Types of steel reinforcement by type of production

The properties of steel reinforcement directly depend on the method of its production:

- hot rolled steel (marked with the letter A) is processed at very high temperatures, which lead to some changes in the structure of the alloy. The result is a very durable material that is suitable for use even in critical facilities. Such steel is perfectly welded, therefore it is used in those cases when individual rods must be connected by welding (however, this method is only suitable for stable soil);

- cold-rolled steel (marked with the letter B) is produced by impacting rolls on the steel wire rod, which roll out the workpiece to the required diameter, then the rollers give it a relief. The finished reinforcement is wound into coils, which at the construction site can be unwound, cut and used for their intended purpose. Rebar diameters - 3-8 mm. Cold-rolled steel is also used in the construction of the foundation, but its use is not always possible - it is worthwhile to carry out calculations in advance;

- rope steel (K) is too strong for building a foundation, it is economically unprofitable to use it, but when it comes to the construction of structures that will work under extreme conditions, about large-span buildings, etc., then its use is justified.

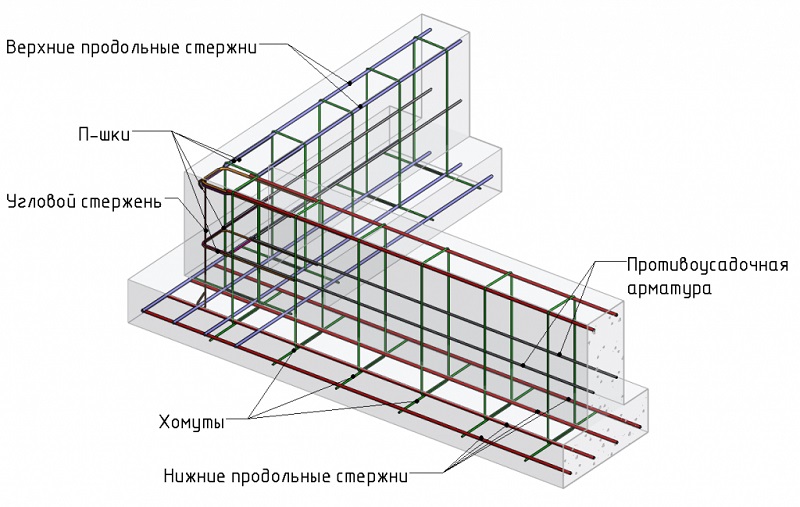

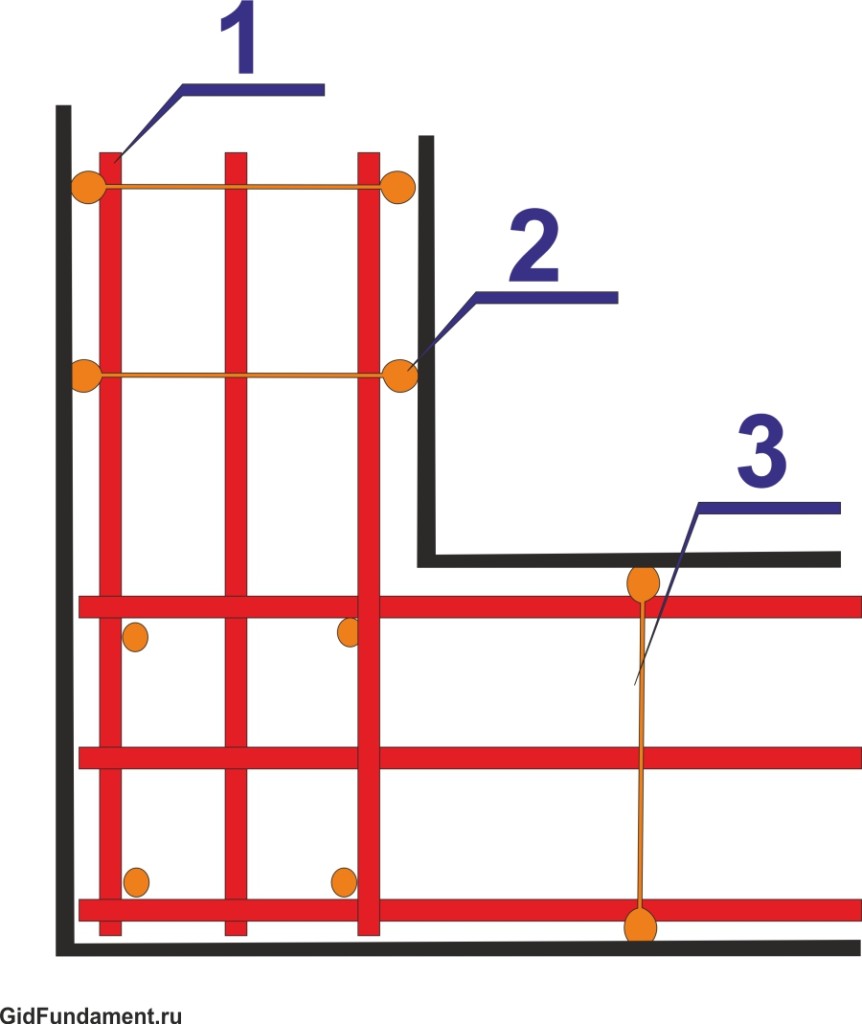

Corner tying rules

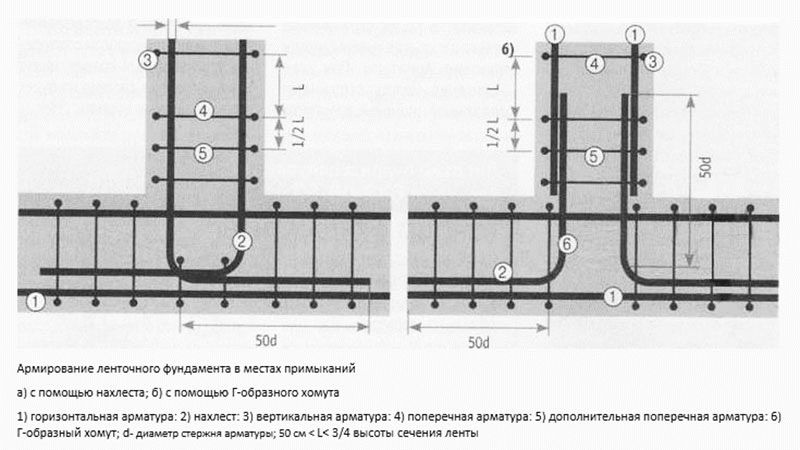

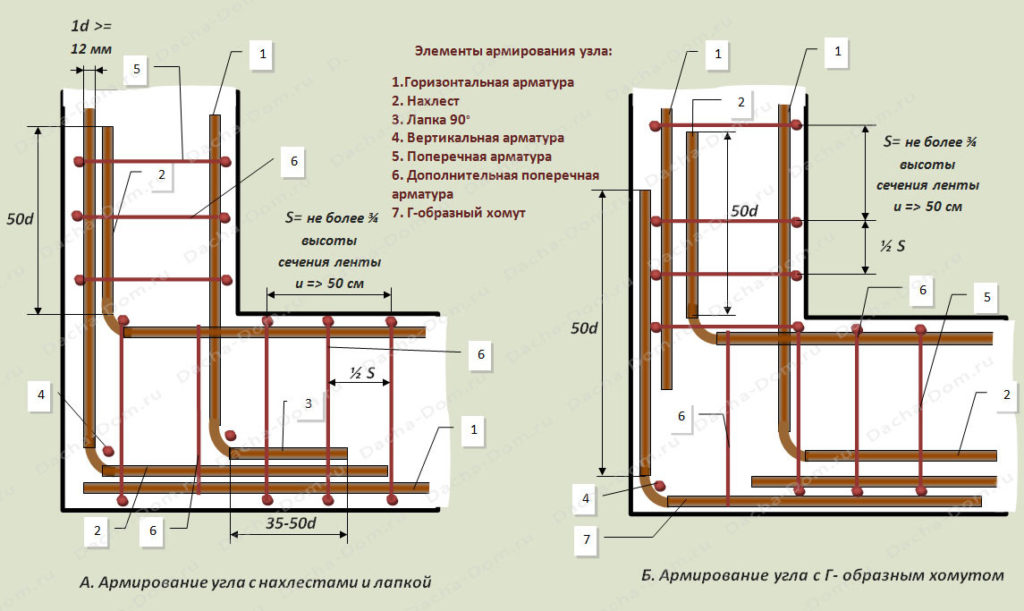

The nodes must comply with the requirements of building codes (according to GOST), and not be tied with simple, fragile material. It is necessary to knit the reinforcement with a wire that has been subjected to heat treatment (or a polypropylene clamp, clamps are also used).

For work, you need pliers and a special hook. In addition to manual tying, a construction gun has been developed that automatically ties the reinforcement.

