We make bituminous mastic ourselves

Here's the easiest way to do it at home. You need to purchase bitumen - lumpy, one that goes by 25 kg, or in a paper bucket of 20 kg. It should be split into smaller pieces with an ordinary sledgehammer and melted over a fire to a liquid state.

Now mining is topped up - this is in order to give the bitumen the necessary elasticity, and after cooling it will no longer crack.

Thus, exactly 5 liters of mining is required for a bitumen briquette weighing 25 kg. The resulting mixture should be smeared on the foundation with a bitumen brush (there is one), but it is advisable to take a metal handle to it and screw it onto the screws.

One briquette will take one brush - and after making it unusable, it will not be difficult to screw on another handle.

A layer of waterproofing on such a foundation will turn out to be 3-4 mm, which in itself is already reliable and not at all difficult. By the way, if the soil is dry, then the waterproofing in the outer surface can be limited to only one double coating of bitumen. But, if the groundwater level is high enough, drainage is needed, which will protect the foundation from moisture.

To prevent rainwater and melted snow from falling directly under the foundation and destroying it from below, a blind area is needed. This is a strip of concrete up to one meter wide, which, as it were, encircles the entire foundation of the bath from its outer side. Its width is calculated depending on the so-called roof overhang, i.e. its protrusion, which should be at least 30 cm above the blind area.

A blind area is made under a slight slope - 2-5 degrees, and in the corners of the bath, special recesses are made in it for draining from the drainpipes and removing melt water.

Bituminous mastic for roof waterproofing

The scope of application of bituminous mastic in the construction industry is quite wide. Currently, many of its formulations have appeared, which have a narrow specialization.

Bituminous mastic for waterproofing the roof is easy to manufacture, it is easy to do it yourself. What is needed for this and what components should be used?

Purpose of bitumen mastic It is a liquid waterproofing, which, in addition, performs the function of protecting against the appearance of mold and mildew.

To use it, it is enough to apply the composition to the work surface with a brush or roller, depending on the consistency.

Application of bitumen to the roof The unique performance characteristics of this material are due to its properties. At normal temperatures, the classic mastic will be hard.

But it is enough to warm it up to + 180 ° С, and it will turn into a liquid state. The density and viscosity of the resulting liquid will be high enough that it can be applied to almost any surface.

Due to these properties, bituminous mastic is used in the following works:

- Arrangement and repair of roofs.

- Formation of a protective layer on steel structures.

- Waterproofing reinforced concrete and concrete surfaces - walls, foundations.

- Improving protection against water in rooms with high humidity.

Many experts advise purchasing ready-made formulations. However, with large volumes of work, an increase in the repair budget will be observed. Therefore, in some cases, the best option is to make your own bitumen mastic.

Consumption of bituminous mastic

The amount of consumable mastic with the addition of crumb rubber and rubber will depend on the thickness of the layer, and how many will be applied. For example, if you want to glue roofing material, then the consumption will be up to 800 g per m2.

If the material is used as insulation, then with a layer of 10 millimeters, it takes up to 18 kilograms per m2. With a latex additive, the material consumption will be up to 7 kilograms per m2.

The material consumption for surface insulation is not small, but the coating is of high quality. If the insulation is carried out in one layer, for example, for basements, foundations and other structures, then the consumption of mastic with latex will be up to 7 kilograms per m2. For roof processing, usually up to 4 layers are made, while a special reinforcing mesh is used. When using mastic with the addition of oils, the consumption is up to 1.5 kilograms, if two layers are applied, then up to 3.

Bituminous mastic is used for various purposes: roofing surface, roof repair, filling seams and joints, protection and waterproofing of various surfaces.

In order to dilute the bituminous mastic, solvent, toluene, gasoline, white spirit are used, in extreme cases, kerosene can be used. Some formulations may be thinned with regular or used oil. Before diluting the composition, it must be warmed up. This surface will take slightly longer to dry than without thinning.

