Vertical stacking method

Foundation insulation scheme

Basement insulation options

The vertical version is suitable both for houses that are still under construction and for those that are in operation. It is best used for a home under construction. This method consists of the following steps.

Step 1. The surface must first be dug out, cleaned of soil, debris, including construction, mold, dust and greasy stains.

Excavation

Step 2. Then it is leveled with cement mortar and the waterproofing is done without using solvent-based mastic. This is necessary in order to avoid wetting the foundation from groundwater.

Prices for bituminous mastic

Bituminous mastic

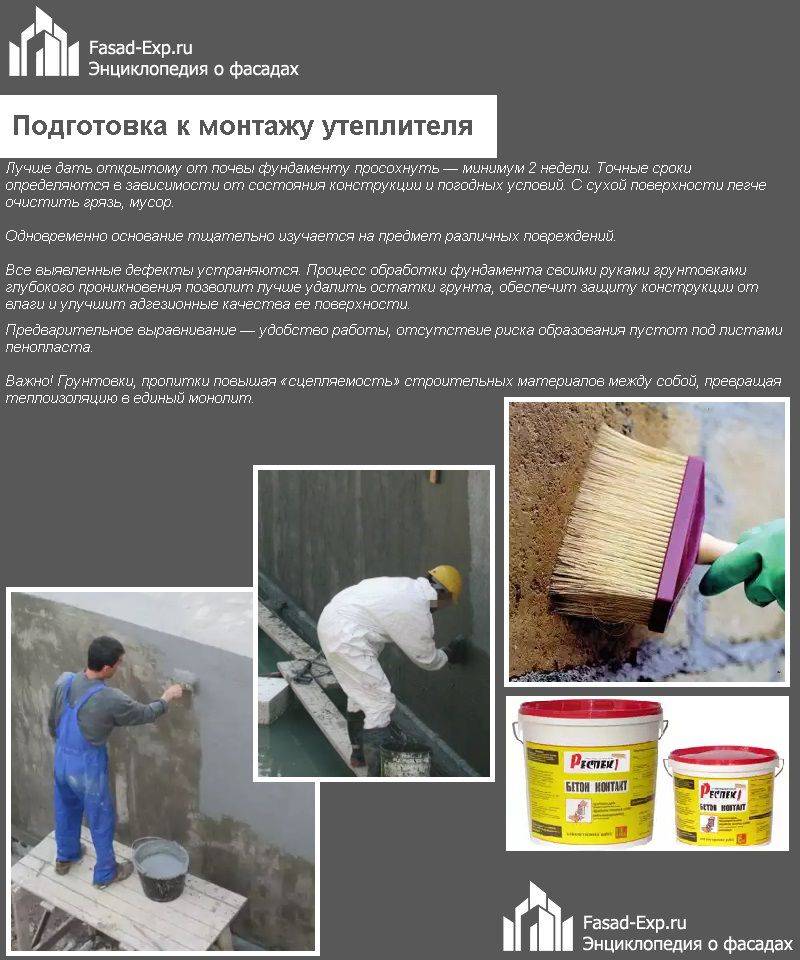

Preparation for the installation of insulation

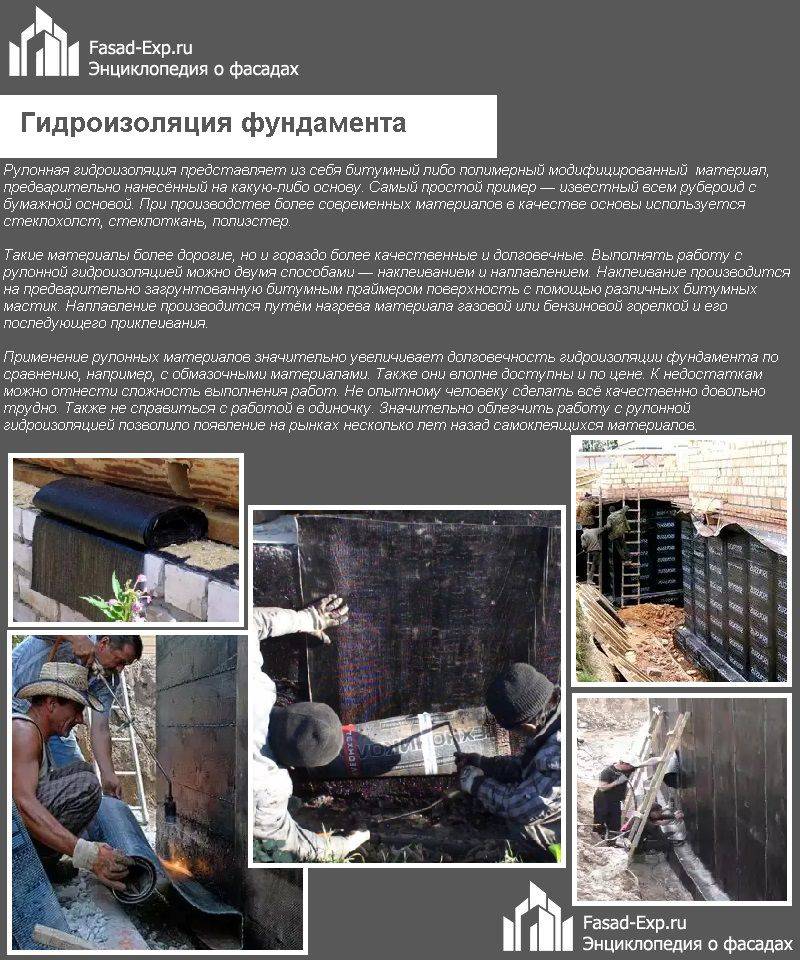

Foundation waterproofing

Step 3. The contact adhesive is diluted and, while it matures, mark the lower boundary of the laying on the working surface. Plates can be buried a little.

