Plywood selection criteria for formwork

What is the best plywood to use for formwork? The building materials market offers a huge selection of different types of plywood, differing in composition and processing options. In addition, the product line is presented from numerous manufacturers.

And if you still doubt which formwork material is best, pay attention to certain criteria:

plywood thickness for foundation formwork. The final price of plywood depends on this indicator, and it is quite understandable that the desire to save money immediately appears. But one should act wisely. If the plywood turns out to be too thin, you will not achieve a good result - the formwork panels will bend from the pressure created by the concrete solution, and their destruction may occur. The optimal solution is considered to be a plywood thickness of 1 - 1.2 cm, and if concrete is to be poured with a thick layer, experts recommend using a more reliable 18 - 20 mm film faced plywood;

grade. Plywood material is of different classes, the most expensive of which is considered "extra". Samples of I - IV classes are considered cheaper. The material should be selected taking into account its intended use, and most often it is plywood of I and II classes, which has a good margin of safety;

feedstock

When purchasing plywood, you need to pay attention not only to the glue used in the production, but also to the veneer material. Preference is most often given to coniferous woods or birch

Each of these varieties is affordable. More expensive materials include fir, larch and teak plywood sheets. If difficult operating conditions are expected, it is recommended to buy a reliable and expensive material that can withstand a large number of work cycles.

GOST defines several options:

- the standard is square sheets, the length of the sides is 122 and 152.5 cm. There are rectangular sheets, the length and width of which is 152.5 and 122 cm, respectively. The main advantage of such material is its acceptable cost;

- large format. On sale you will find film faced plywood, the parameters of which are 3000 x 1500 x 18 mm. It is more convenient to use such sheets of material in the construction of plywood formwork for walls. Their cost is slightly higher than the standard ones, but the shields are made without joining seams. In addition, for pouring 2 meter walls, the formwork panels will turn out to be solid;

- non-standard. It is possible to manufacture plywood material according to individual customer requests. This creates certain advantages, but the cost of such an order increases significantly.

An important criterion that you should pay attention to when choosing plywood is the quality with which the surface of the material is processed. The ideal solution would be flat and smooth sheets.

Their application will allow:

- speed up the dismantling work, because plywood sheets separate from the hardened concrete much easier;

- the monolithic surface is smooth, plywood lends itself better to subsequent processing.

An important feature of the choice of film faced plywood for formwork is the country in which the product was produced. Today, material from domestic and Chinese manufacturers is in demand, while plywood from China is less expensive.

It is used as an economy option when a low-rise facility or structure with small architectural forms is being built. As a rule, such black plywood used for formwork can withstand a limited number of cycles, but is well worth the cost.

With large working volumes, it is recommended to purchase domestic material and, for the reliability of its use, install plywood formwork on metal racks. To increase the turnover rate of laminated plywood for formwork, experienced specialists advise using special lubricants - barrier or chemically active. In the first case, you create additional protection, and in the second, you increase the plywood's resistance to moisture.

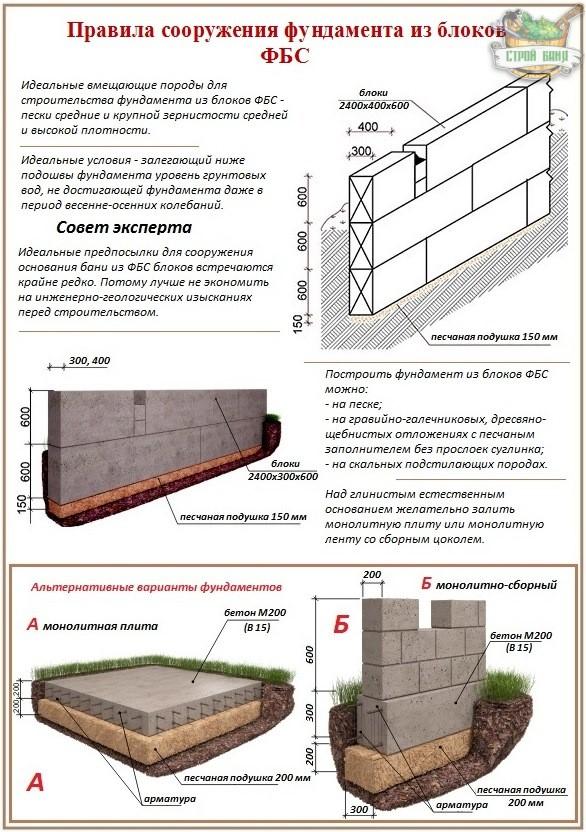

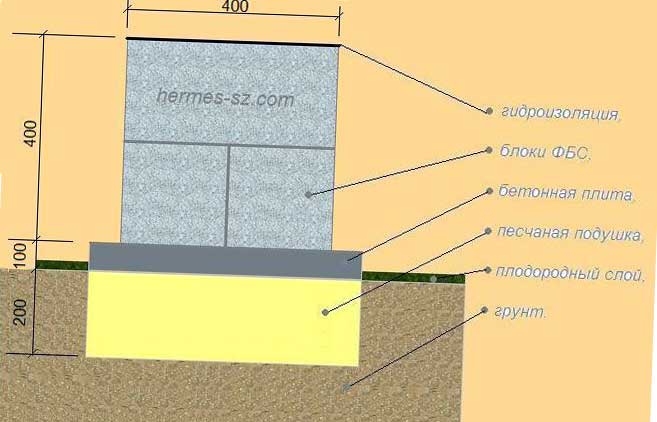

Standard sizes of FBS products

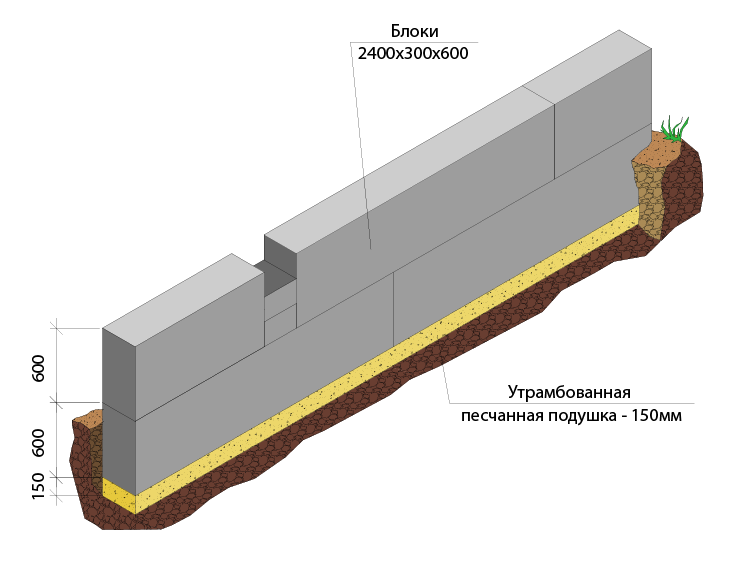

The FBS foundation is one of the types of blocks, the technical regulations for the production of which are specified in GOST 13579-78. The normative document considers materials, structural characteristics and rules for the transportation of products. Solid blocks of increased strength are made from a mixture based on concrete 1.8 t / m3 in terms of density. To build a block foundation, elements of several standard sizes are used:

- width from 30 to 60 cm in 10 cm increments;

- lengths 9, 12 and 24 dm;

- 30 or 60 cm high.

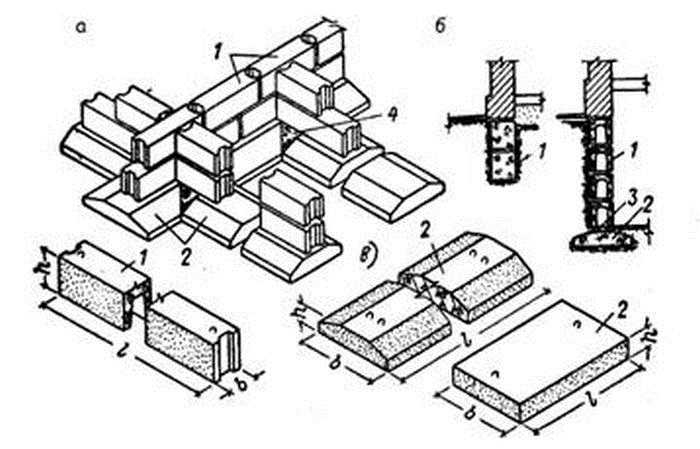

FBS-type blocks, from which the foundation is made, are fixed with a mounting loop or bent. A good storage option is location on a wooden platform 3 cm thick Laying the foundation from FBS blocks with your own hands

How to lay FBS

In any row, styling starts from the corners. Then blocks are placed in places where the walls are taken off. They are called lighthouses, and then everyone else is equal to them. The verticality of their exposure is checked, corrections are made if necessary. More often than not, the unit needs to be lifted again, moved and put in place.

After the lighthouse elements are exposed, the moorings are pulled - the cords along which they are guided when installing the following blocks. They mark the boundaries of the wall, and so that the FBS are symmetrical about the middle of the FL block (pillow block). The maximum permissible deviation is 12 mm. All subsequent rows of blocks should also be placed exactly above the middle.

When stacking blocks, make sure that they are stacked one above the other without too much displacement.

It is more convenient to pull the cords 2-3 mm from the side surfaces of the lighthouse blocks. It will be easier to exhibit this way. Intermediate blocks are set starting with the largest: first they put everything 2.4 meters long, then 1.2 and then 0.9. The correctness of their installation is checked with respect to marking cords, verticality - with a plumb line.

How to choose the size of FBS blocks

You can determine how many blocks you need for your foundation by selection. You can do this yourself on a plan drawn to scale. On the plan, you mark each block on the same scale.

The sizes of blocks for the FBS foundation are chosen based on a simple rule: to increase the strength of the structure, you need to use the largest block sizes. Therefore, first you draw the blocks of 2.4 meters installed in the corners, then, if they fit, draw them in the places where the walls adjoin. Between them, also put the largest blocks that can fit there. Where they no longer become, put a smaller one. If there are any gaps in which even the smallest block (0.9 meters) does not fit, it is not scary - these gaps are filled with brickwork.

Two types of prefabricated strip foundations made of FBS - with and without cushion (shallow tape)

Draw the second row in a similar way, not forgetting about the offset of the seams. If necessary, draw the third in the same way. Then count the required number of blocks of each size. Do not throw away the resulting plan: it will come in handy when installing the prefabricated foundation already on the site.

Masonry mortar FBS

For the laying of foundation blocks, a standard cement-sand mortar of the M-100 brand is used. It can be obtained using different cement uterus and the amount of sand:

- for 1 part of cement M300 take 2.5 parts of sand;

- for 1 part of cement M400 sand is already 3 parts;

- when using M500 sand, add 4 parts.

First, dry components are mixed until a uniform composition and color is obtained. Then gradually add 0.5 parts of water. If the solution turns out to be too thick, the water is gradually added in small portions. The consistency should be like thick sour cream: not a lump, but not flowing either.

Pit and pillow construction

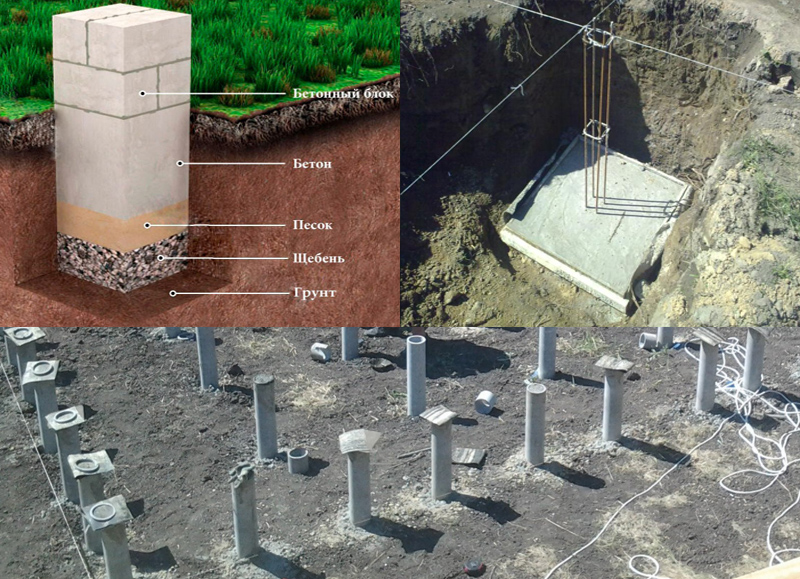

Diagram of the device of a columnar foundation made of FBS.