Bituminous mastics can contain various additives that change the properties of the composition, for example, crumb rubber or rubber contributes to the elasticity of the material, it does not lend itself to cracks and damage during stretching. If the bituminous mastic is too thick, and it is difficult to apply, then the composition is diluted to the required consistency using organic solvents. The application of the material by a mechanical method is of better quality, since it allows the composition to lie evenly on the surface and to process hard-to-reach areas.

Bituminous mastics have become very popular today, they are used for various types of work, for example, for waterproofing building structures, for performing road and roofing works. The bituminous mastic used can have different properties, which is due to the options for adding to the mixture. Before starting work, it is necessary to carefully determine under what conditions the mastic will be used, what properties it needs to maximize the quality of the applied insulation. The mastic itself can be used not only as a separate material, but also as an auxiliary material, for example, for gluing roofing material.

For a high-quality result of the preparation of mastic, it is recommended to decide in advance for the purpose of its use.

Types of bituminous mastic

Varieties of mastic

Bitumen-based mastic can be of different types, it all depends on the composition of the material and the technology of its use. In this regard, the division is carried out according to the following criteria:

Application technology.

This process has two flavors:

- Hot application. The peculiarity of hot mastic is that it requires heating to a certain temperature before application. At the same time, there are mastics of high heat resistance, which require the maximum temperature to achieve a working condition. This includes mastics used as an adhesive for waterproofing rolls. If bitumen-based mastic is used as an independent coating waterproofing of the foundation, then it heats up to a viscous state with slight heating. Experts do not recommend mixing types of mastics with different temperature characteristics. Hot bitumen mastic for the foundation requires strict adherence to safety rules and technological process. Therefore, it is best to invite a specialist to work with hot mastic.

- Cold mastic is applied without preliminary preparation, but requires thorough mixing before work.It is worth noting that for the application of the cold version of the coating waterproofing at negative temperatures, a certain heating is required.

Dissolution options.

Depending on the components included in the composition, bitumen mastic can be water-soluble or made on the basis of organic solvents. Therefore, you can get a more liquid consistency by diluting with a liquid similar to the mastic base.

Number of components

Bitumen-based mastics for waterproofing foundations can differ in the number of components for preparing the mixture:

Components of the mastic

- One-component mastics are ready to use. To work, you need to open the package, mix the mastic and apply.

- To prepare a two-component bitumen mastic, it is necessary to combine the two components in compliance with certain proportions. Such mixtures freeze quickly enough, therefore, the composition must be prepared immediately before application. Two-component mastics can be stored for a long time in a closed container. In addition, they have high operating strength.

Composition of components

Depending on the additional substances introduced into the composition, the following types of mastics can be found:

Bituminous mastic compositions

- Bituminous mineral. It contains chalk, cement or quartz additives. The content of these substances does not exceed 20%. In addition, a plasticizer is necessarily present in the composition of such a mastic. The technology for the production of bitumen-mineral mastic allows the content of 5% of this substance. In cold mastic, lacoil can play the role of a plasticizer. Such a waterproofing compound does not harden in air and can withstand any stress without damage. This allows the use of a waterproofing material for recessed areas of the base.

- Bituminous rubber. The composition of such a material is supplemented with rubber powder or synthetic rubber. These substances give elasticity to the material. A special mineral oil can be used as a plasticizer.

- Bituminous rubber. Such a mixture has good viscosity, so the coating is dense and elastic, while it perfectly protects the foundation from moisture.

- Bituminous-polymer. This mastic is made on the basis of modified polymers. The absence of organic solvents allows the use of the material inside the house.

- Bituminous latex. A mastic made on the basis of an aqueous emulsion with the addition of synthetic rubber.

- Bituminous oil. This mixture can be used to waterproof the buried parts of the base. Gasoline or white spirit can be used to dilute the composition.

- Bituminous primer. Such material has a more liquid consistency than conventional mastic. Depending on the base, it can be diluted with solvent or water. The main purpose is to prepare the surface for waterproofing work.

