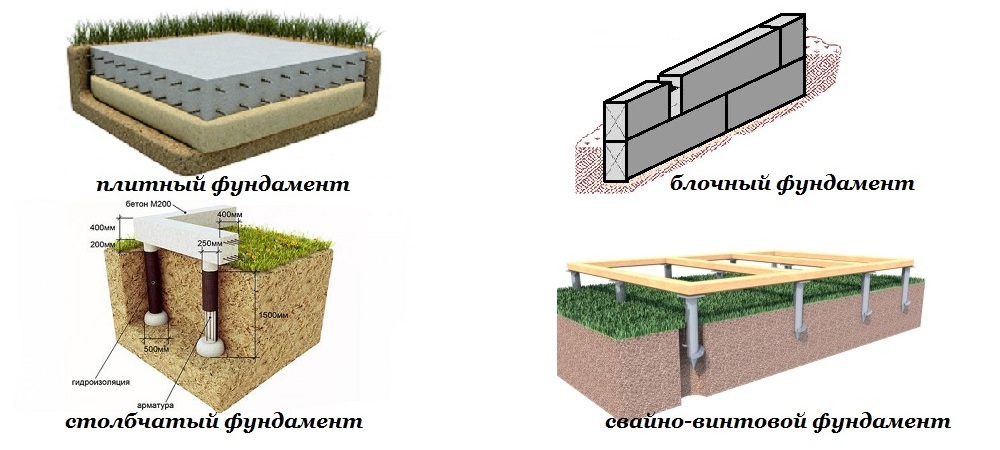

Column foundation

The device of such a base is a system of rubble, stone or brick pillars. Supports are erected with a step of about 1.2 to 2.5 meters under the most critical points of concentration of the loads of the future house (intersections of walls, corners, in places where heavy boiler equipment is installed, etc.). In order to combine the free-standing pillars into a reliable structure, strapping beams are laid on top, thus a ready-made foundation is obtained.

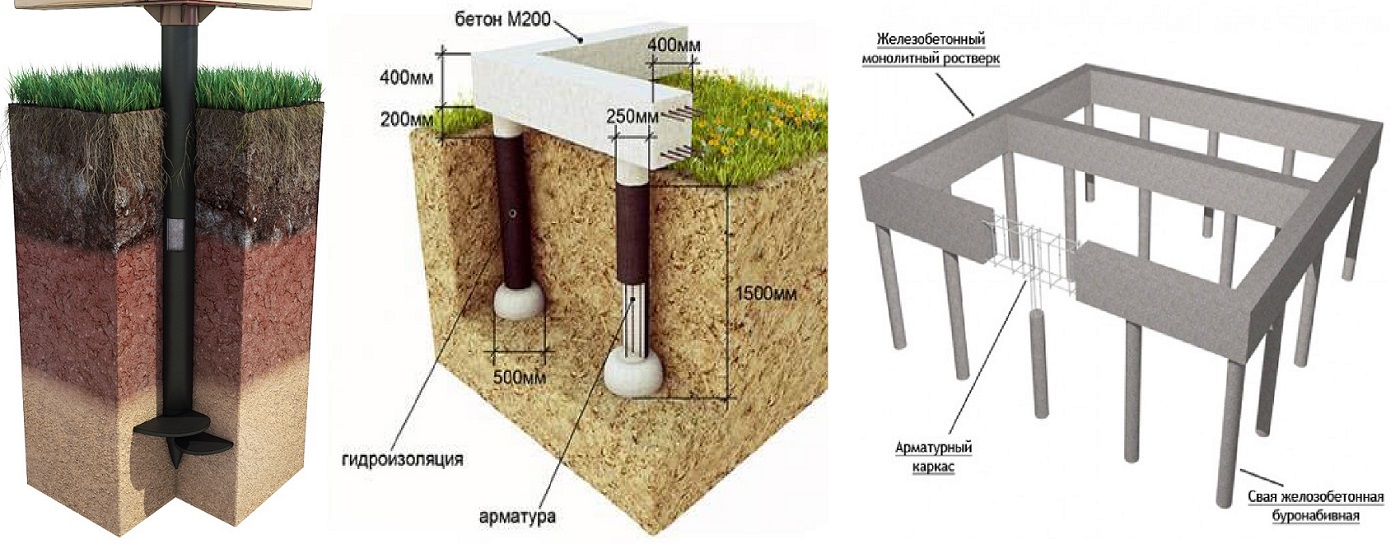

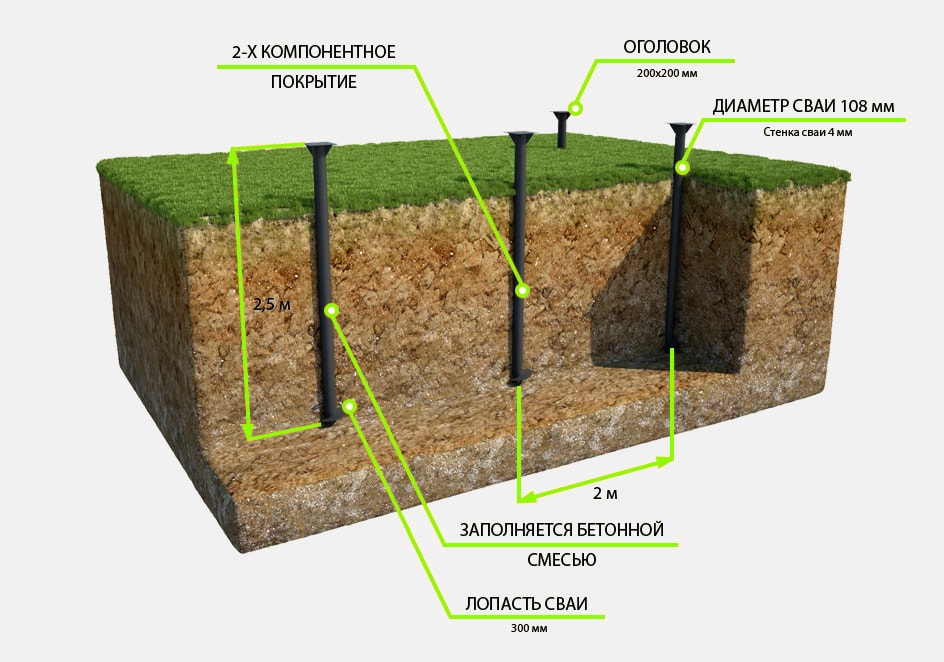

Separately, we can note the columnar foundation according to the technology (today very popular) TISE. Its essence lies in the construction of wells in the places where the supports are installed, their reinforcement and filling with concrete. Such foundations are also called columnar monolithic. The lower part of the support (sole) with expansion.