When everything is ready, you can start working directly on the foundation. First, according to the project, you need to dig a pit of the required depth, and then level it using a good roller. It is not necessary to backfill the bottom, but if the groundwater is relatively shallow, then you can play it safe by sprinkling the bottom with gravel with a layer of about 1-3 cm.

Now is the time to take care of the sole arrangement. To do this, you can use two options: concreting the base or covering it with a mesh. Better to use good concrete to prevent all kinds of holes and crevices in the sole. If you have chosen a masonry mesh, then use it in combination with reinforcement.

When this is done, at the bottom of the pit, it is necessary to make the main backfill with crushed stone of the middle fraction or sand, level it. And only after that it is allowed to install the formwork. Pull the cord well in advance to avoid future distortions.

Before installing the formwork, foundation reinforcement is mounted on the inner walls. The fittings are made both on the bottom of the pit and on the sides. For this, the rods are laid across each other to achieve greater structural rigidity.

The scheme of the ligation of the foundation blocks.

Now from the edges, if necessary, you can install wooden planks to support the upper part of the formwork, and then pour it. This is done with a thick solution, which is well mixed in advance with a special mixer. After that, everything is covered with a film and left until completely set. This takes approximately 7-10 days, during which time the pillow needs to be moistened.

So that such a pillow dries faster and does not lose a lot of moisture, which is especially important in summer, when there is a strong heat outside, you should sprinkle it with fresh large sawdust before covering it with polyethylene. They will keep the foundation from drying out

Instructions for making a foundation for a fence

Almost any base for a fence can be made with your own hands, if you carefully study the technology and follow all its instructions.

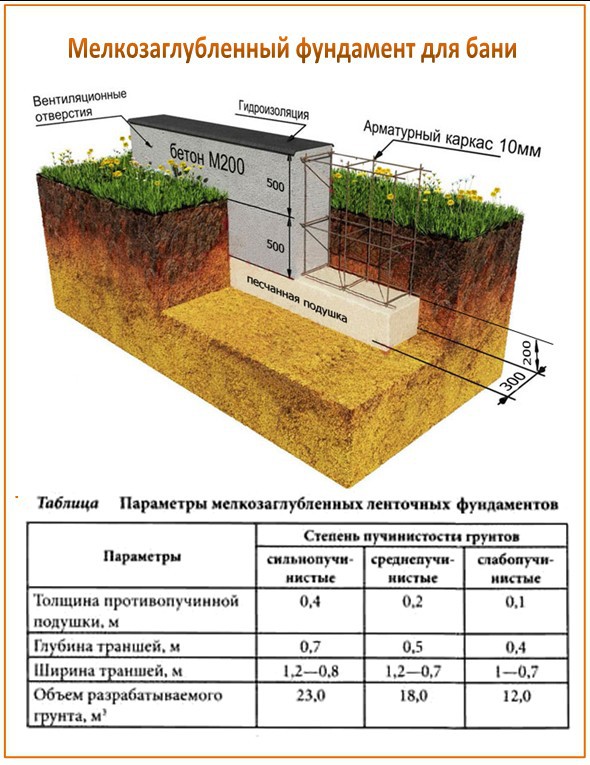

Strip foundation

The process of creating this type of fence base consists of certain sequential stages. With the consistent and careful execution of each of them, in the end you will get a solid foundation for your fence. So, you need:

- Carry out the marking of the territory. To do this, along the perimeter of the site, which will be surrounded by a fence, you need to drive in pegs, between which to pull the string. Separately, it is necessary to designate the location of the wicket and gates.

- Dig a trench. The depth of the ditch is not less than 35 cm, in the places where the supports are installed - 60–90 cm. The width is about 40 cm.

- Install the support posts. Any material can be used in their capacity. Usually these are pipes with a diameter of about 80 mm. Their height should be such that when digging into the ground, it will be enough for the entire height of the future fence. They need to be installed in prepared holes, covered with broken brick, gravel or stone.

The strip foundation can be considered the optimal solution for the fence

Formwork is usually made from planks

The tape should protrude slightly above ground level

Video: strip foundation for a fence with your own hands

Base for a light fence made of corrugated board

For a fence made of profiled sheet, the foundation may not be so solid. Such a fence can be installed on a columnar foundation:

- First, the marking is carried out, while it is necessary to indicate the location of the pillars.The distance between them should be about 2 m.

The posts must be treated with an anti-corrosion solution.

It won't take a lot of time to build a fence from corrugated board

To increase the strength of the foundation, you can additionally dig a shallow trench, the bottom of which is covered with geotextile, covered with rubble and covered with a film. Next, install the formwork, reinforce the bottom, then fill it with a cement mixture.

Video: post base for the fence

Brick fence foundation

A brick fence needs a solid and solid foundation, because the mass of such a structure is impressive. The consequences of not following the technology or choosing the wrong type of base can manifest itself in the form of cracks on the fence itself. There are two options for arranging the foundation for a brick fence, which are equally suitable for both a three-meter structure and a small fence:

- strip foundation (depth 40-50 cm, width 40 cm), part of which is located above the ground (it must be reinforced with reinforcement 12-14, two at the top and bottom);

- the grillage is set up in the locations of the pillars to the depth of freezing, that is, 120–1250 cm deep into the soil, and between them is the usual reinforced tape.

The second option for arranging the foundation is more reliable in the case of building a brick fence.

Brick fence requires a solid foundation

There are secrets, knowing which you can significantly increase the life of the foundation:

- under the tape, you can equip a sand cushion, which is additionally moistened with water, which will significantly reduce the risk of displacement of the base;

- use cement not lower than M-200 grade;

- pour concrete in one go;

- if you do not make the solution yourself, but ordered from a specialized company, then you need to order 10% more, since part of the water will necessarily be absorbed into the soil;

- there must be a waterproofing layer between the foundation and the brickwork.

The basement part of the fence is integral with the foundation

Fence foundation with brick pillars

Brick pillars perform rather a decorative function than a practical one. However, such a fence can be installed in those areas when it is necessary to slightly equalize the height difference in the area.