Coating technique

The method is used to protect against capillary moisture. Combined with horizontal insulation, the coating is more effective. In this case, bituminous, bitumen-polymer, rubber compositions are used.

It is easy to hide cracks in the base with bitumen

The main stages of the arrangement of the foundation waterproofing coating:

The surface of the foundation must be completely cleaned of dust and any dirt. Next, round off all the protrusions and corners with a grinder. Make sure that the radius of the rounding is more than 3 cm, otherwise damage to the waterproofing layer may be caused by external pressure.

Before applying a layer of waterproofing, the surface must be primed. That is to improve the adhesion of the film to the walls of the foundation. Leave the worked surface to dry for 2-3 hours.

It is recommended to apply bituminous varnish under bituminous and bitumen-polymer mastics, which ensures good adhesion. This is done either with a brush with vertical strokes, or by spraying.You need to process the entire surface of the foundation.

Now you need to prepare the material. This stage depends on the composition used. The one-component materials are simply mixed and diluted if necessary with a suitable solvent. The two-component are mixed according to the instructions.

Liquid material can be applied with a wide brush, roller or spatula. And you need to try so that there are no gaps. The direction of the strokes is vertical. For the reliability of waterproofing, there must be at least two layers. Each subsequent one can be applied only after the previous one has completely dried.

If you are just building a building, then you need to reinforce the waterproofing. This is to prevent damage during shrinkage. Fiberglass and fiberglass are ideal for this. They need to be glued to the first layer of mastic.

Particular attention is paid to corners and fillets.

When using hot mastic, it must be preheated to a temperature of 160-180 degrees. It is better to do this in a metal container over an open fire.

It is applied with a spatula and then leveled with a hard brush.

The principle of arranging a coating waterproofing with any formulations involves careful application of funds to the surface. For this purpose, you can also use cement-based mixtures, which include modifiers that fill the porous structure of the foundation. This prevents moisture from acting on the structure and its further destruction.

Bitumen for waterproofing

To protect the foundation of buildings, bitumen and mixtures based on it are often used. This is due to the fact that the product closes the pores in concrete well, withstands temperature extremes and is easy to use. Also, the popularity of bitumen is due to its low cost, and it can be used independently. At the same time, the layers of bituminous waterproofing require regular renewal, which should be carried out approximately once every 10 years.

Bitumen is flexible and easy to use

The bituminous composition is supplemented with roll materials, for example, geotextiles. This protects the waterproofing layer from mechanical damage. For processing with bitumen, it is necessary to warm up the briquettes to 30 - 50 ° C, and then apply with a wide brush on the primed surface. Heating is carried out over a fire in an iron container. All actions must be active, since the product quickly loses its elastic properties. It is possible to apply about 3 coats, but each should dry well. After the previous layer stops sticking, you can apply the next one.

You can apply bitumen with a roller

Mastic treatment

Waterproofing the foundation with mastic requires the choice of the type of composition. Mixes for cold application do not need to be preheated. Hot mastic needs heating

In this case, you need to pay special attention to the composition of the product, because each component requires a certain processing temperature:

- Gudrokampolymerny mastic must be heated to 70 ° C;

- tar up to 130–150 ° С;

- bituminous rubber composition up to 170–180 ° С;

- bituminous agent up to 160–180 ° С.

Before applying any mastic, you should clean the surface from dirt and dust, apply a primer, and then prepare the composition. Further, the product is applied with any convenient tool that allows you to create an even layer. The brush is ideal for this purpose.

The roller allows you to evenly apply the composition

After applying each layer, you need to pause for the composition to dry. Any type of mastic can be supplemented with roll-up waterproofing, which is fixed over the dried layer.

Features of waterproofing the foundation with bitumen

At the heart of a significant volume of liquid waterproofing, construction bitumen is used - a viscous composition of natural origin, consisting of various hydrocarbon components and their derivatives.Depending on the composition of the bituminous waterproofing, ordinary bituminous mastics and bitumen-polymer are distinguished. Polymer mastics are a separate class, but we will not talk about them in this article. As you already know, there are several ways to protect the foundation from the negative effects of moisture. You may like the result that is guaranteed by waterproofing the foundation with liquid glass, penetrating waterproofing, the use of roll materials. However, small foundations are best treated with conventional bitumen-based coating waterproofing - it is quick, inexpensive and convenient!