Features of a columnar foundation:

- Suitable for light soils that are not subject to strong heaving and movement (especially in the horizontal plane). It has proven itself perfectly in heaving soils, subject to their deep freezing.

- An excellent solution for low-rise construction (timber houses, frame houses, panel houses).

- Affordable cost, minimal labor costs (in comparison with other types of bases)

- There is no need for a waterproofing device.

- Used for houses without a basement.

Reliable, inexpensive foundation, is actively used in suburban construction.

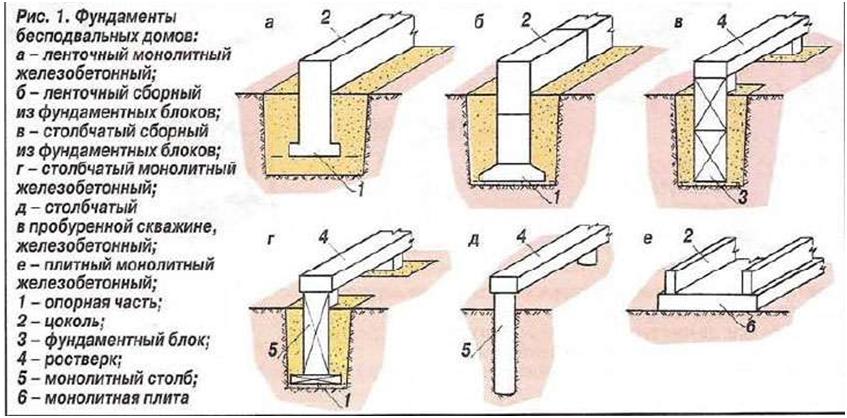

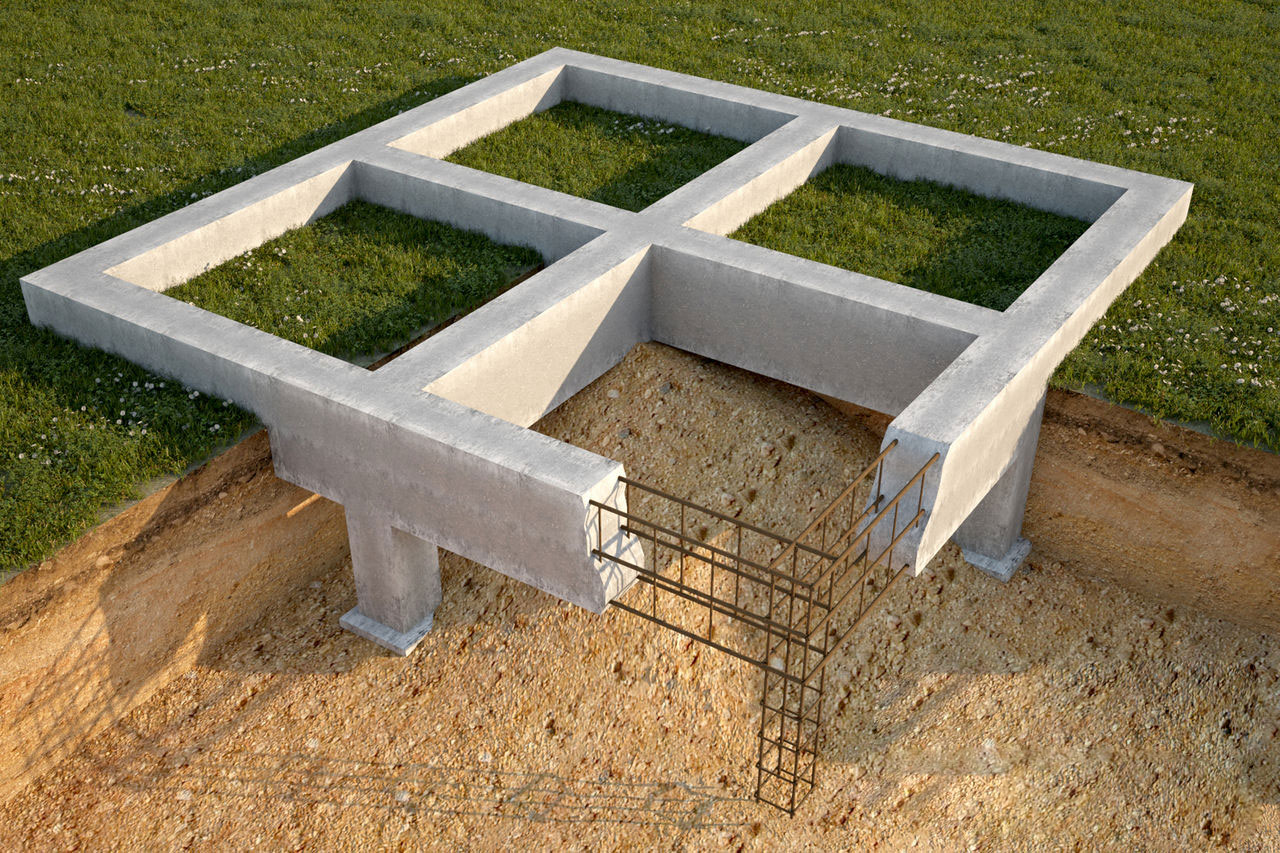

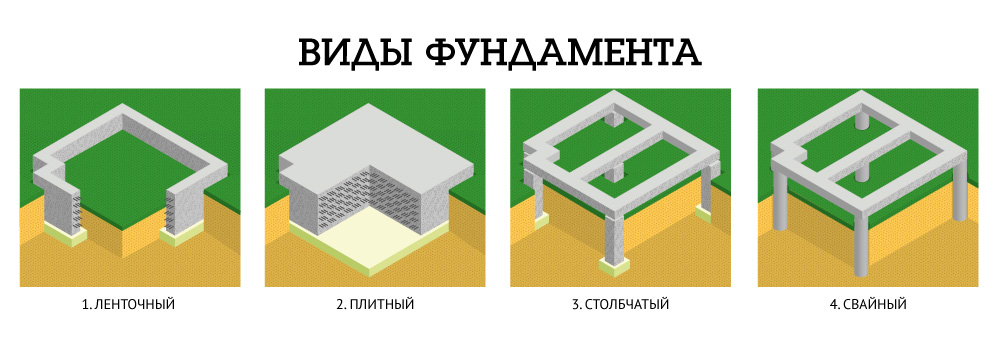

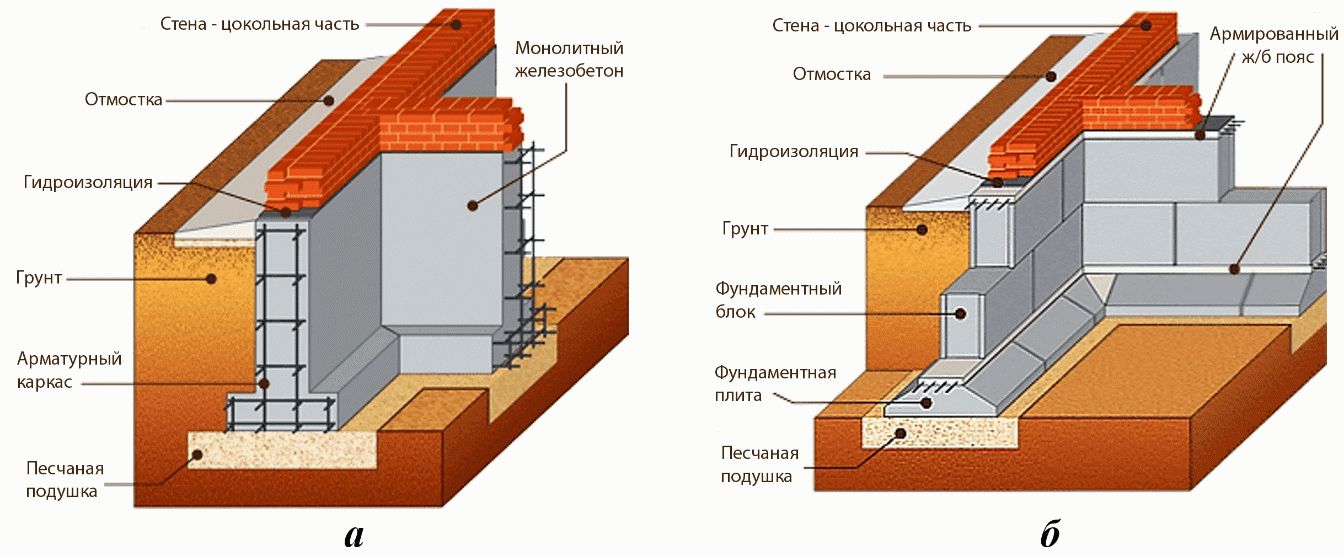

Overview of strip foundations