There is also a method for welding rods and tying them. This option has its advantages and disadvantages (possible threat to integrity). This depends on the characteristics of the buildings, the desired project. So, in order to choose the correct option for connecting reinforcement, you should think over all the nuances that can affect the entire project, both positively and negatively.

Calculation of loads on the base

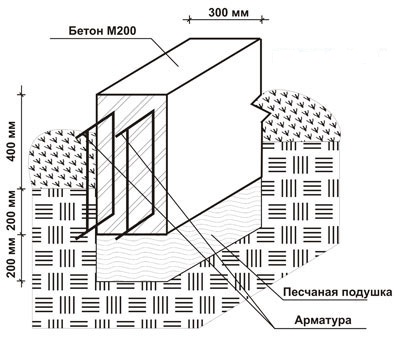

Shallow tape reinforced monolithic foundation used for wooden houses and baths on heaving grounds.

Calculating the load, which means not only choosing the diameter of the reinforcement, but also determining which reinforcement to use, is a rather complicated operation. Usually it is carried out by a specialist when designing a residential building. It is necessary to use fittings with a diameter of 6 and 8 mm. This is only valid for light, small structures in rocky or gravelly soils.

The depth depends on the magnitude of the load, the load on the base, and the composition of the soil.

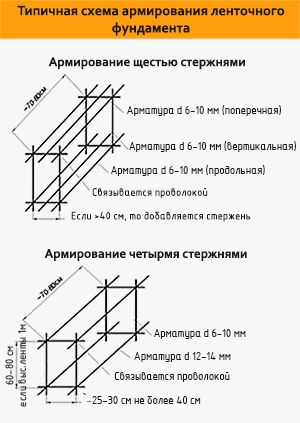

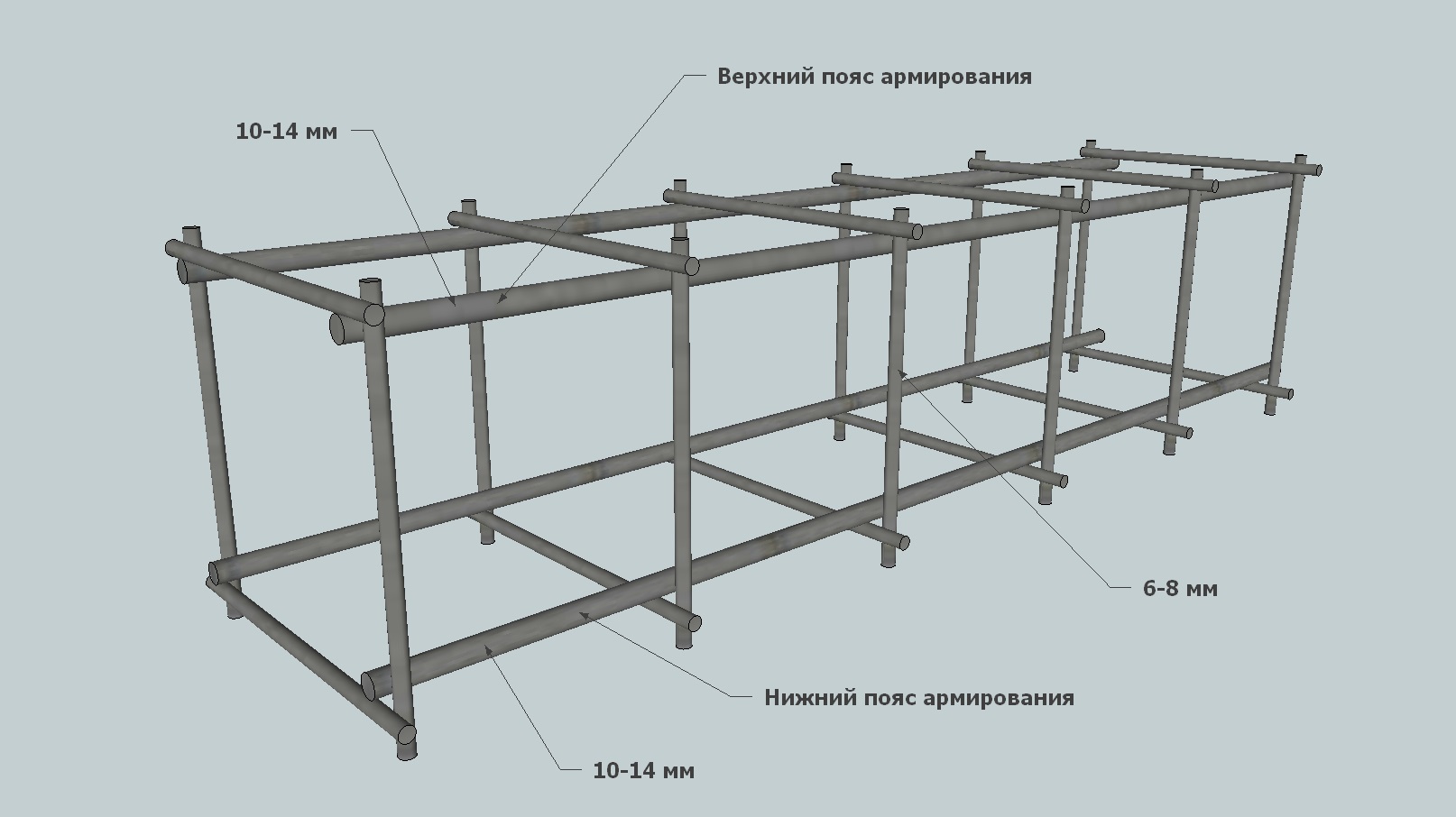

The greatest loads are taken only by the longitudinal element of the strip foundation frame. Therefore, for longitudinal laying, ribbed profile reinforcement is used, diameter 10-14 mm. If the quality indicators of the soil are different over the area of the entire foundation, then the diameters of the reinforcing attachments should be appropriate.

What is the purpose of the reinforcement

The strip foundation web is subjected to uneven loads during operation. This is due to the heterogeneity of the soil density and differences in the elements of the building structure. The concrete base is highly resistant to compression, and reinforcement is needed to increase the resistance to bending and stretching.