A few words about the assortment of bituminous mastic

We did not set out to advertise any particular type of bitumen mastic. The range of such a waterproofing agent is really wide, and bitumen mastic from different manufacturers with the same characteristics can vary significantly in price. Trust the big players in the construction market, carefully study the inscriptions indicating the appointment of mastic on buckets with liquid waterproofing - you will not go wrong.

Advantages and disadvantages of liquid foundation waterproofing

The advantages of bituminous mastic for carrying out work on waterproofing the foundation are the following:

- the ability to create a seamless waterproof screen;

- excellent adhesion to any surface;

- there is no need for assistants - you can gradually apply the entire volume of mastic to the surface of the foundation with your own hands;

- high speed of work;

- durability of the created waterproofing layer;

- you can work at both high and low air temperatures (bitumen mastic is selected based on the working conditions);

- resistance of the waterproofing layer to aggressive environments;

- affordable price and ease of transportation of waterproofing

The disadvantages of using bitumen mastic can be attributed to the laboriousness of work with large processed areas of the foundation. In some cases, you will have to wait until the waterproofing layer polymerizes and gains all the necessary properties.

Stages of work

To create an effective waterproof layer, you can use bitumen mastic, which requires preheating to 160-180 degrees, organic solvent mastic or bitumen emulsions. Hot mastic, after hardening, forms an elastic layer of waterproofing, so it is better to use it for surfaces that are not exposed to strong mechanical stress. Compositions based on organic solvents are best used for external waterproofing of the foundation; for certain reasons, it is recommended to process the foundation inside the basement with bitumen emulsions on water.

The first step is to calculate the total surface area of the foundation. It is necessary to protect the foundation from moisture from all sides - not only from the side of the soil. After that, we determine the consumption of mastic per square meter

Please note that many manufacturers indicate the average consumption of mastic on their products, so it will not be difficult for you to decide on the required amount of material (it is better to buy everything at once - it’s cheaper). The surface of the foundation is leveled, cleaned of dust and small stones

A few words about primers - special formulations that serve to create a preparatory layer (primer). You can buy ready-made material, or you can simply dilute the bitumen mastic with the solvent that is included in its composition. If the surface of the foundation has pores, it is better to “saturate” them with such a primer, which will improve the adhesion of the waterproofing layer to the mineral base. To increase the life of the waterproofing layer, a special penetrating waterproofing can be used.

To apply mastic when waterproofing a foundation, you can use brushes, rollers - any convenient tool that allows you to evenly apply the composition to the surface of the foundation. The mastic is applied in 2 layers, and a technological pause is maintained between the applications of the topcoat, the value of which depends on the characteristics of the composition.

Features of waterproofing foundations

The foundation, even if it is under a small building, takes on an enormous load, to which the ground pressure is added. In most cases, for capital buildings, a tape or monolithic type is chosen, but one way or another, careful waterproofing must be done. It protects from destruction not only the concrete visited outside the foundation, but also the reinforcement inside, which is responsible for the rigidity of the entire structure. If it starts to rust, the base will not last very long.

If the waterproofing is of poor quality (we are not talking about its absence), underground or sedimentary water will quickly penetrate through the porous structure of concrete and damage the metal frame. As a result, the base will not be able to withstand the load from walls, ceilings and roofs, and the house will literally begin to crack at the seams.

Regardless of the chosen method of waterproofing, it is necessary to perform some preparatory work:

- Find out at what depth the groundwater lies on the construction site (the type of waterproofing, the choice of materials and the thickness of the application depend on this).

- Consider the possibility of flooding the site, especially if it is located in a lowland or on loose soil.

- Determine the degree of heaving of the soil (on heaving soils, the foundation requires additional strengthening, otherwise in the spring the earth will simply push the house out, or it will warp).