Tape bases in private construction are used more often than other types. This look can be done simply from concrete or reinforced concrete. It has the same width along its entire perimeter and one to one will repeat the lines of the bearing walls of the building. Such foundations are laid under houses with rather heavy brick, stone, concrete or block walls. It is built under all load-bearing walls, and this always requires a certain amount of earthwork and additional use of building materials. A do-it-yourself strip foundation is the best option among other options in cases where you plan to start building a basement of a house, an underground garage or a basement floor.

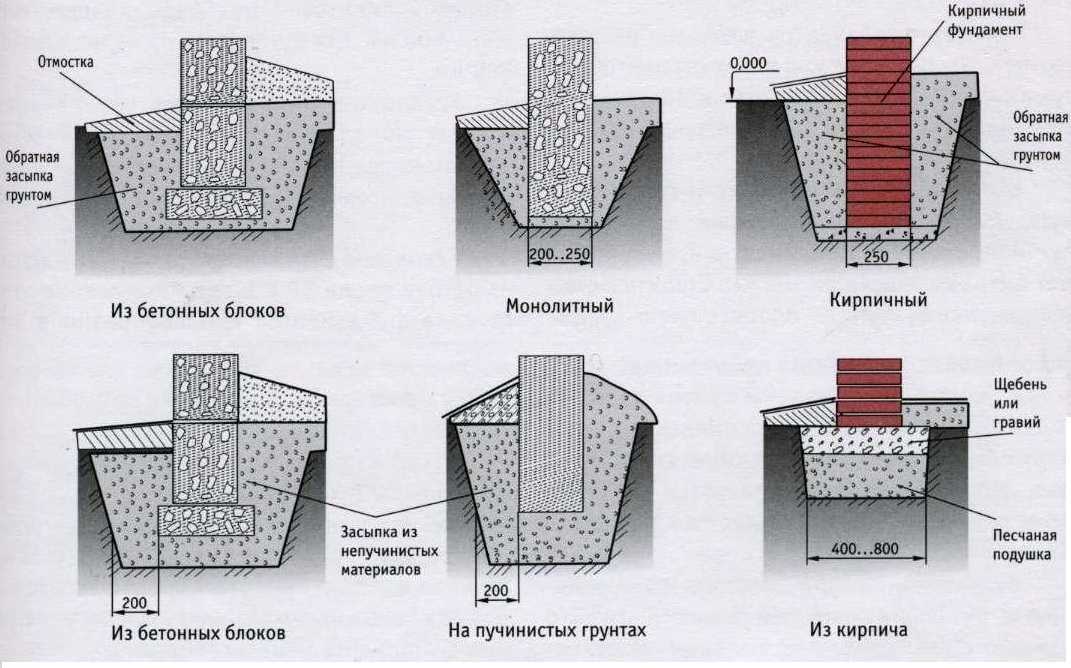

Further, the following types of strip foundations can be distinguished:

- Monolithic;

- Made.