For this, vertically and horizontally located rods are fastened with a wire and assembled into a frame, which gives the concrete product monolithic rigidity.Its strength and durability depends not only on the type of concrete used, but, to a large extent, on the reliability of the reinforcing cage.

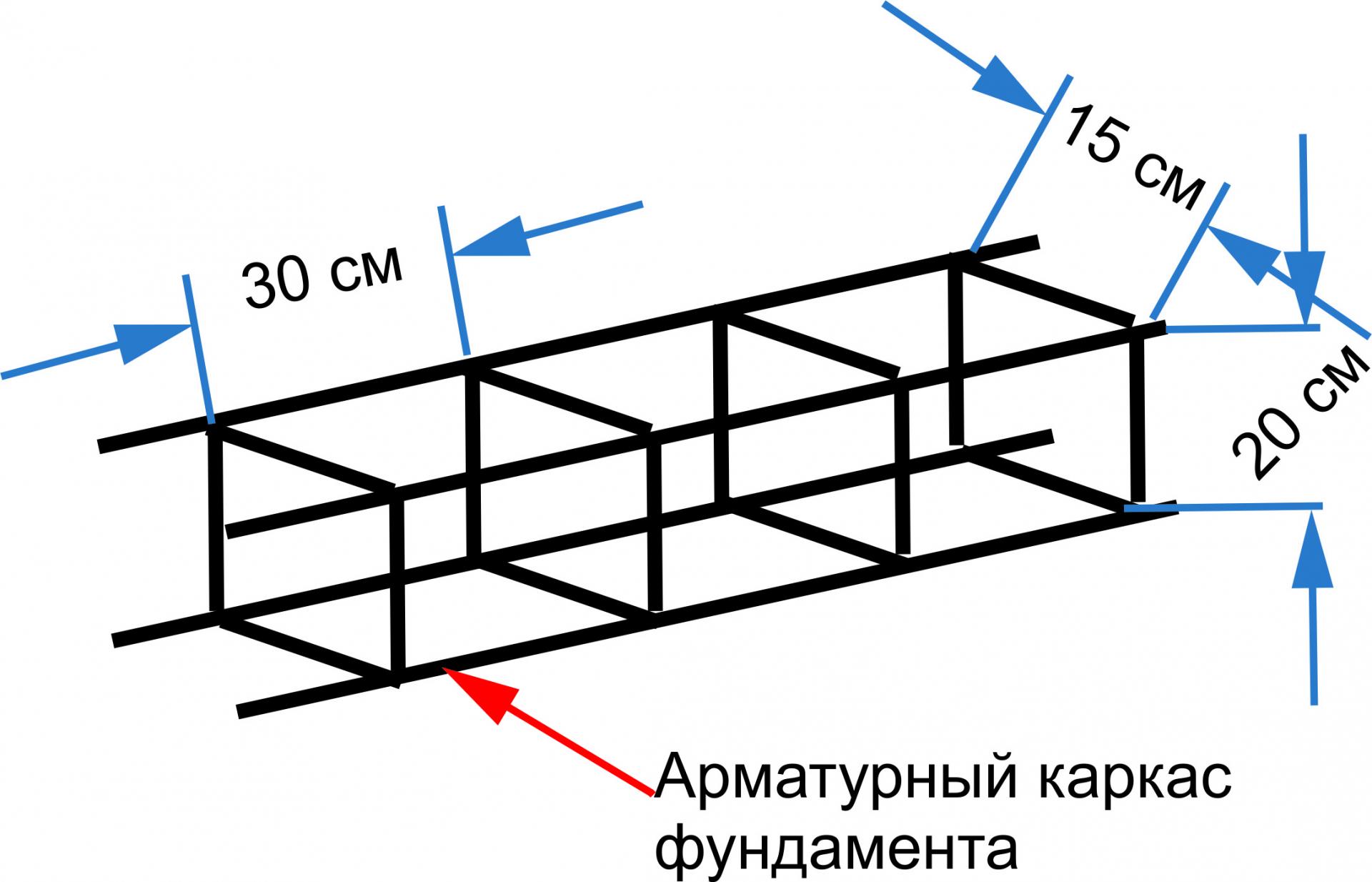

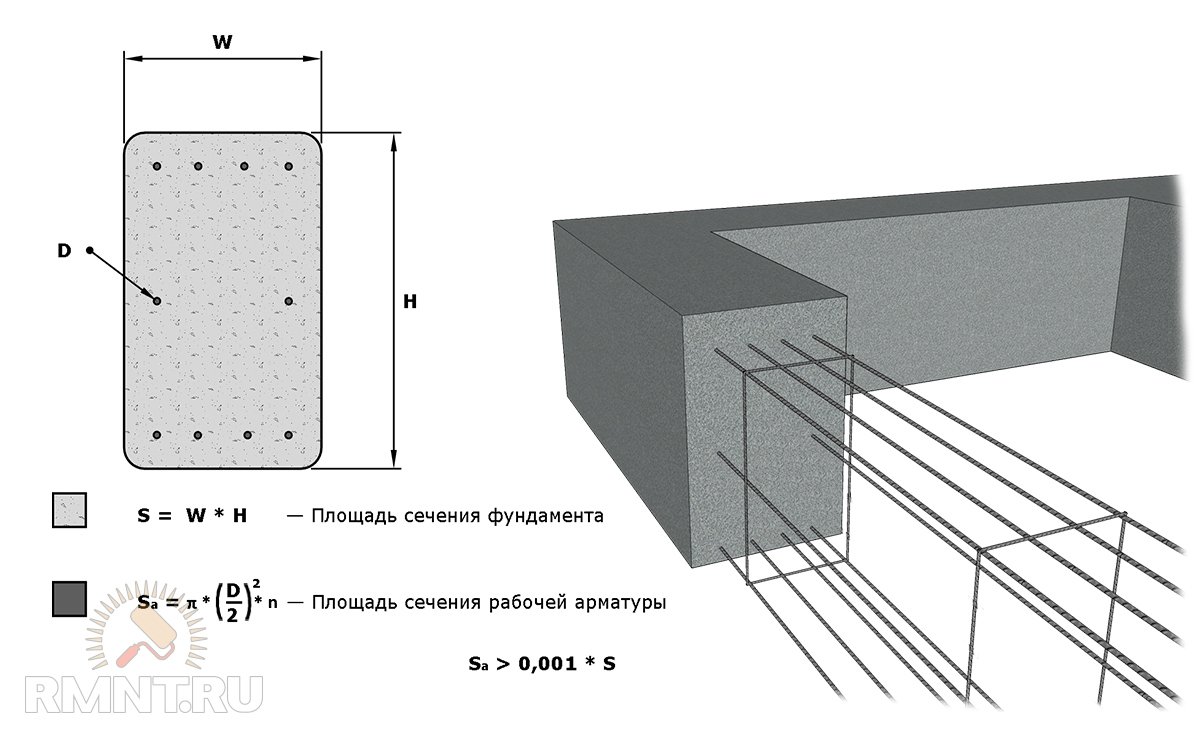

Rebar diameter selection method

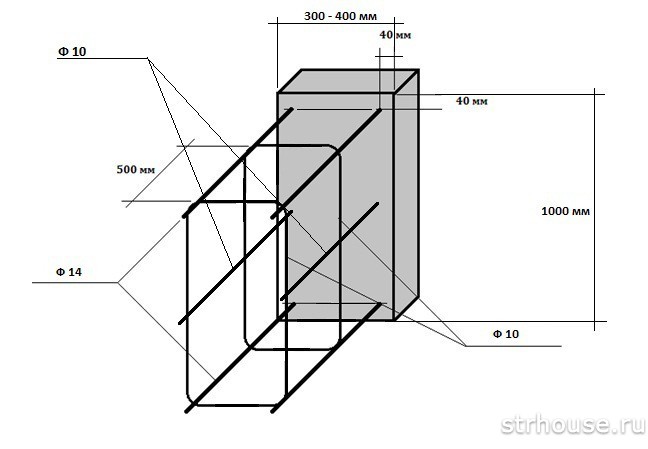

Suppose we have conceived the construction of a strip foundation 300 mm (30 cm) wide and 1000 mm (100 cm) high.