- Operating conditions of the future building (if you are building a warehouse, then waterproofing should be maximum).

- Financial opportunities (fortunately, the price of waterproofing the foundation with bitumen mastic is not too high, regardless of the amount of work).

Foundation waterproofing methods

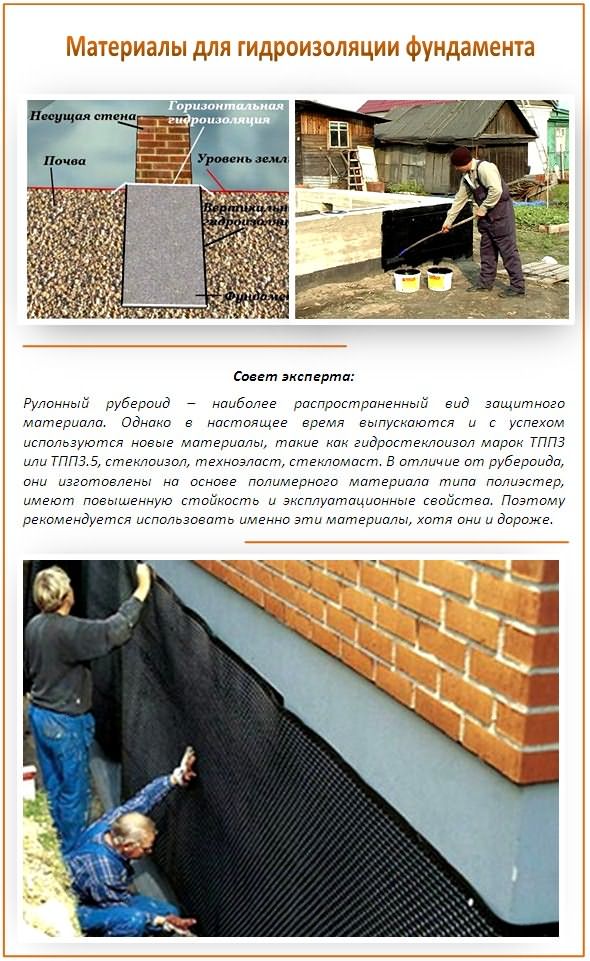

There are only two types of foundation waterproofing: vertical and horizontal. In the first case, the walls of the foundation are processed using roll materials. This work is relevant both when building a house and after putting it into operation.

Horizontal waterproofing is carried out during the construction of a house, and this work takes about 10-17 days. The process involves not only treating the base with a waterproofing material, but also laying a so-called drainage cushion made of sand, crushed stone and gravel. Drainage is mandatory in all cases, especially if the groundwater runs close to the surface.

The foundation waterproofing option shown in the figure above is best suited for protecting strip and monolithic bases. In the case of a monolithic type, experts recommend using combined insulation, combining vertical and horizontal methods. However, if only horizontal is chosen, then it is best to use roll-bitumen materials or liquid rubber, since they reliably protect the joints and gaps between the elements.

Basic application techniques

To implement reliable waterproofing with your own hands, you need to clearly adhere to the technology of work:

- The first step is to prepare the planes well and thoroughly. To do this, they are cleaned of debris and dust, all irregularities and cracks are sealed with a solution, then everything is degreased.

- The next stage involves priming the surface for greater adhesion. Ready-made soil solutions are used or they are made independently by mixing a solvent with mastic. The liquid is applied with a brush.

- Further, after carrying out preparatory measures, the container with the substance is opened and it is thoroughly mixed, using a drill, or manually.

- They take a pre-prepared tool - a roller or a hard brush and, without haste, apply a starting layer of insulation.

- After waiting for it to completely solidify, the procedure is repeated the required number of times.

- As soon as the last layer is dry, you can proceed to insulation or backfilling of the soil.

The application technology is simple and does not require special skills and knowledge. The only thing is that bituminous liquid is a very viscous material and you have to tinker a little.