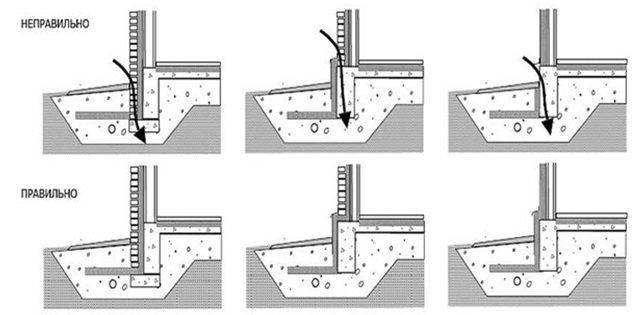

Rules for fixing foam and polystyrene foam

Step 4. The glue is applied in stripes around the perimeter and in the center, after a minute the board must be pressed to the base and kept in this position for several seconds. If necessary, align it and fix the next one by inserting it into the groove. It is better to use a level to avoid distortions. If a second layer is needed, it is positioned so as to overlap the seams of the previous one. This arrangement of the slabs contributes to better insulation.

How to insulate the foundation

Rules for bandaging foam in the corners

Step 5. The part of the foundation that remains underground is not strengthened in any way - then it will still be pressed down by the soil.

Step 6. After the glue dries, the boards are attached to the remaining surface using dowel nails. They are hammered into the surface by 4 cm.