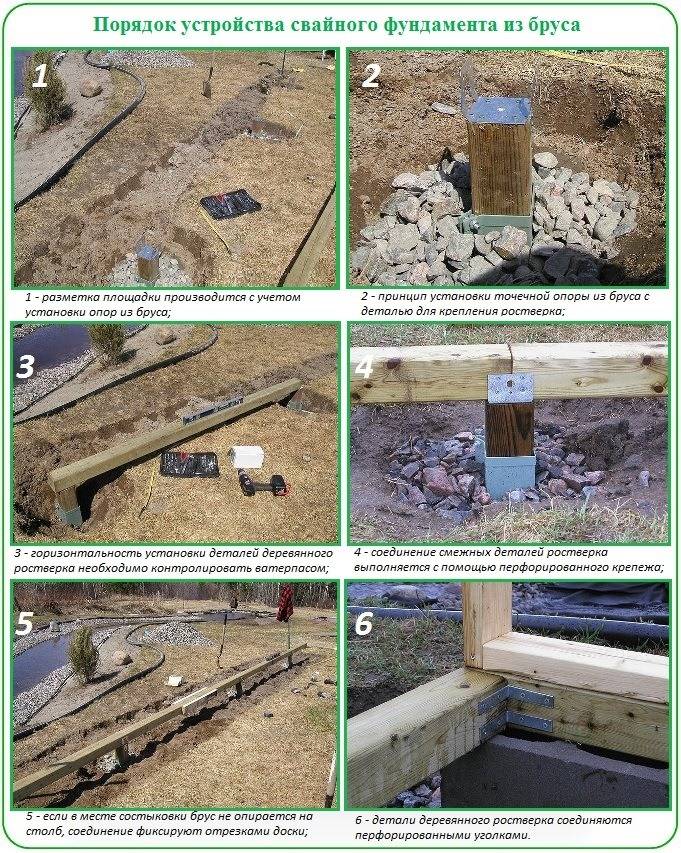

A pile foundation can be used under brick pillars.

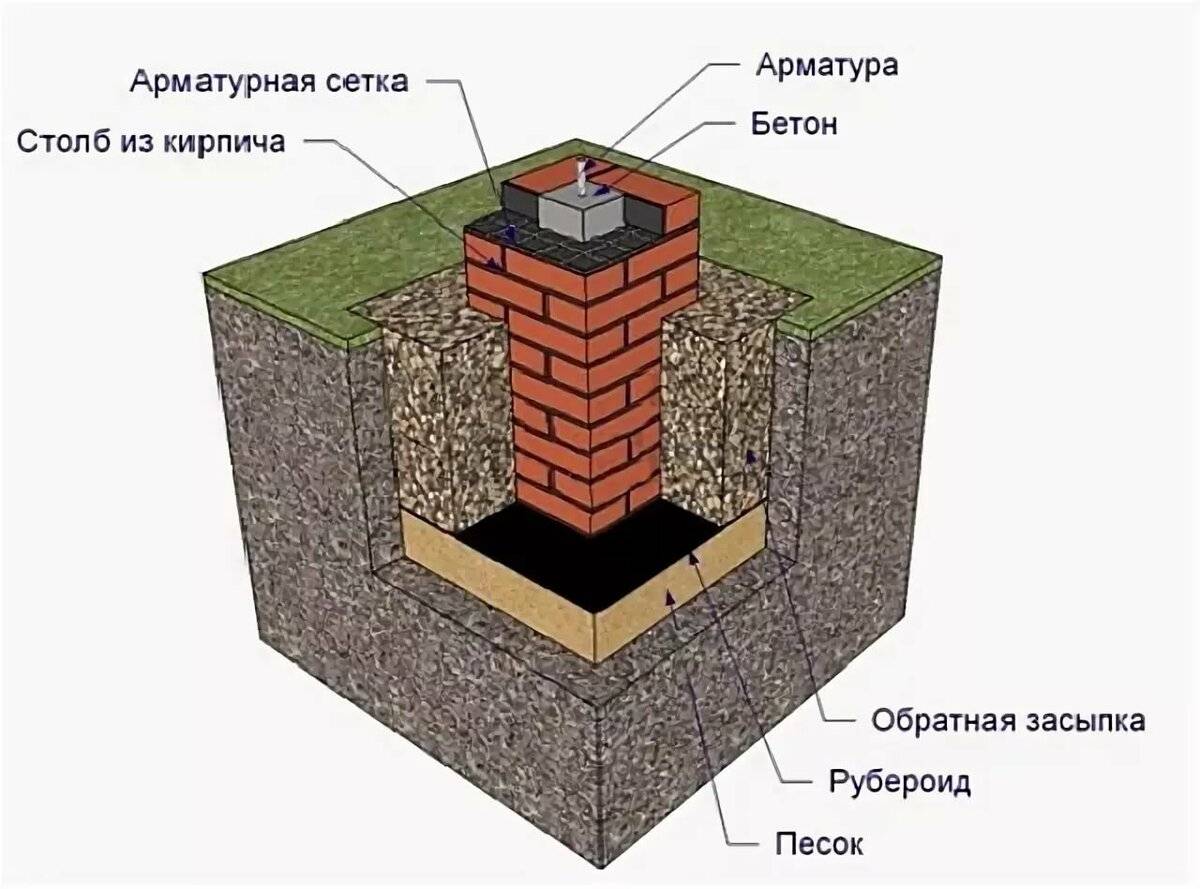

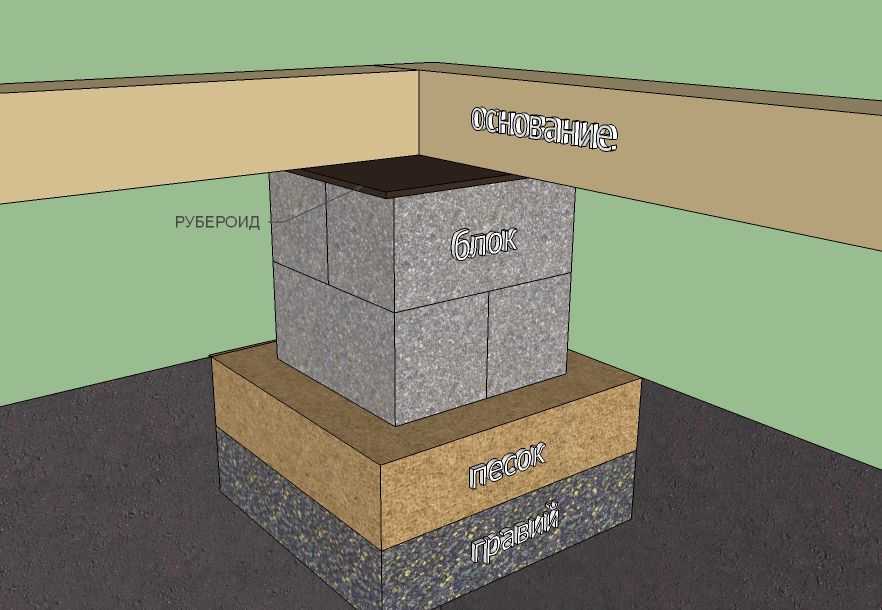

The process of creating the foundation takes place according to the following plan:

- Dig a ditch around the perimeter of the future fence up to 70 cm deep and at least 80 cm wide.

