Reinforcement of the strip foundation - ongoing work

- Calculation of how much reinforcement should be used for vertical and transverse reinforcement of the supporting structure;

- Calculation of the force of foundation pressure on the ground, reinforcement step;

- Selection of the type of reinforcement, its maximum section and connection method;

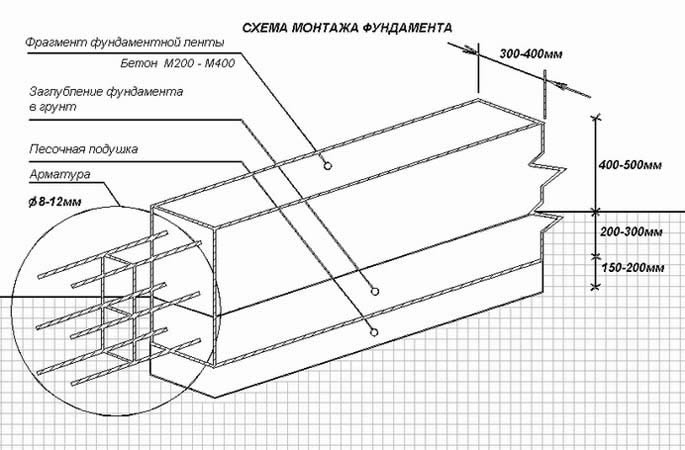

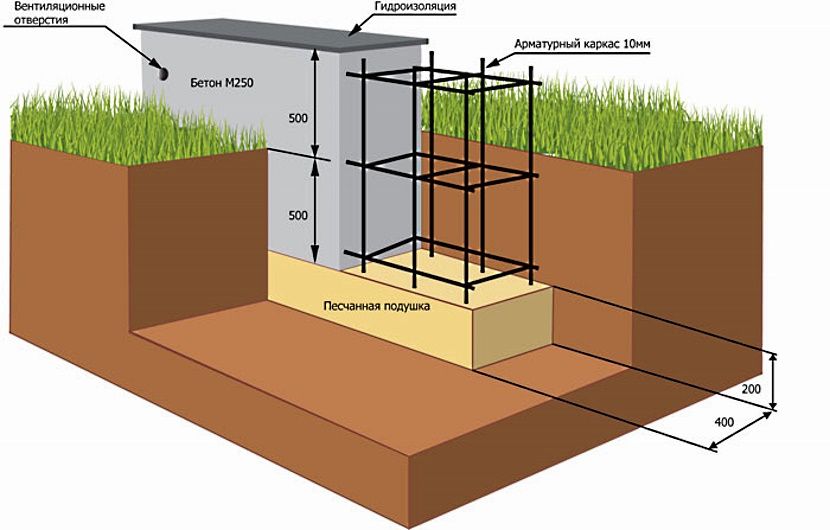

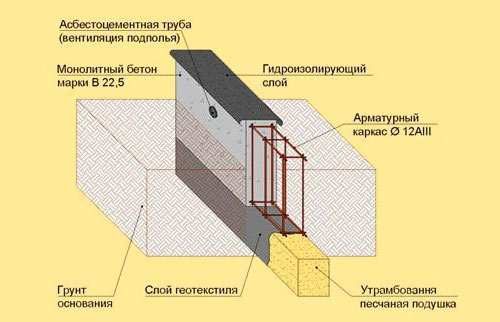

- A trench is pulled out along the perimeter of the future building; it is imperative to fill in a sand and gravel pillow at the bottom;

- Reinforcement vertical formwork is being made. Its device is simple: with a step of 200 cm, the reinforcement is stuck into the ground, and it must stand in strictly calculated places and be of the appropriate height;

- It is necessary to tie or weld horizontal reinforcement to the vertical pins so that no more than 5 cm remains to the foundation surface. Reinforcement protrusions are allowed, but small. If desired, the pins can be lowered even below the level of the pillow and additionally put a layer of wire directly on top of the pillow in order to create a stronger formwork.

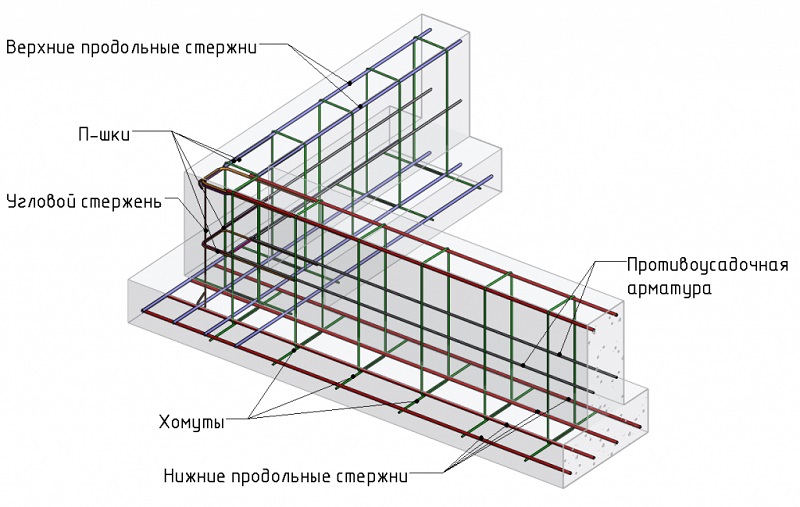

Strip foundation and corner reinforcement.

Strip foundation and corner reinforcement.

Some builders who do DIY reinforcement, in order to achieve a more rigid structure, fragments of bricks, scrap metal, rusty wire are used. As practice has shown, almost never correctly laid and connected fittings were not superfluous - you just need to take this work with responsibility.

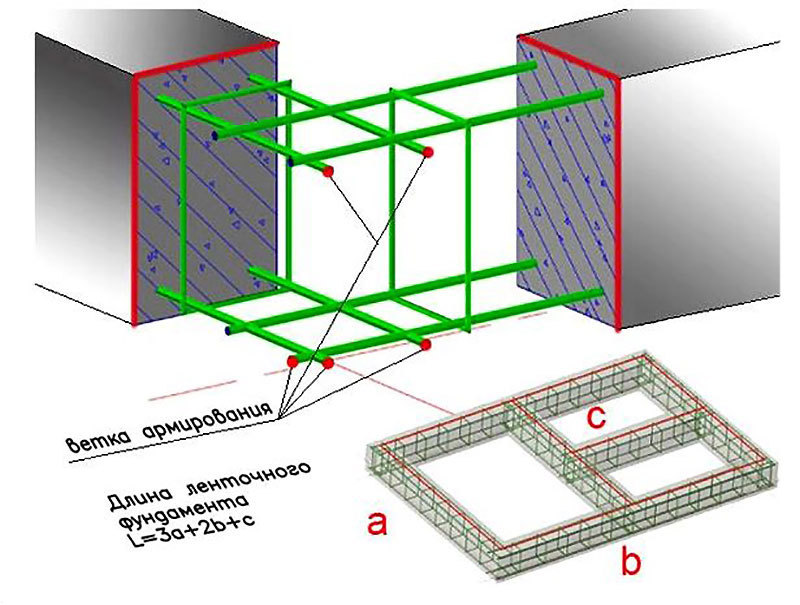

In this case, you need to connect straight concrete strips together.

Reinforcement of the corners of the strip foundation of buried or shallow types - the structure of the base in such cases does not play any role, the technology remains the same.