How to insulate the foundation with expanded polystyrene

Insulation of the foundation with penoplex

An example of basement insulation with two layers of foam

Insulation of the blind area together with insulation of the foundation

Operational features of modern heaters

The modern market of insulation materials offers a wide range of required products. However, despite the large assortment of goods, among consumers, foam plastic, expanded clay, polystyrene and polyurethane foam are most often in demand. Often, foam glass is also used for insulation outside.

| Insulation | Operational Features |

| Polyurethane foam | An expensive material, for the installation of which it is necessary to use special equipment. It is applied to the surface of the foundation by spraying. Differs in high thermal insulation capabilities. |

| Styrofoam | More affordable products in terms of price. The special structure of such a material contributes to the emergence of difficulties during installation - during cutting, the foam crumbles very strongly. During the work, additional waterproofing may be required. |

| Expanded clay | The expanded clay layer is capable of absorbing moisture very well, due to which this material is positioned as a very good heat insulator. It creates a kind of pillow around the base of the house and prevents the penetration of cold air. |

| Foam glass | Used relatively recently. It is easy to process and prevents moisture penetration. |

| Polystyrene | Given the flammability of such a material, it is strongly recommended to refrain from using it as a facade insulation. But for underground insulation, polystyrene is ideal.Its resistance to increased moisture deserves special attention. |

Earth as insulation

The simplest way to insulate the foundation of a wooden house with your own hands is to backfill with earth. However, there are many questions to this method. It is advisable to use this method only before the start of the construction of the walls.

The difficulty of this method of warming lies in the need to use a large volume of soil. Otherwise, it will be very difficult to achieve a positive final result. Moreover, even if you insulate the foundation from outside with earth, you may not get the expected effect. This is due to the low thermal insulation potential of the material.

It should also be added here that warming the foundation with earth with your own hands will be associated with great difficulties. In this case, it becomes necessary to use specialized equipment, the rental of which is not cheap.

Thermal insulation of concrete tape

Warming the strip foundation of a wooden house is a rather laborious process.

- The first step is to dig a trench to the very bottom of the base. The width of such a ditch should be about a meter, since the blind area will be insulated at the same time. If the support of the building is very deep, then you can make a trench along the width of the blind area for the first 40 centimeters, and then reduce the width of the ditch to half a meter. If the house was built a long time ago, and wide cracks have already appeared on the concrete foundation, it is imperative to cover them with cement mortar. Small cracks in width can be repaired with a mixture of building glue and cement.

- Do not proceed with thermal insulation if the base has not been insulated from moisture. This must be done, since the tree begins to rot due to exposure to water and cold. Any available roll materials can be used for waterproofing. Roofing material is most often used. To attach the material to concrete, you must first cover the foundation with bitumen mastic, and then glue roofing material on top of it. It must be remembered that for effective protection, the sheets must be glued overlapping each other and additionally coated with mastic.

- Then you can start fixing the polystyrene plates. Most often they are installed using dowels, however, professional builders prefer liquid nails and construction glue. How to insulate the foundation of a wooden house can be seen in the video.

- After attaching all sheets to the foundation, it is imperative to fill all joints with liquid foam. Geotextiles can also be attached over the thermal insulation material. This material significantly reduces the influence of the soil on the foundation.

- At the end of the insulation, the dug ditch is filled up to the level of the blind area, then a small pillow of sand and crushed stone is made, after which the insulation is also laid, concrete is poured on top, which can be combined with reinforcement for greater strength.

Insulation of foundations of operating buildings

Insulation of the foundation of an operating house

Insulation of foundations of operating buildings

A more complex case requires a substantial amount of manual excavation. We will use polystyrene foam plates as insulation. We recommend using expanded polystyrene for all types of insulation, among all its "brothers" it has the highest indicators of physical strength. The thermal conductivity of expanded polystyrene is slightly higher, but the difference is so insignificant that it does not have any noticeable effect.

Technical characteristics of plates from extruded polystyrene foam styroplex

Styrofoam Size Chart

Step 1. Assess the condition of the object, think over the issues with temporary storage of land. The work will continue for several days, heavy rains may occur. If problems with land and temporary drainage of rainwater are not thought out in advance, then flooding along the perimeter of the dug trench is inevitable.And this is very dangerous, the waterlogged earth under the foundation tape sharply lowers its bearing capacity, the consequences can be extremely unpleasant.