- Place a drainage pad on the bottom. You need to use sand and coarse gravel for this.

- Lay roofing material.

- Pour a 20 cm layer of cement mortar. In this layer, lay the reinforcement mesh. Use a rebar with a diameter of 6 mm.

- After the concrete has completely hardened, cover it with roofing felt.

- Now you can equip the tape with two bricks. It will have to be raised to ground level.

- Now you need to reinforce the locations of the pillars. A wire with a diameter of 3 mm will suffice.

- Lay out a brick base, and both the base and the pillars are laid out as a whole. Further, the pillars are laid out with monolithic masonry.

The strip foundation looks original under the fence with brick pillars

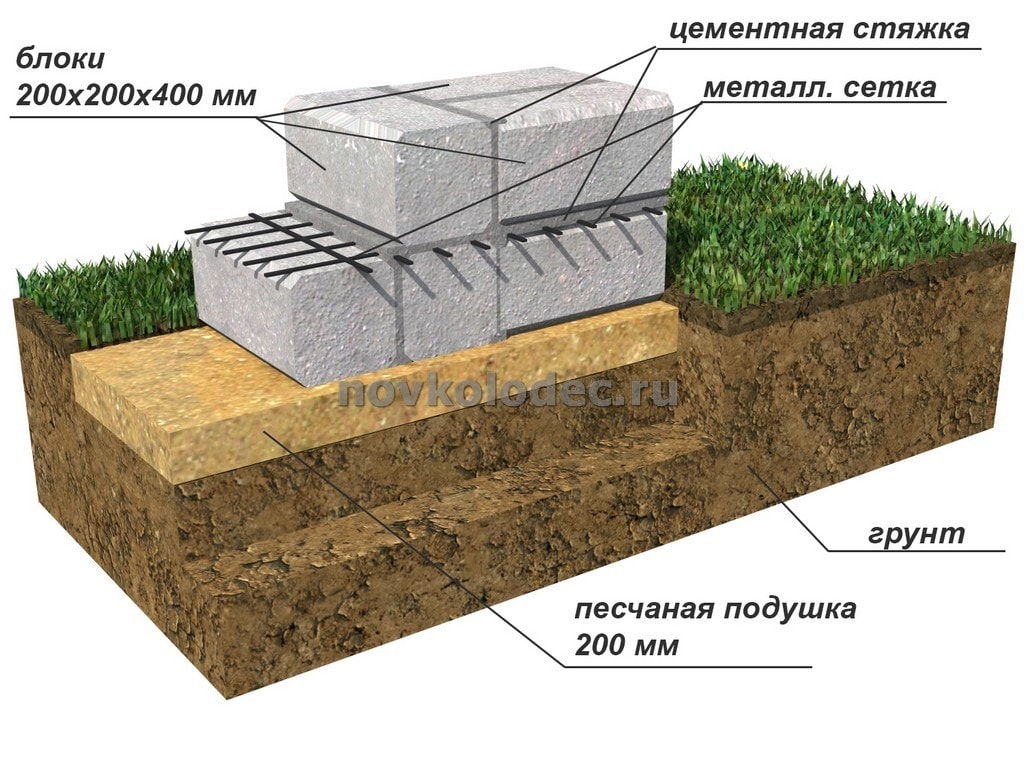

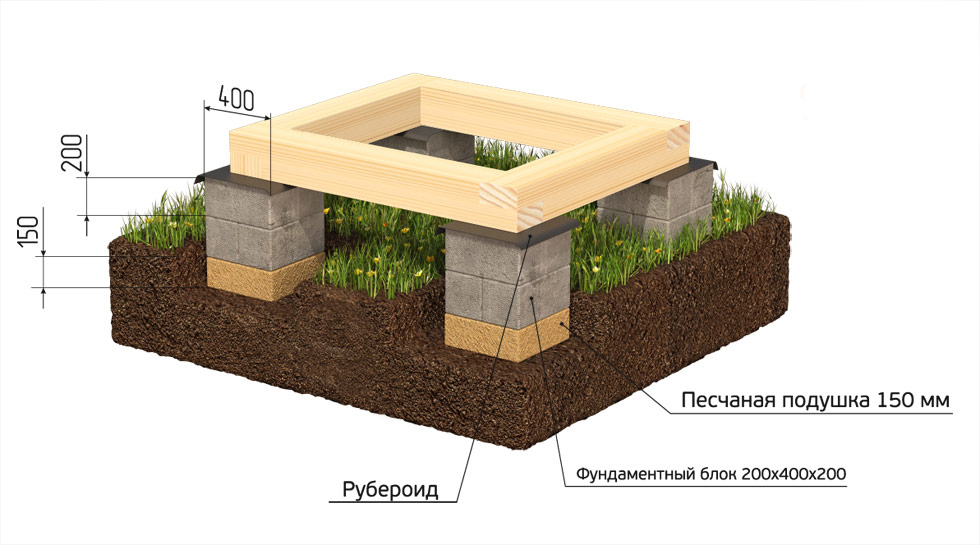

Technology for making a columnar base from prefabricated blocks

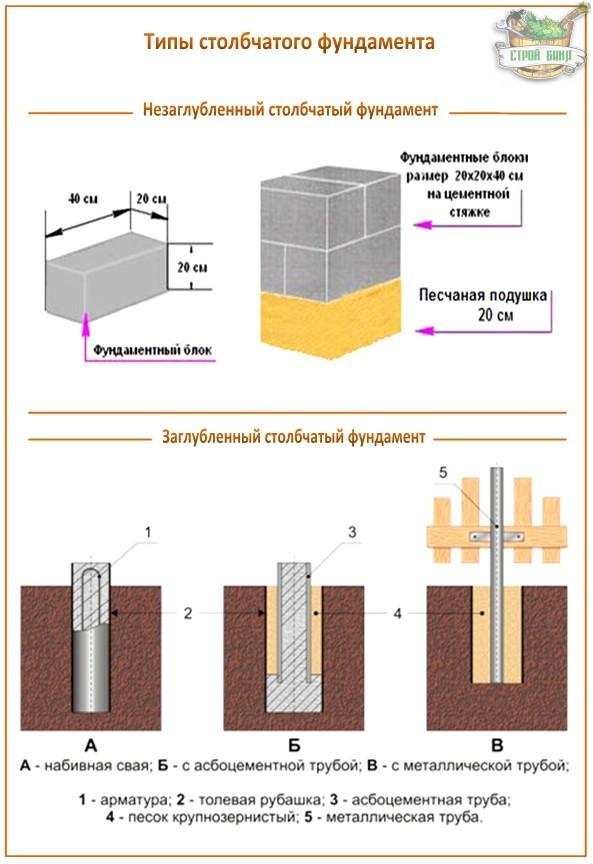

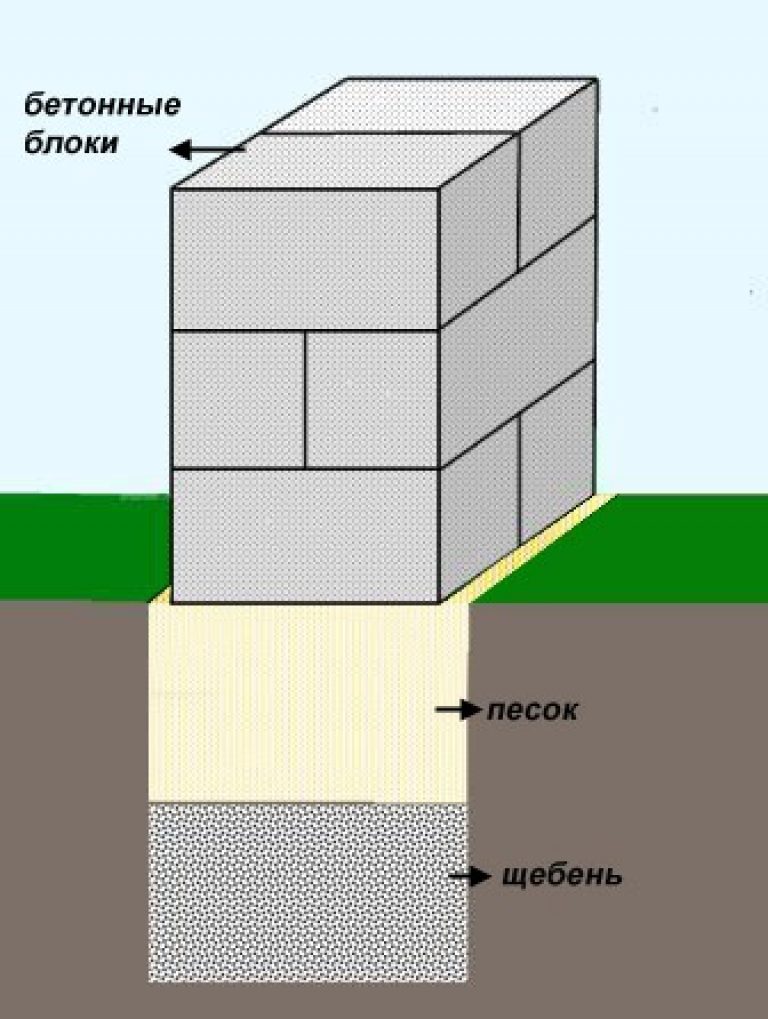

A columnar foundation of blocks is usually used for the construction of low-rise facilities of a small volume; it is very common to use a foundation of this type in summer cottages and garden plots for the construction of residential and utility buildings.

Preparatory work

Pillars are mounted at the intersection of important nodes of the house

Pillars are mounted at the intersection of important nodes of the house

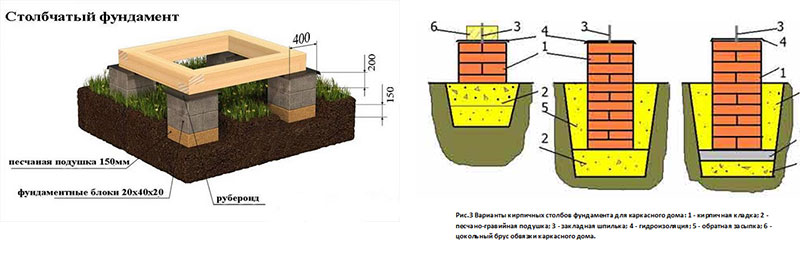