Monolithic

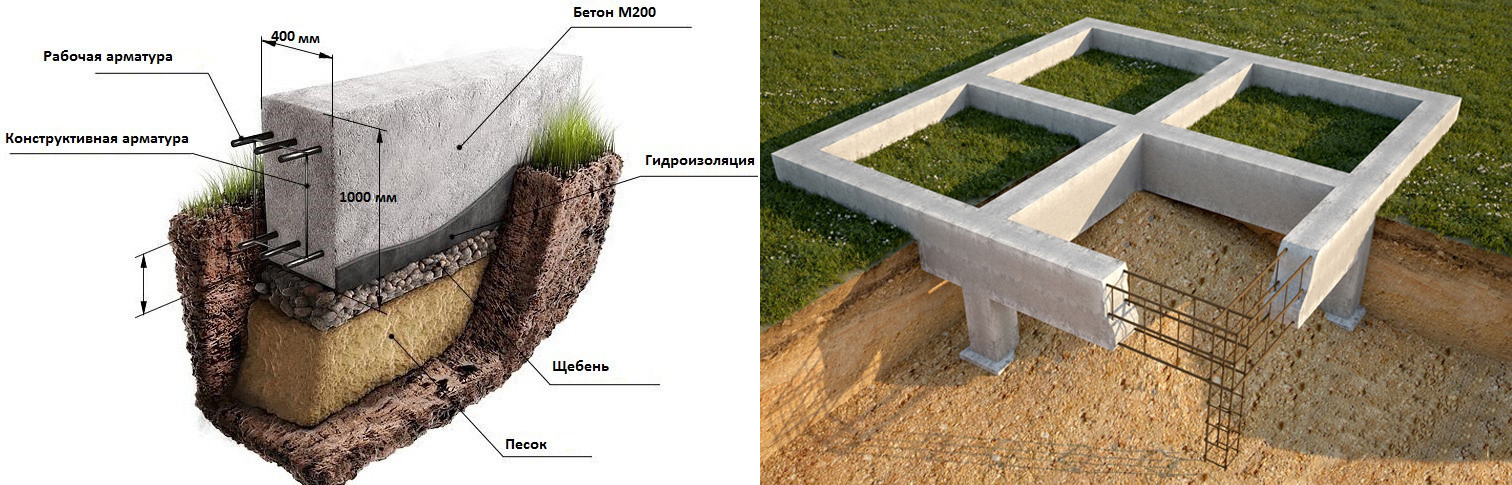

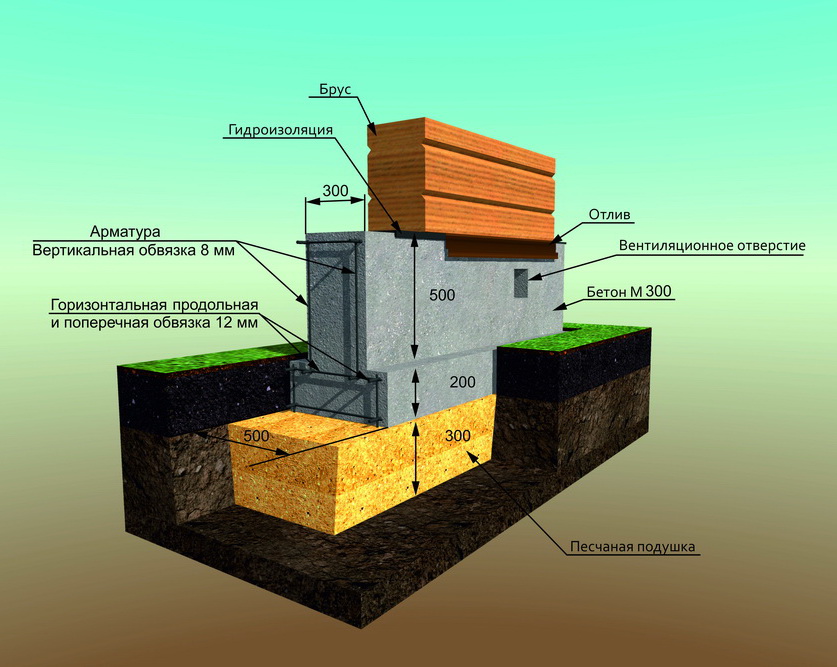

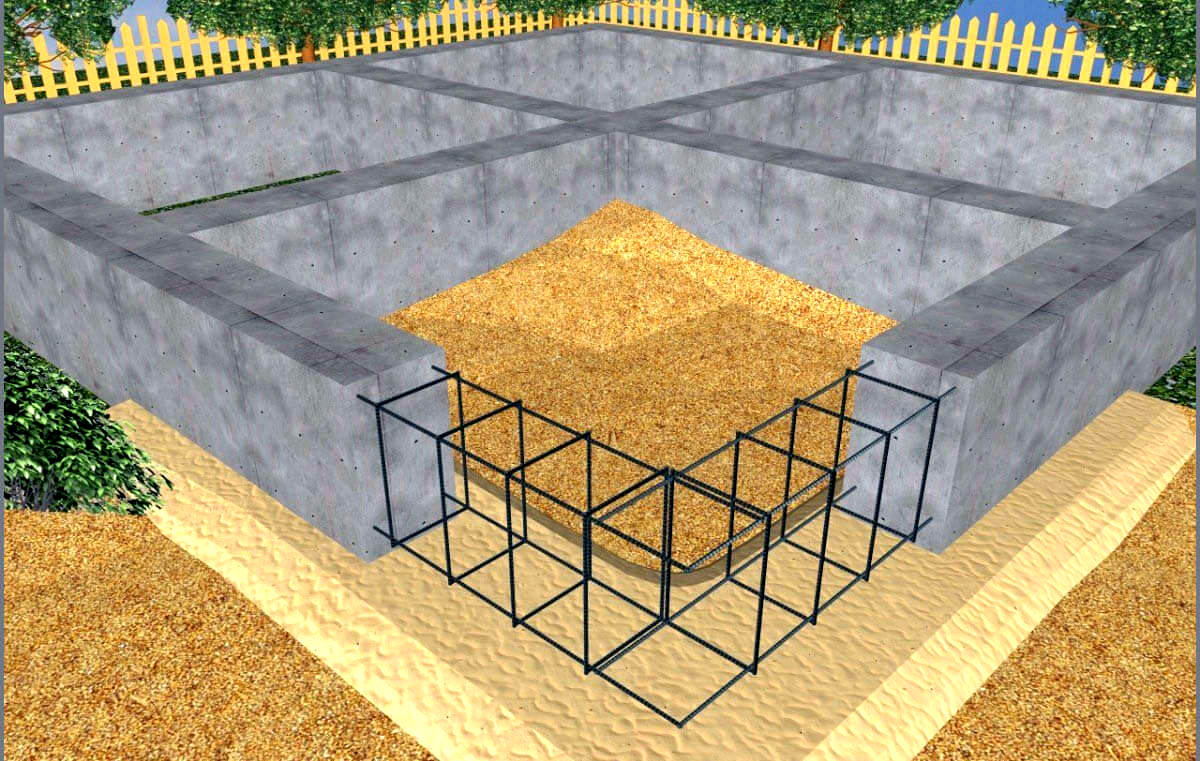

When a monolithic tape structure is being built, a trench of the required width is dug (usually it is 40-80 cm). The dimensions of the trench to be prepared should be slightly larger than the width of the base itself (about 10 cm on each side of the trench). This is done in order to complete the formwork. Further, inside the formwork, a mesh of reinforcement for the foundation (reinforcing mesh) will be knitted and a concrete mixture will be poured.

The main advantage of such monolithic structures, among other types, will be that they have the ability to withstand significant loads and will be suitable for various types of structures, for example, fences. If you are interested, you can see how the fence from corrugated board is being installed.