Technology for performing reinforcement of a buried strip foundation

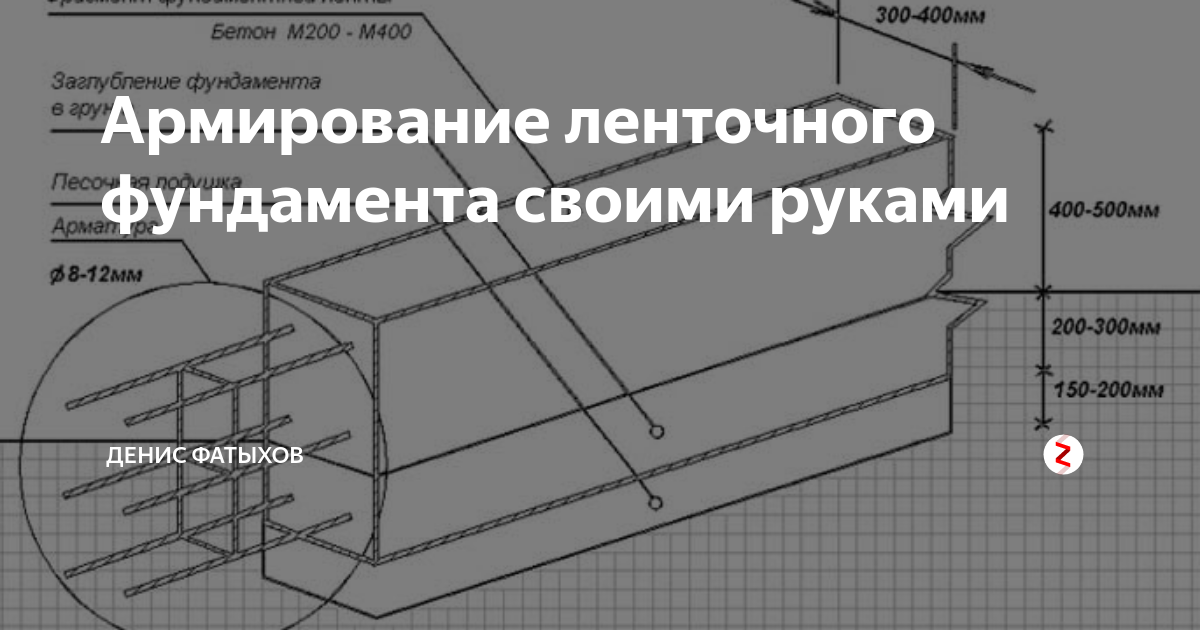

Reinforcement device and technology.

Reinforcement device and technology.

The properties of any concrete are such that it is susceptible to frost and water and, over time, begins to crack and lose its bearing characteristics. The optimal solution to eliminate the effects of negative climatic phenomena is to use fittings.