To begin with, it is worth calculating the number of pillars that will be required to provide a reliable support for the house. Building rules prescribe the installation of columnar supports at all corners of the structure and at the junction of internal walls. Under each node of intersection of walls or load-bearing partitions, it is necessary to provide for the installation of concrete pillars made of precast concrete.

In the intervals between the main support pillars, additional supports are installed, which are located at a distance of about 2 to 3 meters from each other.

In no case should the gaps between the supports be increased, in this case it is necessary to fear the occurrence of deformations of building structures. More frequent installation of supports will lead to an unreasonable rise in the cost of construction.

Excavation

You can start digging holes after marking their location on the site. You can dig out recesses for the installation of concrete blocks manually, or even better, use a special drill.

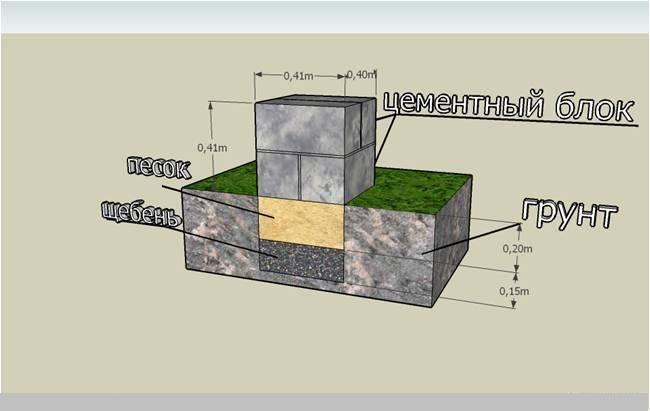

Coarse quartz sand is poured at the bottom of the pits, the layer thickness should not be less than 10-15 cm. The sand filling should be carefully tamped, moistening the sand. Work is carried out until the sand cushion is completely compacted. The next operation is the device of a support platform for the support, the technology of the device of pillars from concrete blocks provides, but for some objects such support platforms are not performed.