The cross-sectional area of the tape will be: 30 × 100 = 3000 cm2

Multiply this value by 0.001 and obtain the minimum cross-sectional area of rebars: 3000 × 0.001 = 3 cm2

From the table above, we see that this value corresponds to 6 rods with a diameter of 8 mm or 4 - with a diameter of 10 mm. Those. strip foundation reinforcement is laid in two belts, either 3 rods in each, or 2. Taking into account the difference in the price of reinforcement, the choice becomes obvious - it is more economical to accept 4 rods with a diameter of 10 mm for installation. However, if the length of each side of the foundation exceeds 3 meters, then the minimum value of the diameter (referred to in the design manual "Reinforcement of elements of monolithic reinforced concrete buildings") will be 12 mm. Therefore, here it is already necessary to look at a specific example. If, with the above parameters of the foundation, the length of the tape exceeds 3 m, then we can safely use 12 mm rods.

For a slab foundation, the operating procedure is similar, only in this case it is necessary to take into account not only the transverse, but also the longitudinal section of the foundation (it is necessary to focus on the latter). Suppose we need to reinforce a slab of 6000 x 8000 x 300 mm (600 x 800 x 30 cm).

Longitudinal sectional area: 800 × 30 = 24000 cm2

Calculated cross-sectional value of reinforcement: 24000 × 0.001 = 24 cm2

The number of rods installed with a step of 20 cm (optimal mesh sizes that make it convenient to pour concrete for the foundation and ensure the full operation of reinforced concrete) in two grids: 2 × 800/20 = 80 pcs.

We multiply the values for 10 rods in the table column by 8 and choose an option that slightly exceeds 24 cm2.

We see that the closest use is 80 pcs. fittings with a diameter of 8 mm. Because the size of the side exceeds 3 m, then we take d = 12 mm for the installation.

Reinforcement thickness and its functional purpose

In the table below, we have presented the types of reinforcement by its diameter, functional purpose and application in individual construction. As a rule, elements with a diameter of 6-8 mm are used as mounting elements. Anything more - rebars with a periodic profile, which are already working in bending.

As you can see, the type of reinforcement selected in terms of thickness does not depend on what proportions of concrete for the foundation we use and other parameters.

| Rebar diameter, mm | Profile | Appointment |

|---|---|---|

| 6 | smooth | mounting / for forming clamps |

| 8 | assembly / can be used as reinforcing elements of bored piles | |

| 10 | periodic (grooved, ribbed) | working / used for small buildings, taking into account soil parameters |

| 12 | working / the most common options for construction tape or slab reinforced concrete base | |

| 14 | ||

| 16 | working / used for large houses on difficult ground |

Features of reinforcement of various types of foundations

Depending on the design load, relief and geological features of the area where construction work will be carried out, various types of foundations are equipped. The most common are the following concrete bases:

- tape type;

- in the form of a monolithic slab;

- on support piles.

The tape-type foundation is used in the construction of houses with basements; it can withstand the weight of buildings made of concrete and brick well.

