Preparatory and primary work

From the pros and cons, we go directly to the work. Before creating a foundation from rubble, it must be rinsed. Here you need to stock up on both time and patience. One can only imagine how long it will take to wash each stone. But without this there is no way, because otherwise the concrete mixture will not bind to the quarry as it should, and this can lead to the destruction of the base.

Stones for the future foundation weighing more than 30 kg also need to be “skirted”, that is, split into smaller parts. This is done like this:

- The split line is marked with a pencil.

- a nylon rope is taken and pressed into a piece of chalk.

- the marked rope stretches over the marked line and drops sharply onto the stone. This leaves a clearly drawn line on the surface.

- A chisel is placed on the line, driven with a hammer using elbow blows. Further, the tool is placed each time at an angle along the mark; it should be hit with shoulder blows.

It is even better if a seam runs over the stone into which a chisel can be inserted. Then the butt splits along the crack. Now we move on to creating the foundation itself. The creation of rubble (like any other) foundations begins with digging a trench or foundation pit (strictly according to a correctly created plan, otherwise efforts, which are already considerable, may be in vain). So that later everything will coincide, you must first make a markup on the surface, and only then do the excavation.

More than one type of base can be created from natural stone. We will tell you how a rubble strip foundation is built, since this design is more popular than the others. Therefore, at this stage, we have been digging a trench. Now you need to create a sand cushion at the bottom. Sand filling is carried out in layers, each layer is carefully compacted.

Let's not forget to mention the solution. To do this, you need to take fresh cement M - 500 and three times more sand. The consistency should resemble sour cream - then the solution penetrates well into the seams.

Cooking rules

A strip foundation of rubble concrete type has many advantages:

- High strength.

- The ability to withstand structures of 2 floors with a wall thickness equal to two bricks.

- Application of publicly available materials.

- Low cost of all work.

- Ease of the manufacturing process.

Formwork foundations for columns: a - rectangular, b - stepped; 1 - stop bar, 2 - cover board, 3 - spacer, 4 - mortgage board, 5 - wire tie, 6 - mounting nail, 7 - stakes.

But in order to appreciate all the positive aspects of using such a foundation, it is necessary that all its components are selected correctly and of high quality. In addition, certain proportions must be observed. In particular, this foundation should be about half of rubble stones and half of concrete. The number of stones can be reduced to 40% of the total. There is no need to increase their number too much.

The quality of stones and concrete mortar is also of great importance. For a concrete foundation, it is better to take a rubble stone, the length of which is approximately 30 cm and the width is 20 cm

The width of the boot should be about 1/3. The stones should not be dirty, as this prevents them from adhering well to the concrete mixture. It is better to moisten cobblestones before use, as this will facilitate adhesion and prevent moisture loss from the solution

For a concrete foundation, it is better to take a rubble stone, the length of which is approximately 30 cm, and the width is 20 cm. The width of the buta should be about 1/3. The stones should not be dirty, as this prevents them from adhering well to the concrete mixture.It is better to moisten the cobblestones before use, as this will facilitate adhesion and prevent moisture loss from the solution.

There are no special requirements for the shape of the stones. They only need to be approximately the same size and not have cracks on their surface.

The scheme of the blind area for the foundation.

It is quite simple to check the strength of a rubble stone: just hit it with a hammer. If the rubble cobblestone is of good quality, then it will not crack or crumble, but will make a clear and clear sound.

So, it is better to take cement of the M-400 or M-500 brand, so that a heavy mixture is obtained. The size of crushed stone should not exceed 30 mm. Normal sand will do. The proportions of the mixture are standard - 1: 3.

Water is added until a dense, but liquid mixture is obtained. Its viscosity should be less compared to the classic solution, because it will need to fill all the gaps between the stones so that voids do not form.

Stock of width and structure of the base made of rubble concrete

The width of the foundation should be 8 - 10 cm larger than that required to support the walls of the garage, since the stone is not laid directly to the edges, therefore the voids on the sides are about 3 - 4 cm.This condition is determined due to the fact that all stones have different sizes and shapes.

Rubble foundation construction.

From the characteristics of the cobblestones that must be used, it turns out that the strip foundation of the rubble concrete type should have a width of at least 35 cm.

When building garages, a bookmark is usually made. The base must have an optimal shape and support all load-bearing elements of the structure. If we compare this type of foundation with a solid or lattice, then the savings become obvious, of course, if the foundation is not laid on complex soil, where it is more practical to use not this type of foundation.