We recommend watching a video on how to dig holes for the further installation of poles.

Support platforms can be performed in different ways, very often even tiles (sidewalk or facing) are simply placed under the heel of the pillar, but this is wrong, because the load on the pillars from the building is quite large, and the tiles are fragile.

The complexity of this option is somewhat higher, but the stability of the supports also increases several times.

Installation of foundation pillars

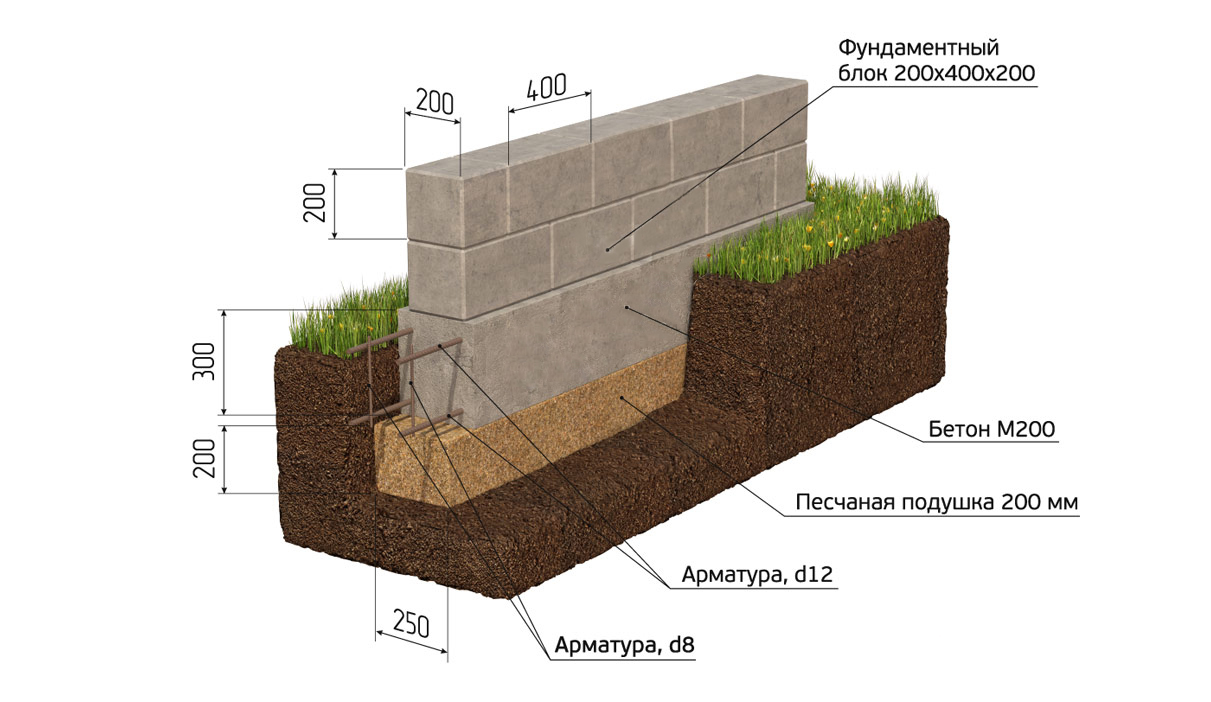

A columnar foundation of blocks 20 x 20 x 40 is most often used in the construction of foundations for low-rise buildings. Blocks should be used full-bodied, as a last resort, concrete blocks with small voids are suitable.

Prefabricated elements are sequentially laid on prepared bases in all pits, after which the upper part of the pillars is covered with sheet waterproofing material, over which a grillage made of wood or metal is laid.

A columnar foundation, like a strip foundation, perfectly distributes the loads from the building to the soil foundation, but the technology for its construction is much simpler.

Installation of foundation blocks

It is better to install the foundation from FBS in the warm season. Summer is the ideal time.

Foundation blocks should not be installed on a wet or damp surface; in adverse weather conditions, construction is better to postpone. Before starting the construction of the block foundation, you need to prepare the base, for this you need to install the axles, and then make a breakdown and dig a trench.

To transfer the axes, pull the axle threads and, using the body kit, transfer the intersection points to the bottom of the excavation. It is worth thinking in advance about a pillow for the foundation - it should be made of sand, which must first be sifted and compacted. The thickness of the pillow is on average 5-10 cm, and its width should exceed the size of the foundation by 20-30 cm. This all refers to the construction of a strip foundation from FBS.

FBS concrete block size table.

If you plan to make a foundation from columnar blocks, you need to create special cabinets and pillows. The pillow should be in all pits and make it according to a special scheme. The bottom of the pit must be crushed, then a cushion of rubble and sand must be made, carefully leveled. The resulting pillow can be spilled with bitumen mastic. The main task is to make all the pits of the same design and length. A regular rope will help you with this, which you need to pull between the support points of the base.

The installation of the foundation must begin with blocks that act as beacons, they are placed at corners, at intersections and on lintels. The correspondence of the direction and dimensions of the foundation with the project depends on how accurately the beacon blocks are installed. Then the mooring must be moved up, this must be done gradually, each time increasing the rows of laid blocks.

Deviations are easily corrected with a crowbar, with the help of which the foundation blocks move where they should be. With the help of the level, compliance with the drawings and the correct placement of the beacon blocks is checked, although the existing deviations are considered the norm. If the level shows that the permissible rate has been exceeded, the unit must be pulled out of the masonry and reassembled.

Advantages and disadvantages of a foundation made of FBS blocks

The benefits include:

- Saving time. No need to mix concrete, count the amount of consumables, observe ideal proportions. FBS laying is carried out quickly and there is no need to fear about the quality of the foundation.

- The manufacturer has provided for all aspects of the installation of the blocks. Large blocks are equipped with special hooks for easy assembly. It is easier to lay the products in the pit during the construction of multi-storey buildings or technically complex objects.

- FSB are equipped with grooves, which additionally strengthen the foundation.

- If the construction is carried out on unprepared ground or in the northern regions, the FBS can easily cope with these problems. Chemicals are added to the material to increase deformation resistance.

Disadvantages when using FBS blocks:

- Price.

- Use of special equipment for installation.

- There is a high risk of foundation subsidence.

The disadvantages of the material include additional waterproofing and insulation, but today it is difficult to do without this stage.