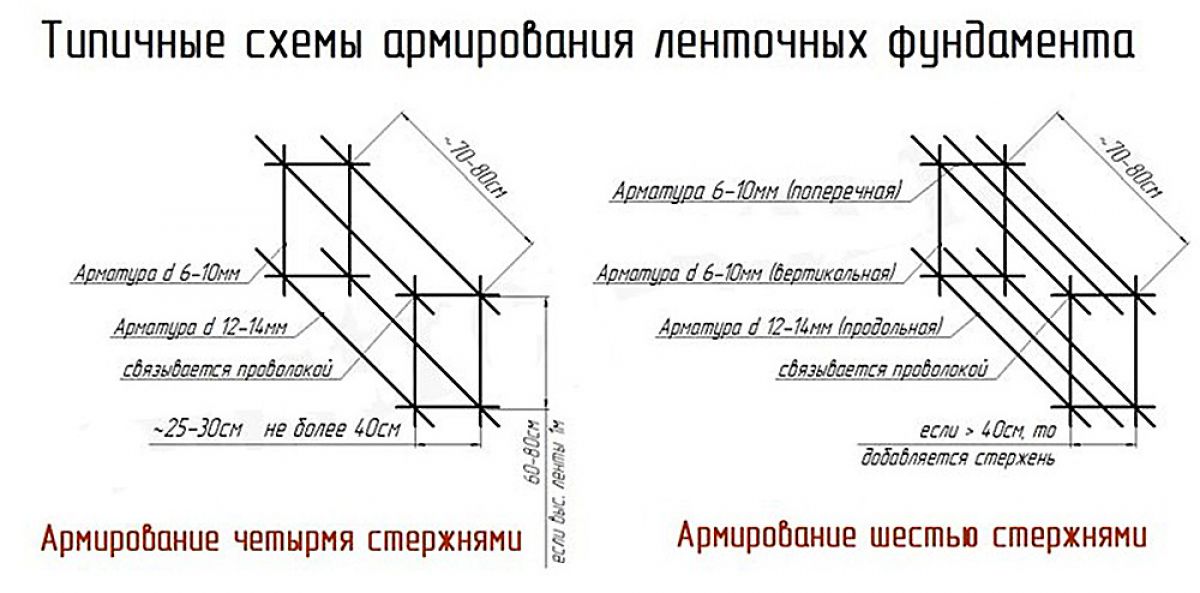

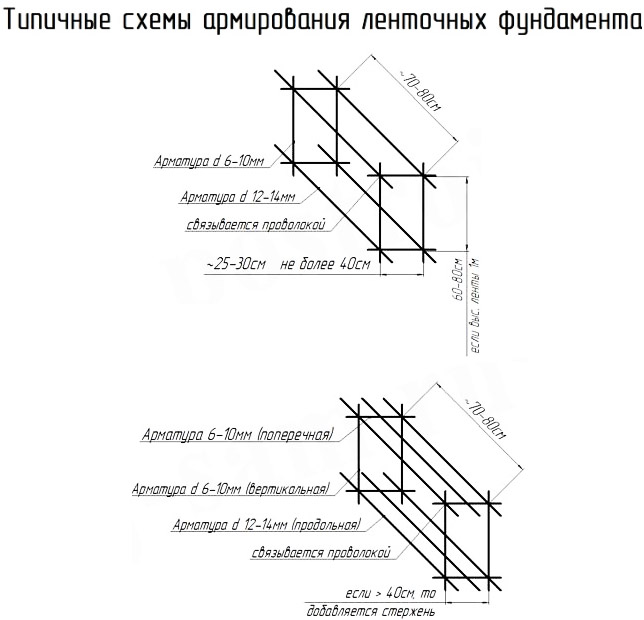

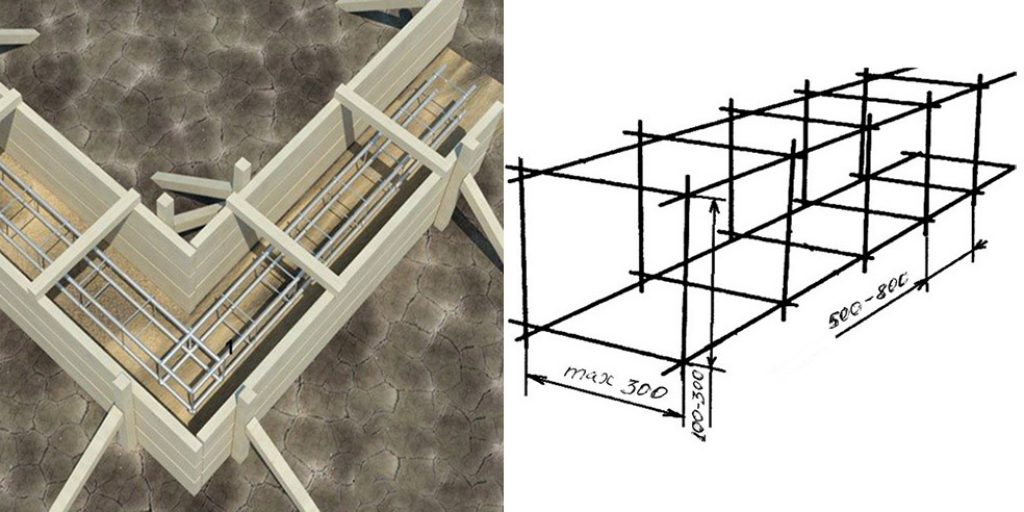

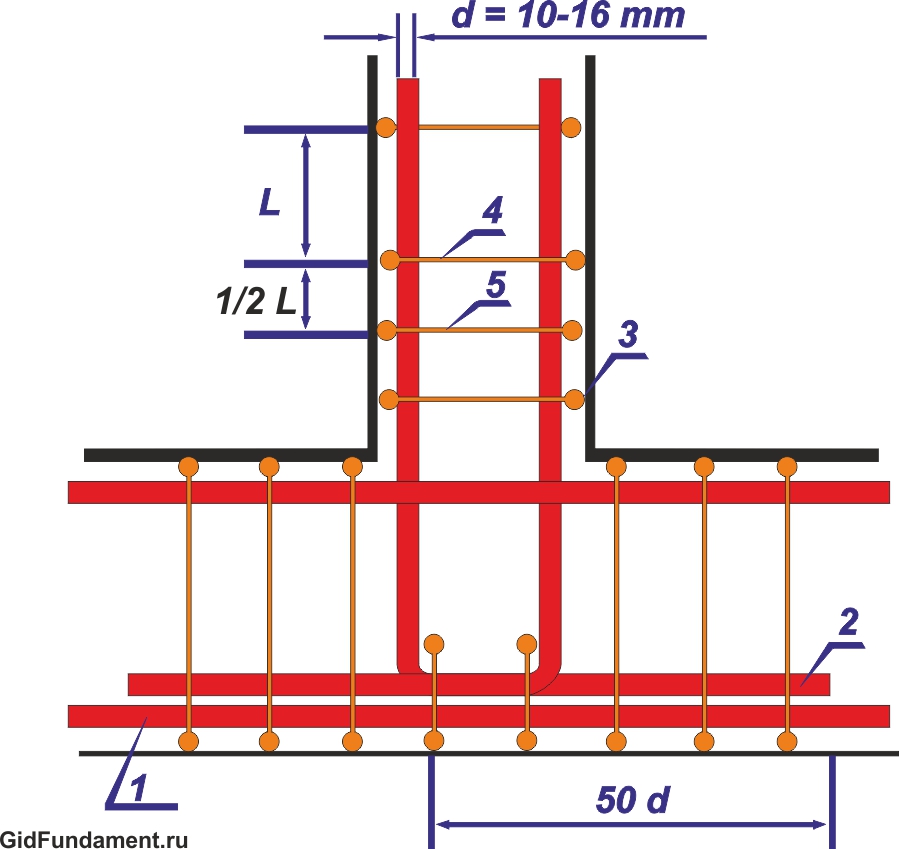

The main load on a foundation of this type is in the longitudinal direction, therefore, two reinforcement belts are performed horizontally.

The slab foundation is a solid concrete slab underneath the constructed building. It settles on unstable soils and can be used in multi-storey construction. Reinforcement of such a base is carried out in the form of a mesh.

The foundation on support piles is used in the construction of frame-panel houses and one-story, lightly loaded objects. The cost of its arrangement is less than that of other types of foundations. Pile supports are buried in the ground by drilling. Here, the main load falls on the vertically located reinforcing rods.

The best reinforcement for strip foundations

For the base in the form of a concrete strip, reinforcing bars of class A 300, A 400, A 800, A 1000 are used. The class of reinforcement is determined by a set of characteristics and the technology of material production. The surface profile of these rods is a fluted pigtail. Thanks to this, the products adhere firmly to the concrete base. They are used for longitudinal strapping in which the rods are laid along the direction of the concrete band.

At least two horizontally located reinforcement levels are created, which bear the main load of the building structure. The higher the mass of the building being erected, the larger the reinforcement section should be.

The smallest diameter of the power rods is 10 mm.

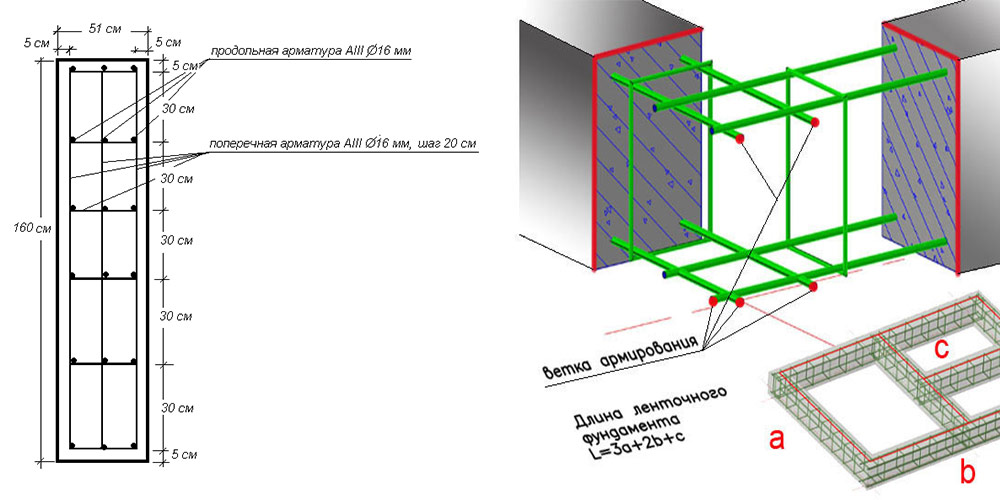

The reinforcement grid must be completely in the mass of the concrete base, the distance to its edges is not less than 5 cm... It is not necessary to increase this distance, as this will reduce the overall cross-section of the reinforcing lattice and its bearing capacity. In this case, the lattice plays the role of a metal beam that strengthens the resistance of the concrete tape to bending loads.