If it is planned to build a heavier structure, then it is better to lay the rubble concrete strip foundation on an expanded base. It is it that will become the support, since it will increase the area that is in contact with the ground. The side indent should be at least 30 cm.

In order for it to be possible to lay a concrete strip foundation on the site, the soil should not have a dense structure and sag.

Rubble concrete foundations can be laid only in low-rise construction, otherwise it will not be possible to save money.

How to make a rubble or rubble concrete foundation?

In this case, as a rule, columnar foundations are used for the construction of light structures from a bar, rounded logs or frame-type buildings. If you are planning to build a bathhouse made of wood, then columnar foundations are a good choice.

If your site is dominated by heaving soils, formed by moist silty sands with interlayers of silt, clay soils prone to frost heaving, then the construction of a strip foundation, including a shallow one, may be a good choice.

How to make a rubble foundation with your own hands?

Whatever type of foundation you choose, depending on the soil conditions and the weight of the building being built, they can be made from various materials.

Today, foundations made of reinforced concrete blocks, monolithic foundations poured into the formwork with a reinforcing cage installed in it, brick foundations, as well as columnar foundations made of pretreated wooden posts are widely used.

In soft soils, a foundation of rubble stone or rubble concrete foundations is often erected.

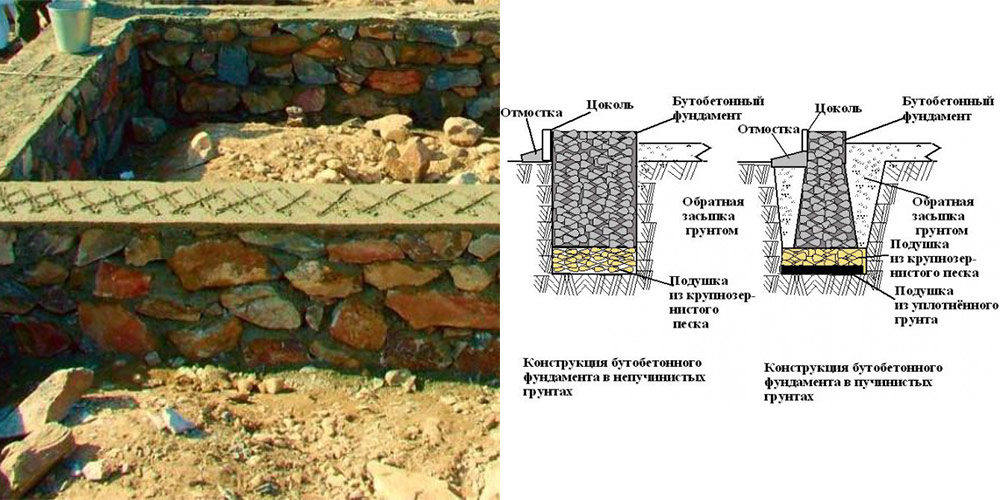

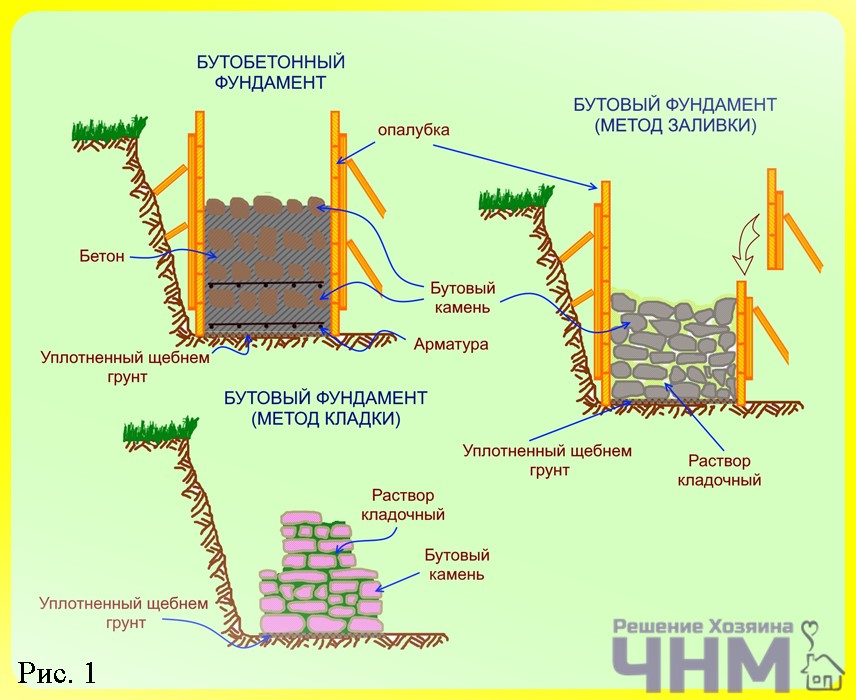

Rubble foundations are made of large stones laid on well-compacted soil of the base. Depending on the soil, the rubble foundation can be erected both in formwork and directly in a trench with sheer walls.

The stones are laid in rows, alternating with layers of pebbles or gravel, compacted with a rammer and poured with cement mortar.filling the voids in the masonry.

The thickness of each row is 15-20 cm. The mortar used for rubble foundations should be prepared in the following proportion: for 1 part of cement, 3 parts of sand. The amount of stone in the masonry should be approximately equal to the amount of mortar. Cement is best to prefer the M400 or M500 brands.

Before starting the construction of the rubble foundation, you should select a sufficient number of stones of the required size, clean them from dirt and dust. For laying the lower rows, it is advisable to choose flat oblong stones up to 20-30 cm long.

Construction of rubble concrete foundation

A concrete foundation differs from rubble in that it is made from the same mortar from which concrete is made. But instead of crushed stone, brick battle, rubble stone, half-timber brick are added to the mixture.

The rubble concrete foundation is also laid in layers - first a layer of mortar with a thickness of 10 cm, then a layer of filler with a thickness of 15-20 cm, etc.