Working with FBS blocks

It's time to put the FBS blocks on the base. It is unrealistic to lay the foundation blocks with your own hands; a crane is used for this. The laying is done, as already mentioned above, in three rows, so that each subsequent row overlaps the seams of the previous one.

The laying is carried out on a special freshly mixed mortar of the M100 brand. Prepare more of it in advance, so that it does not happen that the shortage is revealed already in the process of work, when there is no time to hesitate and you need to do everything at once. If possible, try to manually correct the blocks if you see that they are not laid evenly enough. Several strong men will need to work here to get the material moving.

When this is done, you need to give the foundation of blocks (by the way, many call it the basement part of the house, since the blocks protrude above the ground surface) to grab a little, and then waterproof it. For insulation, a special facade mastic is used, which is applied with a spatula to the seams between the blocks from all sides, wherever possible. For greater reliability, you can also completely smear the entire surface of the blocks.

The last stage is the construction of a special belt made of reinforcement and bricks, which is placed on top of the blocks. It runs in one row. Such a belt will prevent subsidence and provide better adhesion to the FBS slabs of the main material for building walls in the house. The foundation is ready with your own hands.

Not everything is so difficult if you figure it out and make the correct calculations and design of the foundation. The result in the case of quality work will not upset you.

House design

Since March 1, 2019, suburban real estate has been divided into two categories:

- garden house;

- object of individual housing construction (IZHS).

In the first case, the structure can be anything: from a small building for seasonal living to a cottage. In the second, it is a full-fledged housing, in which its owner has the right to obtain a residence permit as in a city apartment. For this type of property, the same sanitary norms and standards apply as for all residential buildings. In order to obtain a document allowing such an object to be considered a full-fledged housing, it is necessary to create and approve a project in state authorities. An organization with an appropriate license should be engaged in its development, including the calculation of the underground part.

Installation of FBS

1.Laying foundation blocks on a frozen base covered with ice, snow or water is prohibited. 2. The foundation blocks are laid on a carefully leveled sand base or sand-cement pad with a thickness of at least 5 cm (on clay base soils). The deviation of the leveling sand layer from the design level should not exceed -15 mm. 3. The installation of the blocks begins with the installation of lighthouse blocks in the corners of the building and at the intersection of the axes. The lighthouse blocks are installed, combining their axial risks with the risks of the alignment axes, in two mutually perpendicular directions. The installation of ordinary blocks should be started after verifying the position of the lighthouse blocks in plan and in height. 4. The foundation blocks are laid on cement mortar not lower than M-50. The horizontal and vertical seams between the blocks are filled with mortar to the entire thickness of the wall and the height of the seam. The thickness of the seams is no more than 20mm. 5. The installation of the basement wall blocks should be carried out in compliance with the dressing (series 2.110-1 "Details of the foundations of residential buildings" issue 1 part 19). For individual residential buildings with a height of up to three floors, the required block size is at least 240 mm. To determine the required number of FBS blocks, you need to make a scan of each wall on which to draw blocks, taking into account their size and compliance with the dressing. An example of an FBS layout drawing. 6. To increase the strength of the structure, reinforcing meshes must be laid at the intersections of the walls. If the doorway in the basement is adjacent to one of the walls, the length of the reinforcing mesh is determined from the figure below (series 2.110-1 "Details of the foundations of residential buildings" issue 1 part 20). Layout diagrams of reinforcing meshes Dimensions of reinforcing meshes for manufacturing Specification of metal for meshes 7. Ordinary blocks should be installed, orienting the bottom along the edge of the blocks of the lower row, the top - along the alignment axis. Exterior wall blocks installed below ground level must be aligned to the inside of the wall, and above to the outside. Vertical and horizontal joints between blocks should be filled with mortar and sewn on both sides. 8. Monolithic sections in wall blocks in contact with the ground (below the surface of the earth) should be made of B 7.5 concrete or KORPo 1NF / 100 / 2.0 / 35 / GOST 530-2007 bricks, followed by plastering outside with cement mortar of grade 50 and hot coating bitumen for 2 times. nine.

Technical characteristics of FBS

For the production of stones, a concrete solution is used, the density of which is 1,800 - 2,400 kg per cubic meter. The strength category of the mortar mixture of FBS blocks for certain grades of concrete is:

- more than B7.5 - concrete M100;

- not lower than B12.5 - M150;

- heavy concrete - B3.5 (M50) - B15 (M200).

Resistance to low temperatures of block stones in accordance with the requirements of GOST should be more than fifty cycles of "freeze-thaw", the moisture resistance index - W2.

When designating the type of the foundation block, its parameters are indicated in "dm", rounding is performed in the direction of increase. In addition to the dimensions of the fbs, the marking of the fbs blocks provides for the designation of the type of concrete material:

- "T" - heavy;

- "P" - expanded clay (with a porous base);

- "C" - silicate.

For example, the block is marked with FBS-24-4-6 tons - this means that the block dimensions are equal to 2,380 x 400 x 580 mm; a heavy grade solution was used in the preparation. The stone is marked in other ways: 24-4-6t; 24.4.6t; 24 4 6t.

The mass of blocks according to GOST starts from 260 kg. This means that during construction for such a material, you will have to attract special equipment. For the construction of residential buildings, they prefer to use small foundation blocks, the thickness of which is 0.6 meters. The weight of such a demanded material is 1,960 kg.

When manufacturing, the technical characteristics of FBS blocks imply permissible errors from dimensional standards: in length - no more than 1.3 cm, in width and height - up to 0.8 cm, along the cutout - up to 0.5 cm.

Before buying supporting concrete blocks, it is imperative to check the compliance of the mass and dimensional parameters. When the weight is lower than indicated on the "T" mark, there are voids in the blocks, the concrete does not compact well, which will have a negative effect on its strength.It is not recommended to purchase such stones for creating a foundation from concrete blocks. DIY-cast foundation blocks will in most cases not correspond to the FBS production technology, and the use can create unpredictable consequences.

At the stage of manufacturing the foundation blocks, it is planned to install special metal lugs located on top. Used for this steel or periodic metal profile. If required, it is possible to order small foundation blocks without mounting hinges. Their standard sizes are determined by GOST.

The surface of the blocks can provide for the use of finishing materials. This feature is inherent in certain types of FBS. The rest of the types of foundation blocks are distinguished by the smoothness of the surface, the absence of cracks.

The factories produce block material under the label FBP. It has voids open to the bottom. There is also a variant of the FBV block stone. This means that the material provides cutouts for laying communication lines.