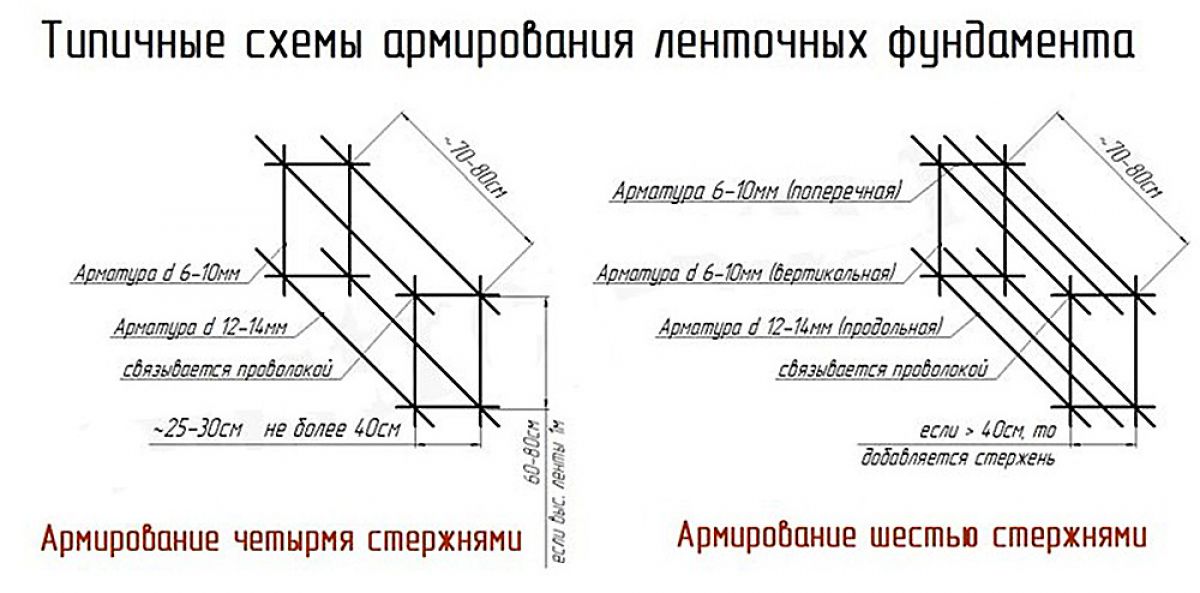

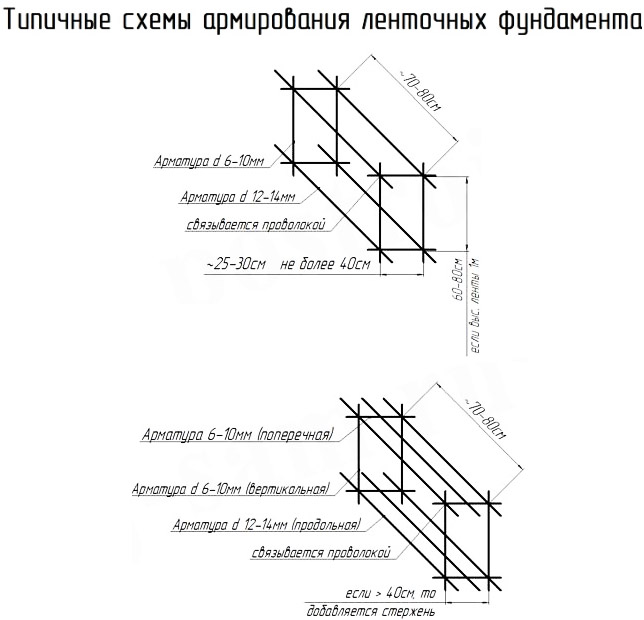

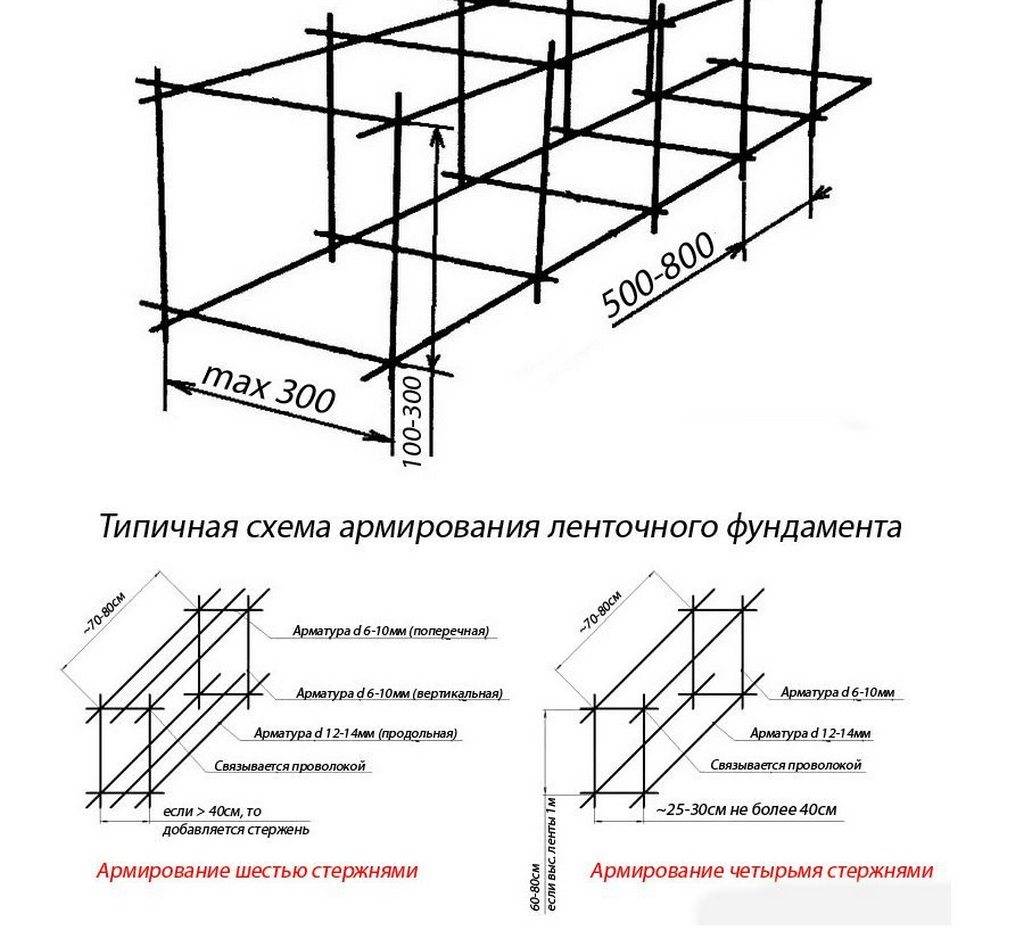

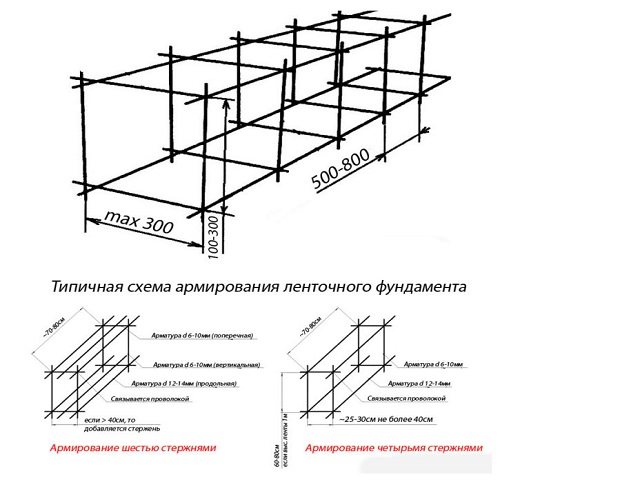

Taking into account the technology of creating any monolithic shallow foundation, where a sand cushion and formwork are used, the optimal solution in such cases is the use of frame reinforcement of tape horizontal and vertical spiral types with an average reinforcement pitch.

Installing the frame, pouring concrete

It is best to assemble the frame from the reinforcement directly in the prepared foundation pit - this allows the elements to be fixed most firmly. But if we are talking about the reinforcement of a buried strip foundation, or if the pit is too narrow for work to be carried out directly in it, then you can assemble the frame from the outside above the trench, and then carefully lower it into place. There are usually no problems here and step-by-step instructions are not needed.

The last and one of the most crucial stages is the pouring of the foundation.

Filling the strip foundation with a concrete pump

It is advisable to use concrete of the M200 grade or higher for this. It has high strength to withstand significant loads, and also has a sufficient frost resistance indicator.

It should be said right away that a large amount of material will be needed for work. Carry out all the necessary calculations in advance - concrete must be poured in one step, avoiding delamination and other separations. Otherwise, the strength of the foundation will significantly decrease, and this will affect the safety of the house. For the same reason, it is advisable to rent a concrete mixer. Today many companies offer this service. In addition, renting cheap models is relatively inexpensive - less than a thousand rubles a day.With intensive work during this time, it is quite possible to cope with the work. In addition, the presence of a concrete mixer allows you to increase productivity - you just need to throw in sand, cement and pour water, getting a finished product soon, which you just need to pour onto the frame installed in the formwork. Working with shovels, such productivity cannot be achieved.

Now you know how to reinforce a strip foundation with your own hands. To do this, it is not at all necessary to have highly specialized skills or buy expensive equipment. It is enough to know, at least in theory, how to reinforce the foundation. Experience will come into the process, and all tools can be replaced with cheap analogs or rented, saving money and time.

How much reinforcement is needed for a strip foundation

An important issue before starting construction is its cost. It is impossible to determine it in the volume of the foundation without determining the required amount of reinforcement. But for an initial assessment, you can use the weighting factor of the reinforcement. Over the decades of design and construction, an indicator of the amount of reinforcement for low-rise buildings was derived. It is equal to approximately 80 kg / m3. That is, if your strip foundation requires 20m3 of concrete, reinforcement on average will need 20x80 = 1600kg. At the same time, it is not difficult to calculate the required volume of concrete - you just need to know the perimeter of the building, the length of the bearing internal walls, set the tape height of 300 mm and multiply by its width.

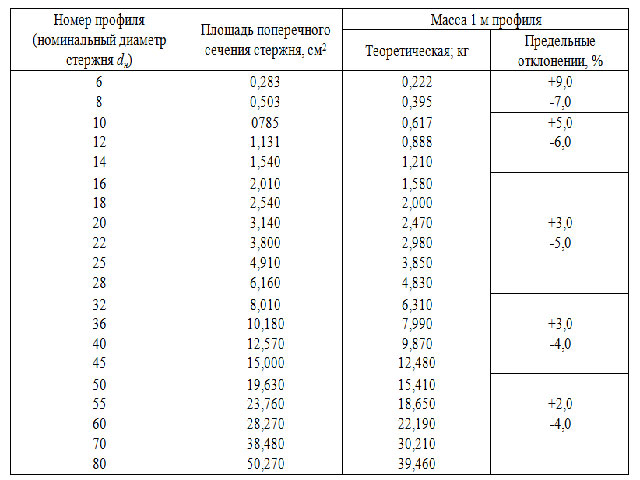

In conditions of economy, it is advisable to perform a more accurate calculation before purchasing fittings. To do this, you will have to draw a reinforcement scheme, determine the total molding of longitudinal and transverse reinforcement, vut, add 5-10% for trimming and then multiply the obtained data by the weight of a running meter for each of the diameters.

