundation is the execution of a blind area along the entire perimeter around the house. The blind area is performed at an angle of at least 5 ° away from the house and serves to drain rainwater flowing from the roof from the foundation. In addition, the blind area completes the overall finish and can be used as a walkway around the house.

How to make a pile foundation with your own hands

The first step is to create a project. It is possible to make a simple plan on paper without any special experience. It is necessary to correctly determine the number of pillars, the optimal installation depth for future piles. For this purpose, you can use online calculators and instructions for marking and design. If you are not sure of your actions, use the services of qualified specialists.

Execution order:

- do the markup. Here you will need to mark the location of the future pillars. Set up an obstruction, pull the string over the circle crosswise. Place pegs at the point where the threads intersect - they will become the center of the pile;

- well drilling. For the base to stand securely, the hole must be lower than the freezing depth of the soil. Accordingly, in the northern regions it is necessary to carry out construction with the creation of a deeper pile foundation. The borehole diameter must match the pipe diameter;

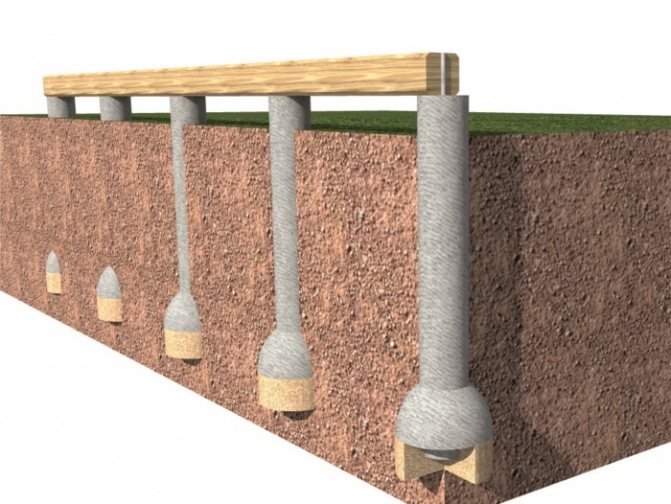

- at the bottom, expansion is performed. For this purpose, you can use a TISE drill or a cut-off bayonet shovel;

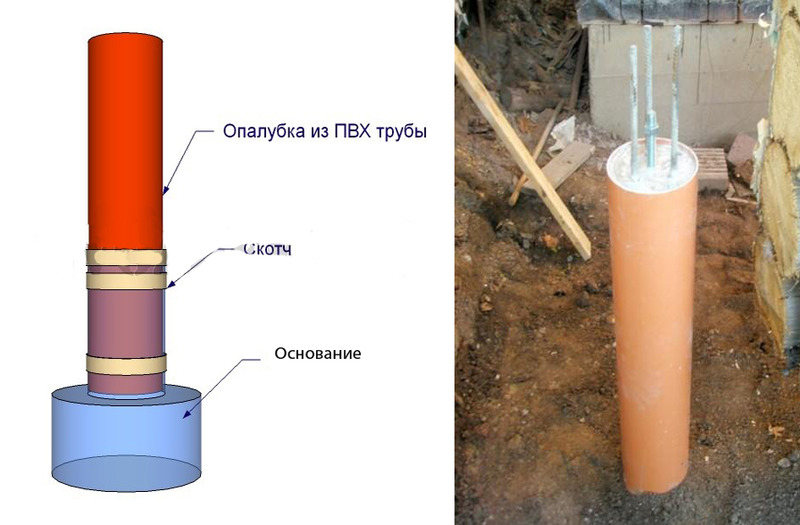

- cut the asbestos-cement pipe to the required length, including aboveground and underground parts. At the bottom of the pipe, secure a plastic bag with tape. It will not allow the broadening of the pile to be poured with concrete mixture and, with nearby groundwater, will not allow the pipe to pass inside from below;