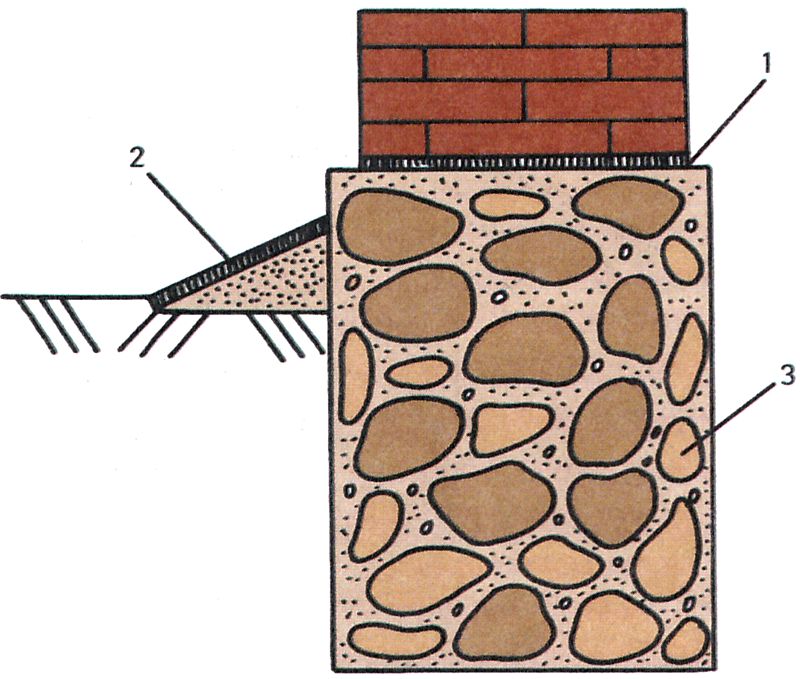

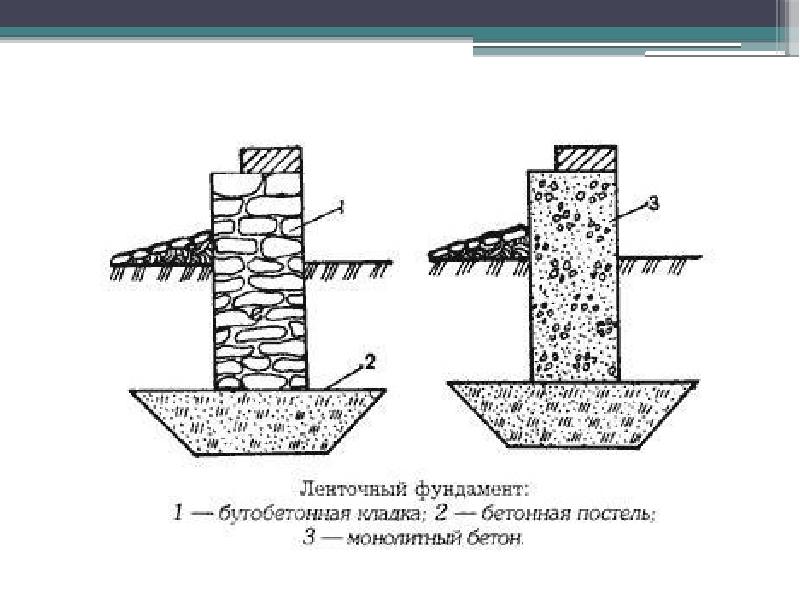

A diagram of the construction of a concrete foundation for brick walls is shown in the figure below:

As you can see, there is a sand cushion for the foundation. allowing more evenly redistribute the loads from the structure to the base soils.

Features of the construction of rubble foundation

Part of the rubble foundation that rises above the earth's surface is recommended to be performed simultaneously with brick cladding.

Fastening of the brick cladding with the above-ground part of the foundation is carried out by laying a bonded row of bricks, embedded on a half-brick in rubble masonry, every 4-6 spoon rows.

The numbers indicate: 1 - insulation, 2 - rubble stone, 3 - brickwork.

If during the construction of rubble foundations it is planned to stop work for more than a day, then to protect the already built part of the foundation from drying out in hot weather, the already built part of the foundation should be spilled with water at least 3-4 times a day, covered with glassine or a film that prevents the solution from drying out.

As you can see, there are no special difficulties in the construction of rubble and rubble concrete foundations, and if you have all the necessary materials, you can always build such a foundation with your own hands.

Furnaces of the Novosibirsk company Termofor have been in increasing demand lately, and this is no coincidence. The Termofor stoves have gained popularity among customers due to their reliability in operation and affordable prices. Today the company is producing a new line of Read.

One of the most popular types of doors is a door with a panel. Due to the simplicity of the design and beautiful appearance, this type of door is often chosen as interior and entrance doors. They are made of various materials, so it will not be read.

Despite the fact that each bath has windows, there is not always enough light that penetrates through them to comfortably steam and wash. Especially if you decide to go to the bathhouse in the evening or in cloudy weather. Therefore, often in Read.

We make a step-by-step laying of rubble concrete foundation

A concrete foundation can be made with your own hands. As a starting point, you must have a carefully designed project, prepared materials and tools, and a minimum experience in building foundations for houses.

Work begins with the preparation of a concrete solution.