The cost of erecting 1 running meter of such a structure, together with the materials and work of the brigade, will be about 11,000 rubles, adjusted for a specific region.

You can buy or rent a formwork for the foundation at OOO MostoStroyEngineering.

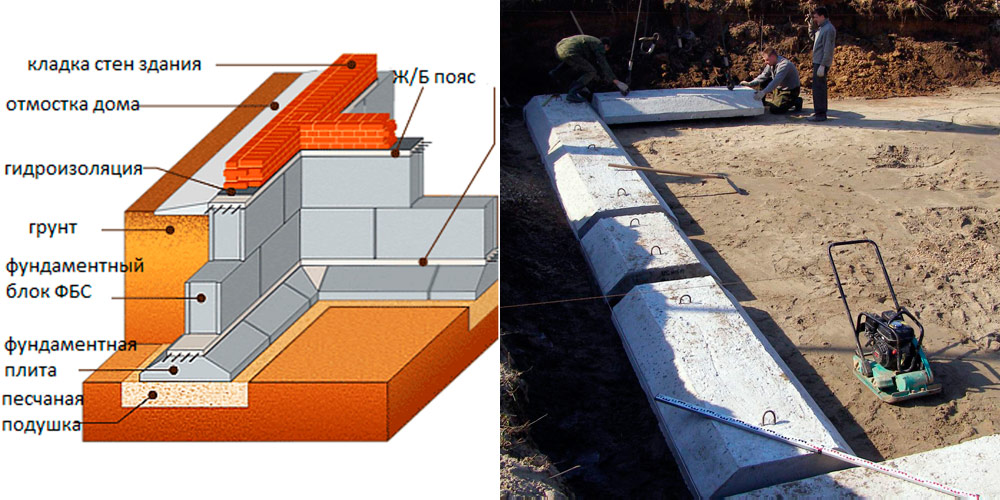

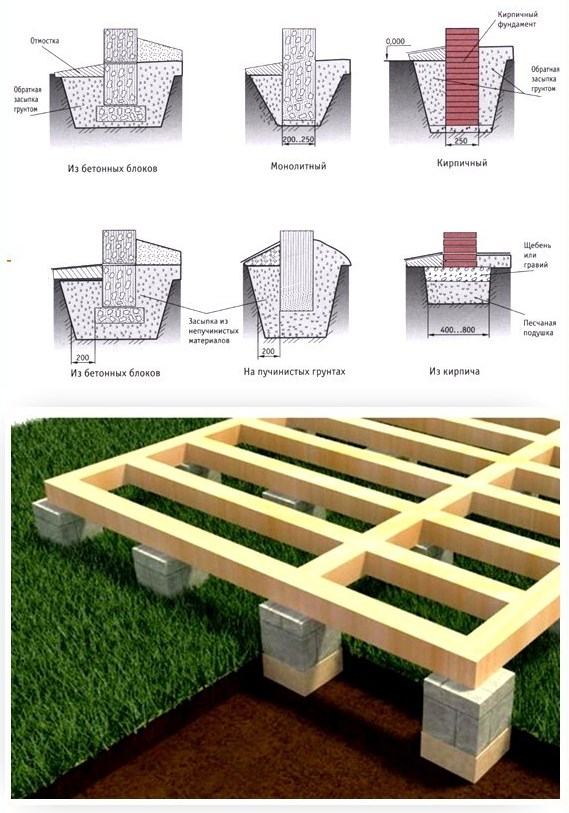

Prefabricated belt structure

Prefabricated belt structures are as follows. Reinforced concrete or conventional concrete building blocks are placed on the concrete mortar and pulled together and tied with steel wire. These types of foundations for a house are built quickly enough, will be strong enough and have a minimum number of defects.The service life of such a prefabricated structure will be approximately 150 years.