Weight table 1 lm reinforcing bar depending on the diameter

2 Work technology

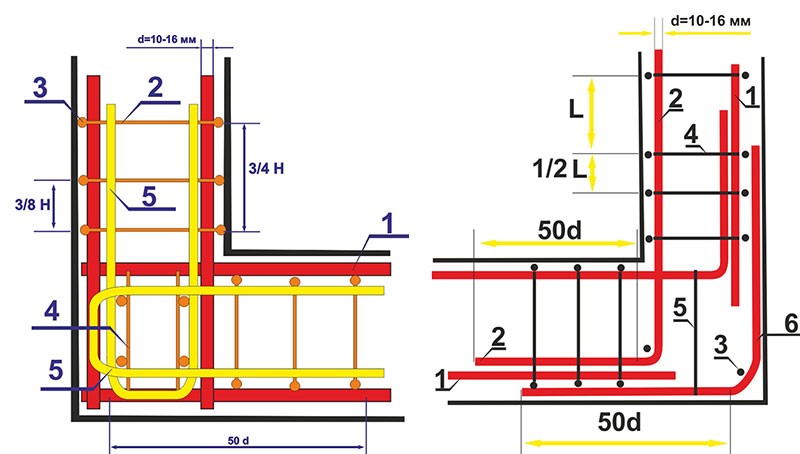

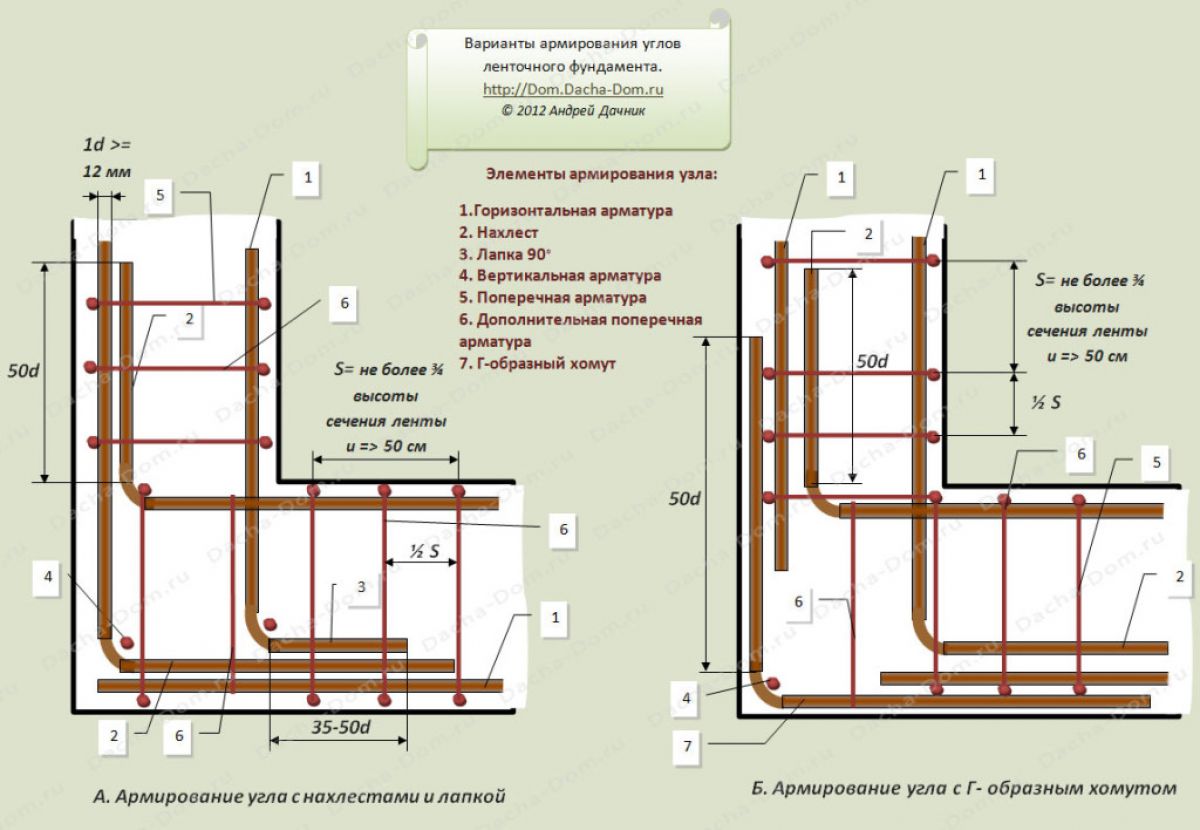

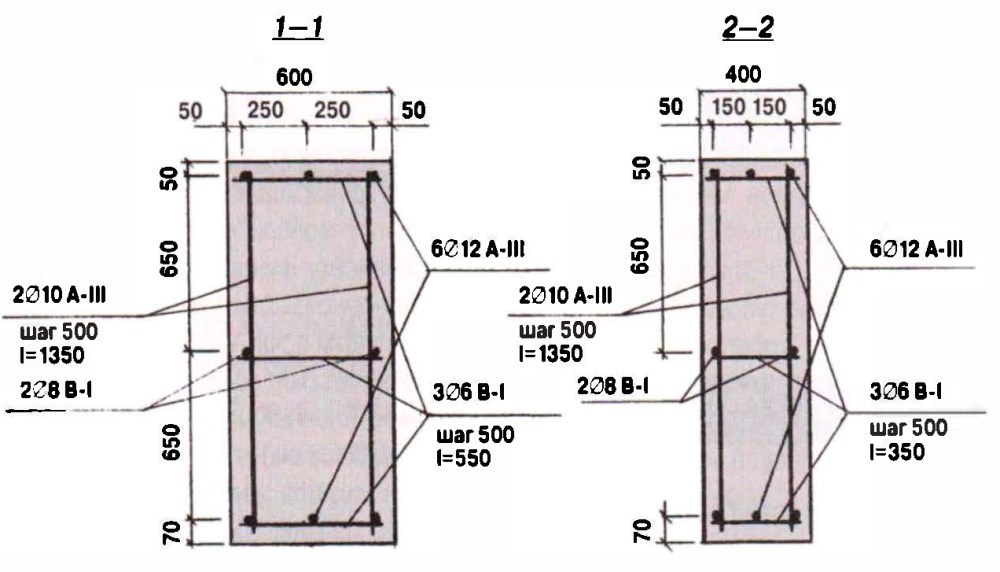

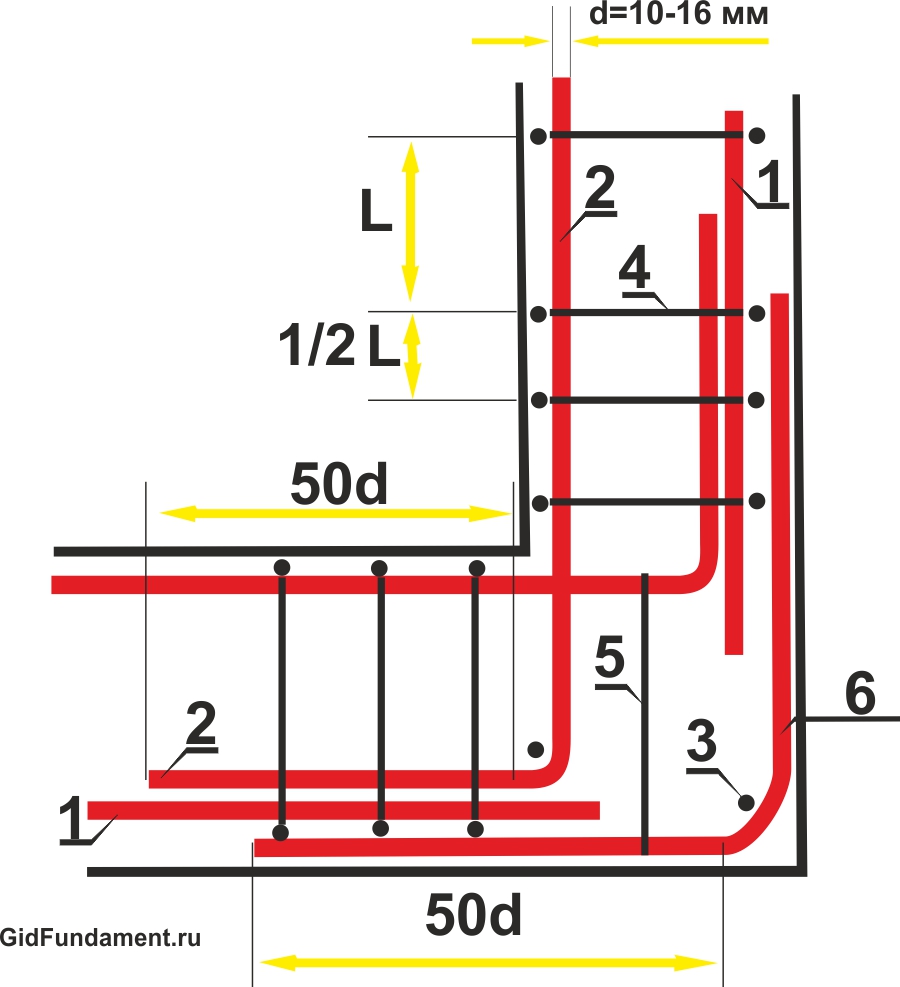

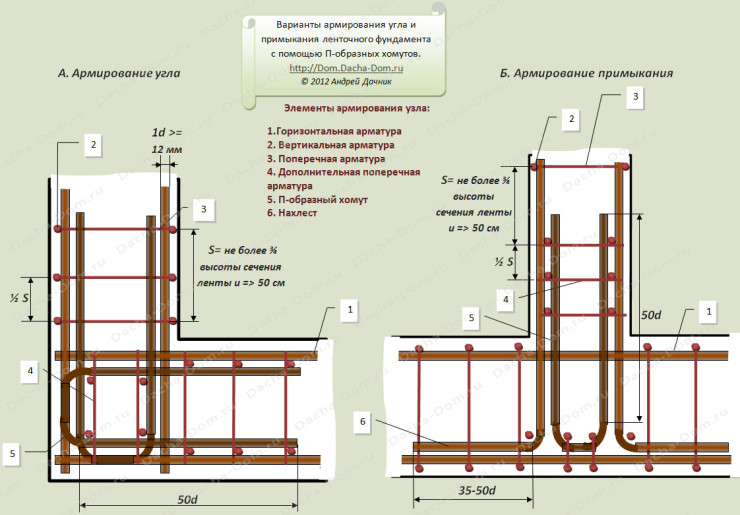

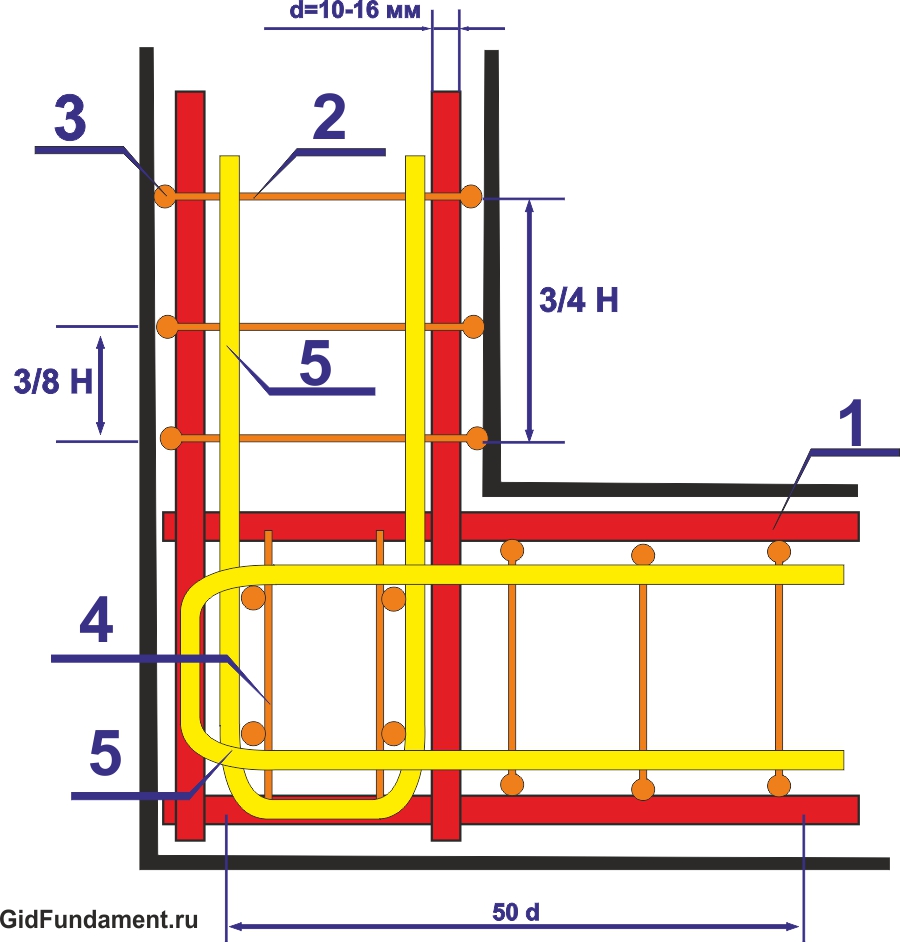

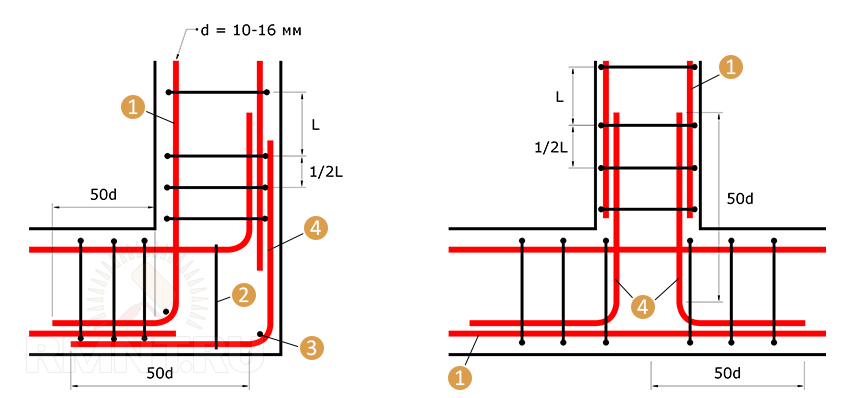

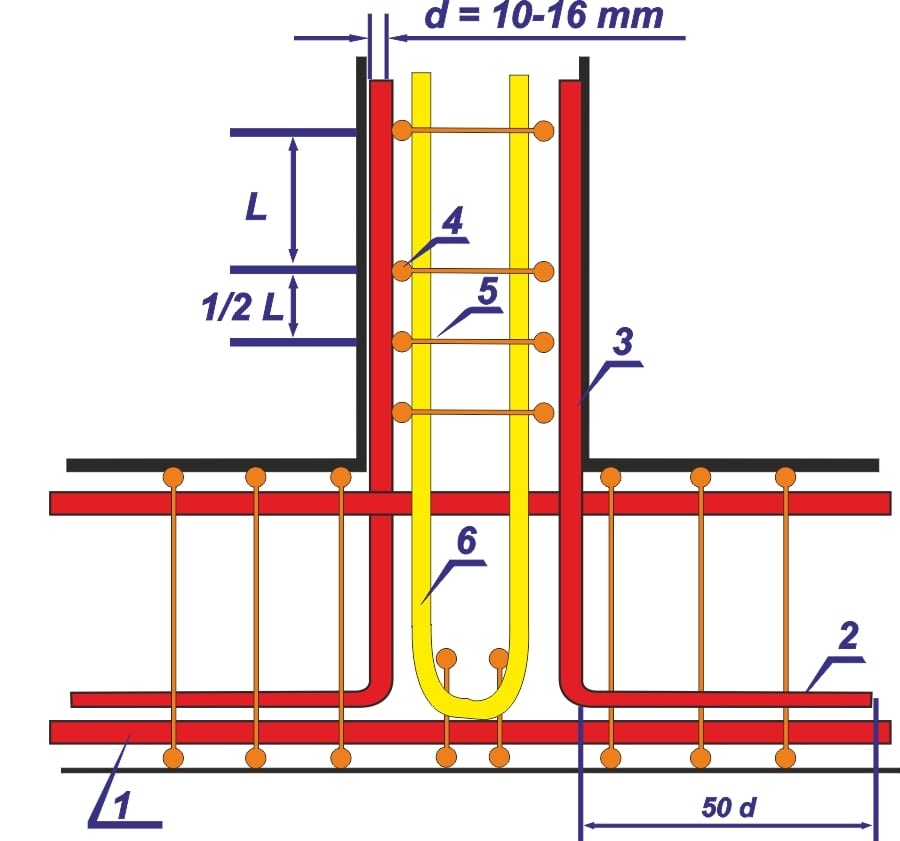

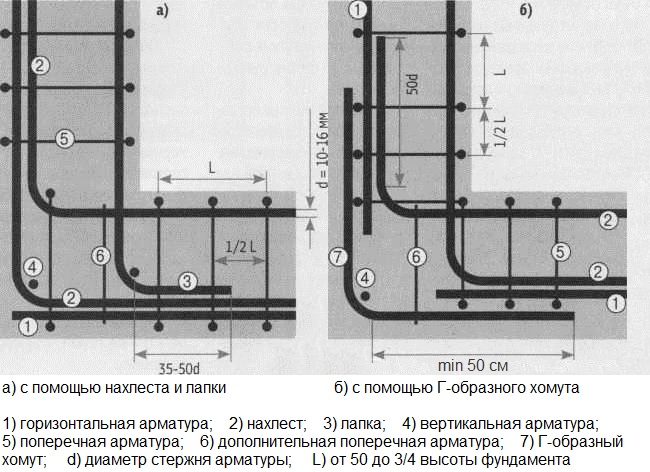

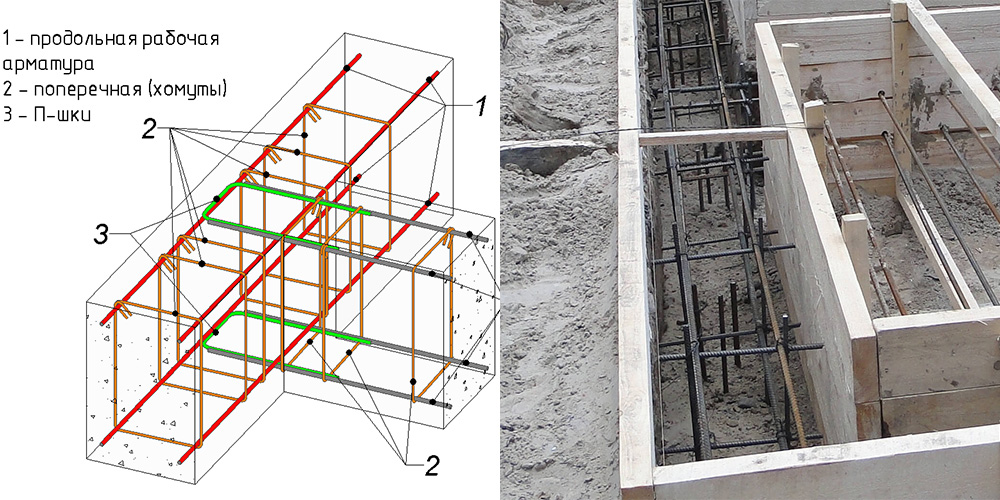

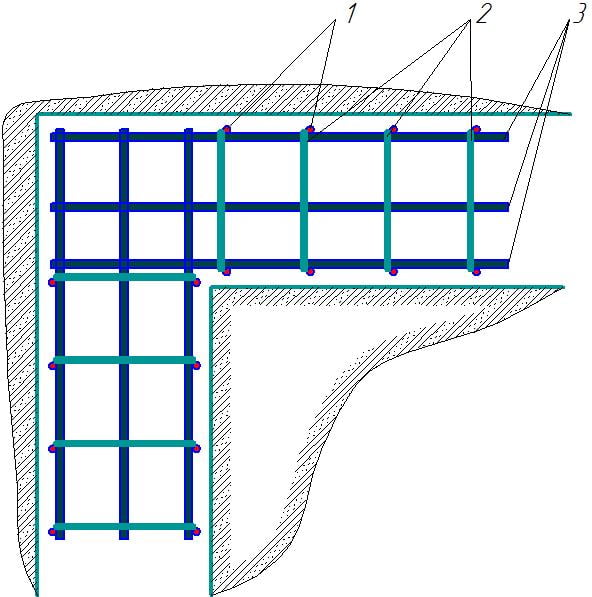

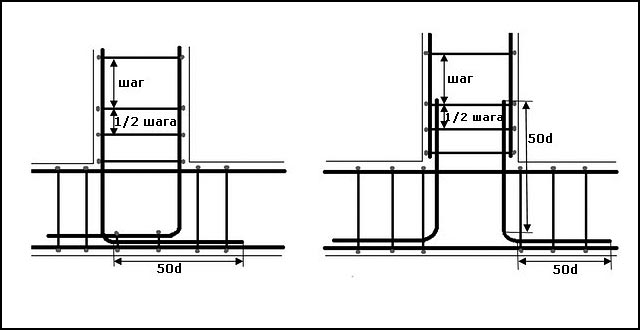

After the number of reinforcement has been determined, a strip foundation reinforcement scheme should be selected, according to which the reinforcement cage will be assembled. Straight sections of the structure are made of solid rods, while at the corner places additional reinforcement is required with a reinforcement curved in a P or L-shaped shape. The use of a perpendicular overlap of individual reinforcement bars at corners and junctions is not allowed.