- After the asbestos-cement pipe is inserted into the well, create a reinforcement cage to strengthen the foundation. For this, reinforcement of 10 or 12 mm is used. Depending on the diameter of the pipes used, 3-4 rods with their bundle are used. The expansion at the bottom of the piles can also be reinforced, for this you need rods bent at the bottom in an “L” shape. After lowering into the pipe, the bends are turned to the extreme points of expansion. When creating a pile-grillage, you need to remove the frame from the reinforcement a few centimeters up. If the supports are connected with a bar, then the reinforcement should be located just below the upper end of the asbestos-cement pipes;

- the pile widening is being poured. Concrete mixed with cement grade M300 or higher is poured in sufficient quantity to fill the expansion zone. Lift the post up - as a result, the concrete will enter the attached bag, filling it and the widening itself. Next, you need to push the pipe down. Provide vibration and bayonet so that there are no air pockets left in the formwork, and the mixture lies as tightly as possible;

- fill. The mixture should fill all the internal space in the pipe, also bayonet to eliminate voids. At this stage, fix the stud anchor, with which it will be possible to tie the post to the timber strapping.

The concrete will fully harden within 28 days, after which you can start building the house. After pouring, cover the top of the pile with plastic wrap to protect the mixture from the environment and speed up its hardening. During construction, make sure that all the pillars remain at the same level - this way the foundation will more securely support the building.

The exact implementation of these instructions will allow you to build a reliable foundation for an outbuilding or even a small wooden cottage.

All work can be done independently, it is only important to select high quality materials and take into account the characteristics of the soil and the region in which the construction is underway

Advantages and disadvantages of the foundation

Plastic is a versatile, inexpensive, non-reactive building material. A columnar foundation made of PVC pipes can be easily erected on your own with minimal knowledge and skills on this issue. The advantages and disadvantages of this design are shown in the table below.

| № | Pros of using plastic pipes | Cons of the created design |

|---|---|---|

| 1 | the material is easy to cut into pieces of the desired length, the pipes protect the concrete from soil water | the base of the columnar type excludes the possibility of building a basement, cellar, or utility room, under the building |

| 2 | work does not require the use of lifting equipment | pipes can burst when the temperature drops below -15 degrees, for this reason, their parts located above the ground are insulated and veneered |

| 3 | the use of pipes allows you to build a foundation as soon as possible and quickly start building a house or other building | the permissible load on one pillar is about 4 tons, therefore, relatively lightweight structures are built on this basis |

| 4 | reduced costs for the construction of the foundation due to the lower cost of working materials and savings on the services of builders, earthworks: compared to the monolithic type, they are almost 3 times less | the plan for the location of the foundation supports must be drawn up with maximum accuracy, because when any of them subsides, the entire structure is deformed, up to the complete destruction of the erected structure |

| 5 | the building erected on towers above the earth's surface is protected from flooding that can occur during rains and floods, also in this case it is easier and faster to supply and maintain communications in the future | compared to a strip or slab base, columnar is relatively short-lived: its service life is from 50 to 80 years, and for a monolith it is 100-150 years |

Mortar-filled support from a sewer pipe

Mortar-filled support from a sewer pipe

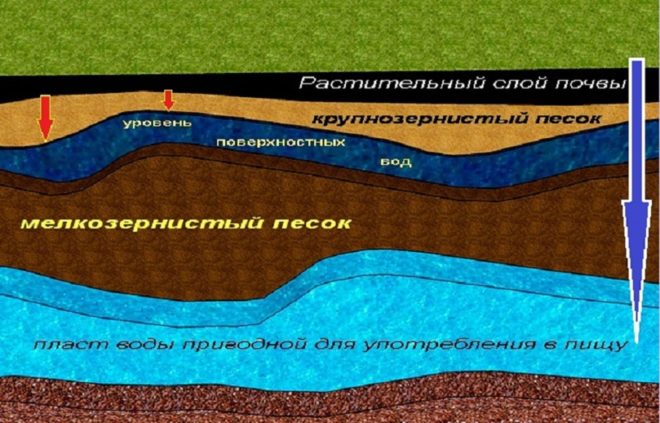

The dependence of the choice of the foundation on the characteristics of the soil and the characteristics of groundwater

Consider the possibility of building a foundation from pipes. It should be borne in mind that this is by no means a universal foundation (excluding the pile foundation with screw piles). In the case of complex soils and a large construction weight, such a foundation will not work, you need to build more complex varieties - monolithic slab, monolithic tape, tape from blocks, monolithic pile. Therefore, in order to have absolute confidence in the correct choice of the foundation from the pipes, you need to order a geodetic survey of your site. It will include a conclusion about the soils, their layered location, the depth of groundwater, the depth of soil freezing and the presence of water "lenses" inside the soil.