The cost of construction is not small - 1 running meter with materials and work in one block will cost about 7,000 rubles, again with amendments.

Buildings that will have basements will have less attractive prefabricated basements. This is because horizontal and vertical seams will reduce the watertightness of the basement, and additional waterproofing will naturally increase the cost of construction. This type is also not suitable for heaving soils that are prone to deep freezing, because in such soils, the number of earthworks increases.

The prefabricated tape structure is suitable only for structures with simple shapes, because for more complex ideas, the building blocks will need to be trimmed.

Work order

A step-by-step instruction for arranging a strip foundation with your own hands is as follows.

Preparatory work

Where should you start? It is determined by the rules for the construction of the strip foundation that it is recommended to act in stages, and the first stage of construction will be to perform the necessary calculations. This has its own specification, so this work should be entrusted to experienced specialists in order to avoid mistakes.

Now you need to mark the construction site in order to know exactly what your strip foundation looks like. The building site is cleared of debris, the soil surface is leveled. When setting up a breakdown, it is necessary to take into account the thickness of the formwork structure, how deep the foundation should be, the possibility of installing a floor.

The sequence of work is as follows:

- corner sections are outlined;

- the evenness of their location and distance is specified;

- the cord is pulled;

- the diagonals of the resulting perimeter are checked;

- the internal walls, veranda, porch are marked step by step.

We begin to dig a trench, which should exactly match the markings. If the strip foundation is supposed to be on sand, then all work is best done manually. When excavating, make sure that the vertical walls of the trench are respected. In difficult areas, preparatory work for pouring the strip foundation is carried out with drilling for piles.

At the bottom of the trench, a sand cushion is arranged, which helps to correctly redistribute the load on the base. Waterproofing material that protects against moisture does not fit on. The material should be wrapped on the walls of the trench by 15 - 20 cm.

Formwork

How to make a formwork structure correctly? It can be knocked down from prepared boards, which are subsequently dismantled. The second option is the non-removable formwork, which in the future plays the role of insulation material.

The prefabricated panel structure should rise above the ground to a height of 35 - 40 cm in order to be able to arrange a basement. The shields are fixed with crossbars and uprights, twisted with wire so that they do not diverge. Many are interested in the question of whether it is possible to make holes in the strip foundation for communications and grounding. This is possible for laying pipes, but it is better to lay the ground wire from the outside. When installing the formwork for the strip foundation, it is necessary to periodically monitor its evenness, remove ledges so that the base surface is smooth.

Fixed formwork is made of polystyrene foam blocks stacked on top of each other. It will also be an insulating material for a stone strip foundation. By the way, in the premises you can fill in a screed with a floor heating system - there will be no loss of energy resources.

Reinforcement

In order for the strip foundation to be made from "a" to "z", it is recommended to arrange a frame of reinforcing rods. Lattices are harvested, the rods are fixed with wire to eliminate discontinuities in the frame of the strip foundation.If it is planned to lay insulation in the formwork, then the reinforcing cuttings must enter it so that the frame is fixed even more reliably.

Concreting

Under which walls the strip foundation is laid, we already know, we also figured out the preparatory work. The crucial stage remains - filling the trench with concrete. This work should be done in one go, but in this case, the concrete will have to be purchased ready-made with delivery to the site. If there are certain peculiarities (removal of the plant, insufficient financial resources), then the concreting of the strip foundation is carried out in stages, in even layers. In each case, compaction will have to be performed to remove air bubbles from the solution. In section, the strip foundation should look like a solid monolithic stone.

Questions often arise: how much does the concrete foundation dry or how much does it “settle”? At least four weeks under favorable climatic conditions. Judging by the reviews of private developers who happened to fill the strip foundation, this period may be increased.

How to choose?

No matter how carefully the footing and drainage are made, if the type of the main foundation is chosen incorrectly, all these works and structures will turn out to be almost useless. When the construction site is built up with easily moving wet clay or dusty sand prone to deep freezing, you should not choose a strip foundation. As soon as spring comes, frosty heaving will be replaced by sinking. This will inevitably lead to cracks and even faults. Worst of all, even an immediate repair in accordance with all the rules with the use of adequate tools and materials will already be powerless.

But if there are no such problems with soils, the tape has a clear advantage - accelerated installation even without the help of professionals. Therefore, it is she who is recommended to be considered primarily for a residential building, courtyard buildings and baths. A monolithic strip foundation made of concrete can work up to 150 years, and at the same time everyone can mount it, even without spending money on renting powerful construction machines. The tape is very expensive and cannot be mounted during the colder months.

Problematic soils, which are encountered quite often, especially in areas of new development, are easy to "defeat" using the slab. The speed of its installation at the same level of preparation is the same as that of the strip base. Slab substrates are confidently poured in 1-2 months on their own. More precisely, pouring is faster, but it takes a lot of time for the mixture to harden. During the ascent and descent, the structures on the slab move uniformly, and this eliminates the risk of their destruction.

The solution to the problem of complex soil is also possible due to piles. Their bored type is mounted exclusively with the help of special equipment, and it is very diverse - you will need concrete pumping systems, and lift hoists, and boring devices. If you plan to equip a clay castle around the pile supports, you will have to supply it with special pumps. Of course, the use of a whole fleet of machines and the involvement of several professionals significantly increases the cost of construction work.

What foundation to choose

The main issue at the design stage or the start of construction is this one. The information presented above can only guide the future customer in various options.

The second side of the issue is that by laying in the project an unreasonably high strength of the foundation, we can significantly increase the cost of construction, since the cost of the foundation is up to 30 percent or more of the cost of the house. How to be? The answer is: the correct choice of foundation is a professional calculation based on a real project, a geological assessment of the soil and the wishes of the customer.For example, if the need for a basement or basement is low, then you can save a significant amount on this by choosing the appropriate options. Thus, the choice of the foundation is a rather complex issue, in the solution of which many conditions and factors should be taken into account.