Manufacturing of rubble concrete foundation

If there is a concrete mixer, then the work is greatly simplified. Otherwise, the mixture will have to be prepared manually, in a special container. Cement and sand are loaded into a mixer in a ratio of 1 to 3. After that, the mixture is thoroughly mixed. Gradually, crushed stone is added to the solution. It is poured so that it is invisible under the layer of mass.

The resulting mixture is still dry, and water is added only after thoroughly mixing all the ingredients.Water is gradually poured in until the mixture turns into a homogeneous mass, which has the required consistency.

When the concrete mix is ready, you can proceed to work on installing the base.

The building spot must be free of debris and other objects that interfere with the work. After that, the staking out of the design position and characteristics of the foundation is carried out. The site is leveled under the established elevation mark and surface slope.

A foundation made of rubble concrete begins with digging a trench. Width, depth and other indicators are preset. The trench is carried out along the entire perimeter of the future building.

The bottom is covered with a pillow of sand and fine crushed stone. Ram. Sprinkle with water.

Waterproofing works are required to ensure the protection of the base from the destructive effects of moisture.

Only after that do they proceed to the assembly and installation of the formwork, which should protrude above the ground by about 25 cm and higher. If the exit is provided significantly above the ground surface, then a rigid formwork should be made from specially prepared shields.

To give the required level of strength, the racks on the formwork are fastened with nails. For structural reliability, the walls are pulled together with additional bridges.

The technology of rubble concrete foundation is not much different from the technology of building a monolithic foundation.

The first layer of concrete mix has a thickness of about 15 cm and is evenly distributed along the entire perimeter of the structure. To prevent the formation of air cavities in the mixture, which is often found with a thick solution, concrete should be pierced with a specially prepared wooden handle, which is sharpened on one side. After that, the solution is left to dry completely and set the set strength. Next, they proceed to pouring the second layer, the thickness of which increases to 25 cm.