Geodetic research must certainly precede the design of the future structure and accompany it as it moves forward.

Soils and their combinations

The classification of soils is presented in reference books; for example, in the textbook “Soils. Foundations. Soil characteristics. Choosing the optimal foundation ":

- Rocky soils are, rather, crystalline rock, rock, not earth, and sedimentary rock (dolomites, compressed sandstones, shales, shell rocks, limestones). Any foundation is acceptable, except for a pile foundation (it is difficult to drill a rock).

- Conglomerates - fragments of different types of rocky soils; do not blur and do not change in volume, freezing; any foundation is acceptable.

- Non-rocky soils:

- related - clay and loamy; deeply freeze; able to "float" and move, only heavy types of foundations are suitable;

- unbound - sandy and sandy loam soils; when wet, they tend to move, freeze shallowly; foundations of any type are suitable.

Different soils that can be found on your site

Knowing this list, you can approximately determine the type of your soil and independently: drill a hole with a garden drill and study soil samples from different depths.

As a result of geodetic work, you will receive complete information about the condition of your site

If a soil sample moistened with water can be kneaded like dough, then your soil is loam. If the earth dissolves in water, there is a large percentage of the loamy component in it. If sediment falls, then there is clay at the bottom, and sand above it.

To determine the type of soil, you need to place the sample in a glass of water.

If you have good, stable soil on your site - a rock mass, untouched sandstone, or sedimentary rocks, or sand, or dense loamy soils, then a foundation made of pipes is quite suitable for any light construction such as a frame house, veranda, gazebo, barn. And the foundation made of screw piles is suitable for any building on any soil.

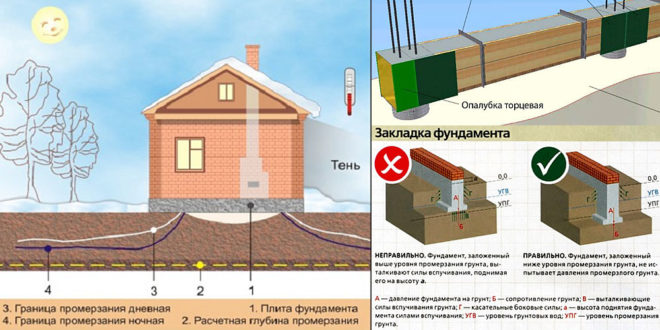

The depth of soil freezing

The freezing depth in central Russia is about one meter, but deviations are possible. The lowest point of the foot of any buried foundation must be below the freezing point of the ground. This most often does not apply to pipes (except for screw piles).

Freezing depth - a factor affecting the depth of the foundation

Ground water level

This is the most important characteristic of soils, and the required type of foundation also directly depends on it.

The groundwater level at the site has a huge impact on the choice of the type of foundation

The foundation of pipes (excluding the pile of screw piles) is applicable only with a low level of groundwater. If this level is high, then other types of foundations should be considered.

However, it is important to consider the water level indicator together with the freezing depth. If the water in the cold season is located at a depth below two meters relative to the freezing point of the soil (you can designate the freezing depth as Z), and the soil is quite dense (clay, sand), then the freezing depth can be ignored

DIY installation of a columnar foundation

Anyone can build a columnar foundation from sewer pipes

a person, subject to the construction technology:

- Design. At this stage, the number of supports, their location is calculated, the depth of immersion of the pillars is determined, and the site is marked.

- Preparation for work. First, you need to cut the blanks into pieces of the required length, prepare the lower part of each blank for concreting the heel. It is also necessary to prepare anchor studs, which will be poured into the upper part of the support to connect the foundation with the grillage.

- Frame fabrication. To increase the bearing capacity of the pillars, it is necessary to make a reinforcing cage, for which ribbed reinforcement bars are used. To reinforce the expansion, the rods are bent in the shape of the letter "L".