Step 2. Remove the tiles around the house or dismantle the concrete blind area. It is much easier with tiles, and the blind area will have to be cut with a grinder with a diamond disc

Use the grinder very carefully, it is one of the most traumatic tools. Moreover, the injuries from him are serious.

Be prepared that during the sawing of the blind area there will be a huge amount of dust: close the windows in the house, if the facades have decorative plaster or are sheathed with wooden clapboard, then it is better to cover them with a film.

Dismantling the blind area

Dismantling the blind area, breaking up old concrete

Step 3. Start digging the trench, the width of the trench should allow you to freely "wield" the shovel. If you do not remember the depth of the foundation, then you will have to make a "test hole" and assess the condition and dimensions of the foundation. This will help you draw up an optimal work plan and calculate the required amount of materials. Sometimes the foundation strips are poured without formwork in the ground, the foundation surface is very uneven, it is not possible to fix it. In this case, there is an old method - to insulate with expanded clay. The work is greatly simplified and cheaper, but the insulation efficiency is low.

An example of a dug pit near the foundation

Expanded clay must be poured into a trench along the entire perimeter of the structure, pour 10 centimeters of sand on top and restore the original appearance of the blind area on it.

An example of expanded clay backfill

There are three ways to solve the problem.

- The first is not to rush to the blind area, but to let the earth stand. This can be done if the building is not in use and it has a rainwater drainage system. It goes without saying that the length of the drain pipes should be greater than the width of the dug trench.

-

The second is to make the new blind area slightly higher than the old one. But we do not recommend restoring the blind area in this way; over time, its horizontal position can be significantly disrupted. It is much better to use paving stones in such cases, lay them in the vacant place. If necessary, it will not be difficult to remove a few stones and align their position.

- There is also a cardinal option - to remove the entire old blind area and make a new one. There is more work, but everything will be done reliably. Choose what you like.

Step 4. If the walls of the foundation are suitable for insulation with expanded polystyrene - excellent. Let the surfaces dry a little, after drying, take a wire brush and carefully remove all residues of the earth. Keep in mind that in the place where the dirt remains, the glue will not hold the insulation.

Prepare the foundation for insulation

Step 5. If possible, remove any large protrusions. Working in a narrow trench is inconvenient, but you have to work hard. Small ones can be cut with a chisel, for large ones you need to take a puncher.

Level the surface. Shoot down the hillocks

Step 6. Lay the polystyrene boards on the glue, check their position with an even strip. The rail should simultaneously overlap at least two slabs, so you can expose several insulation slabs in the same plane. If there are gaps, do not worry, they are perfectly foamed with construction foam.

Laying insulation boards

Step 7. Backfill the trench. Do not pour the entire layer of earth at once, do the work in stages. In order to reduce the inevitable shrinkage of fresh soil, it must be compacted. You will not be able to compact the soil to a depth of more than 20 ÷ 25 centimeters with the help of the handy "pushers" and your own feet. Accordingly, this thickness of fresh soil must be poured after tamping the previous one.It may take more time, but then you will have fewer problems.

An example of backfilling a foundation with insulation

Types of insulation used

Among the thermal insulation materials that meet the above requirements and have an affordable cost, you can name:

- sprayed polyurethane foam;

- sheet expanded polystyrene;

- extruded polystyrene foam;

- expanded clay.

Each of the listed types of thermal insulation has its own characteristics associated with the installation technology, the efficiency of the insulation layer and the cost of purchasing the material.

Polyurethane foam (PPU)

Of all the insulation materials listed, sprayed polyurethane foam is the most expensive material that requires the use of special equipment for its application to the surface. However, it is also the most effective insulation of all existing polymeric materials.

Its main feature is that the polyurethane foam coating does not have connecting seams, being a single continuous layer. This material for insulating the foundation of a house from the outside:

- has excellent adhesion and adheres perfectly even to dirty surfaces;

- has one of the lowest thermal conductivity coefficients;

- after complete curing, it becomes waterproof;

- has good hardness combined with high ductility;

- absolutely unattractive to rodents and insects.