While the concrete solution is in a liquid state, prepared rubble stones should be immersed in it. They are placed so that half remains above the surface of the mixture. The average distance between rubble stones is taken as 6 cm.

Air is removed again, stones are immersed again and concrete is poured.

In the last layer of the mixture, the stones are immersed completely - there should be no sharp edges and corners above the surface.

After additional moistening of the base, it is covered with a tarpaulin.

It is necessary to wait for the set time for the foundation to harden and gain strength, after which a leveling screed is performed, up to 15 cm high.

It takes about 28 days for the concrete base to harden, despite the seemingly fast setting of the surface layers. It is necessary to wait for the allotted time to ensure the strength and reliability of the base.

About the material, its advantages and disadvantages

What is this wild stone? In fact, it is an irregularly shaped cobblestone that is the result of the development of dolomite, limestone and sandstone. One such piece can be up to 500 mm in size and weigh up to 50 kg.

Like any material, rubble stone has its pros and cons. Let's start with the benefits:

Environmental friendliness. Impurities are not added to the bottle, as can be done with concrete mix or clay;

Aesthetics

The foundation made of natural rubble stone looks beautiful, which is important for those who build the foundation above the surface;

Low cost price. The same concrete is much more expensive;

The ability to carry out work without the involvement of equipment

For example, for FBS, a winch is minimally required. And concrete is mixed and pumped in by special machines. It is quite possible to create masonry by hand;

Strength. If brick is chosen for light buildings, then the stone can withstand more serious buildings;

No fear of temperature changes. Such a foundation is not destroyed by sudden cold weather or sudden warming;

Durability. A rubble base can stand for a century and a half.

Now let's talk about the disadvantages. There are few of them:

- Carrying out work exclusively by hand. On the one hand, you can create a foundation of stone with your own hands, on the other hand, technology is not an assistant here;

- Time spent. It will take a long time to tinker here;

- The need to prepare a boot, which also takes a lot of time.

The first step is to check the material for defects such as cracks and delamination - they should not be. Next, it is worth striking with a hammer: if you hear a ringing sound, and the same defects did not appear on the stone, it fits. You can also split the bottle, while it should not dust and crumble.

How to make a rubble foundation in the summer and masonry intermittently

Are there possible breaks in the production of rubble masonry?

Breaks in the production of rubble masonry are allowed only after filling the gaps between the stones of the last laid out row with mortar. The solution is used to cover the surfaces of the stones of this row only when the masonry is renewed. In dry, hot and windy weather, the masonry is protected from rapid drying by covering it with shields or roll materials. When erecting rubble concrete foundations, stones and debris from the dismantling of the masonry laid into the concrete mixture must not be contaminated, otherwise they will not have strong adhesion to the concrete. In dry weather, the fragments are poured with water before placing in the concrete mixture. To ensure the solidity of the masonry, work breaks are arranged only after the stones are embedded in the upper layer of the concrete mixture and compaction. During breaks in laying the foundation in dry summer weather, rubble and rubble concrete masonry is moistened 3-4 times a day by sprinkling with water.

What are the conditions for laying foundations in hot weather?

When performing work in summer in hot weather (at an air temperature of 25 ° C above and a relative humidity of the outside air of less than 50%), the following conditions must be observed: the water-removal ratio of solutions prepared on slag and pozzolanic Portland cements must be increased; the water-holding capacity of each of the compositions of the solutions must be installed at the facility at least once per shift, while the value of the indicator must be at least 75% established in laboratory conditions; the delamination value should be no more than 25 cm3 for solutions with a mobility of 10-12 cm and no more than 40 cm3 for solutions with a mobility of 12-14 cm; clay brick must be abundantly wetted with water before being laid in the structure.

What kind of cement can be used at air temperatures above 25 ° C?

When performing concrete work at an air temperature above 25 ° C and a relative humidity of less than 50%, fast-hardening Portland cements should be used, the grade of which should exceed the grade strength of concrete by at least 1.5 times. It is impossible to use pozzolanic Portland cement, slag Portland cement below M400 and alumina cement for concreting above-ground structures, except for the cases provided for by the project. The temperature when concreting structures with a surface modulus of more than 3 should not exceed 30-35 ° C, and for massive structures with a surface modulus of less than 3 should not exceed 20 ° C.

What is rubble stone

Booth, "savage", "wild stone", "rock" - as soon as it is not called at a construction site, in most cases it is quarried, blasting or otherwise crushing rocks.