Reinforcement in a concrete base plate

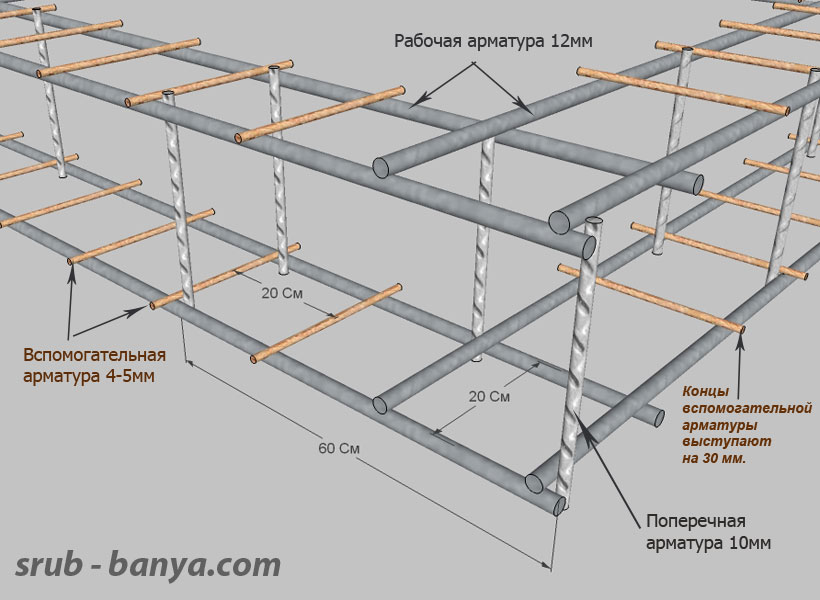

Arrangement of the foundation in the form of a solid concrete slab requires a large consumption of building materials, including reinforcement. The slab foundation is capable of withstanding heavy loads; ribbed reinforcement with a diameter of 10 to 16 mm is used for it. The rods are laid in a horizontal plane, forming a lattice with a cell of 200 * 200 mm.

With a slab thickness less than 15 centimeters, one belt is used, if the concrete base is thicker, at least two layers of reinforcement are performed. The cost of purchasing reinforcement for this type of foundation is about 20% of the cost of works on its arrangement. The construction of a slab foundation requires large material costs, but it is very reliable and has a long service life.

Reinforcement of the pile foundation

The pile foundation consists of supports buried in the ground, poured with concrete. In the vertical direction, the piles are reinforced with ribbed rods having a diameter of ten millimeters.

The horizontally arranged smooth rods with a diameter of 4 mm are not subjected to stress and are used as knitting material to form a single frame. Depending on the cross-section of the pile, from two to four vertically arranged rods are used, the length of which should correspond to the length of the post, slightly exceeding it.

We hope that the information presented will help you to correctly determine the choice of the frame for the foundation. The following is a video with useful information on the selection of fittings.

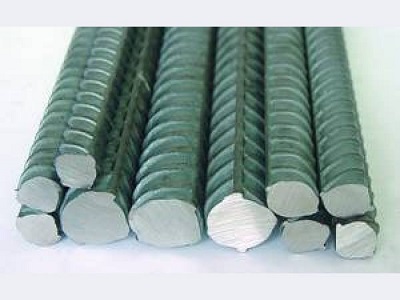

Main types of fittings

There are two main foundation fittings:

- metal (steel);

- fiberglass (composite).

To perform such work as reinforcing foundations, experts recommend using steel rods with a round cross-section. It is better to choose modifications with a ribbed helical surface. Why this particular option is preferable, we will try to find out.

Recently, the reinforcement of the foundation is often carried out using fiberglass reinforcement. According to manufacturers, its density exceeds that of metal rods. Practice, however, clearly demonstrates that fiberglass reinforcement for the foundation is not inferior to metal in terms of quality characteristics. These types are not yet equally applied in the field of construction. So far, preference is given to the option made of steel.But there is every reason to believe that the situation may change in the foreseeable future.

Recently, the reinforcement of the foundation is often carried out using fiberglass reinforcement. According to manufacturers, its density exceeds that of metal rods. Practice, however, clearly demonstrates that fiberglass reinforcement for the foundation is not inferior to metal in terms of quality characteristics. These types are not yet equally applied in the field of construction. So far, preference is given to the option made of steel.But there is every reason to believe that the situation may change in the foreseeable future.

Calculation of working reinforcement

When erecting serious structures, detailed calculations of the strip foundation are required, which will accurately determine which reinforcement to use for a given structure. All calculations in construction are carried out according to limiting states, that is, the minimum conditions are determined in which the element will perform its function.

- The first group of limiting states is strength analysis. Reliability and safe operation of the structure is ensured.

- The second group of limiting states is stiffness calculation. Prevents excessive crack opening, distortions, large deflections.

Calculations using these formulas are laborious and require technical education. To simplify the design of small private buildings, the strip foundation reinforcement is taken based on the minimum values.