The waterproofness of polyurethane foam makes it possible to abandon the installation of a waterproofing layer. This significantly reduces the time required to insulate the foundation of the house from the outside, reducing the overall cost.

Conventional Styrofoam Boards

This material is made by heating the raw material, poured into a mold, with hot steam. Under the influence of temperature, expanded polystyrene granules expand, forming a porous mass that occupies the entire volume of the mold. This technology is used for the manufacture of most soft foams.

PPP is supplied to the market in the form of flat slabs with a locking recess at all ends. This shape allows for partial overlapping of the joints at the junction of adjacent slabs and avoids the formation of cold bridges.

The material is cheaper than polyurethane foam, but the presence of connecting joints cannot guarantee the surface protection from moisture. Therefore, before installing the thermal insulation layer, a mandatory waterproofing device is required.

Extruded polystyrene foam

This material differs from the previous version in the manufacturing technology and quality of the plates. Forming of plates provides for the supply of ready-made molten polymer mixture through a special extrusion machine. In this case, the foaming of the composition occurs by filling it with neutral or carbon dioxide. Regular air is not used for this, because this will affect the fire hazard.

Extruded polystyrene foam is somewhat more expensive than usual, but, thanks to this method of molding, it does not have a single open pore on a smooth and even surface. This means a longer service life and improved thermal insulation properties.

Expanded clay

The main advantage of expanded clay granules is the lowest cost among all heaters used for foundations. In terms of other technical indicators, expanded clay, frankly, loses to foamed polymers. The use of new modern technologies for thermal insulation of building structures has made this material poorly demanded, its use is now rare.

The ability of expanded clay to partially absorb water over time increases its thermal conductivity by 25-30%.Therefore, ensuring the effectiveness of the bulk heat-insulating layer requires a large thickness, and, therefore, a significant consumption of material. This, in turn, leads to an increase in costs and, as a consequence, a complete leveling of the previously mentioned main advantage of expanded clay.

Thermal insulation under construction

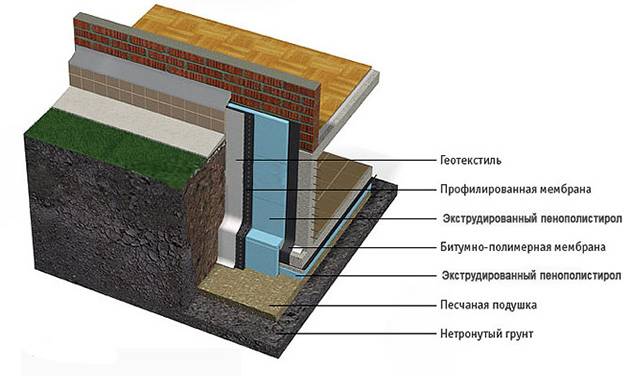

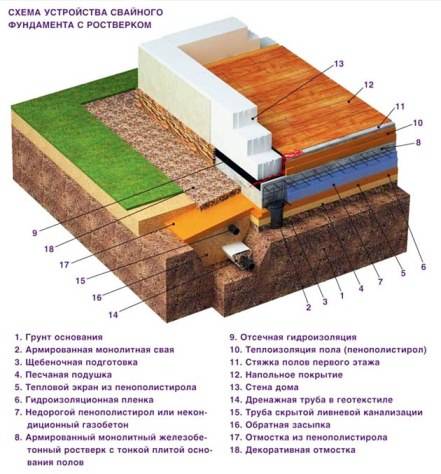

The best way to properly and reliably insulate the entire foundation with penoplex is to do it yourself at the stage of building a house. In this case, a special bituminous mastic is most often used for gluing polystyrene foam plates to concrete. First, the surface is leveled with cement mortar, then cleaned and covered with the first layer of mastic (primer). Roll waterproofing is glued onto it, and insulation is on top. The whole "pie" is shown in the diagram:

As you can see in the diagram, on top of the heat-insulating layer, you can additionally lay a protective coating of geotextile, although often the penoplex is simply covered with soil. Additional protection will not require a lot of costs, but it will significantly extend the life of the insulation. Details about the technology of warming foundations with expanded polystyrene using bituminous materials are shown in the video:

Another interesting way to insulate the base of a house without a basement is used in cases where the foundation is a solid concrete slab. The essence of the method lies in the fact that expanded polystyrene is laid on a sand cushion, and a monolithic concrete base is poured over it. At the same time, it is possible to immediately lay a heating circuit of warm floors inside the monolith. This design is called the Swedish plate, the diagram of its device is shown in the figure:

It can be seen here that the Swedish slab belongs to shallow foundations, insulated not only from below, but also on the sides. In terms of energy efficiency, this technology is one of the best, but it requires a very meticulous approach to work. Failure to comply with technological requirements can lead to cracks in the slab and damage to the underfloor heating system.

The main disadvantage of the Swedish plate is the inability to carry out repairs in case of cracking. But if you lay the insulation of the slab correctly, then such a foundation will calmly stand for several decades. At the same time, the use of a solid slab is possible on various subsidence soils. In practice, this insulated structure is often used to build wooden houses instead of the traditional strip foundations.

Features of insulation

An insulated strip foundation is a base that is protected outside and inside using correctly selected materials, correct calculations and adherence to the technology of work.

Internal thermal insulation

Before insulating the strip foundation inside the house, you need to carefully study the issue. Usually, polystyrene foam plates are used in the work, which are placed on the floor, closing the space that appears between the floor and the ground. Internal insulation is carried out where the foundation is laid at a shallow depth and there is no basement (usually these are shallow foundations).

Insulation of the foundation from the inside allows you to protect the room from below, to cope with the problem of heaving or freezing of the soil, but it cannot protect the base from temperature changes. Therefore, it is usually performed in conjunction with external thermal insulation works. After completing the laying of the layer of thermal insulation, building materials are placed on top and work continues on the construction of the building.

External insulation

Outdoor work begins with digging a trench around the entire perimeter of the building, which is 5-15 meters deep. Then a sand cushion is poured into the pit and heat-insulating materials are laid (usually polystyrene foam plates), which are fixed with mastic. The use of mechanical methods can reduce the strength and impermeability of the layer. Then the trench is covered with expanded clay or sand.

The thermal insulation of the strip foundation from the outside is completed by plastering the part of the foundation protruding above the soil.

Advantages of external protection of the foundation with insulation:

- Frost protection

- Giving the foundation frost resistance and moisture resistance

- Creation of a barrier for storm water and groundwater

- Protection against external mechanical influences

- Creation of an optimal microclimate in the building

Most efficient and most expensive

House insulation with polyurethane foam

House insulation with polyurethane foam

Polyurethane foam is the best material in terms of basement thermal insulation. This is one of the most promising materials for insulating a foundation from the inside.

Thanks to its characteristics, it provides an even and seamless finish. Regardless of the design features and shapes of surfaces, this insulation fits perfectly, is not subject to decay and bacterial aggression.

The material has a high coefficient of thermal conductivity and a wide range of applications: from automotive to construction.

In addition to the fact that this material is quite expensive, it also has a number of significant disadvantages. It does not tolerate ultraviolet radiation and in order to neutralize this minus, it is necessary to protect it with staining.

The second disadvantage is that it gets very hot and there may be a danger of ignition. Due to these features, it is not recommended to come into contact with flammable materials.

The cheapest way

Characteristics of expanded clay

Characteristics of expanded clay

Backfilling of expanded clay insulation cushion is, of course, the most affordable of all these methods. It creates a space that drains water and keeps the floors warm. Usually they are filled with the formwork of the inner part, located along the walls, and the space under the intended basement floor.