Rubble stone

The choice of rocks for rubble stone depends on the region of production. They use both metamorphic or igneous and sedimentary rocks, from granites and basalts to marble or chalk.

Granite quarry

The size of the stones does not exceed 500 mm, the weight is 45-50 kg. The shape of the stones depends on the breed of their constituent, and partly on the method of extraction. Lamellar stones are obtained from layered sedimentary rocks, rocks that do not have a pronounced structure give a stone of an arbitrary shape, smooth rounded stone is mined in river beds.

Whether this type of stone is suitable as a material from which a rubble foundation can be made depends on its properties studied in a construction laboratory.

Which rubble stone to choose?

Booth is not a specific type of rock. Rubble stone is a ragged or rounded natural stone in size from more crushed stone to large stones, whose weight can exceed 30 kg.

Natural stone is used in construction of different rocks: light, heavy sedimentary or volcanic.

Frost resistance

Frost resistance of buta is assessed by the number of consecutive freezing cycles, while the stone should not crumble and lose no more than 5% in weight. This parameter simulates the number of cold seasons for a non-destructive buta.

15 or more cycles are allowed.

The quality of the cement mixture (in terms of strength and frost resistance) must correspond to the selected stone

Flakiness

A characteristic that determines the shape of the grains in the stone. There are 5 groups, depending on the content of lamellar grains from 10% (group 1) to 35-50% (group 5).

Flakiness affects strength (group 1 is stronger than others), and somewhat increases the complexity of work with such a stone.

Radioactivity

Rocks can be dangerously radioactive.

In construction, 2 groups of rocks are allowed in terms of radioactivity:

- Up to 370 Bq / kg - allowed for the construction of residential buildings, as well as construction inside settlements;

- Over 370 Bq / kg - not allowed for the construction of residential buildings, as well as construction inside settlements (such material can only be used for industrial structures).

Expert advice

Trying to figure out what a rubble foundation is and how to lay it, it is worth listening to the advice of experienced craftsmen. A few practical recommendations will help you avoid common mistakes and greatly facilitate the whole process.

Things to remember:

- Before starting work, you need to carefully calculate and think over everything, purchase materials - which means that the strip rubble foundation is mounted only when everything is neatly folded at the facility, and does not come from a hardware store.

- Thanks to the arrangement of gentle slopes for the foundation, it will be possible to create a more comfortable working area for pouring it, as this will accelerate the supply of rock and cement mortar to the object.

- If there are steep slopes on the site and this creates some inconvenience, it is worth mounting wooden scaffolding.

- Before filling, you need to calculate and mark in advance the places where it is planned to lay the ventilation system, various communications, so that later everything can be done easier and faster.

- In the lateral parts of the shallow trench, it is necessary to place containers with a cement-sand composition, between them you can make blanks from cobblestones of the desired size.

- It is advisable to sort the booth by fractions in advance - before the work begins, in the process of studying the type of foundation "rubble foundation" (what is it, how to do it correctly and from what materials). Longitudinal stones with even edges can become the support of the entire foundation and the building, so they must be carefully pressed into the bottom of the trench and in parallel controlled so that the cobblestones do not swing, they were installed along the trench (not across).

It is not difficult to create a rubble foundation for a house with your own hands if you perform the correct calculations and follow the laying technology. The most important thing in the process of making a foundation is to provide it with proper strength, so you should not save money on materials and time when working with a stone. Careful analysis of cobblestones into fractions, selection of only high-quality and capable of creating the correct structure, compliance with all the rules - a guarantee that the foundation will last at least 150 years.

Features and advantages of a foundation made of rubble

The strip base for the house, laid out of rubble, has a number of advantages in comparison with the usual reinforced concrete foundation. The strip base for the house, laid out of rubble, has a number of advantages in comparison with the usual reinforced concrete foundation. Some of the main ones are:

- Reliability and integrity of the entire structure. A house built on a strip-type rubble foundation can last up to 150 years or more.

- Excellent wear resistance of the stone.So, a strip-type base made of rubble is not subject to the effects of winds, wear as a result of natural mechanical influences, resolution under the influence of ultraviolet radiation, etc.

- Low hygroscopicity of buta. As a result, the rubble structure is not able to absorb moisture, which makes such a base even more robust. By comparison, the usual reinforced concrete foundation, even if a vibrator is used when pouring a solution, is a porous structure that is capable of absorbing moisture during the rainy season or melting snow. And this, in turn, negatively affects the integrity of the entire structure.