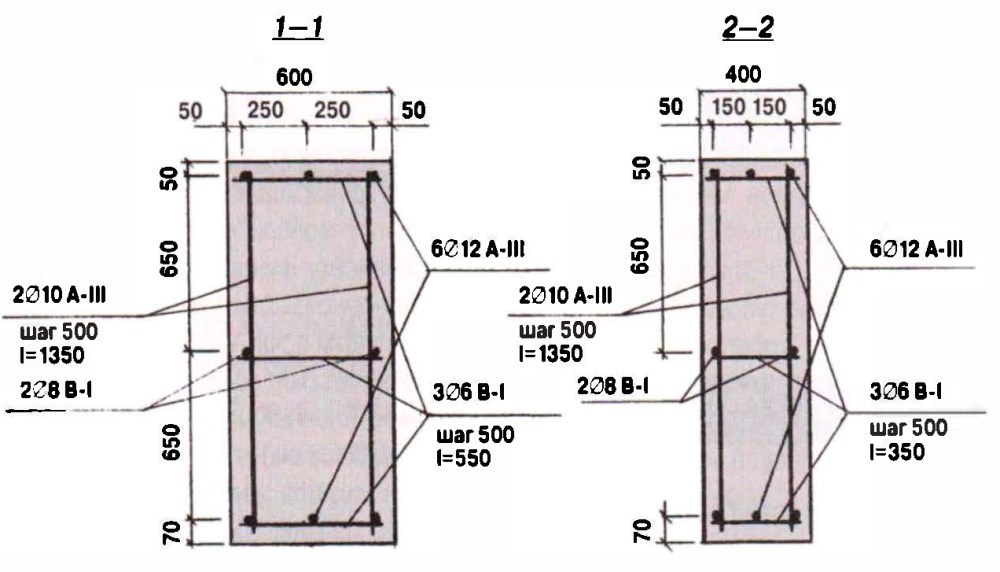

An example of calculating bars for a strip foundation

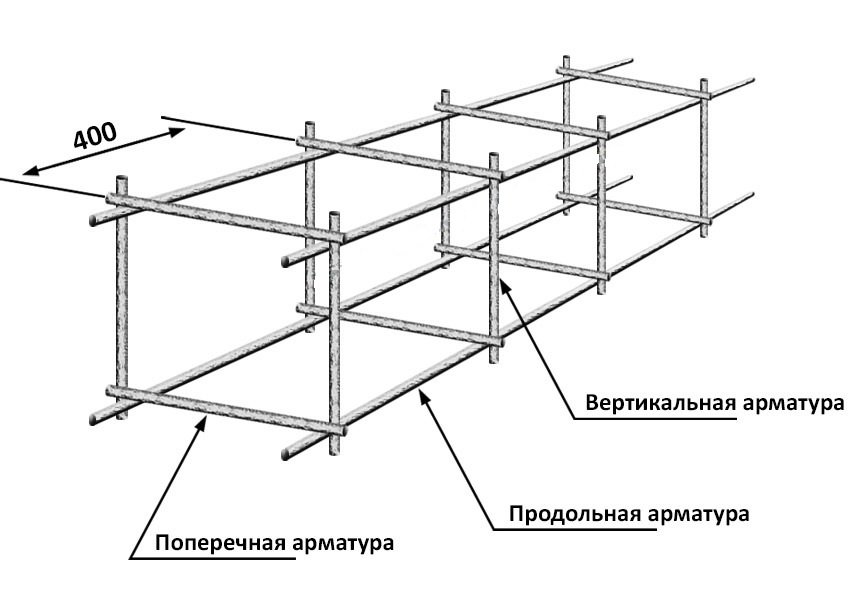

Initial data:

- belt height - 100 cm;

- tape width - 40 cm.

It is required to design a frame for an individual residential building. Longitudinal, transverse and vertical reinforcement is used. The vertical one is taken with a cross-section of 8 mm and is installed with a step of 25 cm. The transverse horizontal is mounted with the same step, but with a diameter of 6 mm.

In order to determine which working armature is needed, a simple calculation is performed

- Cross-sectional area of the foundation = width * height = 100 cm * 40 cm = 4000 cm².

- Required cross-sectional area of reinforcement bars = 0.1% * 4000 cm² = 4 cm².

Further, to determine which reinforcement to use, you need to refer to the assortment. The number of rods is taken to be even in order to evenly distribute them in the lower and upper horizontal layers.

| Rebar diameter, mm | Total calculated cross-sectional area of reinforcing bars, cm2 | Weight of 1 meter of reinforcement, kg | ||||

| 2 rods | 4 rods | 6 rods | 8 rods | 10 rods | ||

| 8 | applies only with a foundation height of 15 cm or less, which is not suitable for tape structures | 2,01 | 3,02 | 4,02 | 5,03 | 0,395 |

| 10 | 3,14 | 4,71 | 6,28 | 7,85 | 0,617 | |

| 12 | 4,52 | 6,79 | 9,05 | 11,31 | 0,888 | |

| 14 | 6,16 | 9,23 | 12,37 | 15,39 | 1,21 | |

| 16 | 8,04 | 12,06 | 16,08 | 20,11 | 1,58 | |

| 18 | 10,18 | 15,27 | 20,36 | 25,45 | 2,0 | |

| 20 | 12,56 | 18,85 | 25,13 | 31,42 | 2,47 |

For this strip foundation, the minimum diameter is 12 mm according to the document “Reinforcement of elements of monolithic reinforced concrete buildings. Design Guide ", and we accept it. According to the assortment, 4 rods are required: 2 are located at the bottom and 2 at the top.

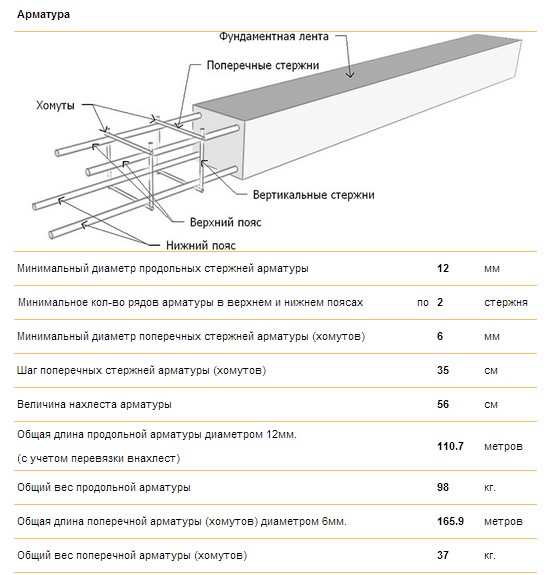

Calculation of the number of reinforcement per foundation

Initial data:

- the materials are indicated in the previous paragraph;

- the length of the walls of the strip foundation - 40 m.

It is required to calculate the mass of reinforcement of all diameters for a strip foundation.

- Length: perimeter of the building * number of rods in the section + margin for overlap when welding rods = 40 * 6 + 5 = 245 m.

- Anchorage of corners: number of bars in the section * number of corners * minimum anchorage length (50 reinforcement diameters) = 6 * 4 * (50 * 12) = 14.4 m.

- Mass: length * mass of one meter = (245 + 14.4) * 0.617 = 230.3 kg of rods with a diameter of 12 mm.

Constructive horizontal reinforcement

The length of the rods is taken depending on the width of the tape wall minus the protective layer of concrete - 2-3 cm on each side. We accept longitudinal rods 34 cm.

- Number of rods: building perimeter / stirrup pitch (in the previous paragraph it was assumed 25 cm) = 40 / 0.25 = 160 pcs.

- Total length: quantity * length of one rod = 160 * 0.34 = 54.4 m.

- Weight: 54.4 * 0.222 (not indicated in the table above, but available in the full range) = 12.1 kg of rods with a diameter of 6 mm.

Structural vertical reinforcement

Everything is as in the previous paragraph, the rods are set with a length equal to:

The height of the strip foundation minus 3 cm * 2 = 100 - 3 * 2 = 94 cm.

- Number of rods: perimeter of the building / step of the clamps (in the previous paragraph it was assumed 25 cm) = 40 / 0.25 = 160 pcs.

- Total length: number * length of one rod = 160 * 0.94 = 150.4 m.

- Weight: 150.4 * 0.395 = 59.41 kg of rods with a diameter of 8 mm.

For convenience, the figures obtained can be summarized in a table.

| Appointment | Diameter | total weight |

| Working | 12 mm | 230.3 kg |

| Transverse | 6 mm | 12.1 kg |

| Vertical | 8 mm | 59.41 kg |

We recommend reading:

Calculation of the diameter of the reinforcement takes no more than 10 minutes, but it will avoid overspending of material or the cost of repairing strip foundations. The table obtained in the last paragraph is convenient to use when purchasing material.

Good publicity

Things to consider when buying

Regulated material requirements are given in clause 6.2 of the joint venture “Concrete and reinforced concrete structures. Basic Provisions ". For ease of purchase, it is recommended to calculate in advance the amount of material of each diameter, taking into account the stock for unforeseen expenses (3-5%). The calculation results can be summarized in a statement, which will indicate the diameter, total length and mass of the bars.

When buying, you should pay attention to the following points:

Correspondence of the material to the required class. The rods of the A400 class have a periodic profile with a crescent pattern (“herringbone”), which makes it easy to distinguish them from the rods A240 and A300.

Compliance with the required diameter. Can be measured by yourself using a ruler or caliper.

The seller has all the necessary documents confirming the quality. These include a certificate of conformity, passport, sanitary and epidemiological conclusion

If they refuse to submit these documents, problems may arise with the quality of the material.

It is important to pay attention to the diameter, class, steel grade and manufacturer indicated in the passport or certificate.

Visual inspection. According to the above joint venture, the reinforcement must be marked, on its surface there can be no mechanical damage, pollution, damage by corrosion (peeling rust), plastic deformations are unacceptable.