Preparation of the base for laying:

- cleaning the surface with a metal brush;

- identification of cracks and damage to the slab, their elimination;

- processing of joints of floors with walls with polyurethane foam.

Laying of communications:

- protection and fixation of pipes using special sleeves, in which

- communications are placed, or the use of polyethylene for winding;

- fixing communications to the floor.

Waterproofing device:

overlapping of dense layers of polyethylene with fastening joints or applying bitumen mastic to the entire surface.

Setting up beacons:

when placing, their parallelism and compliance with the same level are monitored;

Laying expanded clay:

- Dry - backfilling of dry expanded clay without additional sealing materials;

- Wet - consists of two layers: first expanded clay + concrete, and after it has set, a second layer of pure concrete with additional leveling.

Methods for insulating the foundation of a wooden house

Insulation of the foundation from the outside is most often performed using expanded clay, polystyrene or polyurethane foam. The affordable price level of these materials and the high thermal insulation capabilities have a direct impact on this choice. Moreover, it attracts the likelihood of resolving this issue with your own hands.

Warming with expanded clay

The material absorbs moisture and wicks it away from the base of the house. In the case of a properly implemented insulation scheme, an air gap forms, which is also a good heat insulator. Thanks to this, the probability of freezing of the foundation is minimized. Do-it-yourself insulation of the base of the building with expanded clay is carried out in several stages.

Stage 1

When insulating a built house, it is very important to thoroughly clean the surface of the soil. Cracks should be repaired if necessary

Waterproofing can also be carried out.

Stage 2

At the next stage, the trench is covered with soil. On top of the formed embankment, a small blind area is made of concrete. It will protect the thermal insulation material from moisture ingress.The basement of the base of a wooden house can be insulated by plastering.

Stage 3

If necessary, using expanded clay, you can also insulate the basement with your own hands. The insulation is filled in at the stage of flooring. A sand cushion is preliminarily prepared, on top of which a layer of waterproofing is implemented.

Thermal insulation with polystyrene

Polystyrene is presented in the form of a modification of foam, characterized by mechanical strength. To achieve the maximum effect of insulation outside the house, it is recommended to give preference to material with flame retardant additives.

- Foundation preparation. At this stage, the base of the house is freed from soil, dust, traces of oil and bitumen. Cracks are repaired if necessary.

- Installation of polystyrene plates. Insulate to be attached to the base of the building using an adhesive mixture. It may take about 48 hours for the material to dry completely.

- Insulation of the basement. Polystyrene from a wall made of wood material should be separated by using a non-combustible insulation. Basalt wool can be used as such a material.

Insulation with polyurethane foam

The main feature of the use of such a heater lies in the binding to the depth of the location of the material. The larger it is, the higher the quality of thermal insulation will be. To install polyurethane foam, you will need to perform a number of steps:

- Prepare the ground.

- Prepare the foundation.

- Waterproof the base of the house.

- Insulation installation.

- Arrange external protection.

At the stage of earthworks, the base of a wooden house is completely freed from soil and excess dirt. For maximum effect, it is recommended to implement a sand cushion at the bottom of the trench.

The cleaned foundation must be well primed. This will allow the thermal insulation material to perform its direct functions during the maximum time interval.

The implementation of a waterproofing layer minimizes the likelihood of moisture penetration into the room. Due to this, the overall service life of the building will tend to increase.

Polyurethane foam is positioned as a sprayed insulation. This structural feature of the material guarantees seamlessness and perfect evenness of the coating. High adhesion with any coatings facilitates the issue of arranging external protection of the base.

What's the bottom line?

Insulation of the foundation of a wooden house from the outside can be carried out using various heat-insulating materials, which are represented on the market by a wide range. High-quality preparation of the base is the key to a positive final result.