Below is a summary of how to choose a foundation, depending on conditions and various factors:

-

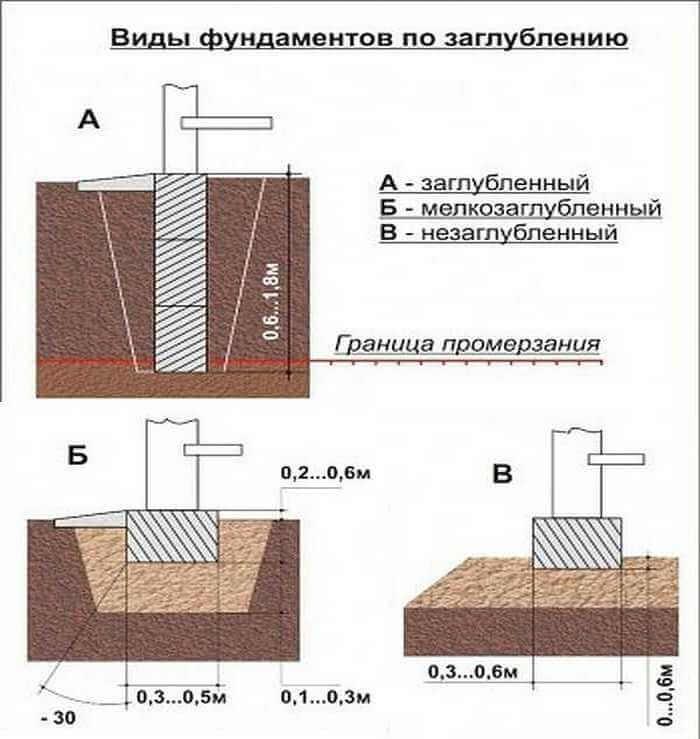

shallow foundations. They are used on soils of different stability, as a rule, for structures with a small load on the foundation. The types can be tape, slab, columnar, monolithic. All of these have been covered in the previous sections;

-

deep foundations. They are used on unstable soils, with a high level of groundwater, for large buildings and structures;

-

concrete foundation. A universal option with the possibility of individual design for specific conditions;

- reinforced concrete foundation. Similar to a concrete foundation, it is a reinforced version using a reinforcing cage;

-

sleepers foundation. Popular due to its low cost, the type used for private buildings is an example of recycling materials. The use of sleepers, treated with a special substance that excludes wood rotting, makes it attractive due to the low labor intensity of the work;

- wooden foundation. A simple option for light and temporary buildings. Wood is used that is slightly rotting, such as larch. Additionally, it can be treated with a special anti-rotting agent;

- driven foundation. One of the many options for pile foundations. Each driven version is usually the result of an individual project or technical solution for specific conditions.

Any customer can find the best option for housing construction for himself and his conditions, however, more and more often, a technologically and economically correct decision is made on the basis of a project developed in a specialized company that has established itself in this market. In this case, the choice of the foundation will be part of an integral and balanced project, in which taking into account the wishes of the customer and choosing the best option will be the result of professional calculations. It should be expected that the price and quality of such a project will be high.

Video: types and properties of foundations

A reasonable choice of foundation guarantees a quality project in which this task is only one of many in a balanced overall solution. The main result is the correct ratio of the construction budget to the final quality.

Factors influencing the choice of the type of foundation

The choice of the type of foundation is determined by many factors:

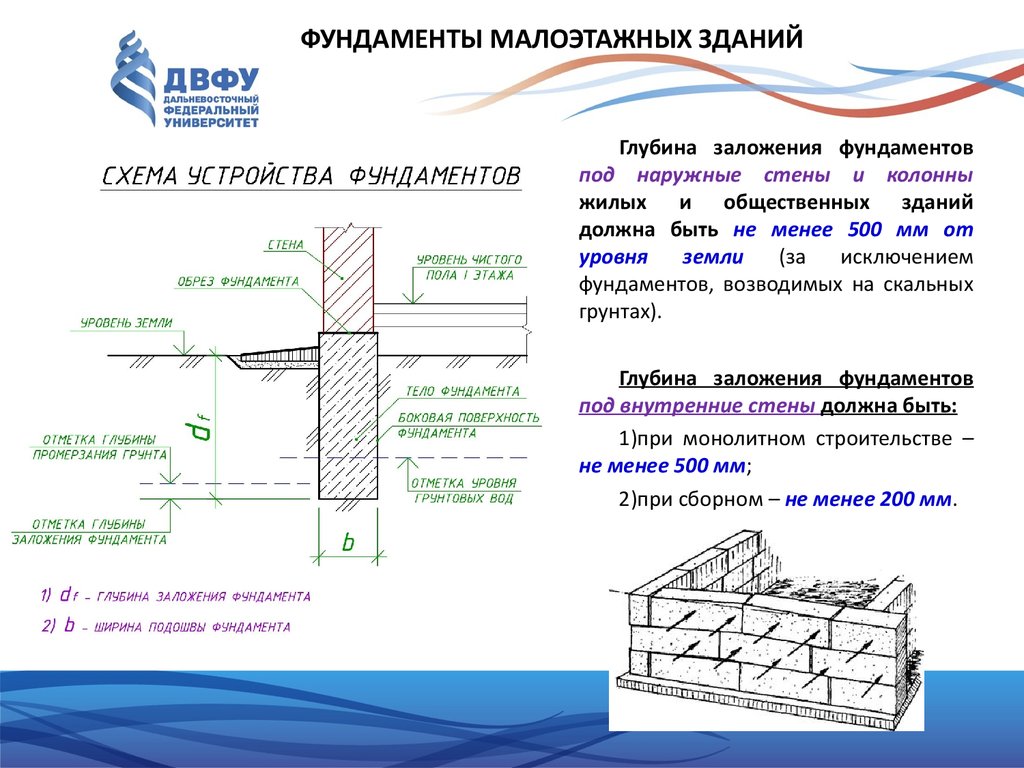

۩ What needs to be considered first is the type of soil prevailing in the area, which can be determined by a geotechnical technician. The entire mass of soils under the structure serves as its base. Thus, the bearing capacity of the foundation is determined by the magnitude of the load under which the soil settles. In this case, the soil is deformed not only from the load itself, but also under the influence of temperature changes. And the water in the pores of the soil expands in case of freezing, pushing the base up. Since each type of soil is characterized by a different sediment, it is possible to consider a particular type of foundation in more detail only after carrying out the necessary geological procedures.