Summarizing, we can say that it is necessary to pay attention to the following points when buying, to prevent problems during the operation of the foundation:

- class and diameter of rods;

- steel grade;

- availability of a passport and the necessary certificates for the material;

- no external damage to the rods.

We recommend: Do-it-yourself strip foundation step by step.

Good publicity

Reinforcement requirements

To understand what kind of reinforcement is needed for a strip foundation, it is necessary to perform calculations and consider the main types of material. To perform the work, mechanically hardened, hot-rolled construction heat treated reinforcement... The class is chosen according to the maximum loads, taking into account the tensile characteristics, ductility, weldability, corrosion resistance, the ability to withstand temperature differences, etc.

The main brands of rods: hot-rolled rod (A), cold-deformed wire (Bp), very strong rope (K). For the frameworks of the foundation, rods of class A400 (AIII) yield strength with a crescent herringbone pattern are selected.

Correct reinforcement involves the use of these types of rods:

- Workers - for perimeter stacking

- Transverse vertical

- Cross horizontal (clamps)

- Additional - usually used instead of knitting wire

To understand which fittings are best to use, you need to remember some rules. To strengthen the base of one-, two-story buildings and light structures, rods with a diameter of 10-24 millimeters are suitable. The strength characteristics of thicker (and much more expensive) reinforcement are unlikely to be used.

The rods must be grooved, as they provide excellent adhesion to the concrete mortar, their thickness must clearly correspond to the values specified in the documents. Smooth rods are cheaper, but they will not allow you to create a reliable and durable reinforcing cage. They can be used only in transverse joints, where a not very large load is noted.

When creating a strip foundation frame on a homogeneous soil, you can choose a material with a diameter of 10-14 millimeters, on a heterogeneous one - 16-24 is better.If the side of the building is more than 3 meters, the working reinforcement of the monolithic foundation is made from rods of at least 12 millimeters, but not more than 40.

The technology requires that horizontal clamps in diameter are not less than a quarter of the working rods - they usually take 6 millimeters. Vertical rods for low-cut foundations of 80 centimeters or less should be at least 6 millimeters in cross section. Having thought everything over, you can determine what diameter of the rods is needed for different types of work.

Connection methods

You can assemble the reinforcement into a single frame using two methods:

- welding;

- knitting.

If plastic fittings are used, then no welding is involved. However, metal fittings are also rarely welded, since the welding points become weak points in the structure, they can withstand less stress, and are more susceptible to corrosion. Welding provides too rigid adhesion of the rods, eliminating even the slightest backlash. Such a structure perceives deformation worse, and cannot be used when working on moving soils. Moreover, you can cook only those fittings in the marking of which there is the letter C.

It is much more practical to use wire knitting. It is folded in half, the free end is crocheted into the resulting loop, and then twisted so that the connected rods cannot move freely. Simple, cheap, reliable, but long - an experienced builder will be able to complete up to 20 connections per minute, and a beginner - no more than 5-6.

You can simplify the knitting process with a special knitting gun. It is leaned against the intersection of the steel rods, the trigger is pulled - and the connection is ready. Up to 40-50 such operations can be performed per minute. The downside is the high cost of equipment and the need to use expensive wire.

Finally, we note that when buying, in addition to the diameter, class and type of surface, it is worth paying attention to the availability of the appropriate documentation for the product (first of all, this is a certificate of conformity). The final touch - visual inspection

If you notice traces of rust, scratches and other mechanical damage on the fittings, then it is better to abandon the purchase and find really high-quality products - without exaggeration, the whole house will hold on to them.

Reinforcement types by purpose

Depending on the purpose, the reinforcement is divided into three types for any foundation. Some design types may not use all of them. The division into types is presented in a variety of regulations governing the design of the foundations of a house, for example, JV "Concrete and Reinforced Concrete Structures".

By location and purpose, there are:

- Working reinforcement. The location depends on the type of foundation. For strip foundations, reinforcement is represented by longitudinal rods, which are laid in one or two rows at the top and bottom of the strip. For slab foundations, the working reinforcement is meshes or rods located in both directions. The number of rows of bars or meshes is influenced by the thickness of the foundation. If it is 150 mm or less, then the rods are laid in one row; with a higher structure height, at least two rows of working reinforcement must be used.

- Transverse reinforcement. They are horizontal clamps that ensure the joint operation of individual working rods. This type of rods should be used when building a strip foundation for a house. Not required when pouring monolithic slabs.

- Vertical reinforcement. Clamps located between two rows of fittings and ensure their joint work. Not required for a structure thickness of 150 mm or less.

It is best to draw a sketch or reinforcement scheme in advance, assign diameter, pitch and number of rods for each type.

Purchase of material

Quite rarely, rebar is sold in running meters. Usually, rebar sellers consider it in kilograms.In order to accurately determine the required amount, a calculation table is needed. Enterprises producing rolled metal products must use and comply with GOST 5781-82. It indicates the mass per meter of the product. There is also GOST 2590-88, which determines the weight of steel round products. I would like to clarify that the numbers in both documents are the same. Which one should you prefer? Everything will depend on the ease of use of this reference literature.

Build rules

The parameters of the frame for the strip foundation are determined, you can proceed to the installation processes. First of all, you need to cut the reinforcement into elements along the length. With vertical and transverse it is clear. In our example, this will be:

- vertical 90 cm;

- transverse 40 cm.

The amount is calculated taking into account the total length of the trenches. For example, the length of the dug trenches under the walls is 100 m, this figure must be divided by the step of laying the reinforcement. If it is 20 cm, then 100 / 0.2 = 500 pieces of both types.

As for the longitudinal rods, the parameter of the length of one rod is taken as a basis. It is equal to 11.7 m, taking into account the knitting overlap, a value of 10 m is applied. Therefore, in one row of longitudinal rods: 100/10 = 10 pieces. In the case with a step of 20 cm, rows 5, plus two lattices, it turns out that it will be required to assemble the frame: 10x5x2 = 100 pieces of reinforcing rods 10 m long.

Features of reinforcement for slab foundations

When laying a slab foundation, you cannot do without the use of a reinforcing cage. Most often, such a base is chosen when constructing buildings from structures made of brick and concrete. Reinforcement is carried out in full compliance with applicable building codes. At the same time, what brand of steel rod to choose, and how much is required, the decision should be made by an experienced specialist who should be entrusted with making calculations.

When laying a slab foundation, you cannot do without the use of a reinforcing cage. Most often, such a base is chosen when constructing buildings from structures made of brick and concrete. Reinforcement is carried out in full compliance with applicable building codes. At the same time, what brand of steel rod to choose, and how much is required, the decision should be made by an experienced specialist who should be entrusted with making calculations.

A very important indicator is the diameter of the bar used for reinforcement. For a slab foundation, the cross-section of the reinforcement should under no circumstances be less than one centimeter. The strength of the frame depends on the diameter. Accordingly, the thicker the rod is used, the more pressure it will be able to withstand.

When laying the foundation, it should be understood that it can be influenced by a number of different factors: the characteristics of the soil on the site, the weight of the building, etc. The more severe the operating conditions of the valve, the more serious the requirements are imposed on it. So, on normal, problem-free soil, twigs with a diameter of 1 cm are enough.If the soil is not good enough, it is better to increase this indicator by at least one and a half times.

The step between the rods in the frame for the slab foundation should be about 20 cm. The reinforcement is laid in two layers - the upper and the lower.