The correct reinforcement of the corners of the strip foundation is shown in the diagram:

Reinforcement of foundation corners

Scheme of reinforcement of the strip foundation at the junctions:

Reinforcement of abutments

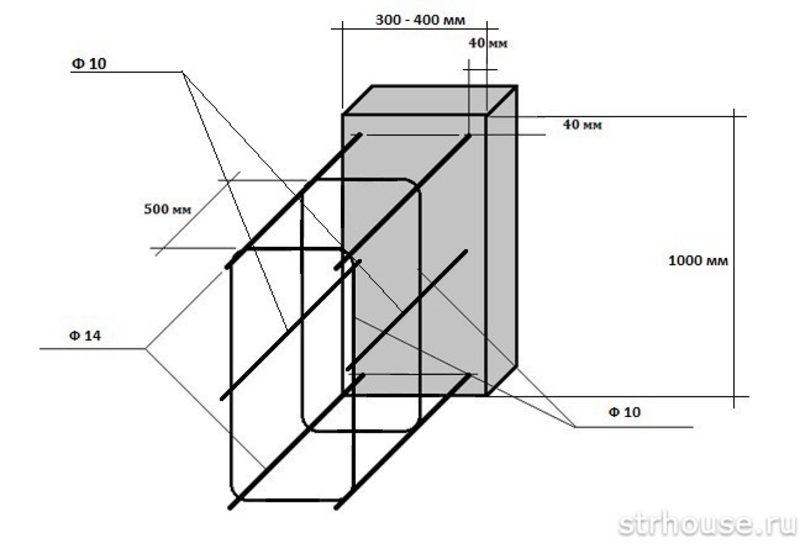

Reinforcing the strip foundation with your own hands involves assembling the frame in a convenient place and then placing it inside the formwork. The technology requires bending fittings into rectangular clamps, which can be easily done at home using a homemade device.

On the 20th channel, you need to cut grooves with a grinder, into which the reinforcement is subsequently inserted, and a piece of steel pipe is put on the bar, which is used as a lever. Finished rings must be fastened by welding or tied with wire. For rods with a diameter of 10-15 mm, wire 1.2-1.5 mm is used.

The length of the bars on the longitudinal belt should be equal to the length of the side of the house. The rods are threaded inside the ring and fixed with a knitting wire at the corners of the clamp and in its central part. The step between the clamps is 30 cm. At the exit, you should have 4 component parts of the frame - 2 equal to the length and 2 smaller ones equal to the width of the house. Next, the frames are laid in the trench and connected with angled reinforcement bars in accordance with the above diagram.

Bending of clamps from reinforcement

When installing the frame inside the trench, the following rules must be observed:

- the frame must be raised above the bottom of the trench with the help of stands by 5 cm - the requirements of SNiP do not allow the use of fragments of bricks for this purpose;

- laying should be carried out strictly on a horizontal level;

- the frame must be fixed relative to the side walls of the trench with pins driven into its walls so that the reinforcement does not move during concreting.