- Well drilling. With the help of a hand drill, it is necessary to drill wells in accordance with the diameter of the sewer pipe. The depth of the well depends on the level of freezing of the soil, it is necessary to go down below this mark by 20-25 cm.

- Expansion at the bottom of the wells. Using special nozzles for a hand drill, an expansion is made at the bottom of each recess. This increases the stability of the posts.

- Prepared products are inserted into the well and an expansion is formed. To do this, concrete mortar is poured into the pipe and the future support is slightly raised. Before fastening, each plastic post is vertically aligned using a building level. After that, from the outside, they are covered with sand, crushed stone and earth.

- Aligning the supports. All sewer piles must be of the same height. To do this, they beat off the horizontal using a laser level, pull the construction cord and cut each support at the level with a grinder.

Reinforcement and concreting

Reinforcement. The prepared frame made of reinforcing rods is inserted into the pipe. The bent rods are turned to the sides to strengthen the expanded base of the pillar.

Concreting. The prepared post must be filled with concrete mortar. Concrete is fed in small portions, constantly piercing the mixture with a thin rod to compact

In doing so, care should be taken to avoid damaging the plastic product. In the upper part of each support, an anchor pin is installed to secure the grillage.

It is very important to build a foundation from sewer pipes with your own hands in accordance with construction technology. Its violation can lead to negative consequences:

- Exceeding the permissible load on plastic supports leads to their destruction. Additional strengthening of the pillars helps to solve the problem.

- Under heavy load, the pillars can fall into the ground. In this case, the pipe supports are raised to the desired level and fastened to each other with reinforcing rods.

Types of foundations for building a house

The design and construction of a house, as a rule, begins with its foundation. As you know, the cost of building a foundation is often half the cost of the house itself.

A foundation is a part of a structure that transfers the load from its above-ground part to the base. The foundation is laid below the freezing point of the soil. This is necessary so that when the soil buckles, no deformation of the structure occurs in the winter.

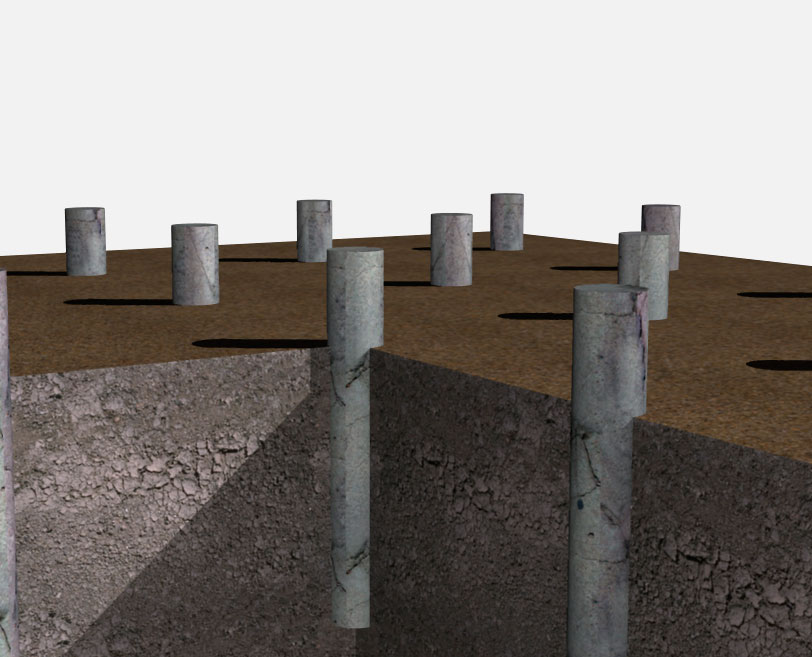

An example of a finished pile foundation

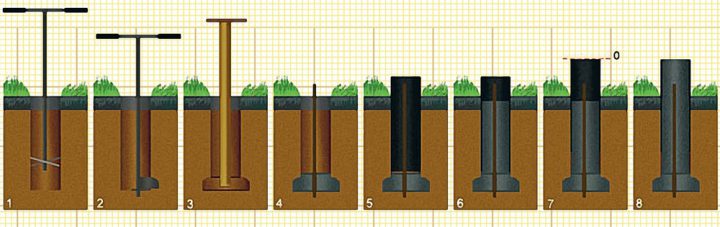

Foundations can be conditionally divided into six groups:

- slab;

- tape;

- pile;

- pile-grillage;

- columnar;

- continuous.