Roller application of mastic

The choice of mastic

Bituminous resin treatment of 1 m² of the surface is very expensive, the film "flows" in the heat, cracks in the cold. Therefore, modern mastics contain components that improve the properties of the material:

- plasticizer - rubber chips, latex resin, rubber, mineral oil;

- filler - ash, brick dust, quartz, lime;

- reinforcing additives - asbestos, basalt wool;

- inhibitors - metal corrosion inhibitors.

Cold (liquid) mastic.

Cold mastic is more convenient to work with, hardens immediately after evaporation of the solvent. Hot waterproofing for the foundation is preheated to 160 - 180 degrees, hardens when it cools.

Average consumption for one coat per 1 m² is:

- hot waterproofing - 2 kg (2 mm film layer);

- water base - 1 - 1.5 kg (film 0.6 - 1.2 mm);

- on a solvent - 1 - 1.5 kg (0.5 - 1 mm film).

Hot (hard) mastic

Under normal conditions (no precipitation, 20 degrees), cold mastic dries for 5-24 hours (solvent, dispersion, respectively), hot modifications harden in 4 hours. When choosing which layer is better to apply than to cover reinforced concrete structures, factors are taken into account:

- terms of work;

- coating consumption;

- atmospheric conditions;

- the price of materials;

- resource of the film layer.

The minimum permissible outside air temperature is -5 degrees for hot products, solvent-based mastics. For water-based compositions, this threshold is +5 degrees, but twice the moisture content of the base is allowed (8% instead of 4%).

If for the majority of paints and varnishes the characteristic is important - hiding power, then for mastics the "dry residue" is much more important. This property is indicated by most manufacturers on the packaging, it allows you to determine how much substance remains on the surface after curing. Waterproofing coatings with a dry residue of 60 - 70% are preferable, rather than 20 - 40%, since the total material consumption and labor costs are reduced.

Hot mastics are cheaper, comply with GOST 2889, but require additional equipment (heating, application). The main characteristics of the most popular waterproofing coatings are as follows:

- Bituminous-rubber mastic - 25 years resource, suitable for inclined surfaces of 45 degrees (does not slip when heated), frost resistance -60 degrees, permissible operational heating +100 degrees, antiseptic, even coating, heating is not needed.

- Rubber-bitumen coating - drying - 24 hours, strength gain - 7 days, vibration-resistant, tear-resistant film (stretching 200%).

- Bituminous-oil modifications are cheaper than others, they are not afraid of heating, frost, they do not form a film, the coating is considered self-healing, not suitable for processing inclined planes.

- Bituminous-latex mastic - suitable for operation from -35 to +80 degrees, reliably seals the seams of roll insulation, is suitable for gluing materials, withstands pressure pressure.

For sealing the seams of prefabricated strip foundations, it is better to use special compounds. For example, waterproofing plasters, penetrating mixtures.

Basic concepts of foundation waterproofing

Most often, the base of buildings is made of materials that can absorb moisture, which later leads to irreversible disastrous consequences.To increase the resistance of the foundation to the adverse effects of groundwater, atmospheric collisions, mechanical damage can be done with the help of high-quality waterproofing.

The need for waterproofing

The concrete foundation that is not protected from the penetration of liquid collapses. Through concrete pores, moisture penetrates above the foundation and leads to other troubles:

- destruction of reinforcement;

- the appearance of mold, mildew;

- the expansion of pores in winter and the collapse of buildings.

Waterproofing is also a necessary action in cases where the foundation is installed without the use of concrete. Wooden and iron structures at the base of buildings without protection from moisture are subject to decay and corrosion processes.

Corrosion of foundation components can cause destruction of buildings

Stages of work

Waterproofing should be understood as special actions that further prevent the harmful effects of water on the foundation.

Spraying liquid rubber is carried out using special devices

The full range of measures for the protective treatment of the foundation includes:

- Horizontal isolation from moisture.

- Vertical protection against groundwater penetration.

- Drainage creation.

- Installation work for the construction of a blind area around the perimeter of the building.