Reinforcement of the strip foundation according to the execution technology is identical for shallow and buried bases. After installing the reinforcement cage, the concreting stage begins - concrete of the M200 brand is used for pouring. You can determine the required amount of concrete based on the volume of the foundation - you need to multiply the length, width and perimeter of the tape.

Reinforcement frame for foundation tape

Note that the technology of construction of a strip foundation requires the obligatory arrangement at the bottom of the trench of a sealing cushion made of layers of sand and crushed stone of the same thickness (thickness from 10 to 20 cm each)

A pillow is used to protect the foundation from vertical heaving loads, which is especially important when arranging a shallow foundation located in a layer of freezing soil

Reinforcement portal »Reinforcement» Strip foundation reinforcement technology

How to make a frame correctly?

Before proceeding with the reinforcement of the strip foundation, the drawings of suitable frames should be studied. Indeed, it depends on the strength of the frame whether the base will serve for many decades or will be covered with cracks in the very first spring due to seasonal fluctuations in the soil level.

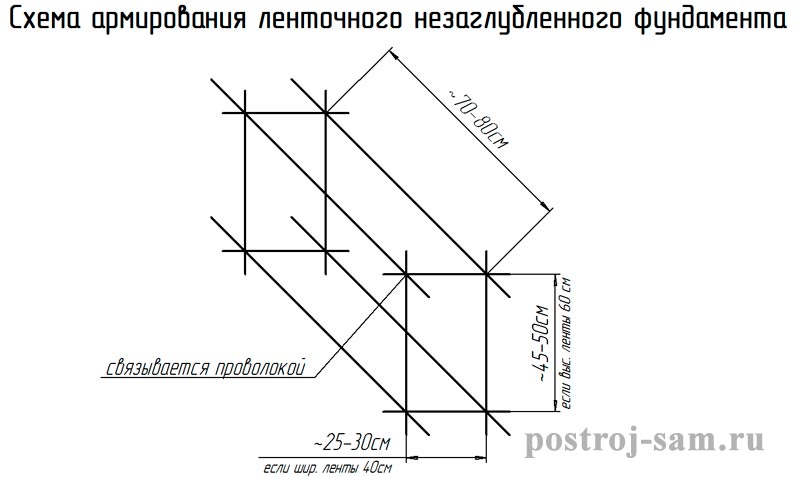

Reinforcement scheme for strip foundation

In order not to be mistaken in manufacturing, you need to remember a few rules:

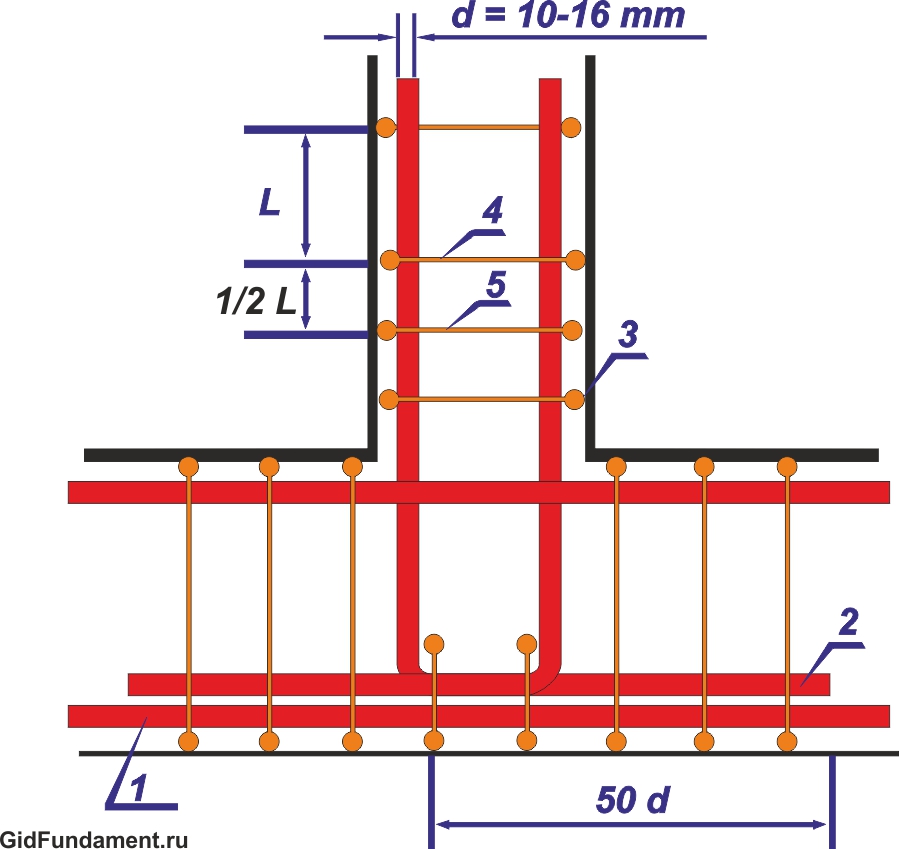

- The overlap (distance from the knitting point to the edge of the rod) should be at least 5 centimeters.

- On corner joints, perpendicularly running rods must be connected to each other - in no case should you use two separate blocks that are not connected to each other. The ideal solution would be corners made of bent reinforcement - such a foundation reinforcement scheme is the most reliable. But for this you need to have special equipment, if the reinforcement has a diameter of 14 millimeters or more, smaller diameters can be bent at home.

- Wire connections must be tight - if using a crochet hook, tighten the wire as far as it will go so that there is no free space between the clamp and the main reinforcement. Also check with your hand, if the clamp moves from touch, you should make an additional tie with wire.

- The overlap during reinforcement should be equal to 40-50 reinforcement diameters. There should be a gap between adjacent connecting rods, and the upper and lower layers, according to the design.

- The reinforcing frame must stand level in the formwork. It is also necessary to take care of the concrete cover for the reinforcement, made according to the requirements of the drawing. It should be remembered that the minimum cover is equal to the diameter of the reinforcement.

Corner reinforcement scheme

Junction reinforcement scheme

As you can see, the rules are as simple as possible. But some inexperienced builders do not suspect or forget about their existence. This leads to the fact that the technology of reinforcement of the strip foundation is violated and its service life is significantly reduced.