۩ It is very important to determine the depth of soil freezing. In this case, it is also necessary to take into account the fact that for unheated premises, the depth of freezing must be taken 10% more than the average.

The depth of freezing is measured from the ground, and if a basement or semi-basement is provided in an unheated building, then from the level of their floor.For heated premises, the frost depth will be less by about 20 - 30%.

۩ However, a foundation built below the freezing depth cannot yet fully guarantee one hundred percent protection against the effects of frost heaving (especially for light buildings). It can be reduced in several ways, for example: by reducing the side surface of the foundation; giving the foundation the shape of a trapezoid with a narrowing upward; filling his sinuses with non-porous soil; as well as the creation of the side surface of the sliding layer using a material having a low coefficient of friction.

Among other things, the level of groundwater also affects the depth of the foundation. It can be determined by conducting special engineering and geological studies by drilling at the site of pits, taking soil samples and conducting chemical analysis of water. If it is planned to build a wooden house on the site, then the depth of these wells can be up to 5 m, and if brick or stone, then about 7-10 m. At the same time, at least 4 wells are drilled in the corners of the future house.

۩ When choosing the type of foundation, the main factors are the purpose and design of the house.

If, for example, you decide to build a brick cottage, then you first need to decide on the thickness of the walls and the height of the house, whether a garage, basement or some other utility rooms will be equipped. For such a cottage, a strip foundation should be laid out with such a depth that would best match the type of soil in this area. Walls made of reinforced concrete panels and blocks are erected on a strip foundation. The construction of a slab foundation is possible provided that buildings are erected on the slopes of hills, clay-sandy soils, swampy soils, etc.

If the walls of the house are planned to be made of wood or they will have a frame-panel structure, then there is an opportunity to save some money on the foundation without prejudice to the future structure. For such a house, a shallow foundation will be quite enough. To do this, it will be necessary to remove the top layer of soil 50 cm thick, then lay crushed stone and tamp it. Further, a drainage pipe is installed along the entire perimeter. On top of the crushed stone layer, a road membrane-film is covered, on which a layer of compacted wet sand, insulation is placed, reinforcement is strengthened and waterproofing is performed. And finally, concrete is poured, resulting in a solid monolith.

In conclusion, I note that the service life of the house itself will largely depend on how correct and accurate the foundation of your future home will be, as well as on the strength and quality of the materials from which it is made. After all, the main supporting part of any building that takes all the load of the building onto itself is the foundation.

Of course, the price of a solid, reliable and durable foundation is, as a rule, from 15-20% of the cost of the house itself. But, despite this, one of the most widely used types of foundations in construction today is a strip monolithic concrete foundation.

And my advice to you: for the construction of the foundation on all issues, it is best to contact the specialists who will make the foundation of the future home strong and reliable and provide a guarantee for all work performed.

Materials (edit)

Much when choosing the type of foundation and its optimal organization depends on the type of building materials used at the top. For example, a brick wall is heavier than a comparable (or even slightly large) wooden structure, so you will need to create a solid, stable base under it. A building with a deep laying of a support is recognized by most specialists as the most reliable and stable, but the complexity of preparing such an element makes it acceptable only for a large brick house.

In addition to concrete strips, three types of piles are often installed:

- bored;

- screw;

- clogged.

Even without special geological and geophysical studies, it is obvious that the properties of the soil in different places are not the same. Its composition and mechanical parameters directly affect the choice of the optimal and acceptable type of material.

It is also worth taking into account the freezing zone, the characteristics of the aboveground structure, the climate, groundwater, the funds available to the developer

- reinforced concrete;

- asbestos pipes;

- metal constructions.

But wood, even especially durable and processed in accordance with all the rules of protection, cannot be recognized as a completely effective solution. In most cases, independent developers choose reinforced concrete because this material is versatile and suitable for all known types of soils. It can be prepared using cement, sand of various fractions, crushed stone and reinforcing rods. The installation of steel strips is done in the formwork, after their connection, mortar is poured inside.

When erecting a building on solid soil, composed of stone rocks, natural stone and light grades of rubble concrete can be used for laying the foundation. The same materials are recommended for use on most soils that are not subject to heaving in winter.

But it should be noted that adherence to the work methodology becomes critical. The irregularity of the contours of natural stones makes it difficult for them to densely homogeneous layout

It is very difficult to correct the discovered deficiencies; for this, it is almost always necessary to call in lifting equipment.

Therefore, simple concrete is much more often chosen (even without reinforcing reinforcing inserts). As a binder, in addition to cement, sometimes polymers of a special composition and a combination of silica with lime are used for the production of concrete. But the last type, which makes it possible to make silicate concrete, shows itself very poorly where the soil is abundantly saturated with moisture or prone to freezing to a great depth.

Of course, much attention should be paid to the sand. In addition to being a part of the concrete solution, it is "marked" in one more role - the underlying cushion

It is recommended to create such pads if the rocks below are loose and by themselves will not tolerate the created load. Both cases, when sand is used in the construction of the foundation, require mainly its quarry variety with a large fraction. As reinforcement, special rods are used, the geometry of which is designed for ideal adhesion to the concrete mass.

The tree is used in the form of supports, in formwork structures. The cheapness and availability of this material do not allow, unfortunately, to ignore its main problem, that is, a short period of operation. When choosing a natural stone, you should carefully understand not only its characteristics and cost, but also transportation costs. Quarry stone is cheaper and more practical than granite or sandstone, it can be obtained without excessive costs. Expanded clay is traditionally used to insulate foundations, but it makes sense to think about other, more modern and practical insulating materials.