- Attractive design that does not require additional finishing.

- Comparative savings on building materials, but on condition that the rubble deposits are located in close proximity to the building plot.

- The environmental friendliness of the material is an additional plus when erecting such a base.

What is rubble stone

It is customary to call a rubble stone fragments of natural rocks of specific dimensions and shapes.

Rubble stone is fragments of various natural rocks

They are formed during the manufacture of crushed stone during fractionation. For production, in most cases, sorting and crushing complexes are used. However, quite often the stone is also selected by hand, so the cost of such a stone is very different.

Given the variety of species, rocks and groups of similar stones, it can be used in private and industrial construction, architecture, and landscape design. In addition, rubble stone has excellent characteristics in terms of environmental friendliness.

In order for the foundation of this material to be of high quality and durable, you should choose the right stone.

For the foundation, you can use stones that meet the following criteria:

- The dimensions of the stone should be approximately equal to 20x25 cm. Too large stones will reduce the strength of the foundation, and the use of small stones will increase the consumption of the cement mixture.

- Stone with noticeable cracks can adversely affect the integrity of the surface, especially some time after the start of use.

- Contaminated material does not adhere well to the building mixture, but this nuance can be corrected. To do this, you need to wet the stone immediately before pouring the concrete solution.

- The material used must be checked for strength. This is done with an ordinary hammer. If a stone crumbles during a blow with a tool, this indicates its poor quality. If the stone remains intact and emits a ringing sound upon impact, then the cobblestone is suitable for making a base.

Careful selection of stones improves the waterproofing of the structure and extends the life of the foundation.

Correct column reinforcement

All supports of the columnar foundation must be reinforced for the reliability and strength of the structure

All supports of the columnar foundation must be reinforced for the reliability and strength of the structure. The only exceptions are pillars of circular cross-section, poured into the formwork of metal or asbestos-cement fixed pipes.

All columns are reinforced with steel rods. For longitudinal installation, rods of class AIII with a cross section of 12 to 16 mm are used. For transverse reinforcement, you can use rods with a smooth surface with a cross section of 6-8 mm.

For pillars of circular cross-section, the reinforcement is made of three longitudinal rods with ribs located transversely. Their step should be 15-20 cm. For square supports, the technology for creating a reinforcing frame is the same, with the only difference that four longitudinal rods are used.