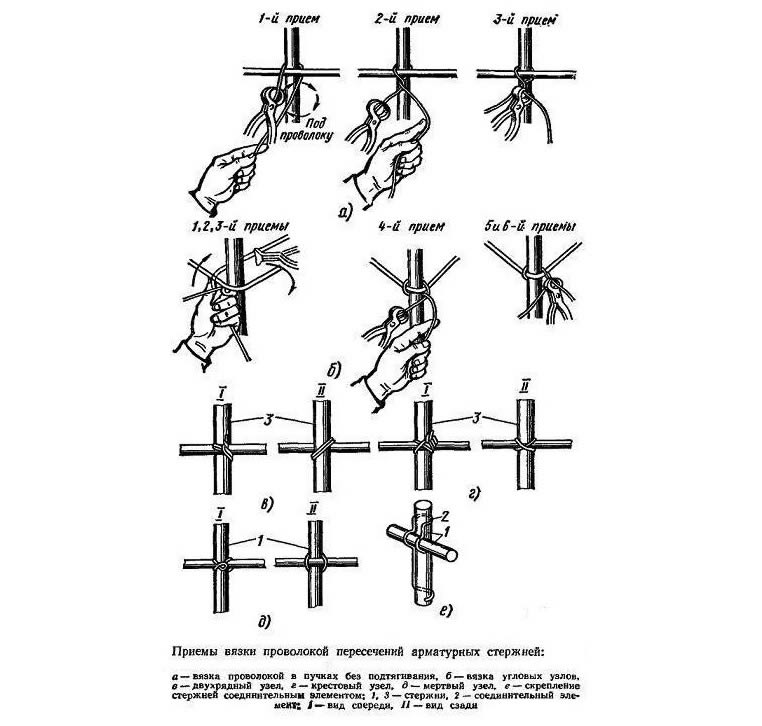

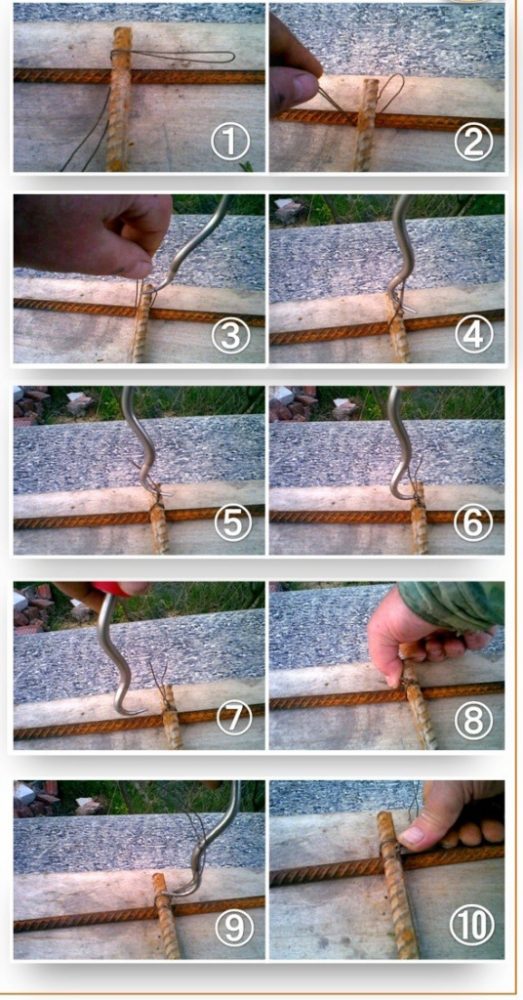

Using a crochet hook

Before reinforcing a strip foundation, it is worth learning how to use a working tool. A special gun is rarely used for private housing construction; such equipment requires additional costs. Investing in a tool is beneficial only for fulfilling orders, and not when building one house.

For this reason, a crochet hook has become the most common knitting tool in private housing construction. It will be easier to use it if you prepare special templates in advance. This part works like a workbench and greatly facilitates the work. Things will go faster.To make a template, wooden blocks are required, the width of which is about 30-50 cm, and the length cannot be more than 3 m, since such a workbench is inconvenient to use.

The most common way to knit is crochet

The most common way to knit is crochet

In a wooden fixture, you need to drill grooves and holes that will repeat the outlines of the rods in the frame. Pieces of knitting wire 20 cm long are laid out in such holes in advance, and then reinforcement rods are fixed.

In order to understand the technology of knitting, you can consider examples. During construction, two options will be required: for crosshairs (when the elements are located perpendicular to each other) and for overlapping joints. In a strip foundation, a second technology is often needed; when erecting a slab structure, the first will be most relevant.

Knitting methods

Knitting methods

To connect the laid frame into a single whole when connecting with an overlap, the hook should be used in the following order:

connections are made in several places along the length of the joint, the location of the wire is assigned so that it is in the recessed part of the reinforcement profile;

the wire is folded in half and laid under the junction;

using a hook to pry on the loop;

the free end is brought to the instrument and placed on it with a slight bend;

begin to rotate the hook, twisting the wire;

remove the tool carefully.

For one overlap joint, the procedure is repeated 3-5 times. It is not enough to connect the elements in one go, as it is done with a cross-connection. In this case, tying reinforcement under the strip foundation will be unreliable, since fixing at one point does not prevent the elements from shifting.

For one overlap joint, the procedure is repeated 3-5 times. It is not enough to connect the elements in one go, as it is done with a cross-connection. In this case, tying reinforcement under the strip foundation will be unreliable, since fixing at one point does not prevent the elements from shifting.

Competent connection of the frame will guarantee the reliability, strength and durability of the supporting part of the building.

Reinforcement requirements

During the reinforcement of strip foundations, the type and controlled values of the quality of the reinforcement are established. The standards allow for use of hot-rolled construction reinforcement of a periodic profile, heat-treated reinforcement or mechanically hardened reinforcement.

Construction fittings

The class of reinforcement is selected taking into account the guaranteed value of the yield point at maximum loads. In addition to tensile characteristics, plasticity, corrosion resistance, weldability, resistance to negative temperatures, relaxation resistance and permissible elongation before the onset of destructive processes are normalized.

Reinforcement class table and steel grades

| Profile type | Class | Diameter, mm | steel grade |

|---|---|---|---|

| Smooth profile | A1 (A240) | 6-40 | St3kp, St3ps, St3sp |

| Periodic profile | A2 (A300) | 10-40, 40-80 | St5sp, St5ps, 18G2S |

| Periodic profile | A3 (A400) | 6-40, 6-22 | 35GS, 35G2S, 32G2Rps |

| Periodic profile | A4 (A600) | 10-18 (6-8), 10-32 (36-40) | 80С, 20ХГ2Ц |

| Periodic profile | A5 (A800) | 10-32 (6-8), (36-40) | 23X2G2T |

| Periodic profile | A6 (A1000) | 10-22 | 22Х2Г2АЮ, 22Х2Г2Р |

The calculation of the strip foundation is carried out in accordance with the recommendations of GOST 27751, the indicators of the limiting loaded states are calculated by groups.

The first group includes conditions that lead to the complete unsuitability of the foundation, the second group includes conditions that lead to a partial loss of stability, complicating the normal and safe operation of buildings. According to the maximum permissible states of the second group, the following are produced:

- calculations for the appearance of primary cracks on the surface of the strip foundation;

- calculations for the time period of the increase in the formed cracks in concrete structures;

- calculations for linear deformations of strip foundations.

The main indicators for resistance to deformation and strength of building reinforcement include the maximum tensile or compressive strength, determined in laboratory conditions on special test benches. The technology and test methods are spelled out in state standards.In some cases, the manufacturer may use the regulatory and technical documentation developed by the enterprise. At the same time, the regulatory and technical documentation must be approved by the regulatory authorities without fail.

For concrete structures, these values may be limited by the maximum rate of change in the linearity of the concrete. The actual diagrams of the state of the reinforcement under short-term unilateral exposure to the calculated standard loads are taken as generalized indicators. The nature of the state diagrams of building reinforcement is established taking into account its specific type and brand. During the engineering design of the reinforced foundation, the state diagram is determined after replacing the standard indicators with the actual ones.

Knitting reinforcement with a special device

To make the device, you will need several boards with a thickness of about 20 mm, the quality of lumber can be arbitrary. It is not difficult to make a template, and it will greatly simplify the work.

Step 1. Cut four boards along the length of the reinforcement, connect them in two at a distance of a step of the vertical posts. You should get two identical templates. Make sure that the marking of the distance between the rails is the same, otherwise there will be no vertical position of the connecting elements.

Step 2. Make two vertical supports, the height of the supports should correspond to the height of the reinforcement mesh. Supports should have lateral corner stops that prevent them from overturning. All knitting work must be carried out on a level surface. Check the stability of the assembled device, exclude the possibility of it tipping over during the work.

Step 3. Place the legs of the stops on the two knocked-down boards, place the two upper boards on the upper shelf of the stops. Fix their position in any way.

Reinforcement knitting scheme using clamps

You have got a model of the reinforcement mesh, now the work can be done quickly and without assistance. Install the prepared vertical struts of the reinforcement in the marked places, temporarily fix their position with the help of nails. Place a bar of reinforcement on each horizontal metal jumper. This operation should be repeated on all sides of the frame. Check their position again. That's right - take the wire and hook and start knitting. It is advisable to make a fixture if you have many identical sections of the reinforcement mesh.