The base of the building must be reliably protected from the penetration of groundwater; horizontal waterproofing will help eliminate the likelihood of their adverse impact. Vertical protection will be needed to deal with the abundant groundwater that is increasing due to heavy rainfall. If groundwater crosses the conditional boundary of the base of the base, then vertical protection will not be enough; drainage systems are used to preserve the integrity of the building. Reliable blind areas will help to divert the abundance of water that accumulates after precipitation near the building, and to prevent the penetration of moisture into the basement or foundation.

Building regulations

SNiP (building codes and regulations) for waterproofing regulate the creation of a high-quality foundation of buildings. List of documents that will help in carrying out such work:

- SNiP 3.04.01–87 "Insulation and finishing coatings". This document "permits" an individual choice of material for waterproofing a building in accordance with the project of the facility under construction and taking into account all the features of its construction.

- SNiP "Waterproofing of foundations" gives a list of materials that are unacceptable when carrying out waterproofing work.

- SNIP 3.04.03–85 "Protection of building structures from corrosion" regulates the implementation of special measures to protect external waterproofing from corrosive effects.

- SNIP 3.02.01–87 "Earthen Structures, Foundations and Foundations" will help builders in creating high-quality water lowering and drainage systems.

Peculiarities

When carrying out protective work, one should not neglect some characteristics:

- soil composition;

- forces of heaving of the earth in winter;

- the depth of the location of groundwater;

- technical and operational data of the building itself.

Slab foundation waterproofing technology

An important clarification: if a slab foundation is waterproofed, then due to its large surface area, it must be carefully leveled initially with a cement screed - and only then the foundation is waterproofed with roofing material and mastic. Then - insulation, for insulation - a screed from a solution, on a screed - floor covering

So, the order of work:

- Step 1. A layer of cement mortar 2 or 3 cm is laid, leveled and dried well.

- Step 2. A layer of insulating material is applied, i. E. Roofing material - only 2-3 cm. Height from the ground - not less than 20 cm. After that, a heated bituminous mastic is placed on the surface of the roofing material, into which fluff lime was added in advance.By the way, it is necessary to dilute bituminous mastic based on the calculation that one part of the lime should be taken into two parts of the mastic. Moreover, the mastic itself must be laid in layers, each of which does not exceed 7-10 mm in thickness.

- Step 3. Now two layers of waterproofing are spread dry - and with an overlap of at least 15 cm. After that, the upper part of the foundation is treated with bitumen mastic and the second layer is applied.

Foundation waterproofing with mastic

Coating various surfaces with bitumen, a resinous mixture that has certain waterproofing properties, has long been considered the most effective and generally available way to protect building structures from water. Previously, in order to use this mixture, it was necessary to melt the bitumen at a high temperature - over a fire, and then cover the surfaces with a still hot mass. Now everything is much simpler - there is an opportunity to use solvents. To apply a mixture of bitumen solution with additives to the surface, no more than two workers will be needed, besides, bitumen mastic is quite effective and easy to use. Let's consider in more detail what types of mastics are and their features.

Recommendations and Tips

For quality performance waterproofing the foundation with its The mastic can be applied by hand using airless spraying units, which reduce material consumption and create an even coating. When working with such units, it is necessary to ensure that the pressure in the sprayer is approximately 150 bar.

Spraying waterproofing mastic

To reduce the consumption of bitumen, it is also necessary to monitor the thickness of the applied layers. When bitumen is applied in two layers, the thickness of each should be no more than 1.5 mm. When applying mastic in 3-4 layers, each of them should be about 1 mm. It is recommended to use a universal thickness gauge to determine the thickness of the layers.

The drying time of the mastic depends on the thickness of the layer and on the weather conditions. On average, it takes about 4-6 hours to solidify. If the weather is cold, it will take longer.

Depending on whether mastic is applied to horizontal or vertical surfaces, its consumption may be different. For horizontal sections, the consumption is about 1-2 kg per m2, for vertical sections - 0.5-0.7 kg.