Formwork installation

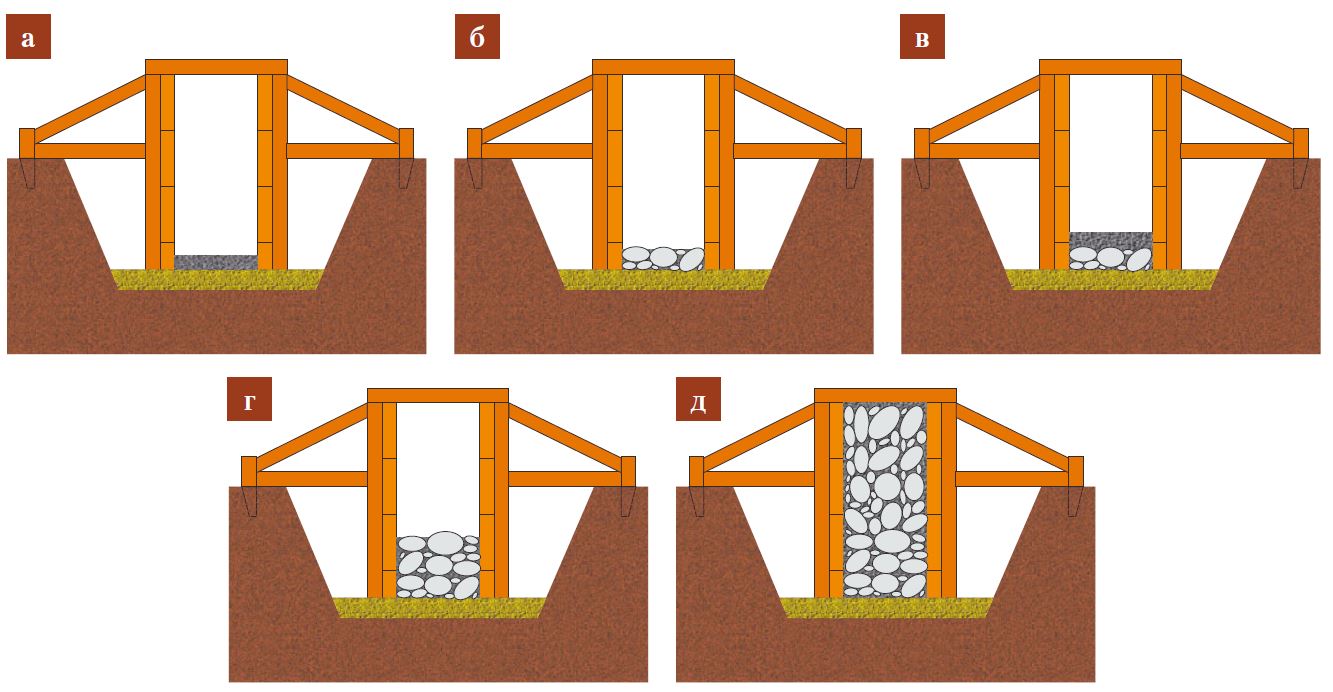

The choice of the mold for pouring, and therefore the installation of the formwork, is primarily influenced by the characteristics of the soil.On solid dry rocky, clay and sandy soils, it is allowed to install traditional formwork with a rectangular section (Fig. A). On moist heaving soils - with a conical section (Fig. B) so that the wider part is at the base. At the same time, the supporting and fixing parts can be installed with a step of 1.5–2 m, since the load on the expansion of the shields during the laying of rubble concrete is much lower than when pouring the monolith.

Regardless of the characteristics of the soil, before installing the formwork, they must arrange a pillow of coarse sand, crushed stone, gravel or pebbles 10-15 cm thick, and an additional layer of dense clay soil is laid on heaving soils.

Before laying the rubble concrete in the formwork, prepare the filler - the rubble - in a ratio to the concrete solution 1: 1. The best are oblong torn stones and rock fragments of arbitrary length and width no more than 1/3 of the width of the foundation. Oval stones are also suitable, but they are not recommended to be laid in the foundation under heavy structures made of brick, stone, blocks or monolithic panels. The strength characteristics of the filler are checked without fail: if the stones crack and crumble when the hammer hits, they cannot be used.

Formwork installation scheme:

- a - on non-porous soils;

- b - on heaving soils,

- where 1 - formwork shield; 2 - a peg; 3 - spacer; 4 - support; 5 - crossbar.

Professional recommendations

With a professional approach to work, you can reduce the time required for pouring the foundation by several times. To do this, there is such an instruction:

Work with buta on the marked area

- The marking of the site is being done.

- Trenches are dug and formwork is installed.

- A little sand is poured into the finished trench and stones are placed there, pressing them into the created "pillow".

- All gaps resulting from laying are covered with crushed stone and tamped.

- A mixture of concrete is prepared (1: 3) and the first row is poured with it to make it more durable.

- Another row is laid out according to the same principle. In this case, do not forget to "bandage" the seams, as when laying brick material.

- The rows that will protrude above the ground are reinforced with wire or embossed reinforcement.

Following these fairly simple guidelines, you can lay out the rubble base much faster. The result is a robust and durable structure that can withstand the heaviest buildings and is built to last.

When can I use

Although it is possible to build such a foundation on a wide variety of soil types, there are certain limitations. First of all, the construction of a small structure that does not have a large bearing capacity is allowed. If you are attracted by this type of technology, then contacting our company, specialists and engineers will make the necessary calculations to see the real value of the expected load.

Fig 1.2: A concrete foundation for a small building is a completely justified decision

When calculating and determining the mass of the foundation, it is extremely important to entrust the work to highly qualified specialists. So, experts from know the technology for the use of reinforced concrete piles in combination with rubble concrete

Plus, the soil should not have a tendency to subsidence, landslides and heaving. Taking this into account, our specialists primarily carry out geological survey and soil analysis. Thanks to this, you can be sure of its reliability, or vice versa.

| Expert advice! The construction of such a foundation is allowed only at positive temperatures. In cold weather, the stone absorbs heat from the solution, which deteriorates its technical characteristics, and the foundation itself becomes less durable. |

In contrast to this, the reinforced concrete pile foundation does not have such restrictions. For this reason, it is widely used in the territory of the Russian Federation.

See also

Brick house foundation

Foundation for a block house

Column foundation with grillage