When choosing one or another type of foundation, it is necessary to take into account the characteristics of the soil and its ability to heave. Heavily soils include clay soils: clay, loam, sandy loam, because such soils retain moisture well. When freezing, due to the formation of ice, the soil rises, it begins to swell.

In heaving soils, with a significant freezing depth, the installation of columnar foundations is especially effective. In horizontally moving soils, the use of columnar foundations can lead to pushing it out of the ground, raising and overturning the entire structure.

House project with an attic on a pile foundation

If the terrain on which the building is installed has an uneven surface, in order to avoid its lateral shift, a prerequisite is the installation of a rigid reinforced concrete cushion between the supports.

The most common and reliable is the strip foundation. When building a private house, it is worth listening to the feedback of specialists, because the strip foundation may not always be applicable.

The pile foundation will create a solid structure that is independent of the movement of surface water.

What kind of foundation is applicable for a given area, the calculation of its depth, as well as the selection of the necessary building materials, will be helped by experienced specialists.

Scheme for the installation of a pile foundation

Metal pipe foundation

Metal pipes can be used for the manufacture of bored, driven and screw bases.

Drive-in foundation

For the manufacture of driven piles from steel, ordinary products for pipelines are suitable - they are quite reliable and durable. Pile deepening is carried out by driving with a mechanical head, a press or a sledgehammer. The pile production technology in this case is quite simple. First of all, on the one hand, the future structure must be equipped with a pointed conical tip, and on the other hand, with a head.

Tapered pipe piles

Tapered pipe piles

To make the tip, one end of the workpiece is cut with a welding machine or grinder so that several triangular teeth are formed. After that, the petals of the teeth are bent towards the center so that their tops and edges coincide with each other. Further, the petals are welded together, eventually forming a cone-shaped tip. It is also possible to install a tip made of cross-welded triangular blanks.

On the opposite side, it will be necessary to make a so-called head. By its design, the head is a metal square shelf that serves as a support for the future structure. It is made of structural steel and welded to the top of the pile.

Screw foundation

For the production of screw piles, the same technology is used as for driven ones. The only difference is that a spiral blade is welded onto the buried part. It is made of sheet steel. For this, a round workpiece is cut out 10-20 cm wider than the diameter of the future pile. A hole is cut in the center of the workpiece to fit the pipe. An incision is also made from the inner edge to the outer edge so that the blades can be spirally shaped.After that, the workpiece is welded in the form of a spiral to the bottom of the pile, just above the tapered point. Watch the video on how to make screw piles yourself.

Advantages and disadvantages of pile foundations

In real construction conditions, various types of piles can be used. But regardless of the design of such products, a number of advantages can be distinguished that foundations on pile foundations have:

- the ability to use on any soil, excluding rocky;

- quick installation of the support base. The foundation for a residential country house can be installed within one day;

- no need for earthworks, formwork, concreting and long waiting for the final hardening of concrete;

- availability for do-it-yourself manufacturing. It will not work on your own only with driven piles. To install them, special equipment is required;

-

relatively low costs. Pile foundations are cheaper than strip or slab foundations, the cost of which can be up to a third of the cost of the entire house.

The main disadvantage of the pile foundation is the shrinkage of the support base. The result can be a skewed foundation, leading to the destruction of the superstructure. The reasons often lie in the incorrect installation of piles, when they are not buried to stable solid soils. It is also possible that the wrong choice of the type of supports that are not suitable for the nature of the soil at the construction site is possible. Therefore, it is better to consult with an experienced specialist regarding the selection of the type of piles.

Some types of piles, for example, screw piles, are quite expensive, which can also be attributed to their relative disadvantages.

Bored piles from an asbestos pipe will cost significantly less than screw